The Influence of Selected Properties of Sintered Iron Doped with Lubricants on Its Tribological Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Testing Materials

2.1.1. Iron Powder

2.1.2. Lubricant Additives

- -

- Hexagonal boron nitride (h-BN, 99.9%) with an average particle size of 0.5 μm and 1.5 μm;

- -

- Molybdenum disulfide (MoS2, 99.9%) with an average particle size of 1.5 μm;

- -

- Tungsten disulfide (WS2, 99.9%) with an average particle size of 0.6 μm.

2.2. Sample Preparation and Test Procedures

Preparation of Samples for Testing

2.3. Research Procedures

2.3.1. Density and Porosity Tests

2.3.2. Hardness Tests

2.3.3. UNMT Surface Layer Characterization Test Kit

2.3.4. Tribological Measurements

- -

- A 3.175 mm (1/8”) diameter ball made of tungsten carbide (WC);

- -

- Load—2.79 N, to ensure pressure under the ASTM G-133 standard;

- -

- Amplitude—2 mm, resulting from the ball used;

- -

- Test duration—1000 s;

- -

- Frequency—5 Hz;

- -

- Total number of cycles—5000;

- -

- Friction path—20 m, resulting from the reduced amplitude.

3. Results and Discussion

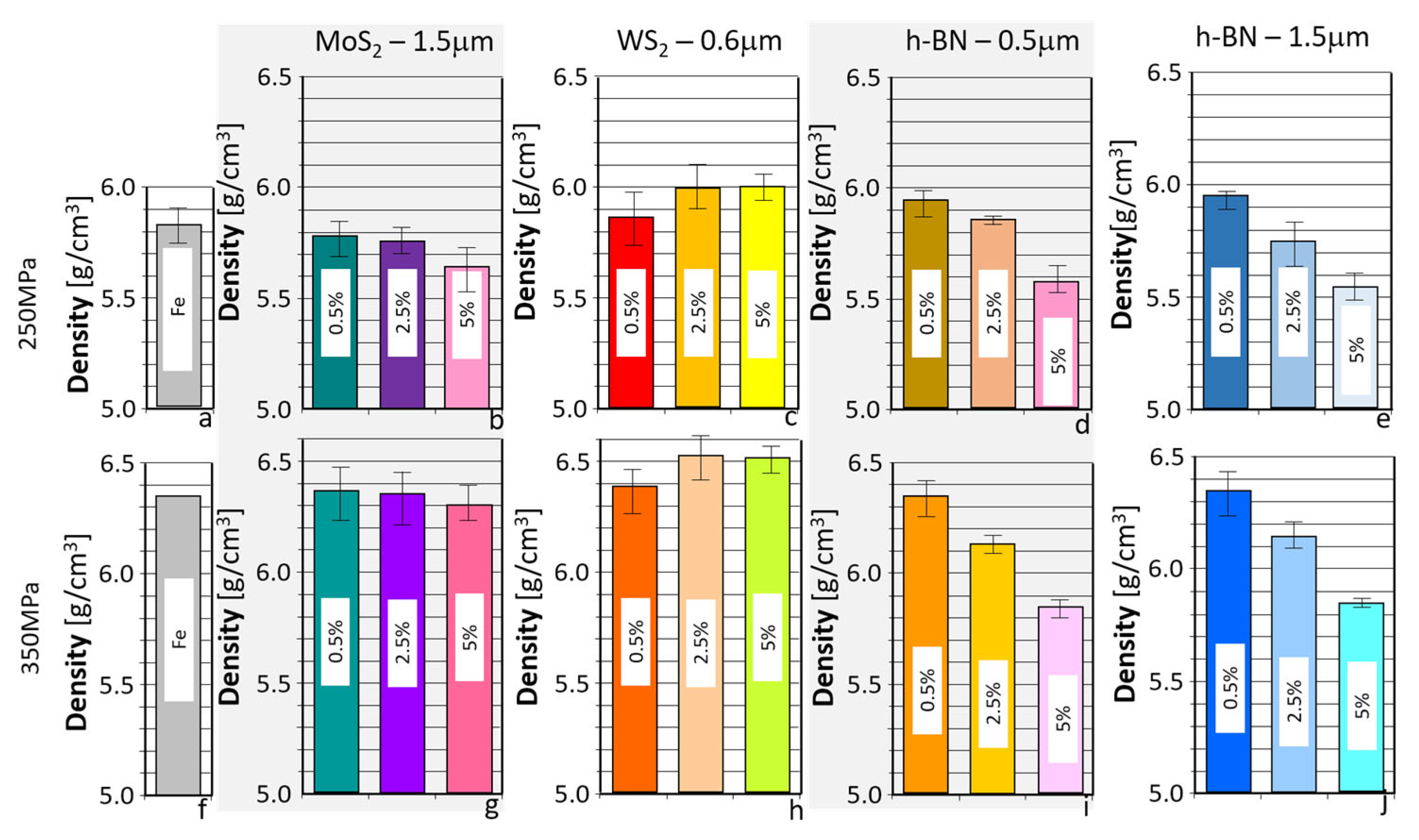

3.1. Density and Porosity Measurement Results

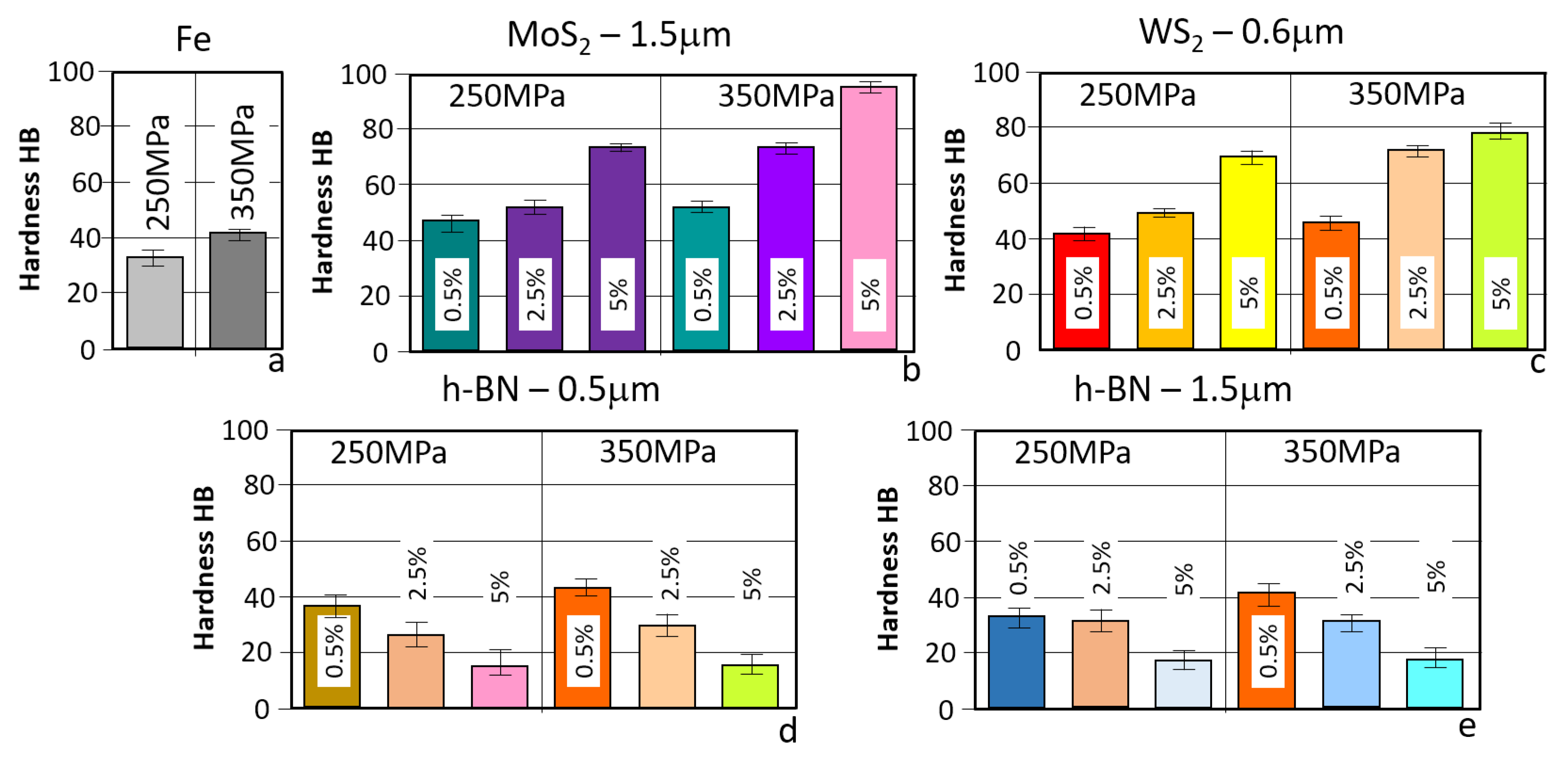

3.2. Hardness Test Results

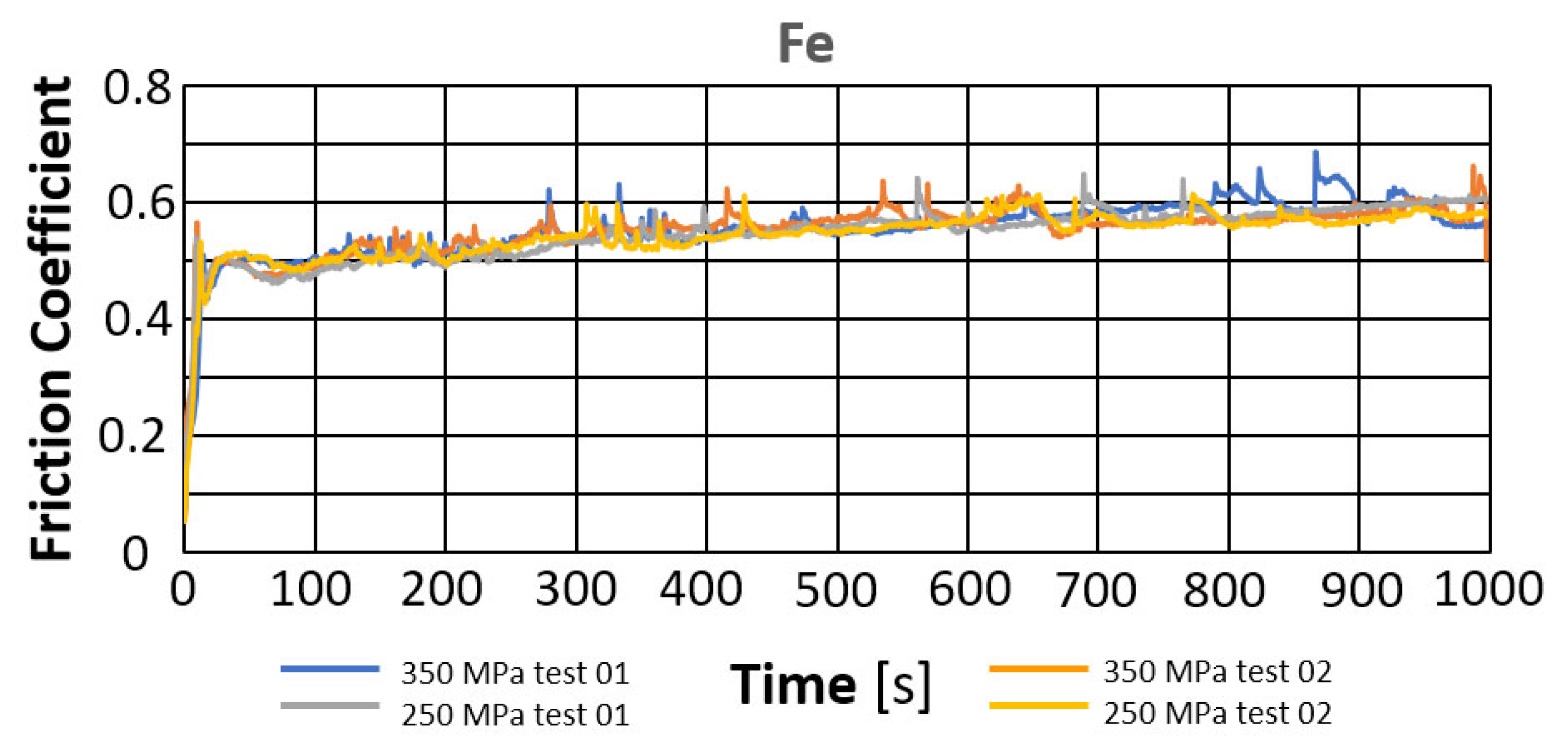

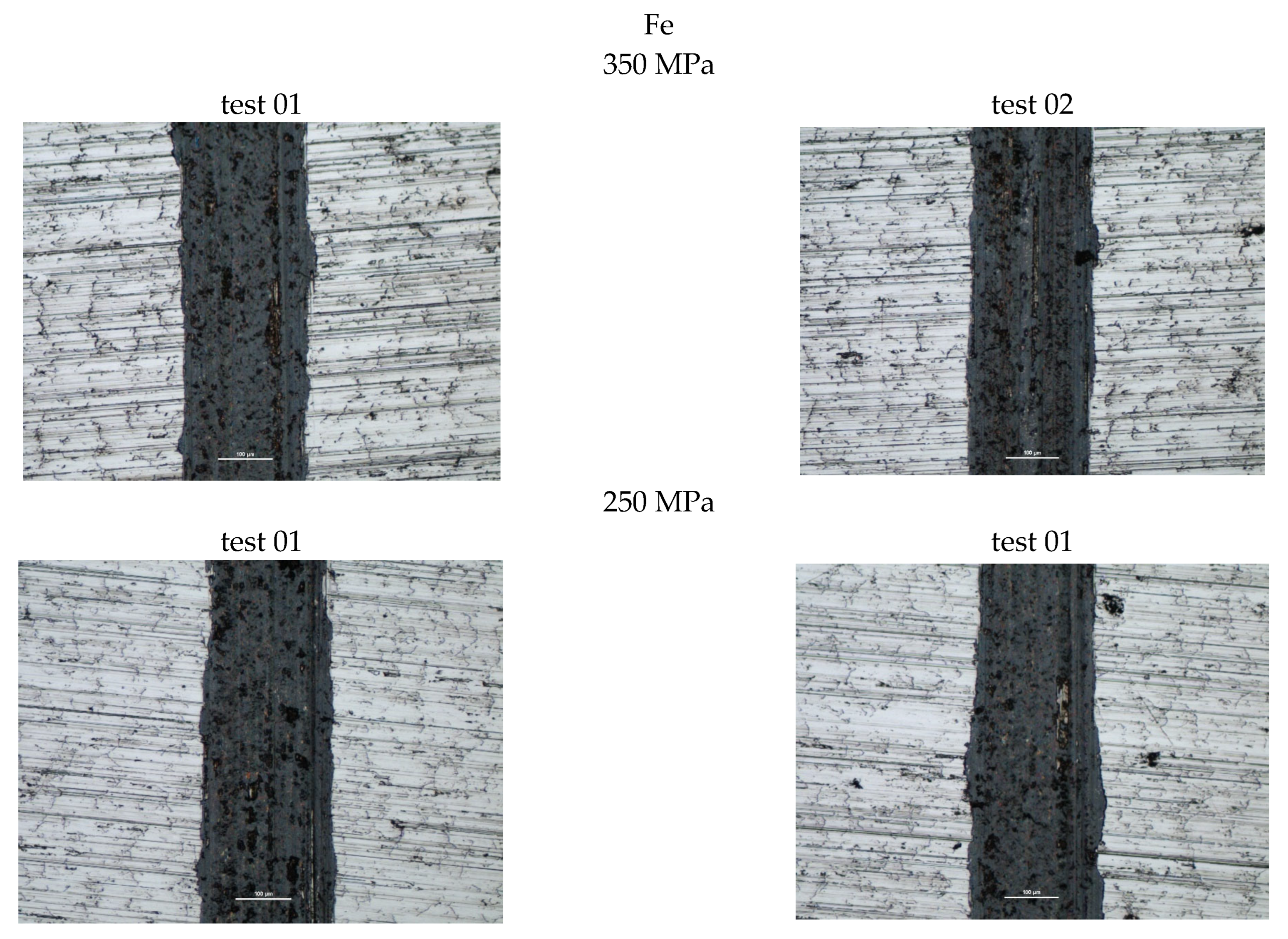

3.3. Tribological Test Results

- Evaluation of the change in the friction coefficient and wear marks for samples without lubricant additives.

