Improvement of Microstructure and Mechanical Properties of SiC–VC System Obtained by Electroconsolidation

Abstract

1. Introduction

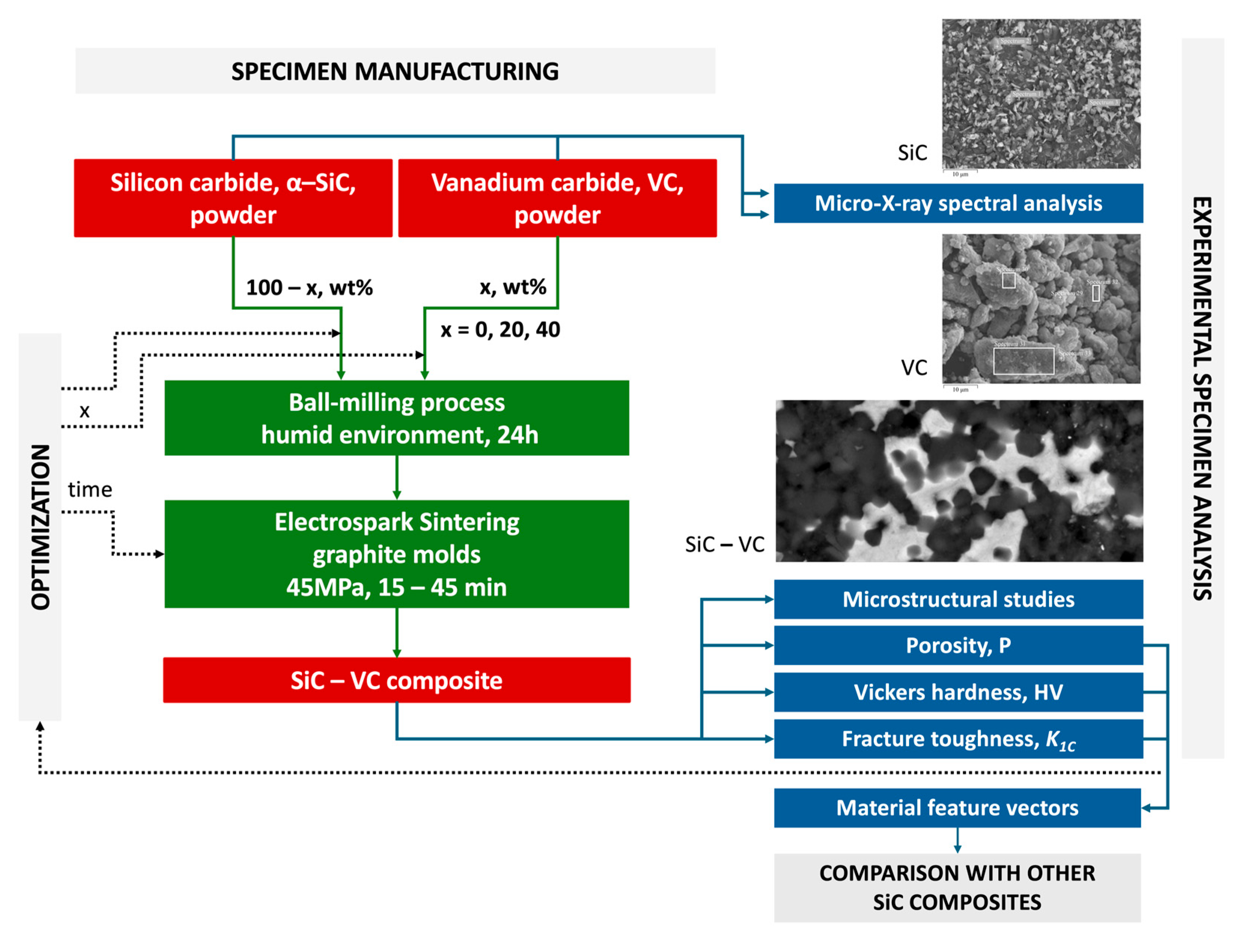

2. Materials and Methods

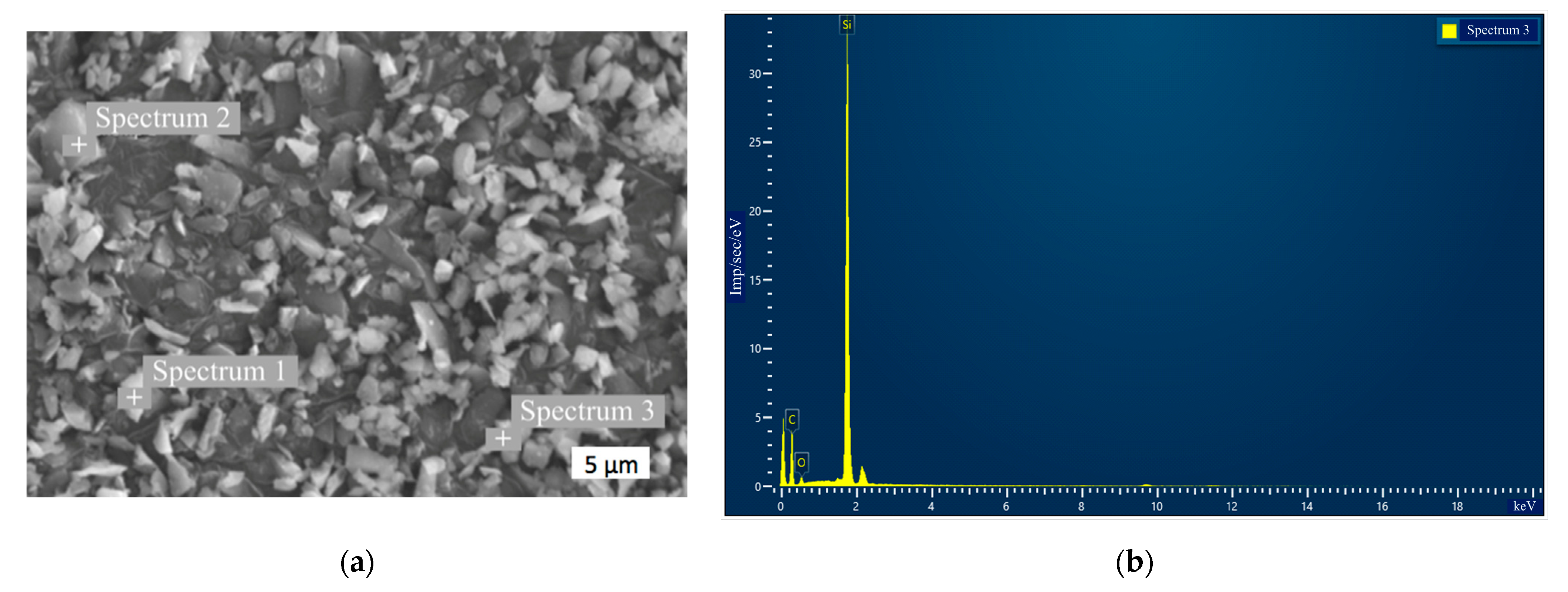

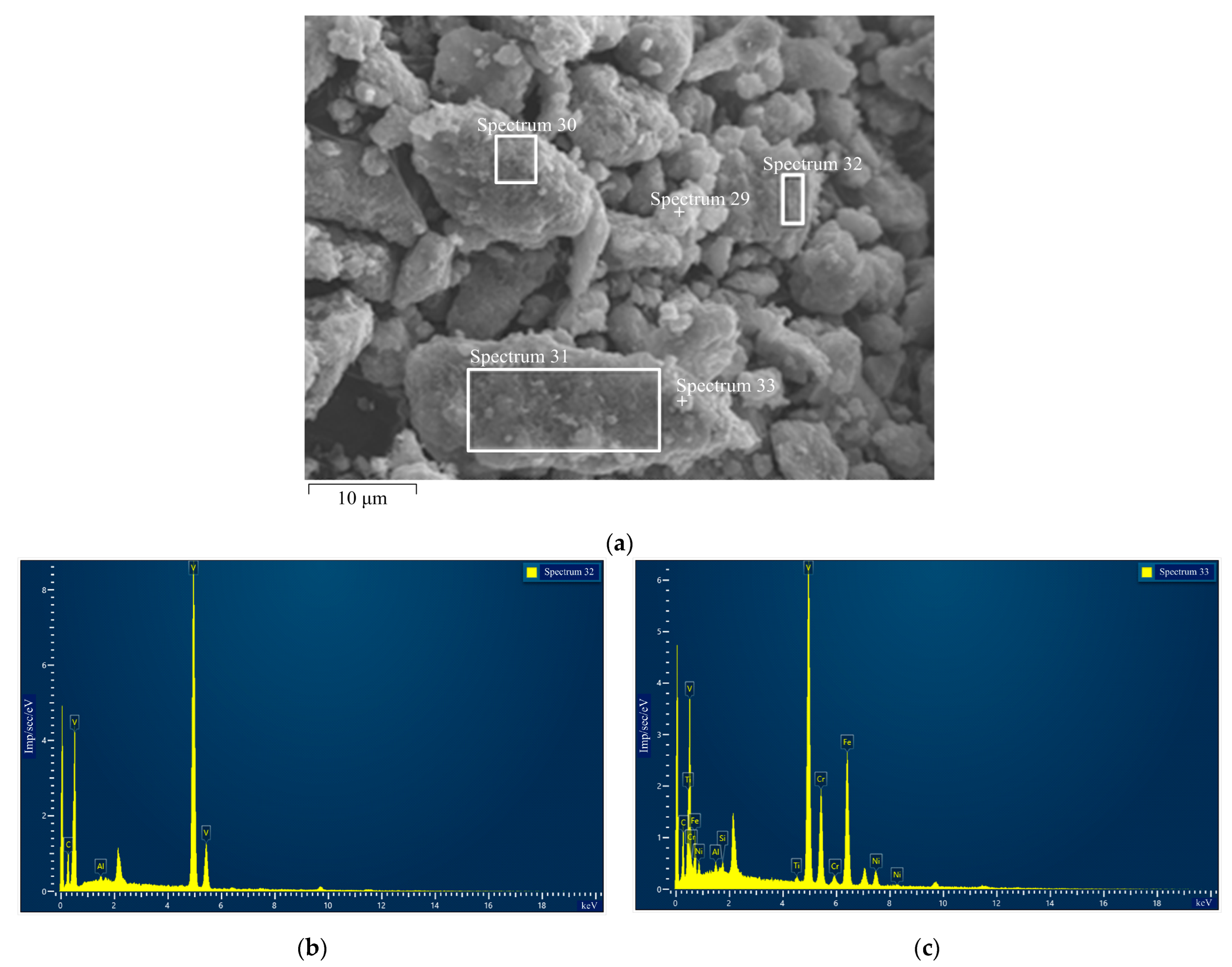

2.1. Raw Materials

2.2. Material Processing

2.3. Material Characterization

3. Results and Discussion

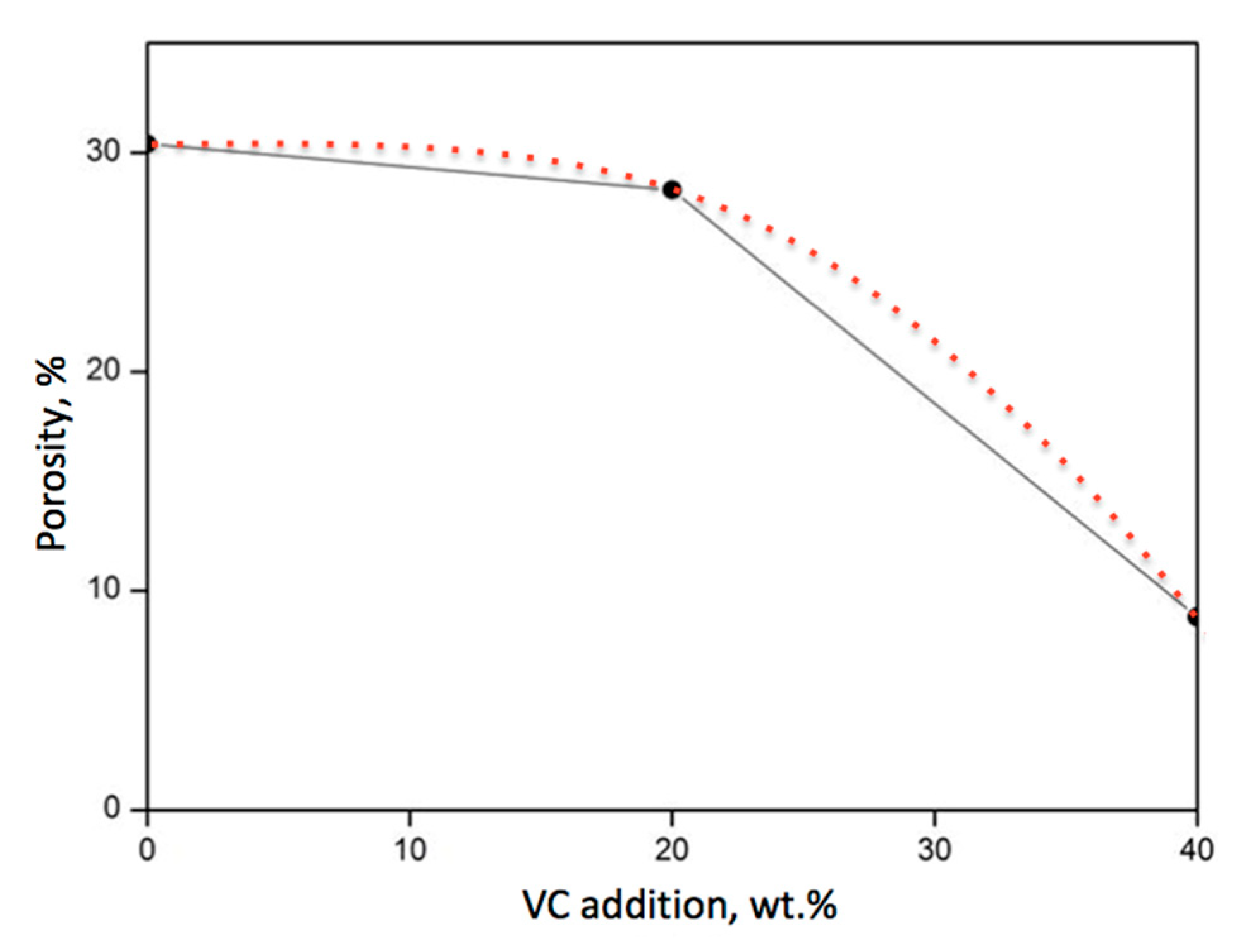

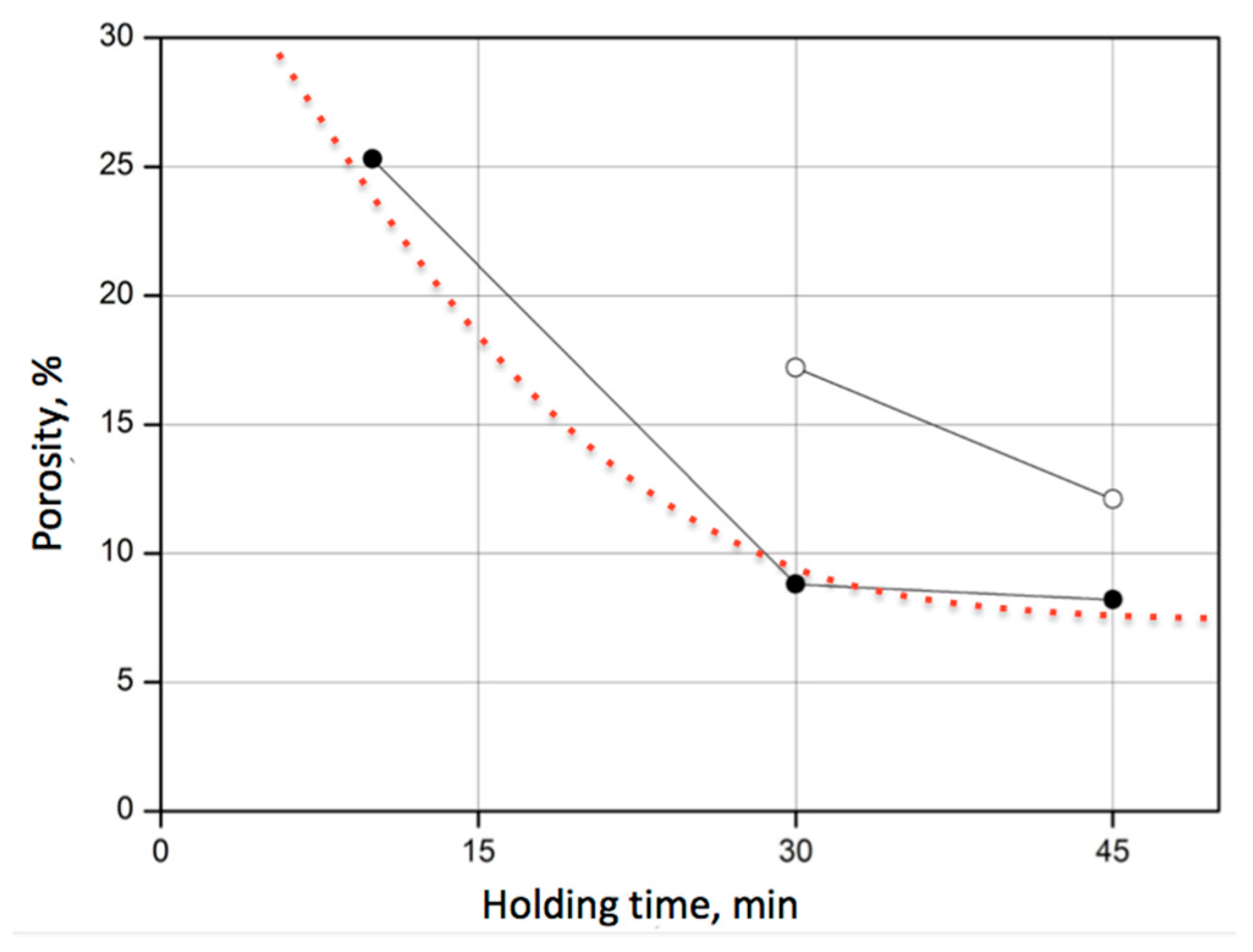

