Advancements in In-Situ Monitoring Technologies for Detecting Process-Induced Defects in the Directed Energy Deposition Process: A Comprehensive Review

Abstract

1. Introduction

- The nature and formation of process-induced defects,

- Current advancements in in-situ monitoring approaches for defect detection, and

- Advanced methods for precise localisation of defects within DED-LB/M fabricated structures.

2. Directed Energy Deposition Background

3. Directed Energy Deposition Process

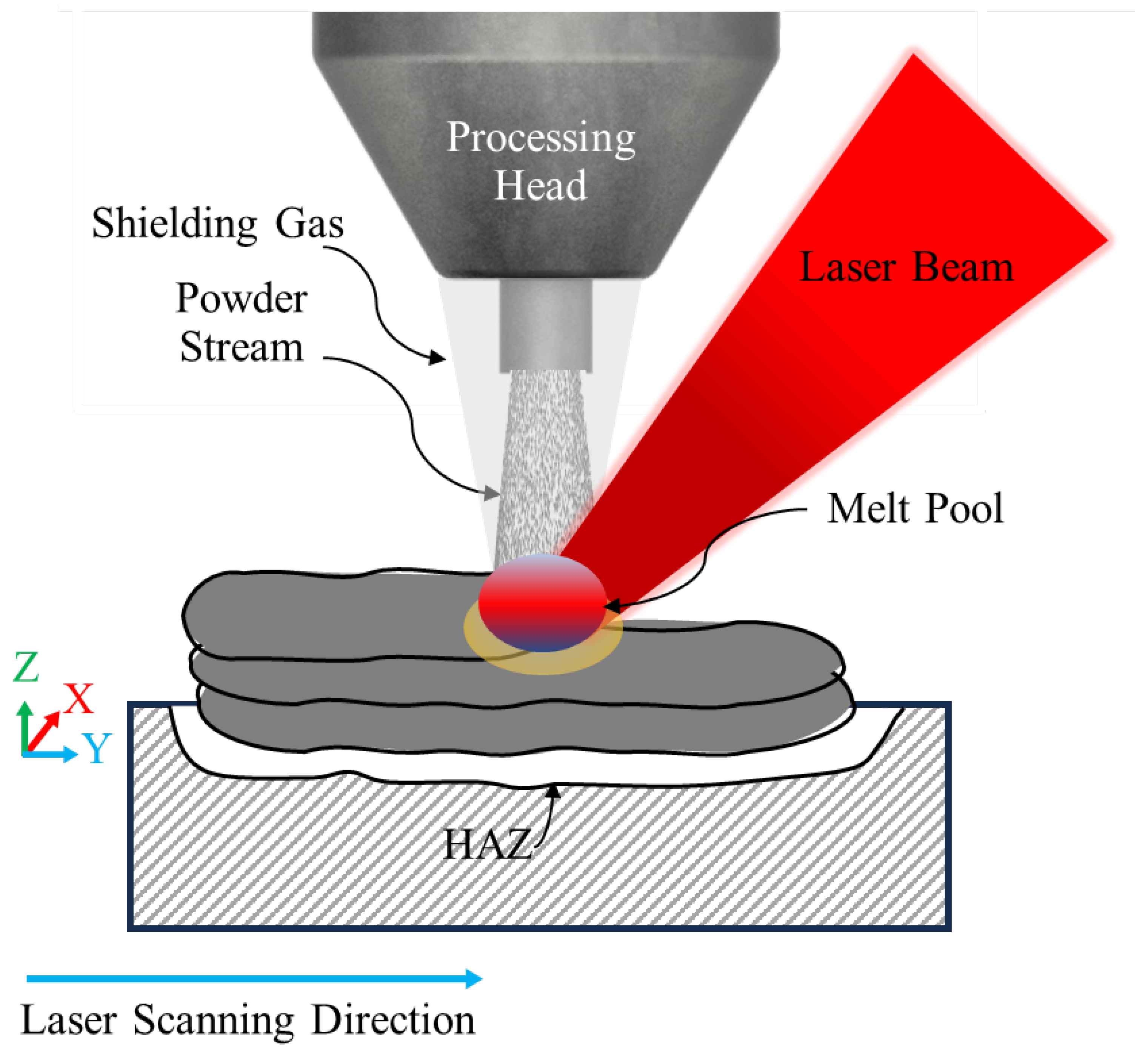

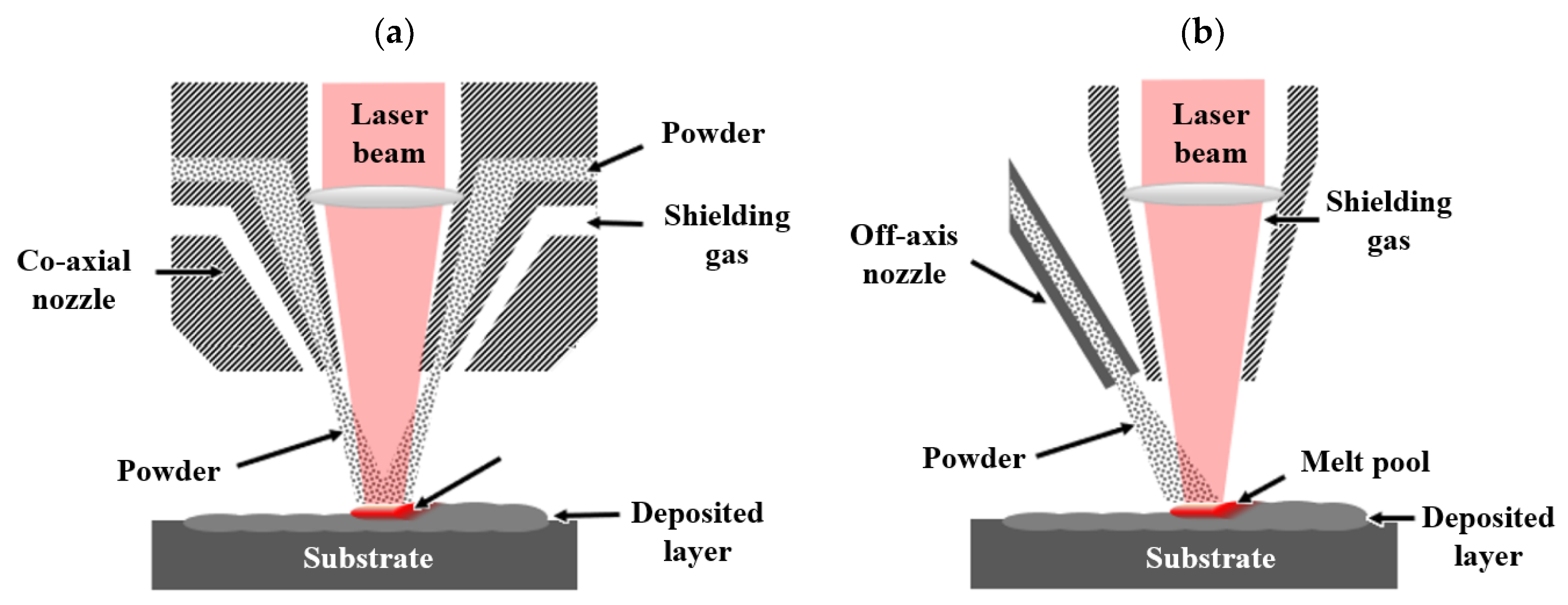

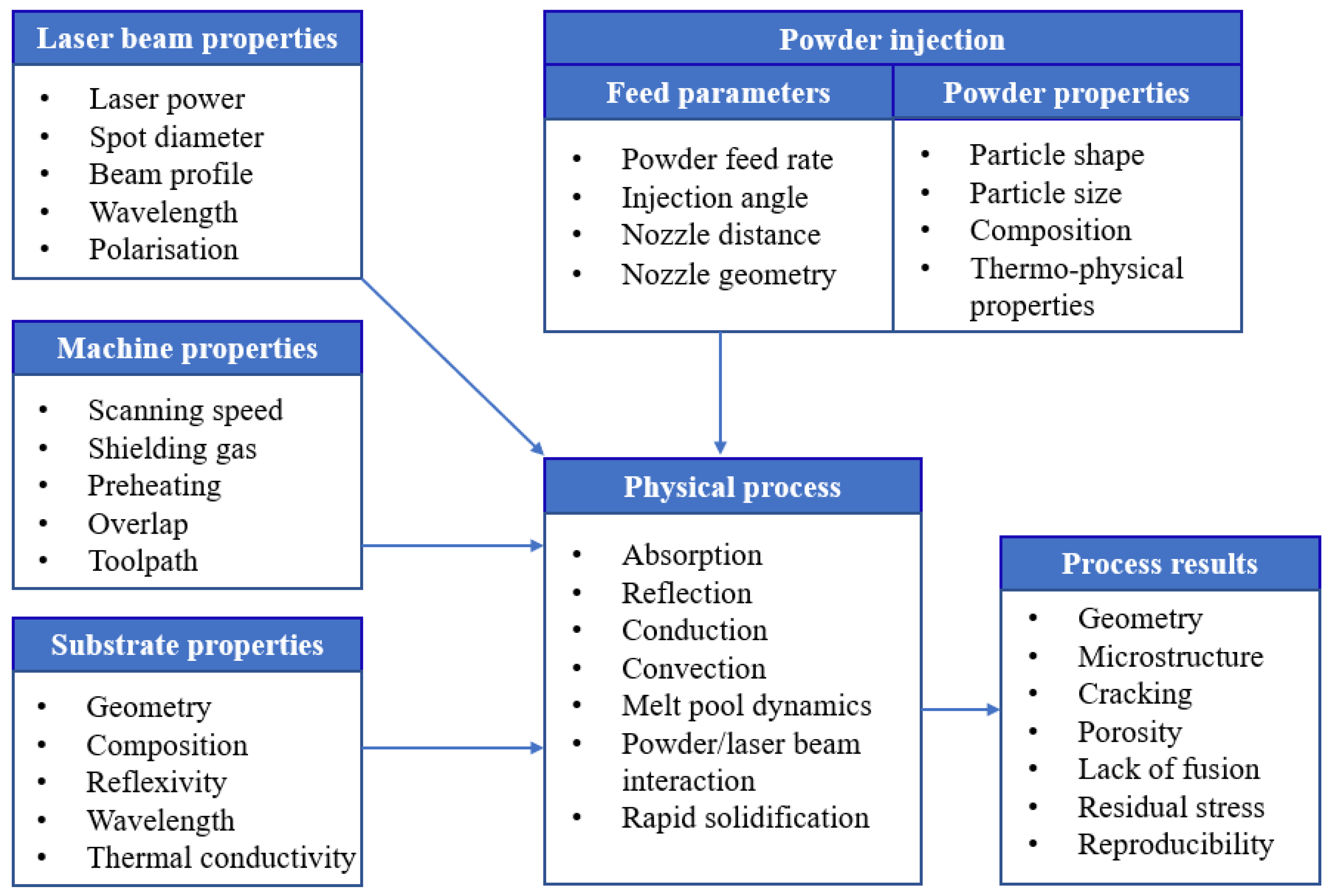

3.1. Principle of DED-LB/M Process

3.1.1. Process Parameters

3.1.2. DED-LB/M Materials

3.1.3. Process-Induced Defects

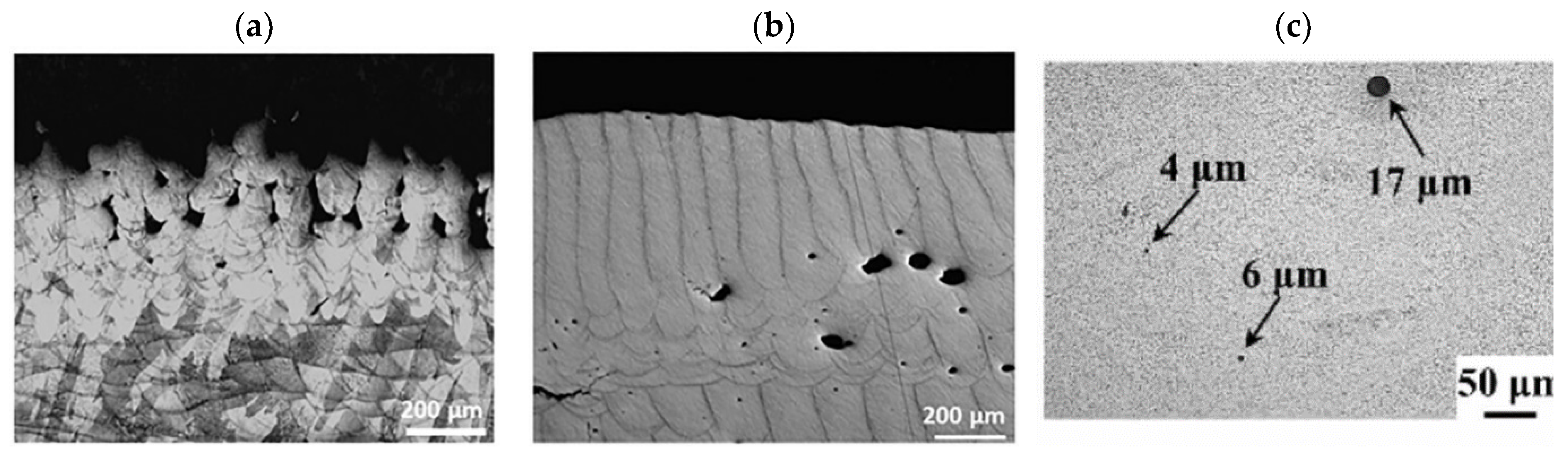

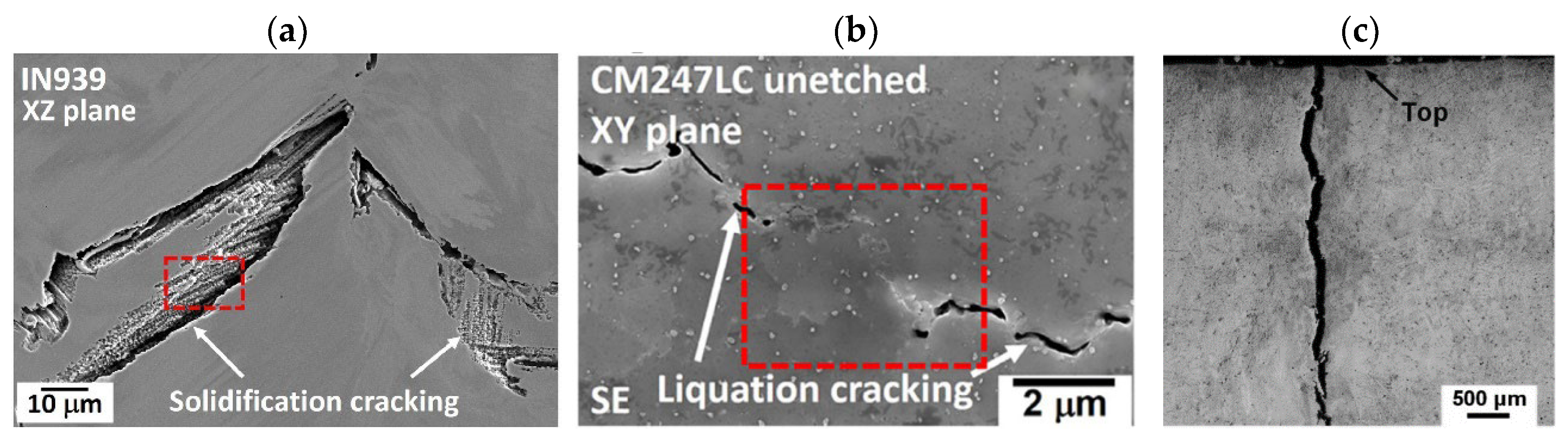

Cracking

Porosity

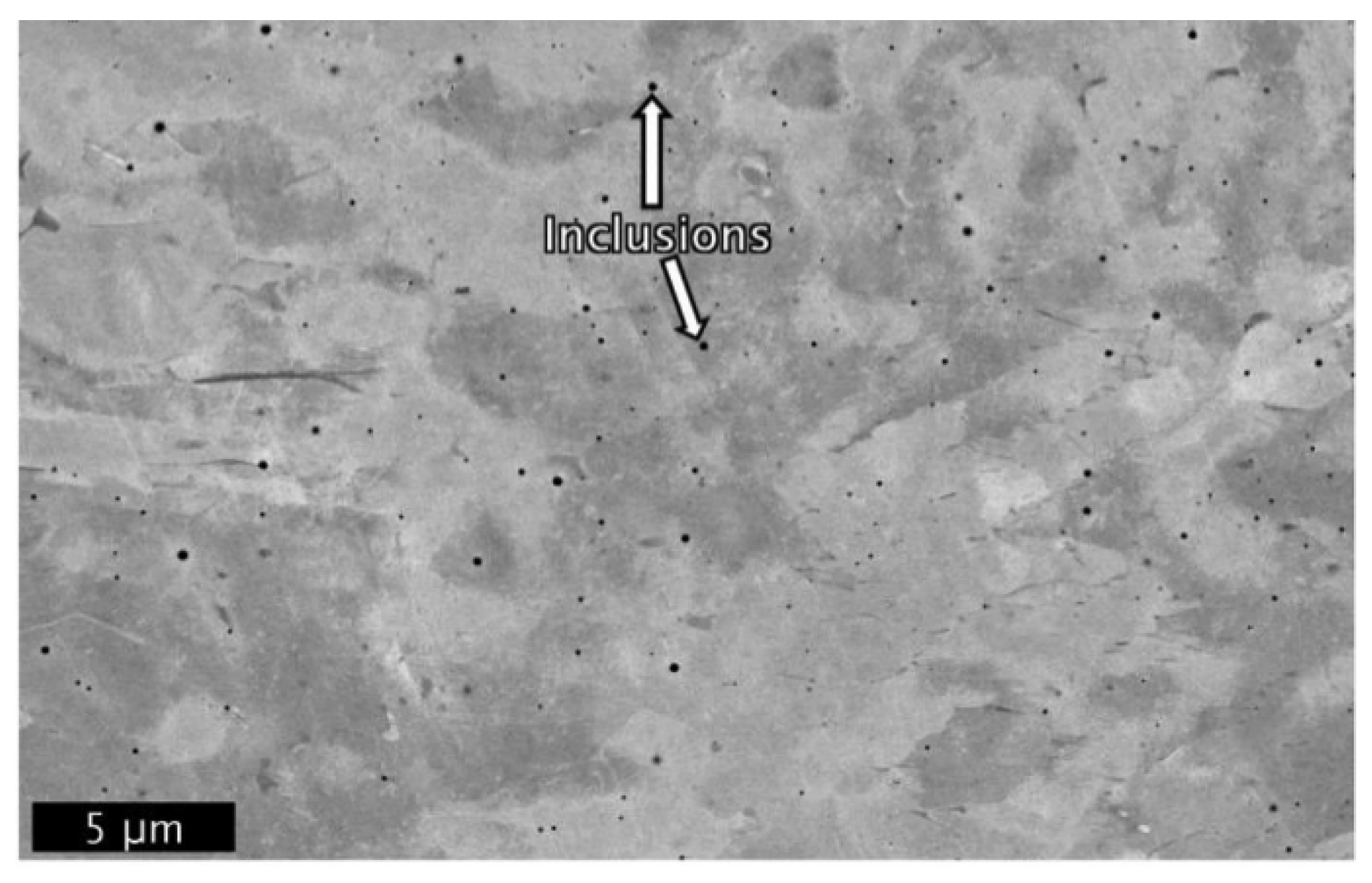

Inclusions

3.2. In-Situ Process Monitoring Techniques in DED-LB/M Process

- Process signature collection,

- Feature extraction, and

- Defect correlation.

- 4.

- Vision sensing

- 5.

- Thermal sensing

- 6.

- Spectral sensing and

- 7.

- Acoustic emission

3.2.1. Vision Sensing

Sensor Type

Process Signatures

Analysis of Melt Pool Features to Predict Defects

| Process | Devices Used | Extracted Features (Input) | ML Algorithms | Defect Detection | Performance indicators | Ref. |

|---|---|---|---|---|---|---|

| DED-LB/M | CCD Camera (Off-Axis) Spectrometer (Off-Axis) | Melt pool plume area, line-to-continuum ratio signatures | SVM | Lack-of-fusion | F-score—85% | Montazeri et al. [132] |

| CCD Camera (Off-Axis) | Geometric characteristics of melt pool (e.g., area, length, width, etc.). | D-CNN | Spatters | Accuracy—95% | Mi et al. [117] | |

| High-speed digital camera (Co-axial) | Geometric characteristics of melt pool (e.g., area, length, width, etc.) | CNN | Porosity | Accuracy—91.2% | Zhang et al. [139] | |

| CCD Camera (Co-axial) | Geometric characteristics of melt pool (e.g., area, length, width, etc.) | RF, SVM, k-NN | Porosity | Accuracy—97% | Pandiyan et al. [134] | |

| CCD Camera (Off-Axis) Pyrometer (Off-Axis) | Melt pool size (area, width, height), and temperature | KNN, SVM, ANN | Porosity, Melting balls | Avg. Accuracy—92.7% | Shin et al. [116] | |

