Recycled Components in 3D Concrete Printing Mixes: A Review

Abstract

1. Introduction

Environmental Issues

2. Recycled Concrete Additives

2.1. Addition of Fly Ash and Coal Bottom Ash

| FA Class | % Replacement in Cement | Particles Size | Density | Compressive Strength (MPa) | Specimens Type | Reference |

|---|---|---|---|---|---|---|

| F | 10, 30, 50% | - | - | 23.02 MPa, 19.73 MPa, and 19.25 MPa, respectively | cast specimens | [50] |

| F | 50% | <10 µm | 2.2 g/cm3 | cast specimens | [51] | |

| F | 25, 50% | - | 2.08 | 46 MPa and 36 MPa, respectively | 3D-printed specimens | [47] |

| HFA (high-temperature fly ash) | 35% | <400 µm | 2.41 g/cm3 | 40 MPa | 3D-printed specimens | [52] |

| C | 0%, 25%, 50% | <100 µm | - | 29–40 MPa. | 3D-printed specimens | [53] |

| F | 5, 10, 15% | ≤1 µm (nano-FA) | ~2.20 g/cm3 | Increase strength up to ~35 MPa after 28 days | 3D-printed specimens | [45] |

| C | 100% | - | - | 32.63–34.86 (28 days) | 3D-printed specimens | [48] |

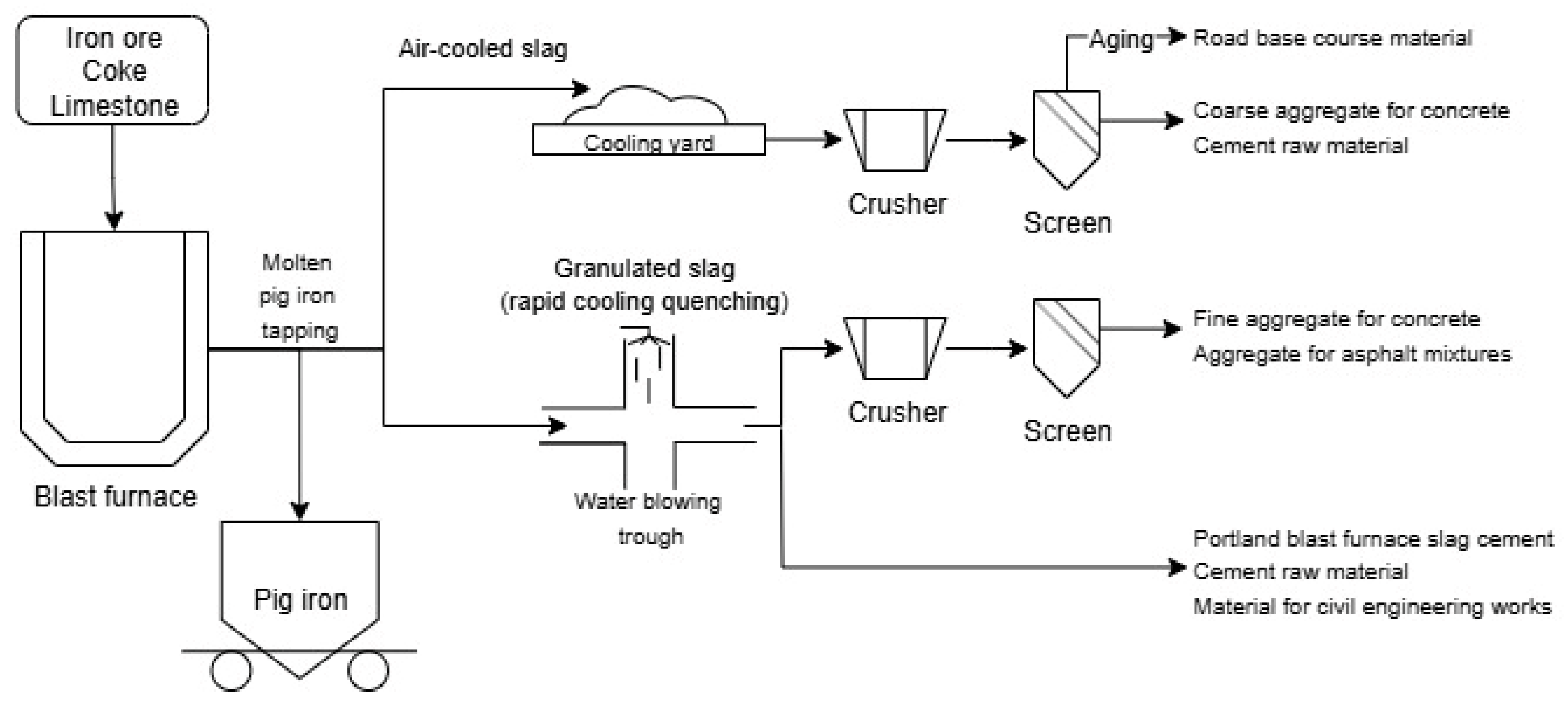

2.2. Addition of Ground Granulated Blast Furnace Slag

2.3. Addition of Coal Slag

| Oxides | Liu et al. [85] | Rezayt Khargerdi et al. [82] | Trinh et al. [80] | Rudziewicz et al. [83] | Ren et al. [84] |

|---|---|---|---|---|---|

| Na2O | 0.58 | 1.21 | 0.43 | - | 1.78 |

| MgO | 2.06 | 1.65 | 1.40 | 1.20 | 1.47 |

| Al2O3 | 22.19 | 22.84 | 24.2 | 31.94 | 15.93 |

| SiO2 | 58.55 | 44.22 | 54.4 | 48.38 | 43.11 |

| SO3 | 0.33 | 2.72 | - | 3.41 | 0.62 |

| SrO | 0.23 | - | - | 0.20 | |

| K2O | 2.36 | 4.5 | 3.59 | 2.61 | 1.30 |

| CaO | 6.28 | 1.28 | 1.30 | 1.73 | 16.69 |

| TiO2 | 1.13 | 1.72 | 0.78 | 1.71 | - |

| P2O5 | 0.22 | 0.40 | 0.08 | 0.60 | - |

| Cr2O3 | 0.04 | - | - | 0.03 | - |

| MnO | 0.06 | - | 0.03 | 0.02 | - |

| Fe2O3 | 5.66 | 19.5 | - | 7.66 | 18.60 |

2.4. Addition of Silica Fume

2.5. Waste Glass Powder

2.6. Addition of Construction and Demolition Waste

| Recycled Materials | Replaced Materials | Replacement Ratio [%] | Particle Size [mm] | Fresh Properties | Mechanical Properties | References |

|---|---|---|---|---|---|---|

| Recycled sand | Natural sand | 12.5–50 | 0.9 | Increased extrudability | Slight reduction in compressive strength, limited effect on anisotropy | [109] |

| Recycled sand | Natural sand | 50–100 | 3 | Decreased workability | Increased porosity, reduced strength with higher replacement rates | [115] |

| Recycled concrete coarse aggregate | Quarry stone | 50–100 | 5–12 | Decreased flowability; increased buildability; shorter open time | Yield stress grows exponentially with time; shear modulus grows linearly - | [116] |

| Recycled concrete coarse aggregate | Nature coarse aggregate | 50–100 | 5–12 | Increased buildability | Decrease in strength with increased replacement ratio and age | [111] |

| Fine recycled aggregates (concrete & brick) | Natural fine aggregate | 25–100 | - | Fresh consistency ≥ 150 mm | Compressive strength (>50 MPa at 28 days); acceptable for 3D printing | [117] |

| Recycled brick aggregate | Natural aggregate | 64 | 4.75 | - | Reduction in strength due to porous RBA | [118] |

| Recycled glass | Natural sand | 50 | 0.796 | - | Increased porosity, negative impact on flexural strength | [99] |

| Recycled glass | River sand | 100 | 0.15–1.7 | Better flow properties | Lower buildability and mechanical properties | [110] |

| Recycled plastic eco-aggregate (RESIN8) | Natural sand | 5–15% | <1 mm/<5 mm | Higher flowability, lower thixotropy; poorer buildability | Decrease in compression and flexural strength; improved interlayer bond strength | [119] |

| Polyethylene terephthalate (PET) | Natural sand | 10–50 | 4 | Decreased buildability | Decreased buildability and mechanical properties, improved freeze–thaw resistance | [120] |

| Recycled plastic waste | Natural sand | 5–15 | 5 | Increased flowability and porosity | Decreased strength | [119] |

| Recycled crumb rubber | River sand | 15 | 2.36 | - | Anisotropic compressive strength | [121] |

| Waste tire rubber | Natural sand | 25–100% | 1–3 | Decreased workability | - | [122] |

| Waste tire rubber | Natural sand | 50 | 1–3 | - | Lower environmental impact and energy effectiveness in 3D printing | [123] |

| Rubber aggregates | Natural sand | 5–15 | 0.1–3 | Decreased extrudability, improved buildability | - | [124] |

| Copper slag as fine aggregate | River sand | up to 100% | - | Increased workability | Mechanical properties can be maintained at full sand replacement (requires mix optimization) | [125] |

| Steel slag as fine aggregate | River sand | up to 100% | - | Mixtures fall within the printability window; good buildability | Printable elements; strength depends on steel slag aggregate-to-cement ratio (SA/C) | [126] |

Impact of RCA/FRCA on Extrusion-Relevant Rheology: Quantitative Benchmarks

2.7. Long-Term Durability of 3D-Printed Concrete Mixes with Recycled Materials

| Recycled Constituent | Typical Effect on F–T | Typical Effect on Chlorides | 3DCP Process Levers | Reference |

|---|---|---|---|---|

| GGBFS (20–30%) | ↑ F–T (densification, ↓ porosity) | ↓ migration/diffusion (pore refinement) | Balance against open time; >40% often needs SP | [69,71,73] |

| Silica fume (5–10%) | ↑ F–T; sealed ITZ | ↓ porosity → reduced ingress | Tight viscosity/extrusion control; w/b and SP | [86,87,88] |

| Fly ash (FA) | neutral to ↑ F–T (indirect via densification) | ↓ migration/diffusion (pozzolanic; in GGBFS hybrids) | GGBFS + FA hybrids; manage rheology and open time | [154,155,156] |

| PET/other plastics | sometimes ↑ F–T at moderate contents | no single trend (mix-dependent) | Limit dosage; pair with SCMs (GGBFS/SF/FA) | [120] |

| RFA/RCA (25–50%) | risk of ↓ F–T (↑ absorption, weaker interfaces) | ↑ vulnerability to ingress (interlayer pathways) | SP, particle packing, curing; control τ0 and print window | [94,109,115,116,117,133,134,135] |

3. Calculation of the Benefits of Using Secondary Raw Materials

- A1–A3 (product stage): raw material acquisition, binder and admixture production, mixture manufacturing (the so-called cradle-to-gate).

- A4–A5 (construction): transportation to site and placement.

- B (use stage): service life of the element/structure (in concrete, carbonation is particularly relevant—gradual CO2 uptake by the material).

- C (end-of-life): demolition, crushing, recovery, or landfilling.

- D (beyond system boundaries): credits/burdens from substitution of primary materials due to recycling or energy recovery.

- Production of cementitious binders, particularly process emissions from clinker decarbonation (calcination) and kiln fuel/energy use;

- Transportation of raw materials and fresh concrete;

- Manufacturing (electricity and heat at batching plants);

- End-of-life stage (crushing, sorting, transport, disposal).

- ISO 21930:2017—rules for Environmental Product Declarations (EPDs) of construction products (complementary to ISO 14025) [169];

- EN 15804:2012+A2:2019—European core PCR for all construction products: mandatory modules A1–A3, C1–C4, D; expanded set of indicators, including the breakdown of GWP into fossil, biogenic, LULUC, and total [164].