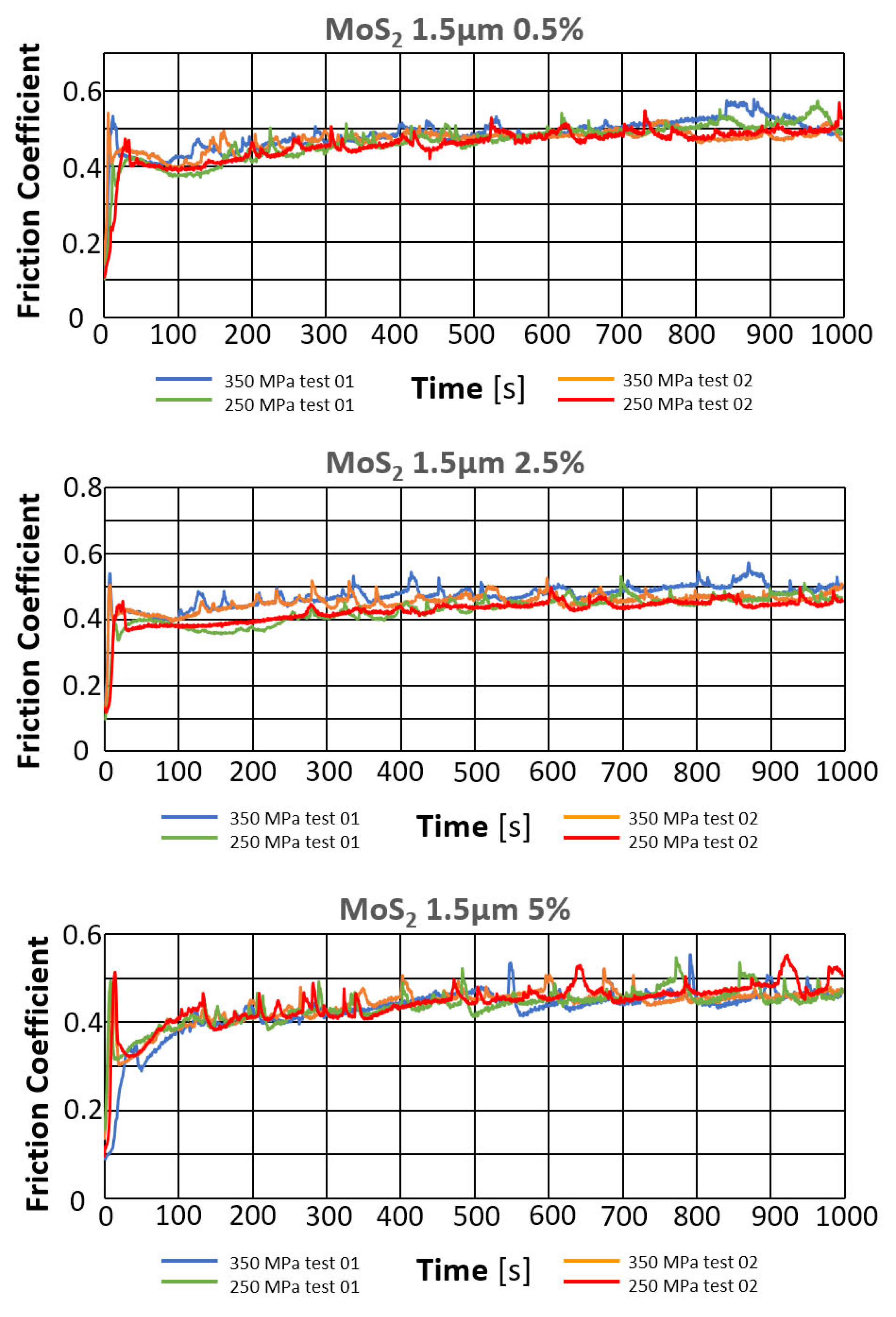

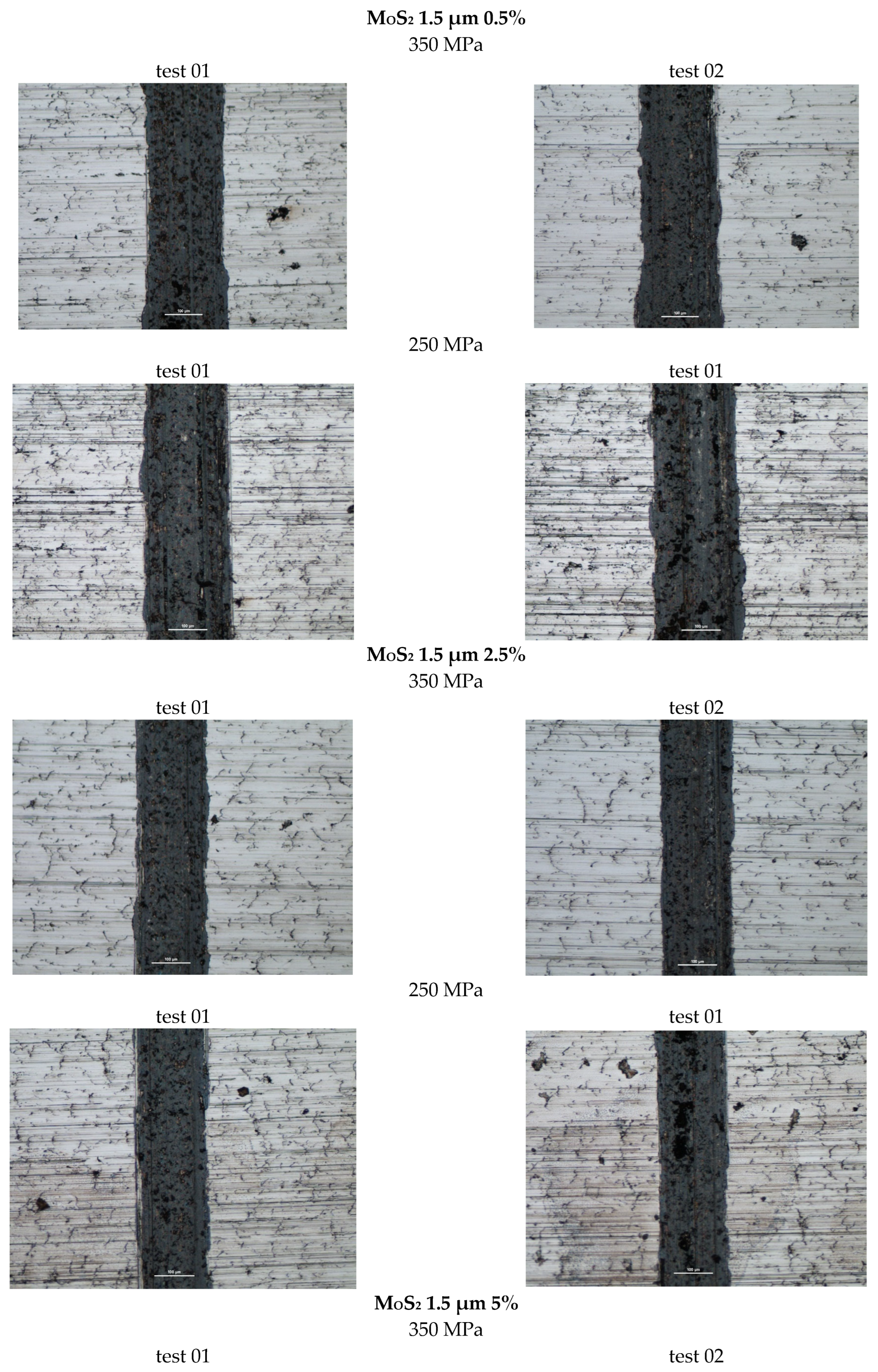

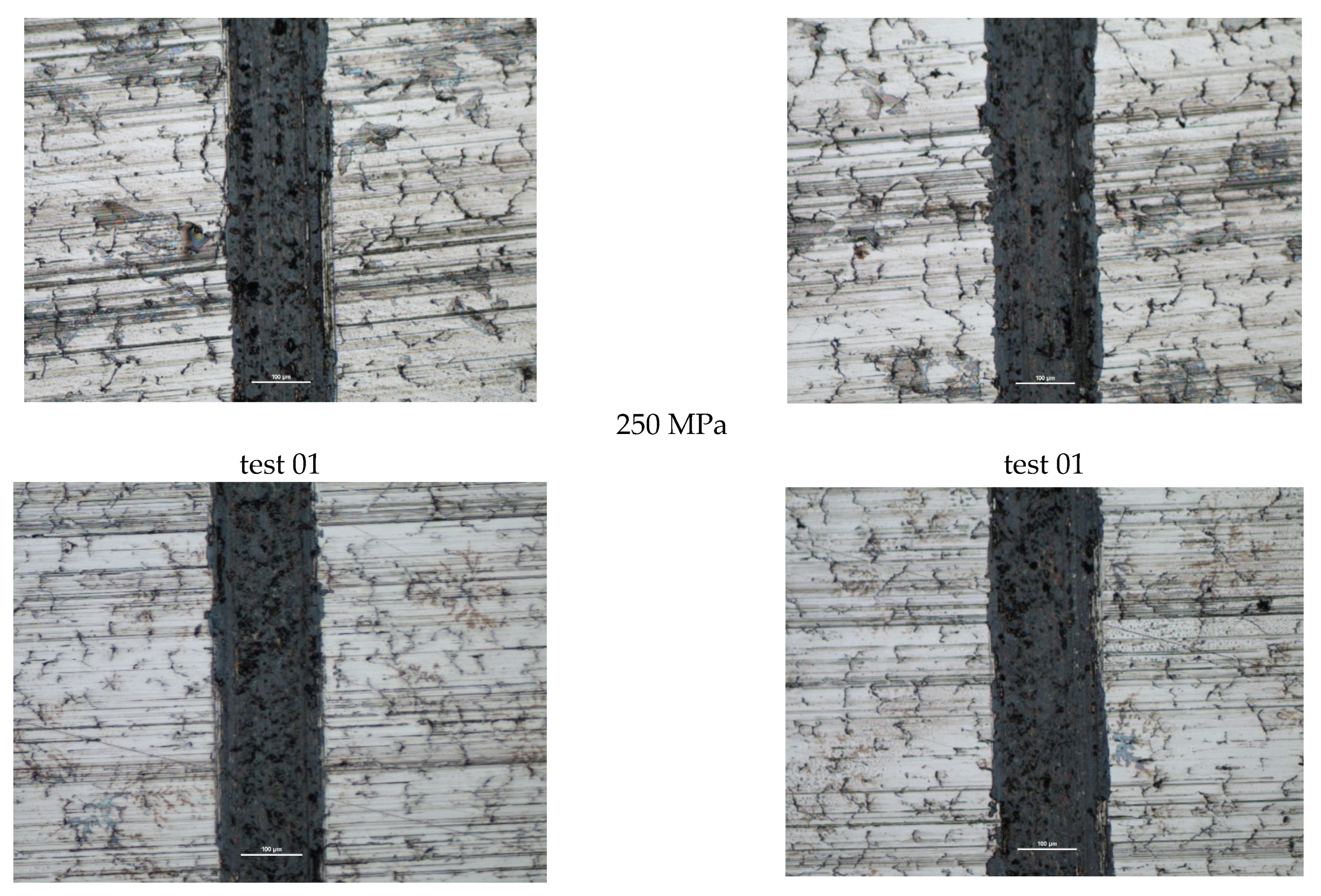

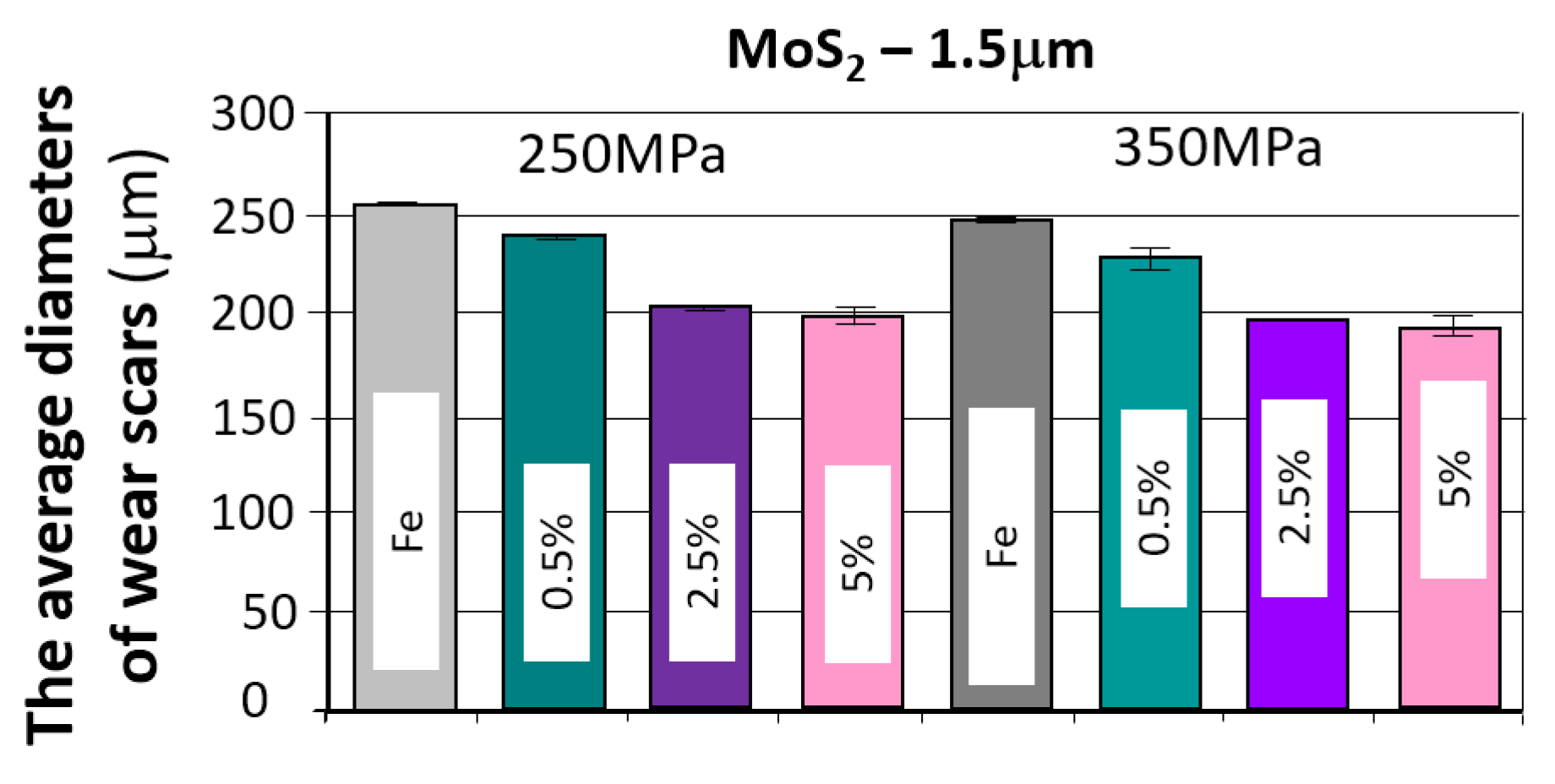

3.3.1. Samples with MoS2 Addition

- Evaluation of the change in friction coefficient and wear marks for sintered steel samples in which 1.5 µm MoS2 was used as a lubricant additive in amounts of 0.5%, 2.5%, and 5% by weight.

