Properties of Geopolymers Based on Fly Ash with the Addition of Asphalt from Road Surface Demolition

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Examination Methods

2.3.1. X-Ray Diffraction Studies (XRD)

2.3.2. Chemical Composition Analysis by X-Ray Fluorescence (XRF)

2.3.3. Particle Size Distribution

- vibrator operating time: 70%,

- vibrator frequency: 50 Hz,

- air pressure: 2000 mbar.

2.3.4. Density

2.3.5. Strength Properties

2.3.6. Abrasion Test

2.3.7. Water Mass Sorption Capacity

- Initial step—determining the dry mass of the sample (Gd).

- Partial immersion—the sample was placed in a beaker and then filled with distilled water to half its height.

- First measurement—after 2 h, the sample was removed from the water, gently dried on the surface with a soft paper towel, and immediately weighed. The obtained mass was recorded as the first measurement (Gw,2h).

- Complete immersion—after the first mass measurement, the sample was immersed in distilled water so that it was completely immersed.

- Daily measurement—measurements were taken successively after 24 h of immersion, and then daily for the next 7 days. Each time, the sample was removed from the water, dried of surface water, and weighed as soon as possible after removal.

- Weekly measurement—after the weekly series of measurements, when the results stabilized, further measurements were taken at seven-day intervals, continuing observations for one month, while maintaining the same water absorption conditions.