| CMOS Camera (Co-axial) X-ray | Geometric characteristics of melt pool (e.g., area, length, width, etc.) | MBFCNN | Porosity | Accuracy—90.1 % | Yin et al. [137] | |

| CMOS Camera (Off-Axis) | Geometric characteristics of melt pool (e.g., area, length, width, etc.) | CNN | Porosity | Accuracy—99% | Li et al. [138] |

Current Challenges, Existing Limitations, and Paths for Future Exploration

- Vision-based coaxially mounted optical cameras are good at capturing the horizontal dimensions of a melt pool, such as its width, length, and area. However, off-axis cameras are needed to measure the vertical dimensions, like the height and depth. Using multiple camera systems for comprehensive melt pool monitoring is difficult and expensive due to the combination of different hardware and software requirements. Therefore, future research should focus on finding ways to reduce system complexity and cost while still providing accurate melt pool characterisation.

- Another most significant challenge is the inability of vision-based systems to identify subsurface flaws, particularly cracks that may form due to the complex thermal gradients and residual stress patterns inherent to the DED-LB/M process. Therefore, this method may not provide a complete picture of defect formation and propagation throughout the build process. Consequently, it requires a combination with other complementary techniques like X-ray imaging to provide a more comprehensive view of both surface and subsurface defects.

- The high-temperature environment and intense light emissions during the DED-LB/M process can interfere with image quality, potentially leading to inaccurate defect detection. Further investigations are required to design more resilient imaging systems that can operate reliably under these extreme conditions.

- Many current systems struggle with real-time data processing and decision-making. The computational demands of processing high-resolution melt pool images in real-time and the potential latency in defect prediction could hinder immediate responsiveness for in-situ process control. Developing more efficient algorithms and hardware solutions for rapid data processing is crucial.

