Utilization of Birch Bark-Derived Suberinic Acid Residues as Additives in High-Density Fiberboard Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Panels

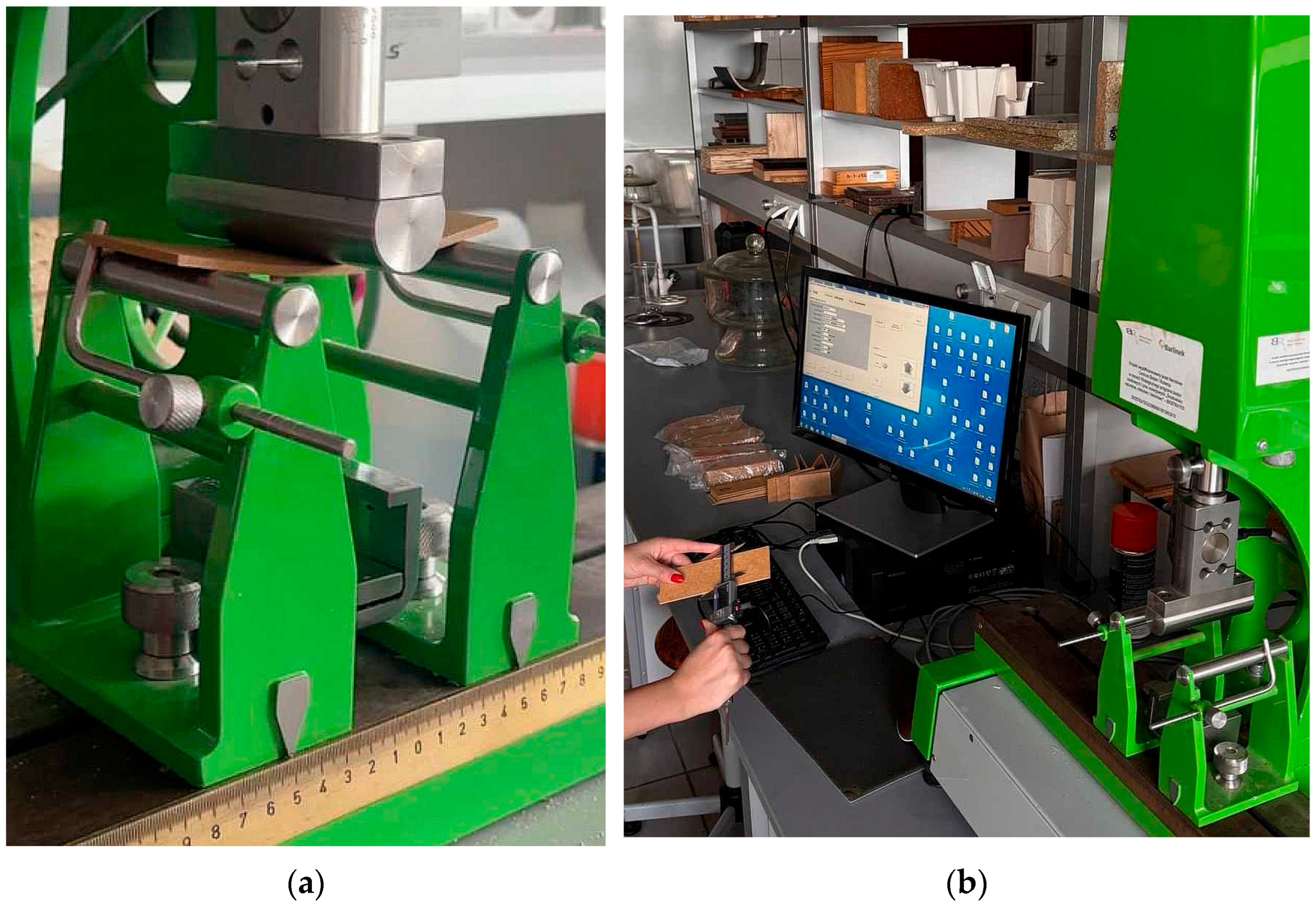