2.3.8. Microscopic Examination

3. Results and Discussion

3.1. Material Characteristics

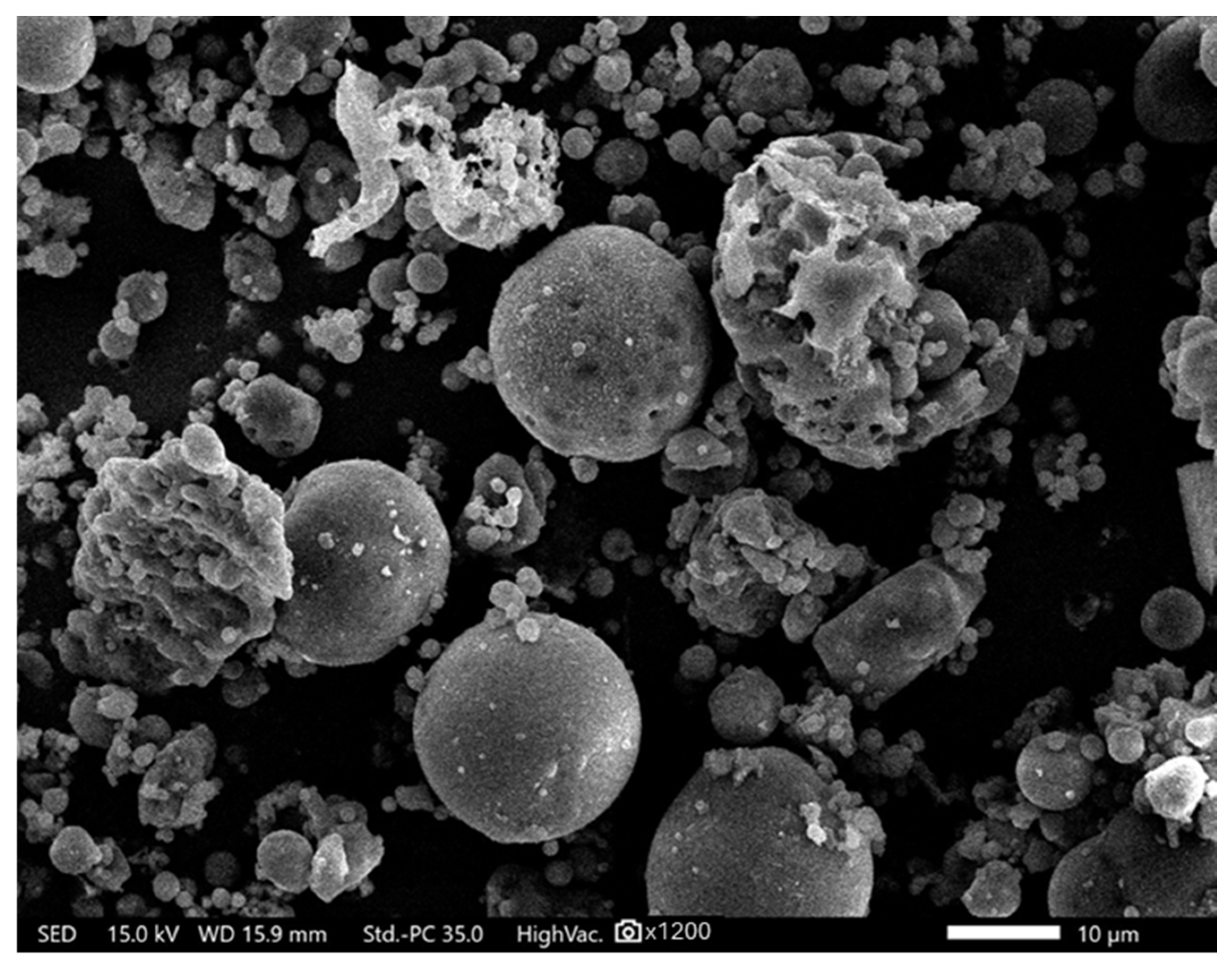

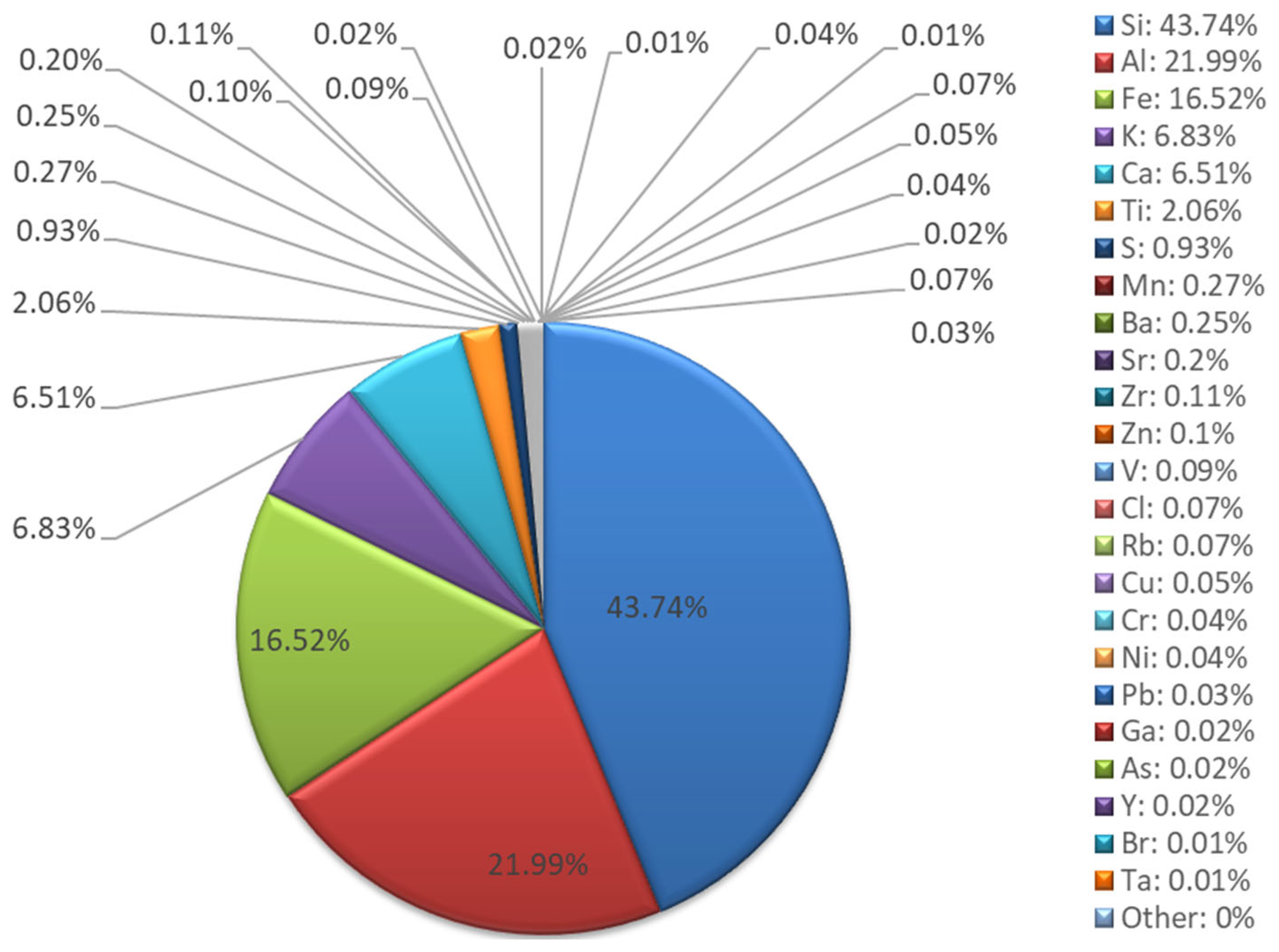

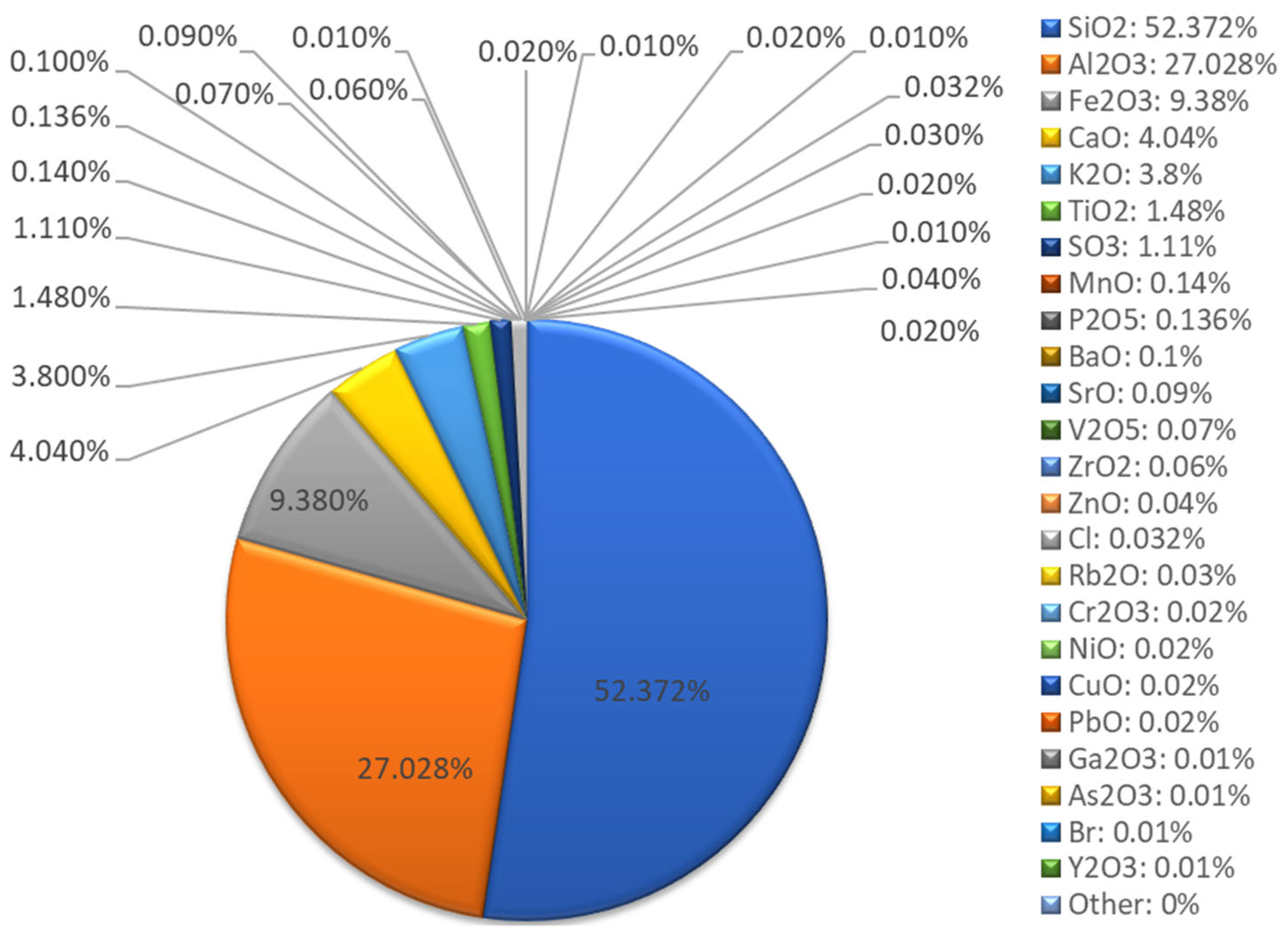

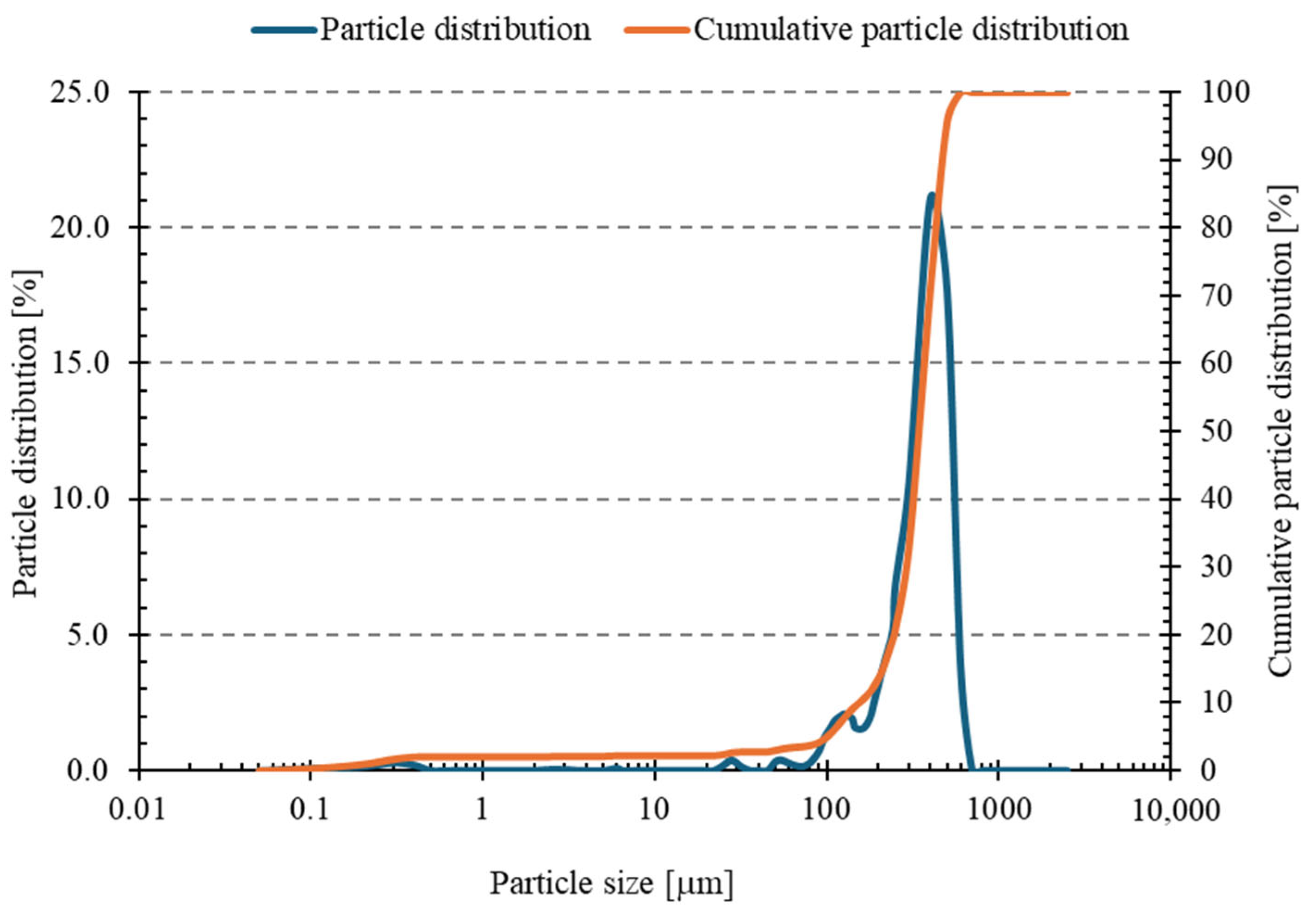

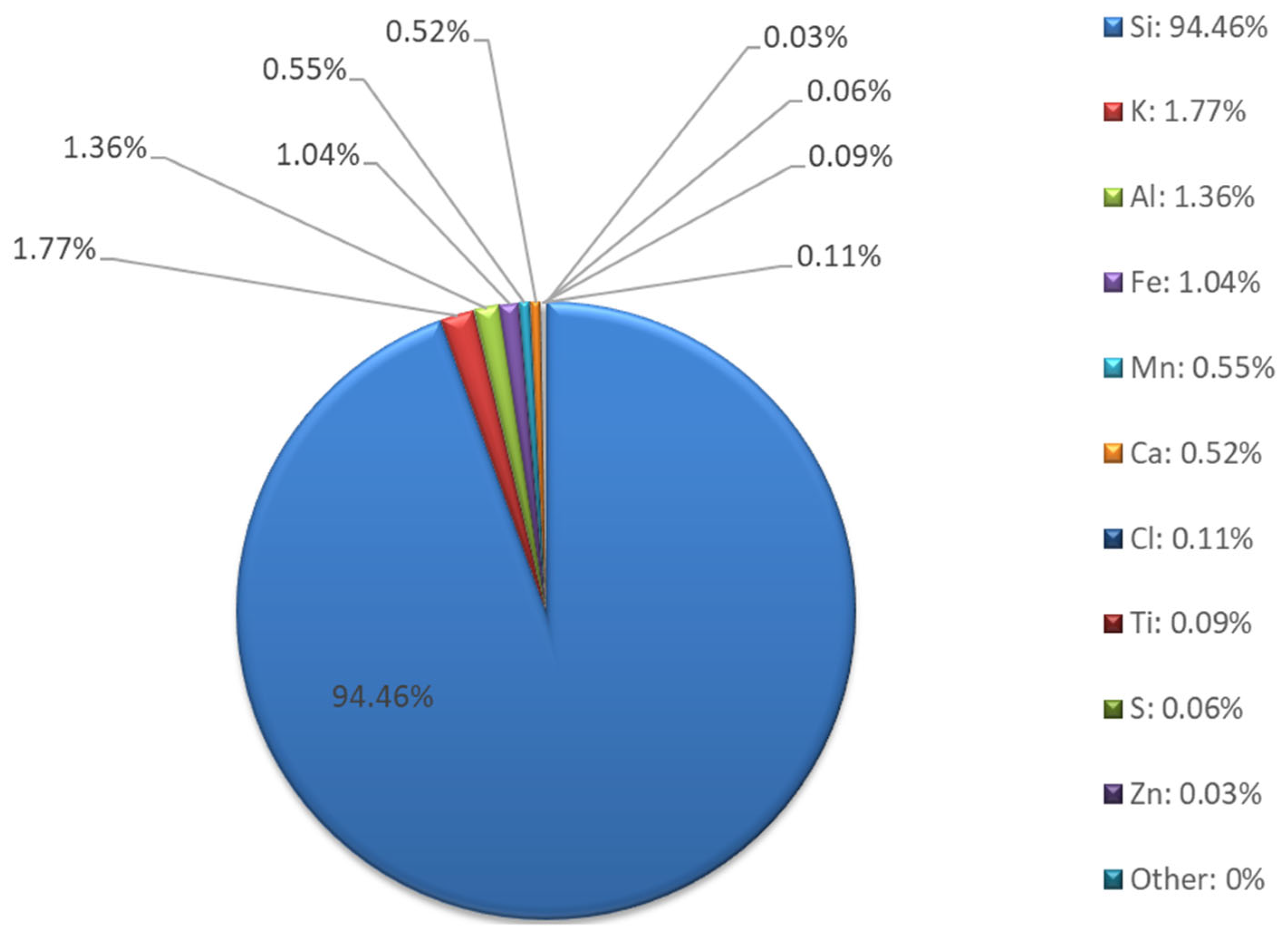

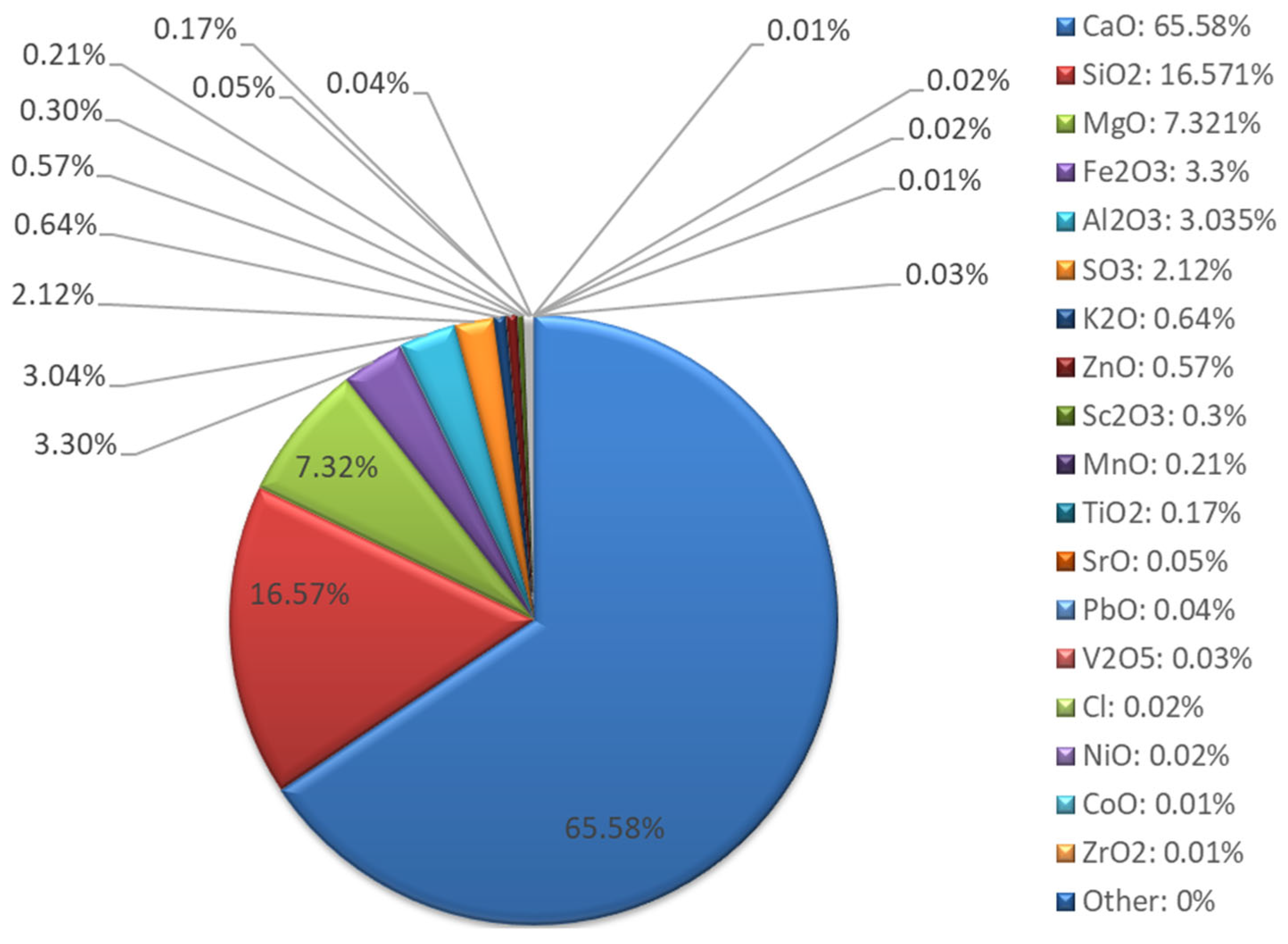

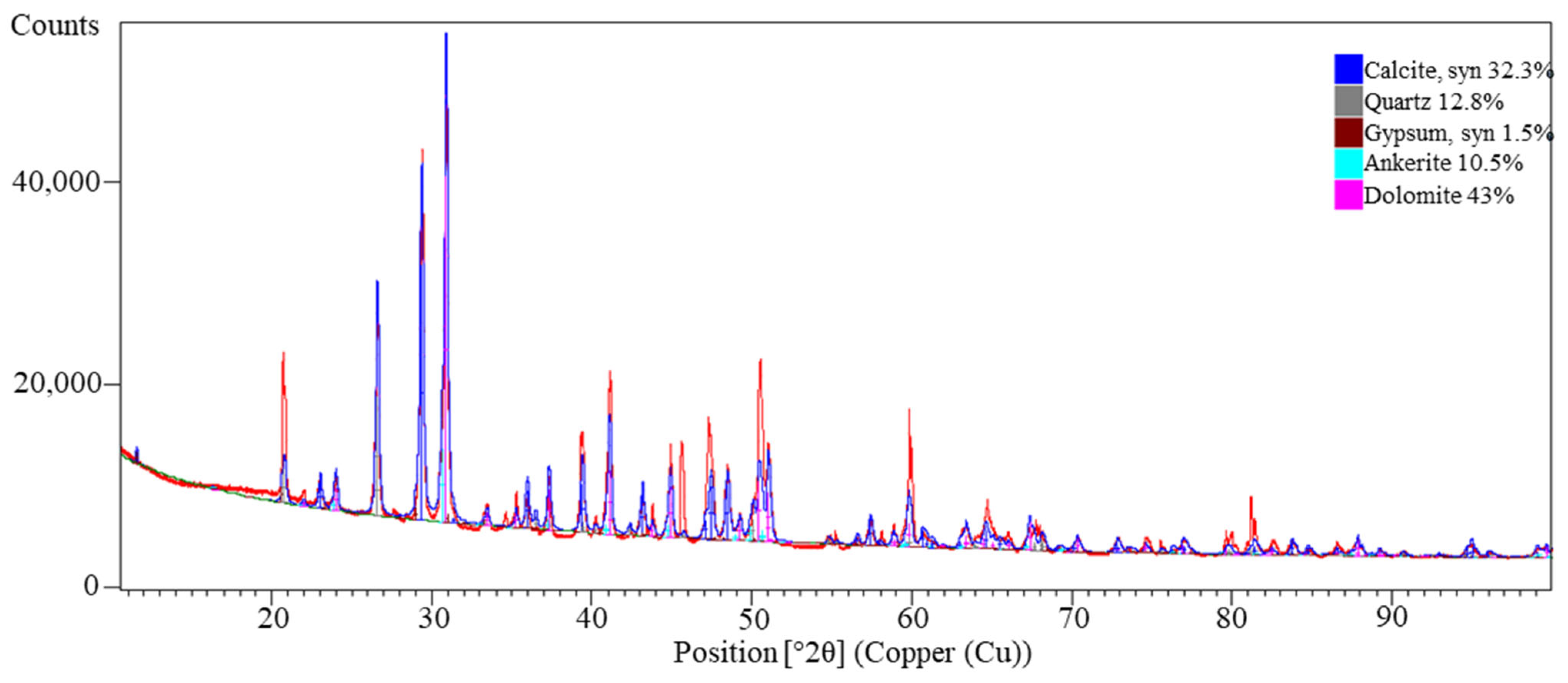

3.1.1. Fly Ash

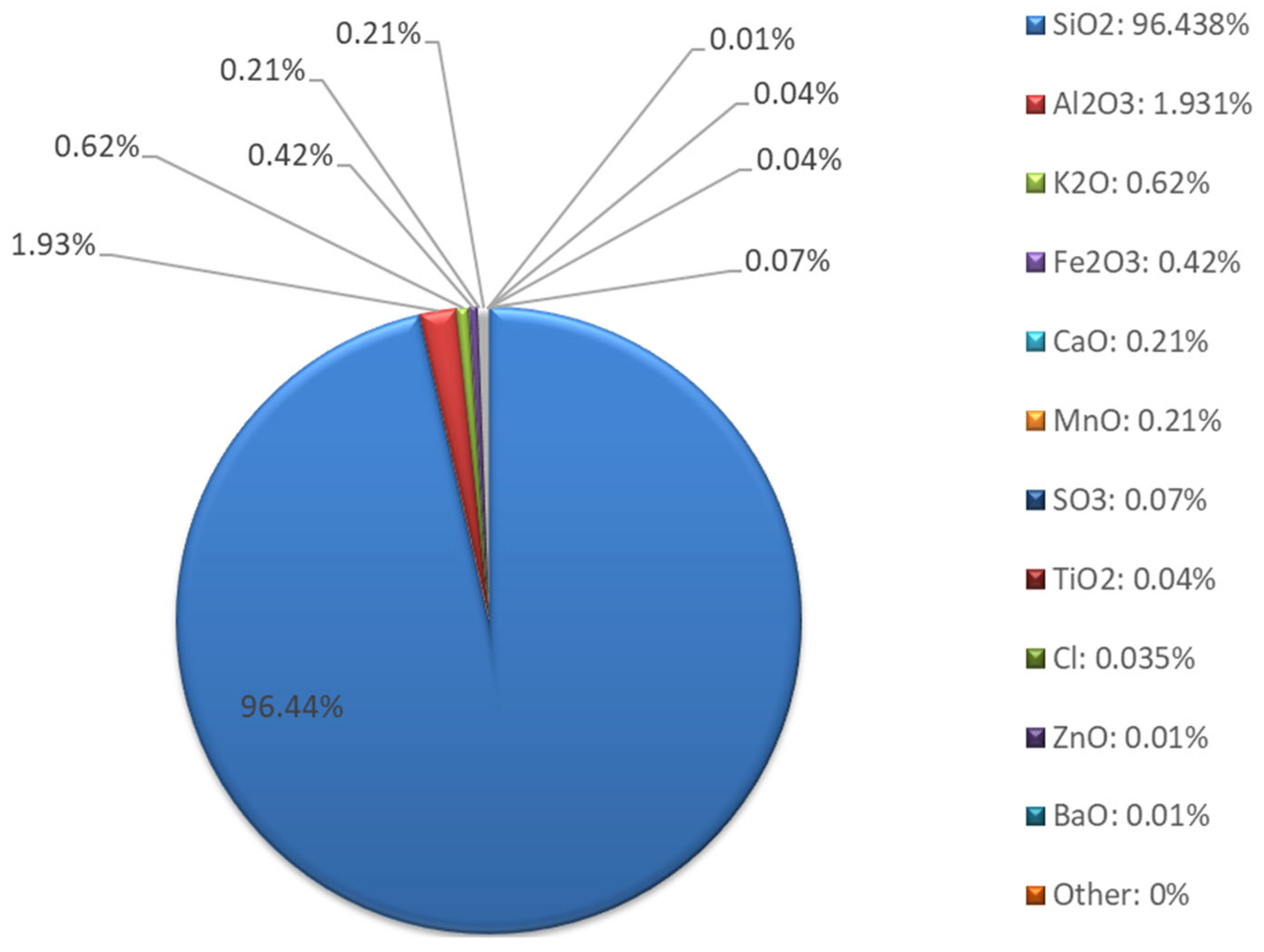

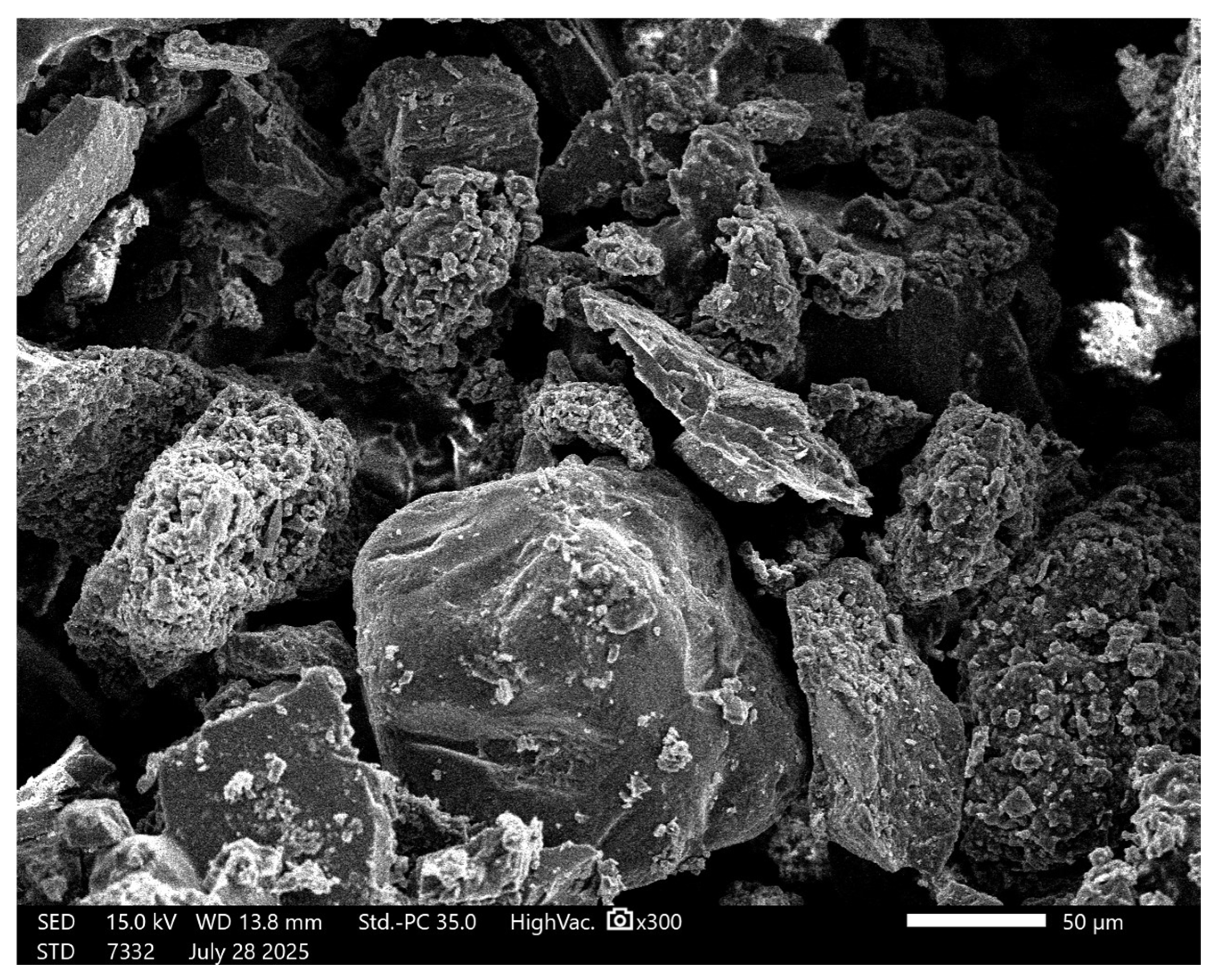

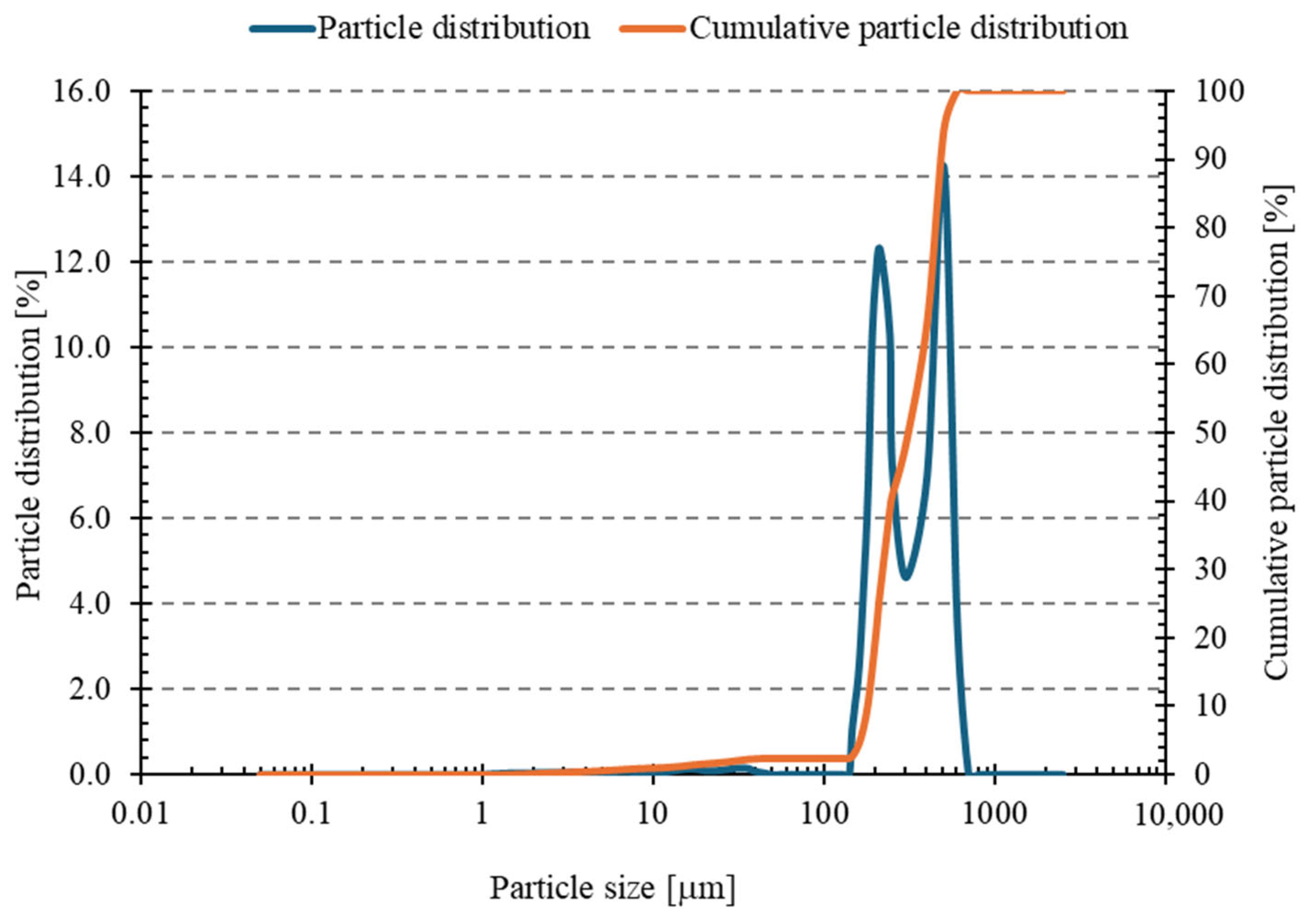

3.1.2. Sand

3.1.3. Asphalt from Road Demolition

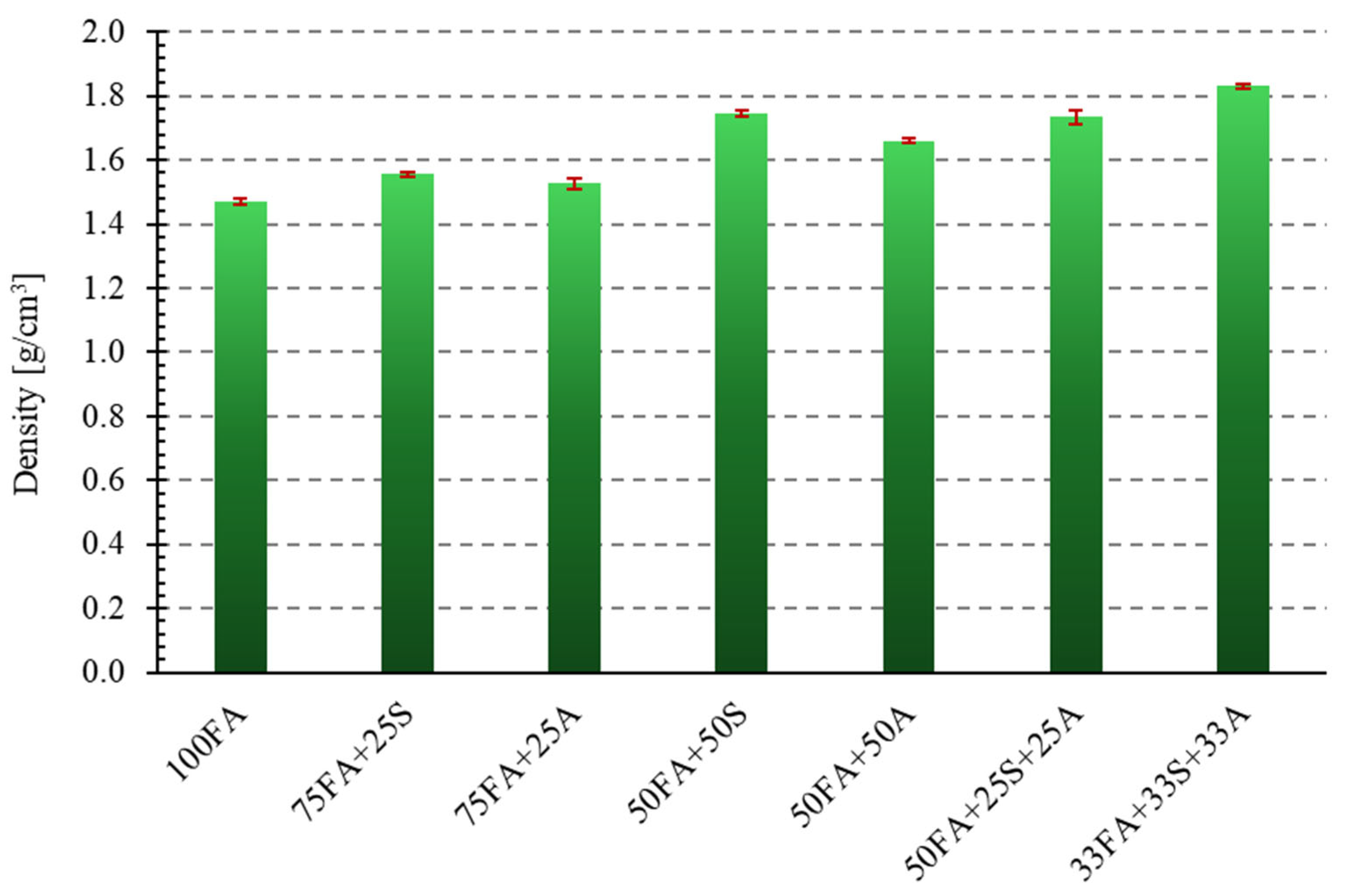

3.2. Density Measurement Results

3.3. Strength Test Results

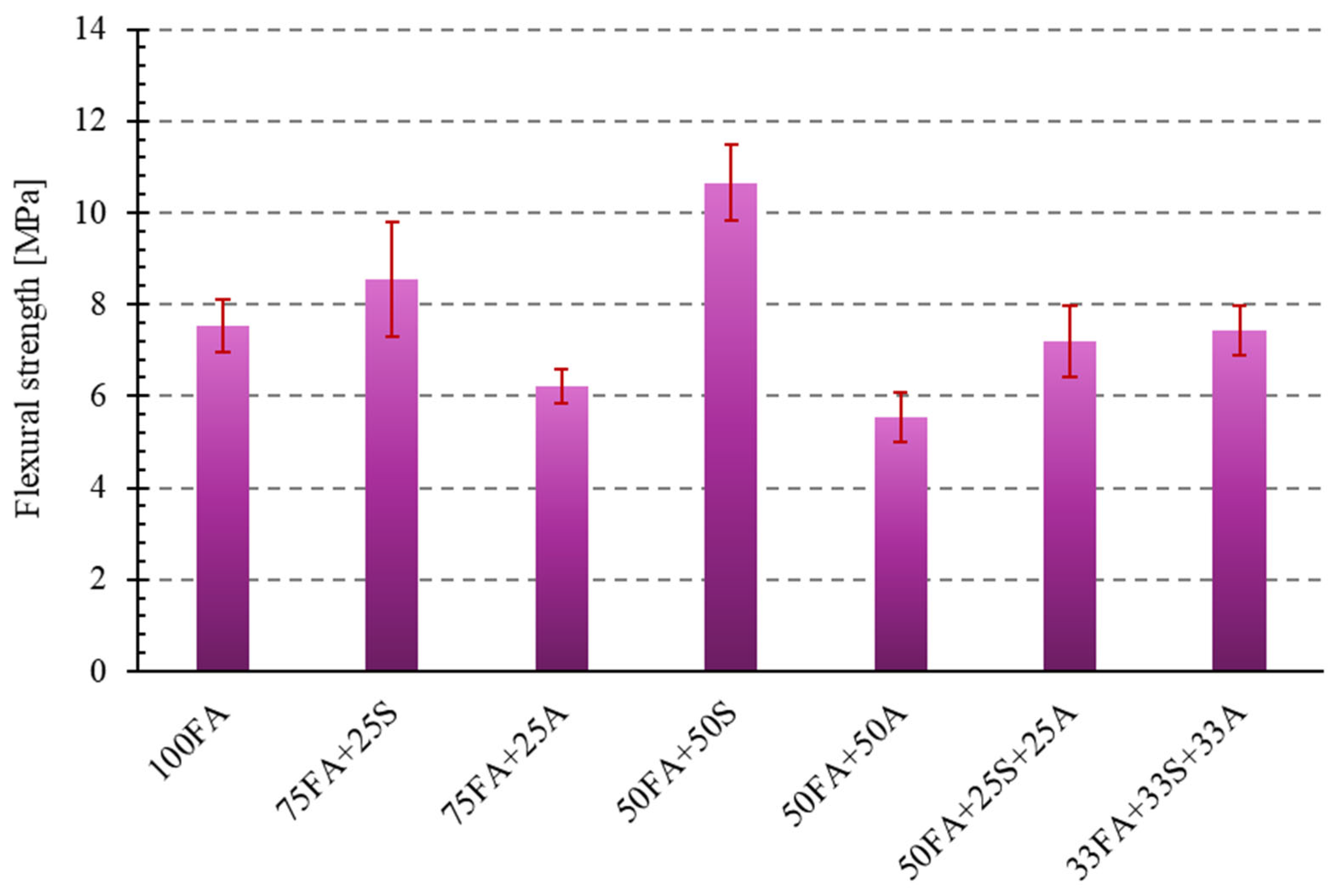

3.3.1. Flexural Strength

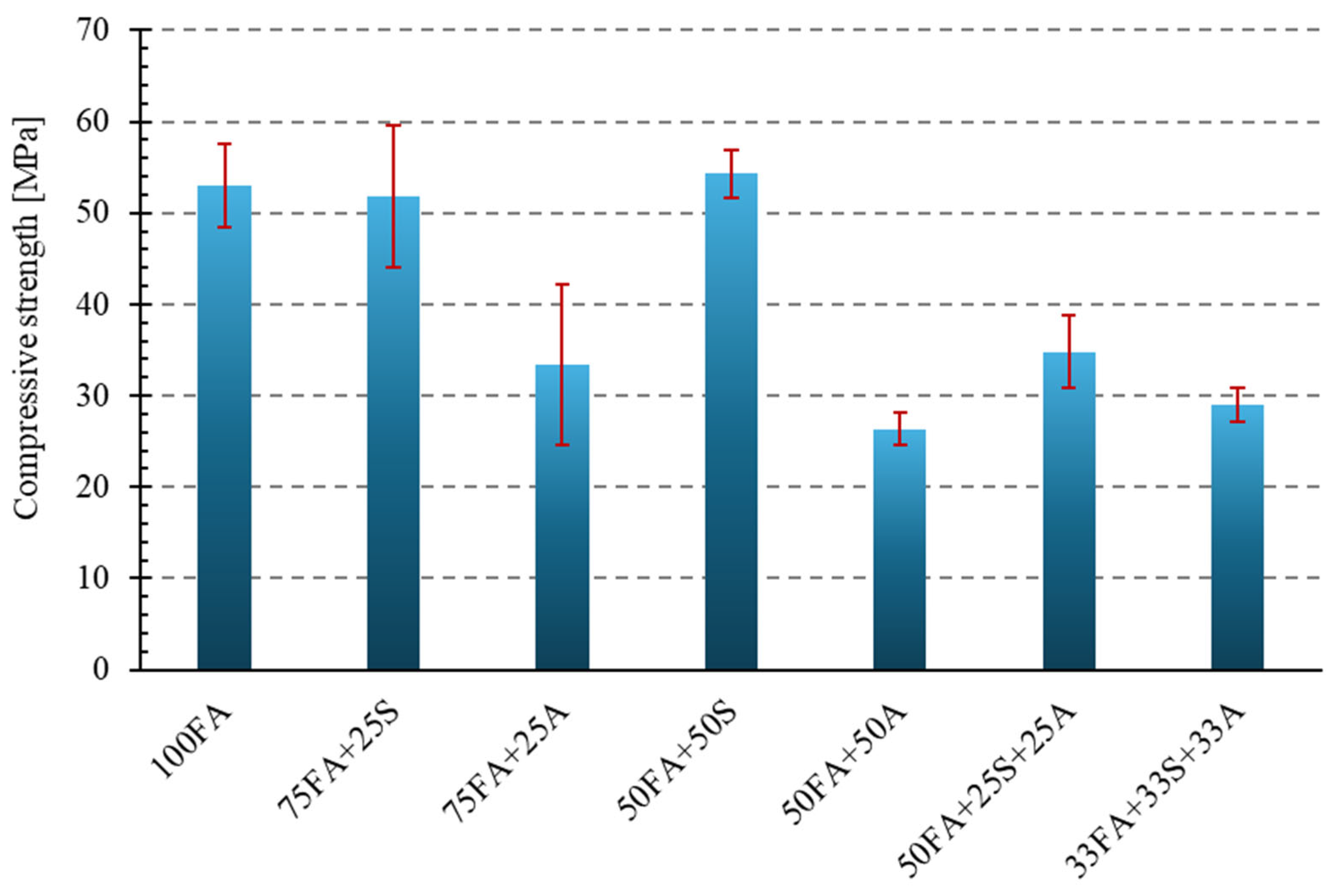

3.3.2. Compressive Strength

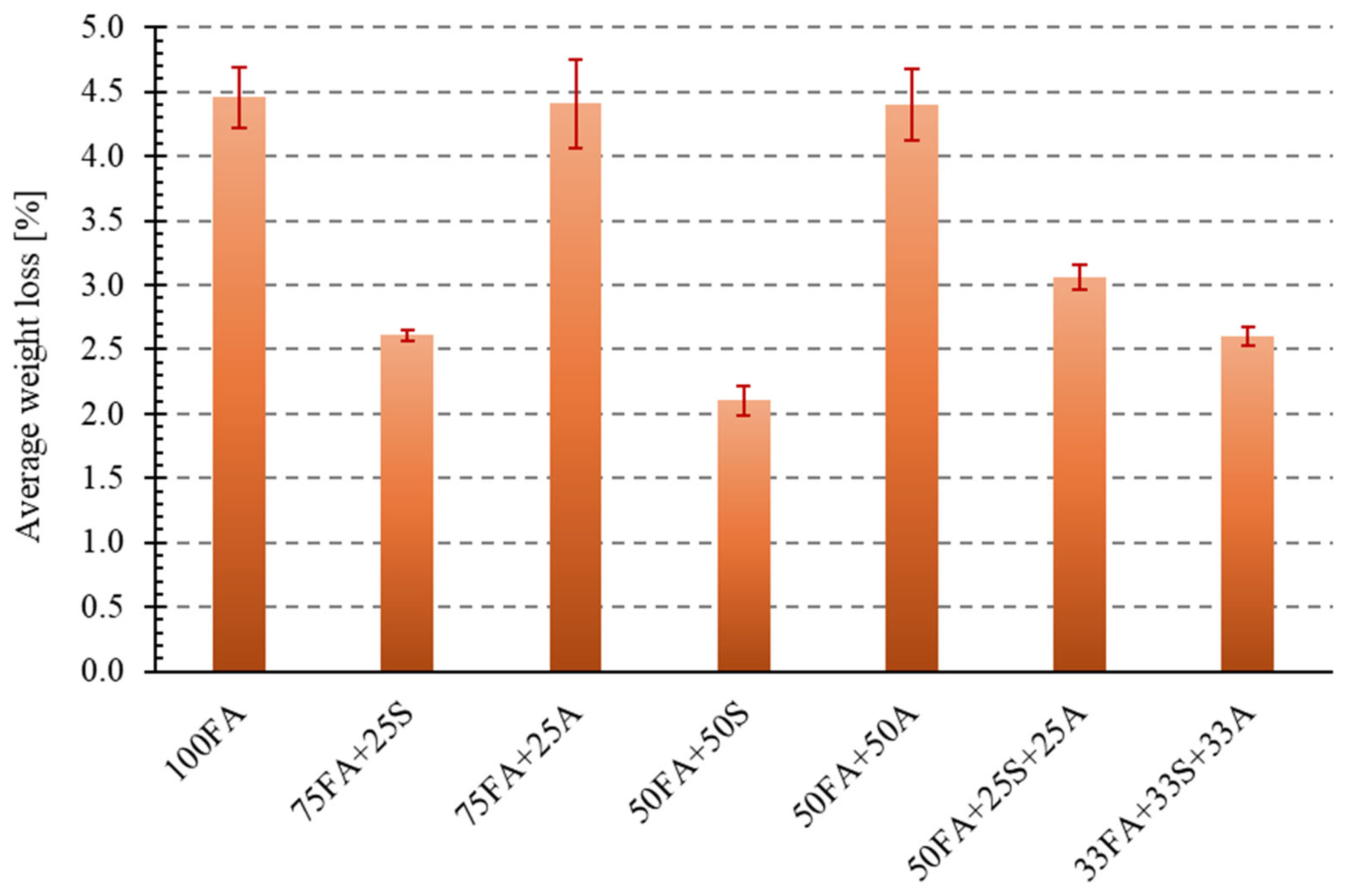

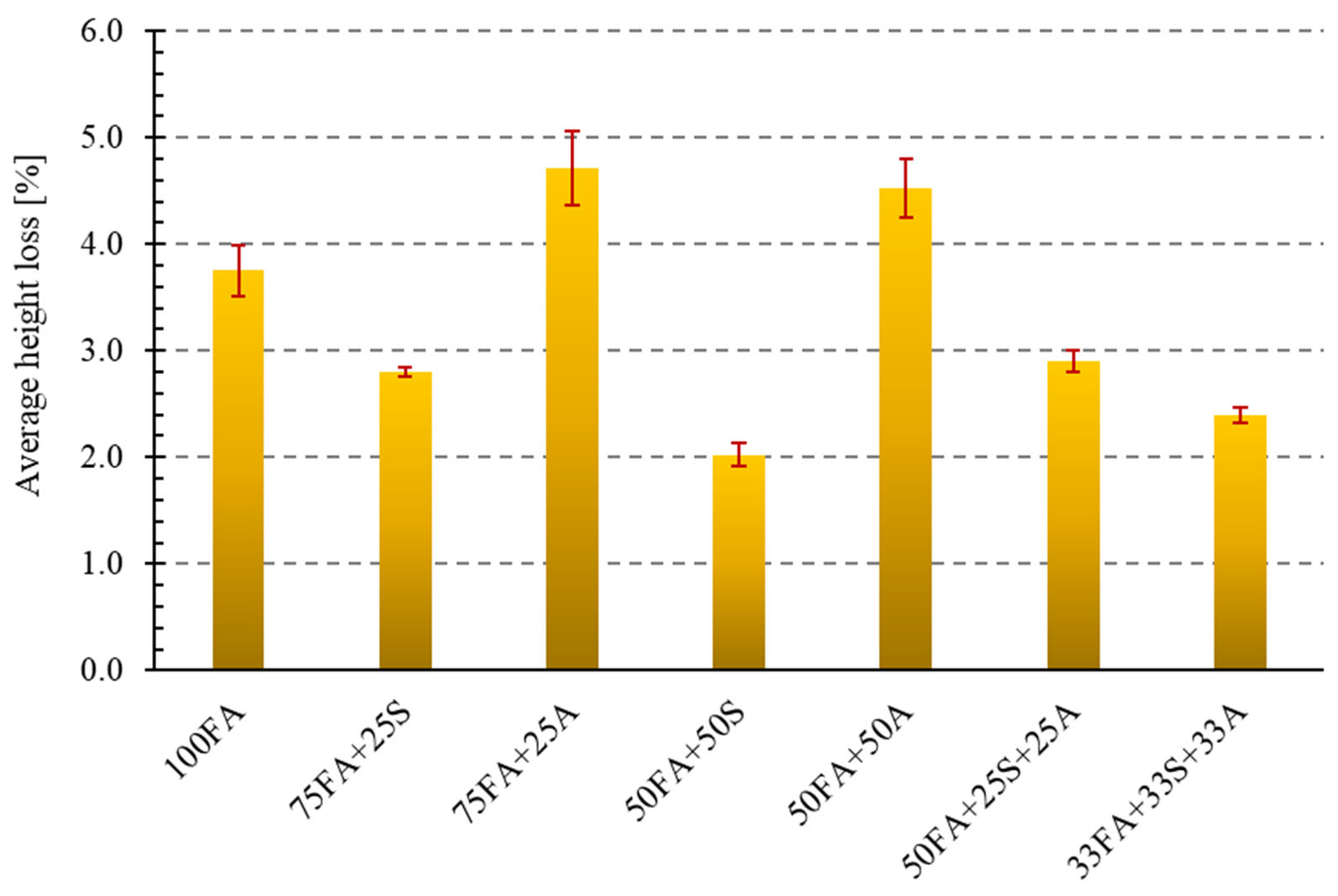

3.4. Abrasion Test Results

3.5. Results of Water Mass Sorption Capacity Tests

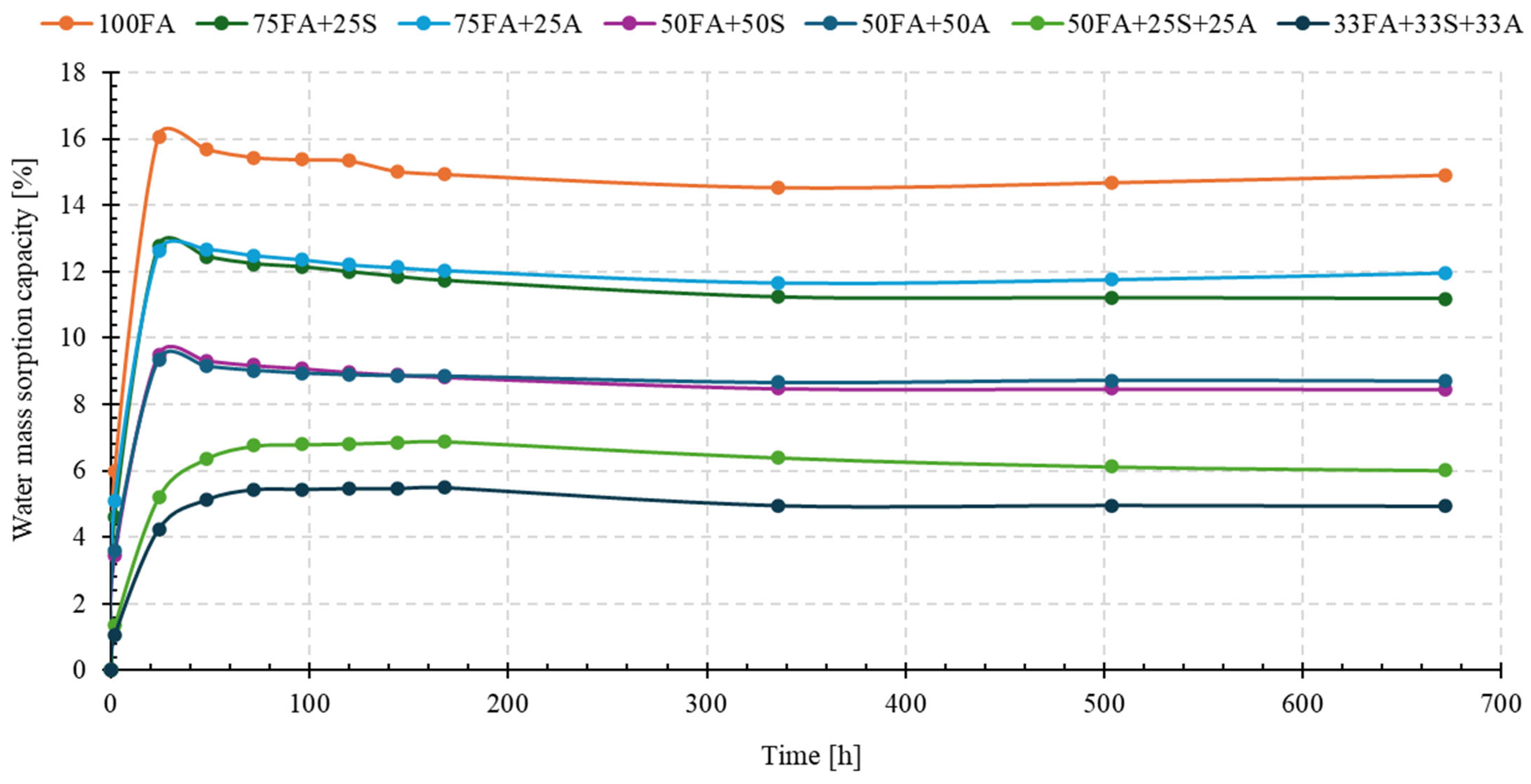

3.6. Chemical Composition of the Tested Geopolymer Composites

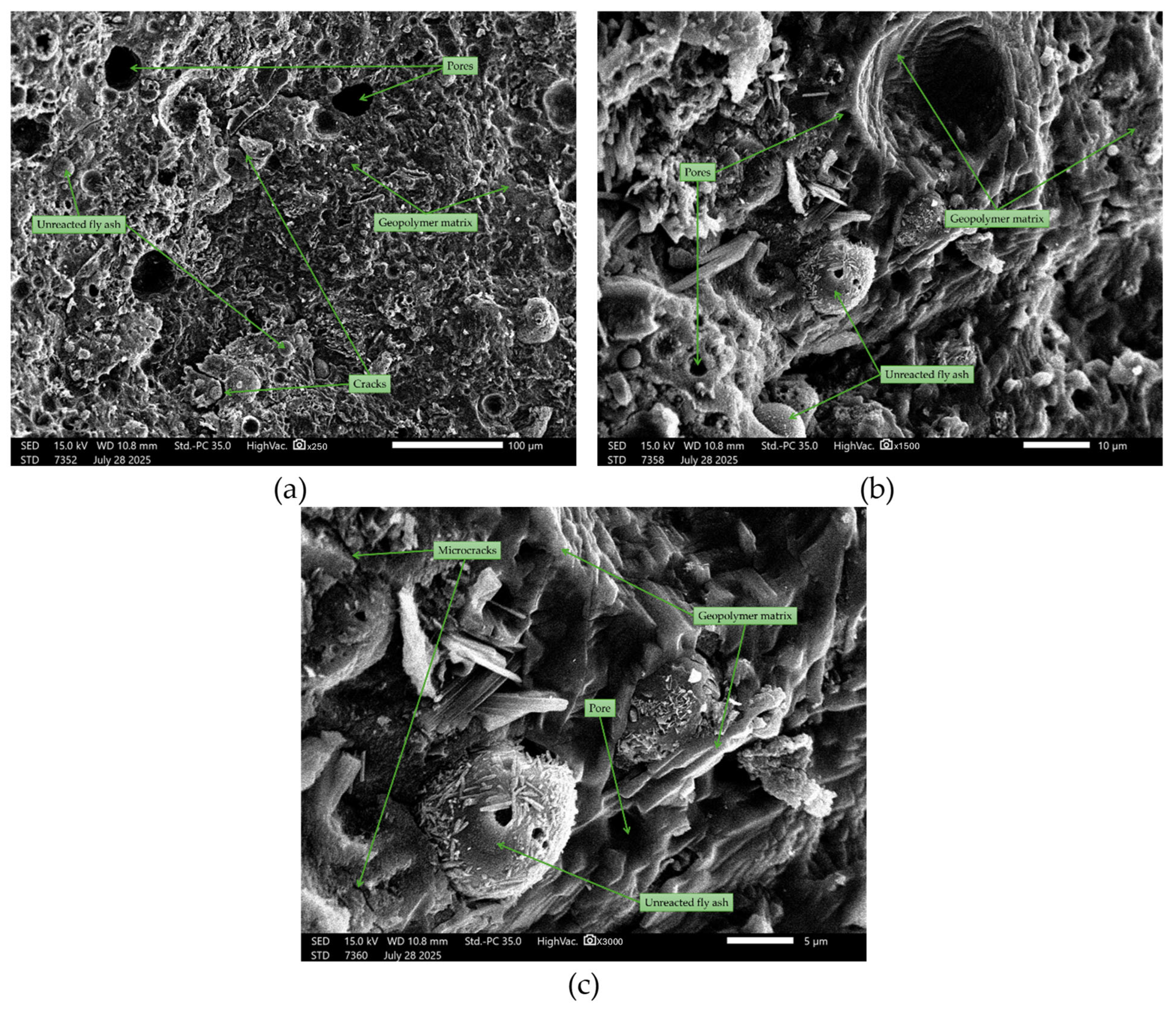

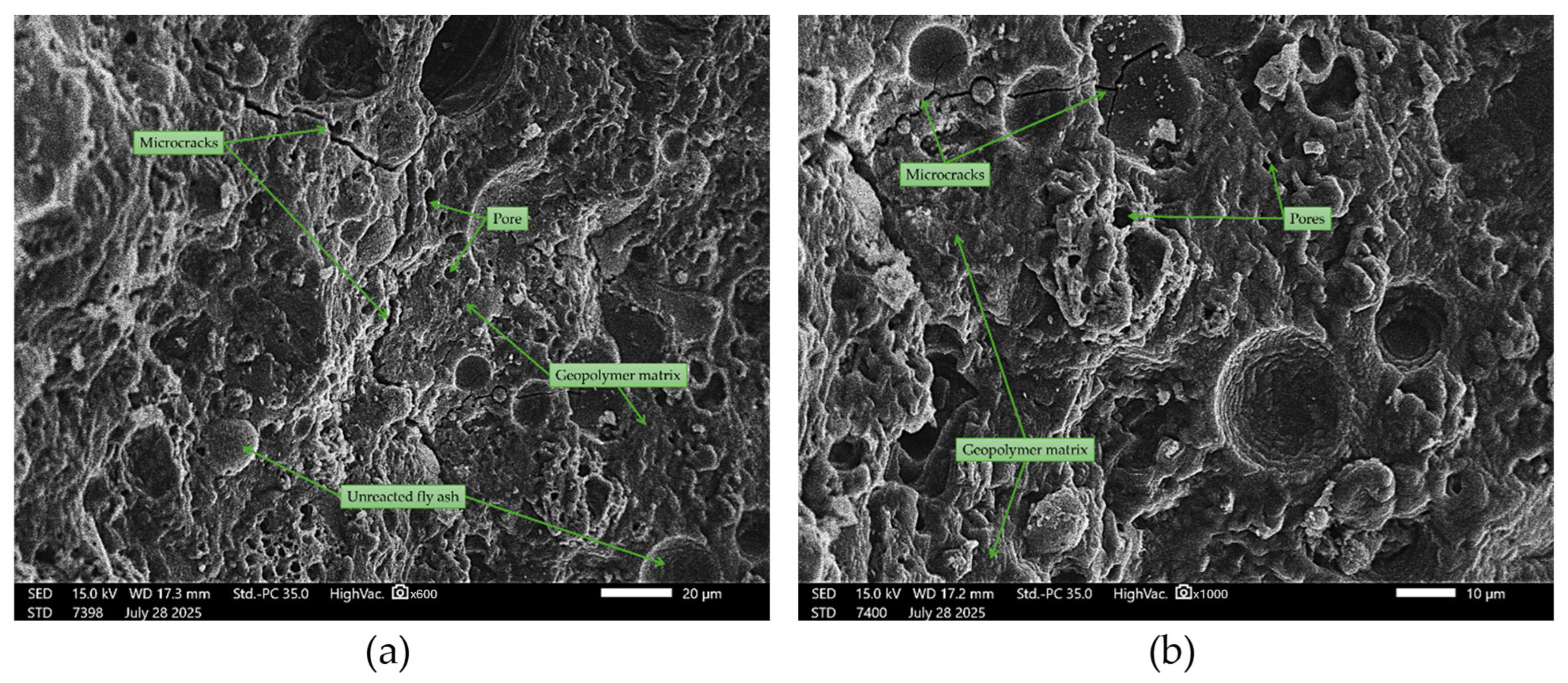

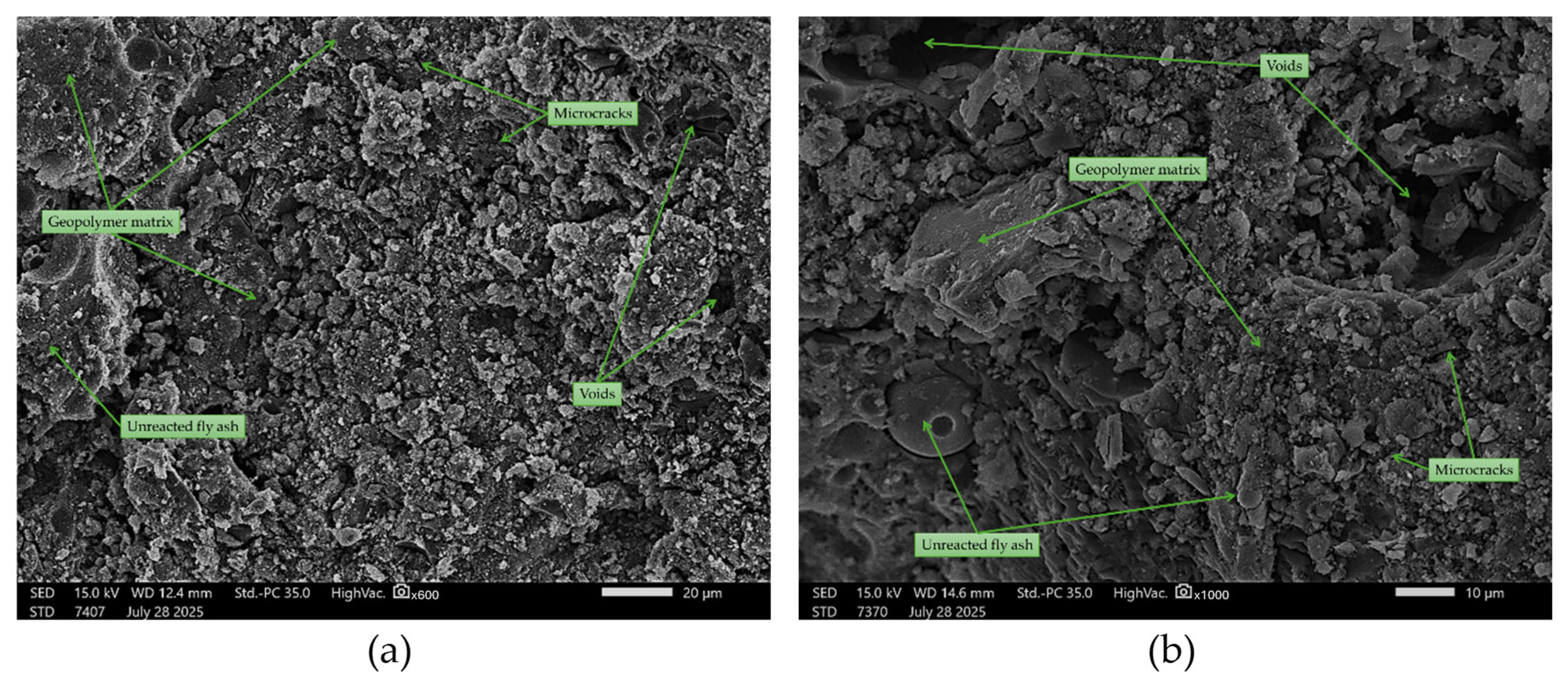

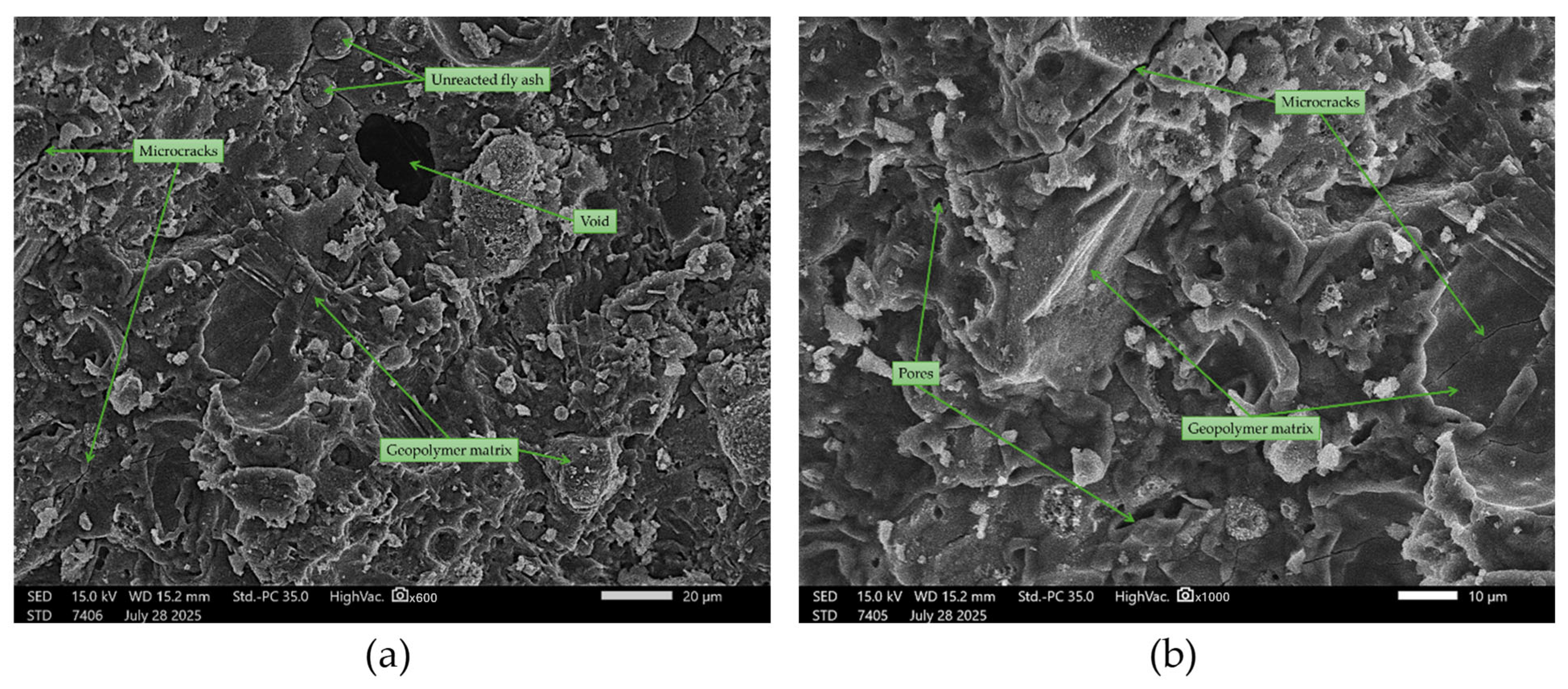