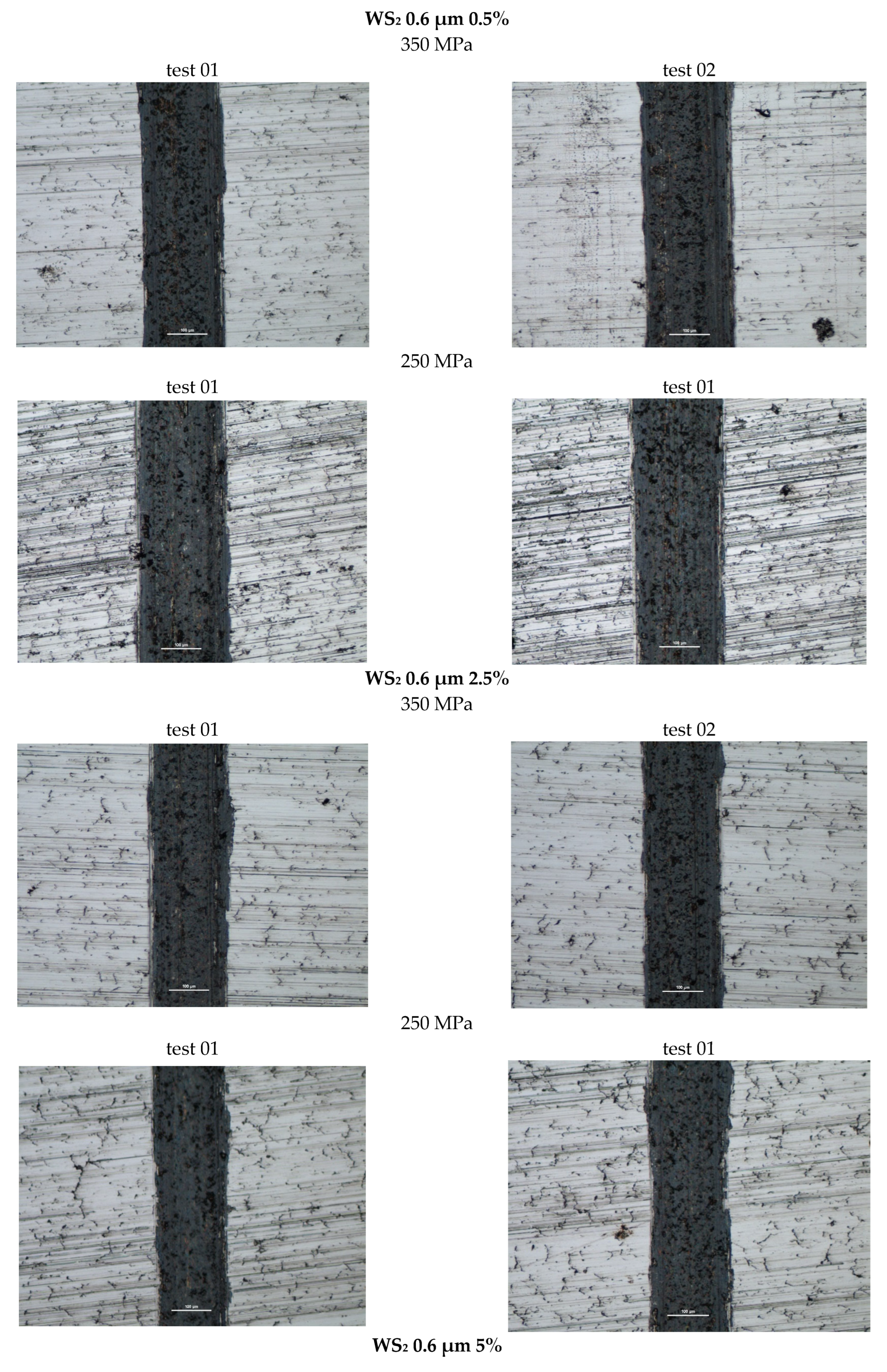

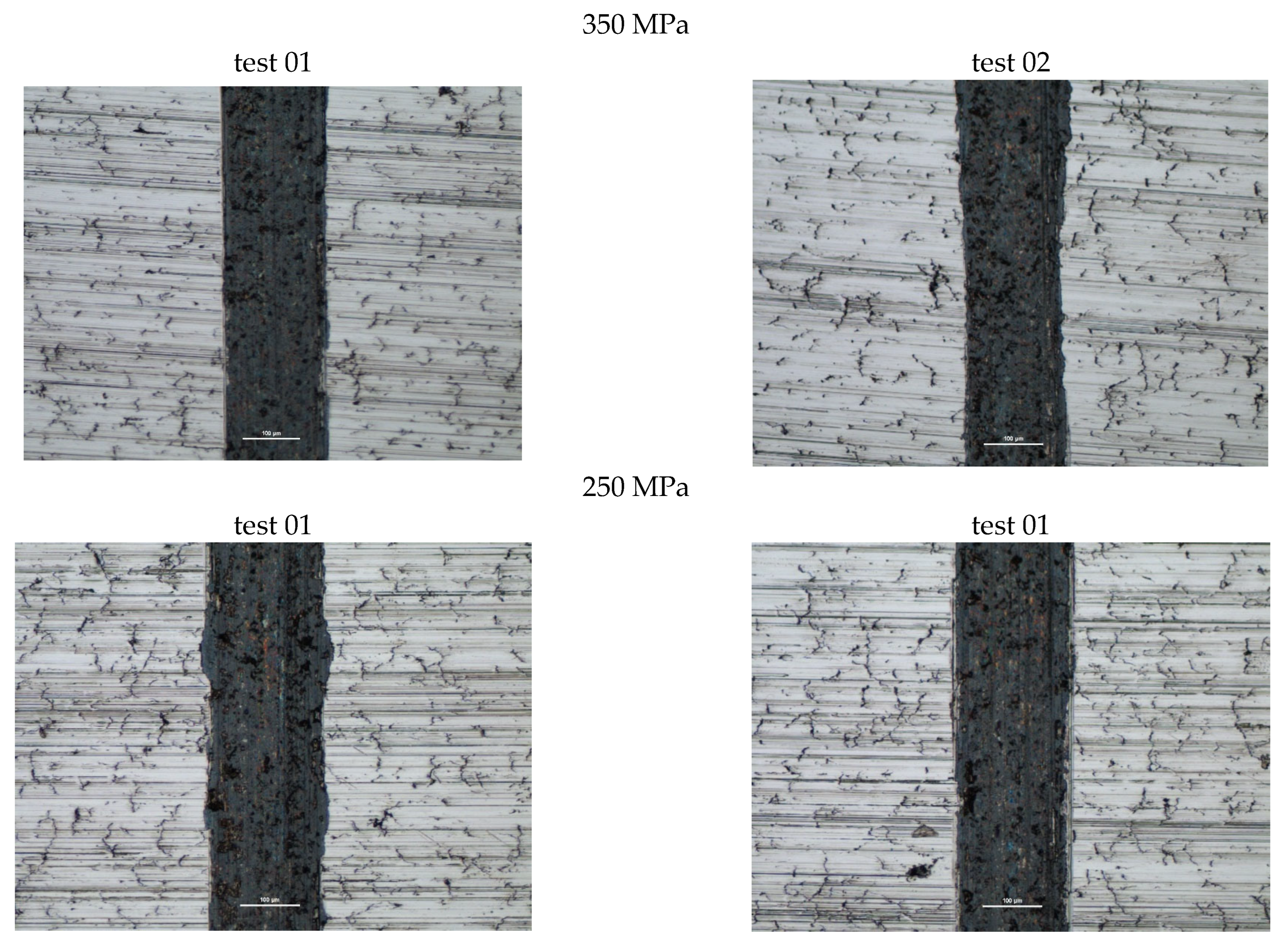

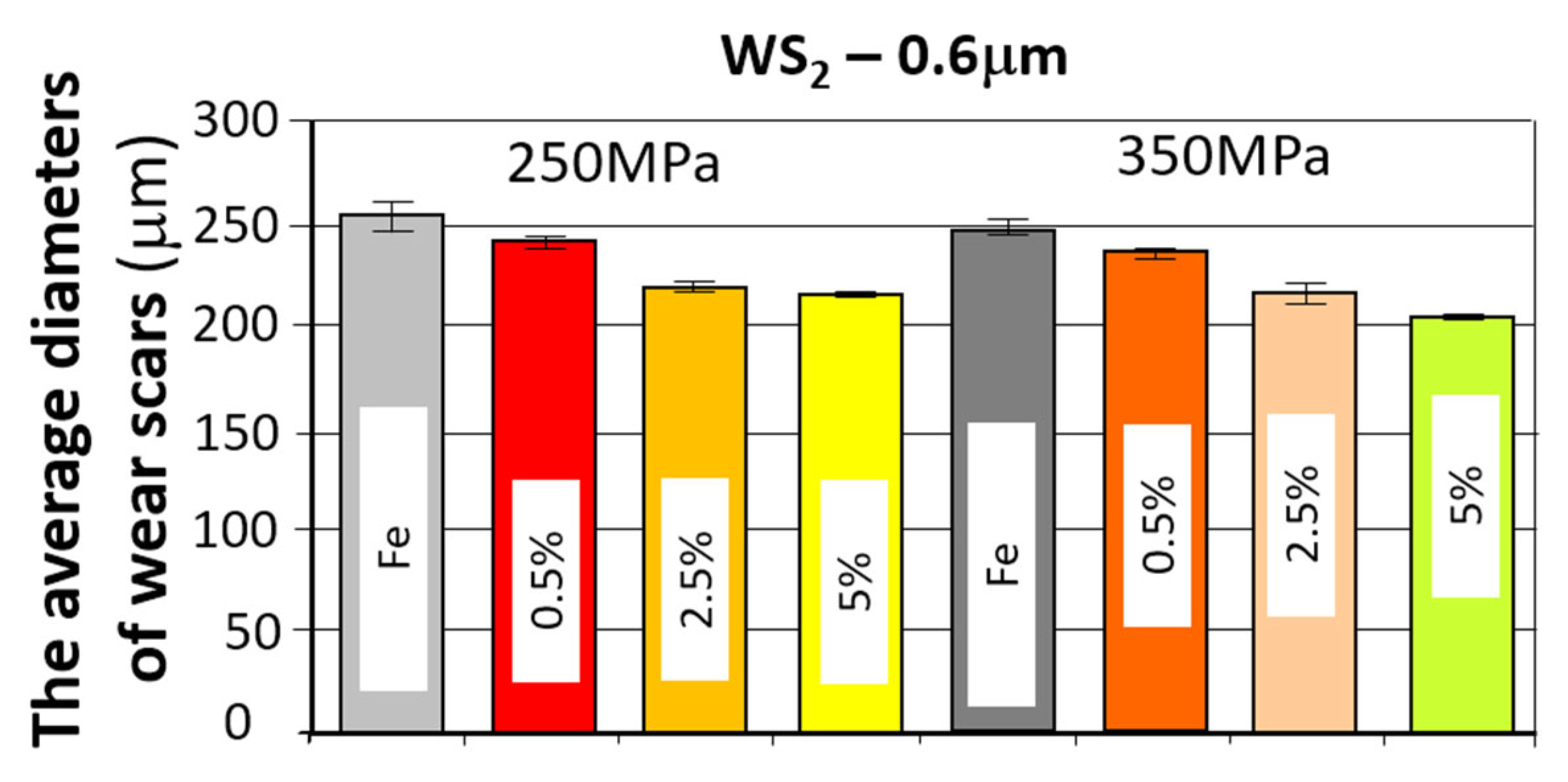

3.3.2. Samples with Added WS2

- Evaluation of the change in friction coefficient and wear marks for sintered steel samples in which 0.6 µm WS2 was used as a lubricant additive in amounts of 0.5%, 2.5%, and 5% by weight.