2.3. Characterization of the HDF Panels

2.4. Statistical Analysis

3. Results and Discussion

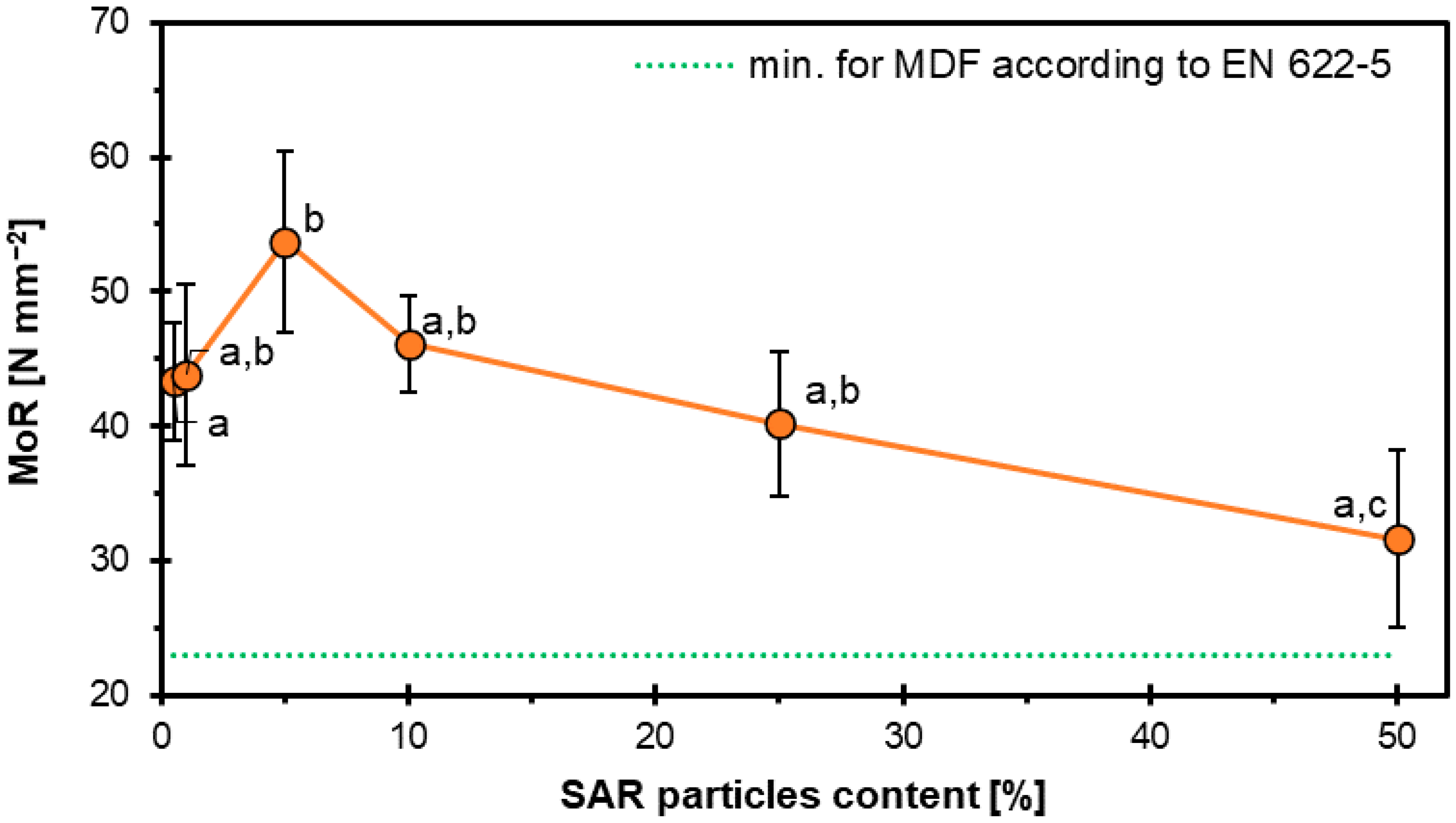

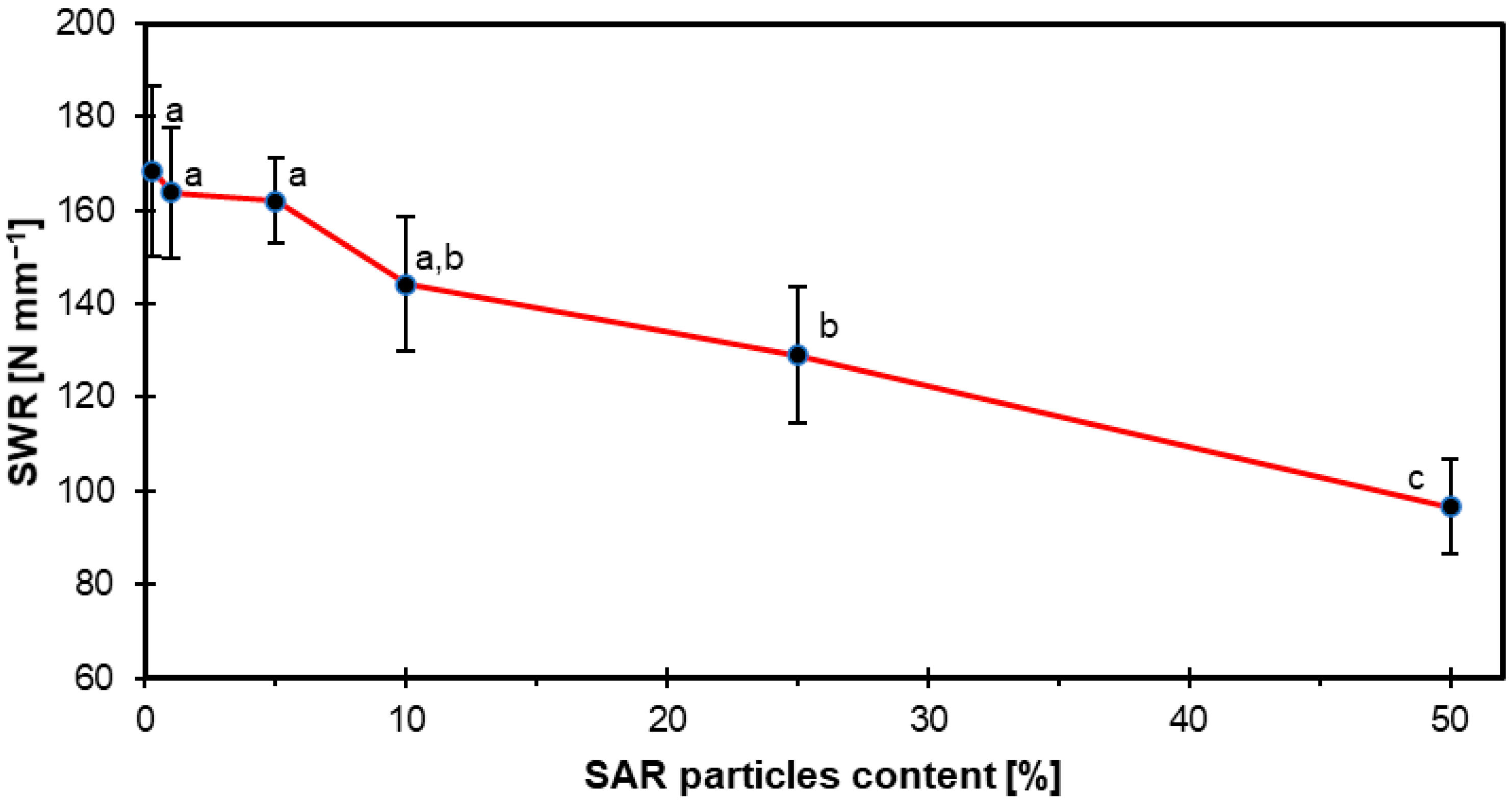

3.1. Modulus of Rupture and Modulus of Elasticity