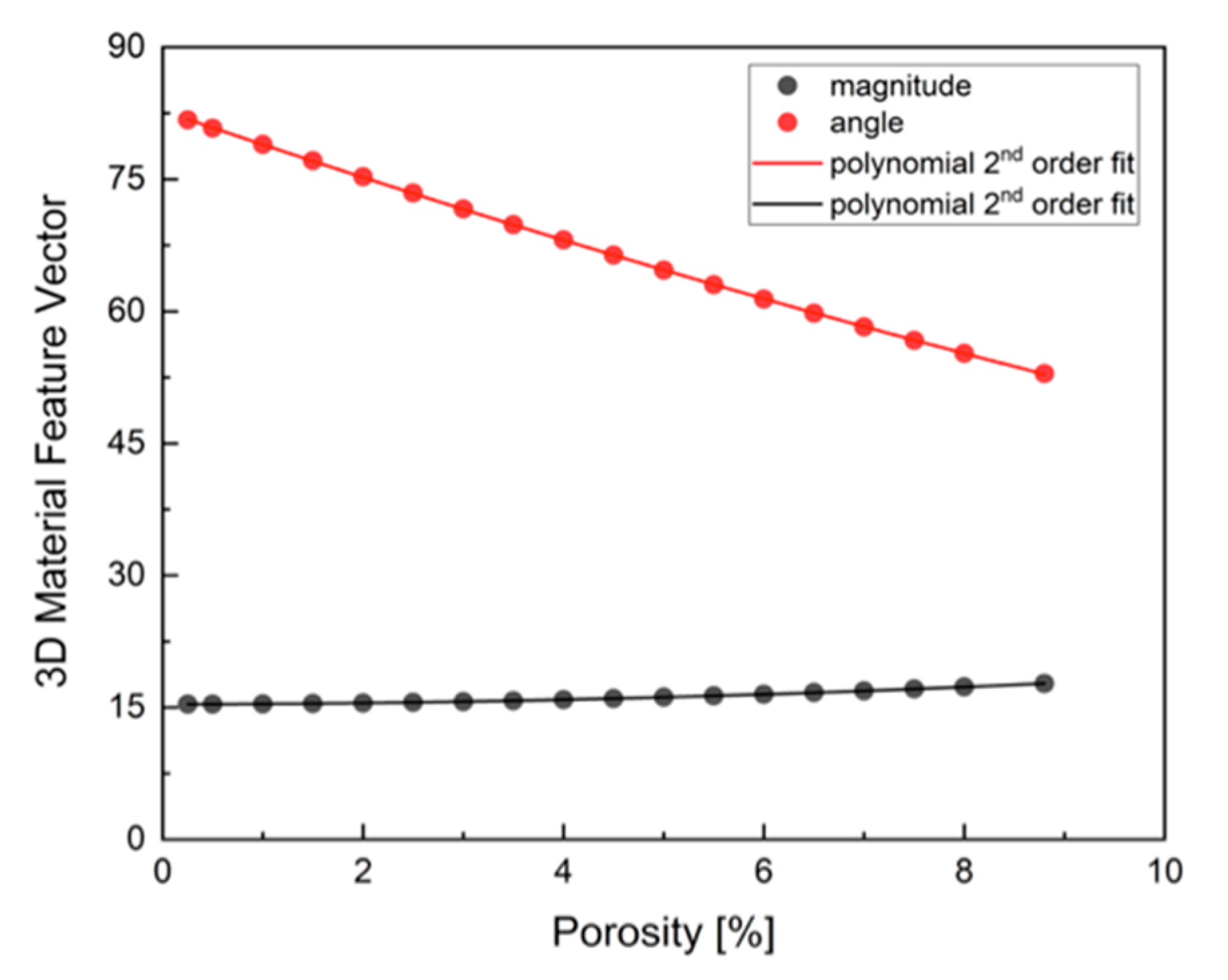

3.1. Densification and Porosity

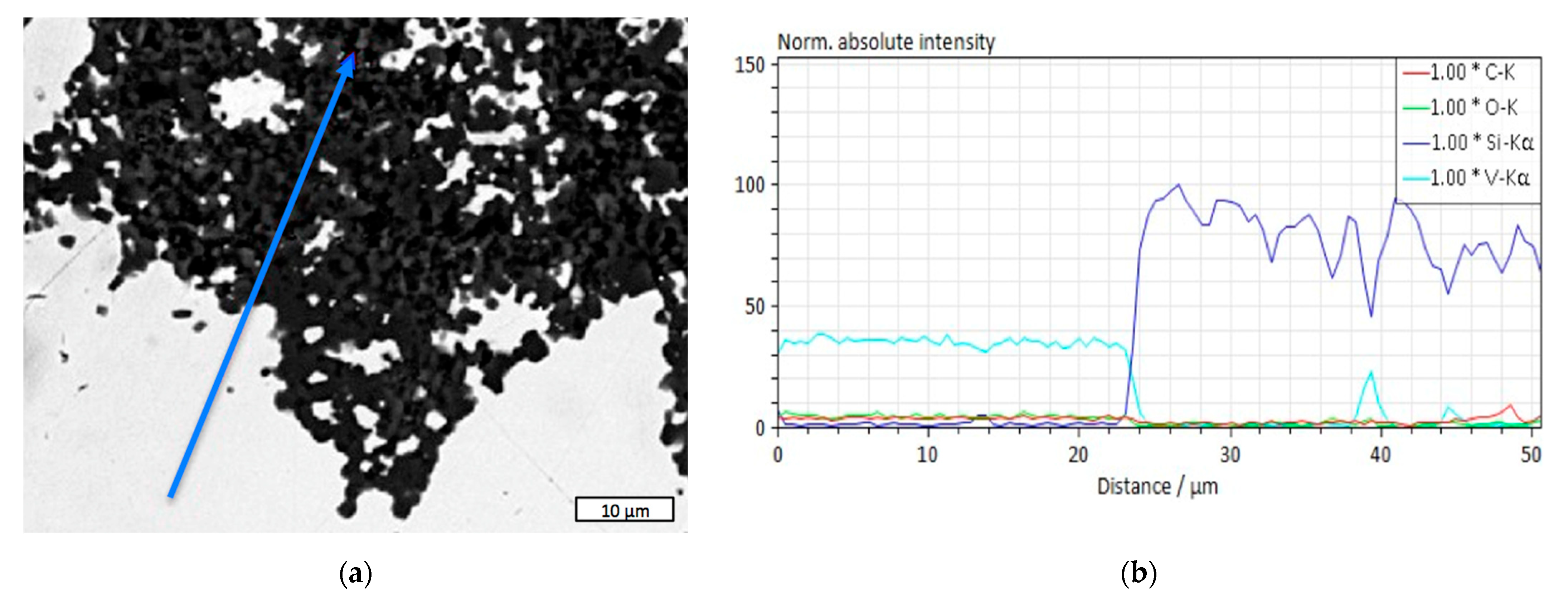

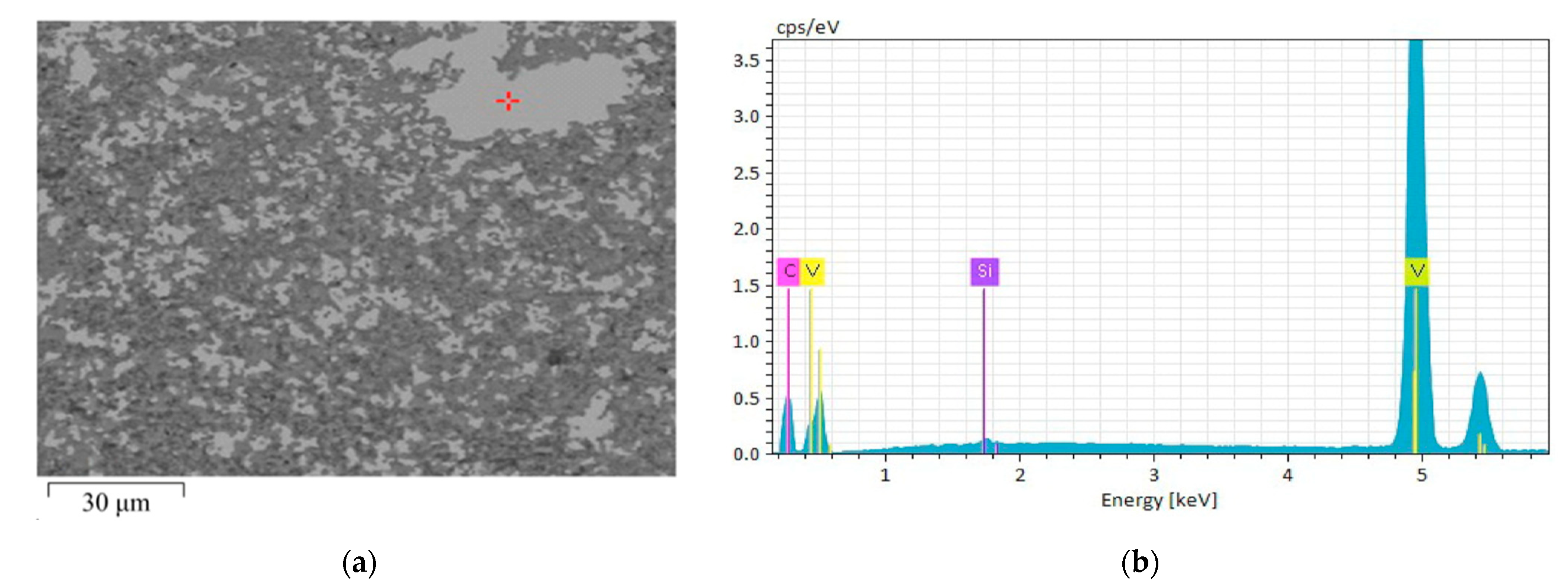

3.2. Structure of SiC–VC Composites

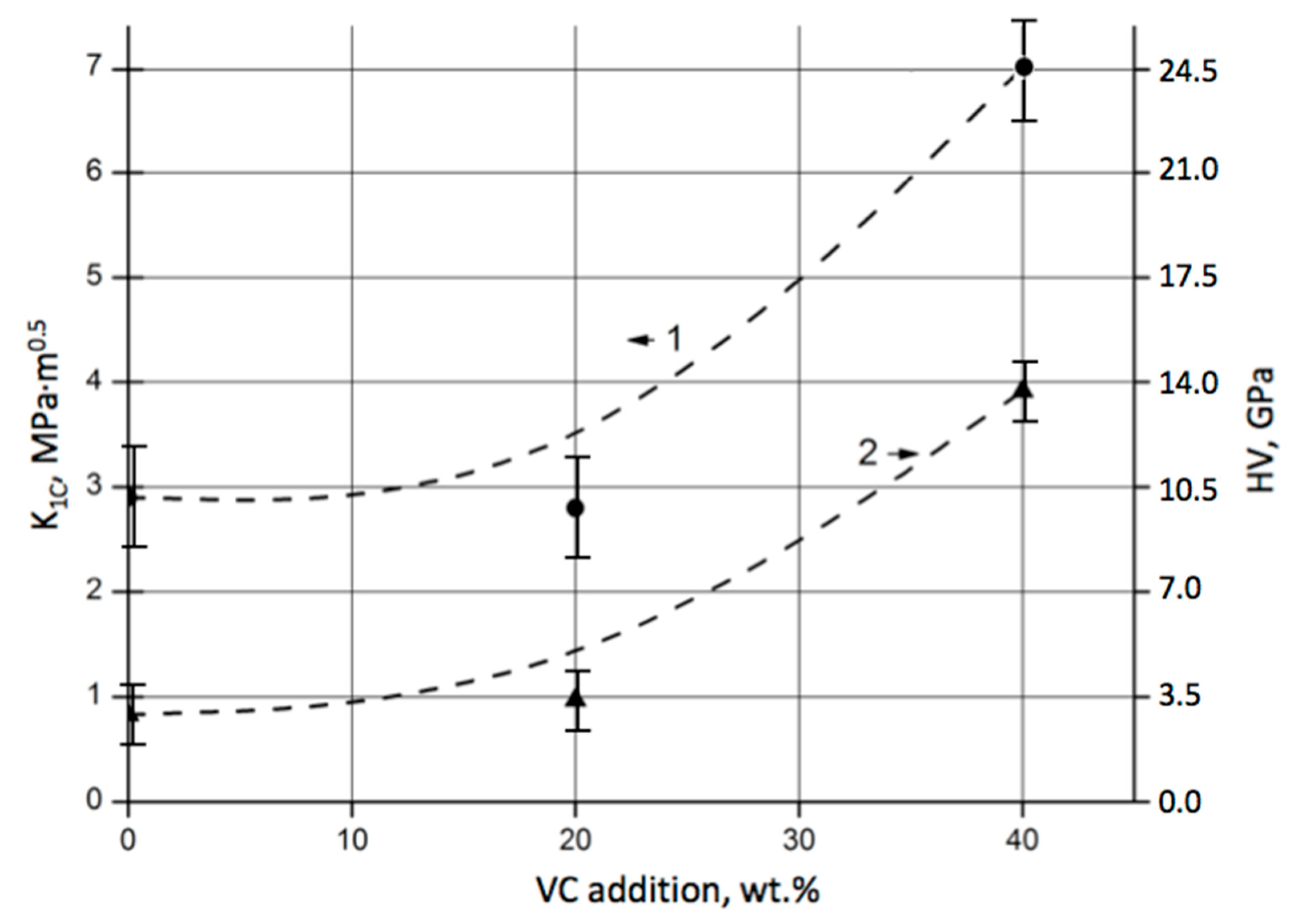

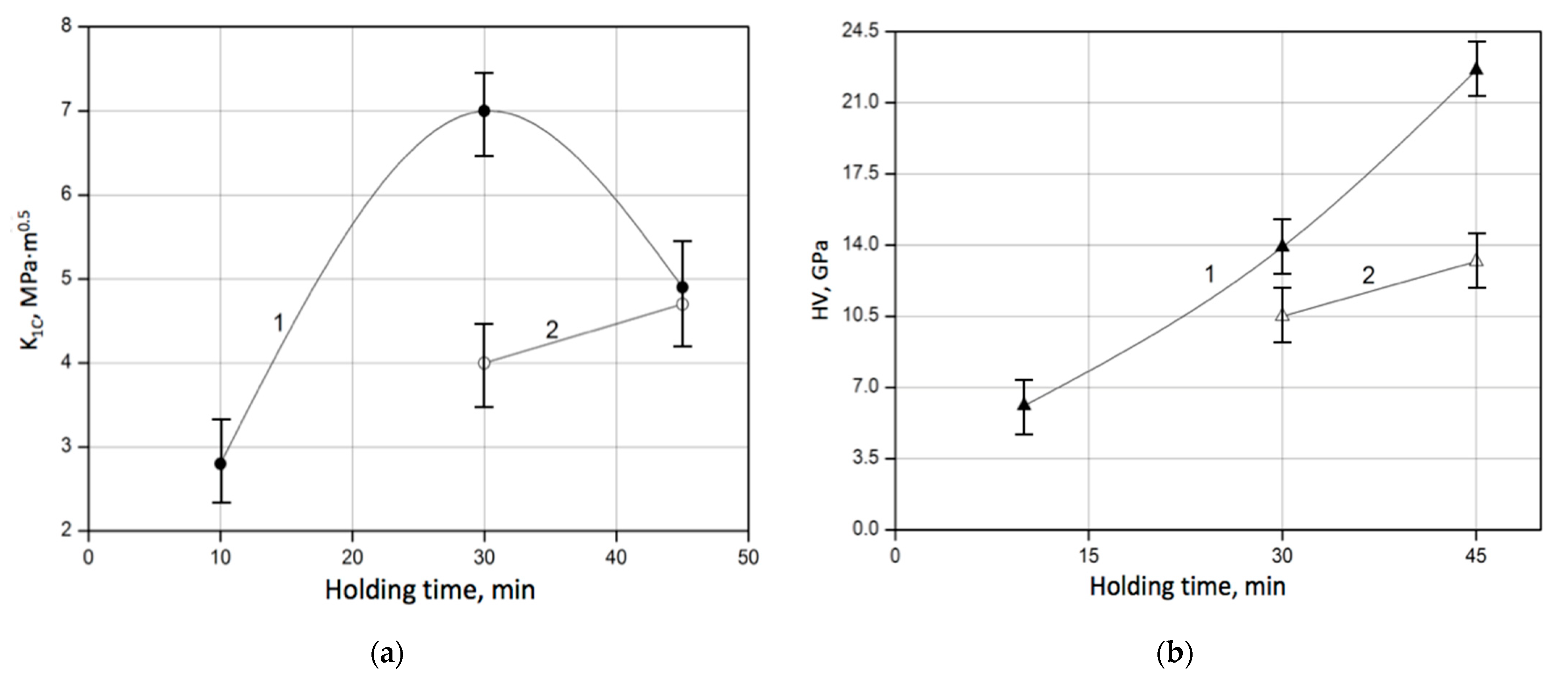

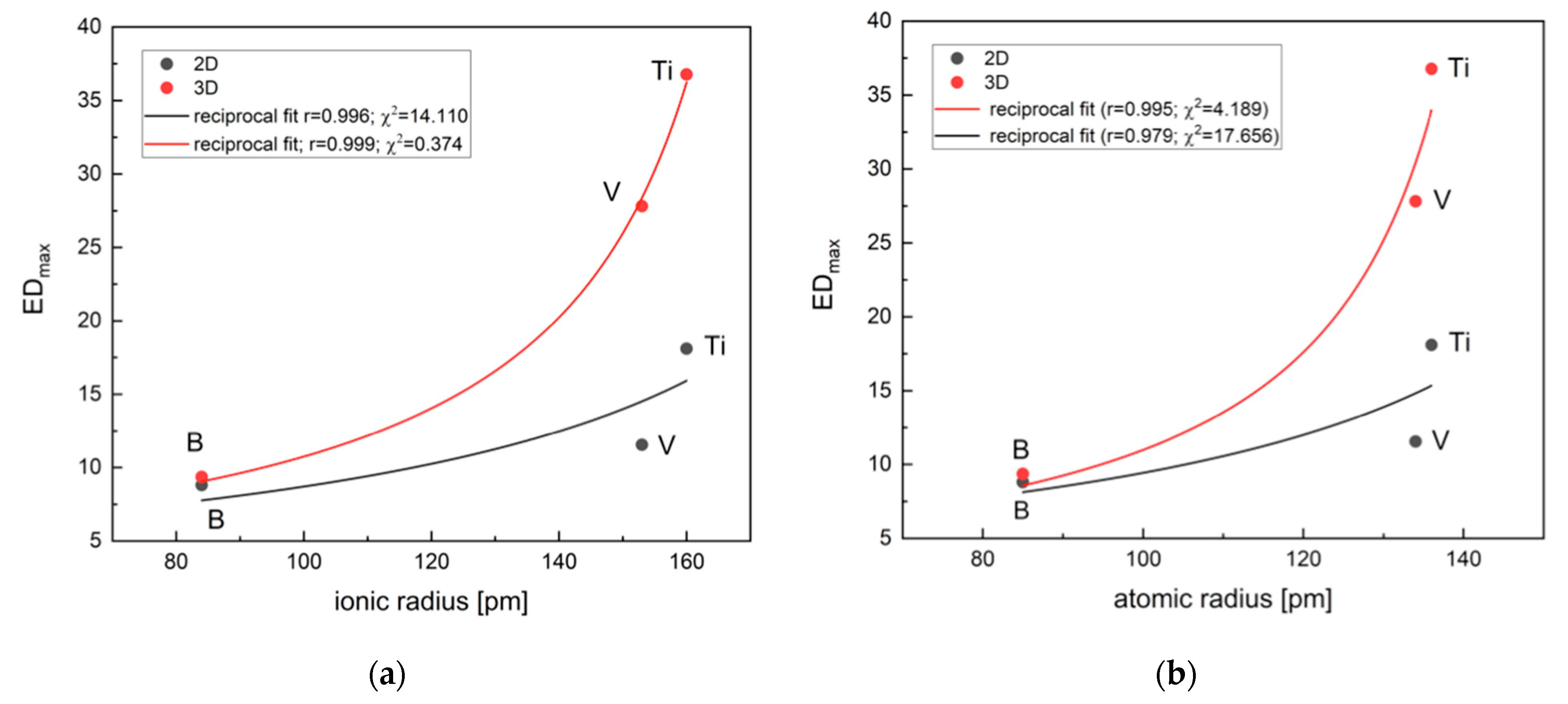

3.3. Properties of SiC–VC Composites

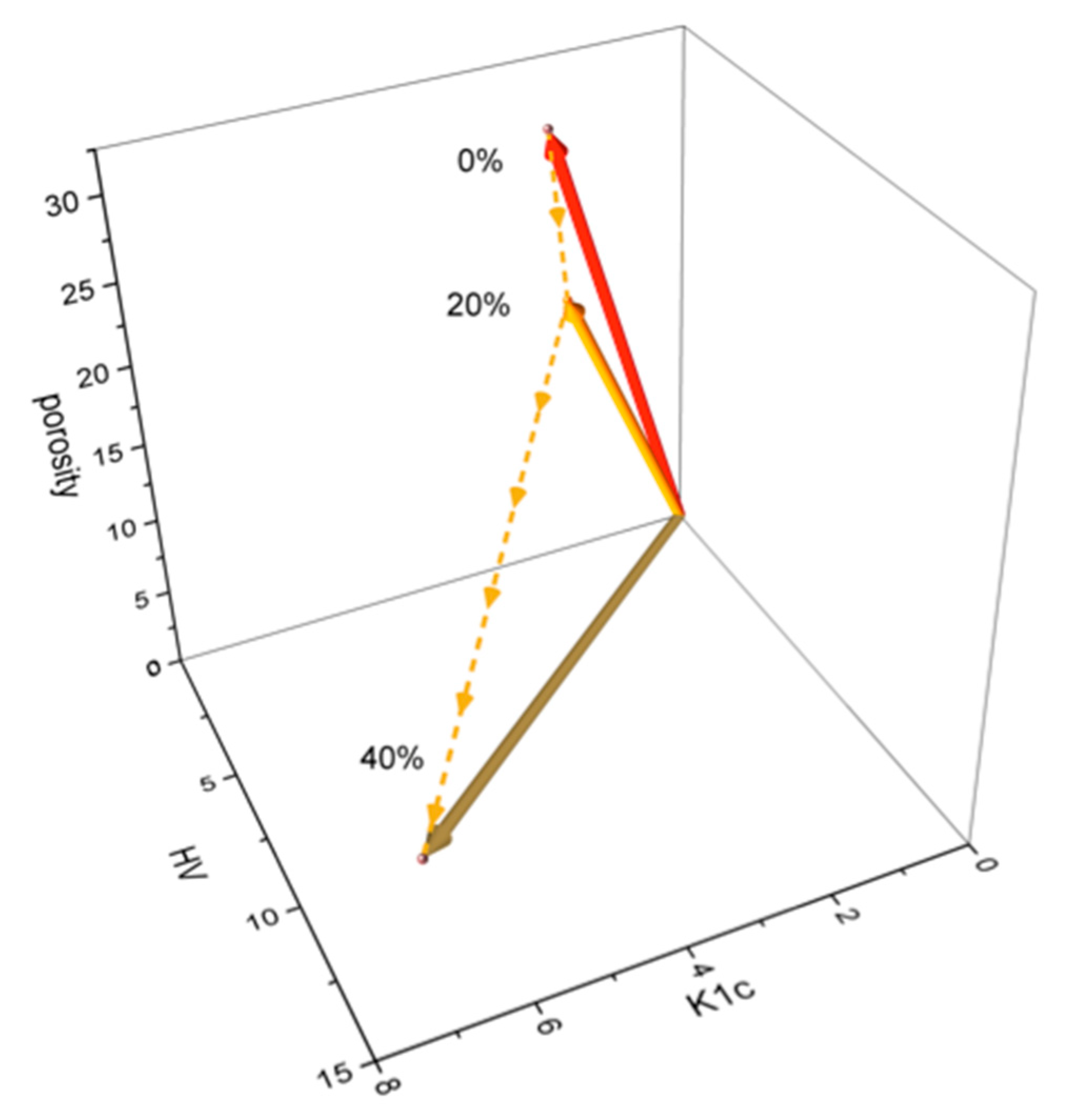

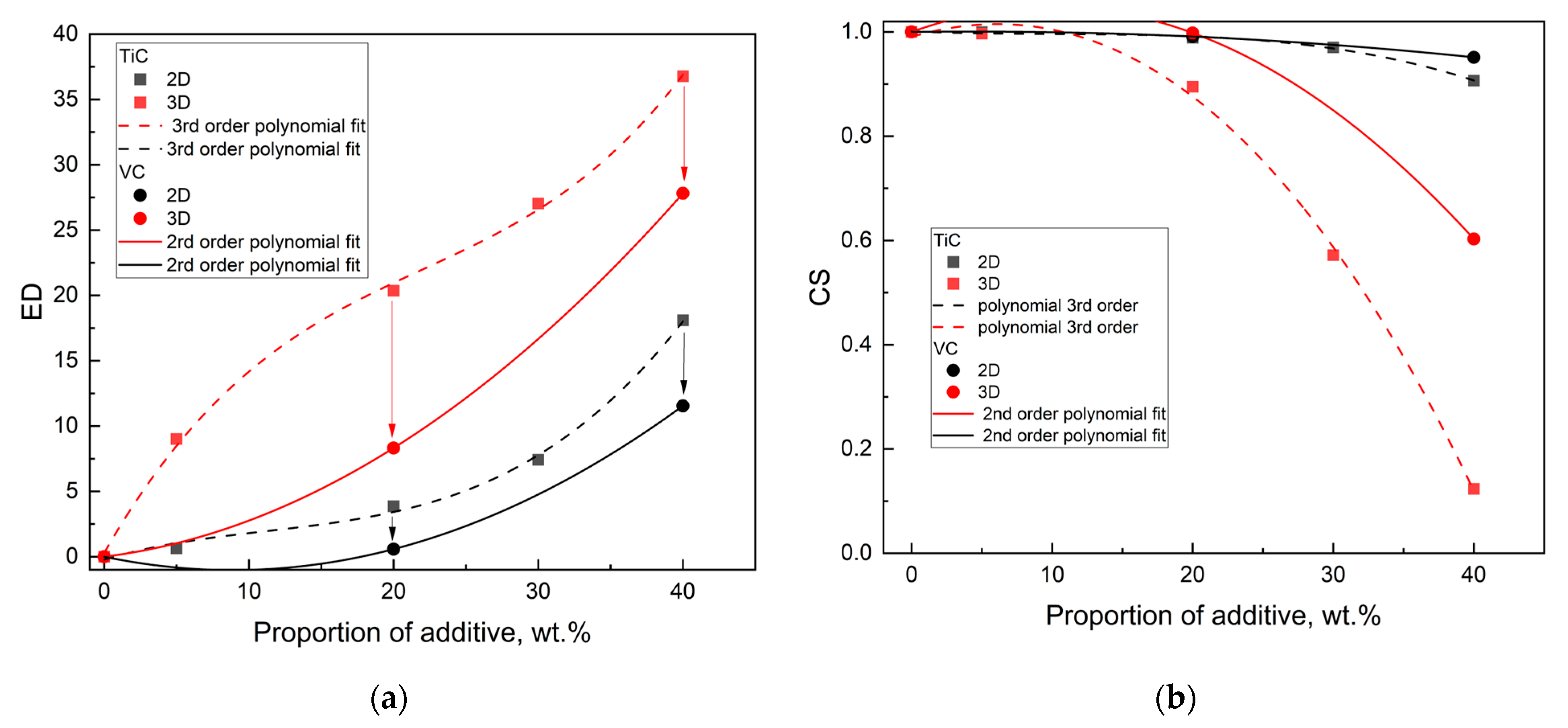