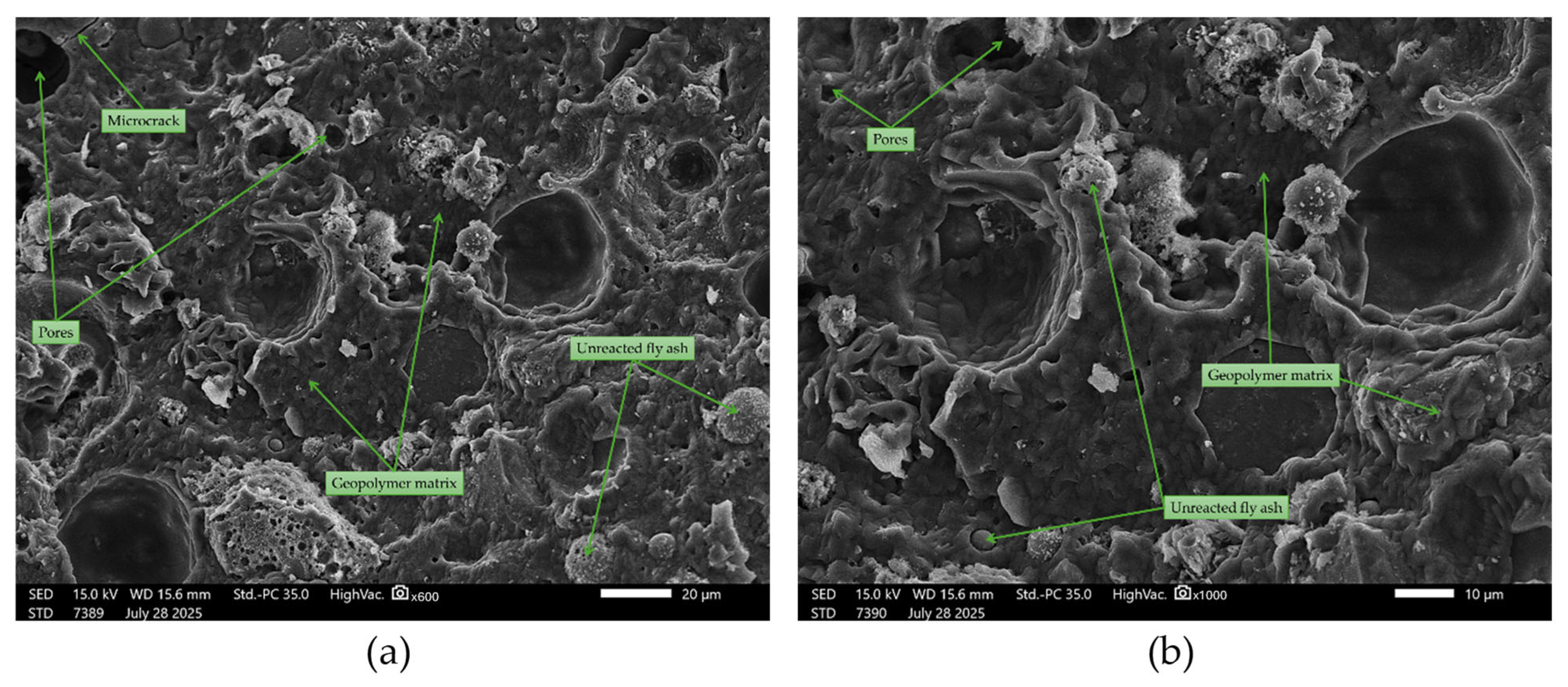

3.7. Microscopic Examination Results

4. Conclusions

- The addition of quartz sand (S) contributed to improved key material parameters. This filler increased density and compressive strength while reducing water absorption and abrasion susceptibility, which can be attributed to enhanced grain packing and the favorable role of the silica phase in the cross-linking process of the geopolymer matrix.

- Milled asphalt (A), acting primarily as a passive filler, decreased mechanical strength at higher dosages. At the same time, when combined with sand, it limited water sorption due to its hydrophobic character, which may be advantageous in selected applications.

- Fly ash (FA) remained the main reactive component in the geopolymerization process. Its proportion determined both the reaction progress and the durability of the composites. Reducing FA content restricted the amount of aluminosilicate precursors, resulting in lower strength and modifications to the internal structure.

- Ternary composite materials, especially the 33FA + 33S + 33A variant, offered a balanced compromise between strength, dimensional stability, and moisture resistance, confirming the benefits of properly selected component ratios.