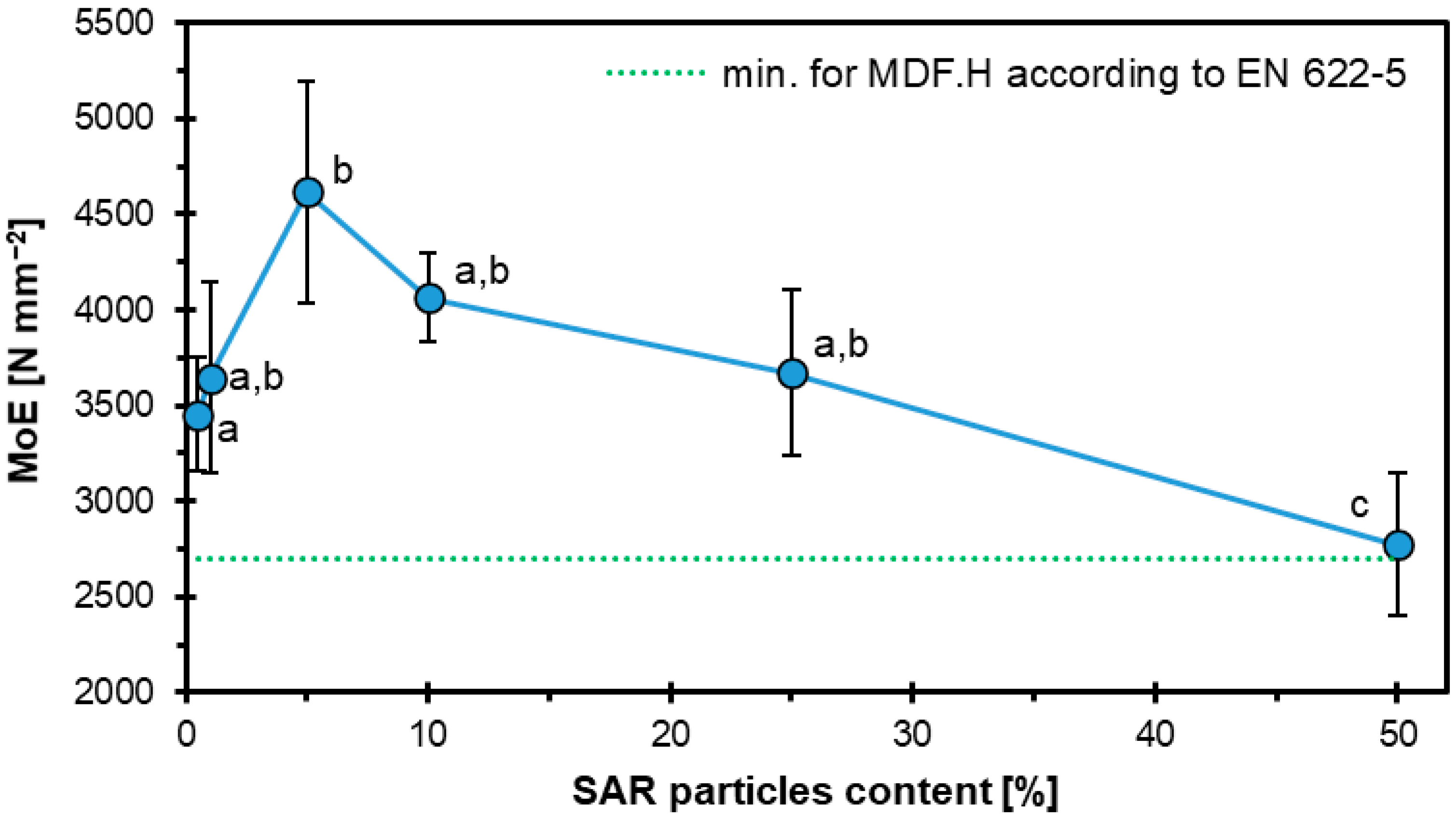

3.2. Screw Withdrawal Resistance

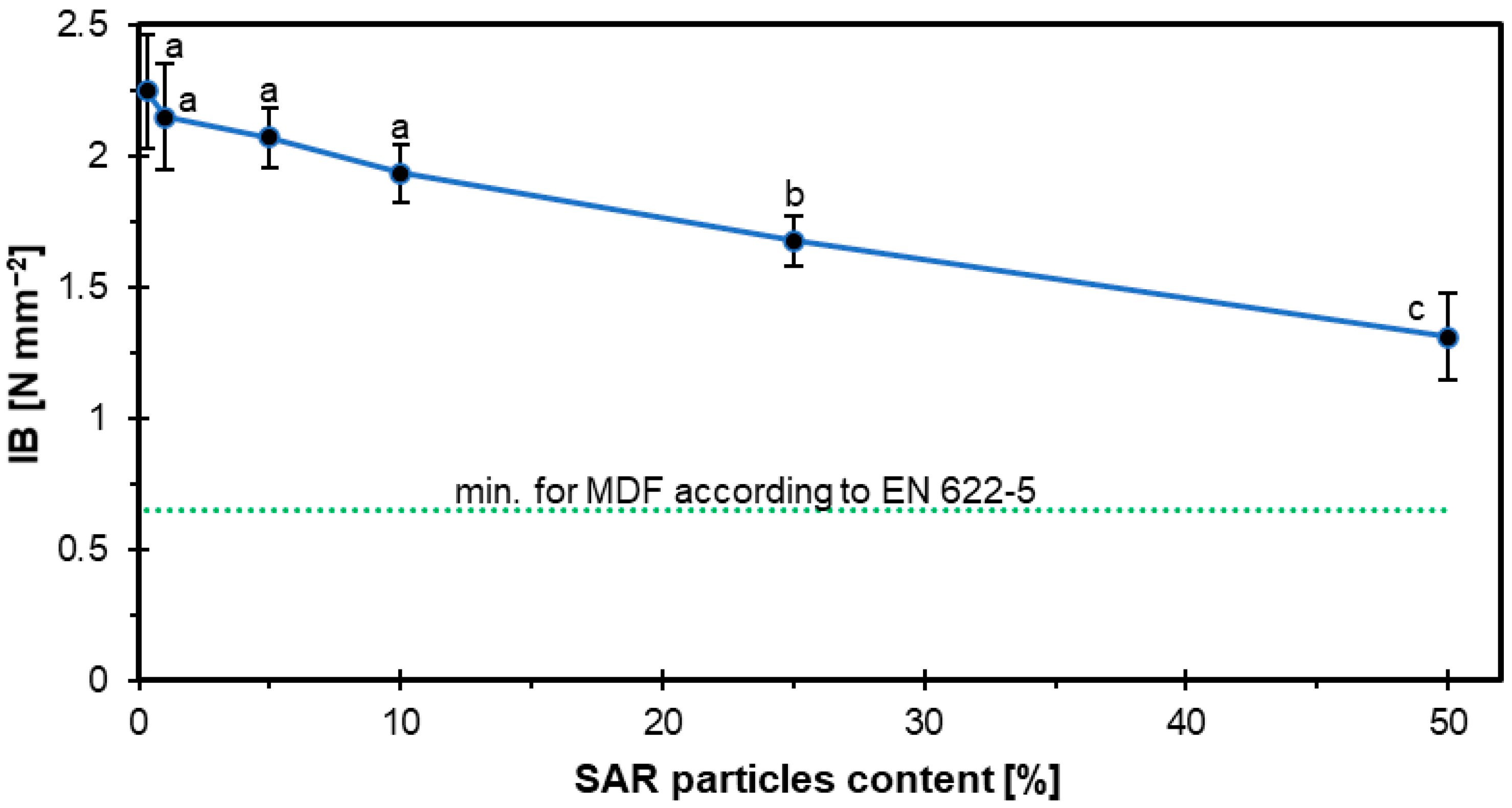

3.3. Internal Bond

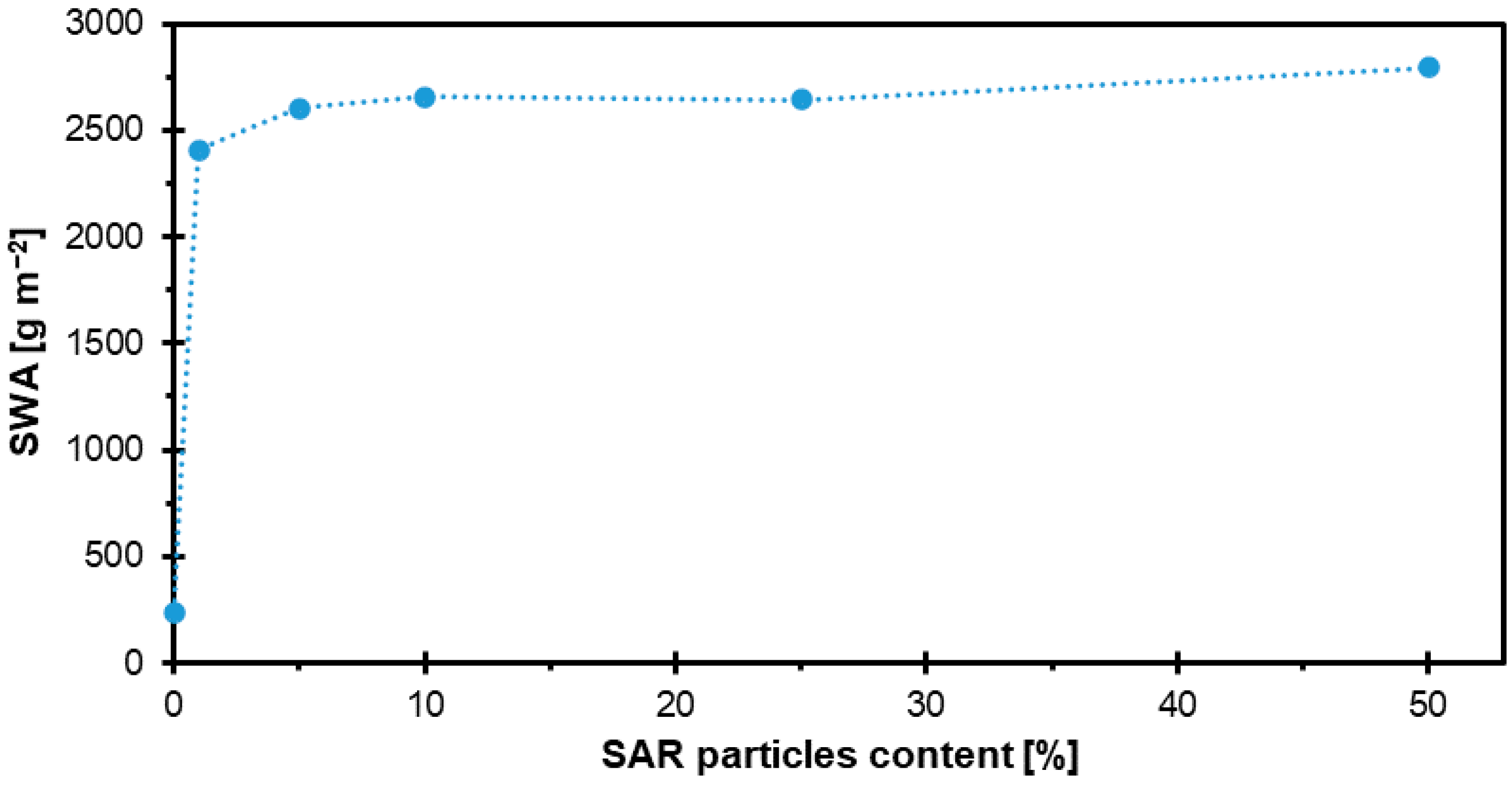

3.4. Surface Water Absorption