- Allocation and cut-off criteria: whether and how environmental burdens are assigned to secondary raw materials entering the system (commonly counted from the “end-of-waste” point).

- Carbonation: inclusion of CO2 uptake during service life (B1) and after crushing at end-of-life (C3); critical for comparing scenarios.

- Module D: accounting for substitution benefits (e.g., recycled aggregate replacing natural aggregate in subsequent cycles).

- Data quality and representativeness: selecting appropriate datasets (e.g., regional electricity mixes, cement production parameters, transport processes) consistent with relevant PCR/EPD rules.

| Intervention/Mixture | Scope & Method | Tool/Database | Result/Change | Reference |

|---|---|---|---|---|

| “Reference” concrete (production) | A1–A3, IPCC | – | ~348 kg CO2-eq/m3 | [165] |

| NAC “cement-only” vs. +25% FA (SCM) | A1–A3, IPCC 2013 | openLCA; ecoinvent | NAC 323–332; −8–17% at 25% FA | [166] |

| “Low-clinker” mixes (high SCM) | A1–A3 (various LCAs) | various tools | ~450 → ~250 kg with high SCM | [182] |

| Prefabricate, CO2-curing; NA/RCA/MCA | A1–A3 (incl. bound CO2 balance) | (measurement + inventory) | 221.26 (NA), 204.38 (RCA), 210.05 (MCA) | [179] |

| RAC, accounting for carbonation in life cycle | B1/C3 (uptake) | – | 4.9–16.4 kg CO2/m3 absorbed (30–100% RCA; 50 years) | [178] |

| Workflow for carbonation (EN 16757) | B1 (k-values) | digital model | Rate ~1.59 mm·year−0·5 (per EN 16,757 for external exposure) | [183] |

| Effect of FA/slag transport | A1–A3 | – | Higher FA/slag content reduces GWP, but long transport distances may offset gains | [180] |

| CO2-cured blocks (comparative) | A1–A3 (variants) | – | 292–454 kg/m3 (scenario-dependent) | [184] |

| Recycled aggregate production | A1 (aggregates) | – | –70.7% impact vs. natural aggregate | [185] |

| Concrete Type/Mix Design | Main Features | Typical GWP100 [kg CO2-eq/m3] | Key Factors Affecting Results | References |

|---|---|---|---|---|

| Conventional concrete (OPC only) | 100% clinker cement, natural aggregates | ~320–450 | High process emissions from clinker calcination; energy-intensive | [186,187,188,189] |

| Blended concrete with SCM | 20–50% clinker replaced by FA, GGBFS, SF, MK | ~250–330 | Reduction depends on SCM level and transport distance | [188,190,191] |

| Recycled aggregate concrete (RAC) | RCA/RFA replacing natural aggregates | ~300–420 | Lower A1 emissions; carbonation in B1/C3; less impact vs. SCM | [192,193,194] |

| Low-carbon hybrid mixes | SCM + RCA combined | ~220–300 | Synergistic effect; possibility of CO2 curing for further reduction | [193,194] |

| Geopolymer concrete | Alkali-activated binders from industrial by-products | ~150–250 | Very low process emissions; strongly influenced by activator type and regional energy mix | [195,196,197] |

| Recycled Material Used in 3DCP Mix | Modification/Role in the Mix | LCA Type (Scope) | GWP Effect (vs. the Reference Mix in the Study) | Key Notes | Reference |

|---|---|---|---|---|---|

| Fly ash (FA) | Partial replacement of binder in printable mixes (SCM/precursor in geopolymers) | Mix-level LCA for 3D-printed building; cradle-to-gate for materials | Higher GWP than GGBFS within the same study set: FA ≈ +37% vs. GGBFS; equivalently ~393 kg CO2e/m3 if GGBFS = 287 kg CO2e/m3 | Comparison is across 3DCP material variants; the lowest footprint in that set was GGBFS; FA and WGP were higher | [198] |

| Ground granulated blast-furnace slag (GGBFS) | Partial replacement of cement in printable mixtures | Mix-level LCA (cradle-to-gate) per unit volume | Lowest GWP in the assessed set: ~287 kg CO2e/m3; in the same analysis FA ~37% higher, WGP ~50% higher | Authors recommend GGBFS as the most effective low-carbon option among compared by-products for 3DCP | [198] |

| Coal slag (CS) (boiler slag) | Potential SCM/fine fraction in 3DCP | data gap for mix-level 3DCP LCA | – | Material reports exist, but no standardized cradle-to-gate GWP for printable mixes | – |

| Silica fume (SF) | Low-dosage SCM in printable mortars | data gap for mix-level 3DCP LCA | – | Directionally reduces clinker content, but mix-level 3DCP LCA with explicit GWP is missing | [199] |

| Recycled concrete powder (RCP/RCBP) | Up to 50% binder replacement in printable paste/mortar | Mix-level LCA (cradle-to-gate); FU = 1 m3 paste/mortar | Up to ~−62% CO2e vs. OPC reference (while maintaining printability after rheology tuning) | Strong sensitivity to yield stress and printability window; admixture adjustments required at high RCP contents | [112,113] |

| Fine recycled aggregate (fRA) (from 3DPC/CDW) | Replacement of sand with concomitant binder reduction | Mix-level LCA for 3DCP (cradle-to-gate) | Up to ~−48% CO2e at the highest fRA levels with cement reduction; ~−20% feasible at ~20% v/v without major performance loss | Effect largely driven by clinker reduction; at >20% v/v monitor green strength and printability window | [159] |

| Ground waste tire rubber (GWTR) | Partial replacement of sand; printable mixes compared with casting | Mix-level LCA (cradle-to-gate) | Environmental credit for GWTR (negative GWP for the aggregate module under “avoided burden”); additionally ~−9.5% GWP when printing vs. casting the same mix | Total reduction depends on allocation for GWTR and rubber content; cement remains the dominant GWP contributor | [123] |

| Waste glass powder (WGP) | 10–30% OPC replacement (SCM) in printable mortars | data gap for mix-level 3DCP LCA | – | Directionally beneficial via clinker reduction; some studies rank GGBFS < FA < WGP in GWP (relative SCM ranking) | [100] |