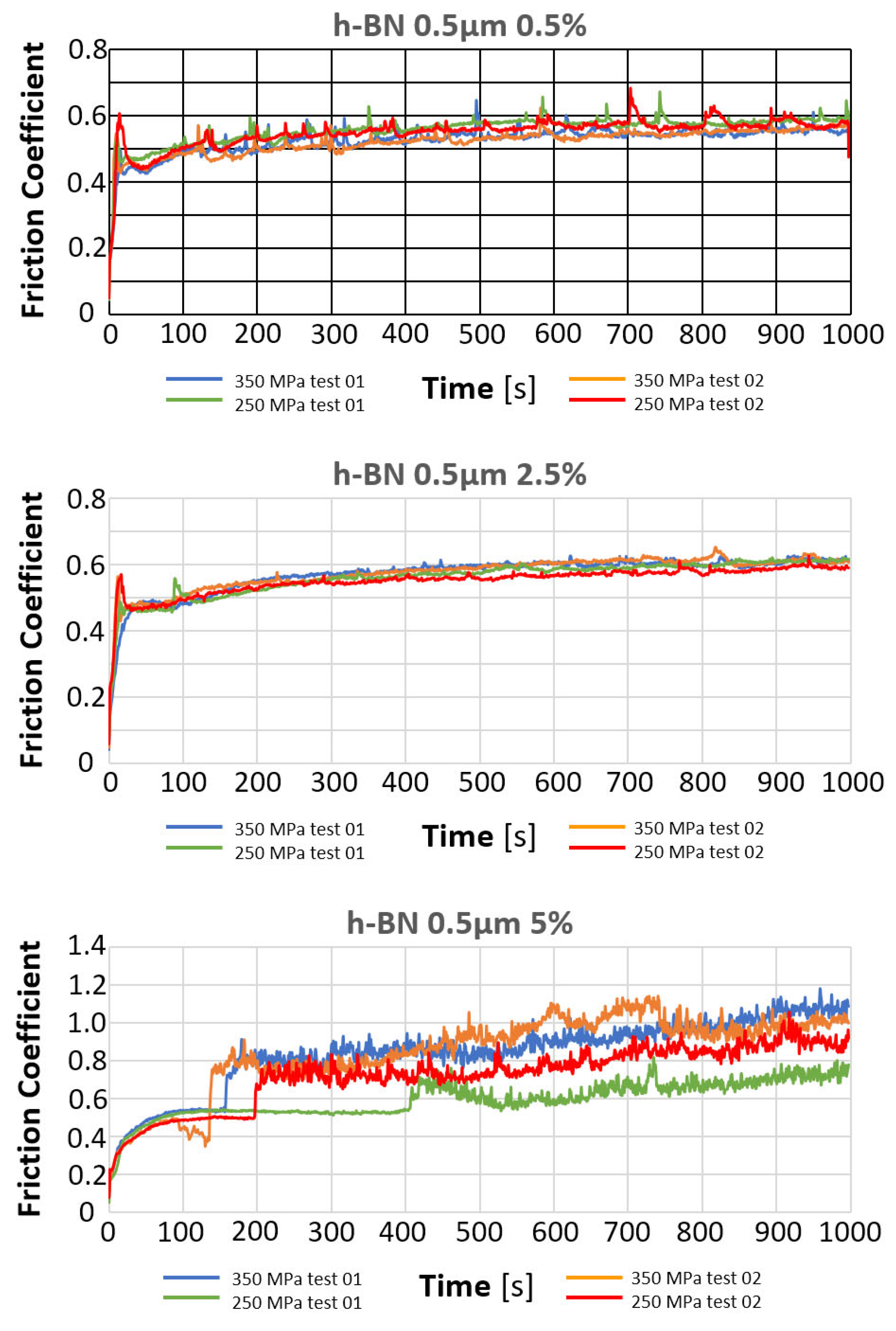

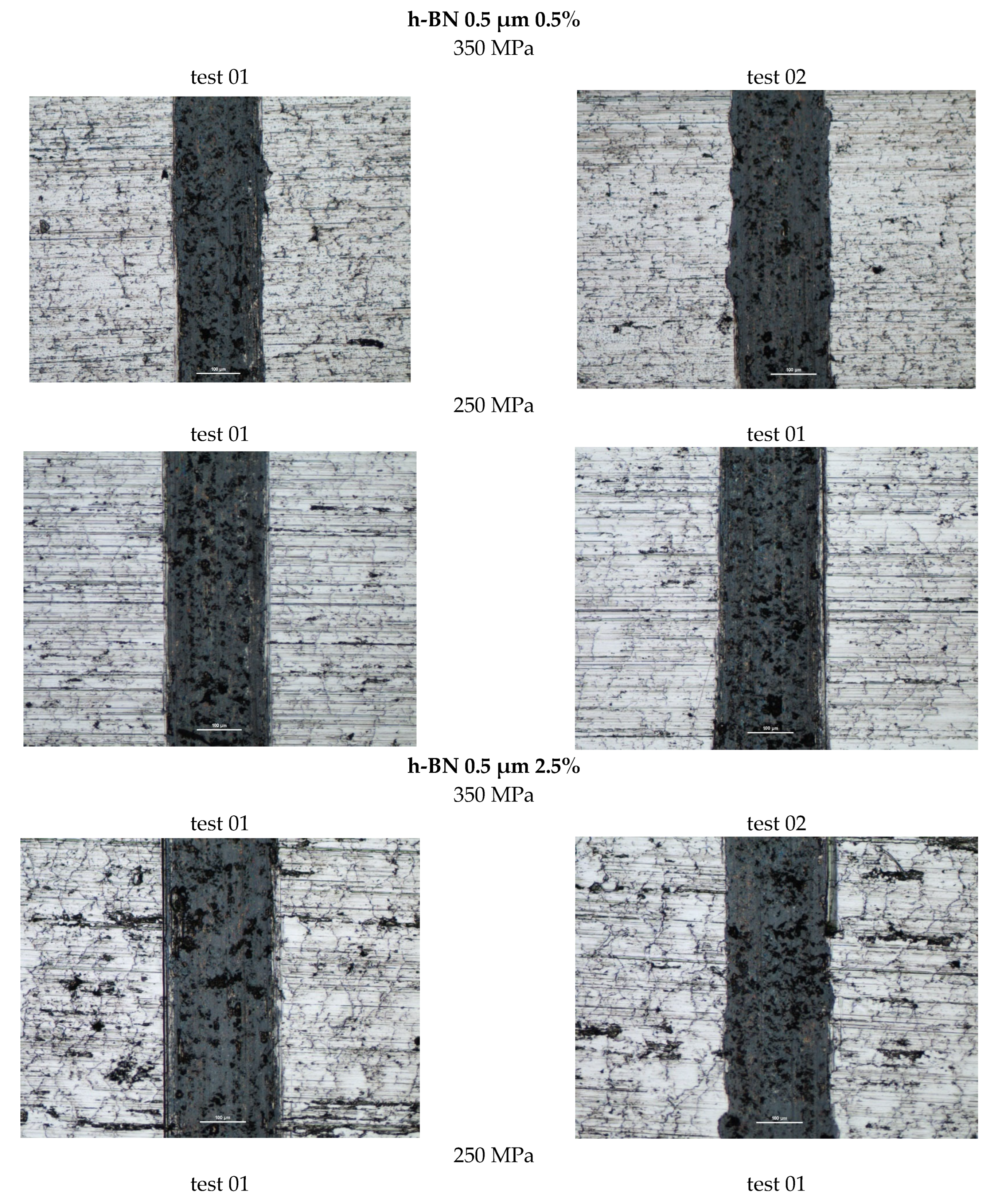

3.3.3. Samples with h-BN 0.5 μm Added

- Evaluation of the change in friction coefficient and wear marks for sintered steel samples in which h-BN 0.5 µm was used as a lubricant in amounts of 0.5%, 2.5%, and 5% by weight.

