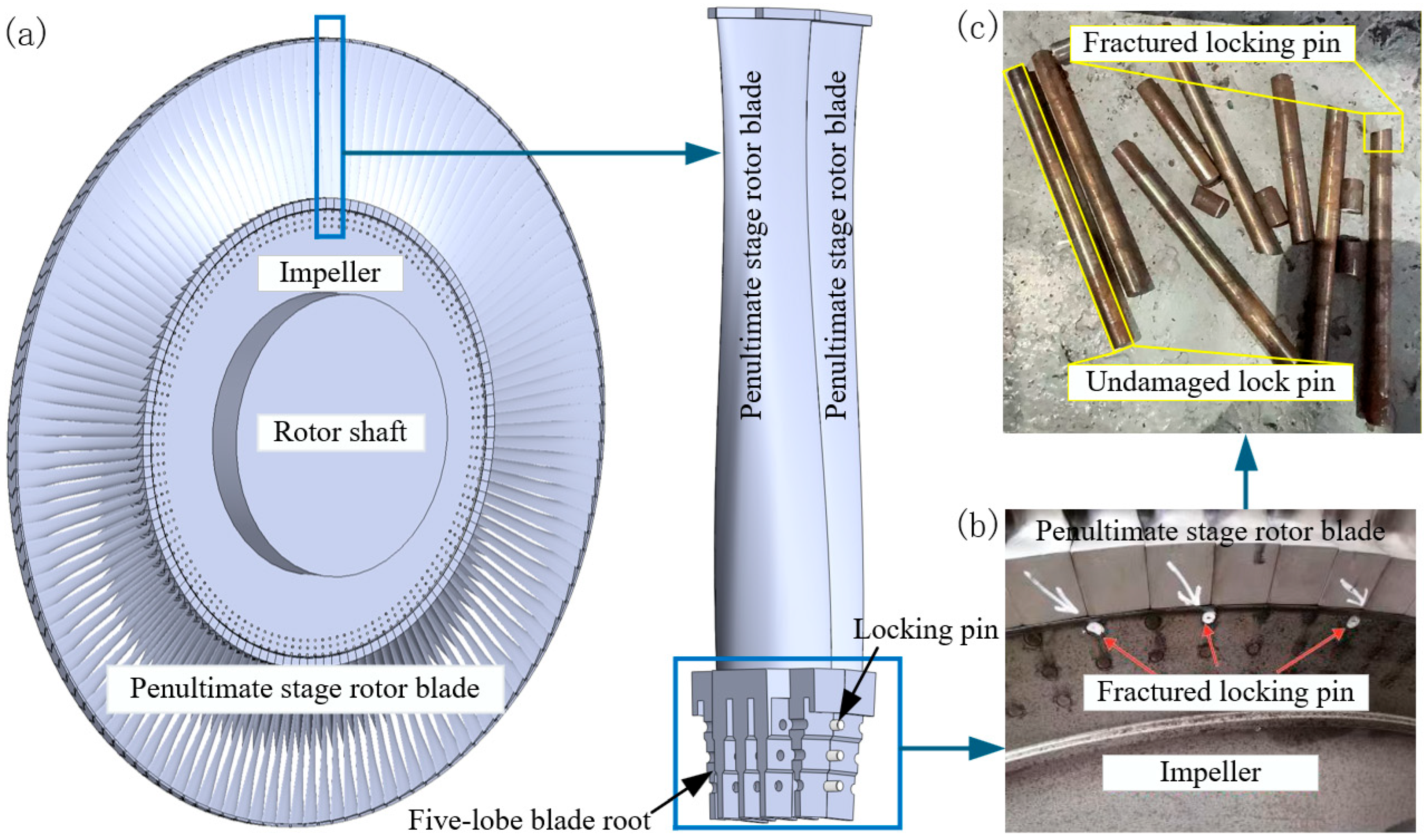

Inspection and Modeling Analysis of Locking Pins in the Penultimate-Stage Blades of a 600 MW Steam Turbine