- Many ML models utilised for defect identification in DED-LB/M processes rely on batch-learning approaches. These approaches require complete datasets from entire DED-LB/M build processes for model development and training. However, these models struggle to adapt quickly to new or unseen data, especially when dealing with the dynamic and complex heat transfer conditions in DED-LB/M processes. The transient thermo-physical behaviour of the melt pool is highly volatile and can vary significantly between structures, making it difficult for the models to adjust to changing conditions or detect new defects during production. As a result, these models may fail to identify defects or anomalies present in the initial training data, potentially leading to quality issues in manufactured structures. To overcome these limitations, there is a need for more advanced, adaptive ML models capable of continuous learning and updating during the DED-LB/M process, providing real-time defect detection capabilities.

3.2.2. Thermal Sensing

Sensor Type

Process Signatures

Analysis of Thermal Features to Predict Defects

Current Challenges, Existing Limitations, and Paths for Future Exploration

- Implementing multiple sensors, such as thermal cameras and pyrometers, in industrial settings can be complex and costly. The installation of these diverse sensors may disrupt existing production workflows and require significant modifications to manufacturing setups. Future research should focus on creating compact, multi-sensor units that can be retrofitted to existing DED machines with minimal disruption to production workflows. Additionally, efforts should be made to standardise sensor interfaces and data formats to facilitate easier integration across different DED-LB/M systems and manufacturers.

- Accurate temperature measurement remains a persistent challenge in DED-LB/M owing to the inherent process variability and the diverse thermal behaviours of different materials. Emissivity calibration is particularly crucial for reliable thermal readings but can be difficult to achieve consistently across different materials and surface conditions. Research into adaptive calibration methods that can account for changing emissivity and surface conditions during the DED-LB/M process could improve temperature measurement accuracy.

- While thermal sensing has shown promise in detecting porosity, there’s a significant gap in reliably correlating thermal characteristics with interlayer crack formation and propagation. The ability to differentiate between defects such as cracks and porosity based on their thermal signatures is an area that requires further investigation. Further investigation into the unique thermal signatures of different types of defects could lead to improved differentiation between cracks, porosity, and other flaws.

- The need for complete datasets often limits Traditional ML models’ ability to detect defects in DED-LB/M fabricated structures and makes them struggle with new or dynamic conditions. Exploring continual online learning, as shown by Ouidadi et al. [144], could significantly improve these models’ adaptability for real-time monitoring and defects identification in DED-LB/M processes.

3.2.3. Spectral Sensing

Sensor Type

Process Signatures

Analysis of Spectra Features to Predict Defects

Current Challenges, Existing Limitations, and Paths for Future Exploration

- The acquisition of spectral data is strongly influenced by the sensor’s relative placement and the thickness of the deposited material. This sensitivity can lead to inconsistent results, especially in DED-LB/M systems where deposition thickness may vary. Further investigations are required to design more resilient sensing strategies capable of accommodating changes in both deposition thickness and sensor placement.

- Some materials may not emit strong line emissions, resulting in a low signal-to-noise ratio, particularly when operating under low laser power conditions. This limitation can affect the accuracy and reliability of spectral analysis for certain materials. Further investigation into enhancing signal detection and processing for a wider range of materials is needed.

- While some approaches, like those proposed by Valdiande et al. [161], aim to simplify computational requirements, many spectral analysis techniques still require significant processing power. This can be a challenge for real-time monitoring in industrial settings. Future work should focus on developing more efficient algorithms and hardware solutions to enable real-time processing of spectral data.

- Current spectral analysis techniques often struggle to classify specific types of defects based on their spectral signatures. While some research has successfully correlated spectral data with porosity, as demonstrated by Mazumder et al. [160] who reported a classification precision of 83% for detecting porosity, the detection of interlayer crack formation using spectral sensing remains largely unexplored. To date, no significant studies have successfully correlated spectral signatures specifically with crack formation in DED-LB/M processes. The ability to differentiate between defects, for instance cracks and porosity, based on their spectral signatures is an area that requires substantial further investigation.

3.2.4. Acoustic Emission

Sensor Type

- Structure-borne acoustic sensor and

- Airborne acoustic sensor.

Process Signatures

Analysis of Acoustic Features to Predict Defects

Current Challenges, Existing Limitations, and Paths for Future Exploration

- The acoustic landscape of DED-LB/M operations is characterised by a complex interplay of multiple components, including normal process emissions, defect-related events, and various disturbances. This intricate acoustic environment presents significant challenges for accurate defect detection due to the presence of extraneous noise in the acoustic signals. Although researchers have employed frequency filtering and signal denoising techniques to address these challenges, there remains a pressing need for more advanced signal processing methods. These sophisticated approaches are necessary for effectively isolating defect-related acoustic signatures from the multitude of process-related sounds and external disturbances. The development of such advanced techniques is crucial for enhancing the reliability and precision of acoustic-based monitoring in DED-LB/M processes.

- AE-based monitoring in DED-LB/M processes has demonstrated significant potential for defect detection and process characterisation, particularly in single-layer or single-track analyses. However, the layered nature of DED-LB/M fabrication introduces thermal complexities that significantly impact the acoustic signatures associated with defect formation and propagation. As successive layers are deposited, heat accumulation within the structure leads to dynamic changes in thermal gradients and stress distributions. Consequently, the acoustic landscape becomes increasingly complex when examining multi-layered structures, presenting new challenges for accurate defect identification and process monitoring. To address these challenges, a layer-by-layer analysis of acoustic signals becomes crucial. This approach allows for the examination of how acoustic signatures fluctuate throughout the build process, potentially revealing the formation of new defects or the propagation of existing ones within the fabricated structures.

- AE-based analysis employing time and frequency domain characteristics has proven invaluable for defect identification in DED-LB/M processes. However, this approach exhibits inherent limitations in precisely localising defects within the fabricated structures. This limitation arises primarily from the focus of traditional acoustic analysis on identifying the occurrence of defects rather than their exact positioning. Consequently, the current methodologies, while effective in detecting defects, lack the capability to provide detailed spatial information about their locations within the fabricated structure. To address this shortcoming and enhance the overall effectiveness of acoustic monitoring in DED-LB/M processes, there is a critical need to develop an advanced acoustic source localisation system. Such a system would complement existing defect detection capabilities by providing location-specific information.

3.2.5. Comparison of Different Sensing Methods

3.3. Summary

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 168781401882288. [Google Scholar] [CrossRef]

- Le, V.T.; Paris, H.; Mandil, G. Process Planning for Combined Additive and Subtractive Manufacturing Technologies in a Remanufacturing Context. J. Manuf. Syst. 2017, 44, 243–254. [Google Scholar] [CrossRef]

- Hegab, H.; Khanna, N.; Monib, N.; Salem, A. Design for Sustainable Additive Manufacturing: A Review. Sustain. Mater. Technol. 2023, 35, e00576. [Google Scholar] [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A Comparison of Traditional Manufacturing vs. Additive Manufacturing, the Best Method for the Job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Plocher, J.; Panesar, A. Review on Design and Structural Optimisation in Additive Manufacturing: Towards next-Generation Lightweight Structures. Mater. Des. 2019, 183, 108164. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive Manufacturing Tooling for the Automotive Industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Fasel, U.; Keidel, D.; Baumann, L.; Cavolina, G.; Eichenhofer, M.; Ermanni, P. Composite Additive Manufacturing of Morphing Aerospace Structures. Manuf. Lett. 2020, 23, 85–88. [Google Scholar] [CrossRef]

- Pollock, T.M. Alloy Design for Aircraft Engines. Nat. Mater. 2016, 15, 809–815. [Google Scholar] [CrossRef]

- Murr, L.E. Metallurgy Principles Applied to Powder Bed Fusion 3D Printing/Additive Manufacturing of Personalized and Optimized Metal and Alloy Biomedical Implants: An Overview. J. Mater. Res. Technol. 2020, 9, 1087–1103. [Google Scholar] [CrossRef]

- Bax, B.; Rajput, R.; Kellet, R.; Reisacher, M. Systematic Evaluation of Process Parameter Maps for Laser Cladding and Directed Energy Deposition. Addit. Manuf. 2018, 21, 487–494. [Google Scholar] [CrossRef]

- Liu, W.-W.; Tang, Z.-J.; Liu, X.-Y.; Wang, H.-J.; Zhang, H.-C. A Review on In-Situ Monitoring and Adaptive Control Technology for Laser Cladding Remanufacturing. Procedia CIRP 2017, 61, 235–240. [Google Scholar] [CrossRef]

- Li, M.; Huang, K.; Yi, X. Crack Formation Mechanisms and Control Methods of Laser Cladding Coatings: A Review. Coatings 2023, 13, 1117. [Google Scholar] [CrossRef]

- Fatemeh Nabavi, S.; Farshidianfar, A.; Dalir, H. Comprehensive Review: Advancements in Modeling Geometrical and Mechanical Characteristics of Laser Powder Bed Fusion Process. Opt. Laser Technol. 2025, 180, 111480. [Google Scholar] [CrossRef]

- Ansari, M.J.; Arcondoulis, E.J.G.; Roccisano, A.; Schulz, C.; Schlaefer, T.; Hall, C. Optimized Analytical Approach for the Detection of Process-Induced Defects Using Acoustic Emission during Directed Energy Deposition Process. Addit. Manuf. 2024, 86, 104218. [Google Scholar] [CrossRef]

- Soltani-Tehrani, A.; Chen, P.; Katsarelis, C.; Gradl, P.; Shao, S.; Shamsaei, N. Laser Powder Directed Energy Deposition (LP-DED) NASA HR-1 Alloy: Laser Power and Heat Treatment Effects on Microstructure and Mechanical Properties. Addit. Manuf. Lett. 2022, 3, 100097. [Google Scholar] [CrossRef]

- Müller, M.; Gerdt, L.; Schrüfer, S.; Riede, M.; López, E.; Brueckner, F.; Leyens, C. Laser-Based Directed Energy Deposition and Characterisation of cBN-Reinforced NiAl-Based Coatings. Int. J. Adv. Manuf. Technol. 2024, 134, 657–675. [Google Scholar] [CrossRef]

- Ahn, D.-G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf.-Green Tech. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021(En); Additive Manufacturing—General Principles—Fundamentals and Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 14 November 2024).

- Brennan, M.; Keist, J.S.; Palmer, T.A. Defects in Metal Additive Manufacturing Processes. In Additive Manufacturing Processes; Bourell, D.L., Frazier, W., Kuhn, H., Seifi, M., Eds.; ASM International: Almere, The Netherlands, 2020; pp. 277–286. ISBN 978-1-62708-290-7. [Google Scholar]

- Chen, Y.; Peng, X.; Kong, L.; Dong, G.; Remani, A.; Leach, R. Defect Inspection Technologies for Additive Manufacturing. Int. J. Extrem. Manuf. 2021, 3, 022002. [Google Scholar] [CrossRef]

- Fang, Q.; Xiong, G.; Zhou, M.; Tamir, T.S.; Yan, C.-B.; Wu, H.; Shen, Z.; Wang, F.-Y. Process Monitoring, Diagnosis and Control of Additive Manufacturing. IEEE Trans. Automat. Sci. Eng. 2022, 21, 1041–1067. [Google Scholar] [CrossRef]

- Weber, J.U.; Emmelmann, C. Localized Defect Frequencies for Laser Metal Deposition Processes. Procedia CIRP 2024, 124, 331–334. [Google Scholar] [CrossRef]

- Chua, Z.Y.; Ahn, I.H.; Moon, S.K. Process Monitoring and Inspection Systems in Metal Additive Manufacturing: Status and Applications. Int. J. Precis. Eng. Manuf.-Green Tech. 2017, 4, 235–245. [Google Scholar] [CrossRef]

- Singh, R.; Gupta, A.; Tripathi, O.; Srivastava, S.; Singh, B.; Awasthi, A.; Rajput, S.K.; Sonia, P.; Singhal, P.; Saxena, K.K. Powder Bed Fusion Process in Additive Manufacturing: An Overview. Mater. Today Proc. 2020, 26, 3058–3070. [Google Scholar] [CrossRef]