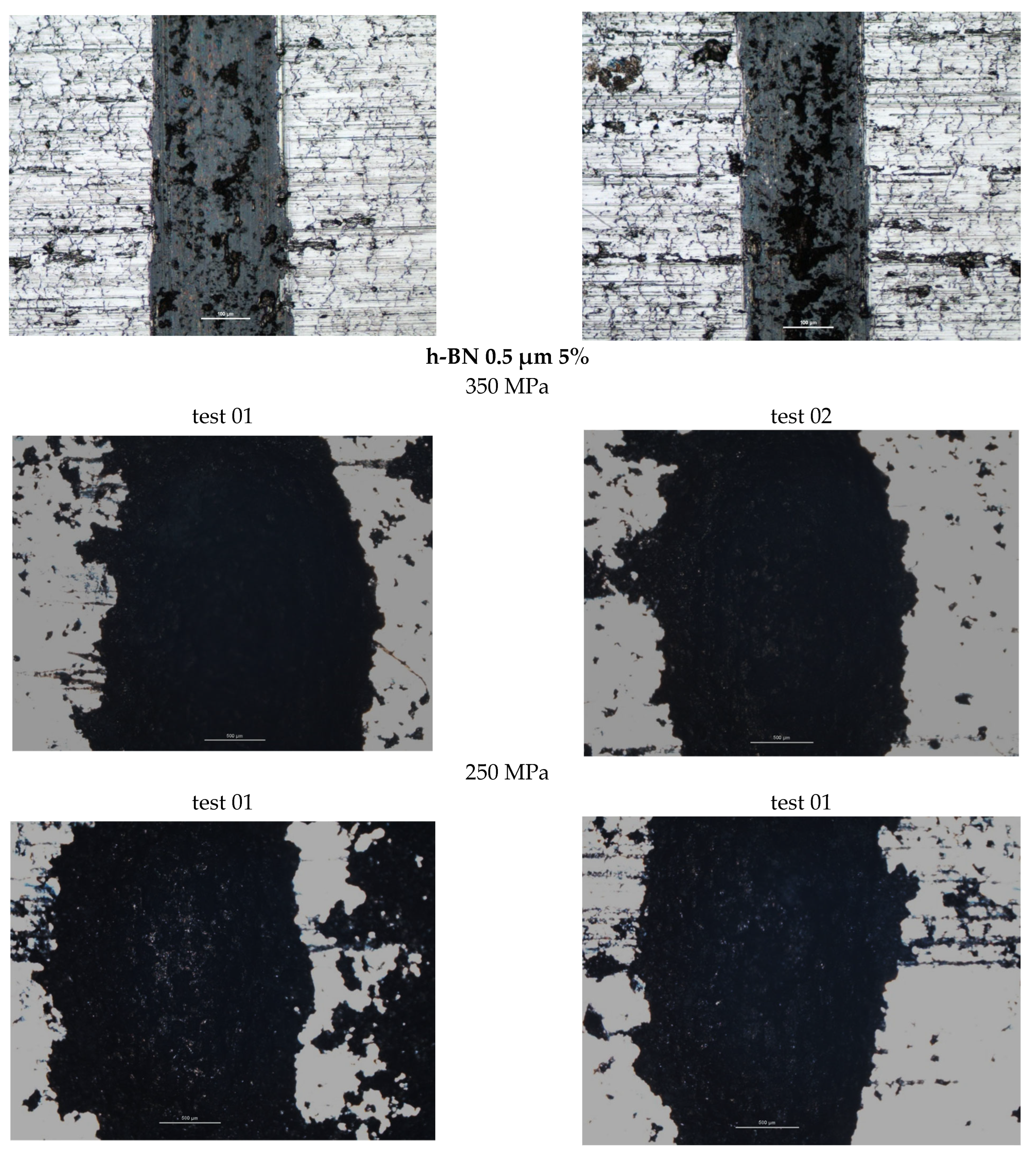

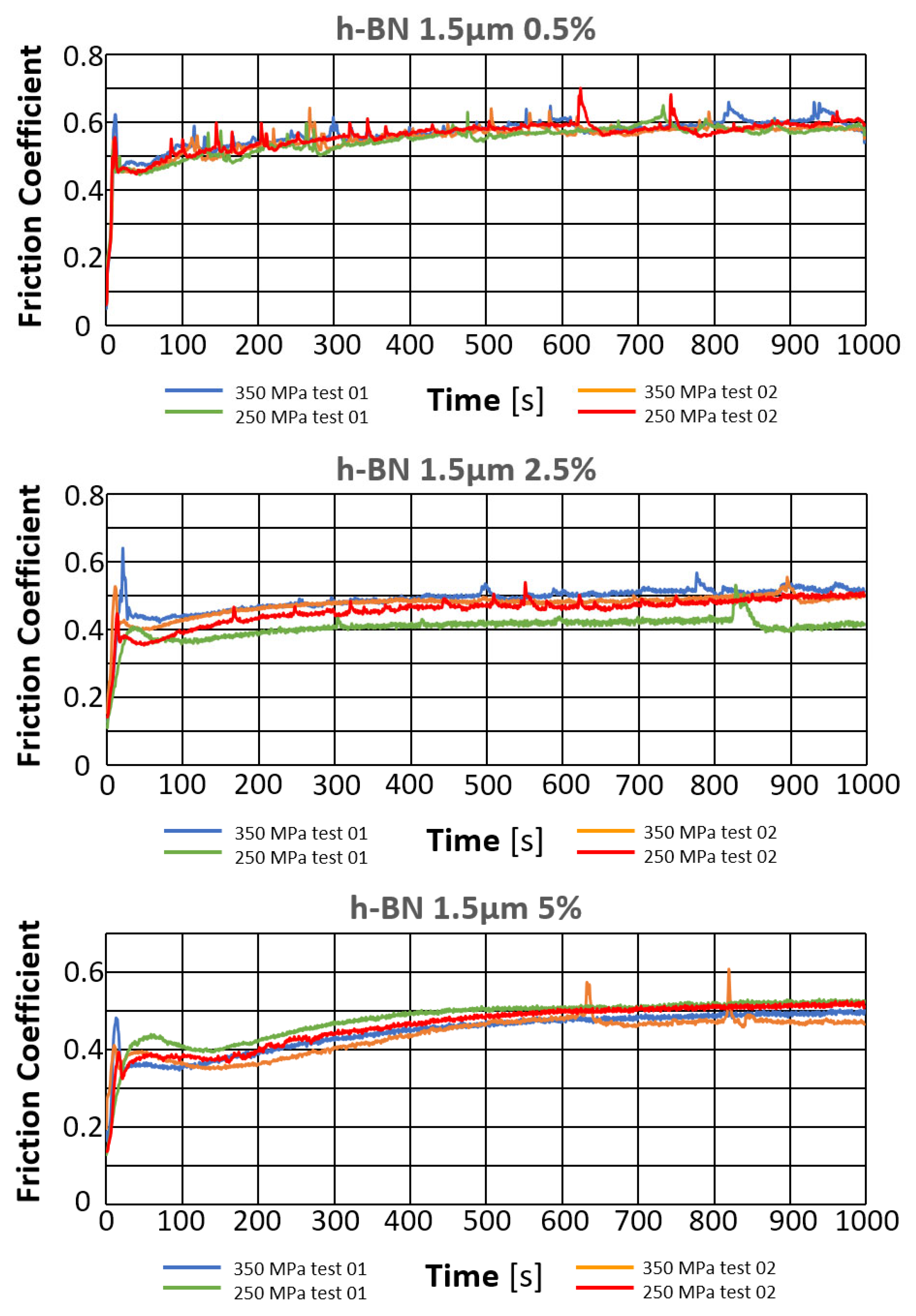

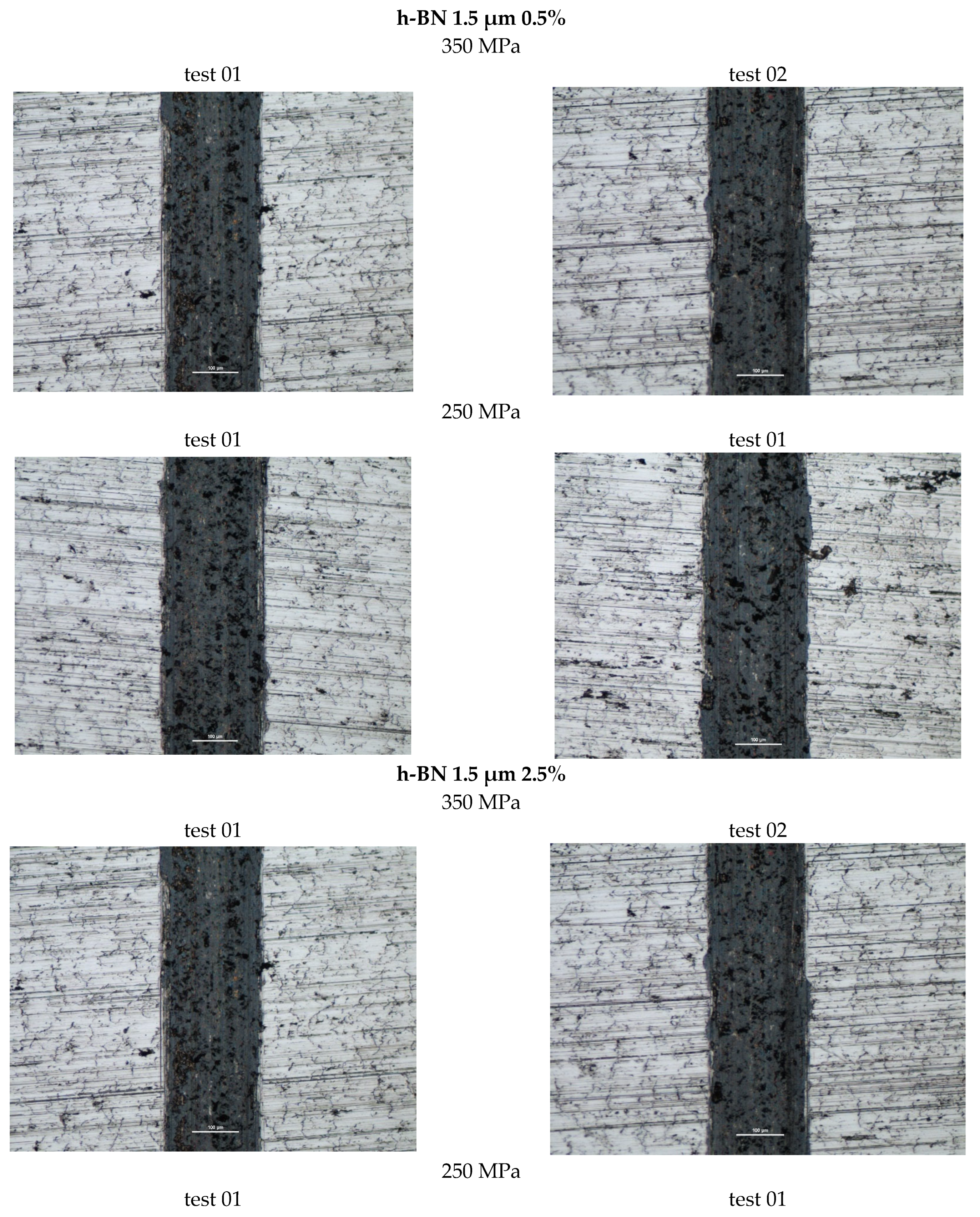

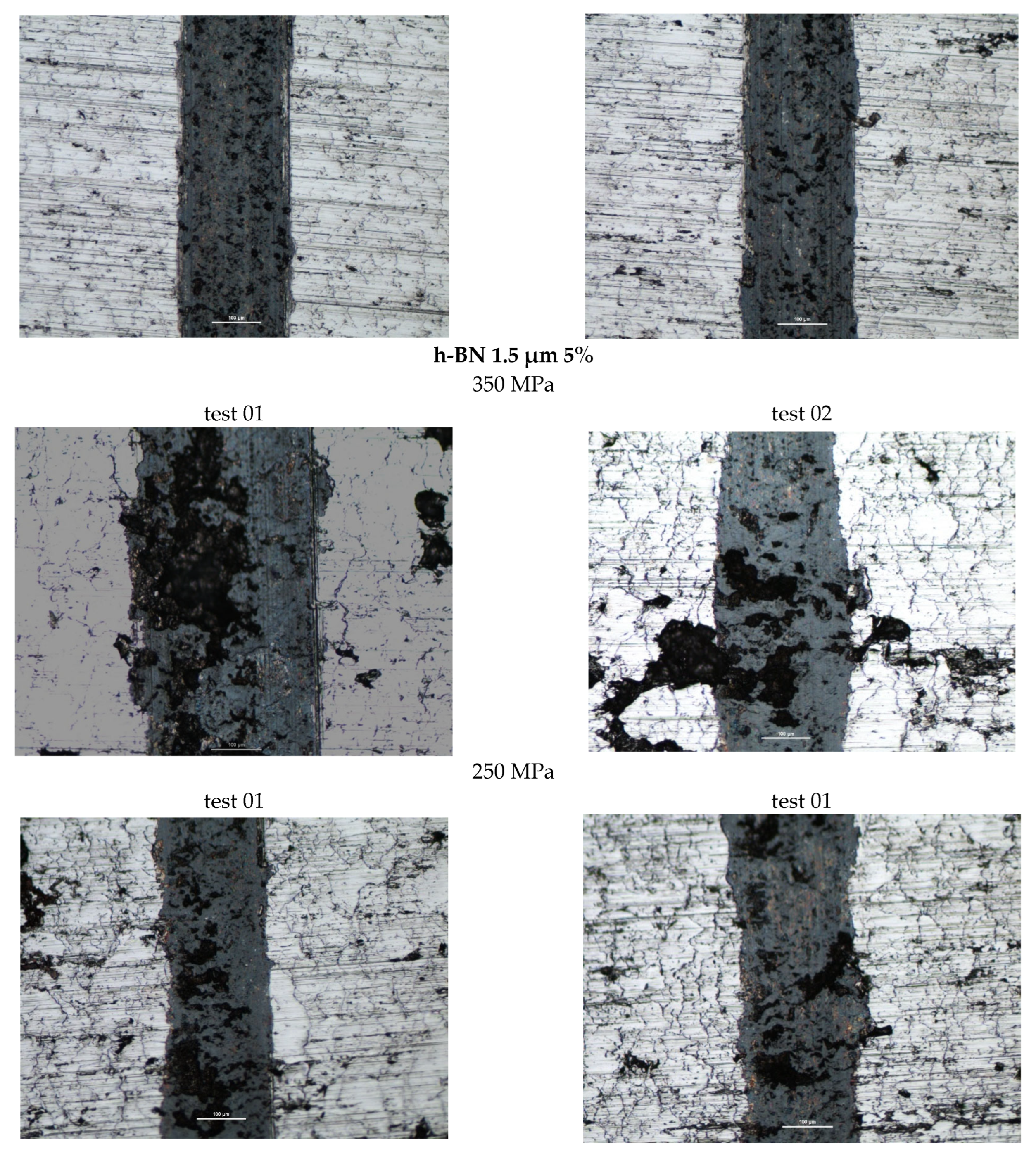

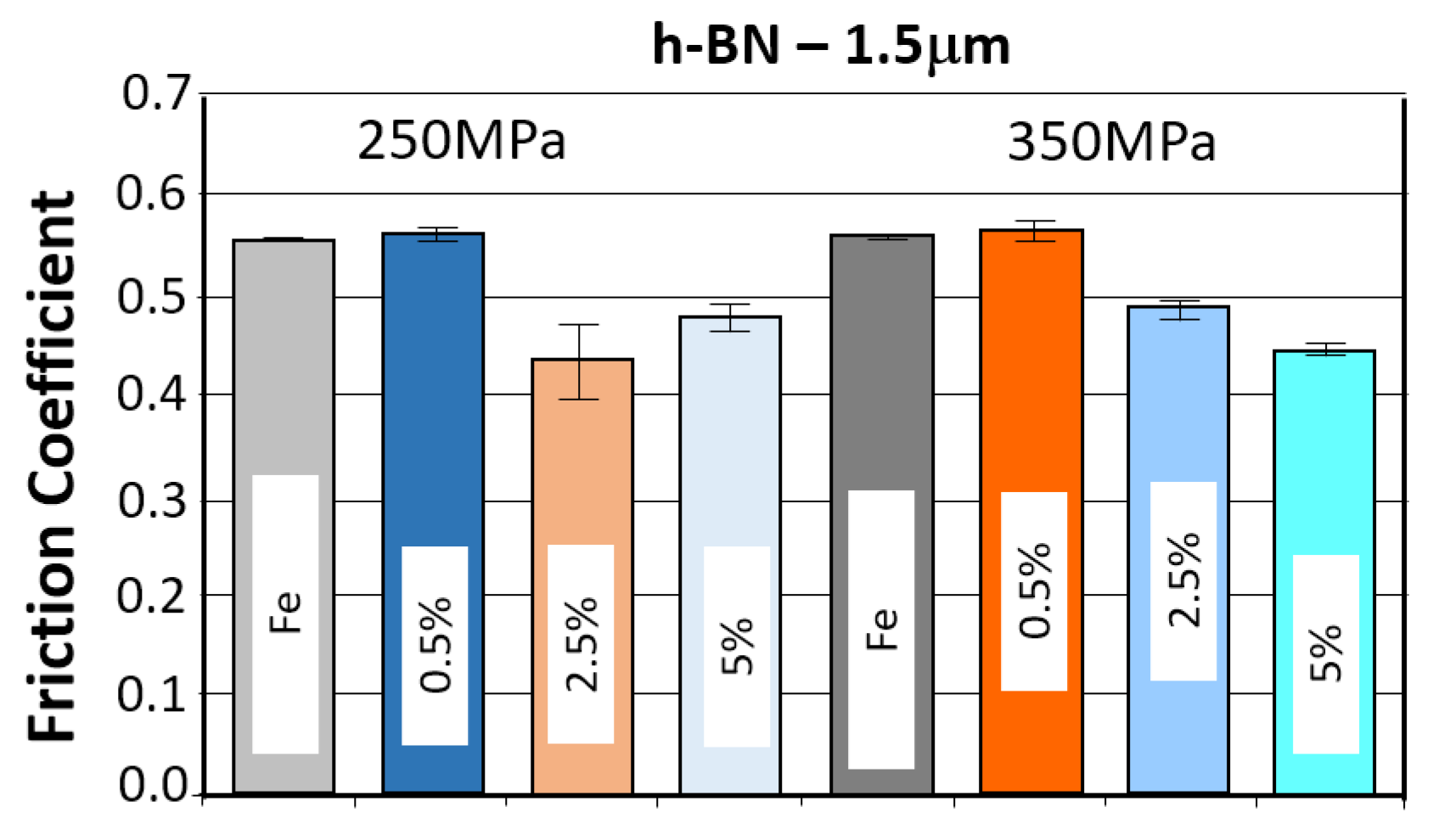

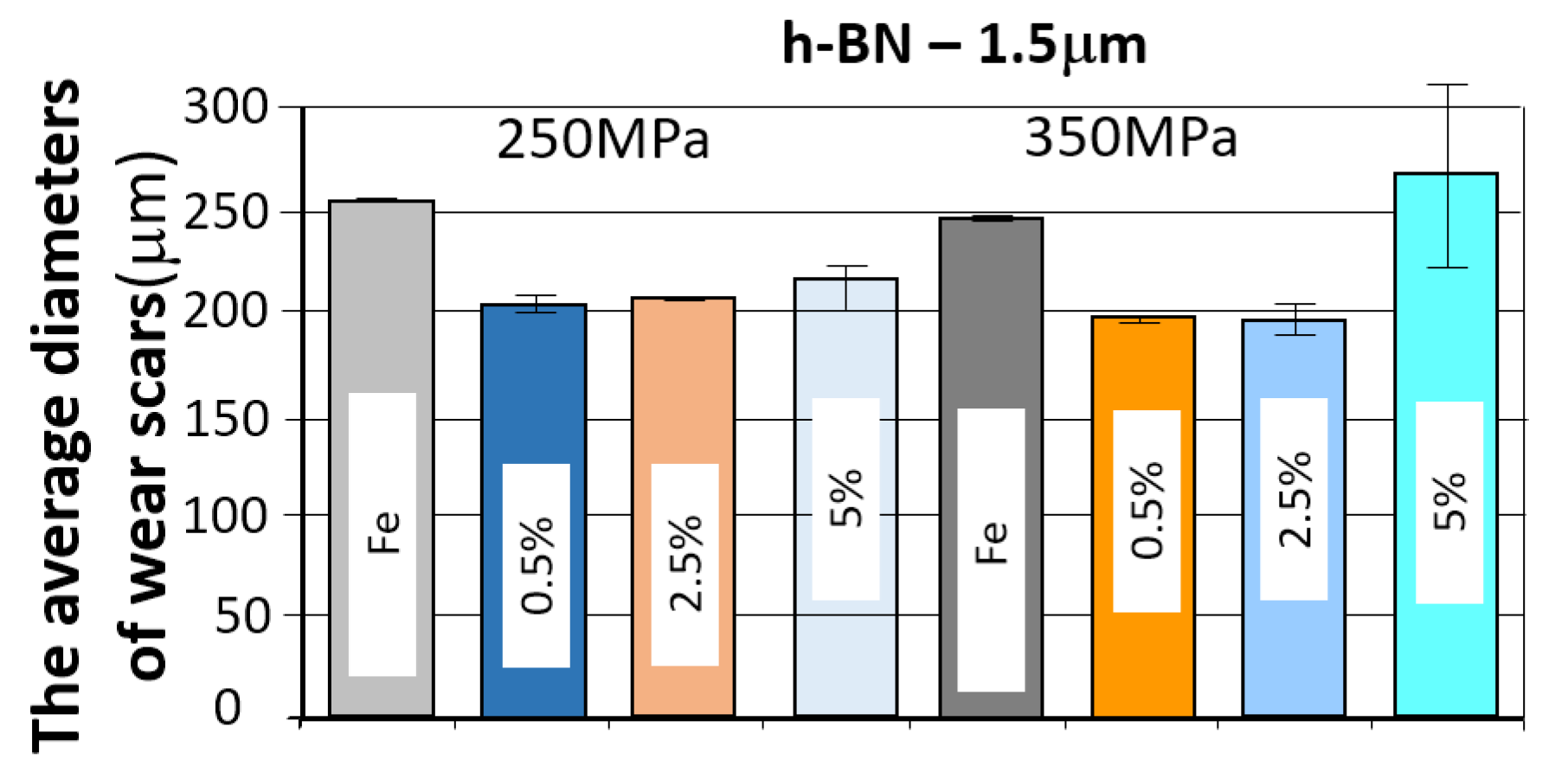

3.3.4. Samples with h-BN 1.5 μm Added

- Evaluation of the change in friction coefficient and wear marks for sintered steel samples in which h-BN 1.5 µm was used as a lubricant additive in amounts of 0.5%, 2.5%, and 5% by weight.