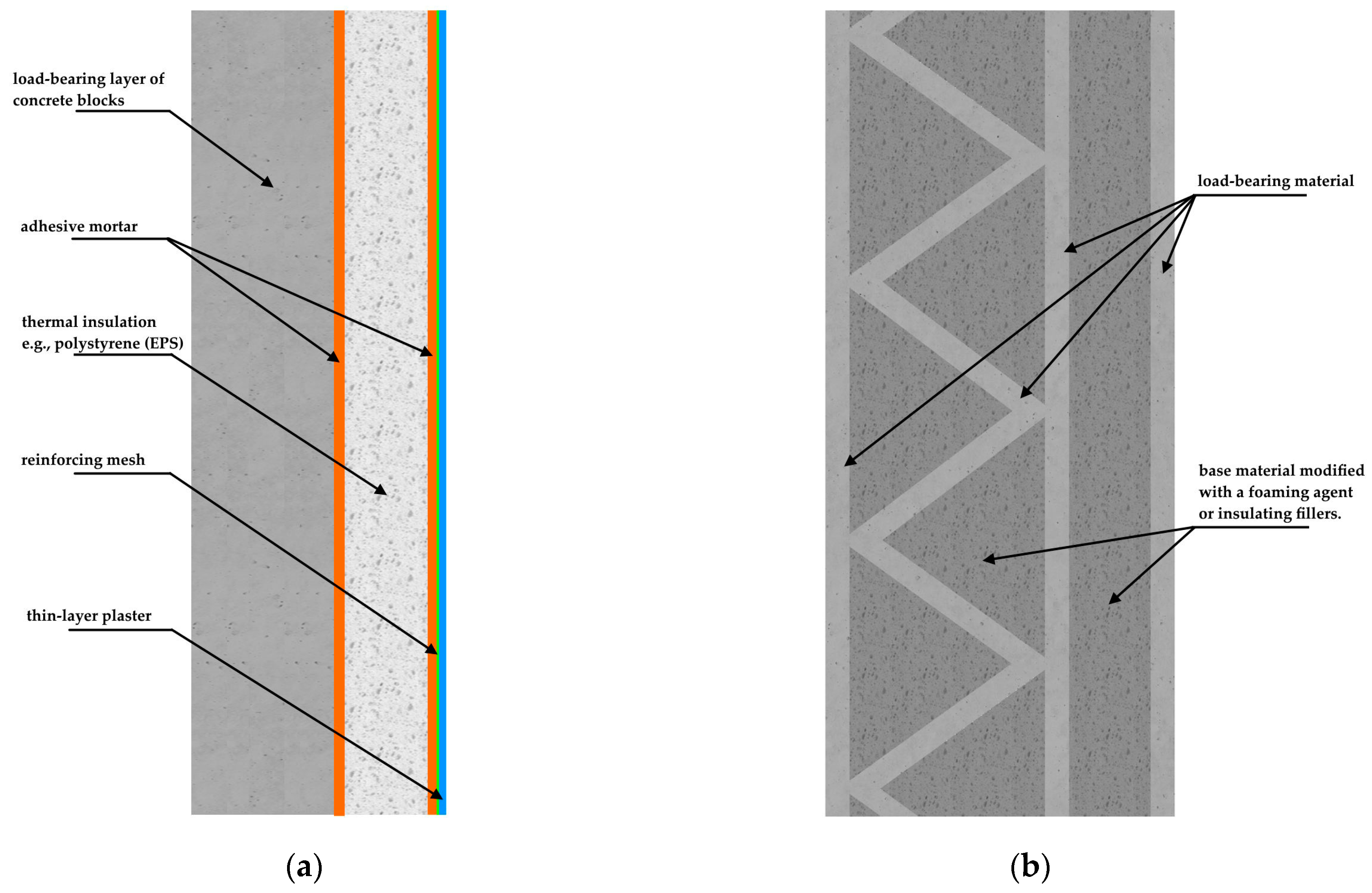

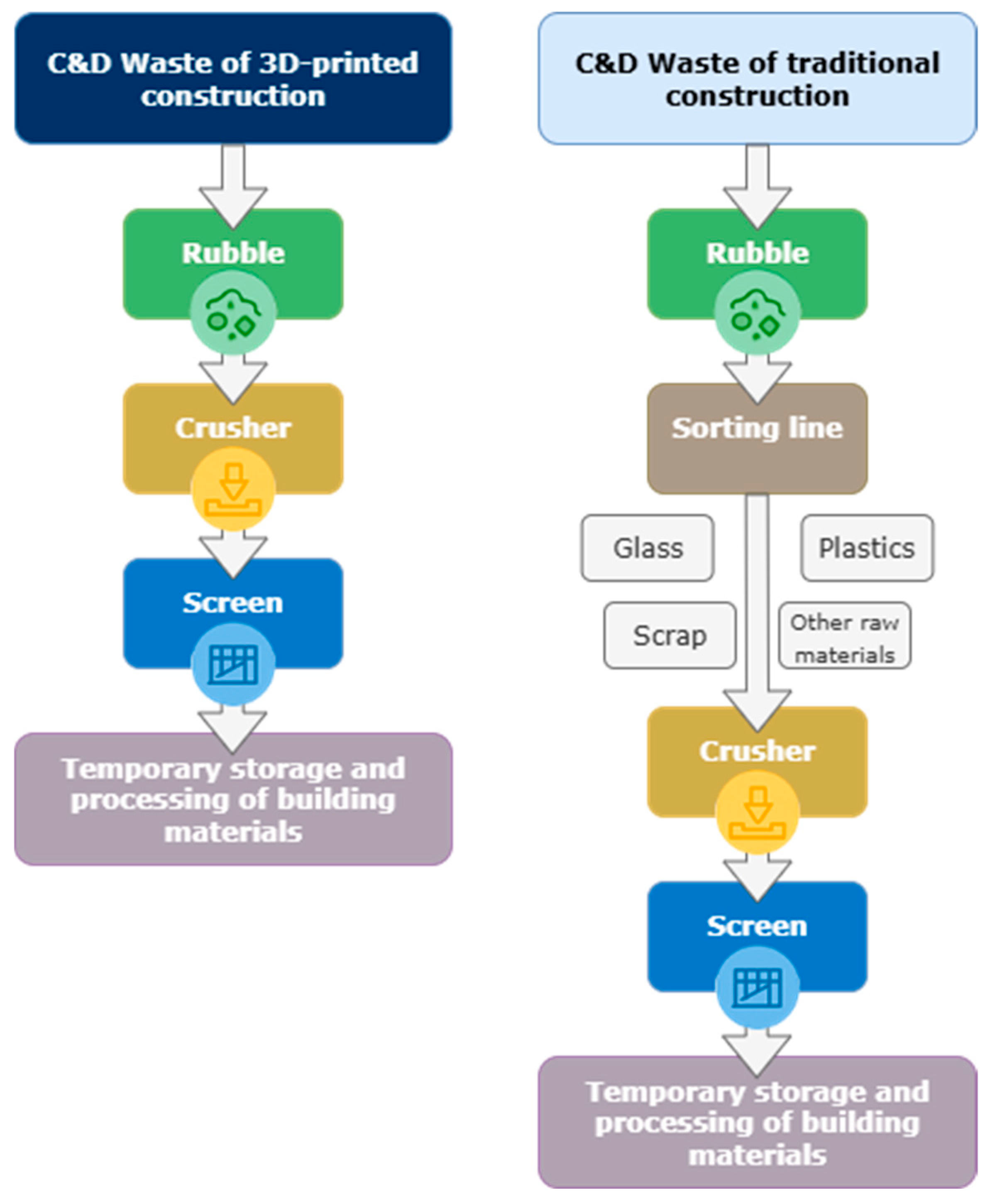

4. Material Reuse in 3D-Printed Concrete: A Comparison with Traditional Methods

- Lower contaminant load—fewer gypsum, wood, plastics, and adhesive residues that otherwise depress concrete strength when recycled [200];

- Simplified disassembly and shorter processing chains—often fewer steps before crushing/screening, with reduced handling, storage, and time;

- Reduced metallic content—many 3DCP systems rely on geometry and localized reinforcement, limiting extensive steel meshes and hazardous resin-bonded mortars common in ETICS or render systems;

- Logistics benefits—less bulky polymeric insulation (e.g., EPS) to transport and compact; EPS’s very low bulk density makes long-haul transport particularly inefficient in conventional retrofits and demolitions;

- Higher traceability—digital fabrication enables accurate mass balances and targeted reuse pathways;

- Compatibility with closed-loop reuse—on-site or local crushing/sieving can yield RCA tailored to new 3DCP mixes, limiting primary aggregate demand.

5. Three-Dimensional Printing of Concrete with Recycled Materials as a Tool for Sustainable Development and Decarbonization of Construction

| Trade Name | Company | Materials | Material of Secondary Raw Materials in 1 m3 of the Product (%) | Certificate |

|---|---|---|---|---|

| Rebetong C20/25 | SKANSKA | Portland cement, recycled aggregate, sand, fillers, chemical additives, water | 75.5% | Technical and Test Institute for Construction Prague |

| Rebetong C25/30 | SKANSKA | Portland cement recycled aggregate sand, fillers, chemical additives, water | 72.3% | Technical and Test Institute for Construction Prague |

| ercconcrete | ERC-TECH | mix of cement, finely ground recycled brick, ceramics, concrete, microsilica, lightweight artificial aggregate and/or char and/or slag and/or polystyrene and/or at least one organic filler | from 40% to 100% | Technical and Test Institute for Construction Prague |

| Trade Name | Company | Materials | CO2 Emission Reduction (%) | Certificate |

|---|---|---|---|---|

| ECOPlanet 4B (CEM IV/B (V) 42.5 N—LH/NA) | LAFARGE | pozzolanic cement, limestone LL ≤0.20% of stone weight, silica fly ash, gypsum/REA-gypsum, dusts from the production of Portland cement, chromium (VI) reducer | up to 40% and 20% recycled material | Building Research Institute (ITB) |

| Vertua Plus | CEMEX | Portland clinker, limestone, silica fly ash, REA-gypsum, chromium(VI) reducer—iron(II) sulfate | up to 50% | Building Research Institute (ITB) |

| EcoCrete | Heidelberg Cement | no data | up to 66% | no data |

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled Aggregate from C&D Waste & Its Use in Concrete—A Breakthrough towards Sustainability in Construction Sector: A Review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). 2019 Global Status Report for Buildings and Construction; International Energy Agency (IEA): Paris, France, 2019. Available online: https://www.iea.org/reports/global-status-report-for-buildings-and-construction-2019 (accessed on 3 September 2025).

- World Economic Forum. Cement Production Is Responsible for 8% of Global Emissions. Here’s How to Make It More Sustainable; World Economic Forum: Geneva, Switzerland, 2024. [Google Scholar]

- Hasheminezhad, A.; King, D.; Ceylan, H.; Kim, S. Comparative Life Cycle Assessment of Natural and Recycled Aggregate Concrete: A Review. Sci. Total Environ. 2024, 950, 175310. [Google Scholar] [CrossRef]

- Bun, P.; Cyr, M.; Laniesse, P.; Bun, K.N.; Idir, R. Concrete Made of 100% Recycled Materials—Feasibility Study. Resour. Conserv. Recycl. 2022, 180, 106199. [Google Scholar] [CrossRef]

- Obermeier, N.; Wiese, F.; Kustermann, A.; Stengel, T. 3D Printing Cement-Based Materials Using 100% of Recycled Aggregates. In Building for the Future: Durable, Sustainable, Resilient; Ilki, A., Çavunt, D., Çavunt, Y.S., Eds.; Lecture Notes in Civil Engineering; Springer Nature: Cham, Switzerland, 2023; Volume 349, pp. 648–657. ISBN 978-3-031-32518-2. [Google Scholar]

- Ramesh, A.; Navaratnam, S.; Rajeev, P.; Sanjayan, J. Thermal Performance and Life Cycle Analysis of 3D Printed Concrete Wall Building. Energy Build. 2024, 320, 114604. [Google Scholar] [CrossRef]

- Neri, M.; Licciardello, L.; Reggia, A.; Pilotelli, M.; Lezzi, A.M. Improving the Energy Performance of a 3D-Printed Wall Using Recycled Material. J. Phys. Conf. Ser. 2024, 2685, 012034. [Google Scholar] [CrossRef]

- Dziura, P.; Maroszek, M.; Góra, M.; Rudziewicz, M.; Pławecka, K.; Hebda, M. Influence of the In-Fill Pattern of the 3D Printed Building Wall on Its Thermal Insulation. Materials 2023, 16, 5772. [Google Scholar] [CrossRef] [PubMed]

- Purvis, B.; Celebi, D.; Pansera, M. A Framework for a Responsible Circular Economy. J. Clean. Prod. 2023, 400, 136679. [Google Scholar] [CrossRef]

- CEMBUREAU. Use of Secondary Raw Materials in the EU Cement Industry; CEMBUREAU: Brussels, Belgium, 2023; Available online: https://cembureau.eu/media/kj3no0w3/230123-cembureau-qa-secondary-materials.pdf (accessed on 3 September 2025).

- European Commission. Energy Performance of Buildings Directive. 2025. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en (accessed on 3 September 2025).

- International Energy Agency. Technology Roadmap—Low-Carbon Transition in the Cement Industry; IEA: Paris, France, 2018. Available online: https://www.iea.org/reports/technology-roadmap-low-carbon-transition-in-the-cement-industry (accessed on 3 September 2025).

- Van Oss, H.G.; Padovani, A.C. Cement Manufacture and the Environment Part II: Environmental Challenges and Opportunities. J. Ind. Ecol. 2003, 7, 93–126. [Google Scholar] [CrossRef]

- Stowarzyszenie Producentów Cementu. Informator 2023 SPC; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2023; Available online: https://www.polskicement.pl/informatory/informator-2023-spc/ (accessed on 3 September 2025).

- Jankovic, A.; Valery, W.; Davis, E. Cement Grinding Optimisation. Miner. Eng. 2004, 17, 1075–1081. [Google Scholar] [CrossRef]

- Torgal, F.P.; Jalali, S. Eco-Efficient Construction and Building Materials; Springer: London, UK, 2011; ISBN 978-0-85729-891-1. [Google Scholar]

- Rudnicki, T.; Stałowski, P. Performance Research of Cement Concrete Pavements with a Lower Carbon Footprint. Materials 2024, 17, 3162. [Google Scholar] [CrossRef]

- European Commission. A Renovation Wave for Europe—Greening Our Buildings, Creating Jobs, Improving Lives; European Commission: Brussels, Belgium, 2020. Available online: https://eur-lex.europa.eu (accessed on 3 September 2025).

- Tait, M.W.; Cheung, W.M. A Comparative Cradle-to-Gate Life Cycle Assessment of Three Concrete Mix Designs. Int. J. Life Cycle Assess. 2016, 21, 847–860. [Google Scholar] [CrossRef]

- Ernst & Young (EY) Polska. Economic Analysis of the Impact of Implementing CCS in the Cement Industry on the Construction Sector and the Economy; Ernst & Young Polska (EY): Warsaw, Poland, 2024. [Google Scholar]

- Global Cement and Concrete Association (GCCA). Concrete Future—Roadmap to Net Zero. 2021. Available online: https://gccassociation.org/concretefuture/ (accessed on 25 September 2025).

- SPC Technologie. CCS Jedyną Szansą na Zachowanie Konkurencyjności Sektora Cementowego w Polsce; Stowarzyszenie Producentów Cementu (SPC): Krakow, Poland, 2024; Available online: https://www.polskicement.pl/technologie-ccs-jedyna-szansa-na-zachowanie-konkurencyjnosci-sektora-cementowego-w-polsce/ (accessed on 3 September 2025).

- Hoenig, V.; Schall, A.; Sultanov, N.; Papkalla, S.; Ruppert, J. Status and Prospects of Alternative Raw Materials in the European Cement Sector; European Cement Research Academy (ECRA): Düsseldorf, Germany, 2022. [Google Scholar]

- European Commission. European Research Area Progress Report 2018; Directorate General for Research and Innovation; European Commission: Warsaw, Poland, 2019.