- Dev Singh, D.; Mahender, T.; Raji Reddy, A. Powder Bed Fusion Process: A Brief Review. Mater. Today Proc. 2021, 46, 350–355. [Google Scholar] [CrossRef]

- Sahar, T.; Rauf, M.; Murtaza, A.; Khan, L.A.; Ayub, H.; Jameel, S.M.; Ahad, I.U. Anomaly Detection in Laser Powder Bed Fusion Using Machine Learning: A Review. Results Eng. 2023, 17, 100803. [Google Scholar] [CrossRef]

- Chua, C.; Liu, Y.; Williams, R.J.; Chua, C.K.; Sing, S.L. In-Process and Post-Process Strategies for Part Quality Assessment in Metal Powder Bed Fusion: A Review. J. Manuf. Syst. 2024, 73, 75–105. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Era, I.Z.; Farahani, M.A.; Wuest, T.; Liu, Z. Machine Learning in Directed Energy Deposition (DED) Additive Manufacturing: A State-of-the-Art Review. Manuf. Lett. 2023, 35, 689–700. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the Art in Directed Energy Deposition: From Additive Manufacturing to Materials Design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Gradl, P.R.; Cervone, A.; Gill, E. Surface Texture Characterization for Thin-Wall NASA HR-1 Fe–Ni–Cr Alloy Using Laser Powder Directed Energy Deposition (LP-DED). Adv. Ind. Manuf. Eng. 2022, 4, 100084. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Vyatskikh, A.; Das, M.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Laser-Based Directed Energy Deposition (DED-LB) of Advanced Materials. Mater. Sci. Eng. A 2022, 840, 142967. [Google Scholar] [CrossRef]

- Arias-González, F.; Barro, O.; del Val, J.; Lusquiños, F.; Fernández-Arias, M.; Comesaña, R.; Riveiro, A.; Pou, J. Laser-Directed Energy Deposition. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 121–157. ISBN 978-0-12-818411-0. [Google Scholar]

- Velu, R.; Kumar, A.V.; Balan, A.S.S.; Mazumder, J. Laser Aided Metal Additive Manufacturing and Postprocessing. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 427–456. ISBN 978-0-12-818411-0. [Google Scholar]

- Yadav, S.; Paul, C.P.; Jinoop, A.N.; Rai, A.K.; Bindra, K.S. Laser Directed Energy Deposition Based Additive Manufacturing of Copper: Process Development and Material Characterizations. J. Manuf. Process. 2020, 58, 984–997. [Google Scholar] [CrossRef]

- Ansari, M.J.; Roccisano, A.; Arcondoulis, E.J.G.; Schulz, C.; Schläfer, T.; Hall, C. Relationship between Associated Acoustic Emission and Crack Position during Directed Energy Deposition of a Metal Matrix Composite. J. Manuf. Process. 2025, 147, 177–190. [Google Scholar] [CrossRef]

- Kumar, S.P.; Elangovan, S.; Mohanraj, R.; Srihari, B. Critical Review of Off-Axial Nozzle and Coaxial Nozzle for Powder Metal Deposition. Mater. Today Proc. 2021, 46, 8066–8079. [Google Scholar] [CrossRef]

- Dias da Silva, M.; Partes, K.; Seefeld, T.; Vollertsen, F. Comparison of Coaxial and Off-Axis Nozzle Configurations in One Step Process Laser Cladding on Aluminum Substrate. J. Mater. Process. Technol. 2012, 212, 2514–2519. [Google Scholar] [CrossRef]

- Guner, A.; Bidare, P.; Jiménez, A.; Dimov, S.; Essa, K. Nozzle Designs in Powder-Based Direct Laser Deposition: A Review. Int. J. Precis. Eng. Manuf. 2022, 23, 1077–1094. [Google Scholar] [CrossRef]

- Chen, L.; Bi, G.; Yao, X.; Su, J.; Tan, C.; Feng, W.; Benakis, M.; Chew, Y.; Moon, S.K. In-Situ Process Monitoring and Adaptive Quality Enhancement in Laser Additive Manufacturing: A Critical Review. J. Manuf. Syst. 2024, 74, 527–574. [Google Scholar] [CrossRef]

- Mahamood, R.M. Laser Metal Deposition Process of Metals, Alloys, and Composite Materials; Engineering Materials and Processes; Springer International Publishing: Cham, Switzerland, 2018; pp. 37–57. ISBN 978-3-319-64984-9. [Google Scholar]

- Salmi, A.; Piscopo, G.; Pilagatti, A.N.; Atzeni, E. Evaluation of Porosity in AISI 316L Samples Processed by Laser Powder Directed Energy Deposition. J. Manuf. Mater. Process. 2024, 8, 129. [Google Scholar] [CrossRef]

- Jeon, I.; Sohn, H. Online Melt Pool Depth Estimation in Laser Metal Deposition Using a Coaxial Thermography System. J. Laser Appl. 2022, 34, 022001. [Google Scholar] [CrossRef]

- Goodarzi, D.M. Analysis of Laser Cladding Process Parameter Influence on the Clad Bead Geometry. Weld. World 2017, 61, 883–891. [Google Scholar] [CrossRef]

- Goodarzi, D.M.; Pekkarinen, J.; Salminen, A. Effect of Process Parameters in Laser Cladding on Substrate Melted Areas and the Substrate Melted Shape. J. Laser Appl. 2015, 27, S29201. [Google Scholar] [CrossRef]

- Kenevisi, M.S.; Yu, Y.; Lin, F. A Review on Additive Manufacturing of Al–Cu (2xxx) Aluminium Alloys, Processes and Defects. Mater. Sci. Technol. 2021, 37, 805–829. [Google Scholar] [CrossRef]

- Lu, N.; Lei, Z.; Hu, K.; Yu, X.; Li, P.; Bi, J.; Wu, S.; Chen, Y. Hot Cracking Behavior and Mechanism of a Third-Generation Ni-Based Single-Crystal Superalloy during Directed Energy Deposition. Addit. Manuf. 2020, 34, 101228. [Google Scholar] [CrossRef]

- 20 kW Laser System for Producing High Purity Crystals—Fraunhofer ILT. Available online: https://www.ilt.fraunhofer.de/en/press/press-releases/2024/2-9-laser-based-crystal-growing.html (accessed on 29 October 2024).

- Guan, B.; Qin, L.; Yang, G.; Ren, Y.; Wang, X. Laser Polishing of Directed Energy Deposition Metal Parts: A Review. Addit. Manuf. Front. 2024, 3, 200174. [Google Scholar] [CrossRef]

- Bréhier, M.; Weisz-Patrault, D.; Tournier, C. Revisiting the Influence of the Scanning Speed on Surface Topography and Microstructure of IN718 Thin Walls in Directed Energy Deposition Additive Manufacturing. Procedia CIRP 2022, 108, 470–476. [Google Scholar] [CrossRef]

- Mahamood, R.; Aweda, J.; Ajao, K.; AbdulKareem, S.; Ajimotokan, H. Scanning Speed Influence on the Physical Properties of Laser Metal Deposition Titanium Alloy. Nig. J. Tech. 2016, 36, 132–137. [Google Scholar] [CrossRef]

- Erinosho, M.F.; Akinlabi, E.T.; Johnson, O.T. Effect of Scanning Speed on the Surface Roughness of Laser Metal Deposited Copper on Titanium Alloy. Mat. Res. 2019, 22, e20190297. [Google Scholar] [CrossRef]

- Bayode, A.; Pityana, S.; Akinlabi, E.T.; Shongwe, M.B. Effect of Scanning Speed on Laser Deposited 17-4PH Stainless Steel. In Proceedings of the 2017 8th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 3 February 2017; pp. 1–5. [Google Scholar]

- Fillingim, K.B.; Kannan, R.; Heinrich, L.; Saleeby, K.; Nandwana, P.; Feldhausen, T. Process Parameter Translation Strategies for Variable Directed Energy Deposition Spot Size Using 316L, Copper, and Inconel 625. Heliyon 2024, 10, e37658. [Google Scholar] [CrossRef] [PubMed]

- Mahamood, R.M. Processing Parameters in Laser Metal Deposition Process. In Laser Metal Deposition Process of Metals, Alloys, and Composite Materials; Mahamood, R.M., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 61–92. ISBN 978-3-319-64985-6. [Google Scholar]

- Platz, J.; Huber, M.; Kirsc, B.; Aurich, J.C. Investigation on Different Laser Beam Profiles in High-Speed Directed Energy Deposition. Procedia CIRP 2024, 126, 609–614. [Google Scholar] [CrossRef]

- Errico, V. Study of Innovative Solutions to Improve the Quality of Metallic Components Manufactured by Additive Manufacturing Technologies 2023. Available online: https://tesidottorato.depositolegale.it/handle/20.500.14242/64907 (accessed on 12 December 2024).

- Ye, J.; Bab-hadiashar, A.; Alam, N.; Cole, I. A Review of the Parameter-Signature-Quality Correlations through in Situ Sensing in Laser Metal Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2022, 124, 1401–1427. [Google Scholar] [CrossRef]

- Qin, J.; Hu, F.; Liu, Y.; Witherell, P.; Wang, C.C.L.; Rosen, D.W.; Simpson, T.W.; Lu, Y.; Tang, Q. Research and Application of Machine Learning for Additive Manufacturing. Addit. Manuf. 2022, 52, 102691. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D.; Lang, M.; Juhasz, M.; Eliaz, N.; Bose, S. Alloy Design via Additive Manufacturing: Advantages, Challenges, Applications and Perspectives. Mater. Today 2022, 52, 207–224. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y. Development of Metal Matrix Composites by Laser-Assisted Additive Manufacturing Technologies: A Review. J. Mater. Sci. 2020, 55, 9883–9917. [Google Scholar] [CrossRef]

- Mansfield, B.; Torres, S.; Yu, T.; Wu, D. A Review on Additive Manufacturing of Ceramics. In Proceedings of the MSEC2019, Erie, PA, USA, 10 June 2019; Volume 1. [Google Scholar]

- Simunovic, K.; Saric, T.; Simunovic, G. Different Approaches to the Investigation and Testing of the Ni-Based Self-Fluxing Alloy Coatings—A Review. Part 2: Microstructure, Adhesive Strength, Cracking Behavior, and Residual Stresses Investigations. Tribol. Trans. 2014, 57, 980–1000. [Google Scholar] [CrossRef]

- Li, S.-H.; Kumar, P.; Chandra, S.; Ramamurty, U. Directed Energy Deposition of Metals: Processing, Microstructures, and Mechanical Properties. Int. Mater. Rev. 2022, 68, 605–647. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser Additive Manufacturing of Metallic Components: Materials, Processes and Mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Bayode, A. Advanced Material Development: Functionally Graded Stainless Steel Alloy Composites. Ph.D. Thesis, University of Johannesburg, Johannesburg, South Africa, 2018. [Google Scholar]

- Tyagi, S.A.; Manjaiah, M. Laser Additive Manufacturing of Titanium-Based Functionally Graded Materials: A Review. J. Mater. Eng Perform 2022, 31, 6131–6148. [Google Scholar] [CrossRef]

- Lathabai, S. Additive Manufacturing of Aluminium-Based Alloys and Composites. In Fundamentals of Aluminium Metallurgy; Elsevier: Amsterdam, The Netherlands, 2018; pp. 47–92. ISBN 978-0-08-102063-0. [Google Scholar]

- Karmakar, R.; Maji, P.; Ghosh, S.K. A Review on the Nickel Based Metal Matrix Composite Coating. Met. Mater. Int. 2021, 27, 2134–2145. [Google Scholar] [CrossRef]