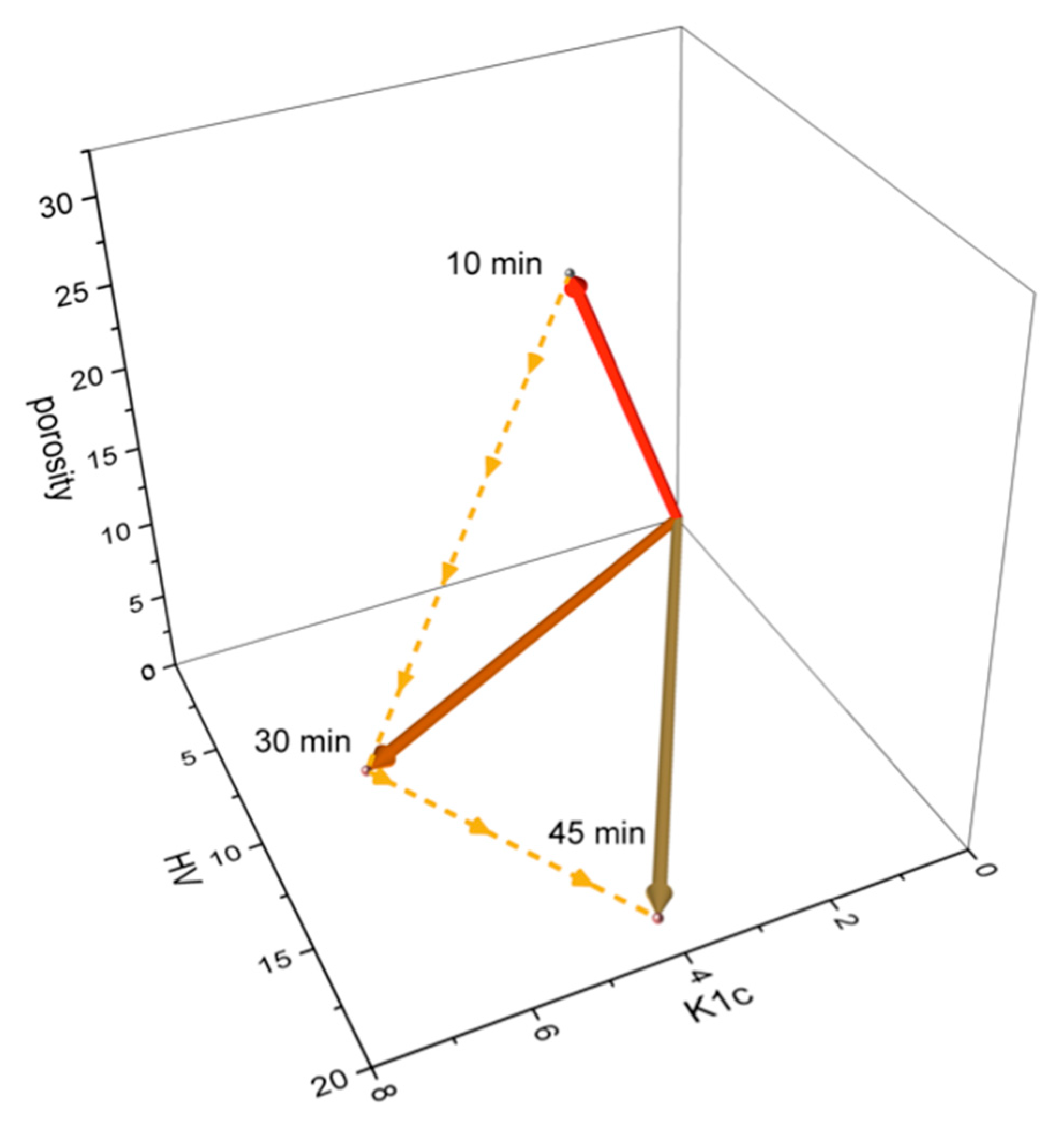

3.4. Material Feature Vectors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Element | Spectrum 1, % | Spectrum 2, % | Spectrum 3, % | Max | Min | Average | Standard Deviation |

|---|---|---|---|---|---|---|---|

| C | 54.99 | 59.30 | 59.94 | 59.94 | 54.99 | 58.08 | 2.69 |

| O | 6.34 | 4.58 | 4.17 | 6.34 | 4.17 | 5.03 | 1.15 |

| Si | 38.67 | 36.12 | 35.89 | 38.67 | 35.89 | 36.90 | 1.54 |

| Total | 100.00 | 100.00 | 100.00 | – | – | – | – |