- The study also demonstrates that the geopolymer matrix based on fly ash is the dominant factor governing the overall performance of the composites. Additives such as sand or milled asphalt cannot be considered equivalent replacements for the geopolymer gel; instead, they act as modifying phases that influence density, porosity, and water uptake. Quartz sand enhanced densification and strength, while asphalt, despite reducing compressive strength at high contents, contributed to lower water sorption. These results highlight that the observed effects arise from the interaction between the geopolymer gel and the fillers, and not from equivalent matrices with altered compositions, which is crucial for assessing their practical applicability.

- Based on these findings, further research is recommended in three directions:

- limiting the milled asphalt content to a maximum of 25% to minimize loss of strength,

- improving asphalt fragmentation to obtain a more uniform structure and reduce internal defects,

- and testing higher molarity activators or additional reactive precursors such as metakaolin to enhance polycondensation and improve the mechanical performance of the composites.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kolade, A.S.; Ikotun, B.D.; Oyejobi, D.O. A Review of the Chemistry, Waste Utilization, Mix Design and Performance Evaluation of Geopolymer Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025, 2025, 1–34. [Google Scholar] [CrossRef]

- Shamsah, M.; Kalfat, R.; Subramaniam, K.V.L.; Hanumananaik, M. Calcium Enhanced Ambient Cured Fly Ash Based Geopolymer Binders. Sci. Rep. 2025, 15, 25603. [Google Scholar] [CrossRef]

- Liew, Y.M.; Kamarudin, H.; Al Bakri, A.M.M.; Bnhussain, M.; Luqman, M.; Nizar, I.K.; Ruzaidi, C.M.; Heah, C.Y. Effect of Curing Regimes on Metakaolin Geopolymer Pastes Produced from Geopolymer Powder. Adv. Mat. Res. 2013, 626, 931–936. [Google Scholar] [CrossRef]

- Gezer, T.; Akarken, G.; Cengiz, U. Production and Characterization of Heat Retardant Fiber-Reinforced Geopolymer Plates. J. Sustain. Constr. Mater. Technol. 2022, 7, 282–290. [Google Scholar] [CrossRef]

- Chokkha, S. Effect of Fly Ash on Compressive Strength of Metakaolin Based Geopolymer. Appl. Mech. Mater. 2017, 873, 170–175. [Google Scholar] [CrossRef]

- Okeyinka, O.M.; Oloke, D.A.; Adebisi, W.A.; Ayininuola, G.M. Investigation into the Applicability of Brewery Sludge Residue-Ash as a Base Material for Geopolymer Concrete. Constr. Build. Mater. 2019, 223, 28–32. [Google Scholar] [CrossRef]