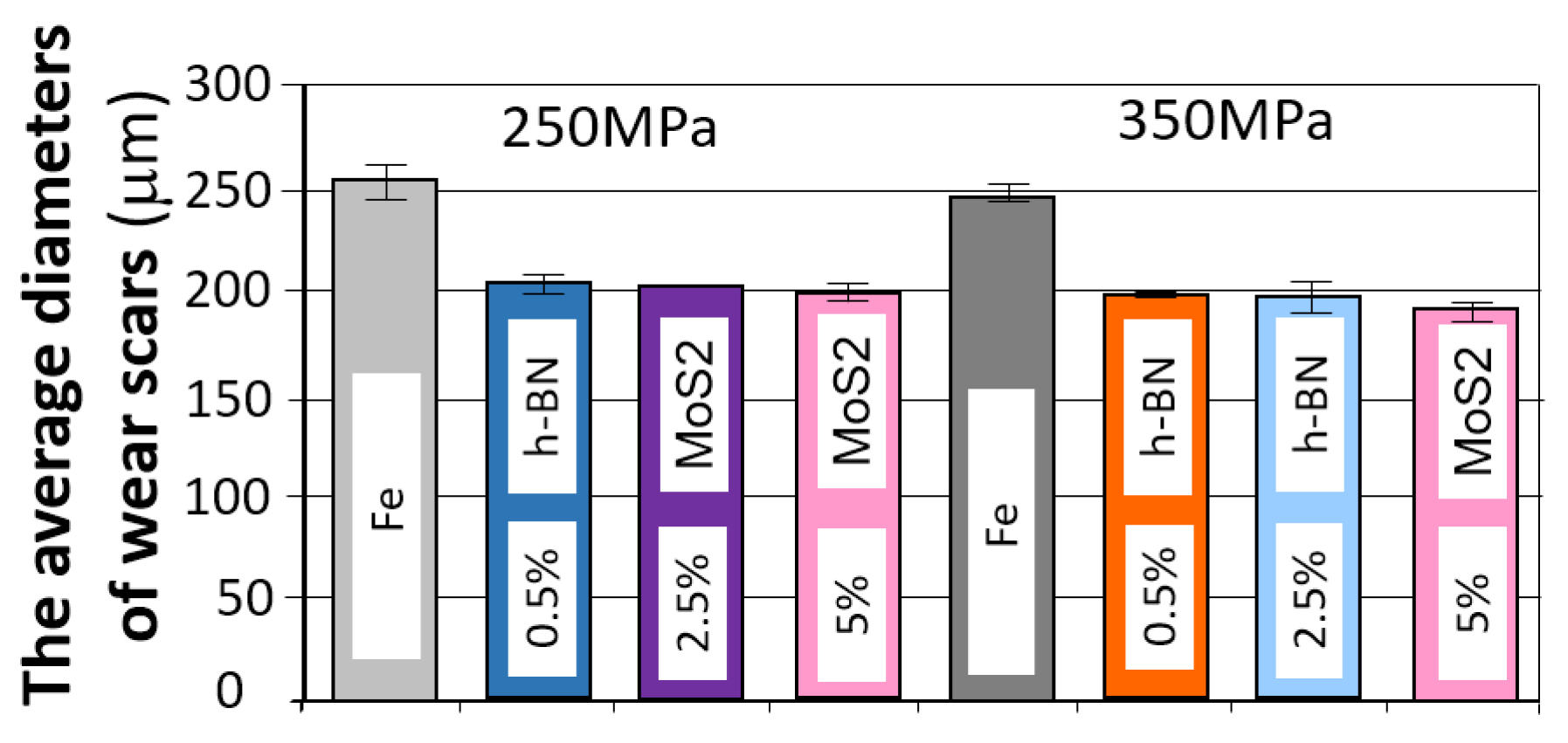

3.3.5. Comparison of the Results of the Tribological Test

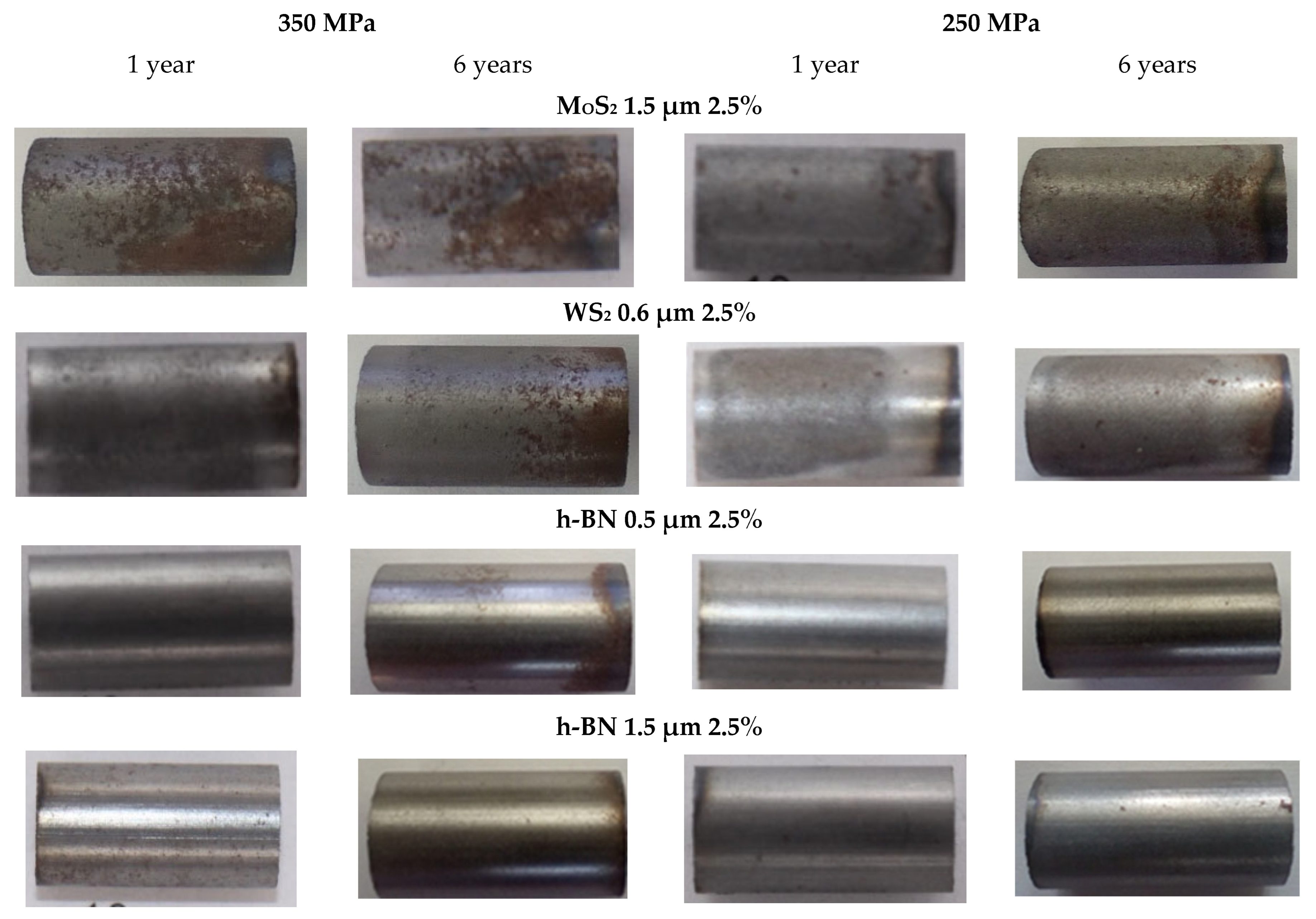

3.4. Assessment of the Appearance of Samples After Storage

4. Conclusions

- Hardness tests indicated that samples containing MoS2 and WS2 exhibited an increase in hardness with the addition of more layers and higher compaction pressure, reaching values up to 100% higher than samples containing only Fe, sintered and compacted at 350 MPa. In contrast, samples with h-BN showed a decrease in hardness of up to 50% as the amount of added h-BN increased, compared to pure Fe samples, regardless of grain size and compaction pressure.

- Based on the evaluation of samples stored for six years under the same conditions, it can be concluded that samples containing h-BN are significantly better suited for storage; even after the entire storage period, they showed only traces of corrosion. Samples containing WS2, or even more so, MoS2, displayed clear signs of corrosion after just a few days, which worsened over time.

- Self-lubricating materials for sintered bearings made from iron powder containing h-BN are highly suitable for storage, even though they have slightly lower hardness and a marginally higher coefficient of friction compared to other materials. However, materials with MoS2 or WS2 are not ideal for storage unless they are given additional corrosion protection.

- The results showed that increasing the amount of lubricant additives (for WS2 and MoS2) led to higher hardness, lower porosity, and a reduced coefficient of friction. The decrease in porosity may be because the added lubricants act similarly to Kenolube, reducing friction between powder particles during compaction.

- In the case of boron nitride (h-BN), these relationships are less clear, as increasing the amount of lubricant additives can lead to a decrease in hardness and, in some cases, to an increase in the coefficient of friction.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Betz, U.A.K.; Arora, L.; Assal, R.A.; Yang, J.Y.C.; Zhao, G. Game changers in science and technology—Now and beyond. Technol. Forecast. Soc. Change 2023, 193, 122588. [Google Scholar] [CrossRef]

- Holomberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Rizwan, H.M.; Cheema, T.A.; Karim, M.R.A.; Rehman, M.M.U.; Park, C.W. Experimental thermal performance intensification of gravitational water vortex heat exchanger using hexagonal boron nitride-water nanofluid. Appl. Therm. Eng. 2024, 254, 123834. [Google Scholar] [CrossRef]

- Kong, Y.C.; Dong, J.W.; Liu, Z.; Cheng, Z.L. In situ study of structure–activity relationship between structure and tribological properties of bulk layered materials by four-ball friction tester. ACS Omega 2020, 5, 14212–14220. [Google Scholar] [CrossRef]

- Pawlak, Z.; Kałdoński, T.; Lisewski, M.; Urbaniak, W.; Oloyede, A. The effect of hexagonal boron nitride additive on the effectiveness of grease-based lubrication of a steel surface. Ind. Lubr. Tribol. 2012, 64, 84–89. [Google Scholar] [CrossRef]

- Ali, S.; Ismail, P.M.; Humayun, M.; Bououdina, M. Hexagonal boron nitride: From fundamentals to applications. Desalination 2025, 599, 118442. [Google Scholar] [CrossRef]

- Chkhartishvili, L.; Tabatadze, G.; Nackebia, D.; Bzhalava, T.; Kalandadze, I. Hexagonal Boron nitride as a solid lubricant additive (An overview). Nano Stud. 2016, 14, 91–98. [Google Scholar]

- Ramteke, S.; Chelladurai, H. Examining the role of hexagonal boron nitride nanoparticles as an additive in the lubricating oil and studying its application. Proc. Inst. Mech. Eng. Part N 2020, 234, 19–36. [Google Scholar] [CrossRef]

- Bin Abdollah, M.F.; Amiruddin, H.; Alif Azmi, M.; Mat Tahir, N.A. Lubrication mechanisms of hexagonal boron nitride nano-additives water-based lubricant for steel–steel contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 1038–1046. [Google Scholar] [CrossRef]

- Vadiraj, A.; Kamraj, M.; Sreenivasan, V. Wear and friction behavior of alloyed gray cast iron with solid lubricants under boundary lubrication. Tribol. Int. 2011, 44, 48–56. [Google Scholar] [CrossRef]

- Maharaj, D.; Bhusahan, B. Effect of MoS2 and WS2 Nanotubes on Nanofriction and Wear Reduction in Dry and Liquid Environments. Tribol. Lett. 2013, 49, 323–339. [Google Scholar] [CrossRef]

- Charoo, M.S.; Hanief, M. Improving the tribological characteristics of a lubricating oil by nano sized additives. Mater. Today Proc. 2020, 28, 1205–1209. [Google Scholar] [CrossRef]

- Urbaniak, W.; Majewski, T.; Powązka, I.; Śmigielski, G.; Petelska, A.D. Study of Nano h-BN Impact on Lubricating Properties of Selected Oil Mixtures. Materials 2022, 15, 2052. [Google Scholar] [CrossRef]

- Senyk, S.; Gocman, K.; Wachowski, M.; Kałdoński, T. Role of Base Grease Type on the Lubrication Performance of Hexagonal Boron Nitride Nanoparticles and Microparticles. Materials 2025, 18, 2196. [Google Scholar] [CrossRef]

- Gachechiladze, A.; Tsagareishvili, O.; Margiev, B.; Rukhadze, L.; Darchiashvili, M.; Chkhartishvili, L. Nanopowdered h-BN as a wear-reducing eco-friendly material. In Handbook of Ecomaterials; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Gupta, A.; Sharma, S.M.; Anand, A.; Ul Haq, M.I.; Raina, A.; Kumar, R.; Singh, A.; Jayalakshmi, S.; Kamal, M. Tribological behaviour of Fe–C–Ni self-lubricating composites with WS2 solid lubricant. Mater. Res. Express 2019, 6, 126507. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of Nanoparticles in Lubricating Oil: A Critical Review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Cheng, Y.; Bu, Y.; Guan, P.; Yang, Y.; Qing, J. Tribological properties of hexagonal boron nitride nanoparticles as a lubricating grease additive. Lubr. Sci. 2023, 356, 449–458. [Google Scholar] [CrossRef]

- Senyk, S.; Chodkiewicz, A.; Gocman, K.; Szczęśniak, B.; Kałdoński, T. Hexagonal Nano and Micro Boron Nitride: Properties and Lubrication Applications. Materials 2022, 15, 955. [Google Scholar] [CrossRef]

- Gocman, K.; Kałdoński, T.; Giemza, B.; Król, A. Permeability and Load Capacity of Iron Porous Bearings with the Addition of Hexagonal Boron Nitride. Materials 2022, 15, 5112. [Google Scholar] [CrossRef]

- Spalvins, T. A review of recent advances in solid film lubrication. J. Vac. Sci. Technol. 1987, 5, 212–219. [Google Scholar] [CrossRef]

- Israelachvili, J.N. Intermolecular and Surface Forces, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar] [CrossRef]

- Urbaniak, W.; Kaldonski, T.; Hagner-Derengowska, M.; Madhani, J.T.; Kruszewski, Z.; Pawlak, Z. Impregnated porous bearings textured with a pocket on sliding surfaces: Comparison of h-boron nitride with graphite and molybdenum disulphide up to 150 °C. Meccanica 2015, 50, 1343–1349. [Google Scholar] [CrossRef]

- Rabaso, P.; Dassenoy, F.; Ville, F.; Diaby, M.; Vacher, B.; Le Mogne, T.; Beli, M.; Cavoret, J. An investigation on the reduced ability of IF-MoS2 nanoparticles to reduce friction and wear in the presence of dispersants. Tribol. Lett. 2014, 55, 503–516. [Google Scholar] [CrossRef]

- Rabaso, P.; Ville, F.; Dassenoy, F.; Diaby, M.; Afanasiev, P.; Cavoret, J.; Vacher, B.; Le Mogne, T. Boundary lubrication: Influence of the size and structure of inorganic fullerene-like MoS2 nanoparticles on friction and wear reduction. Wear 2014, 320, 161–178. [Google Scholar] [CrossRef]

- Shahnazar, S.; Bagheri, S.; Hamid, S.B.A. Enhancing lubricant properties by nanoparticle additives. Int. J. Hydrogen Energy 2016, 41, 3153–3170. [Google Scholar] [CrossRef]

- Chodkiewicz, A.; Kałdoński, T. Effect of Hexagonal Boron Nitride with Different Particle Granulation on the Lubrication Properties of Mineral Oil with an Addition of Surfactants. Tribologia 2023, 2, 7–16. [Google Scholar] [CrossRef]

- Kałdoński, T. Tribologiczne Zastosowania Azotku Boru [Tribological Applications of Boron Nitride], 2nd ed.; MUT: Warsaw, Poland, 2013. (In Polish) [Google Scholar]

- Urbaniak, W.; Kaldonski, T.; Kaldonski, T.J.; Pawlak, Z. Hexagonal boron nitride as a component of the iron porous bearing: Friction on the porous sinters up to 150 °C. Meccanica 2016, 51, 1157–1165. [Google Scholar] [CrossRef]

- Urbaniak, W.; Majewski, T.; Wozniak, R.; Sienkiewicz, J.; Kubik, J.; Petelska, A.D. Research on the Influence of the Manufacturing Process Conditions of Iron Sintered with the Addition of Layered Lubricating Materials on its Selected Properties. Materials 2020, 13, 4782. [Google Scholar] [CrossRef]

- Dhanasekaran, S.; Gnanamoorthy, R. Abrasive wear behavior of sintered steels prepared with MoS2 addition. Wear 2007, 262, 617–623. [Google Scholar] [CrossRef]