- Madhu, K.S.; Sharath, B.N.; Karthik, S.; Pradeep, D.G.; Puttegowda, M.; Yashas Gowda, T.G.; Premkumar, B.G.; Raghavendra Rao, R. An Introduction to Metal Matrix Composites and Their Applications. In Applications of Composite Materials in Engineering; Elsevier: Amsterdam, The Netherlands, 2025; pp. 45–73. ISBN 978-0-443-13989-5. [Google Scholar]

- Chen, L.-Y.; Qin, P.; Zhang, L.; Zhang, L.-C. An Overview of Additively Manufactured Metal Matrix Composites: Preparation, Performance, and Challenge. Int. J. Extrem. Manuf. 2024, 6, 052006. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, S.; Li, S.; Zhang, W.; Lan, L.; Jiang, Y.; He, B. Research Progress of Laser Additive Manufacturing Nickel-Based Alloy Metal Matrix Composites. Metals 2023, 13, 129. [Google Scholar] [CrossRef]

- Wei, Q.; Xie, Y.; Teng, Q.; Shen, M.; Sun, S.; Cai, C. Crack Types, Mechanisms, and Suppression Methods during High-Energy Beam Additive Manufacturing of Nickel-Based Superalloys: A Review. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100055. [Google Scholar] [CrossRef]

- Rao, J.; Leong Sing, S.; Liu, P.; Wang, J.; Sohn, H. Non-Destructive Testing of Metal-Based Additively Manufactured Parts and Processes: A Review. Virtual Phys. Prototyp. 2023, 18, e2266658. [Google Scholar] [CrossRef]

- Imran, M.M.; Che Idris, A.; De Silva, L.C.; Kim, Y.-B.; Abas, P.E. Advancements in 3D Printing: Directed Energy Deposition Techniques, Defect Analysis, and Quality Monitoring. Technologies 2024, 12, 86. [Google Scholar] [CrossRef]

- Haley, J.; Karandikar, J.; Herberger, C.; MacDonald, E.; Feldhausen, T.; Lee, Y. Review of in Situ Process Monitoring for Metal Hybrid Directed Energy Deposition. J. Manuf. Process. 2024, 109, 128–139. [Google Scholar] [CrossRef]

- Mo, B.; Li, T.; Shi, F.; Deng, L.; Liu, W. Crack Initiation and Propagation within Nickel-Based High-Temperature Alloys during Laser-Based Directed Energy Deposition: A Review. Opt. Laser Technol. 2024, 179, 111327. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J.; Shim, D.-S.; Park, S.-H.; Choi, Y.S. Micro-Cracking in Medium-Carbon Steel Layers Additively Deposited on Gray Cast Iron Using Directed Energy Deposition. Met. Mater. Int. 2020, 26, 708–718. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, F.; Zhang, K.; Nie, P.; Elmi Hosseini, S.R.; Feng, K.; Li, Z. Dendritic Microstructure and Hot Cracking of Laser Additive Manufactured Inconel 718 under Improved Base Cooling. J. Alloys Compd. 2016, 670, 312–321. [Google Scholar] [CrossRef]

- Ghasemi-Tabasi, H.; De Formanoir, C.; Van Petegem, S.; Jhabvala, J.; Hocine, S.; Boillat, E.; Sohrabi, N.; Marone, F.; Grolimund, D.; Van Swygenhoven, H.; et al. Direct Observation of Crack Formation Mechanisms with Operando Laser Powder Bed Fusion X-Ray Imaging. Addit. Manuf. 2022, 51, 102619. [Google Scholar] [CrossRef]

- Park, G.-W.; Shin, S.; Kim, J.-Y.; Koo, Y.-M.; Lee, W.; Lee, K.-A.; Park, S.S.; Jeon, J.B. Analysis of Solidification Microstructure and Cracking Mechanism of a Matrix High-Speed Steel Deposited Using Directed-Energy Deposition. J. Alloys Compd. 2022, 907, 164523. [Google Scholar] [CrossRef]

- Li, Y.; Chen, K.; Tamura, N. Mechanism of Heat Affected Zone Cracking in Ni-Based Superalloy DZ125L Fabricated by Laser 3D Printing Technique. Mater. Des. 2018, 150, 171–181. [Google Scholar] [CrossRef]

- Zhang, X.; Mu, Y.; Ma, L.; Liang, J.; Zhou, Y.; Sun, X.; Li, J. Cracking on a Nickel-Based Superalloy Fabricated by Direct Energy Deposition. China Foundry 2024, 21, 311–318. [Google Scholar] [CrossRef]

- Guo, C.; Li, G.; Li, S.; Hu, X.; Lu, H.; Li, X.; Xu, Z.; Chen, Y.; Li, Q.; Lu, J.; et al. Additive Manufacturing of Ni-Based Superalloys: Residual Stress, Mechanisms of Crack Formation and Strategies for Crack Inhibition. Nano Mater. Sci. 2023, 5, 53–77. [Google Scholar] [CrossRef]

- Alam, Z.; Iqbal, F.; Khan, D.A. (Eds.) Post-Processing Techniques for Additive Manufacturing, 1st ed.; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Tao, W. Crack Initiation and Propagation Behavior of WC Particles Reinforced Fe-Based Metal Matrix Composite Produced by Laser Melting Deposition. Opt. Laser Technol. 2016, 82, 170–182. [Google Scholar] [CrossRef]

- Yu, J.; Rombouts, M.; Maes, G. Cracking Behavior and Mechanical Properties of Austenitic Stainless Steel Parts Produced by Laser Metal Deposition. Mater. Des. 2013, 45, 228–235. [Google Scholar] [CrossRef]

- Song, J.L.; Li, Y.T.; Deng, Q.L.; Cheng, Z.Y.; Chin, B. Cracking Mechanism of Laser Cladding Rapid Manufacturing 316L Stainless Steel. KEM 2009, 419–420, 413–416. [Google Scholar] [CrossRef]

- Tang, Y.T.; Panwisawas, C.; Ghoussoub, J.N.; Gong, Y.; Clark, J.W.G.; Németh, A.A.N.; McCartney, D.G.; Reed, R.C. Alloys-by-Design: Application to New Superalloys for Additive Manufacturing. Acta Mater. 2021, 202, 417–436. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Xu, L.; Xu, J.; Ren, X.; Chen, X. Cracking Mechanism and Susceptibility of Laser Melting Deposited Inconel 738 Superalloy. Mater. Des. 2019, 183, 108105. [Google Scholar] [CrossRef]

- Wang, Z.; Beese, A.M. Effect of Chemistry on Martensitic Phase Transformation Kinetics and Resulting Properties of Additively Manufactured Stainless Steel. Acta Mater. 2017, 131, 410–422. [Google Scholar] [CrossRef]

- Weng, F.; Gao, S.; Jiang, J.; Wang, J.; Guo, P. A Novel Strategy to Fabricate Thin 316L Stainless Steel Rods by Continuous Directed Energy Deposition in Z Direction. Addit. Manuf. 2019, 27, 474–481. [Google Scholar] [CrossRef]

- Lough, C.S. Development of In-Situ Radiometric Inspection Methods for Quality Assurance in Laser Powder Bed Fusion. Ph.D. Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2021. [Google Scholar]

- Sohn, H.; Liu, P.; Yoon, H.; Yi, K.; Yang, L.; Kim, S. Real-Time Porosity Reduction during Metal Directed Energy Deposition Using a Pulse Laser. J. Mater. Sci. Technol. 2022, 116, 214–223. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Effects of Defects on Mechanical Properties in Metal Additive Manufacturing: A Review Focusing on X-Ray Tomography Insights. Mater. Des. 2020, 187, 108385. [Google Scholar] [CrossRef]

- Nam, S.; Cho, H.; Kim, C.; Kim, Y.-M. Effect of Process Parameters on Deposition Properties of Functionally Graded STS 316/Fe Manufactured by Laser Direct Metal Deposition. Metals 2018, 8, 607. [Google Scholar] [CrossRef]

- Bustillos, J.; Kim, J.; Moridi, A. Exploiting Lack of Fusion Defects for Microstructural Engineering in Additive Manufacturing. Addit. Manuf. 2021, 48, 102399. [Google Scholar] [CrossRef]

- Dos Santos Paes, L.E.; Pereira, M.; Xavier, F.A.; Weingaertner, W.L.; Vilarinho, L.O. Lack of Fusion Mitigation in Directed Energy Deposition with Laser (DED-L) Additive Manufacturing through Laser Remelting. J. Manuf. Process. 2022, 73, 67–77. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, Y.; Marussi, S.; Fan, X.; Fitzpatrick, M.; Bhagavath, S.; Majkut, M.; Lukic, B.; Jakata, K.; Rack, A.; et al. Pore Evolution Mechanisms during Directed Energy Deposition Additive Manufacturing. Nat. Commun. 2024, 15, 1715. [Google Scholar] [CrossRef] [PubMed]

- Sinha, S.; Mukherjee, T. Mitigation of Gas Porosity in Additive Manufacturing Using Experimental Data Analysis and Mechanistic Modeling. Materials 2024, 17, 1569. [Google Scholar] [CrossRef]

- Wolff, S.J.; Wang, H.; Gould, B.; Parab, N.; Wu, Z.; Zhao, C.; Greco, A.; Sun, T. In Situ X-Ray Imaging of Pore Formation Mechanisms and Dynamics in Laser Powder-Blown Directed Energy Deposition Additive Manufacturing. Int. J. Mach. Tools Manuf. 2021, 166, 103743. [Google Scholar] [CrossRef]

- Sinclair, L.; Hatt, O.; Clark, S.J.; Marussi, S.; Ruckh, E.; Atwood, R.C.; Jones, M.; Baxter, G.J.; Lun Alex Leung, C.; Todd, I.; et al. An in Situ Imaging Investigation of the Effect of Gas Flow Rates on Directed Energy Deposition. Mater. Des. 2024, 244, 113183. [Google Scholar] [CrossRef]

- Drissi-Daoudi, R.; Pandiyan, V.; Logé, R.; Shevchik, S.; Masinelli, G.; Ghasemi-Tabasi, H.; Parrilli, A.; Wasmer, K. Differentiation of Materials and Laser Powder Bed Fusion Processing Regimes from Airborne Acoustic Emission Combined with Machine Learning. Virtual Phys. Prototyp. 2022, 17, 181–204. [Google Scholar] [CrossRef]

- Park, G.-W.; Song, S.; Park, M.; Shin, S.; Kim, D.-J.; Koo, Y.-M.; Kim, S.; Lee, K.-A.; Kim, B.J.; Park, S.S.; et al. Effect of Residual Stress on Pore Formation in Multi-Materials Deposited via Directed Energy Deposition. Addit. Manuf. 2024, 81, 104016. [Google Scholar] [CrossRef]

- Smith, T.R.; Sugar, J.D.; San Marchi, C.; Schoenung, J.M. Strengthening Mechanisms in Directed Energy Deposited Austenitic Stainless Steel. Acta Mater. 2019, 164, 728–740. [Google Scholar] [CrossRef]

- Barkia, B.; Aubry, P.; Haghi-Ashtiani, P.; Auger, T.; Gosmain, L.; Schuster, F.; Maskrot, H. On the Origin of the High Tensile Strength and Ductility of Additively Manufactured 316L Stainless Steel: Multiscale Investigation. J. Mater. Sci. Technol. 2020, 41, 209–218. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Bosio, F.; Bassini, E.; Librera, E.; De Chirico, M.; Biamino, S.; Ugues, D.; Fino, P.; Lombardi, M. An Investigation on the Effect of Powder Recycling on the Microstructure and Mechanical Properties of AISI 316L Produced by Directed Energy Deposition. Mater. Sci. Eng. A 2019, 766, 138360. [Google Scholar] [CrossRef]