- Sitarz, M.; Hager, I.; Choińska, M. Evolution of Mechanical Properties with Time of Fly-Ash-Based Geopolymer Mortars under the Effect of Granulated Ground Blast Furnace Slag Addition. Energies 2020, 13, 1135. [Google Scholar] [CrossRef]

- Souza Junior, F.G. de Geopolymer: A Review of Structure, Applications and Properties of Fiber Reinforced Composites. Res. Dev. Mater. Sci. 2018, 7, 666. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Beskopylny, A.N.; Shcherban, E.M.; Elshaeva, D.; Chernilnik, A.; Kuimov, D.; Evtushenko, A.; Oganesyan, S. Geopolymer Concrete Physical and Mechanical Properties on a Combined Binder Reinforced with Dispersed Polypropylene Fiber. Polymers 2025, 17, 1710. [Google Scholar] [CrossRef] [PubMed]

- Wongruk, R.; Songpiriyakij, S.; Sukontasukkul, P.; Chindaprasirt, P. Properties of Steel Fiber Reinforced Geopolymer. Key Eng. Mater. 2015, 659, 143–148. [Google Scholar] [CrossRef]

- Meng, T.; Yang, X.; Yu, Y.; Yu, H.; Huang, M. Hybrid Effect of PVA Fibre and Carbon Nanotube on the Mechanical Properties and Microstructure of Geopolymers. Front. Mater. 2021, 8, 773103. [Google Scholar] [CrossRef]