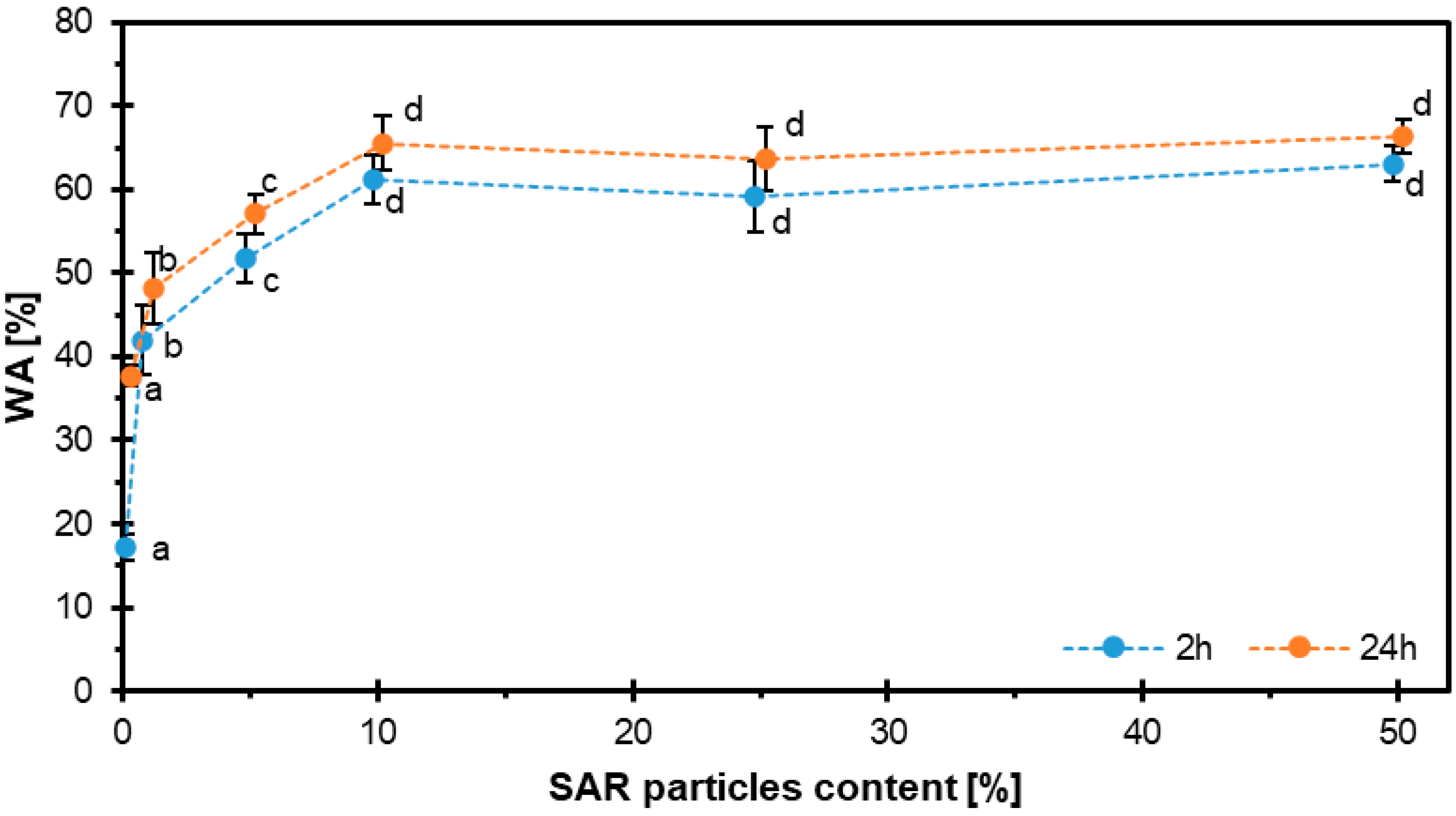

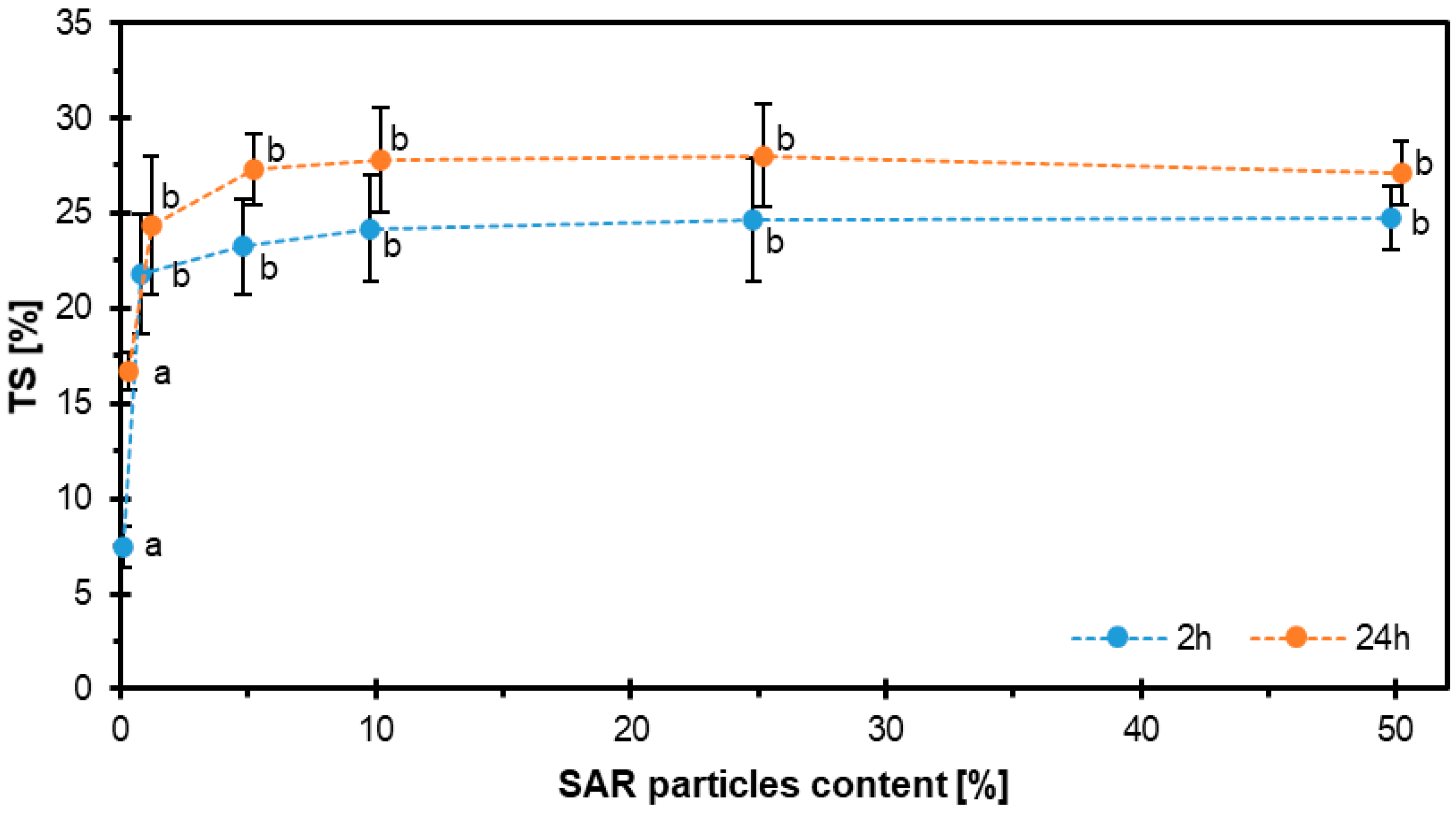

3.5. Water Absorption and Thickness Swelling

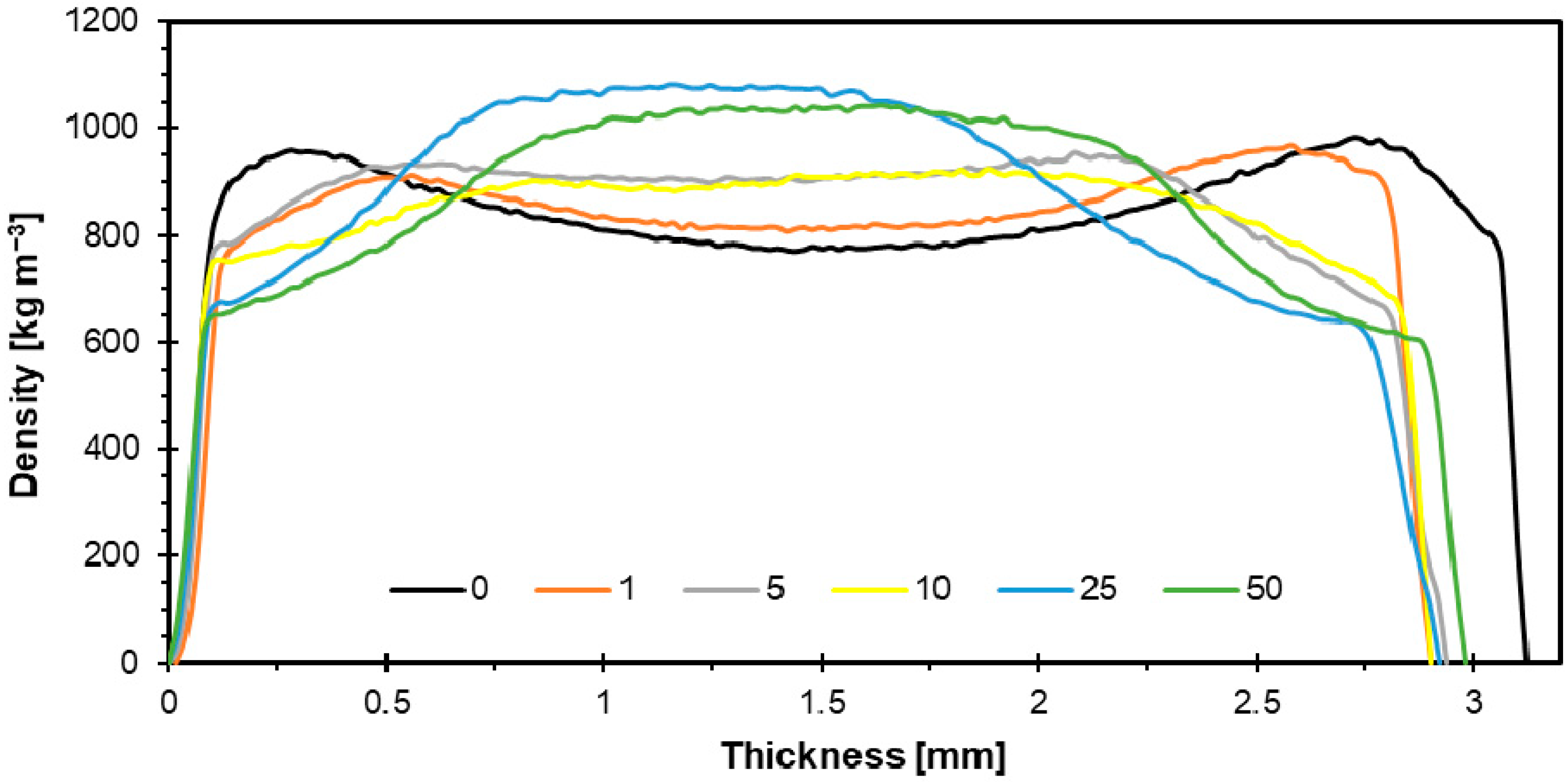

3.6. Density Profile

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fang, L.; Lu, X.; Mo, X.; Zhang, X.; Gui, C. Performance of Impregnated Paper Decorated Blockboard Manufactured Using HDF as Equilibrium Layer. Materials 2022, 15, 6342. [Google Scholar] [CrossRef]

- Roziņš, R.; Iejavs, J.; Jakovļevs, V.; Spulle, U. The Properties of Lightweight Stabilised Blockboard Panels. Drewno. Pr. Nauk. Doniesienia Komun. Wood. Res. Pap. Rep. Announc. 2020, 63, 103–119. [Google Scholar] [CrossRef]