- Smith, T.R.; Sugar, J.D.; San Marchi, C.; Schoenung, J.M. Microstructural Development in DED Stainless Steels: Applying Welding Models to Elucidate the Impact of Processing and Alloy Composition. J. Mater. Sci. 2021, 56, 762–780. [Google Scholar] [CrossRef]

- Chen, L.; Liu, W.; Song, L. A Multiscale Investigation of Deformation Heterogeneity in Additively Manufactured 316L Stainless Steel. Mater. Sci. Eng. A 2021, 820, 141493. [Google Scholar] [CrossRef]

- Marya, M.; Singh, V.; Marya, S.; Hascoet, J.Y. Microstructural Development and Technical Challenges in Laser Additive Manufacturing: Case Study with a 316L Industrial Part. Met. Mater. Trans B 2015, 46, 1654–1665. [Google Scholar] [CrossRef]

- Lu, Q.Y.; Wong, C.H. Additive Manufacturing Process Monitoring and Control by Non-Destructive Testing Techniques: Challenges and in-Process Monitoring. Virtual Phys. Prototyp. 2018, 13, 39–48. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Barnard, A.S.; Matthews, M.J.; Jared, B.H.; Andreaco, A.M.; Bartsch, K.; Murphy, A.B. Machine Learning-Assisted in-Situ Adaptive Strategies for the Control of Defects and Anomalies in Metal Additive Manufacturing. Addit. Manuf. 2024, 81, 104013. [Google Scholar] [CrossRef]

- Liu, W.; Wang, T.; Liu, B.; Li, W.; Hu, G.; Lyu, Z. Research of On-Line Monitoring Technology and Control Strategy for Laser-Directed Energy Deposition: A Review. Int. J. Adv. Manuf. Technol. 2024, 133, 3105–3132. [Google Scholar] [CrossRef]

- Herzog, T.; Brandt, M.; Trinchi, A.; Sola, A.; Molotnikov, A. Process Monitoring and Machine Learning for Defect Detection in Laser-Based Metal Additive Manufacturing. J. Intell. Manuf. 2024, 35, 1407–1437. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, W.; Li, L. In-Process Measurement of Melt Pool Cross-Sectional Geometry and Grain Orientation in a Laser Directed Energy Deposition Additive Manufacturing Process. Opt. Laser Technol. 2020, 129, 106280. [Google Scholar] [CrossRef]

- Shin, H.; Lee, J.; Choi, S.-K.; Lee, S.W. Development of Multi-Defect Diagnosis Algorithm for the Directed Energy Deposition (DED) Process with in Situ Melt-Pool Monitoring. Int. J. Adv. Manuf. Technol. 2023, 125, 357–368. [Google Scholar] [CrossRef]

- Mi, J.; Zhang, Y.; Li, H.; Shen, S.; Yang, Y.; Song, C.; Zhou, X.; Duan, Y.; Lu, J.; Mai, H. In-Situ Monitoring Laser Based Directed Energy Deposition Process with Deep Convolutional Neural Network. J. Intell. Manuf. 2023, 34, 683–693. [Google Scholar] [CrossRef]

- Yin, J.; Yang, L.; Yang, X.; Zhu, H.; Wang, D.; Ke, L.; Wang, Z.; Wang, G.; Zeng, X. High-Power Laser-Matter Interaction during Laser Powder Bed Fusion. Addit. Manuf. 2019, 29, 100778. [Google Scholar] [CrossRef]

- Sampson, R.; Lancaster, R.; Sutcliffe, M.; Carswell, D.; Hauser, C.; Barras, J. An Improved Methodology of Melt Pool Monitoring of Direct Energy Deposition Processes. Opt. Laser Technol. 2020, 127, 106194. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z.; Xu, P.; Liu, Z. Recent Research and Development Status of Laser Cladding: A Review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Herzog, T.; Brandt, M.; Trinchi, A.; Sola, A.; Hagenlocher, C.; Molotnikov, A. Defect Detection by Multi-Axis Infrared Process Monitoring of Laser Beam Directed Energy Deposition. Sci. Rep. 2024, 14, 3861. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Z.; Tian, L.; Lauria, S.; Liu, X. Melt Pool Segmentation for Additive Manufacturing: A Generative Adversarial Network Approach. Comput. Electr. Eng. 2021, 92, 107183. [Google Scholar] [CrossRef]

- Song, L.; Wang, F.; Li, S.; Han, X. Phase Congruency Melt Pool Edge Extraction for Laser Additive Manufacturing. J. Mater. Process. Technol. 2017, 250, 261–269. [Google Scholar] [CrossRef]

- Lei, K.; Qin, X.; Liu, H.; Ni, M. Analysis and Modeling of Melt Pool Morphology for High Power Diode Laser Cladding with a Rectangle Beam Spot. Opt. Lasers Eng. 2018, 110, 89–99. [Google Scholar] [CrossRef]

- Yan, J.; Xu, Z.; Wu, Z.; Li, Q.; Tang, M.; Ling, J. Edge Detection Method of Laser Cladding Pool Image Based on Morphology. In Proceedings of the AOPC 2021: Advanced Laser Technology and Applications, Beijing, China, 23–25 June 2021; Wei, Z., Ma, J., Shi, W., Lin, X., Li, W., Liu, Z., Xu, X., Song, Y., Huang, Y.-Z., Zhang, J., Eds.; SPIE: Beijing, China, 2021; p. 62. [Google Scholar]

- Wang, Y.; Hu, K.; Li, W.; Wang, L. Prediction of Melt Pool Width and Layer Height for Laser Directed Energy Deposition Enabled by Physics-Driven Temporal Convolutional Network. J. Manuf. Syst. 2023, 69, 1–17. [Google Scholar] [CrossRef]

- Barua, S.; Liou, F.; Newkirk, J.; Sparks, T. Vision-Based Defect Detection in Laser Metal Deposition Process. Rapid Prototyp. J. 2014, 20, 77–85. [Google Scholar] [CrossRef]

- Kao, I.-H.; Hsu, Y.-W.; Lai, Y.H.; Perng, J.-W. Laser Cladding Quality Monitoring Using Coaxial Image Based on Machine Learning. IEEE Trans. Instrum. Meas. 2020, 69, 2868–2880. [Google Scholar] [CrossRef]

- Donadello, S.; Motta, M.; Demir, A.G.; Previtali, B. Monitoring of Laser Metal Deposition Height by Means of Coaxial Laser Triangulation. Opt. Lasers Eng. 2019, 112, 136–144. [Google Scholar] [CrossRef]

- Liu, T.; Huang, L.; Chen, B. Real-Time Defect Detection of Laser Additive Manufacturing Based on Support Vector Machine. J. Phys. Conf. Ser. 2019, 1213, 052043. [Google Scholar] [CrossRef]

- Yang, L.; Sohn, H.; Ma, Z.; Jeon, I.; Liu, P.; Cheng, J.C.P. Real-Time Layer Height Estimation during Multi-Layer Directed Energy Deposition Using Domain Adaptive Neural Networks. Comput. Ind. 2023, 148, 103882. [Google Scholar] [CrossRef]

- Montazeri, M.; Nassar, A.R.; Stutzman, C.B.; Rao, P. Heterogeneous Sensor-Based Condition Monitoring in Directed Energy Deposition. Addit. Manuf. 2019, 30, 100916. [Google Scholar] [CrossRef]

- Guerra, M.G.; Mazzarisi, M.; Latte, M.; Lavecchia, F.; Campanelli, S.; Galantucci, L.M. Off-Axis Monitoring of the Melt Pool Spatial Information in Laser Metal Deposition Process. Procedia CIRP 2024, 121, 144–149. [Google Scholar] [CrossRef]

- Pandiyan, V.; Cui, D.; Richter, R.A.; Parrilli, A.; Leparoux, M. Real-Time Monitoring and Quality Assurance for Laser-Based Directed Energy Deposition: Integrating Co-Axial Imaging and Self-Supervised Deep Learning Framework. J. Intell. Manuf. 2023, 36, 909–933. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, S.; Shin, Y.C. In-Process Monitoring of Porosity during Laser Additive Manufacturing Process. Addit. Manuf. 2019, 28, 497–505. [Google Scholar] [CrossRef]

- McGowan, E.; Gawade, V.; Guo, W. (Grace) A Physics-Informed Convolutional Neural Network with Custom Loss Functions for Porosity Prediction in Laser Metal Deposition. Sensors 2022, 22, 494. [Google Scholar] [CrossRef] [PubMed]

- Yin, M.; Zhuo, S.; Xie, L.; Chen, L.; Wang, M.; Liu, G. Online Monitoring of Local Defects in Robotic Laser Additive Manufacturing Process Based on a Dynamic Mapping Strategy and Multibranch Fusion Convolutional Neural Network. J. Manuf. Syst. 2023, 71, 494–503. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Y.; Lei, Y.; Wei, H.; Chen, C.; Liu, F.; Zhao, P.; Wang, K. A Single-Sensor Multi-Scale Quality Monitoring Methodology for Laser-Directed Energy Deposition: Example with Height Instability and Porosity Monitoring in Additive Manufacturing of Ceramic Thin-Walled Parts. Addit. Manuf. 2024, 79, 103923. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, S.; Li, H.; Hu, Y. Review of in Situ and Real-Time Monitoring of Metal Additive Manufacturing Based on Image Processing. Int. J. Adv. Manuf. Technol. 2022, 123, 1–20. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, W.; Wang, Y.; Saleheen, K.M.; Liu, Z.; Peng, S.; Zhang, Z.; Zhang, H. A Review on in Situ Monitoring Technology for Directed Energy Deposition of Metals. Int. J. Adv. Manuf. Technol. 2020, 108, 3437–3463. [Google Scholar] [CrossRef]

- Kim, S.; Jeon, I.; Sohn, H. Infrared Thermographic Imaging Based Real-Time Layer Height Estimation during Directed Energy Deposition. Opt. Lasers Eng. 2023, 168, 107661. [Google Scholar] [CrossRef]

- AbouelNour, Y.; Gupta, N. In-Situ Monitoring of Sub-Surface and Internal Defects in Additive Manufacturing: A Review. Mater. Des. 2022, 222, 111063. [Google Scholar] [CrossRef]

- Li, J.; Liu, T.; Zhang, K.; Zou, Z.; Lu, X.; Zhu, Z. The Thermal History of the Directed Energy Deposition Process Monitored by Pyrometer and Camera. Meas. Sci. Technol. 2024, 35, 045204. [Google Scholar] [CrossRef]

- Ouidadi, H.; Guo, S.; Zamiela, C.; Bian, L. Real-Time Defect Detection Using Online Learning for Laser Metal Deposition. J. Manuf. Process. 2023, 99, 898–910. [Google Scholar] [CrossRef]

- Bappy, M.M.; Liu, C.; Bian, L.; Tian, W. Morphological Dynamics-Based Anomaly Detection Towards In Situ Layer-Wise Certification for Directed Energy Deposition Processes. J. Manuf. Sci. Eng. 2022, 144, 111007. [Google Scholar] [CrossRef]

- Mazzarisi, M.; Angelastro, A.; Latte, M.; Colucci, T.; Palano, F.; Campanelli, S.L. Thermal Monitoring of Laser Metal Deposition Strategies Using Infrared Thermography. J. Manuf. Process. 2023, 85, 594–611. [Google Scholar] [CrossRef]

- Khanzadeh, M.; Chowdhury, S.; Marufuzzaman, M.; Tschopp, M.A.; Bian, L. Porosity Prediction: Supervised-Learning of Thermal History for Direct Laser Deposition. J. Manuf. Syst. 2018, 47, 69–82. [Google Scholar] [CrossRef]