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

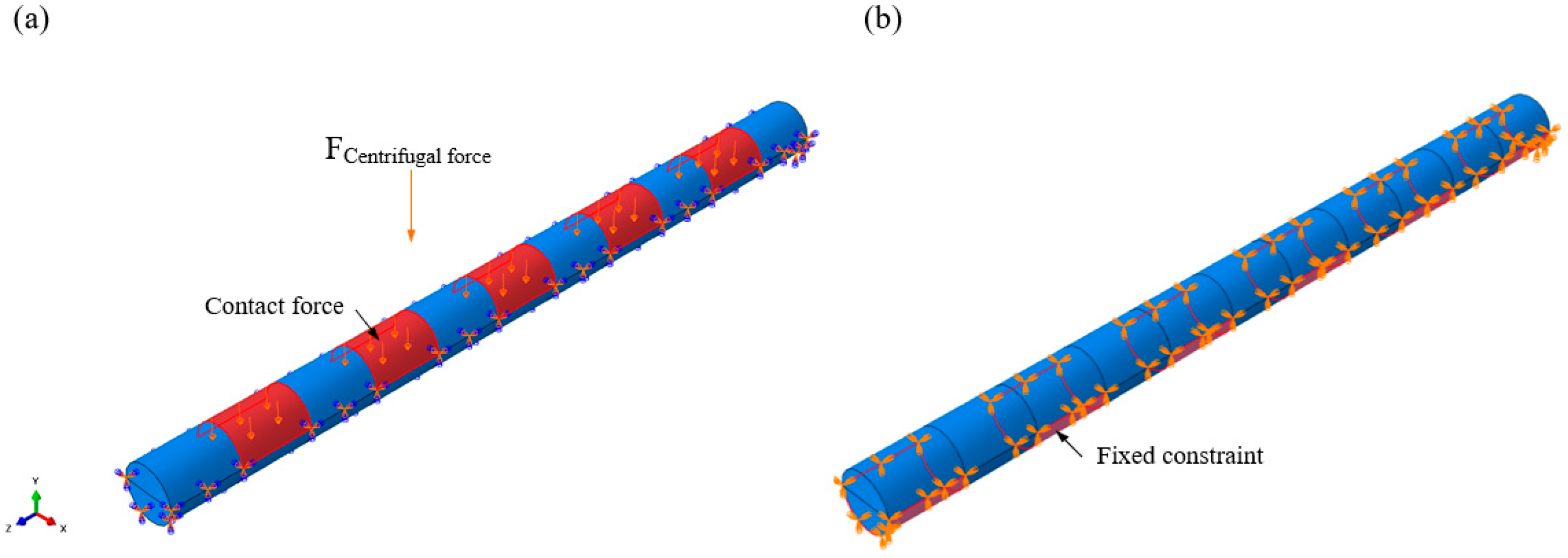

2.2. Methods

3. Results

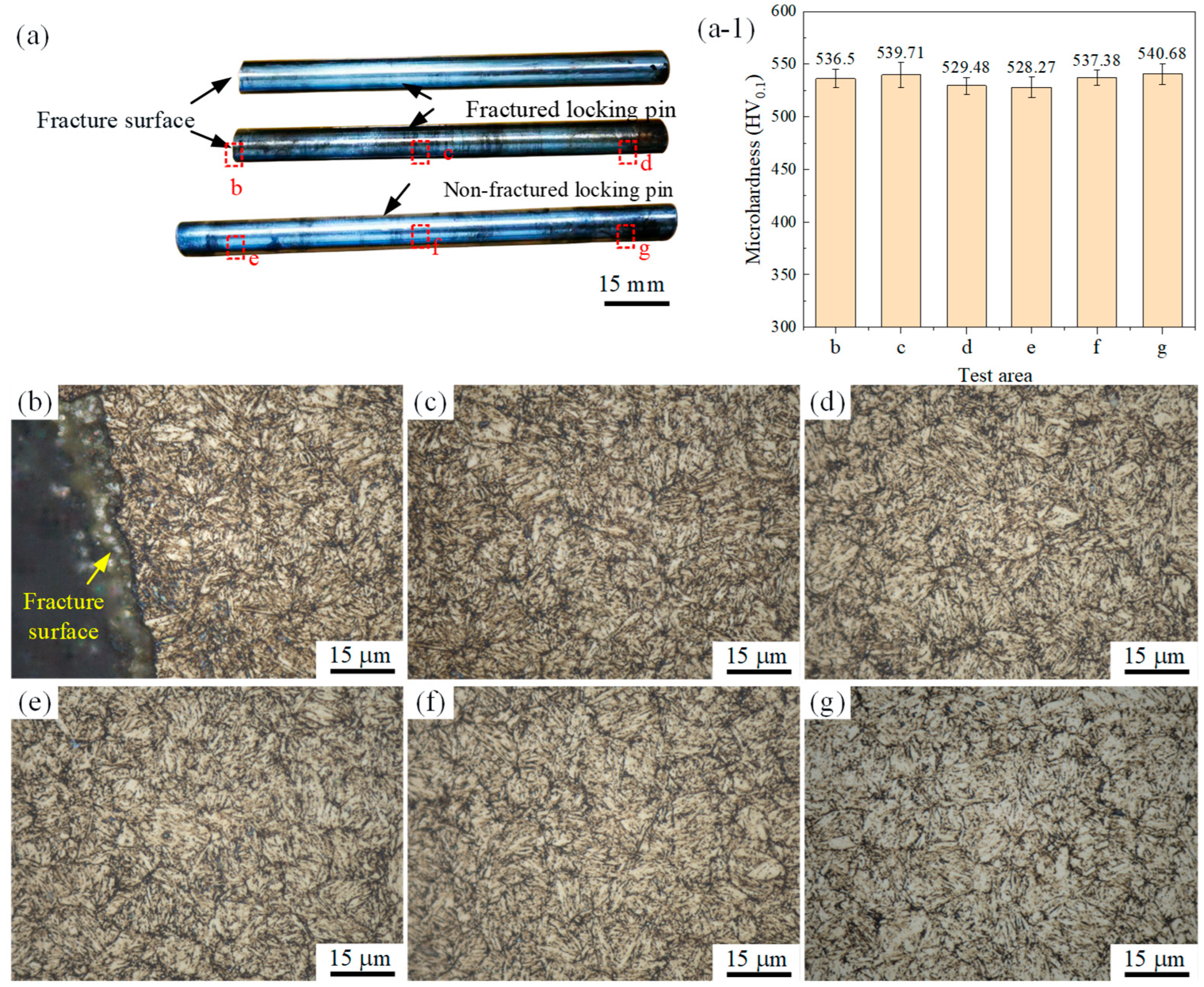

3.1. Chemical Composition and Microhardness

3.2. Microstructural Analysis