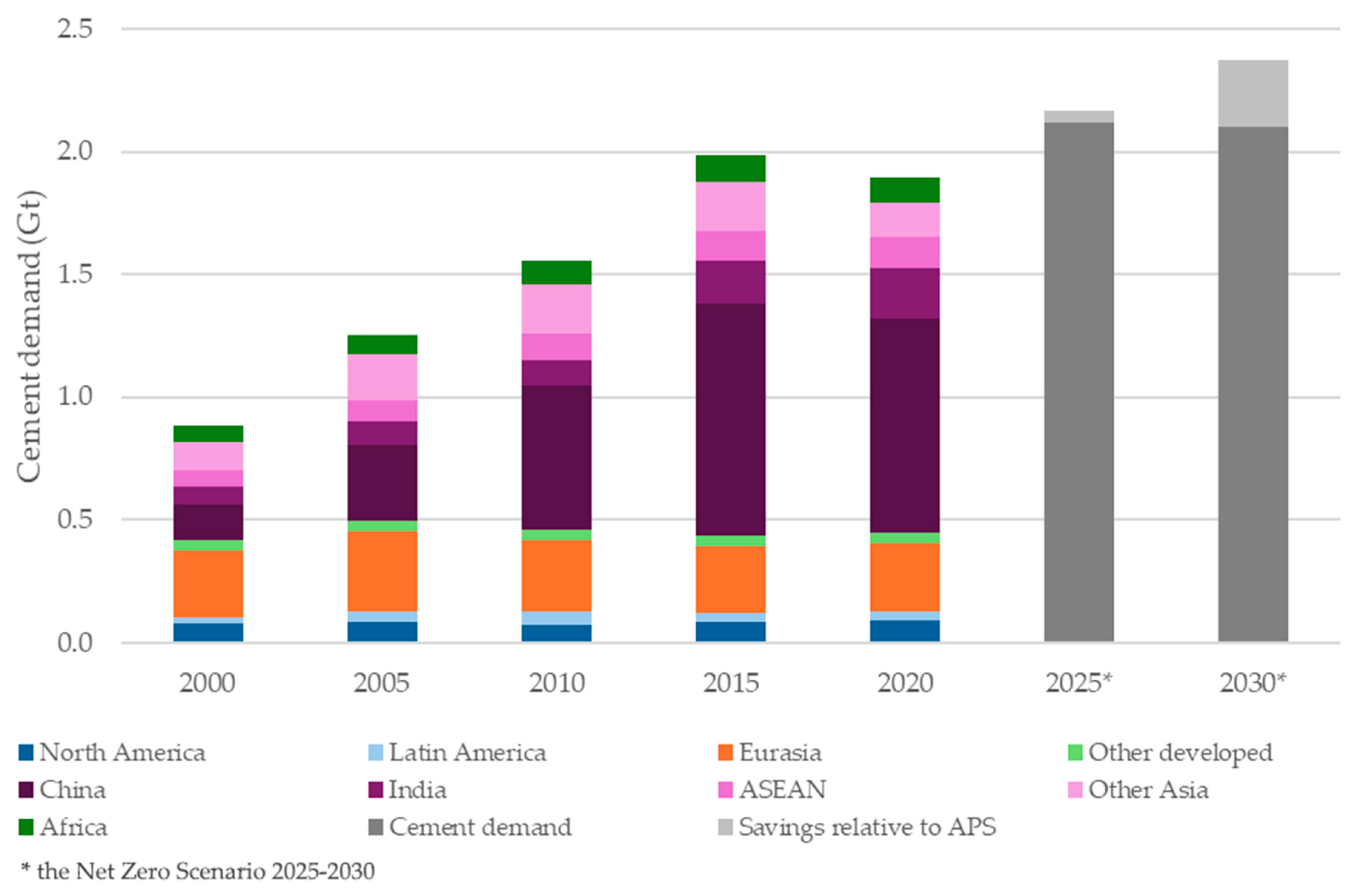

- International Energy Agency (IEA). Global Cement Demand for Building Construction, 2000–2020, and in the Net Zero Scenario, 2025–2030; International Energy Agency (IEA): Paris, France, 2021. Available online: https://www.iea.org/data-and-statistics/charts/global-cement-demand-for-building-construction-2000-2020-and-in-the-net-zero-scenario-2025-2030 (accessed on 3 September 2025).

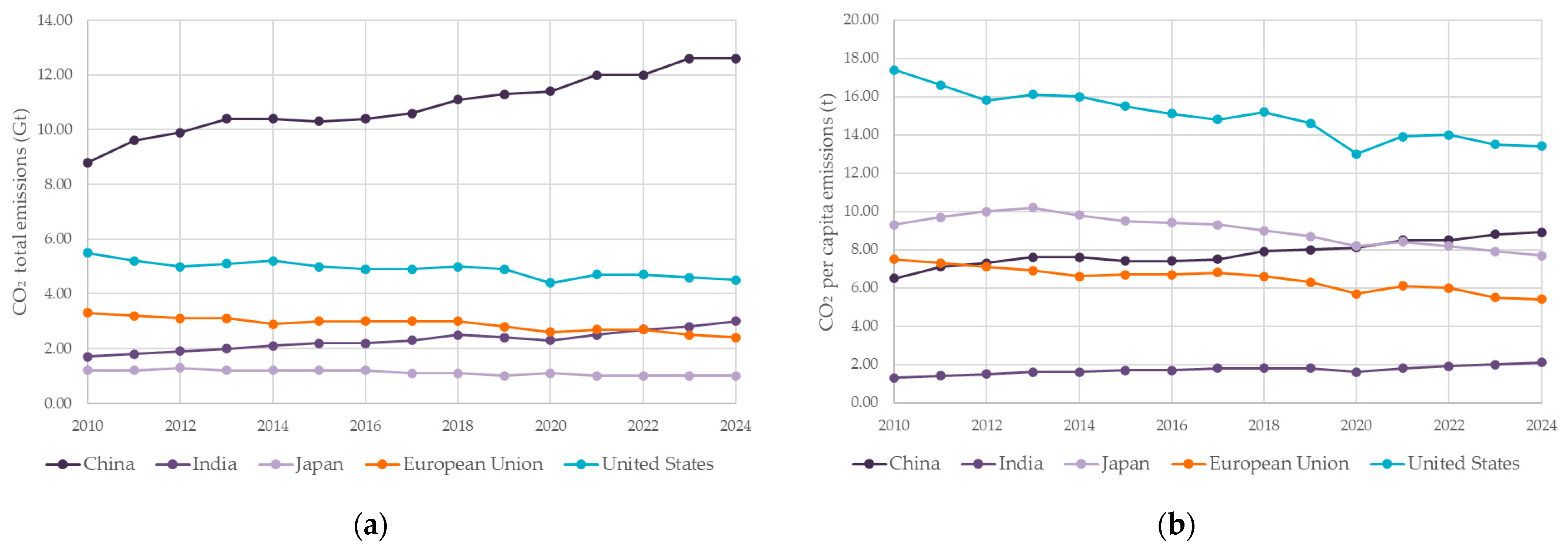

- International Energy Agency (IEA). Global Energy Review 2025; International Energy Agency (IEA): Paris, France, 2025. Available online: https://www.iea.org/reports/global-energy-review-2025 (accessed on 3 September 2025).

- International Energy Agency (IEA). CO2 Total Emissions by Region, 2000–2024; International Energy Agency (IEA): Paris, France, 2025. Available online: https://www.iea.org/data-and-statistics/charts/co2-total-emissions-by-region-2000-2024 (accessed on 10 September 2025).

- International Energy Agency (IEA). CO2 per Capita Emissions by Region, 2000–2024; International Energy Agency (IEA): Paris, France, 2025. Available online: https://www.iea.org/data-and-statistics/charts/co2-per-capita-emissions-by-region-2000-2024 (accessed on 10 September 2025).

- Padavala, S.S.A.B.; Noolu, V.; Paluri, Y.; Bijivemula, S.K.R.; Akula, U.K. A Study on the Synthesis and Performance Evaluation of Fly Ash and Alccofine as Sustainable Cementitious Materials. Sci. Rep. 2024, 14, 19115. [Google Scholar] [CrossRef]

- Rudziewicz, M.; Maroszek, M.; Góra, M.; Dziura, P.; Mróz, K.; Hager, I.; Hebda, M. Feasibility Review of Aerated Materials Application in 3D Concrete Printing. Materials 2023, 16, 6032. [Google Scholar] [CrossRef] [PubMed]

- Venugopal Reddy, P.; Nakkeeran, G.; Roy, D.; Alaneme, G.U. Evaluating the Use of Recycled Fine Aggregates in 3D Printing: A Systematic Review. Discov. Appl. Sci. 2024, 6, 630. [Google Scholar] [CrossRef]

- Krishnan, A.K.; Wong, Y.C.; Zhang, Z.; Arulrajah, A. A Transition towards Circular Economy with the Utilisation of Recycled Fly Ash and Waste Materials in Clay, Concrete and Fly Ash Bricks: A Review. J. Build. Eng. 2024, 98, 111210. [Google Scholar] [CrossRef]

- Chen, Y.; Fan, Y.; Huang, Y.; Liao, X.; Xu, W.; Zhang, T. A Comprehensive Review of Toxicity of Coal Fly Ash and Its Leachate in the Ecosystem. Ecotoxicol. Environ. Saf. 2024, 269, 115905. [Google Scholar] [CrossRef] [PubMed]

- Szcześniak, A.; Siwiński, J.; Stolarski, A.; Piekarczuk, A.; Nasiłowska, B. The Influence of the Addition of Microsilica and Fly Ash on the Properties of Ultra-High-Performance Concretes. Materials 2024, 18, 28. [Google Scholar] [CrossRef]

- Singh, G.B.; Prasad, V.D. Environmental Impact of Concrete Containing High Volume Fly Ash and Ground Granulated Blast Furnace Slag. J. Clean. Prod. 2024, 448, 141729. [Google Scholar] [CrossRef]

- Ahmed, A. Assessing the Effects of Supplementary Cementitious Materials on Concrete Properties:A Review. Discov. Civ. Eng. 2024, 1, 145. [Google Scholar] [CrossRef]

- Priyadarshini, M.; Patnaik, M.; Giri, J.P. A Probabilistic Approach for Identification of Compressive Strength of Fly Ash Bricks. Innov. Infrastruct. Solut. 2018, 3, 56. [Google Scholar] [CrossRef]

- Ram, A.K.; Reddy, M.V.R.K.; Mohanty, S. Identification of Preferable Method for the Precise Estimation of Coefficient of Consolidation (Cv) for Coal Ash. Eur. J. Environ. Civ. Eng. 2023, 27, 860–892. [Google Scholar] [CrossRef]

- Panda, L.; Dash, S. Characterization and Utilization of Coal Fly Ash: A Review. Emerg. Mater. Res. 2020, 9, 921–934. [Google Scholar] [CrossRef]

- Alterary, S.S.; Marei, N.H. Fly Ash Properties, Characterization, and Applications: A Review. J. King Saud Univ. Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

- Sahoo, D.K.; Kishor, M.S.V.R.; Sahoo, D.P.; Sarkar, S.; Behera, A. Nanoscale Analysis on Spark Plasma Sintered Fly-Ash Bricks and Their Comparative Study with SiN-Zr Refractory Bricks. Micro Nanosyst. 2020, 12, 122–128. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, D.; Li, H.; Sun, X.; Zhao, K.; Wang, Y. Effect of FA and GGBFS on Compressive Strength, Rheology, and Printing Properties of Cement-Based 3D Printing Material. Constr. Build. Mater. 2022, 339, 127685. [Google Scholar] [CrossRef]

- Paritala, S.; Singaram, K.K.; Bathina, I.; Khan, M.A.; Jyosyula, S.K.R. Rheology and Pumpability of Mix Suitable for Extrusion-Based Concrete 3D Printing—A Review. Constr. Build. Mater. 2023, 402, 132962. [Google Scholar] [CrossRef]

- Abu Taqa, A.; Mohsen, M.O.; Aburumman, M.O.; Naji, K.; Taha, R.; Senouci, A. Nano-Fly Ash and Clay for 3D-Printing Concrete Buildings: A Fundamental Study of Rheological, Mechanical and Microstructural Properties. J. Build. Eng. 2024, 92, 109718. [Google Scholar] [CrossRef]

- Luo, S.; Jin, W.; Wu, W.; Zhang, K. Rheological and Mechanical Properties of Polyformaldehyde Fiber Reinforced 3D-Printed High-Strength Concrete with the Addition of Fly Ash. J. Build. Eng. 2024, 98, 111387. [Google Scholar] [CrossRef]

- Tseng, K.-C.; Chi, M.; Yeih, W.; Huang, R. Influence of Slag/Fly Ash as Partial Cement Replacement on Printability and Mechanical Properties of 3D-Printed Concrete. Appl. Sci. 2025, 15, 3933. [Google Scholar] [CrossRef]