- Ye, J.; Bab-Hadiashar, A.; Hoseinnezhad, R.; Alam, N.; Vargas-Uscategui, A.; Patel, M.; Cole, I. Predictions of In-Situ Melt Pool Geometric Signatures via Machine Learning Techniques for Laser Metal Deposition. Int. J. Comput. Integr. Manuf. 2023, 36, 1345–1361. [Google Scholar] [CrossRef]

- Wu, Y.; Cui, B.; Xiao, Y. Crack Detection during Laser Metal Deposition by Infrared Monochrome Pyrometer. Materials 2020, 13, 5643. [Google Scholar] [CrossRef]

- D’Accardi, E.; Chiappini, F.; Giannasi, A.; Guerrini, M.; Maggiani, G.; Palumbo, D.; Galietti, U. Online Monitoring of Direct Laser Metal Deposition Process by Means of Infrared Thermography. Prog. Addit. Manuf. 2023, 9, 983–1001. [Google Scholar] [CrossRef]

- Tian, Q.; Guo, S.; Melder, E.; Bian, L.; Guo, W. “Grace” Deep Learning-Based Data Fusion Method for In Situ Porosity Detection in Laser-Based Additive Manufacturing. J. Manuf. Sci. Eng. 2021, 143, 041011. [Google Scholar] [CrossRef]

- Gaikwad, A.; Yavari, R.; Montazeri, M.; Cole, K.; Bian, L.; Rao, P. Toward the Digital Twin of Additive Manufacturing: Integrating Thermal Simulations, Sensing, and Analytics to Detect Process Faults. IISE Trans. 2020, 52, 1204–1217. [Google Scholar] [CrossRef]

- Khanzadeh, M.; Chowdhury, S.; Tschopp, M.A.; Doude, H.R.; Marufuzzaman, M.; Bian, L. In-Situ Monitoring of Melt Pool Images for Porosity Prediction in Directed Energy Deposition Processes. IISE Trans. 2019, 51, 437–455. [Google Scholar] [CrossRef]

- Deng, S.; Gao, R.; Wang, Y.; Mao, W.; Zheng, W. Structure of a Semantic Segmentation-Based Defect Detection Network for Laser Cladding Infrared Images. Meas. Sci. Technol. 2023, 34, 085601. [Google Scholar] [CrossRef]

- Guo, W.; Tian, Q.; Guo, S.; Guo, Y. A Physics-Driven Deep Learning Model for Process-Porosity Causal Relationship and Porosity Prediction with Interpretability in Laser Metal Deposition. CIRP Ann. 2020, 69, 205–208. [Google Scholar] [CrossRef]

- Song, L.; Mazumder, J. In-Situ Spectroscopic Analysis of Laser Induced Plasma for Monitoring of Composition during Direct Metal Deposition Process. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Anaheim, CA, USA, 26–30 September 2010; Laser Institute of America: Orlando, FL, USA, 2010; pp. 166–171. [Google Scholar]

- Song, L.; Wang, C.; Mazumder, J. Identification of Phase Transformation Using Optical Emission Spectroscopy for Direct Metal Deposition Process. In Proceedings of the High Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications, San Francisco, CA, USA, 9 February 2012; Beyer, E., Morris, T., Eds.; SPIE: Cergy-Pontoise, France; p. 82390G.

- Wasmer, K.; Wüst, M.; Cui, D.; Masinelli, G.; Pandiyan, V.; Shevchik, S. Monitoring of Functionally Graded Material during Laser Directed Energy Deposition by Acoustic Emission and Optical Emission Spectroscopy Using Artificial Intelligence. Virtual Phys. Prototyp. 2023, 18, e2189599. [Google Scholar] [CrossRef]

- Choi, J.; Wooldridge, M.; Mazumder, J. Spectroscopy-Based Smart Optical Monitoring System in the Applications of Laser Additive Manufacturing. J. Laser Appl. 2023, 35, 012030. [Google Scholar] [CrossRef]

- Ren, W.; Wen, G.; Zhang, Z.; Mazumder, J. Quality Monitoring in Additive Manufacturing Using Emission Spectroscopy and Unsupervised Deep Learning. Mater. Manuf. Process. 2022, 37, 1339–1346. [Google Scholar] [CrossRef]

- Valdiande, J.J.; Mirapeix, J.; Nin, J.; Font, E.; Seijas, C.; Lopez-Higuera, J.M. Laser Metal Deposition On-Line Monitoring via Plasma Emission Spectroscopy and Spectral Correlation Techniques. IEEE J. Select. Top. Quantum Electron. 2021, 27, 1–8. [Google Scholar] [CrossRef]

- Monfared, V.; Ramakrishna, S.; Nasajpour-Esfahani, N.; Toghraie, D.; Hekmatifar, M.; Rahmati, S. Science and Technology of Additive Manufacturing Progress: Processes, Materials, and Applications. Met. Mater. Int. 2023, 29, 3442–3470. [Google Scholar] [CrossRef]

- Nassar, A.R.; Spurgeon, T.J.; Reutzel, E.W. Sensing Defects during Directed-Energy Additive Manufacturing of Metal Parts Using Optical Emissions Spectroscopy; University of Texas at Austin: Austin, TX, USA, 2014. [Google Scholar] [CrossRef]

- Chen, B.; Yao, Y.; Tan, C.; Huang, Y.; Feng, J. A Study on Spectral Characterization and Quality Detection of Direct Metal Deposition Process Based on Spectral Diagnosis. Int. J. Adv. Manuf. Technol. 2018, 96, 4231–4241. [Google Scholar] [CrossRef]

- Ren, W.; Mazumder, J. In-Situ Porosity Recognition for Laser Additive Manufacturing of 7075-Al Alloy Using Plasma Emission Spectroscopy. Sci. Rep. 2020, 10, 19493. [Google Scholar] [CrossRef]

- Squires, B.; Flannery, D.; Bivens, T.; Banerjee, R.; McWilliams, B.; Cho, K.; Neogi, A.; Dahotre, N.B.; Voevodin, A.A. Laser-Induced Breakdown Spectroscopy for Composition Monitoring during Directed Energy Deposition of Graded Fe-Ni Alloys. Int. J. Adv. Manuf. Technol. 2024, 132, 3877–3888. [Google Scholar] [CrossRef]

- Li, S.; Chen, B.; Tan, C.; Song, X. In Situ Identification of Laser Directed Energy Deposition Condition Based on Acoustic Emission. Opt. Laser Technol. 2024, 169, 110152. [Google Scholar] [CrossRef]

- Taheri, H.; Koester, L.W.; Bigelow, T.A.; Faierson, E.J.; Bond, L.J. In Situ Additive Manufacturing Process Monitoring With an Acoustic Technique: Clustering Performance Evaluation Using K-Means Algorithm. J. Manuf. Sci. Eng. 2019, 141, 041011. [Google Scholar] [CrossRef]

- Gaja, H.; Liou, F. Defects Monitoring of Laser Metal Deposition Using Acoustic Emission Sensor. Int. J. Adv. Manuf. Technol. 2017, 90, 561–574. [Google Scholar] [CrossRef]

- Li, K.; Li, T.; Ma, M.; Wang, D.; Deng, W.; Lu, H. Laser Cladding State Recognition and Crack Defect Diagnosis by Acoustic Emission Signal and Neural Network. Opt. Laser Technol. 2021, 142, 107161. [Google Scholar] [CrossRef]

- Gaja, H.; Liou, F. Defect Classification of Laser Metal Deposition Using Logistic Regression and Artificial Neural Networks for Pattern Recognition. Int. J. Adv. Manuf. Technol. 2018, 94, 315–326. [Google Scholar] [CrossRef]

- Hauser, T.; Reisch, R.T.; Kamps, T.; Kaplan, A.F.H.; Volpp, J. Acoustic Emissions in Directed Energy Deposition Processes. Int. J. Adv. Manuf. Technol. 2022, 119, 3517–3532. [Google Scholar] [CrossRef]

- Chen, L.; Yao, X.; Moon, S.K. In-Situ Acoustic Monitoring of Direct Energy Deposition Process with Deep Learning-Assisted Signal Denoising. Mater. Today Proc. 2022, 70, 136–142. [Google Scholar] [CrossRef]

- Chen, L.; Bi, G.; Yao, X.; Tan, C.; Su, J.; Ng, N.P.H.; Chew, Y.; Liu, K.; Moon, S.K. Multisensor Fusion-Based Digital Twin for Localized Quality Prediction in Robotic Laser-Directed Energy Deposition. Robot. Comput.-Integr. Manuf. 2023, 84, 102581. [Google Scholar] [CrossRef]

- Chen, L.; Yao, X.; Tan, C.; He, W.; Su, J.; Weng, F.; Chew, Y.; Ng, N.P.H.; Moon, S.K. In-Situ Crack and Keyhole Pore Detection in Laser Directed Energy Deposition through Acoustic Signal and Deep Learning. Addit. Manuf. 2023, 69, 103547. [Google Scholar] [CrossRef]

- Chen, L.; Moon, S.K. In-Situ Defect Detection in Laser-Directed Energy Deposition with Machine Learning and Multi-Sensor Fusion. J. Mech. Sci. Technol. 2024, 38, 4477–4484. [Google Scholar] [CrossRef]

- Kim, H.-S.; Park, S.-H. Acoustic Signal Monitoring Using Audible Cracking Sounds for Efficient In-Situ Crack Detection in Laser Directed Energy Deposition of Hard Surfaces. Addit. Manuf. Lett. 2024, 9, 100210. [Google Scholar] [CrossRef]

- Wu, C.-Y.; Lu, M.-C.; Yang, W.-C.; Chi, N.-C. Experimental Study of Balling Defect Generation and Audible Sound Analysis in Directed Energy Deposition Metal Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2024, 134, 205–221. [Google Scholar] [CrossRef]

- Prieto, C.; Fernandez, R.; Gonzalez, C.; Diez, M.; Arias, J.; Sommerhuber, R.; Lücking, F. In Situ Process Monitoring by Optical Microphone for Crack Detection in Laser Metal Deposition Applications. In Proceedings of the 11th CIRP Conference on Photonic Technologies [LANE 2020], Fürth, Germany, 7–10 September 2020. [Google Scholar]

- García de la Yedra, A.; Pfleger, M.; Aramendi, B.; Cabeza, M.; Zubiri, F.; Mitter, T.; Reitinger, B.; Scherleitner, E. Online Cracking Detection by Means of Optical Techniques in Laser-Cladding Process. Struct. Control Health Monit. 2019, 26, e2291. [Google Scholar] [CrossRef]

- Weber, J.U.; Bauch, A.; Jahnke, J.; Emmelmann, C. Acoustic Emissions of Laser Metal Deposited NiTi Structures. In Proceedings of the Lasers in Manufacturing, Munich, Germany, 21–24 June 2021. [Google Scholar]

- Weber, J.U.; Knabe, M.; Sayilgan, V.; Emmelmann, C. Signal Processing of Airborne Acoustic Emissions from Laser Metal Deposited Structures. Procedia CIRP 2022, 111, 359–362. [Google Scholar] [CrossRef]