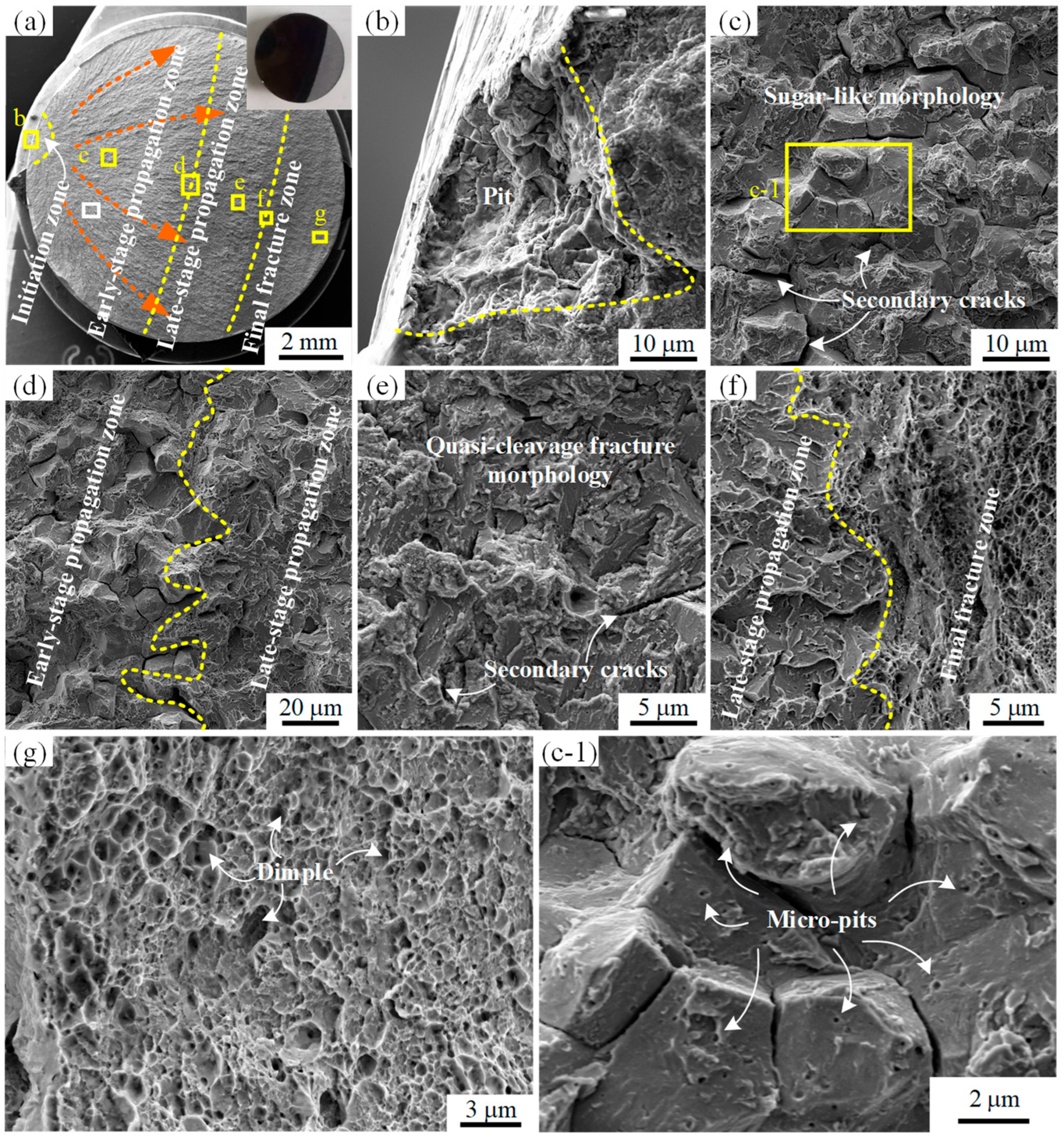

3.3. Fracture Morphology

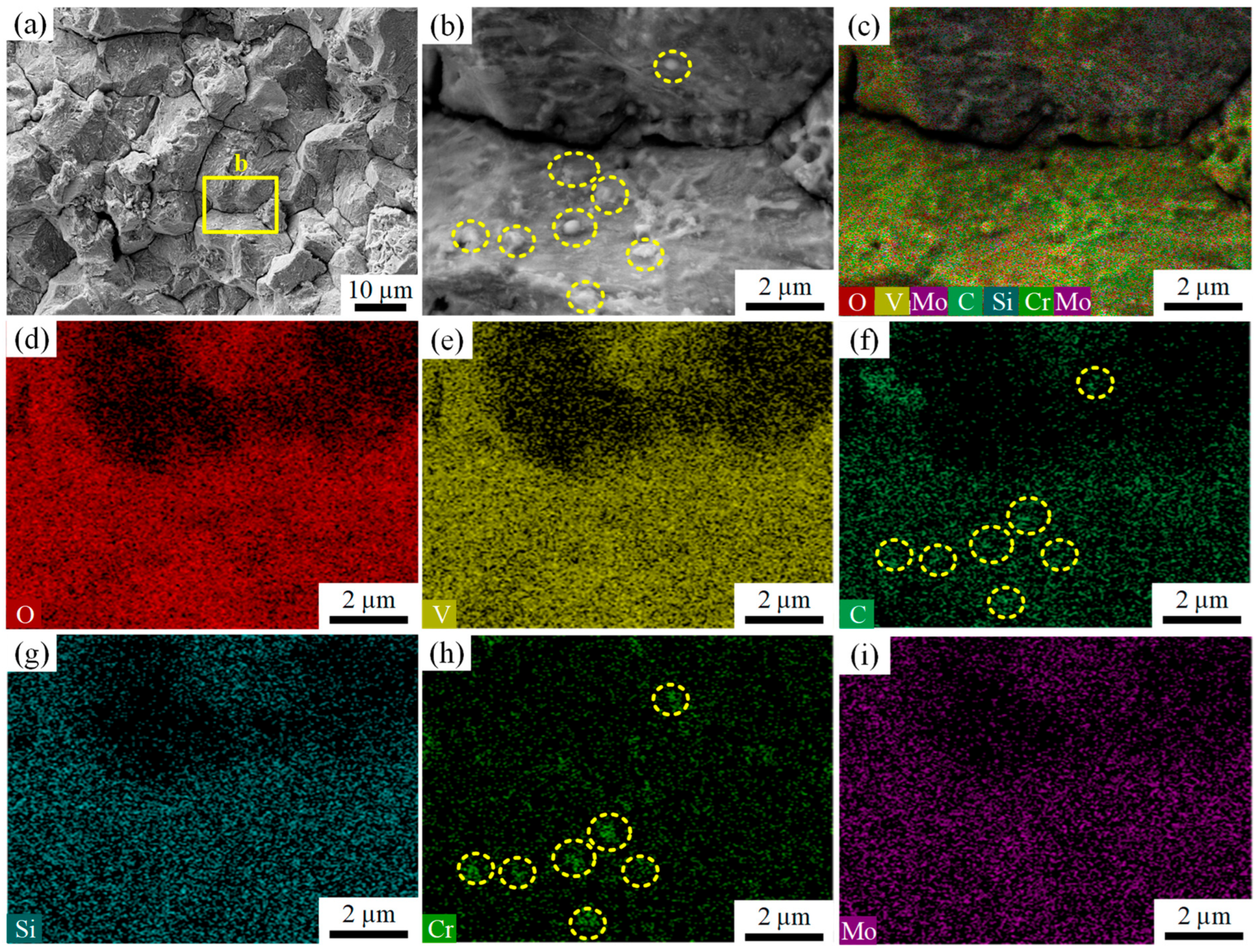

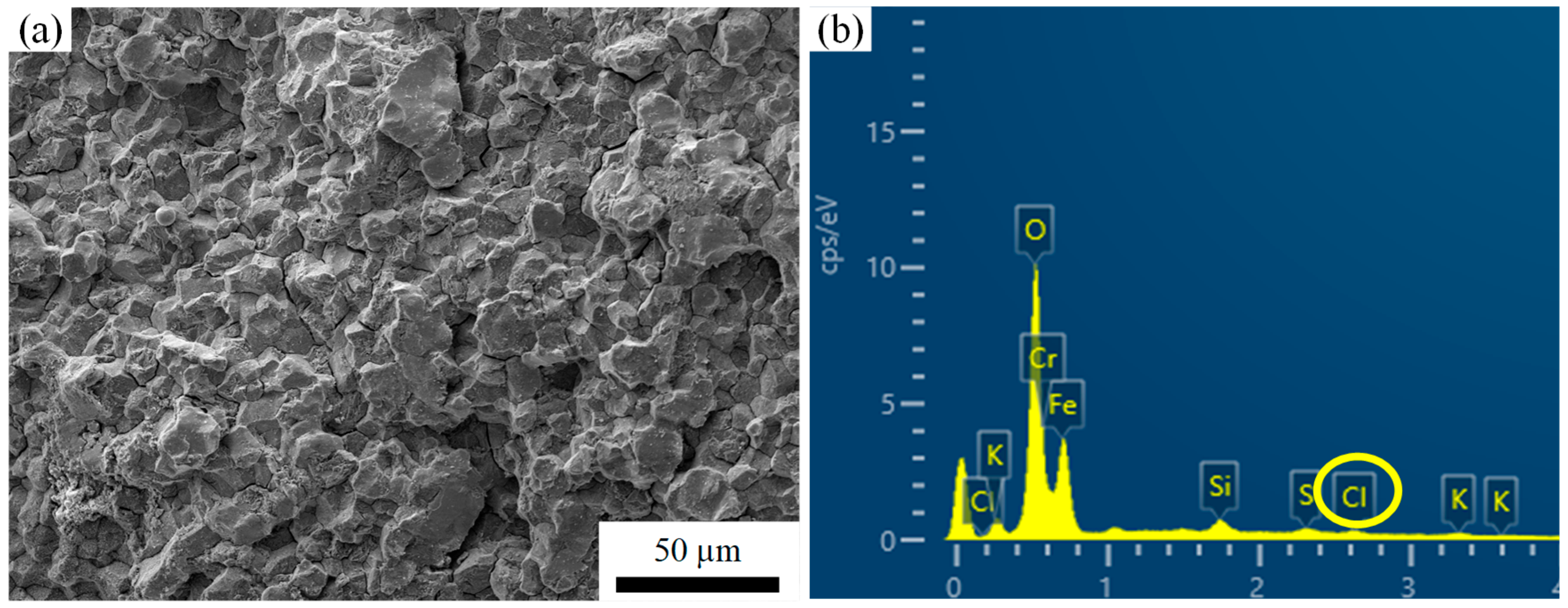

3.4. EDS Analysis

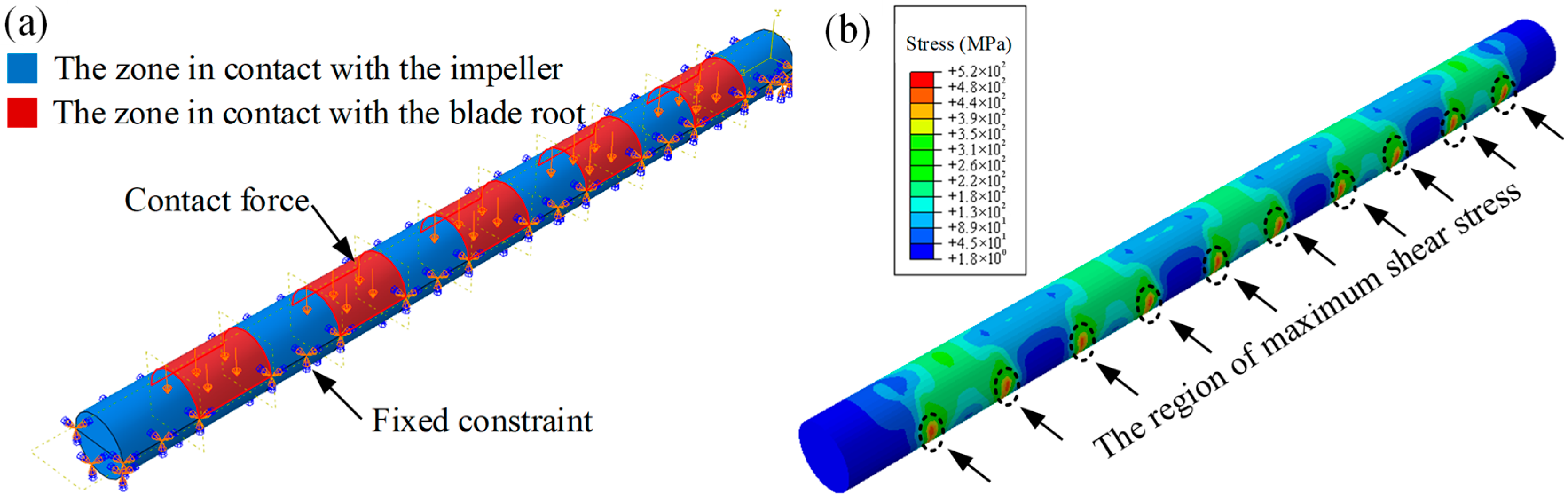

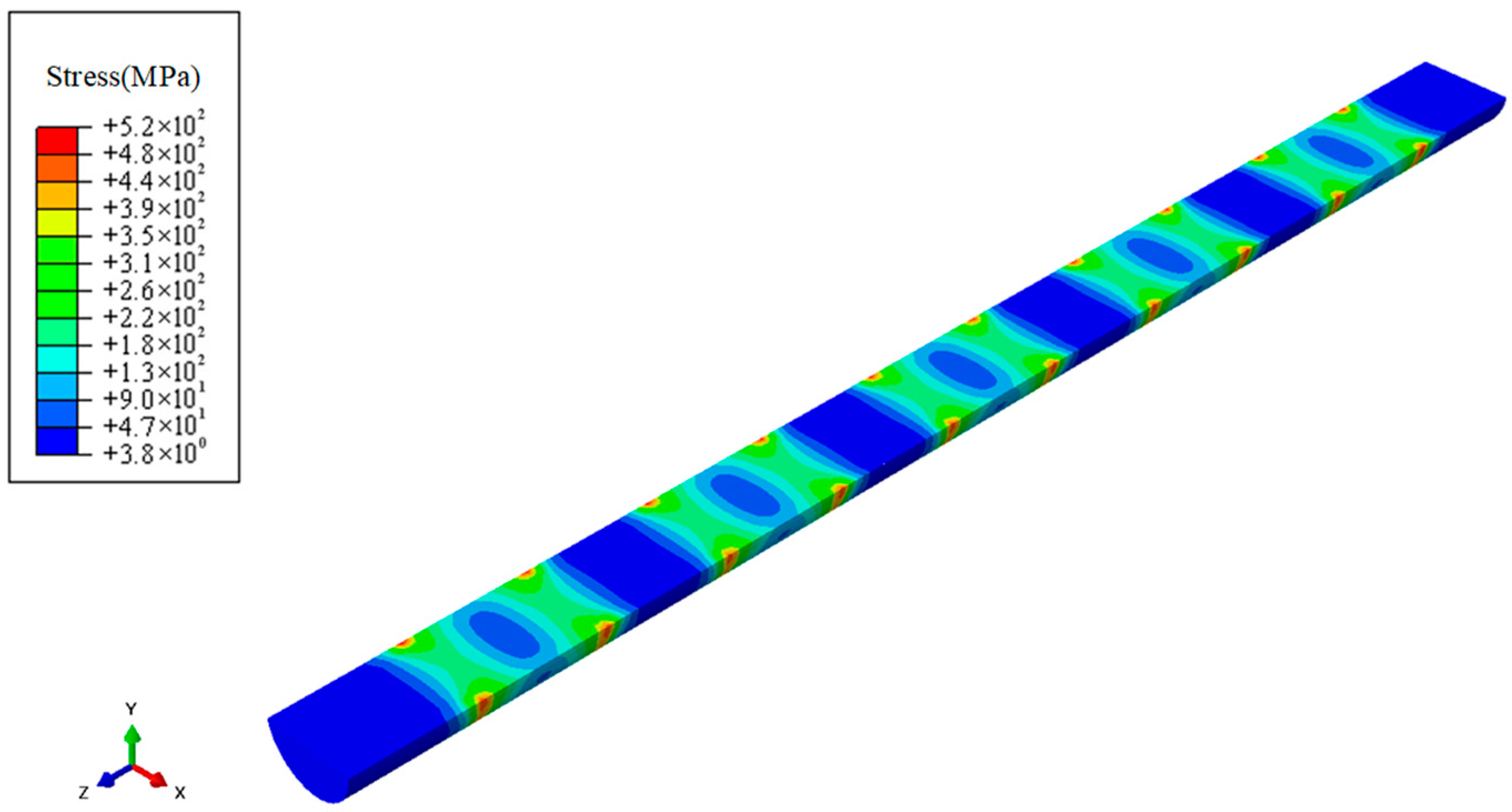