- Giannotas, G.; Kamperidou, V.; Barboutis, I. Tree Bark Utilization in Insulating Bio-Aggregates: A Review. Biofuels Bioprod. Biorefining 2021, 15, 1989–1999. [Google Scholar] [CrossRef]

- Deng, Y.; Zhao, Y.; Padilla-Zakour, O.; Yang, G. Polyphenols, Antioxidant and Antimicrobial Activities of Leaf and Bark Extracts of Solidago canadensis L. Ind. Crops Prod. 2015, 74, 803–809. [Google Scholar] [CrossRef]

- Yahiaoui, S.; Kati, D.E.; Chaalal, M.; Ali, L.M.A.; El Cheikh, K.; Depaepe, G.; Morère, A.; Menut, C.; Bettache, N.; Bachir-Bey, M. Antioxidant, Antiproliferative, Anti-Inflammatory, and Enzyme Inhibition Potentials of Ficus Carica Wood Bark and Related Bioactive Phenolic Metabolites. Wood Sci. Technol. 2024, 58, 1051–1075. [Google Scholar] [CrossRef]

- Dikamu, M.; Ezez, D.; Birhanu, H.; Mamo, A.; Tefera, M. Analysis of Phytochemical Constituents Using GC–MS, Evaluation of Antioxidants and Antibacterial Activities of Maerua Oblongifolia Root Bark Extracts. Discov. Appl. Sci. 2025, 7, 417. [Google Scholar] [CrossRef]

- Wenig, C.; Dunlop, J.W.C.; Hehemeyer-Cürten, J.; Reppe, F.J.; Horbelt, N.; Krauthausen, K.; Fratzl, P.; Eder, M. Advanced Materials Design Based on Waste Wood and Bark. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2021, 379, 20200345. [Google Scholar] [CrossRef] [PubMed]

- Hordyjewska, A.; Ostapiuk, A.; Horecka, A.; Kurzepa, J. Betulin and Betulinic Acid: Triterpenoids Derivatives with a Powerful Biological Potential. Phytochem. Rev. 2019, 18, 929–951. [Google Scholar] [CrossRef]

- Chudzik, M.; Korzonek-Szlacheta, I.; Król, W. Triterpenes as Potentially Cytotoxic Compounds. Molecules 2015, 20, 1610–1625. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhao, H.; Jiang, J.; Liu, G.; Yang, C. Analysis of Three Types of Triterpenoids in Tetraploid White Birches (Betula platyphylla Suk.) and Selection of plus Trees. J. For. Res. 2015, 26, 623–633. [Google Scholar] [CrossRef]

- Rizhikovs, J.; Zandersons, J.; Dobele, G.; Paze, A. Isolation of Triterpene-Rich Extracts from Outer Birch Bark by Hot Water and Alkaline Pre-Treatment or the Appropriate Choice of Solvents. Ind. Crops Prod. 2015, 76, 209–214. [Google Scholar] [CrossRef]

- Scheffler, A. The Wound Healing Properties of Betulin from Birch Bark from Bench to Bedside. Planta Med. 2019, 85, 524–527. [Google Scholar] [CrossRef]

- Godina, D.; Sosins, G.; Paze, A.; Rizikovs, J.; Makars, R.; Treu, A. Evaluating the Potential of Birch Bark Suberinic Acids for Solid Wood Impregnation. J. Renew. Mater. 2025, 13, 147–161. [Google Scholar] [CrossRef]

- Jasinskas, A.; Mieldažys, R.; Jotautiene, E.; Domeika, R.; Vaiciukevičius, E.; Marks, M. Technical, Environmental, and Qualitative Assessment of the Oak Waste Processing and Its Usage for Energy Conversion. Sustainability 2020, 12, 8113. [Google Scholar] [CrossRef]

- Vuppaladadiyam, A.K.; Vuppaladadiyam, S.S.V.; Sahoo, A.; Murugavelh, S.; Anthony, E.; Bhashkar, T.; Zheng, Y.; Zhao, M.; Duan, H.; Zhao, Y.; et al. Bio-Oil and Biochar from the Pyrolytic Conversion of Biomass: A Current and Future Perspective on the Trade-off between Economic, Environmental, and Technical Indicators. Sci. Total Environ. 2023, 857, 159155. [Google Scholar] [CrossRef]

- Koetlisi, K.A.; Muchaonyerwa, P. Pyrolysis Temperature Effects on Yield, Physico-Chemical Characteristics of Pine-Bark Biochars and Cadmium Sorption. Indian J. Environ. Prot. 2018, 38, 197–212. [Google Scholar]

- Şen, A.U.; Nobre, C.; Durão, L.; Miranda, I.; Pereira, H.; Gonçalves, M. Low-Temperature Biochars from Cork-Rich and Phloem-Rich Wastes: Fuel, Leaching, and Methylene Blue Adsorption Properties. Biomass Convers. Biorefinery 2022, 12, 3899–3909. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Rizhikovs, J.; Grinins, J.; Paze, A.; Andzs, M.; Brazdausks, P.; Puke, M.; Plavniece, A. Investigation of Suberinic Acids-Bonded Particleboard. Eur. Polym. J. 2019, 113, 176–182. [Google Scholar] [CrossRef]

- Godina, D.; Feldmanis, A.R.; Makars, R.; Paze, A.; Rizikovs, J. Birch Bark Based Suberinic Acid Sample Fractionation and Characterisation Using Instrumental Methods. In Proceedings of the European Biomass Conference and Exhibition, Bologna, Italy, 5–8 June 2023; pp. 1043–1049. [Google Scholar]

- Aydogan, A.; Montoya, L.D. Formaldehyde Removal by Common Indoor Plant Species and Various Growing Media. Atmos. Environ. 2011, 45, 2675–2682. [Google Scholar] [CrossRef]

- Oyabu, T.; Sawada, A.; Hashimoto, T.; Yoshioka, T. Removing Characteristic of Indoor Air Pollutants According to Activated Carbon Pot and Plant Using a Tin Oxide Gas Sensor. Electrochemistry 2004, 72, 813–817. [Google Scholar] [CrossRef]