| Mahalanobis distance | 1.954 | 1.139 | 1.138 | – | – | – | – |

| Element | Spectrum 29, % | Spectrum 30, % | Spectrum 31, % | Spectrum 32, % | Spectrum 33, % | Max | Min | Average | Standard Deviation |

|---|---|---|---|---|---|---|---|---|---|

| C | 14.43 | 10.26 | 7.46 | 11.92 | 12.50 | 14.43 | 7.46 | 11.31 | 2.62 |

| Al | 0.83 | 0.57 | 0.46 | 0.62 | 0.65 | 0.83 | 0.46 | 0.63 | 0.13 |

| Si | – | – | – | – | 0.42 | 0.42 | 0.00 | – | – |

| Ti | 0.58 | – | – | – | 0.59 | 0.59 | 0.00 | – | – |

| V | 80.32 | 89.17 | 92.08 | 87.47 | 42.14 | 92.08 | 42.14 | 78.24 | 20.64 |

| Cr | 1.01 | – | – | – | 7.84 | 7.84 | 0.00 | – | – |

| Fe | 2.84 | – | – | – | 30.72 | 30.72 | 0.00 | – | – |

| Ni | – | – | – | – | 5.13 | 5.13 | 0.00 | – | – |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | – | – | – | – |

| Mahalanobis distance | 1.784 | 0.651 | 1.649 | 1.573 | 1.789 | - | - | - | - |

Appendix B. Data Processing

Appendix B.1. The Mahalanobis Distance

Appendix B.2. Material Feature Vector Approach

Appendix B.3. Pareto Multi-Objective Optimization of Material Feature Vectors

Appendix C. Theoretical Background

Appendix C.1. Sinterability of SiC–VC System

Appendix C.2. Thermodynamic Considerations

References

- Ovali-Döndaş, D. Room-temperature mechanochemical synthesis of SiC-based ceramic powders. Ceram. Int. 2025; in press. [Google Scholar] [CrossRef]