- Abudawaba, F.; Gomaa, E.; Gheni, A.; ElGawady, M. Developing Mix Proportions for Class C Fly Ash-Based Alkali-Activated 3D-Printed Concrete Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2022, 2676, 197–212. [Google Scholar] [CrossRef]

- Samrani, P.; Cao, Y.; Fimbres-Weihs, G.; Sanjaya, E.; Abbas, A. Effect of Fly Ash and Ground Waste Glass as Cement Replacement in Concrete 3D-Printing for Sustainable Construction. Front. Built Environ. 2024, 10, 1430174. [Google Scholar] [CrossRef]

- Wibowo, A.P.; Saidani, M. Mortar with Fly Ash as a Partial Cement Replacement: Analysing the Compressive Strength and Heat of Hydration. In Proceedings of the Third International Conference of Construction, Infrastructure, and Materials (ICCIM 2023), Jakarta, Indonesia, 27–29 July 2023; Volume 429, p. 05033. [Google Scholar] [CrossRef]

- Choi, Y.-C.; Park, B. Effects of Fly Ash Particle Size and Chemical Activators on the Hydration of High-Volume Fly Ash Mortars. Materials 2024, 17, 5485. [Google Scholar] [CrossRef] [PubMed]

- Melichar, J.; Žižková, N.; Brožovský, J.; Mészárosová, L.; Hermann, R. Study of the Interaction of Cement-Based Materials for 3D Printing with Fly Ash and Superabsorbent Polymers. Buildings 2022, 12, 2008. [Google Scholar] [CrossRef]

- Abudawaba, F.; Gomaa, E.; Gheni, A.A.; Feys, D.; ElGawady, M.A. Evaluation of Fresh Properties of High Calcium Content Fly Ash-Based Alkali-Activated 3D-Printed Mortar. J. Build. Eng. 2025, 104, 112244. [Google Scholar] [CrossRef]

- Schackow, A.; Andrade Neto, J.D.S.; Hack, L.; Folgueras, M.V.; Kirchheim, A.P.; Rodríguez Martinez, E.D.; Matos, P.R.D. Coal Bottom Ash as Supplementary Cementitious Material: Optimizing Reactivity Through Particle Grinding. Sustainability 2025, 17, 5031. [Google Scholar] [CrossRef]

- Argiz, C.; Sanjuán, M.Á.; Menéndez, E. Coal Bottom Ash for Portland Cement Production. Adv. Mater. Sci. Eng. 2017, 2017, 6068286. [Google Scholar] [CrossRef]

- Hokkaido Electric Power Co., Inc. About Coal Ash. What Is Coal Ash? 2020. Available online: https://www.hepco.co.jp/english/environment/coal_ash_about.html (accessed on 3 September 2025).

- Ganesan, H.; Sachdeva, A.; Petrounias, P.; Lampropoulou, P.; Sharma, P.K.; Kumar, A. Impact of Fine Slag Aggregates on the Final Durability of Coal Bottom Ash to Produce Sustainable Concrete. Sustainability 2023, 15, 6076. [Google Scholar] [CrossRef]

- Chuang, C.-W.; Chen, T.-A.; Huang, R. Effect of Finely Ground Coal Bottom Ash as Replacement for Portland Cement on the Properties of Ordinary Concrete. Appl. Sci. 2023, 13, 13212. [Google Scholar] [CrossRef]

- Oruji, S.; Brake, N.A.; Nalluri, L.; Guduru, R.K. Strength Activity and Microstructure of Blended Ultra-Fine Coal Bottom Ash-Cement Mortar. Constr. Build. Mater. 2017, 153, 317–326. [Google Scholar] [CrossRef]

- Guan, X.; Wang, L.; Mo, L. Effects of Ground Coal Bottom Ash on the Properties of Cement-Based Materials under Various Curing Temperatures. J. Build. Eng. 2023, 69, 106196. [Google Scholar] [CrossRef]

- Aydin, E. Novel Coal Bottom Ash Waste Composites for Sustainable Construction. Constr. Build. Mater. 2016, 124, 582–588. [Google Scholar] [CrossRef]

- Poudel, S.; Menda, S.; Useldinger-Hoefs, J.; Guteta, L.E.; Dockter, B.; Gedafa, D.S. The Use of Ground Coal Bottom Ash/Slag as a Cement Replacement for Sustainable Concrete Infrastructure. Materials 2024, 17, 2316. [Google Scholar] [CrossRef] [PubMed]

- Al Biajawi, M.I.; Embong, R.; Muthusamy, K.; Ismail, N.; Obianyo, I.I. Recycled Coal Bottom Ash as Sustainable Materials for Cement Replacement in Cementitious Composites: A Review. Constr. Build. Mater. 2022, 338, 127624. [Google Scholar] [CrossRef]

- Miyamoto, T.; Akahane, K.; Torii, K.; Hayashiguchi, S. Production and Use of Blast Furnace Slag Aggregate for Concrete. 2015. Available online: https://www.nipponsteel.com/en/tech/report/nssmc/pdf/109-18.pdf (accessed on 3 September 2025).

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M.A. A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Omer, B.; Saeed, N.M.; Dheyaaldin, M.H.; Jamal, A.S.; Kurda, R. Evaluating the Long-Term Strength of GGBFS-Blended Cement across Various Water-to-Binder and Superplasticizer Ratios under Heating/Cooling Cycles. PLoS ONE 2025, 20, e0319923. [Google Scholar] [CrossRef]

- Jozić, D.; Ljubičić, B.; Petrović, A.; Čović, A.; Juradin, S. The Influence of GGBFS as an Additive Replacement on the Kinetics of Cement Hydration and the Mechanical Properties of Cement Mortars. Buildings 2023, 13, 1960. [Google Scholar] [CrossRef]

- Akhlaq, H.; Peng, T.; Ajmal, M.M.; Khan, M.S.; Riaz, M. Impact of GGBS on the Rheology and Mechanical Behavior of Pumpable Concrete. Front. Mater. 2025, 12, 1614951. [Google Scholar] [CrossRef]

- Rahmat, N.F.; Ali, N.; Abdullah, S.R.; Abdul Hamid, N.A.; Salleh, N.; Shahidan, S. Fresh Properties and Flexural Strength of 3D Printing Sustainable Concrete Containing GGBS as Partial Cement Replacement. In Proceedings of the IOP Conference Series: Earth Environmental Science, Wuhan, China, 6–11 June 2023; IOP Publishing: Bristol, UK, 2023; Volume 1205, p. 012042. [Google Scholar] [CrossRef]

- Shoueb, M.B. Characterization of Fresh and Hardened Properties of 3D Printable Cementitious Materials Produced with Ground-Granulated Blast-Furnace Slag. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2021. [Google Scholar]

- Shreyas, K. Characteristics of GGBS as an Alternate Material in Conventional Concrete. Int. J. Creat. Res. Thoughts 2017, 5, 3174–3184. [Google Scholar]

- Roszak, W.; Kubiczek, F. Concretes Made of Lightweight Aggregates; Arkady: Warsaw, Poland, 1989. [Google Scholar]

- Rehman, A.U.; Kim, J.-H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Microstructural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef]

- Chan, L.-J.; Padil, K.H.; Chin, C.-L.; Ibrahim, I.S.; Ma, C.-K.; Chiew, S.-M.; Ler, K.-H.; Ab Ghafar, M.A.I. Strategies to Enhance Interlayer Bonding in 3D Printed Concrete: A Review. J. Build. Eng. 2025, 113, 114077. [Google Scholar] [CrossRef]

- Tao, Y.; Lesage, K.; Van Tittelboom, K.; Yuan, Y.; De Schutter, G. Influence of Substrate Surface Roughness and Moisture Content on Tensile Adhesion Performance of 3D Printable Concrete. Cem. Concr. Compos. 2022, 126, 104350. [Google Scholar] [CrossRef]

- Strzałkowska, E. Characteristics of Physicochemical and Mineralogical Properties of Selected Coal Combustion By-Products; Silesian University of Technology Publishing House: Gliwice, Poland, 2011. [Google Scholar]

- Smarzewski, P. Long-Term Behavior and Microstructure of High-Performance Concrete with Coal Slag. Materials 2025, 18, 2585. [Google Scholar] [CrossRef]

- Guteta, L.E.; Menda, S.; Poudel, S.; Useldinger-Hoefs, J.; Gedafa, D.S.; Dockter, B. Effect of Coal Bottom Ash and Coal Bottom Slag on Fresh, Mechanical, and Durability Properties of Concrete. In Proceedings of the International Conference on Transportation and Development, Atlanta, GA, USA, 13 June 2024; American Society of Civil Engineers: Reston, VA, USA, 2024; pp. 197–208. [Google Scholar]

- Regulation of the Council of Ministers of 2 January 2007 on the Requirements for the Content of Natural Radioactive Isotopes of Potassium K-40, Radium Ra-226, and Thorium Th-228 in Raw Materials and Materials Used in Buildings Intended for the Stay of People and Livestock, as Well as in Industrial Waste Used in Construction, and the Control of the Content of These Isotopes (Dz.U. 2007 nr 4, poz. 29). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20070040029 (accessed on 25 September 2025).

- Trinh, Q.V.; Mucsi, G.; Dang, T.V.; Le, L.P.; Bui, V.H.; Nagy, S. The influence of process conditions on ground coal slag and blast furnace slag based geopolymer properties. Rud. Geološko Naft. Zb. 2020, 35, 15–20. [Google Scholar] [CrossRef]

- Luo, B.; Su, Y.; Ding, X.; Chen, Y.; Liu, C. Modulation of Initial CaO/Al2O3 and SiO2/Al2O3 Ratios on the Properties of Slag/Fly Ash-Based Geopolymer Stabilized Clay: Synergistic Effects and Stabilization Mechanism. Mater. Today Commun. 2025, 47, 113295. [Google Scholar] [CrossRef]

- Khargerdi, H.R.; Movahedifar, S.M.; Motavalizadehkakhky, A.; Honarbakhsh, A.; Zhiani, R. Effects of FeNi3 Nanoparticles and Coal Slag on Mechanical and Durability Properties of Concrete against Acidic Environments. Adv. Civ. Eng. 2023, 2023, 5596917. [Google Scholar] [CrossRef]

- Rudziewicz, M.; Hutyra, A.; Maroszek, M.; Korniejenko, K.; Hebda, M. 3D-Printed Lightweight Foamed Concrete with Dispersed Reinforcement. Appl. Sci. 2025, 15, 4527. [Google Scholar] [CrossRef]

- Ren, D.; Shi, D.; Guo, X. Mechanical Properties, Pore Structure, and Carbon Emission of Concrete by Using Coal-Fired Slag Powder to Partially Replace Cement. Case Stud. Constr. Mater. 2025, 23, e04972. [Google Scholar] [CrossRef]

- Liu, K.; Qiu, R.; Gou, J.; Ning, B.; Cui, C.; Chen, Y.; Wang, T. Experimental and Numerical Exploration of a New Application of Coal Slag to Treat Loose Sand Foundation. J. Clean. Prod. 2024, 441, 140936. [Google Scholar] [CrossRef]

- Khan, A.M.; Elahi, A.; Waqas, R.M.; Kırgız, M.S.; Nagaprasad, N.; Ramaswamy, K. Influence of Bentonite, Silica Fume, and Polypropylene Fibers on Green Concrete for Pavement and Structural Durability. Sci. Rep. 2025, 15, 29567. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Z.; Yi, M.; Yuan, Q.; Wang, D.; Liu, J. Study on the Durability of Silica Fume Concrete in High Sulfate Environment of Plateau. In Proceedings of Conference on Sustainable Traffic and Transportation Engineering in 2023; Bieliatynskyi, A., Komyshev, D., Zhao, W., Eds.; Lecture Notes in Civil Engineering; Springer Nature: Singapore, Singapore, 2024; Volume 603, pp. 15–29. ISBN 978-981-97-5813-5. [Google Scholar]