- Assaedi, H.; Alomayri, T.; Siddika, A.; Shaikh, F.; Alamri, H.; Subaer, S.; Low, I.M. Effect of Nanosilica on Mechanical Properties and Microstructure of PVA Fiber-Reinforced Geopolymer Composite (PVA-FRGC). Materials 2019, 12, 3624. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Jiang, J.; Gao, X.; Ding, M. Improving the Mechanical Properties of Fly Ash-Based Geopolymer Composites with PVA Fiber and Powder. Materials 2022, 15, 2363. [Google Scholar] [CrossRef] [PubMed]

- Frydrych, M.; Hýsek, Š.; Fridrichová, L.; Le Van, S.; Herclík, M.; Pechociaková, M.; Chi, H.L.; Louda, P. Impact of Flax and Basalt Fibre Reinforcement on Selected Properties of Geopolymer Composites. Sustainability 2020, 12, 118. [Google Scholar] [CrossRef]

- Taye, E.A.; Roether, J.A.; Schubert, D.W.; Redda, D.T.; Boccaccini, A.R. Hemp Fiber Reinforced Red Mud/Fly Ash Geopolymer Composite Materials: Effect of Fiber Content on Mechanical Strength. Materials 2021, 14, 511. [Google Scholar] [CrossRef] [PubMed]

- Lv, C.; Liu, J.; Guo, G.; Zhang, Y. The Mechanical Properties of Plant Fiber-Reinforced Geopolymers: A Review. Polymers 2022, 14, 4134. [Google Scholar] [CrossRef]

- Bazan, P.; Kozub, B.; Łach, M.; Korniejenko, K. Evaluation of Hybrid Melamine and Steel Fiber Reinforced Geopolymers Composites. Materials 2020, 13, 5548. [Google Scholar] [CrossRef]

- Li, Q.; Chen, S.; Zhang, Y.; Hu, Y.; Wang, Q.; Zhou, Q.; Yan, Y.; Liu, Y.; Yan, D. Effect of Curing Temperature on High-Strength Metakaolin-Based Geopolymer Composite (HMGC) with Quartz Powder and Steel Fibers. Materials 2022, 15, 3958. [Google Scholar] [CrossRef]

- Liu, J.; Shi, X.; Zhang, G.; Li, L. Study the Mechanical Properties of Geopolymer under Different Curing Conditions. Minerals 2023, 13, 690. [Google Scholar] [CrossRef]

- Rashedi, A.; Marzouki, R.; Raza, A.; Ali, K.; Olaiya, N.G.; Kalimuthu, M. Glass FRP-Reinforced Geopolymer Based Columns Comprising Hybrid Fibres: Testing and FEA Modelling. Polymers 2022, 14, 324. [Google Scholar] [CrossRef]

- Carpenter, C. Geopolymer Implemented in Primary Casing Cementing. J. Pet. Technol. 2024, 76, 105–108. [Google Scholar] [CrossRef]

- Owsiak, Z.; Szczykutowicz, K. Physical and Mechanical Properties of Meta-Halloysite-Based Geopolymer Mortars. Cem. Wapno Beton 2023, 28, 351–361. [Google Scholar] [CrossRef]

- Batubara, B.N.; Istiqomah, I.; Kudwadi, B.; Alfan, D. Karakteristik Beton Geopolimer Pada Aktivator Natrium Hidroksida (Naoh) Dan Natrium Silikat (Na2sio3). Kokoh 2022, 20, 85–92. [Google Scholar] [CrossRef]

- Insyira, A.H.; Wijayanti, Y.; Setyandito, O.; Putra, D.P.; Adi Soekotjo, N.; Sasongko, E.; Anda, M. Study of Using Coal Fly Ash (CFA) and Rice Husk Ash (RHA) on the Compressive Strength of Geopolymer Concrete. E3S Web Conf. 2023, 426, 01011. [Google Scholar] [CrossRef]

- Liu, J.; Feng, H.; Zhang, Y.; Zheng, K. Performance Investigation of Geopolymer Grouting Material with Varied Mix Proportions. Sustainability 2022, 14, 13046. [Google Scholar] [CrossRef]

- Isa, M.N.; Awang, H. Development of User Friendly Geopolymer Mortar Using Wood Ash Lye as Alkaline Activator. Adv. Sci. Technol. 2025, 159, 19–25. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Napiah, M.; Sutanto, M.H.; Usman, A.; Jagaba, A.H.; Mani, A.U.; Ahmad, A. Geopolymer Utilization in the Pavement Industry—An Overview. IOP Conf. Ser. Earth Environ. Sci. 2022, 1022, 012025. [Google Scholar] [CrossRef]

- Tian, Q.; Pan, Y.; Bai, Y.; Yao, S.; Sun, S. A Bibliometric Analysis of Research Progress and Trends on Fly Ash-Based Geopolymer. Materials 2022, 15, 4777. [Google Scholar] [CrossRef]

- Iqbal, R.M.; Supriadi, W.; Burhan, R.Y.P.; Nurherdiana, S.D.; Hidayati, R.E.; Subaer, S.; Bayuaji, R.; Fansuri, H. Fabrication and Characterization of Fly Ash-Based Geopolymer and Its Performance for Immobilization of Heavy Metal Cations. Commun. Sci. Technol. 2022, 7, 112–118. [Google Scholar] [CrossRef]

- Disale, A.; Nayak, C.; Suryawanshi, N.; Jadhav, N.; Jagdale, U.; Thakare, S.; Pandey, S.P.; Sharma, P.; Saxena, A.; Kate, G. Evaluation of Properties of Concrete Without Cement Produced Using Fly Ash—Based Geopolymer. Macromol. Symp. 2024, 413, 2300003. [Google Scholar] [CrossRef]

- Li, J.; Dang, X.; Zhang, J.; Yi, P.; Li, Y. Mechanical Properties of Fly Ash-Slag Based Geopolymer for Repair of Road Subgrade Diseases. Polymers 2023, 15, 309. [Google Scholar] [CrossRef] [PubMed]

- Hemra, K.; Yamaguchi, S.; Kobayashi, T.; Aungkavattana, P.; Jiemsirilers, S. Compressive Strength and Setting Time Modification of Class C Fly Ash-Based Geopolymer Partially Replaced with Kaolin and Metakaolin. Key Eng. Mater. 2018, 766, 157–163. [Google Scholar] [CrossRef]

- Kozub, B.; Bazan, P.; Gailitis, R.; Korniejenko, K.; Mierzwiński, D. Foamed Geopolymer Composites with the Addition of Glass Wool Waste. Materials 2021, 14, 4978. [Google Scholar] [CrossRef] [PubMed]

- Sharmin, S.; Biswas, W.K.; Sarker, P.K. Exploring the Potential of Using Waste Clay Brick Powder in Geopolymer Applications: A Comprehensive Review. Buildings 2024, 14, 2317. [Google Scholar] [CrossRef]

- Kurian, S.T.N.; Dominic, J. Experimental Study on Rubberized Geopolymer Concrete with Sugarcane Bagasse Ash. E3S Web Conf. 2024, 529, 01027. [Google Scholar] [CrossRef]

- Yu, X. Research on the Sustainable Materials in Building Construction. Appl. Comput. Eng. 2024, 60, 119–125. [Google Scholar] [CrossRef]

- Bujang, H.; Aman, M.Y.; Arumugam, T.N.; Taher, M.N.M. Physical Characterization of Modified Asphalt Binder with Differing Fly Ash Geopolymer Contents. Int. J. Integr. Eng. 2023, 15, 331–338. [Google Scholar] [CrossRef]

- Albidah, A.S. Influence of Reclaimed Asphalt Pavement Aggregate on the Performance of Metakaolin-Based Geopolymer Concrete at Ambient and Elevated Temperatures. Constr. Build. Mater. 2023, 402, 132945. [Google Scholar] [CrossRef]

- Dwibedy, S.; Parhi, S.K.; Panda, S.; Panigrahi, S.K. Performance of Precursor Characteristics in the Realisation of Geopolymer Concrete: A Review. Mag. Concr. Res. 2024, 76, 1404–1423. [Google Scholar] [CrossRef]

- PN-EN 12390-5:2019-08; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. Polish Committee for Standardization (PKN): Warsaw, Poland, 2020.

- PN-EN 12390-3:2019-07; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Polish Committee for Standardization (PKN): Warsaw, Poland, 2020.

- PN-EN 14157:2017-11; Natural Stone Test Methods—Determination of the Abrasion Resistance. Polish Committee for Standardization (PKN): Warsaw, Poland, 2017.

- Ellecosta, P. Determining Abrasivity for Hard Rock TBM Tunnelling; Technical University of Munich: Munich, Germany, 2020. [Google Scholar]

- Suraneni, P.; Burris, L.; Shearer, C.R.; Hooton, D. ASTM C618 Fly Ash Specification: Comparison with Other Specifications, Shortcomings, and Solutions. ACI Mater. J. 2021, 118, 157–167. [Google Scholar] [CrossRef]

- Mishra, J.; Nanda, B.; Patro, S.K.; Krishna, R.S. Sustainable Fly Ash Based Geopolymer Binders: A Review on Compressive Strength and Microstructure Properties. Sustainability 2022, 14, 15062. [Google Scholar] [CrossRef]

- Lu, X.; Liu, B.; Zhang, Q.; Wen, Q.; Wang, S.; Xiao, K.; Zhang, S.; Mokrzycki, E.; Uliasz-Boché, A.; Lu, X.; et al. Recycling of Coal Fly Ash in Building Materials: A Review. Minerals 2022, 13, 25. [Google Scholar] [CrossRef]

- Nuruddin, M.F.; Malkawi, A.B.; Fauzi, A.; Mohammed, B.S.; Almattarneh, H.M. Evolution of Geopolymer Binders: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 012052. [Google Scholar] [CrossRef]

- Aiken, T.A.; Kwasny, J.; Sha, W. Resistance of Fly Ash Geopolymer Binders to Organic Acids. Mater. Struct. Mater. Constr. 2020, 53, 115. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Avudaiappan, S.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Klyuev, S.; Gholampour, A. Fly Ash-Based Eco-Efficient Concretes: A Comprehensive Review of the Short-Term Properties. Materials 2021, 14, 4264. [Google Scholar] [CrossRef]

- Donatello, S.; Kuenzel, C.; Palomo, A.; Fernández-Jiménez, A. High Temperature Resistance of a Very High Volume Fly Ash Cement Paste. Cem. Concr. Compos. 2014, 45, 234–242. [Google Scholar] [CrossRef]

- Das, D. Role of Particle Size on the Mechanical and Microstructural Properties of Fly Ash-Based Geopolymer. Interactions 2024, 245, 277. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Zuo, Y.; Chen, W.; Ye, G. Chemical Deformation of Metakaolin Based Geopolymer. Cem. Concr. Res. 2019, 120, 108–118. [Google Scholar] [CrossRef]

- Vogt, O.; Ballschmiede, C.; Ukrainczyk, N.; Koenders, E. Evaluation of Sulfuric Acid-Induced Degradation of Potassium Silicate Activated Metakaolin Geopolymers by Semi-Quantitative SEM-EDX Analysis. Materials 2020, 13, 4522. [Google Scholar] [CrossRef]

- Borges, P.H.R.; Ramos, F.C.R.; Caetano, T.R.; Panzerra, T.H.; Santos, H. Reuse of Iron Ore Tailings in the Production of Geopolymer Mortars. REM Int. Eng. J. 2019, 72, 581–587. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Cocnrete; Pearson Education Ltd.: Harlow, UK, 2011; pp. 1–799. [Google Scholar]

- Provis, J.L.; van Deventer, J.S.J. (Eds.) Geopolymers Structures, Processing, Properties and Industrial Applications; Woodhead Publishing: Sawston, UK, 2009. [Google Scholar]

- Galan, J.J.; Silva, L.M.; Pasandín, A.R.; Pérez, I. Evaluation of the Resilient Modulus of Hot-Mix Asphalt Made with Recycled Concrete Aggregates from Construction and Demolition Waste. Sustainability 2020, 12, 8551. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Abdullahi, M.; Hoong, C.K. Statistical Models for Concrete Containing Wood Chipping as Partial Replacement to Fine Aggregate. Constr. Build. Mater. 2014, 55, 13–19. [Google Scholar] [CrossRef]

- Gao, J.W.; Li, H.; Zhong, W.L.; Fan, L.F.; Jiang, D. Effects of Artificial Geopolymer Sand as an Alternative to Natural Sand on Dynamic Mechanical Properties of Cement Mortar. Constr. Build. Mater. 2023, 394, 132181. [Google Scholar] [CrossRef]

- Tracz, T.; Zdeb, T.; Hager, I.; Kozub, B.; Miernik, K.; Gądek, S. A Study of Fly Ash-Based Geopolymers with Basalt Flour Addition. Mater. Proc. 2023, 13, 3. [Google Scholar] [CrossRef]

- Zawrah, M.F.; Abo Sawan, S.E. Hardened and Fired Geopolymer Mortars Fabricated from Cyclone’s Waste Clay and Submicron Sand: A Comparative Study. Constr. Build. Mater. 2023, 364, 129998. [Google Scholar] [CrossRef]

- Kozub, B.; Rodziewicz, M. Effect of Granite Flour Proportion on the Strength Properties of Geopolymer Mortar Based on Fly Ash. Materwiss Werksttech 2023, 54, 441–449. [Google Scholar] [CrossRef]

- Mekonnen Lakew, A.; Al-Mashhadani, M.M.; Canpolat, O. Strength and Abrasion Performance of Recycled Aggregate Based Geopolymer Concrete. Sigma J. Eng. Nat. Sci. 2022, 40, 155–161. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, P.; Guo, J.; Wang, F. Abrasion Resistance Assessment of Geopolymer Concrete Reinforced with Nano-SiO2 and Steel-Polyvinyl Alcohol Hybrid Fiber. Constr. Build. Mater. 2025, 487, 142071. [Google Scholar] [CrossRef]

- Kriven, W.M.; Leonelli, C.; Provis, J.L.; Boccaccini, A.R.; Attwell, C.; Ducman, V.S.; Ferone, C.; Rossignol, S.; Luukkonen, T.; van Deventer, J.S.J.; et al. Why Geopolymers and Alkali-Activated Materials Are Key Components of a Sustainable World: A Perspective Contribution. J. Am. Ceram. Soc. 2024, 107, 5159–5177. [Google Scholar] [CrossRef]