- Liu, H.; Xing, M.; Fan, Q. Novel direct and wide bandgap SiC semiconductors: High-throughput screening and density functional theory. Results Phys. 2024, 65, 107966. [Google Scholar] [CrossRef]

- Xu, M.; Girish, R.Y.; Rakesh, K.P.; Wu, P.; Manukumar, H.M.; Byrappa, S.M.; Udayabhanu; Byrappa, K. Recent advances and challenges in silicon carbide (SiC) ceramic nanoarchitectures and their applications. Mater. Today Commun. 2021, 28, 102533. [Google Scholar] [CrossRef]

- Yang, F.; Chen, Y.; Hai, W.; Yan, S.; Cao, T.; Yuan, Z.; Huang, Z.; Huang, Q.; Li, Y. Research progress on high-thermal-conductivity silicon carbide ceramics. Ceram. Int. 2025, 51, 4095–4109. [Google Scholar] [CrossRef]

- Zhang, W. Recent progress in B4C–SiC composite ceramics: Processing, microstructure, and mechanical properties. Mater. Adv. 2023, 4, 3140–3191. [Google Scholar] [CrossRef]

- Boehmler, J.; Moitrier, F.; Bourré, T.; Rossit, J.; Delorme, F.; Lemonnier, S. Influence of powder state and rheology on sintering behaviour of SiC. Open Ceram. 2021, 8, 100192. [Google Scholar] [CrossRef]

- Gong, M.; Zhang, H.; Hai, W.; Liu, M.; Chen, Y. High strength of SiC–AlN–TiB2–VC multiphase ceramics induced by interface reactions. Ceram. Int. 2024, 50 Pt A, 45016–45024. [Google Scholar] [CrossRef]

- Yeom, J.A.; Kim, Y.W.; Jung, W.K.; Cheong, D.I.; Kang, E.S. Pressureless sintering of SiC ceramics with improved specific stiffness. J. Eur. Ceram. Soc. 2023, 43, 3941–3949. [Google Scholar] [CrossRef]

- Ge, S.; Yao, X.; Liu, Y.; Duan, H.; Huang, Z.; Liu, X. Effect of Sintering Temperature on the Properties of Highly Electrical Resistive SiC Ceramics as a Function of Y2O3-Er2O3 Additions. Materials 2020, 13, 4768. [Google Scholar] [CrossRef] [PubMed]

- Woźniak, J.; Petrus, M.; Moszczyńska, D.; Lachowski, A.; Cygan, T.; Broniszewski, K.; Olszyna, A. The consolidation of SiC ceramics using MAX phases as a new family of sintering activators. Arch. Civ. Mech. Eng. 2024, 24, 101. [Google Scholar] [CrossRef]

- Zheng, S.; Zhang, B.; Liu, X.; Chen, Z.; Huang, Z.; Yin, J. β→α Phase Transformation and Properties of Solid-State-Sintered SiC Ceramics with TaC Addition. Materials 2023, 16, 3787. [Google Scholar] [CrossRef] [PubMed]

- Das, D.; Lucio, M.D.S.; Oh, Y.; Kim, Y.W. Tuning the electrical, thermal, and mechanical properties of porous SiC ceramics using metal carbides. J. Eur. Ceram. Soc. 2024, 44, 3020–3030. [Google Scholar] [CrossRef]

- Jiang, L.; Shi, P.; Zhang, C.H.; Wu, M. First-principles study on interfacial structure and strength of SiC/VC nano-layered hard coatings. Comput. Mater. Sci. 2023, 230, 112532. [Google Scholar] [CrossRef]

- Zou, J.; Zhang, G.J.; Kan, Y.M.; Wang, P.L. Hot-Pressed ZrB2–SiC Ceramics with VC Addition: Chemical Reactions, Microstructures, and Mechanical Properties. J. Am. Ceram. Soc. 2009, 92, 2838–2846. [Google Scholar] [CrossRef]

- Ivzhenko, V.; Latosińska, J.N.; Hevorkian, E.; Rucki, M.; Kosenchuk, T.; Shamsutdinova, N.; Szumiata, T.; Chishkala, V.; Kilikevicius, A. Optimization of SiC–TiC Composite Manufacturing by Electroconsolidation Method. Materials 2025, 18, 2062. [Google Scholar] [CrossRef]

- Ivzhenko, V.; Vovk, R.; Hevorkian, E.; Kosenchuk, T.; Chyshkala, V.; Nerubatskyi, V.; Cherniavskyi, V.; Shamsutdinova, N. Investigation of Electrospark Sintering of Composites of SiC–TiC, SiC–VC Systems. Materials 2025, 18, 508. [Google Scholar] [CrossRef]

- Mahalanobis, P.C. On the Generalised Distance in Statistics. Sankhya: Indian J. Stat. 2018, 80, 1–7. [Google Scholar] [CrossRef]

- Hevorkian, E.S.; Nerubatskyi, V.P.; Rucki, M.; Kilikevicius, A.; Mamalis, A.G.; Samociuk, W.; Morozow, D. Electroconsolidation Method for Fabrication of Fine-Dispersed High-Density Ceramics. Nanotechnol. Percept. 2024, 20, 100–113. [Google Scholar]

- Piotrkiewicz, P.; Zygmuntowicz, J.; Wachowski, M.; Cymerman, K.; Kaszuwara, W.; Midor, W.A. Al2O3-Cu-Ni Composites Manufactured via Uniaxial Pressing: Microstructure, Magnetic, and Mechanical Properties. Materials 2022, 15, 1848. [Google Scholar] [CrossRef]

- Gross, E.; Dahan, D.B.; Kaplan, W.D. The role of carbon and SiO2 in solid-state sintering of SiC. J. Eur. Ceram. Soc. 2015, 35, 2001–2005. [Google Scholar] [CrossRef]

- Kim, G.D.; Kim, Y.W.; Song, I.H.; Kim, K.J. Effects of carbon and silicon on electrical, thermal, and mechanical properties of porous silicon carbide ceramics. Ceram. Int. 2020, 46 Pt A, 15594–15603. [Google Scholar] [CrossRef]

- Zhang, W. An overview of the synthesis of silicon carbide–boron carbide composite powders. Nanotechnol. Rev. 2023, 12, 20220571. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Du, X.-W.; Xing, W.-H.; Wang, W.-M.; Zhang, J.-Y.; Fu, Z. Effect of SiC Content on B4C-SiC Composites Fabricated by Mechanical Alloying-hot Pressing. J. Inorg. Mater. 2014, 29, 695–700. Available online: https://www.jim.org.cn/EN/10.3724/SP.J.1077.2014.13521 (accessed on 10 August 2025).

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The Effect of Electric Field and Pressure on the Synthesis and Consolidation of Materials: A Review of the Spark Plasma Sintering Method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- German, R.M. Sintering Theory and Practice; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Kang, S.-J.L. Sintering: Densification, Grain Growth and Microstructure; Elsevier: Oxford, UK, 2005. [Google Scholar]

- Gevorkyan, E.; Mamalis, A.; Vovk, R.; Semiatkowski, Z.; Morozow, D.; Nerubatskyi, V.; Morozova, O. Special features of manufacturing cutting inserts from nanocomposite material Al2O3-SiC. J. Instrum. 2021, 16, P10015. [Google Scholar] [CrossRef]

- Mamalis, A.G.; Gevorkyan, E.S.; Prokopiv, M.M.; Nerubatskyi, V.P.; Hordiienko, D.A.; Morozow, D.; Kharchenko, O.V. Peculiarities of the formation of the structure of CMCs based on Al2O3 micropowder and SiC nanopowder in the process of electrosintering. Nanotechnol. Percept. 2023, 19, 39–53. [Google Scholar]

- Colkesen, P.; Kaplan, G.; Yoon, D.-H. Densification and high-temperature oxidation behavior of SiC sintered with multicomponent rare-earth additives. Ceram. Int. 2023, 49, 31163–31174. [Google Scholar] [CrossRef]

- Zamora, V.; Ojalvo, C.; Guiberteau, F.; Ortiz, A.L. Fabricating ultrahard boron carbide–silicon carbide–zirconium diboride composites by spark plasma sintering from B4C with ZrSi2 aids. J. Eur. Ceram. Soc. 2024, 44, 4323–4329. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Q.; Zhang, B.; Zhang, H.; Jin, Y.; Zhong, Z.; Ye, J.; Ren, Y.; Ye, F.; Wang, W. Microstructure and mechanical behaviour of transient liquid phase spark plasma sintered B4C–SiC–TiB2 composites from a B4C–TiSi2 system. Ceram. Int. 2021, 47, 10665–10671. [Google Scholar] [CrossRef]

- Lytovchenko, S.V.; Gevorkyan, E.S.; Nerubatskyi, V.P.; Chyshkala, V.O.; Voloshyna, L.V. A study of the peculiarities of molding and structure formation of compacted multicomponent silicide composites. J. Superhard Mater. 2022, 44, 176–190. [Google Scholar] [CrossRef]