- Alhajiri, A.M.; Akhtar, M.N. Enhancing Sustainability and Economics of Concrete Production through Silica Fume: A Systematic Review. Civ. Eng. J. 2023, 9, 2612–2629. [Google Scholar] [CrossRef]

- Rashidian-Dezfouli, H.; Afshinnia, K.; Rangaraju, P.R. Efficiency of Ground Glass Fiber as a Cementitious Material, in Mitigation of Alkali-Silica Reaction of Glass Aggregates in Mortars and Concrete. J. Build. Eng. 2018, 15, 171–180. [Google Scholar] [CrossRef]

- Ahmad, J.; Martinez-Garcia, R.; Algarni, S.; de-Prado-Gil, J.; Alqahtani, T.; Irshad, K. Characteristics of Sustainable Concrete with Partial Substitutions of Glass Waste as a Binder Material. Int. J. Concr. Struct. Mater. 2022, 16, 21. [Google Scholar] [CrossRef]

- Barkauskas, K. The effect of ground glass waste on properties of hardened cement paste and mortar. Ceram. Silik. 2020, 64, 478–487. [Google Scholar] [CrossRef]

- Muhedin, D.A.; Ibrahim, R.K. Effect of Waste Glass Powder as Partial Replacement of Cement & Sand in Concrete. Case Stud. Constr. Mater. 2023, 19, e02512. [Google Scholar] [CrossRef]

- Őze, C.; Badacsonyi, N.; Makó, É. Mechanochemical Activation of Waste Clay Brick Powder with Addition of Waste Glass Powder and Its Influence on Pozzolanic Reactivity. Molecules 2024, 29, 5740. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Wu, Y.; Bai, G.; He, C.; Yao, Y.; Zhang, R.; Wang, Y. 3D Printing Concrete with Recycled Coarse Aggregates: The Influence of Pore Structure on Interlayer Adhesion. Cem. Concr. Compos. 2022, 134, 104742. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, H.; Wang, Y.; Xiong, L.; Wu, X. Effect of Clay Brick Powder and Recycled Fine Aggregates on Properties of 3D Printed Concrete after High Temperature Exposure. Constr. Build. Mater. 2025, 491, 142676. [Google Scholar] [CrossRef]

- Ge, Z.; Sun, R.J.; Zheng, L. Mechanical Properties of Concrete with Recycled Clay-Brick-Powder. Adv. Mater. Res. 2011, 250, 360–364. [Google Scholar] [CrossRef]

- Letelier, V.; Henríquez-Jara, B.I.; Manosalva, M.; Parodi, C.; Ortega, J.M. Use of Waste Glass as A Replacement for Raw Materials in Mortars with a Lower Environmental Impact. Energies 2019, 12, 1974. [Google Scholar] [CrossRef]

- Poudel, S.; Bhetuwal, U.; Kharel, P.; Khatiwada, S.; Kc, D.; Dhital, S.; Lamichhane, B.; Yadav, S.K.; Suman, S. Waste Glass as Partial Cement Replacement in Sustainable Concrete: Mechanical and Fresh Properties Review. Buildings 2025, 15, 857. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Gunasekara, C.; Fox, K.; Tran, P. 3D-Printed Concrete with Recycled Glass: Effect of Glass Gradation on Flexural Strength and Microstructure. Constr. Build. Mater. 2022, 314, 125561. [Google Scholar] [CrossRef]

- Deng, Q.; Zou, S.; Xi, Y.; Singh, A. Development and Characteristic of 3D-Printable Mortar with Waste Glass Powder. Buildings 2023, 13, 1476. [Google Scholar] [CrossRef]

- EN 206-1:2000; Concrete—Part 1: Specification, Performance, Production and Conformity. NSAI Standard: Dublin, Ireland, 2000.

- Colman, C.; Bulteel, D.; Elkarim, B.M.; Rémond, S.; Courard, L. Expansion of Concrete by Secondary Ettringite Formation Due to Fine Recycled Aggregates Contaminated with Gypsum. Adv. Cem. Res. 2023, 35, 480–488. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of Amount of Recycled Coarse Aggregates and Production Process on Properties of Recycled Aggregate Concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Wardeh, G.; Ghorbel, E.; Gomart, H. Mix Design and Properties of Recycled Aggregate Concretes: Applicability of Eurocode 2. Int. J. Concr. Struct. Mater. 2015, 9, 1–20. [Google Scholar] [CrossRef]

- Meddah, M.; Al-Harthy, A.A.; Ismail, M. Recycled Concrete Aggregates and Their Influences on Performances of Low and Normal Strength Concretes. Buildings 2020, 10, 167. [Google Scholar] [CrossRef]

- Reis, G.S.D.; Quattrone, M.; Ambrós, W.M.; Grigore Cazacliu, B.; Hoffmann Sampaio, C. Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef]

- García-González, J.; Rodríguez-Robles, D.; Juan-Valdés, A.; Morán-del Pozo, J.; Guerra-Romero, M. Pre-Saturation Technique of the Recycled Aggregates: Solution to the Water Absorption Drawback in the Recycled Concrete Manufacture. Materials 2014, 7, 6224–6236. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Ayoub, M.; Aljaghoub, H.; Alasad, S.; Abdelkareem, M.A. 3D Concrete Printing: Recent Progress, Applications, Challenges, and Role in Achieving Sustainable Development Goals. Buildings 2023, 13, 924. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Wang, Y. Hardened Properties of Layered 3D Printed Concrete with Recycled Sand. Cem. Concr. Compos. 2020, 113, 103724. [Google Scholar] [CrossRef]

- Ting, G.H.A.; Tay, Y.W.D.; Qian, Y.; Tan, M.J. Utilization of Recycled Glass for 3D Concrete Printing: Rheological and Mechanical Properties. J. Mater. Cycles Waste Manag. 2019, 21, 994–1003. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Wu, Y.; Bai, G.; He, C.; Zhang, R.; Wang, Y. Hardened Properties of 3D Printed Concrete with Recycled Coarse Aggregate. Cem. Concr. Res. 2022, 159, 106868. [Google Scholar] [CrossRef]

- Cavalcante, T.C.; Filho, R.D.T.; Reales, O.A.M. Rheological and Environmental Implications of Recycled Concrete Powder as Filler in Concrete 3D Printing. Buildings 2025, 15, 1280. [Google Scholar] [CrossRef]

- Cavalcante, T.C.; Toledo Filho, R.D.; Reales, O.A.M. Influence of Recycled Concrete Powder on Rheology of Printable Cement-Based Matrixes. Mat. J. 2024, 121, 69–80. [Google Scholar] [CrossRef]

- Zhuang, Z.; Xu, F.; Ye, J.; Hu, N.; Jiang, L.; Weng, Y. A Comprehensive Review of Sustainable Materials and Toolpath Optimization in 3D Concrete Printing. NPJ Mater. Sustain. 2024, 2, 12. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, C.; Bai, G.; Liu, H.; Meng, Y.; Wang, Z. 3D Printed Concrete with Recycled Sand: Pore Structures and Triaxial Compression Properties. Cem. Concr. Compos. 2023, 139, 105048. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, C.; Liu, H.; Zhang, Z.; He, C.; Liu, S.; Zhang, R.; Wang, Y.; Bai, G. Study on the Rheology and Buildability of 3D Printed Concrete with Recycled Coarse Aggregates. J. Build. Eng. 2021, 42, 103030. [Google Scholar] [CrossRef]

- Pepe, M.; Lombardi, R.; Lima, C.; Paolillo, B.; Martinelli, E. Experimental Evidence on the Possible Use of Fine Concrete and Brick Recycled Aggregates for 3D Printed Cement-Based Mixtures. Materials 2025, 18, 583. [Google Scholar] [CrossRef] [PubMed]

- Christen, H.; Van Zijl, G.; De Villiers, W. The Incorporation of Recycled Brick Aggregate in 3D Printed Concrete. Clean. Mater. 2022, 4, 100090. [Google Scholar] [CrossRef]

- Oosthuizen, J.D.; Babafemi, A.J.; Walls, R.S. 3D-Printed Recycled Plastic Eco-Aggregate (Resin8) Concrete. Constr. Build. Mater. 2023, 408, 133712. [Google Scholar] [CrossRef]

- Skibicki, S.; Pułtorak, M.; Kaszyńska, M.; Hoffmann, M.; Ekiert, E.; Sibera, D. The Effect of Using Recycled PET Aggregates on Mechanical and Durability Properties of 3D Printed Mortar. Constr. Build. Mater. 2022, 335, 127443. [Google Scholar] [CrossRef]

- Liu, J.; Setunge, S.; Tran, P. 3D Concrete Printing with Cement-Coated Recycled Crumb Rubber: Compressive and Microstructural Properties. Constr. Build. Mater. 2022, 347, 128507. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Chougan, M.; Ghaffar, S.H. Composite Alkali-Activated Materials with Waste Tire Rubber Designed for Additive Manufacturing: An Eco-Sustainable and Energy Saving Approach. J. Mater. Res. Technol. 2023, 24, 3098–3117. [Google Scholar] [CrossRef]

- Sambucci, M.; Biblioteca, I.; Valente, M. Life Cycle Assessment (LCA) of 3D Concrete Printing and Casting Processes for Cementitious Materials Incorporating Ground Waste Tire Rubber. Recycling 2023, 8, 15. [Google Scholar] [CrossRef]

- Zou, M.; Liu, C.; Zhang, K.; Li, W.; Cao, Q.; Zhang, L.; Gu, T.; Zhang, G.; Liu, L. Evaluation and Control of Printability and Rheological Properties of 3D-Printed Rubberized Concrete. J. Build. Eng. 2023, 80, 107988. [Google Scholar] [CrossRef]

- Ambily, P.S.; Kaliyavaradhan, S.K.; Sebastian, S.; Shekar, D. Sustainable 3D Printable Concrete Mix Using Copper Slag. J. Build. Eng. 2025, 101, 111950. [Google Scholar] [CrossRef]

- Tran, N.; Van Tran, M.; Tran, P.; Nguyen, A.K.; Nguyen, C.Q. Eco-Friendly 3D-Printed Concrete Using Steel Slag Aggregate: Buildability, Printability and Mechanical Properties. Int. J. Concr. Struct. Mater. 2024, 18, 66. [Google Scholar] [CrossRef]

- Pavlů, T.; Pešta, J.; Fořtová, K.; Řepka, J. Recycled Concrete in Foundations: Mechanical and Environmental Insights. Buildings 2025, 15, 1237. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Babeker Elhag, A.; Deifalla, A.F.; Soomro, M.; Isleem, H.F.; Qaidi, S. A Step towards Sustainable Concrete with Substitution of Plastic Waste in Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Crystals 2022, 12, 944. [Google Scholar] [CrossRef]

- Sbardelotto, E.K.; Vieira, M.G.; Ferreira Dos Santos, K.; Pereira Dos Santos, S.; Martins Toralles, B. Exploratory Study on the Rheological Behaviour of 3D Printable Mortars Incorporating Fine Recycled Concrete Aggregates (FRCA). MATEC Web Conf. 2025, 409, 06005. [Google Scholar] [CrossRef]

- Gao, H.; Jin, L.; Chen, Y.; Chen, Q.; Liu, X.; Yu, Q. Rheological Behavior of 3D Printed Concrete: Influential Factors and Printability Prediction Scheme. J. Build. Eng. 2024, 91, 109626. [Google Scholar] [CrossRef]