- Prem, P.R.; Sanker, A.P.; Sebastian, S.; Kaliyavaradhan, S.K. A Review on Application of Acoustic Emission Testing During Additive Manufacturing. J. Nondestruct. Eval. 2023, 42, 96. [Google Scholar] [CrossRef]

| Setup/Strategy | Advantages | Disadvantages | References |

|---|---|---|---|

| Co-axial Camera | Directional independence; undistorted, top-down views; accurate horizontal melt pool measurement. | Complex optics; sensitive to plume interference; limited vertical dimension capture. | [114,120] |

| Off-axis Camera | Simpler setup; useful side view; layer height and melt pool profile. | Single field of view; geometric distortion needing calibration; directional limits. | [58,113] |

| Dual/Multi-camera Setup | Complementary views; more complete melt pool info; enhanced defect detection. | Higher cost/complexity; data synchronisation and integration challenges. | [116,121] |

| Filtering Strategies | Improved image clarity; sensor protection; enhanced temperature measurement. | Possible signal loss; limited spectral range. | [117,118] |

| Process | Devices Used | Extracted Features (Input) | ML Algorithms | Defect Detection | Performance Indicators | Ref. |

|---|---|---|---|---|---|---|

| DED-LB/M | IR thermal camera (Off-axis) Pyrometer (Co-axial) | Morphological features of melt pools (e.g., area, length, width, etc.). Melt pool temperature distribution. | DT, KNN, SVM, LDA, QDA SOMs | Porosity | Recall—98.44% Accuracy—96% | Khanzadeh et al. [147] |

| IR thermal camera (Off-axis) Pyrometer (Co-axial) | Melt pool temperature distribution (mean and standard deviation) | SVM | Porosity | Accuracy—90% | Gaikwad et al. [152] | |

| IR thermal camera (Off-axis) Pyrometer (Co-axial) | Morphological features of melt pools (e.g., area, length, width, etc.). Melt pool temperature distribution. | CNN, LRCN | Porosity | Accuracy—96% | Tian et al. [151] Guo et al. [155] | |

| Pyrometer (Co-axial) | Morphology dynamics of melt pools and HAZs | SVM | Porosity | Accuracy—96% | Bappy et al. [145] | |

| IR thermal camera (Off-axis) Pyrometer (Co-axial) | Morphological features of melt pools (e.g., area, length, width, etc.). Melt pool temperature distribution. | K-means clustering SOM | Porosity | Accuracy—97% | Ouidadi et al. [145] | |

| IR thermal cameras (Off-axis and Coaxial) | Morphological features of melt pools (e.g., area, length, width, etc.). | Statistical Analyses | Porosity | Undetermined | Herzog et al. [121] | |

| IR thermal cameras (Off-axis) | Melt pool temperature distribution. | Statistical analyses, Analysis of variance (ANOVA) | Process-induced defects | Undetermined | D’Accardi et al. [150] | |

| IR thermal cameras (Off-axis) | Melt pool temperature distribution. | Statistical Analyses | Crack | Undetermined | Mazzarisi et al. [146] |

| Process | Devices Used | Extracted Features (Input) | ML Algorithms | Defect Detection | Performance indicators | Ref. |

|---|---|---|---|---|---|---|

| DED-LB/M | Spectrometer | Spectral features such as emission energy of Al & Mg lines, line-to-continuum ratio etc. | LSTM-Autoencoder, K-means clustering | Porosity | Undetermined | Mazumder et al. [160] |

| Spectrometer | Spectral features such as line-to-continuum ratio, average raw spectra intensity, background-subtracted emission line intensities, etc. | RF | Porosity | Accuracy—83% | ||

| ICP® Microphone Optical Emission Spectroscopy (OES) Sensors | Time domain & frequency domain characteristics, intensity of all spectra | LDA, LogReg, LSVM, LinearSVM, SVM, kNN, MLP, RF | Conduction mode, Lack-of- fusion | Accuracy (AE)—73.3% Accuracy (OES)—90% | Wasmer et al. [158] | |

| Spectrometer | Spectral intensity of different wavelength | Statistical process control | Process defects | Undetermined | Chen et al. [164] | |

| Spectrometer | Plasma RMS signal | Multiplicative scatter correction | Variations in the gas or powder flow | Undetermined | Valdiande et al. [161] |

| In situ Monitoring Method | Devices Used | Frequency Range | |

|---|---|---|---|

| Acoustic Emission | Structure-borne acoustic sensors | Piezoelectric sensor (i.e., AE Sensors) [167,168,169,170,171] | 50–130 kHz [167] 100–1000 kHz [169,171] 1.0 kHz–1.0 MHz [170] |

| Air-borne acoustic sensors | ICP® Microphone [172,173,174,175,176,177] | 10 Hz–10 kHz [178] 50 Hz–20 kHz [172,173,174,175,176] 6.3–20 kHz [177] | |

| Optical Microphone [179,180] | 10 Hz–1 MHz [179,180] | ||

| Directional Microphone [181,182] | 40 Hz to 20 kHz [181,182] | ||

| Feature Type | Feature Name | Description | Reference |

|---|---|---|---|

| Time- domain | Mean | The average amplitude of the acoustic signal over time. | [167] |

| Peak Amplitude | The maximum amplitude value (xi) within the acoustic signal window, indicating the loudest point in the signal during that time frame. | [167] | |

| Absolute mean | The average of the absolute amplitude values, indicating the signal’s magnitude. | [167] | |

| RMS (Root Mean Square) | The square root of the mean of squared amplitudes, representing signal strength. | [167] | |

| Absolute Std | The standard deviation of absolute values, showing variability in amplitude. | [167] | |

| Std of Envelope Lines | Standard deviation of the upper and lower amplitude envelopes of the signal. | [167] | |

| Kurtosis | A measure of the sharpness of the signal distribution, identifying extreme peaks. | [167,169,171] | |

| Skewness | Describes the asymmetry of the signal amplitude distribution around its mean. | [167] | |

| Acoustic Energy | The average power of the acoustic signal over time. | [167,169,171] | |

| Number of Counts | Number of times the signal crosses a preset threshold. | [169,171] | |

| Duration | Total time length of the acoustic event. | [169,171] | |

| Rise Time | Time from the start of the event to the peak amplitude. | [169,171] | |

| Frequency- domain | Peak Amplitude Frequency | Frequency at which the maximum amplitude occurs in the spectrum. | [169,171] |

| Spectral Centroid | The “centre of mass” of the signal’s spectrum, indicating dominant frequency regions. | [167] | |

| Spectral Skewness | A measure of asymmetry in the signal’s power spectrum, showing spectral bias. | [167] | |

| Spectral Kurtosis | A measure of the peakedness in the frequency domain, highlighting sharp spectral features. | [167] | |

| Time-frequency domain | Short-time Fourier transform (STFT) | Represents how frequency content changes over time. | [174,175,181,182] |

| Continuous Wavelet transforms (CWT) | Provides multi-resolution analysis of non-stationary signals. | [181,182] | |

| Mel-frequency Cepstrum Coefficients (MFCCs) | Represent the short-term power spectrum through a linear cosine transformation of a logarithmic power spectrum mapped onto a nonlinear mel frequency scale. | [174,175] |

| Process | Devices Used | Frequency Range | Extracted Features | Analysis Methods | Defect Detection | Ref |

|---|---|---|---|---|---|---|

| DED-LB/M | Optical Microphone | 10 Hz–1 MHz | Acoustic energy | Peak values in acoustic energy | Crack | García de la Yedra et al. [180] |

| Optical Microphone | 10 Hz–1 MHz | STFT based spectrograms, acoustic energy | Crack detection based on the frequency range, peak values in acoustic energy | Crack, identified crack frequency range, (350 kHz–1 MHz) | Camilo et al. [179] | |

| ICP® Microphone | 50 Hz–20 kHz | Mel frequency spectrum | Process condition detection based on the frequency range | Unstable process condition monitoring, frequency range (2 kHz and 10 kHz) | Hauser et al. [172] | |

| ICP® Microphone | 6–20 kHz | Time-domain, frequency-domain, and time-frequency domain characteristics | Crack detection based on the frequency range | Crack, identified crack frequency range, (12 kHz–16 kHz) | Kim et al. [177] | |

| ICP® Microphone | 10 Hz –10 kHz | Time and frequency domain characteristics | Balling detection based on the frequency range | Balling | Wu et al. [178] | |

| Directional Microphone | 40 Hz –20 kHz | STFT and CWT based spectrograms | Crack and delamination detection based on the frequency range | Crack and delamination. Identified defects frequency range, (11 kHz–18 kHz) | Weber et al. [182] |

| Process | Devices Used | Frequency Range | Extracted Features (Input) | ML Algorithms | Defect Detection | Performance Indicators | Reference |

|---|---|---|---|---|---|---|---|

| DED-LB/M | AE Sensors | 100–1000 kHz | Time domain & frequency domain characteristics | K-means clustering, LR, and ANN | Crack, Porosity | Accuracy—85.7% | Gaja et al. [169,171] |

| Piezoelectric sensor | - | Time domain & frequency domain characteristics | K-means clustering | Classification of different process conditions | Accuracy—87% | Taheri et al. [168] | |

| Piezoelectric sensor | 50–1300 kHz | Time domain & frequency domain characteristics | K-means clustering, SVM, RF, and back propagation neural network (BPNN) | Identification of different operation conditions Powder feeding situation, laser melting situation, abnormal and normal deposition | Accuracy from 88 to 94% | Li et al. [170] | |

| ICP® Microphone | 50 Hz–20 kHz | MFCCs, STFT based spectrograms | CNN architecture | Keyhole pore, crack | Accuracy: 89%, Keyhole pore accuracy: 93% | Chen et al. [174,175] |

| Monitoring Method | Monitored object | Main ML Algorithms | Defects | Advantages | Disadvantages | ||

|---|---|---|---|---|---|---|---|

| Crack | Porosity | Lack-of-Fusion | |||||

| Vision Sensing | Melt pool geometrical characteristics | ANN, SVM, RF, D-CNN | × | √ | √ | Direct observation of melt pool geometry. | Limited to identify surface defects. |

| Thermal Sensing | Melt pool geometrical characteristics and temperature distribution | K-means clustering, ANN, SVM, RF, CNN, LRCN | √ | √ | × | Provides real-time information on melt pool thermal characteristics. | Requires accurate emissivity calibration. Limited to identifying surface and near-surface defects. |

| Spectral Sensing | Spectral features | K-means clustering, RF, KNN, SVM | × | √ | √ | Provides atomic-level information about the process. Can detect subsurface defects. | Sensitive to deposition thickness variations. Requires advanced data processing to extract meaningful information. |

| Acoustic Emission | Acoustic signal | K-means clustering, ANN, SVM, RF, CNN | √ | √ | × | Can detect surface and subsurface defects. | Sensitive to external disturbances and environmental noise |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ansari, M.J.; Roccisano, A.; Arcondoulis, E.J.G.; Schulz, C.; Schläfer, T.; Hall, C. Advancements in In-Situ Monitoring Technologies for Detecting Process-Induced Defects in the Directed Energy Deposition Process: A Comprehensive Review. Materials 2025, 18, 4304. https://doi.org/10.3390/ma18184304

Ansari MJ, Roccisano A, Arcondoulis EJG, Schulz C, Schläfer T, Hall C. Advancements in In-Situ Monitoring Technologies for Detecting Process-Induced Defects in the Directed Energy Deposition Process: A Comprehensive Review. Materials. 2025; 18(18):4304. https://doi.org/10.3390/ma18184304

Chicago/Turabian StyleAnsari, Md Jonaet, Anthony Roccisano, Elias J. G. Arcondoulis, Christiane Schulz, Thomas Schläfer, and Colin Hall. 2025. "Advancements in In-Situ Monitoring Technologies for Detecting Process-Induced Defects in the Directed Energy Deposition Process: A Comprehensive Review" Materials 18, no. 18: 4304. https://doi.org/10.3390/ma18184304

APA StyleAnsari, M. J., Roccisano, A., Arcondoulis, E. J. G., Schulz, C., Schläfer, T., & Hall, C. (2025). Advancements in In-Situ Monitoring Technologies for Detecting Process-Induced Defects in the Directed Energy Deposition Process: A Comprehensive Review. Materials, 18(18), 4304. https://doi.org/10.3390/ma18184304