- Neuman, E.W.; Hilmas, G.E.; Fahrenholtz, W.G. Transition metal diboride-silicon carbide-boron carbide ceramics with super-high hardness and strength. J. Eur. Ceram. Soc. 2022, 42, 6795–6801. [Google Scholar] [CrossRef]

- Oguntuyi, S.D.; Shongwe, M.B.; Tshabalala, L.; Johnson, O.T.; Malatji, N. Effects of SiC on the microstructure, densification, hardness and wear performance of TiB2 ceramic matrix composite consolidated via spark plasma sintering. Arab. J. Sci. Eng. 2023, 48, 2889–2903. [Google Scholar] [CrossRef]

- Williams, W.S. Transition metal carbides, nitrides, and borides for electronic applications. JOM 1997, 49, 38–42. [Google Scholar] [CrossRef]

- Zhu, Y.; Qin, Z.; Chai, J.; Shen, T.; Zhou, Y.; Wang, Z. Effects of sintering additives on microstructure and mechanical properties of hot-pressed α-SiC ceramics. Metall. Mater. Trans. A 2022, 53, 1188–1199. [Google Scholar] [CrossRef]

- Rixecker, G.; Wiedmann, I.; Rosinus, A.; Aldinger, F. High-temperature effects in the fracture mechanical behaviour of silicon carbide liquid-phase sintered with AlN–Y2O3 additives. J. Eur. Ceram. Soc. 2001, 21, 1013–1019. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, G.; Chen, H.; Yi, M.; Zhang, J.; Chen, Z.; Xu, C. Effect of NiTi content on the mechanical properties and microstructure of TiB2–TiN-based composite ceramic material prepared using spark plasma sintering. Ceram. Int. 2023, 49 Pt A, 16690–16699. [Google Scholar] [CrossRef]

- Ma, L.; Yu, J.; Guo, X.; Zhang, Y.; Gong, H. Pressureless densification and properties of TiB2–B4C composite ceramics with Ni as additives. Micro Nano Lett. 2018, 13, 947–950. [Google Scholar] [CrossRef]

- Yoshida, K.; See, C.C.; Yokoyama, S.; Yano, T. Effects of SiC particle size and sintering temperature on microstructure of porous SiC ceramics based on in-situ grain growth. Ceram. Eng. Sci. Proc. 2014, 35, 173–183. [Google Scholar] [CrossRef]

| Element | At. No. | Net | Mass, % | Mass Norm., % | Atom, % | Comp. | St., % | St. Norm., % | Abs. Error, % (1 Sigma) | Rel. Error, % (1 Sigma) |

|---|---|---|---|---|---|---|---|---|---|---|

| C | 6 | 4110 | 18.33 | 19.12 | 50.00 | – | 0.00 | 0.00 | 3.04 | 16.57 |

| Si | 14 | 564 | 0.23 | 0.24 | 0.27 | SiC | 0.33 | 0.35 | 0.05 | 21.81 |

| V | 23 | 111,837 | 77.32 | 80.64 | 49.73 | VC | 95.55 | 99.65 | 2.14 | 2.77 |

| Total | – | – | 95.88 | 100.00 | 100.00 | – | 95.88 | 100.00 | – | – |

| Element | At. No. | Net | Mass, % | Mass Norm., % | Atom, % | Comp. | St., % | St. Norm., % | Abs. Error, % (1 Sigma) | Rel. Error, % (1 Sigma) |

|---|---|---|---|---|---|---|---|---|---|---|

| C | 6 | 964 | 21.34 | 21.96 | 50.00 | – | 0.00 | 0.00 | 5.03 | 23.55 |

| Si | 14 | 42,357 | 18.02 | 18.54 | 18.05 | SiC | 25.72 | 26.47 | 0.80 | 4.46 |

| V | 23 | 76,482 | 57.83 | 59.50 | 31.95 | VC | 71.47 | 73.53 | 1.62 | 2.80 |

| Total | – | – | 97.19 | 100.00 | 100.00 | – | 97.19 | 100.00 | – | – |

| VC Proportion, wt.% | 2D [K1C, HV] | 3D [Porosity, K1C, HV] | ||

|---|---|---|---|---|

| Magnitude | Angle | Magnitude | Angle | |

| 0 | 4.40 | — | 32.30 | — |

| 20 | 4.28 | 7.59° | 22.41 | 3.52° |

| 40 | 15.38 | 17.94° | 17.72 | 52.93° |

| 2D ED | 0 | 20 | 40 | 3D ED | 0 | 20 | 40 |

|---|---|---|---|---|---|---|---|

| 0 | 0 | 0.58 | 11.55 | 0 | 0 | 8.32 | 26.91 |

| 20 | 0.58 | 0 | 11.20 | 20 | 8.32 | 0 | 19.53 |

| 40 | 11.55 | 11.20 | 0 | 40 | 26.91 | 19.53 | 0 |

| 2D CS | 0 | 20 | 40 | 3D CS | 0 | 20 | 40 |

|---|---|---|---|---|---|---|---|

| 0 | 1 | 0.9912 | 0.9514 | 0 | 1 | 0.9981 | 0.6028 |

| 20 | 0.9912 | 1 | 0.9838 | 20 | 0.9981 | 1 | 0.6505 |

| 40 | 0.9514 | 0.9838 | 1 | 40 | 0.6028 | 0.6505 | 1 |

| Holding Time, min | 2000 °C | 1900 °C | ||||||

|---|---|---|---|---|---|---|---|---|

| 2D [K1C, HV] | 3D [Porosity, K1C, HV] | 2D [K1C, HV] | 3D [Porosity, K1C, HV] | |||||

| Magnitude | Angle | Magnitude | Angle | Magnitude | Angle | Magnitude | Angle | |

| 10 | 6.78 | – | 26.15 | – | – | – | – | – |

| 30 | 15.65 | 2.05° | 17.95 | 45.64° | 11.31 | – | 20.56 | – |

| 45 | 23.21 | 64.95° | 24.62 | 35.30° | 14.09 | 1.25° | 18.58 | 15.99° |

| Parameter | Additive | dM | p-Value |

|---|---|---|---|

| 0 wt.% | – | 1.6051 | 0.6582 |

| 5 wt.% | TiC | 0.9565 | 0.8118 |

| 20 wt.% | TiC | 1.7158 | 0.6334 |

| 30 wt.% | TiC | 1.8918 | 0.5952 |

| 40 wt.% | TiC | 1.9350 | 0.5860 |

| 20 wt.% | VC | 1.5137 | 0.6791 |

| 40 wt.% | VC | 2.1558 | 0.5407 |

| 40 wt.%, 10 min, 2000 °C | VC | 1.1760 | 0.7588 |

| 40 wt.%, 30 min, 2000 °C | VC | 2.1365 | 0.5446 |

| 40 wt.%, 45 min, 2000 °C | VC | 2.5096 | 0.4736 |

| 40 wt.%, 30 min, 1900 °C | VC | 0.4697 | 0.9255 |

| 40 wt.%, 45 min, 1900 °C | VC | 0.5099 | 0.9167 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivzhenko, V.; Hevorkian, E.; Rucki, M.; Nerubatskyi, V.; Krzysiak, Z.; Chyshkala, V.; Latosińska, J.N.; Samociuk, W.; Szumiata, T.; Kosenchuk, T.; et al. Improvement of Microstructure and Mechanical Properties of SiC–VC System Obtained by Electroconsolidation. Materials 2025, 18, 4331. https://doi.org/10.3390/ma18184331

Ivzhenko V, Hevorkian E, Rucki M, Nerubatskyi V, Krzysiak Z, Chyshkala V, Latosińska JN, Samociuk W, Szumiata T, Kosenchuk T, et al. Improvement of Microstructure and Mechanical Properties of SiC–VC System Obtained by Electroconsolidation. Materials. 2025; 18(18):4331. https://doi.org/10.3390/ma18184331

Chicago/Turabian StyleIvzhenko, Vyacheslav, Edvin Hevorkian, Miroslaw Rucki, Volodymyr Nerubatskyi, Zbigniew Krzysiak, Volodymyr Chyshkala, Jolanta Natalia Latosińska, Waldemar Samociuk, Tadeusz Szumiata, Tamara Kosenchuk, and et al. 2025. "Improvement of Microstructure and Mechanical Properties of SiC–VC System Obtained by Electroconsolidation" Materials 18, no. 18: 4331. https://doi.org/10.3390/ma18184331

APA StyleIvzhenko, V., Hevorkian, E., Rucki, M., Nerubatskyi, V., Krzysiak, Z., Chyshkala, V., Latosińska, J. N., Samociuk, W., Szumiata, T., Kosenchuk, T., & Caban, J. (2025). Improvement of Microstructure and Mechanical Properties of SiC–VC System Obtained by Electroconsolidation. Materials, 18(18), 4331. https://doi.org/10.3390/ma18184331