- Yang, L.; Gao, Y.; Chen, H.; Jiao, H.; Dong, M.; Bier, T.A.; Kim, M. Three-Dimensional Concrete Printing Technology from a Rheology Perspective: A Review. Adv. Cem. Res. 2024, 36, 567–586. [Google Scholar] [CrossRef]

- Bao, T.M.P.; Yeakleang, M.; Abdelouhab, S.; Courard, L. Testing Mortars for 3D Printing: Correlation with Rheological Behavior. Materials 2024, 17, 5002. [Google Scholar] [CrossRef] [PubMed]

- Al Martini, S.; Khartabil, A.; Saboumi, A.R. Sustainable Concrete Using Recycled Aggregate and Supplementary Cementitious Materials. In Proceedings of the 6th International Conference on Engineering Mechanics and Materials, Vancouver, BC, Canada, 10–13 December 2017. [Google Scholar]

- Li, Q.; Fan, Y.; Shah, S.P. Rheological Properties and Structural Build-Up of Cement Based Materials with Addition of Nanoparticles: A Review. Buildings 2022, 12, 2219. [Google Scholar] [CrossRef]

- Irshidat, M.; Cabibihan, J.-J.; Fadli, F.; Al-Ramahi, S.; Saadeh, M. Waste Materials Utilization in 3D Printable Concrete for Sustainable Construction Applications: A Review. Emergent Mater. 2025, 8, 1357–1379. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of Concrete Made with Commercially Produced Coarse Recycled Concrete Aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Duan, Z.; Hou, S.; Xiao, J.; Li, B. Study on the Essential Properties of Recycled Powders from Construction and Demolition Waste. J. Clean. Prod. 2020, 253, 119865. [Google Scholar] [CrossRef]

- Singh, A.; Miao, X.; Zhou, X.; Deng, Q.; Li, J.; Zou, S.; Duan, Z. Use of Recycled Fine Aggregates and Recycled Powders in Sustainable Recycled Concrete. J. Build. Eng. 2023, 77, 107370. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of Concrete Incorporating Fine Recycled Aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, Y.; Zhao, Y.; Zhang, M.; Tong, J.; Zhu, L.; Guo, S. Impact of Pre-Soaked Lime Water Carbonized Recycled Fine Aggregate on Mechanical Properties and Pore Structure of 3D Printed Mortar. J. Build. Eng. 2024, 89, 109190. [Google Scholar] [CrossRef]

- Emad, W.; Mohammed, A.S.; Kurda, R.; Ghafor, K.; Cavaleri, L.; Qaidi, S.M.; Hassan, A.M.T.; Asteris, P.G. Prediction of Concrete Materials Compressive Strength Using Surrogate Models. Structures 2022, 46, 1243–1267. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of Fine Recycled Concrete Aggregates in Concrete: A Critical Review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D Printing Trends in Building and Construction Industry: A Review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Xiao, J.; Han, N.; Zhang, L.; Zou, S. Mechanical and Microstructural Evolution of 3D Printed Concrete with Polyethylene Fiber and Recycled Sand at Elevated Temperatures. Constr. Build. Mater. 2021, 293, 123524. [Google Scholar] [CrossRef]

- Aboalella, A.A.; Elmalky, A. Use of Crushed Bricks and Recycled Concrete as Replacement for Fine and Coarse Aggregates for Sustainable Concrete Production. Chall. J. Concr. Res. Lett. 2023, 14, 39. [Google Scholar] [CrossRef]

- Zheng, C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical Properties of Recycled Concrete with Demolished Waste Concrete Aggregate and Clay Brick Aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Rudziewicz, M.; Maroszek, M.; Hutyra, A.; Góra, M.; Rusin-Żurek, K.; Hebda, M. Influence of Foaming Agents and Stabilizers on Porosity in 3D Printed Foamed Concrete. Processes 2025, 13, 403. [Google Scholar] [CrossRef]

- Zhang, H.; Ma, J.; Wu, B.; LÜ, Y. Effect of Recycled Fine Aggregate and Clay Brick Powder on Properties of 3D Printed Concrete. Nat. Sci. Ed. 2024, 52, 18–27. [Google Scholar] [CrossRef]

- Peyrot, I.C. Development and Validation of a 3D Computational Tool to Describe Damage and Fracture Due to Alkali-Silica Reaction in Concrete Structures. Ph.D. Thesis, École Nationale Supérieure des Mines de Paris, Paris, France, 2006. [Google Scholar]

- Kim, I.S.; Choi, S.Y.; Yang, E.I. Evaluation of Durability of Concrete Substituted Heavyweight Waste Glass as Fine Aggregate. Constr. Build. Mater. 2018, 184, 269–277. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, Y.; Guo, M.; Zhang, L.; Ning, H.; Liu, S. Mechanical and Fracture Properties of Ultra-High Performance Concrete (UHPC) Containing Waste Glass Sand as Partial Replacement Material. J. Clean. Prod. 2020, 277, 123501. [Google Scholar] [CrossRef]

- Maroszek, M.; Hager, I.; Mróz, K.; Sitarz, M.; Hebda, M. Anisotropy of Mechanical Properties of 3D-Printed Materials—Influence of Application Time of Subsequent Layers. Materials 2025, 18, 3845. [Google Scholar] [CrossRef]

- Mim, N.J.; Shaikh, F.U.A.; Sarker, P.K. Sustainable 3D Printed Concrete Incorporating Alternative Fine Aggregates: A Review. Case Stud. Constr. Mater. 2025, 22, e04570. [Google Scholar] [CrossRef]

- Roussel, N. Rheological Requirements for Printable Concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Şahin, H.G.; Mardani, A.; Mardani, N. Performance Requirements and Optimum Mix Proportion of High-Volume Fly Ash 3D Printable Concrete. Buildings 2024, 14, 2069. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental Study on Mix Proportion and Fresh Properties of Fly Ash Based Geopolymer for 3D Concrete Printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Liu, B.; Huang, X.; Zhang, X.; Ren, S.; Lan, Q.; Luo, C. Numerical and Experimental Studies on the Improvement of Gas Chamber Structure during Gas-Assisted Extrusion. Polymers 2022, 14, 5272. [Google Scholar] [CrossRef] [PubMed]

- Salah, H.A.; Mutalib, A.A.; Kaish, A.B.M.A.; Syamsir, A.; Algaifi, H.A. Development of Ultra-High-Performance Silica Fume-Based Mortar Incorporating Graphene Nanoplatelets for 3-Dimensional Concrete Printing Application. Buildings 2023, 13, 1949. [Google Scholar] [CrossRef]

- Skibicki, S.; Federowicz, K.; Hoffmann, M.; Chougan, M.; Sibera, D.; Cendrowski, K.; Techman, M.; Pacheco, J.N.; Liard, M.; Sikora, P. Potential of Reusing 3D Printed Concrete (3DPC) Fine Recycled Aggregates as a Strategy towards Decreasing Cement Content in 3DPC. Materials 2024, 17, 2580. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Yuan, Q.; Peng, J. Effect of Coarse Aggregate on Printability and Mechanical Properties of 3D Printed Concrete. Constr. Build. Mater. 2023, 405, 133338. [Google Scholar] [CrossRef]

- Wang, X.; Du, L.; Liu, Z.; Li, M.; Weng, Y.; Liu, Z.; Tay, Y.W.D.; Fan, Z.; Wong, T.N.; Tan, M.J. 3D Cementitious Composites Printing with Pretreated Recycled Crumb Rubber: Mechanical and Acoustic Insulation Properties. Virtual Phys. Prototyp. 2024, 19, e2399787. [Google Scholar] [CrossRef]

- Barve, P.; Bahrami, A.; Shah, S. Geopolymer 3D Printing: A Comprehensive Review on Rheological and Structural Performance Assessment, Printing Process Parameters, and Microstructure. Front. Mater. 2023, 10, 1241869. [Google Scholar] [CrossRef]

- Hassan, A.; Alomayri, T.; Noaman, M.F.; Zhang, C. 3D Printed Concrete for Sustainable Construction: A Review of Mechanical Properties and Environmental Impact. Arch. Comput. Methods Eng. 2025, 32, 2713–2743. [Google Scholar] [CrossRef]

- CEN EN 15804:2012+A2:2019/AC:2021; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. CEN: Brussels, Belgium, 2019.

- Gheibi, M.; Karrabi, M.; Shakerian, M.; Mirahmadi, M. Life Cycle Assessment of Concrete Production with a Focus on Air Pollutants and the Desired Risk Parameters Using Genetic Algorithm. J. Environ. Health Sci. Eng. 2018, 16, 89–98. [Google Scholar] [CrossRef] [PubMed]

- Sabău, M.; Bompa, D.V.; Silva, L.F.O. Comparative Carbon Emission Assessments of Recycled and Natural Aggregate Concrete: Environmental Influence of Cement Content. Geosci. Front. 2021, 12, 101235. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO ISO 21930:2017; Sustainability in Buildings and Civil Engineering Works—Core Rules for Environmental Product Declarations of Construction Products and Services. International Organization for Standardization (ISO): Geneva, Switzerland, 2017.

- PRé Sustainability. SimaPro. 2025. Available online: https://simapro.com (accessed on 25 September 2025).

- GreenDelta GmbH. openLCA. 2025. Available online: https://www.openlca.org/ (accessed on 25 September 2025).

- Cerclos Pty Ltd. eToolLCD. 2025. Available online: https://cerclos.com/products/etool (accessed on 25 September 2025).

- Building Transparency. Tally. 2025. Available online: https://apps.autodesk.com (accessed on 25 September 2025).

- One Click LCA Ltd. One Click LCA. 2025. Available online: https://www.oneclicklca.com (accessed on 25 September 2025).

- Global Cement and Concrete Association (GCCA). GCCA Industry EPD Tool. 2025. Available online: https://gccaepd.org (accessed on 27 September 2025).

- CEN EN 16757:2017; Sustainability of Construction Works—EPD—PCR for Concrete and Concrete Elements. CEN: Brussels, Belgium, 2022.

- ISO ISO 14067:2018; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. International Organization for Standardization (ISO): Geneva, Switzerland, 2018.

- Marinković, S.; Josa, I.; Braymand, S.; Tošić, N. Sustainability Assessment of Recycled Aggregate Concrete Structures: A Critical View on the Current State-of-knowledge and Practice. Struct. Concr. 2023, 24, 1956–1979. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Fernández-Ledesma, E.; González-Caro, Á.; Merino-Lechuga, A.M.; Fernández-Rodríguez, J.M.; Jiménez, J.R. Carbon Emission Evaluation of CO2 Curing in Vibro-Compacted Precast Concrete Made with Recycled Aggregates. Materials 2023, 16, 2436. [Google Scholar] [CrossRef]

- Panesar, D.K.; Kanraj, D.; Abualrous, Y. Effect of Transportation of Fly Ash: Life Cycle Assessment and Life Cycle Cost Analysis of Concrete. Cem. Concr. Compos. 2019, 99, 214–224. [Google Scholar] [CrossRef]

- Capon, R.; de Saulles, T. UK Greenhouse Gas Inventory Improvement: Carbonation of Concrete Emissions Sink Modelling; Mineral Products Association (MPA): London, UK, 2023. Available online: https://naei.energysecurity.gov.uk/sites/default/files/cat07/2307071003_UK_GHG_Inventory_Improvement_Recarbonation_Final_Report.pdf (accessed on 3 September 2025).