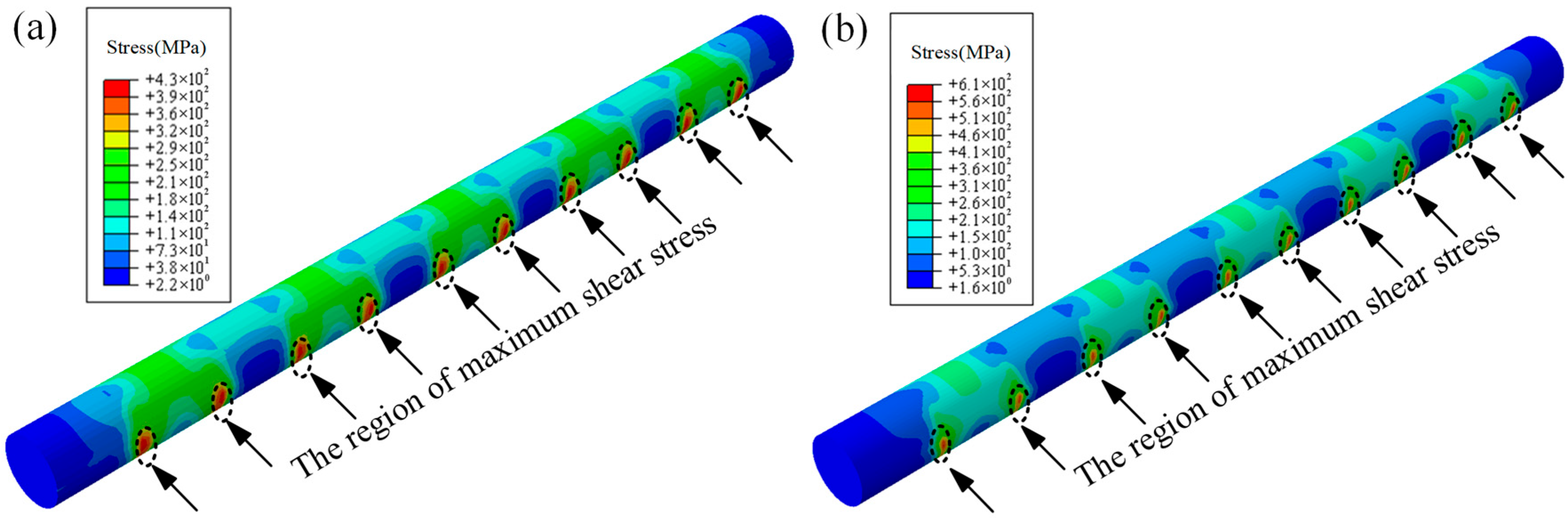

3.5. Load Analysis

4. Discussion

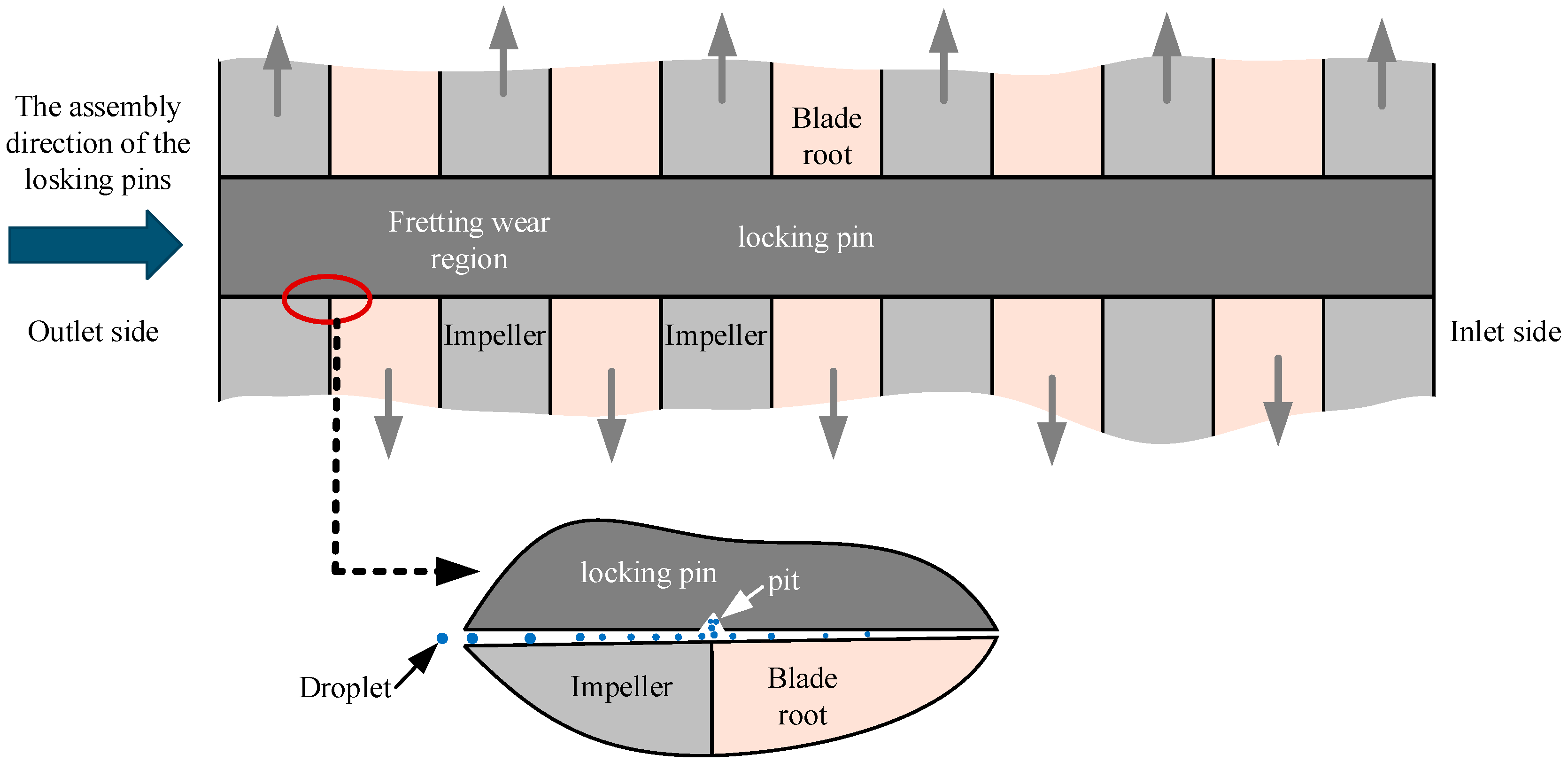

4.1. Formation of Pits

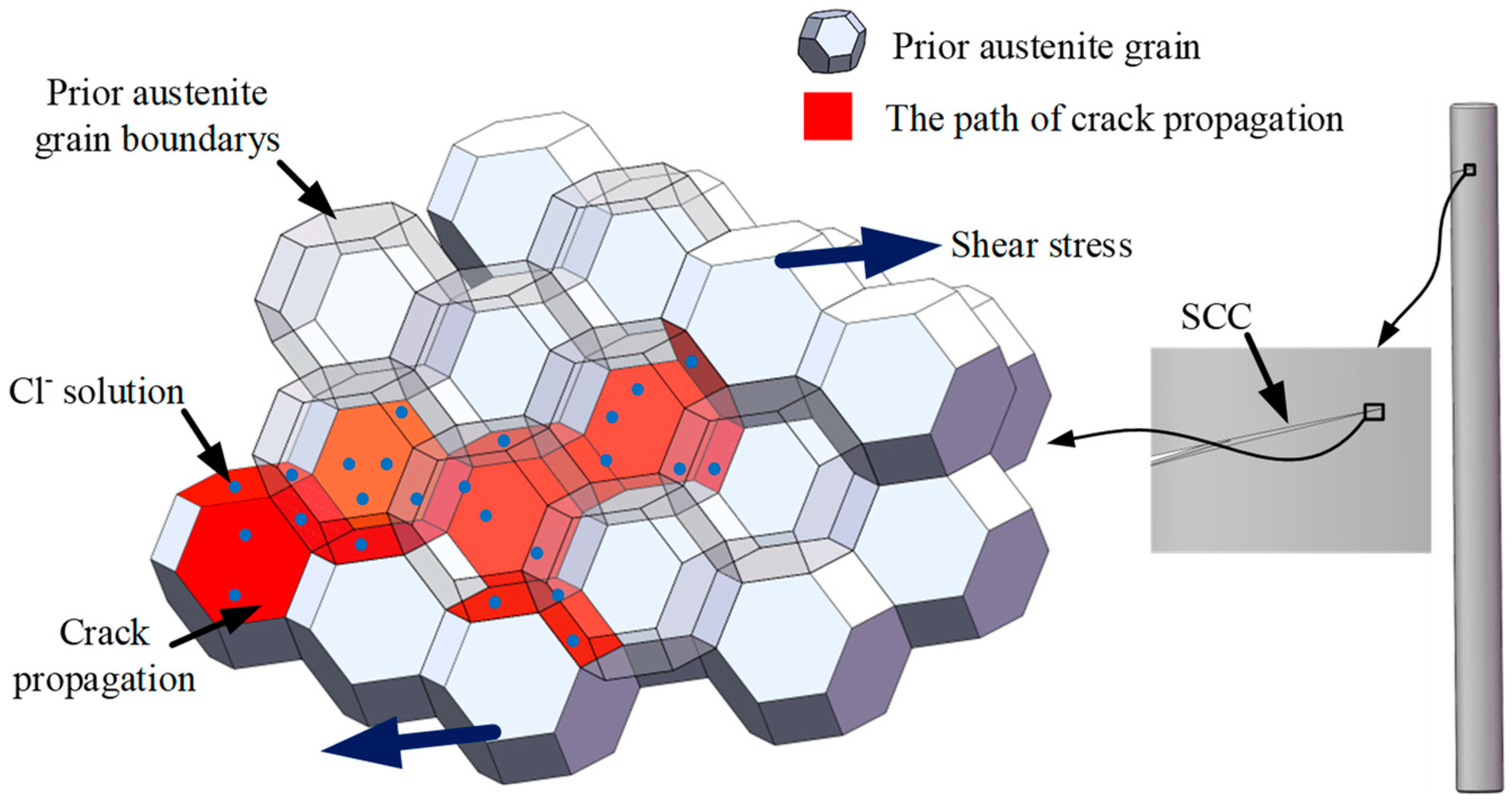

4.2. Crack Initiation and Propagation

5. Conclusions

- 1.

- The fracture of the locking pins was primarily caused by fretting wear and stress corrosion. Specifically, vibrations during deep load-following operations and start–stop cycles led to fretting wear at the junction of the blade root, impeller, and pin, forming pits.

- 2.

- Under the coupled action of a moist steam environment and shear stress, SCC was initiated at the highly stressed pit tips, and the cracks initially propagated along prior-austenite grain boundaries.

- 3.