- Mahathanabodee, S.; Palathai, T.; Raadnui, S.; Tongsri, R.; Sombatsompop, N. Effect of h-BN Content on the Sintering of SS316L/h-BN Composites. Adv. Mater. Res. 2012, 410, 216–219. [Google Scholar] [CrossRef]

- Majewski, T.; Gniadek, M.; Mrela, A.; Petelska, A.D.; Urbaniak, W. Effect of the Nanoparticles h-BN on Improving the Tribological Properties of Biodegradable Vegetable Oils. Coatings 2024, 14, 1517. [Google Scholar] [CrossRef]

- Xiao, J.; Wu, Y.; Zhang, W.; Chen, J.; Zhang, C. Friction of metal-matrix self-lubricating composites: Relationships among lubricant content, lubricating film coverage, and friction coefficient. Friction 2020, 8, 517–530. [Google Scholar] [CrossRef]

- Manu, B.R.; Gupta, A.; Jayatissa, A.H. Tribological Properties of 2D Materials and Composites—A Review of Recent Advances. Materials 2021, 14, 1630. [Google Scholar] [CrossRef]

- Khare, H.S. The Effects of Environmental Water and Oxygen on the Temperature-Dependent Friction of Sputtered Molybdenum Disulfide. Tribol. Lett. 2013, 52, 485–493. [Google Scholar]

- Urbaniak, W. Smarowanie Powierzchni Biologicznych i Inżynieryjnych Występujących w Strukturze Warstwowej; UKW: Bydgoszcz, Poland, 2015. (In Polish) [Google Scholar]

- Miura, K.; Kamiya, S. Observation of the Amontons-Coulomb law on the nanoscale: Frictional forces between MoS2 flakes and MoS2 surfaces. Europhys. Lett. 2002, 58, 610–615. [Google Scholar] [CrossRef]

- Mańkowska, A.; Piekoszowski, W.; Szczerek, M. The investigation of the friction and wear of antiwear coatings in a vacuum. Tribologia 2009, 3, 125–138. (In Polish) [Google Scholar]

| Approx. Particle Size Range [µm] | Apparent Density [g/cm3] | Flow [s/50 g] | H2-Loss [%] | C [%] | Green Density [g/cm3] |

|---|---|---|---|---|---|

| 45–150 | 2.45 | 32 | 0.14 | <0.01 | 7.1 |

| Sample No. | Type of Sinter | Additive Content (% Mass) | Pressing Pressure (MPa) | |||

|---|---|---|---|---|---|---|

| 250 MPa | 350 MPa | |||||

| Density (g/cm3) | Porosity (%) | Density (g/cm3) | Porosity (%) | |||

| 1. | Fe | 0 | 5.82 ± 4% | 26.1 ± 4% | 6.35 ± 2% | 19.3 ± 2% |

| 2. | Fe + h-BN 0.5 μm | 0.5 | 5.93 ± 3% | 23.7 ± 3% | 6.34 ± 4% | 18.5 ± 4% |

| 3. | Fe + h-BN 1.5 μm | 0.5 | 5.92 ± 2% | 23.9 ± 2% | 6.34 ± 5% | |

| 4. | Fe + MoS2 1.5 μm | 0.5 | 5.79 ± 4% | 26.2 ± 4% | 6.37 ± 6% | 18.9 ± 6% |

| 5. | Fe + WS2 0.6 μm | 0.5 | 6.39 ± 5% | 18.8 ± 5% | ||

| 6. | Fe + h-BN 0.5 μm | 2.5 | 5.78 ± 1% | 22.2 ± 1% | 6.13 ± 2% | 17.4 ± 2% |

| 7. | Fe + h-BN 1.5 μm | 2.5 | 5.77 ± 5% | 22.2 ± 5% | 6.15 ± 3% | 17.1 ± 3% |

| 8. | Fe + MoS2 1.5 μm | 2.5 | 5.74 ± 3% | 26.1 ± 3% | 6.36 ± 6% | 18.1 ± 6% |

| 9. | Fe + WS2 0.6 μm | 2.5 | 5.99 ± 6% | 23.8 ± 6% | 6.52 ± 5% | 17.1 ± 5% |

| 10. | Fe + h-BN 0.5 μm | 5 | 5.59 ± 3% | 20.4 ± 3% | 5.84 ± 2% | 16.8 ± 2% |

| 11. | Fe + h-BN 1.5 μm | 5 | 5.56 ± 3% | 20.8 ± 3% | 5.86 ± 1% | 16.5 ± 1% |

| 12. | Fe + MoS2 1.5 μm | 5 | 5.69 ± 5% | 25.7 ± 5% | 6.30 ± 4% | 17.8 ± 4% |

| 13. | Fe + WS2 0.6 μm | 5 | 6.00 ± 3% | 23.5 ± 3% | 6.51 ± 3% | 17.1 ± 3% |

| Sample No. | Type of Sinter | Additive Content (% Mass) | Hardness HB HB2./62.5/15 | |

|---|---|---|---|---|

| 250 MPa | 350 MPa | |||

| 1. | Fe | 0 | 32.4 ± 6% | 41.3 ± 4% |

| 2. | Fe + MoS2 1.5 μm | 0.5 | 46.5 ± 6% | 51.7 ± 4% |

| 3. | Fe + WS2 0.6 μm | 0.5 | 41.5 ± 5% | 45.4 ± 5% |

| 4. | Fe + h-BN 0.5 μm | 0.5 | 36.4 ± 8% | 43.1 ± 6% |

| 5. | Fe + h-BN 1.5 μm | 0.5 | 32.7 ± 7% | 41.3 ± 8% |

| 6. | Fe + MoS2 1.5 μm | 2.5 | 51.5 ± 5% | 73.4 ± 4% |

| 7. | Fe + WS2 0.6 μm | 2.5 | 48.8 ± 3% | 72.0 ± 4% |

| 8. | Fe + h-BN 0.5 μm | 2.5 | 26.1 ± 9% | 29.3 ± 8% |

| 9. | Fe + h-BN 1.5 μm | 2.5 | 30.6 ± 8% | 31.0 ± 6% |

| 10. | Fe + MoS2 1.5 μm | 5 | 73.3 ± 3% | 94.6 ± 4% |

| 11. | Fe + WS2 0.6 μm | 5 | 69.1 ± 5% | 77.6 ± 6% |

| 12. | Fe + h-BN 0.5 μm | 5 | 13.2 ± 9% | 15.9 ± 7% |

| 13. | Fe + h-BN 1.5 μm | 5 | 19.4 ± 7% | 19.7 ± 8% |

| Sample | Friction Coefficient Values | Mean Values | Abrasion Trace Width [µm] | Mean Values [µm] | ||

|---|---|---|---|---|---|---|

| Test 01 | Test 02 | Test 01 | Test 02 | |||

| Fe (350 MPa) | 0.559 | 0.555 | 0.557 ± 0.5% | 244 | 250 | 247 ± 1.7% |

| Fe (250 MPa) | 0.550 | 0.549 | 0.550 ± 0.1% | 259 | 247 | 253 ± 3.4% |

| Sample | Friction Coefficient Values | Mean Value | Abrasion Trace Width [µm] | Mean Value [µm] | ||

|---|---|---|---|---|---|---|

| Test 01 | Test 02 | Test 01 | Test 02 | |||

| MOS2 1.5 µm 0.5% (350 MPa) | 0.487 | 0.472 | 0.480 ± 2.2% | 222 | 229 | 226 ± 2.2% |

| MOS2 1.5 µm 0.5% (250 MPa) | 0.472 | 0.463 | 0.468 ± 1.4% | 237 | 236 | 237 ± 0.3% |

| MOS2 1.5 µm 2.5% (350 MPa) | 0.474 | 0.453 | 0.464 ± 3.2% | 195 | 195 | 195 ± 0% |

| MOS2 1.5 µm 2.5% (250 MPa) | 0.431 | 0.428 | 0.430 ± 0.5% | 200 | 201 | 201 ± 0.4% |

| MOS2 1.5 µm 5% (350 MPa) | 0.434 | 0.440 | 0.437 ± 1% | 187 | 192 | 190 ± 1.9% |

| MOS2 1.5 µm 5% (250 MPa) | 0.436 | 0.445 | 0.441 ± 1.4% | 193 | 198 | 196 ± 1.8% |

| Sample | Friction Coefficient Values | Mean Values | Abrasion Trace Width [µm] | Mean Values [µm] | ||

|---|---|---|---|---|---|---|

| Test 01 | Test 02 | Test 01 | Test 02 | |||

| WS2 0.6 µm 0.5% (350 MPa) | 0.486 | 0.468 | 0.477 ± 2.7% | 234 | 236 | 235 ± 0.6% |

| WS2 0.6 µm 0.5% (250 MPa) | 0.487 | 0.486 | 0.487 ± 0.2% | 242 | 237 | 240 ± 1.5% |

| WS2 0.6 µm 2.5% (350 MPa) | 0.482 | 0.461 | 0.472 ± 3.1% | 218 | 211 | 215 ± 2.3% |

| WS2 0.6 µm 2.5% (250 MPa) | 0.450 | 0.455 | 0.453 ± 0.8% | 219 | 217 | 218 ± 0.6% |

| WS2 0.6 µm 5% (350 MPa) | 0.459 | 0.447 | 0.453 ± 1.9% | 203 | 202 | 203 ± 0.3% |

| WS2 0.6 µm 5% (250 MPa) | 0.465 | 0.463 | 0.464 ± 0.3% | 214 | 213 | 214 ± 0.3% |

| Sample | Friction Coefficient Values | Mean Values | Abrasion Trace Width [µm] | Mean Values [µm] | ||

|---|---|---|---|---|---|---|

| Test 01 | Test 02 | Test 01 | Test 02 | |||

| h-BN 0.5 µm 0.5% (350 MPa) | 0.529 | 0.525 | 0.527 ± 0.5% | 206 | 210 | 208 ± 1.4% |

| h-BN 0.5 µm 0.5% (250 MPa) | 0.560 | 0.552 | 0.556 ± 1% | 240 | 246 | 243 ± 1.7% |

| h-BN 0.5 µm 2.5% (350 MPa) | 0.580 | 0.579 | 0.580 ± 0.1% | 270 | 262 | 266 ± 2.1% |

| h-BN 0.5 µm 2.5% (250 MPa) | 0.566 | 0.553 | 0.560 ± 1.6% | 281 | 260 | 271 ± 5.5% |

| h-BN 0.5 µm 5% (350 MPa) | 0.913 | 0.915 | 0.914 ± 0.2% | 2414 | 2353 | 2384 ± 1.8% |

| h-BN 0.5 µm 5% (250 MPa) | 0.656 | 0.793 | 0.725 ± 13% | 2231 | 2171 | 2201 ± 1.9% |

| Sample | Friction Coefficient Values | Mean Values | Abrasion Trace Width [µm] | Mean Values [µm] | ||

|---|---|---|---|---|---|---|

| Test 01 | Test 02 | Test 01 | Test 02 | |||

| h-BN 1.5 µm 0.5% (350 MPa) | 0.569 | 0.553 | 0.561 ± 2% | 195 | 196 | 196 ± 0.4% |

| h-BN 1.5 µm 0.5% (250 MPa) | 0.551 | 0.562 | 0.557 ± 1.4% | 200 | 205 | 202 ± 1.7% |

| h-BN 1.5 µm 2.5% (350 MPa) | 0.492 | 0.478 | 0.485 ± 2% | 198 | 190 | 194 ± 3% |

| h-BN 1.5 µm 2.5% (250 MPa) | 0.411 | 0.457 | 0.434 ± 7.5% | 204 | 205 | 205 ± 0.3% |

| h-BN 1.5 µm 5% (350 MPa) | 0.438 | 0.446 | 0.442 ± 1.3% | 300 | 232 | 266 ± 18% |

| h-BN 1.5 µm 5% (250 MPa) | 0.485 | 0.466 | 0.476 ± 2.8% | 207 | 220 | 214 ± 4.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urbaniak, W.; Majewski, T.; Śmigielski, G.; Trynda, A.; Petelska, A.D. The Influence of Selected Properties of Sintered Iron Doped with Lubricants on Its Tribological Properties. Materials 2025, 18, 4211. https://doi.org/10.3390/ma18174211

Urbaniak W, Majewski T, Śmigielski G, Trynda A, Petelska AD. The Influence of Selected Properties of Sintered Iron Doped with Lubricants on Its Tribological Properties. Materials. 2025; 18(17):4211. https://doi.org/10.3390/ma18174211

Chicago/Turabian StyleUrbaniak, Wiesław, Tomasz Majewski, Grzegorz Śmigielski, Anna Trynda, and Aneta D. Petelska. 2025. "The Influence of Selected Properties of Sintered Iron Doped with Lubricants on Its Tribological Properties" Materials 18, no. 17: 4211. https://doi.org/10.3390/ma18174211

APA StyleUrbaniak, W., Majewski, T., Śmigielski, G., Trynda, A., & Petelska, A. D. (2025). The Influence of Selected Properties of Sintered Iron Doped with Lubricants on Its Tribological Properties. Materials, 18(17), 4211. https://doi.org/10.3390/ma18174211