- Witte, A.; Garg, N. Quantifying the Global Warming Potential of Low Carbon Concrete Mixes: Comparison of Existing Life Cycle Analysis Tools. Case Stud. Constr. Mater. 2024, 20, e02832. [Google Scholar] [CrossRef]

- Dervishaj, A.; Malmqvist, T.; Silfwerbrand, J.; Gudmundsson, K. A Digital Workflow for Assessing Lifespan, Carbonation, and Embodied Carbon of Reusing Concrete in Buildings. J. Build. Eng. 2024, 96, 110536. [Google Scholar] [CrossRef]

- Huang, H.; Wang, T.; Kolosz, B.; Andresen, J.; Garcia, S.; Fang, M.; Maroto-Valer, M.M. Life-Cycle Assessment of Emerging CO2 Mineral Carbonation-Cured Concrete Blocks: Comparative Analysis of CO2 Reduction Potential and Optimization of Environmental Impacts. J. Clean. Prod. 2019, 241, 118359. [Google Scholar] [CrossRef]

- Linares, R.; López-Uceda, A.; Piccinali, A.; Martínez-Ruedas, C.; Galvín, A.P. LCA Applied to Comparative Environmental Evaluation of Aggregate Production from Recycled Waste Materials and Virgin Sources. Environ. Sci. Pollut. Res. 2024, 31, 44023–44035. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental Impact of Cement Production: Detail of the Different Processes and Cement Plant Variability Evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- National Ready Mixed Concrete Association (NRMCA). Industry-Wide Environmental Product Declaration (EPD) for Ready Mixed Concrete; NRMCA: Alexandria, VA, USA, 2017. [Google Scholar]

- Heidelberg Materials UK. UK Average Ready-Mixed Concrete—EPD According to EN 15804+A2; EPD-Norge: Oslo, Norway, 2024. [Google Scholar]

- Canadian Ready-Mixed Concrete Association (CRMCA). Industry-Wide Environmental Product Declaration (EPD) for Ready-Mixed Concrete; CRMCA: Ottawa, ON, Canada, 2022. [Google Scholar]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary Cementitious Materials: New Sources, Characterization, and Performance Insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and Composition of Recycled Aggregates from Construction and Demolition Waste Suitable for Concrete Production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; De Brito, J. Life Cycle Assessment of Concrete Made with High Volume of Recycled Concrete Aggregates and Fly Ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Imtiaz, L.; Kashif-ur-Rehman, S.; Alaloul, W.S.; Nazir, K.; Javed, M.F.; Aslam, F.; Musarat, M.A. Life Cycle Impact Assessment of Recycled Aggregate Concrete, Geopolymer Concrete, and Recycled Aggregate-Based Geopolymer Concrete. Sustainability 2021, 13, 13515. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon Dioxide Equivalent (CO2-e) Emissions: A Comparison between Geopolymer and OPC Cement Concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Munir, Q.; Abdulkareem, M.; Horttanainen, M.; Kärki, T. A Comparative Cradle-to-Gate Life Cycle Assessment of Geopolymer Concrete Produced from Industrial Side Streams in Comparison with Traditional Concrete. Sci. Total Environ. 2023, 865, 161230. [Google Scholar] [CrossRef]

- Tushar, Q.; Bhuiyan, M.A.; Abunada, Z.; Lemckert, C.; Giustozzi, F. Carbon Footprint and Uncertainties of Geopolymer Concrete Production: A Comprehensive Life Cycle Assessment (LCA). C 2025, 11, 55. [Google Scholar] [CrossRef]

- Yao, Y.; Hu, M.; Di Maio, F.; Cucurachi, S. Life Cycle Assessment of 3D Printing Geo-polymer Concrete: An Ex-ante Study. J Ind. Ecol. 2020, 24, 116–127. [Google Scholar] [CrossRef]

- Chen, Y.; Veer, F.A.; Copuroglu, O. A Critical Review of 3D Concrete Printing as a Low CO2 Concrete Approach. Heron 2017, 62, 167–194. [Google Scholar]

- Wolska-Kotańska, C. Właściwości i zastosowanie kruszywa z recyklingu betonu. Mag. Autostrady 2005, 3, 18–22. [Google Scholar]

- European Insulation Manufacturers Association (EURIMA). Information Sheet on Mineral Wool Waste Handling; EURIMA: Brussels, Belgium, 2016; Available online: https://www.eurima.org/uploads/files/modules/articles/1584367760_SC%20Eurima_waste_handling_Info_Sheet_06_06_2016_final.pdf (accessed on 3 September 2025).

- European Commission. LIFE ReWo—Recycling Mineral Wool Waste into High-Value Products; European Commission: Brussels, Belgium, 2023. Available online: https://webgate.ec.europa.eu/life/publicWebsite/project/LIFE22-ENV-IT-LIFE-ReWo-101113855/recycling-mineral-wool-waste-into-high-value-products (accessed on 3 September 2025).

- Fu, K.; Xue, Y.; Qiu, D.; Wang, P.; Lu, H. Multi-Channel Fusion Prediction of TBM Tunneling Thrust Based on Multimodal Decomposition and Reconstruction. Tunn. Undergr. Space Technol. 2026, 167, 107061. [Google Scholar] [CrossRef]

- Dong, H.; Cao, W.; Bian, J.; Zhang, J. The Fire Resistance Performance of Recycled Aggregate Concrete Columns with Different Concrete Compressive Strengths. Materials 2014, 7, 7843–7860. [Google Scholar] [CrossRef] [PubMed]

- Nemova, D.; Kotov, E.; Andreeva, D.; Khorobrov, S.; Olshevskiy, V.; Vasileva, I.; Zaborova, D.; Musorina, T. Experimental Study on the Thermal Performance of 3D-Printed Enclosing Structures. Energies 2022, 15, 4230. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Gatheeshgar, P.; Upasiri, I.; Poologanathan, K.; Nagaratnam, B.; Rajanayagam, H.; Navaratnam, S. Numerical Study of Fire and Energy Performance of Innovative Light-Weight 3D Printed Concrete Wall Configurations in Modular Building System. Sustainability 2021, 13, 2314. [Google Scholar] [CrossRef]

- Fu, H.; Tian, J.; Chin, C.-L.; Liu, H.; Yuan, J.; Tang, S.; Mai, R.; Wu, X. Axial Compression Behavior of GFRP-Steel Composite Tube Confined Seawater Sea-Sand Concrete Intermediate Long Columns. Eng. Struct. 2025, 333, 120157. [Google Scholar] [CrossRef]

- SKANSKA. Making Better Mixes: Low-Carbon and Circular Concrete. 2024. Available online: https://group.skanska.com (accessed on 3 September 2025).

- Interreg Europe. Erc-Tech—Cutting Edge Use Case of Recycling Concrete. 2021. Available online: https://www.interregeurope.eu (accessed on 3 September 2025).

- Holcim. CEM IV/B (V) 42,5 N-LH/NA. 2023. Available online: https://www.holcim.pl/sites/poland2/files/documents/karta_produktowa_ecoplanet_cem_iv_bv_425_n-lh_na.pdf (accessed on 3 September 2025).

- CEMEX. More Sustainable by Design. 2025. Available online: https://www.cemex.com/products-solutions/vertua (accessed on 3 September 2025).

- Heidelberg Materials. Significant CO2 Reduction: HeidelbergCement Expands Sustainable Concrete Portfolio in Germany Under EcoCrete Brand. 2022. Available online: https://www.heidelbergmaterials.com/en/pr-20-01-2022 (accessed on 3 September 2025).

| Parameter | Fly Ash (FA) | Coal Bottom Ash (CBA) |

|---|---|---|

| Source | Particles from flue gas transport | Clinker-like lumps from boiler bottom |

| Density (g/cm3) | 2.18–2.32 | 2.20–2.40 |

| Moisture content (%) | 0.01–0.11 | 26.5–50.1 |

| Median particle size (mm, d50) | 0.01–0.03 | 0.42–2.19 |

| Sand fraction (%) | 3.5–7.5 | 39.8–56.9 |

| Dust fraction (%) | 77.6–90.2 | 5.3–18.0 |

| SiO2 (%) | 51.1–64.4 | 52.0–64.9 |

| Al2O3 (%) | 19.4–27.9 | 17.9–24.7 |

| Fe2O3 (%) | 3.5–8.0 | 4.9–9.6 |

| CaO (%) | 1.3–6.2 | 2.1–7.1 |

| SO3 (%) | 0–2.1 | 0–1.3 |

| pH | 8.1–12.8 | 8.3–9.7 |

| Loss on ignition (%) | 0.9–2.1 | - |

| Practical properties | Improves workability, durability, increases compactness | Good permeability, water retention, mechanical stability |

| Material | Advantages (3DCP) | Disadvantages (3DCP) | References |

|---|---|---|---|

| Fly ash (FA) | Lowers plastic viscosity and often reduces τ0(dyn) → smoother pumping/extrusion; can stabilize buildability at moderate dosages; tends to widen the printability window. | High dosages may delay setting and reduce early green strength; buildability can drop without viscosity control/admixtures. | [154,155] |

| Ground granulated blast-furnace slag (GGBFS) | In alkali-activated materials/geopolymers (AAM/GP) systems: strong structural build-up (thixotropy) → high buildability; in cement blends with FA: can keep extrusion stable at lower GWP. | Activator sensitivity (Na/K, Si/Al, temperature) → risk of too short printability window or nozzle clogging if poorly tuned. | [47,156] |

| Silica fume (SF) | Strong increase of τ0(stat) and early stiffness → improved buildability and filament shape retention; can mitigate anisotropy via cleaner bead geometry. | Excess dosage raises viscosity → pumpability issues and potential nozzle blocking; requires precise W/B and SP control. | [157,158] |

| Recycled glass powder (WGP/GWG) | At small–moderate dosages: better matrix packing, longer printability window, and stable buildability in printable mortars. | Very high replacements may shorten open time (in GP/AAM) and degrade filament quality without viscosity tuning. | [100] |

| Recycled fine aggregate (RFA) | At modest levels can maintain extrusion; with concurrent cement reduction may keep buildability and extend printability by matrix tuning. | Higher fractions increase water/admixture demand, may raise τ0(dyn) and shorten open time; green strength often drops. | [32,159] |

| Recycled brick aggregate (RBA) | Rough angular surface may enhance interlayer mechanical interlock; feasible sand replacement with controlled grading/moisture. | High absorption/roughness → higher water demand and ↑ τ0(dyn); can reduce filament stability without paste adjustments. | [118] |

| Steel slag aggregate (SSA/SA) | Good extrudability at tuned SA/C and W/C; rough texture helps bead stability; synergy with SF improves buildability. | Higher absorption → water/admixture corrections needed; buildability moderate without viscosity modifiers. | [126,160] |

| Rubber aggregates (crumb rubber, GWTR) | Lighter mixes with damping; can keep extrusion continuity after surface treatment and paste tuning. | Strength reduction and shorter open time if untreated; viscosity ↑ → pumpability must be re-balanced; anisotropy may intensify. | [124,161] |

| Geopolymers (AAM/GP based on FA/GGBFS) | High buildability with fast structural build-up; early green strength enables layer stacking at low deformation; stable extrusion when τ0/viscosity sits in the process window. | High sensitivity to activator chemistry and curing temperature → risk of too short printability or pumpability loss; requires tight process control. | [156,162] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maroszek, M.; Rudziewicz, M.; Hebda, M. Recycled Components in 3D Concrete Printing Mixes: A Review. Materials 2025, 18, 4517. https://doi.org/10.3390/ma18194517

Maroszek M, Rudziewicz M, Hebda M. Recycled Components in 3D Concrete Printing Mixes: A Review. Materials. 2025; 18(19):4517. https://doi.org/10.3390/ma18194517

Chicago/Turabian StyleMaroszek, Marcin, Magdalena Rudziewicz, and Marek Hebda. 2025. "Recycled Components in 3D Concrete Printing Mixes: A Review" Materials 18, no. 19: 4517. https://doi.org/10.3390/ma18194517

APA StyleMaroszek, M., Rudziewicz, M., & Hebda, M. (2025). Recycled Components in 3D Concrete Printing Mixes: A Review. Materials, 18(19), 4517. https://doi.org/10.3390/ma18194517