- As cracks extended further, the effective load-bearing cross-sectional area of the pin decreased, leading to an increase in shear stress. Consequently, crack propagation transitioned from primarily intergranular growth along prior-austenite grain boundaries to propagation along martensitic lath boundaries.

- 4.

- With continued crack growth, the unfractured cross-section diminished, the actual shear stress increased, and once it exceeded the shear strength, final plastic fracture occurred.

- 5.

- This study deepens the understanding of fatigue and fracture mechanisms in high-chromium martensitic steel under service conditions. This work contributes to enhancing the safety and reliability of steam turbines while also providing a theoretical basis for strengthening locking pins.

6. Suggestions

- Improve the shear strength and corrosion resistance of the locking pin material to enhance resistance against shear-induced SCC. For example, high-frequency induction quenching followed by tempering could be applied to increase both shear strength and corrosion resistance.

- Strictly control the Cl− concentration and oxygen content in the water source to reduce the corrosion rate, thereby mitigating the progression of SCC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, B.; Zhao, Y.; Zhang, S.; Zhou, J.; Liu, J.; Zhang, P.; Yan, J. Thermodynamic performance analysis of steam power plants during deep peak shaving processes: Integrating a novel top turbine system in ultra-low loads. Energy 2025, 315, 134425. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, C.; Fan, M.; Wang, Z.; Fang, F.; Liu, M.; Yan, J. Investigation on the allowable load ramping-up rate and wet-to-dry conversion time of a 660 MW supercritical coal-fired power plant with deep peak-shaving work conditions. Energy 2025, 314, 134200. [Google Scholar] [CrossRef]

- Han, X.; Li, Q.; Li, M.; Yao, B.; Han, Z. Flow characteristics and backpressure optimization of low-pressure stages in steam turbines under low flow rate conditions. Appl. Therm. Eng. 2025, 278, 127415. [Google Scholar] [CrossRef]

- He, C.; Guo, T.; Zhao, Q.; Liang, Z. Failure behavior analysis of oxide film formed on super-heater tubes of boiler during deep peak process. J. Supercrit. Fluids 2025, 218, 106474. [Google Scholar] [CrossRef]

- Chen, J.; Lei, J.; Liu, Y.; Han, Y.; Jia, D.; Wang, C.; Deng, W. Occlusion failure analysis and optimization design for steel piston pin hole-pin friction pair. Eng. Fail. Anal. 2025, 169, 109135. [Google Scholar] [CrossRef]

- Soltanloo, M.; Babaee, M.H.; Porhonar, M.; Shajari, Y.; Seyedraoufi, Z.; Jahangiri, M.R. Root cause failure analysis of 320 MW steam turbine: Visual, metallurgical, and mechanical approach. Eng. Fail. Anal. 2025, 177, 109670. [Google Scholar] [CrossRef]

- Xu, H.; Chen, Z.; Yang, Y.; Tao, L.; Chen, X. Effects of Crack on Vibration Characteristics of Mistuned Rotated Blades. Shock Vib. 2017, 2017, 1785759. [Google Scholar] [CrossRef]

- Xiao, D.; Qing, S.; Du, S.; Xiao, H.; Wang, T.; Zhao, L. Comprehensive investigations and simulation study on the mechanism of crack initiation and propagation of compressor blade’s tenon. Mech. Based Des. Struct. Mech. 2022, 50, 3331–3351. [Google Scholar] [CrossRef]

- Ruchert, C.O.F.T.; Carvalho, M.C.D.; Montezuma, M.F.V. Fretting fatigue in-service failure of x20CrMo13 stainless steel turbine blade. Mater. Res. 2021, 139, 106491. [Google Scholar] [CrossRef]

- Gao, J.; Xu, Z.; Tang, Z.; Lei, Y.; Sun, W.; Guo, B.; Zhao, Z. Failure study of steam turbine last-stage rotor blades under a high-speed wet steam environment. Eng. Fail. Anal. 2023, 154, 107643. [Google Scholar] [CrossRef]

- Gu, H.; Wang, R.; Zhang, K.; Li, K.; Sun, L.; Zhang, X.; Tu, S. Damage-driven framework for reliability assessment of steam turbine rotors operating under flexible conditions. Reliab. Eng. Syst. Saf. 2025, 254, 110578. [Google Scholar] [CrossRef]

- Graciano, D.M.; Rodríguez, J.A.; Urquiza, G.; Tecpoyotl-Torres, M. Damage evaluation and life assessment of steam turbine blades. Theor. Appl. Fract. Mech. 2023, 124, 103782. [Google Scholar] [CrossRef]

- Weng, S.; Huang, Y.; Lin, S.; Xuan, F. Stress corrosion crack propagation affected by microstructures for nuclear steam turbine rotor steels in the simulated environment. J. Mater. Res. Technol. 2022, 17, 725–742. [Google Scholar] [CrossRef]

- Pumpyanskii, D.A.; Pyshmintsev, I.Y.; Bityukov, S.M.; Gervas Ev, M.A.; Gusev, A.A. Features of microstructure, phase composition and strengthening capability of stainless steels with chromium content of 13–17. Steel Transl. 2022, 52, 844–851. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Z.; Gao, Y.; Wang, X.; Zheng, C. Effect of Cr Content on Corrosion Resistance of Ni–xCr–Mo Laser-Cladding Coatings under H2S-Induced High-Temperature Corrosion Atmosphere. Materials 2022, 15, 1885. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.; Radhakrishnan, J.; Huang, S.; Chua, Y.; Shi, W.; Ramamurty, U. Corrosion and stress corrosion cracking resistances of the 17-4 precipitation hardened martensitic stainless steel additively manufactured using binder jet printing. Acta Mater. 2024, 281, 120417. [Google Scholar] [CrossRef]

- Tian, S.; Liu, Z.; Fu, R.; Wang, X.; Liang, J. Investigation of stress corrosion cracking behavior and mechanism analysis of a 1900 MPa-grade ultra-high-strength stainless steel. J. Iron Steel Res. Int. 2022, 29, 1474–1484. [Google Scholar] [CrossRef]

- Ding, S.; Zhou, M.; Liu, X.; Liu, C.; Zhang, X. Improving the stress corrosion cracking resistance of aged SA508-309l dissimilar metal weld joints by pulsed electric current. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 849, 143506. [Google Scholar] [CrossRef]

- Nakamichi, H.; Sato, K.; Miyata, Y.; Kimura, M.; Masamura, K. Quantitative analysis of cr-depleted zone morphology in low carbon martensitic stainless steel using FE-(s)TEM. Corros. Sci. 2008, 50, 309–315. [Google Scholar] [CrossRef]