- Rihan, M.A.M.; Onchiri, R.O.; Gathimba, N.; Sabuni, B. Assessing the Durability Performance of Geopolymer Concrete Utilizing Fly Ash and Sugarcane Bagasse Ash as Sustainable Binders. Open Ceram. 2024, 20, 100687. [Google Scholar] [CrossRef]

- Mehmani, A.; Tokan-Lawal, A.; Prodanović, M.; Sheppard, A.P. The Effect of Microporosity on Transport Properties in Tight Reservoirs. In Proceedings of the North American Unconventional Gas Conference and Exhibition, The Woodlands, TX, USA, 14–16 June 2011; pp. 821–834. [Google Scholar] [CrossRef]

- Brantut, N.; Baker, M.; Hansen, L.N.; Baud, P. Microstructural Control of Physical Properties During Deformation of Porous Limestone. J. Geophys. Res. Solid. Earth 2018, 123, 4751–4764. [Google Scholar] [CrossRef]

- Erunkulu, I.O.; Malumbela, G.; Oladijo, O.P. Performance Evaluation of Fly Ash–Copper Slag-Based Geopolymer Bricks. Low-Carbon Mater. Green Constr. 2024, 2, 14. [Google Scholar] [CrossRef]

- Zhang, P.; Shi, B.; Dai, X.; Chen, C.; Lai, C. A State-of-the-Art Review on the Freeze–Thaw Resistance of Sustainable Geopolymer Gel Composites: Mechanisms, Determinants, and Models. Gels 2025, 11, 537. [Google Scholar] [CrossRef]

- Saba, M.; Arairo, W. Perspective Chapter: Geopolymers in Civil and Environmental Engineering Applications. In Advances in Geopolymers; IntechOpen: London, UK, 2024. [Google Scholar] [CrossRef]

- Ikotun, J.O.; Aderinto, G.E.; Madirisha, M.M.; Katte, V.Y. Geopolymer Cement in Pavement Applications: Bridging Sustainability and Performance. Sustainability 2024, 16, 5417. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U. Calcium Wastes as an Additive for a Low Calcium Fly Ash Geopolymer. Sci. Rep. 2023, 13, 16351. [Google Scholar] [CrossRef] [PubMed]

- Prochoń, P.; Piotrowski, T.; Courard, L.; Zhao, Z. The Effects of Calcium and Phosphate Compounds on the Mechanical and Microstructural Properties of Fly Ash Geopolymer Mortars. In Concrete-Polymer Composites in Circular Economy; Springer: Berlin/Heidelberg, Germany, 2025; Volume 61, pp. 230–238. [Google Scholar] [CrossRef]

- Li, Y.; Dong, Y.; El-Naggar, M.R.; Wang, F.; Zhao, Y.; Li, Y.; Dong, Y.; El-Naggar, M.R.; Wang, F.; Zhao, Y. The Influence of Particle Size and Calcium Content on Performance Characteristics of Metakaolin- and Fly-Ash-Based Geopolymer Gels. Gels 2024, 10, 639. [Google Scholar] [CrossRef]

- Lv, Y.; Wang, C.; Han, W.; Li, X.; Peng, H. Study of the Mechanical Properties and Microstructure of Alkali-Activated Fly Ash–Slag Composite Cementitious Materials. Polymers 2023, 15, 1903. [Google Scholar] [CrossRef] [PubMed]

- Saeed, A.; Najm, H.M.; Hassan, A.; Sabri, M.M.S.; Qaidi, S.; Mashaan, N.S.; Ansari, K. Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties. Materials 2022, 15, 8250. [Google Scholar] [CrossRef] [PubMed]

- Peng, H.; Cui, C.; Cai, C.S.; Liu, Y.; Liu, Z. Microstructure and Microhardness Property of the Interface between a Metakaolin/GGBFS-Based Geopolymer Paste and Granite Aggregate. Constr. Build. Mater. 2019, 221, 263–273. [Google Scholar] [CrossRef]

- Malkawi, A.B. Effect of Aggregate on the Performance of Fly-Ash-Based Geopolymer Concrete. Buildings 2023, 13, 769. [Google Scholar] [CrossRef]

| Sample Designation | Weight Fraction [%wt.] | The Liquid-to-Solid (L/S) Ratio | ||

|---|---|---|---|---|

| Fly Ash | Sand | Asphalt | ||

| 100FA | 100 | – | – | 0.4 |

| 75FA + 25S | 75 | 25 | – | 0.4 |

| 75FA + 25A | 75 | – | 25 | 0.425 |

| 50FA + 50S | 50 | 50 | – | 0.4 |

| 50FA + 50A | 50 | – | 50 | 0.45 |

| 50FA + 25S + 25A | 50 | 25 | 25 | 0.425 |

| 33FA + 33S + 33A | 33 | 33 | 33 | 0.425 |

| Abrasion Resistance Class | Average Height Loss [mm] |

|---|---|

| Very high abrasion | >10.0 |

| High abrasion | 7.5–10.0 |

| Low abrasion | 2.5–5.0 |

| Very low abrasion | <2.5 |

| Name | D10 [µm] | D50 [µm] | D90 [µm] | Mean Size [µm] | Span Index |

|---|---|---|---|---|---|

| Mean value | 2.709 | 16.532 | 50.786 | 23.59 | 2.908 |

| Standard deviation | 0.047 | 0.073 | 0.946 | 0.247 | 0.061 |

| Relative standard deviation [%] | 1.74 | 0.44 | 1.86 | 1.05 | 2.09 |

| Name | D10 [µm] | D50 [µm] | D90 [µm] | Mean Size [µm] | Span Index |

|---|---|---|---|---|---|

| Mean value | 182.57 | 341.715 | 474.501 | 374.146 | 0.854 |

| Standard deviation | 29.727 | 6.227 | 3.108 | 5.918 | 0.087 |

| Relative standard deviation [%] | 16.28 | 1.82 | 0.66 | 1.58 | 10.21 |

| Name | D10 [µm] | D50 [µm] | D90 [µm] | Mean Size [µm] | Span Index |

|---|---|---|---|---|---|

| Mean value | 172.948 | 250.576 | 437.076 | 311.536 | 1.177 |

| Standard deviation | 74.589 | 93.463 | 73.374 | 88.079 | 0.481 |

| Relative standard deviation [%] | 43.13 | 37.3 | 16.79 | 28.27 | 40.87 |

| Source of Variation | Sum of Squares SS | Degrees of Freedom df | Mean Square MS | Fisher’s Test Value F | Significance Level p-Value | Critical F Value Fcrit |

|---|---|---|---|---|---|---|

| Between groups | 94.76 | 6 | 15.79 | 35.90 | 6.79·× 10−12 | 2.45 |

| Within groups | 12.32 | 28 | 0.444 | |||

| Total | 107.08 | 34 |

| Source of Variation | Sum of Squares SS | Degrees of Freedom df | Mean Square MS | Fisher’s Test Value F | Significance Level p-Value | Critical F Value Fcrit |

|---|---|---|---|---|---|---|

| Between groups | 5017.522 | 6 | 836.25 | 28.83 | 9.44·× 10−11 | 2.45 |

| Within groups | 812.254 | 28 | 29.01 | |||

| Total | 5829.77 | 34 |

| Element | Concentration [%] | ||||||

|---|---|---|---|---|---|---|---|

| 100FA | 75FA + 25S | 75FA + 25A | 50FA + 50S | 50FA + 50A | 50FA + 25S + 25A | 33FA + 33S + 33A | |

| Mg | 1.94 | 4.39 | 1.54 | 0.9 | 1.97 | 0.00 | 1.27 |

| Al | 13.81 | 12.11 | 11.27 | 10.88 | 13.34 | 9.41 | 10.14 |

| Si | 48.22 | 44.54 | 47.19 | 49.37 | 48.01 | 42.74 | 46.29 |

| P | 0.00 | 0.00 | 0.00 | 0.23 | 0.00 | 0.05 | 0.22 |

| S | 0.69 | 0.39 | 0.9 | 3.89 | 0.26 | 11.09 | 3.75 |

| Cl | 0.12 | 0.11 | 0.11 | 0.07 | 0.13 | 0.05 | 0.08 |

| K | 6.8 | 7.36 | 7.25 | 7.25 | 6.74 | 7.2 | 7.61 |

| Ca | 7.26 | 7.58 | 8.14 | 7.14 | 8.68 | 7.97 | 9.58 |

| Ti | 2.02 | 2.21 | 2.16 | 1.97 | 2.06 | 2.03 | 2.00 |

| V | 0.11 | 0.12 | 0.12 | 0.17 | 0.1 | 0.17 | 0.19 |

| Cr | 0.04 | 0.05 | 0.05 | 0.04 | 0.04 | 0.05 | 0.05 |

| Mn | 0.3 | 0.34 | 0.33 | 0.34 | 0.29 | 0.33 | 0.38 |

| Fe | 17.53 | 19.56 | 19.63 | 16.84 | 17.29 | 17.82 | 17.35 |

| Ni | 0.05 | 0.06 | 0.06 | 0.05 | 0.05 | 0.06 | 0.06 |

| Cu | 0.07 | 0.09 | 0.08 | 0.07 | 0.07 | 0.08 | 0.08 |

| Zn | 0.11 | 0.13 | 0.16 | 0.11 | 0.16 | 0.14 | 0.23 |

| Ga | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| As | 0.02 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 |

| Br | 0.01 | 0.01 | 0.01 | 0.00 | 0.01 | 0.00 | 0.00 |

| Rb | 0.07 | 0.08 | 0.08 | 0.05 | 0.06 | 0.06 | 0.05 |

| Sr | 0.22 | 0.23 | 0.24 | 0.16 | 0.2 | 0.2 | 0.17 |

| Y | 0.02 | 0.01 | 0.01 | 0.00 | 0.01 | 0.01 | 0.00 |

| Zr | 0.13 | 0.14 | 0.14 | 0.1 | 0.11 | 0.12 | 0.1 |

| Rh | 0.00 | 0.00 | 0.00 | 0.00 | 0.02 | 0.00 | 0.00 |

| In | 0.00 | 0.04 | 0.05 | 0.00 | 0.03 | 0.00 | 0.00 |

| Ba | 0.42 | 0.38 | 0.37 | 0.32 | 0.31 | 0.35 | 0.36 |

| Ta | 0.00 | 0.00 | 0.02 | 0.00 | 0.02 | 0.00 | 0.00 |

| Pb | 0.01 | 0.01 | 0.02 | 0.00 | 0.02 | 0.00 | 0.00 |

| Oxide | Concentration [%] | ||||||

|---|---|---|---|---|---|---|---|

| 100FA | 75FA + 25S | 75FA + 25A | 50FA + 50S | 50FA + 50A | 50FA + 25S + 25A | 33FA + 33S + 33A | |

| MgO | 0.987 | 3.675 | 1.728 | 0.252 | 0.936 | 0.00 | 0.00 |

| Al2O3 | 16.721 | 14.298 | 13.512 | 12.761 | 15.992 | 11.126 | 12.417 |

| SiO2 | 60.331 | 57.2 | 60.068 | 61.259 | 60.423 | 53.694 | 59.328 |

| P2O5 | 0.00 | 0.00 | 0.00 | 0.271 | 0.00 | 0.092 | 0.281 |

| SO3 | 0.85 | 0.51 | 1.12 | 4.74 | 0.34 | 13.59 | 4.77 |

| Cl | 0.052 | 0.054 | 0.05 | 0.038 | 0.068 | 0.03 | 0.039 |

| K2O | 3.9 | 4.46 | 4.25 | 4.13 | 3.97 | 4.03 | 4.43 |

| CaO | 4.66 | 5.13 | 5.3 | 4.54 | 5.67 | 4.99 | 6.19 |

| TiO2 | 1.5 | 1.72 | 1.63 | 1.45 | 1.55 | 1.48 | 1.49 |

| V2O5 | 0.08 | 0.09 | 0.09 | 0.13 | 0.08 | 0.13 | 0.14 |

| Cr2O3 | 0.02 | 0.03 | 0.03 | 0.02 | 0.03 | 0.02 | 0.02 |

| MnO | 0.15 | 0.19 | 0.18 | 0.18 | 0.16 | 0.17 | 0.2 |

| Fe2O3 | 10.2 | 12.06 | 11.5 | 9.83 | 10.32 | 10.18 | 10.19 |

| NiO | 0.02 | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| CuO | 0.03 | 0.04 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| ZnO | 0.05 | 0.06 | 0.07 | 0.05 | 0.08 | 0.06 | 0.1 |

| Ga2O3 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.00 |

| As2O3 | 0.01 | 0.01 | 0.01 | 0.02 | 0.01 | 0.02 | 0.02 |

| Rb2O | 0.03 | 0.04 | 0.04 | 0.02 | 0.03 | 0.03 | 0.02 |

| SrO | 0.1 | 0.11 | 0.11 | 0.07 | 0.09 | 0.09 | 0.08 |

| Y2O3 | 0.01 | 0.01 | 0.01 | 0.00 | 0.01 | 0.00 | 0.00 |

| ZrO2 | 0.06 | 0.07 | 0.07 | 0.05 | 0.05 | 0.06 | 0.05 |

| BaO | 0.17 | 0.16 | 0.15 | 0.13 | 0.13 | 0.13 | 0.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozub, B. Properties of Geopolymers Based on Fly Ash with the Addition of Asphalt from Road Surface Demolition. Materials 2025, 18, 4488. https://doi.org/10.3390/ma18194488

Kozub B. Properties of Geopolymers Based on Fly Ash with the Addition of Asphalt from Road Surface Demolition. Materials. 2025; 18(19):4488. https://doi.org/10.3390/ma18194488

Chicago/Turabian StyleKozub, Barbara. 2025. "Properties of Geopolymers Based on Fly Ash with the Addition of Asphalt from Road Surface Demolition" Materials 18, no. 19: 4488. https://doi.org/10.3390/ma18194488

APA StyleKozub, B. (2025). Properties of Geopolymers Based on Fly Ash with the Addition of Asphalt from Road Surface Demolition. Materials, 18(19), 4488. https://doi.org/10.3390/ma18194488