- ASTM A681-08. Standard Specification for Tool Steels Alloy; ASTM International: West Conshohocken, PA, USA, 2022. [Google Scholar]

- Song, C.; Luo, J.; Li, L.; Wu, G. Failure analysis of 06Cr19Ni10 flange fracture at a natural gas processing station. Int. J. Press. Vessel. Pip. 2025, 216, 105536. [Google Scholar] [CrossRef]

- Zhu, H.; Lei, C.; Li, B.; Feng, Y.; He, J.; Peng, J.; Liu, J. Effect of crystallographic orientations on fretting wear mechanisms in DZ4125 nickel-based superalloy. Tribol. Int. 2025, 212, 110960. [Google Scholar] [CrossRef]

- Imran, M.; Wang, D.; Wang, L.; Abdel Wahab, M. Finite element modelling of effect of corrosion on fretting wear in steel wires. Tribol. Int. 2025, 206, 110573. [Google Scholar] [CrossRef]

- Cai, Z.; Guan, H.; Chen, Z.; Qian, H.; Tang, L.; Zhou, Z.; Zhu, M. Impact fretting wear behavior of 304 stainless steel thin-walled tubes under low-velocity. Tribol. Int. 2017, 105, 219–228. [Google Scholar] [CrossRef]

- Zhou, J.; Yan, L.; Tang, J.; Sun, Z.; Ma, L. Interactive effect of ant nest corrosion and stress corrosion on the failure of copper tubes. Eng. Fail. Anal. 2018, 83, 9–16. [Google Scholar] [CrossRef]

- Bland, L.G.; Locke, J.S.W. Chemical and electrochemical conditions within stress corrosion and corrosion fatigue cracks. NPJ Mater. Degrad. 2017, 1, 12. [Google Scholar] [CrossRef]

- Chen, W.; Wang, W.; Liu, L.; Liu, R.; Cui, Y.; Chen, Z.; Wang, Q.; Wang, F. The effect of NaCl-induced corrosion on ti60′s hot salt stress corrosion cracking. Corros. Sci. 2024, 226, 111677. [Google Scholar] [CrossRef]

- Craig, P.; Lamei Ramandi, H.; Chen, H.; Vandermaat, D.; Crosky, A.; Hagan, P.; Hebblewhite, B.; Saydam, S. Stress corrosion cracking of rockbolts: An in-situ testing approach. Constr. Build. Mater. 2021, 269, 121275. [Google Scholar] [CrossRef]

- Krechkovska, H.; Hredil, M.; Student, O.; Svirska, L.; Krechkovska, S.; Tsybailo, I.; Solovei, P. Peculiarities of fatigue fracture of high-alloyed heat-resistant steel after its operation in steam turbine rotor blades. Int. J. Fatigue 2023, 167, 107341. [Google Scholar] [CrossRef]

- Venezuela, J.; Hill, T.; Zhou, Q.; Li, H.; Shi, Z.; Dong, F.; Knibbe, R.; Zhang, M.; Dargusch, M.S.; Atrens, A. Hydrogen-induced fast fracture in notched 1500 and 1700 MPa class automotive martensitic advanced high-strength steel. Corros. Sci. 2021, 188, 109550. [Google Scholar] [CrossRef]

- He, X.; Lv, X.; Wu, Z.; Li, S.; Yong, Q.; Liang, J.; Su, J.; Zhou, L.; Li, J.; Zhao, K. M23C6 precipitation and Si segregation promoted by deep cryogenic treatment aggravating pitting corrosion of supermartensitic stainless steel. J. Iron Steel Res. Int. 2021, 28, 629–640. [Google Scholar] [CrossRef]

- Jiang, W.; Wu, D.; Zhang, Q.; Li, M.; Liu, W. Effect of tempering time on the microstructure and properties of martensitic stainless steel. Metals 2024, 14, 322. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Asnavandi, M.; Zhang, J.; Liu, Y.; Li, S. Failure analysis and rejuvenation heat treatment of a martensitic stainless steel gate valve stem. Eng. Fail. Anal. 2025, 175, 109591. [Google Scholar] [CrossRef]

- Bolli, E.; Fava, A.; Ferro, P.; Kaciulis, S.; Mezzi, A.; Montanari, R.; Varone, A. Cr segregation and impact fracture in a martensitic stainless steel. Coatings 2020, 10, 843. [Google Scholar] [CrossRef]

| Content | C | Si | Mn | P | Cr | Ni | V | Mo |

|---|---|---|---|---|---|---|---|---|

| Specified value | 0.33~0.43 | 0.80~1.25 | 0.20~0.50 | ≤0.030 | 4.75~5.50 | ≤0.25 | 0.30~0.60 | 1.10~1.60 |

| Fractured locking pin | 0.41 | 0.95 | 0.396 | 0.008 | 4.95 | 0.21 | 0.55 | 1.1 |

| Non-fractured locking pin | 0.39 | 0.97 | 0.410 | 0.009 | 5.01 | 0.19 | 0.46 | 1.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, K.; Chen, W.; Zhu, J.; Yi, B.; Hao, Q.; Gao, J.; Xu, Z.; Guo, B.; Chen, S. Inspection and Modeling Analysis of Locking Pins in the Penultimate-Stage Blades of a 600 MW Steam Turbine. Materials 2025, 18, 4487. https://doi.org/10.3390/ma18194487

Tang K, Chen W, Zhu J, Yi B, Hao Q, Gao J, Xu Z, Guo B, Chen S. Inspection and Modeling Analysis of Locking Pins in the Penultimate-Stage Blades of a 600 MW Steam Turbine. Materials. 2025; 18(19):4487. https://doi.org/10.3390/ma18194487

Chicago/Turabian StyleTang, Ke, Weiwen Chen, Jiang Zhu, Binhao Yi, Qing Hao, Jiashun Gao, Zhilong Xu, Bicheng Guo, and Shiqi Chen. 2025. "Inspection and Modeling Analysis of Locking Pins in the Penultimate-Stage Blades of a 600 MW Steam Turbine" Materials 18, no. 19: 4487. https://doi.org/10.3390/ma18194487

APA StyleTang, K., Chen, W., Zhu, J., Yi, B., Hao, Q., Gao, J., Xu, Z., Guo, B., & Chen, S. (2025). Inspection and Modeling Analysis of Locking Pins in the Penultimate-Stage Blades of a 600 MW Steam Turbine. Materials, 18(19), 4487. https://doi.org/10.3390/ma18194487