- Walkiewicz, J.; Kawalerczyk, J.; Mirski, R.; Szubert, Z. The Tea Leaves As a Filler for Uf Resin Plywood Production. Wood Res. 2023, 68, 200–207. [Google Scholar] [CrossRef]

- Yew, M.C.; Ramli Sulong, N.H.; Yew, M.K.; Amalina, M.A.; Johan, M.R. Eggshells: A Novel Bio-Filler for Intumescent Flame-Retardant Coatings. Prog. Org. Coat. 2015, 81, 116–124. [Google Scholar] [CrossRef]

- Kryński, K.; Kowaluk, G. Application of Beeswax as a Hydrophobic Agent in MDF Technology. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2021, 114, 59–69. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. Incorporating Birch Bark Suberinic Acid Residue Powder into Structural Particleboards: Exploring Fractional Influence on Material Properties in Circular Economy Framework. Materials 2024, 17, 5750. [Google Scholar] [CrossRef]

- Jeżo, A.; Wronka, A.; Dębiński, A.; Kristak, L.; Reh, R.; Rizhikovs, J.; Kowaluk, G. Influence of Upcycled Post-Treatment Bark Biomass Addition to the Binder on Produced Plywood Properties. Forests 2023, 14, 110. [Google Scholar] [CrossRef]

- Maksymiuk, G.; Jeżo, A.; Rižikovs, J. Selected Physical and Mechanical Properties of Particleboards Manufactured with Addition of Betula Bark Post-Extraction Residues. Eur. J. Wood Wood Prod. 2024, 82, 1981–1992. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Esmailpour, A.; Majidi, R.; Morrell, J.J.; Mallaki, M.; Militz, H.; Papadopoulos, A.N. Potential Use of Wollastonite as a Filler in UF Resin Based Medium-Density Fiberboard (MDF). Polymers 2020, 12, 1435. [Google Scholar] [CrossRef]

- Gaskin, E.; Reed, G.; Preston, J.; Biza, P. The Use of Minerals in Fiber-Based Packaging and Pulp Molding. TAPPI J. 2024, 23, 25–32. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Mantanis, G.I.; Neykov, N. Medium-Density Fibreboards Bonded with Phenol-Formaldehyde Resin and Calcium Lignosulfonate as an Eco-Friendly Additive. Wood Mater. Sci. Eng. 2021, 16, 42–48. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Trichkov, N.; Krišťák, Ľ.; Réh, R.; Papadopoulos, A.N.; Taghiyari, H.R.; Pizzi, A.; Kunecová, D.; Pachikova, M. Properties of High-Density Fiberboard Bonded with Urea–Formaldehyde Resin and Ammonium Lignosulfonate as a Bio-Based Additive. Polymers 2021, 13, 2775. [Google Scholar] [CrossRef]

- Trisatya, D.R.; Satiti, E.R.; Indrawan, D.A.; Tampubolon, R.M. Durability of Fiber Boards Made of Jabon and Andong Bamboo with Additional Activated Carbon Additives against Dry Wood Termites and Subterranean Termites. IOP Conf. Ser. Earth Environ. Sci. 2020, 415, 012004. [Google Scholar] [CrossRef]

- Camlibel, O. Mechanical and Formaldehyde-Related Properties of Medium Density Fiberboard with Zeolite Additive. BioResources 2020, 15, 7918–7932. [Google Scholar] [CrossRef]

- Makars, R.; Rizikovs, J.; Godina, D.; Paze, A.; Merijs-Meri, R. Utilization of Suberinic Acids Containing Residue as an Adhesive for Particle Boards. Polymers 2022, 14, 2304. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Physical and Mechanical Properties of High-Density Fiberboard Bonded with Bio-Based Adhesives. Forests 2023, 14, 84. [Google Scholar] [CrossRef]

- EN 323; Wood-Based Panels—Determination of Density. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 320; Particleboards and Fibreboards—Determination of Resistance to Axial Withdrawal of Screws. European Committee for Standardization: Brussels, Belgium, 2011.

- EN 317; Particleboards and Fiberboards—Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 382-2; Fibreboards—Determination of Surface Absorption—Part 2: Test Method for Hardboards. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 622-5; Fiberboards. Specifications. Requirements for Dry Process Boards (MDF). European Committee for Standardization: Brussels, Belgium, 2009.

- Wronka, A.; Rdest, A.; Kowaluk, G. Influence of Starch Content on Selected Properties of Hardboard. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2020, 109, 48–52. [Google Scholar] [CrossRef]

- Dasiewicz, J.; Kowaluk, G. Characteristics of High-Density Fibreboard Produced with the Use of Rice Starch as a Binder. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2023, 181, 169–181. [Google Scholar] [CrossRef]

- Pawlik, J.; Kowaluk, G. Non-Food Use of Solid Residues from the Dairy Industry as a Binder in Dry-Formed Fiberboard Technology. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2024, 16, 5–16. [Google Scholar] [CrossRef]

- Fehrmann, J.; Belleville, B.; Ozarska, B.; Gutowski, W.S.; Wilson, D. Influence of Particle Granulometry and Panel Composition on the Physico-Mechanical Properties of Ultra-Low-Density Hemp Hurd Particleboard. Polym. Compos. 2023, 44, 7363–7383. [Google Scholar] [CrossRef]

- Domínguez-Robles, J.; Tarrés, Q.; Delgado-Aguilar, M.; Rodríguez, A.; Espinach, F.X.; Mutjé, P. Approaching a New Generation of Fiberboards Taking Advantage of Self Lignin as Green Adhesive. Int. J. Biol. Macromol. 2018, 108, 927–935. [Google Scholar] [CrossRef]

- Arslan, R.; Karaçay, E.; Maraşlıoğlu, D.; Tanrıverdi, B.A.; Fırat, E.; Tozluoğlu, A.; Uğraş, H.İ.; Candan, Z. Determination of the Properties of Medium-Density Fiberboards Produced Using Urea-Formaldehyde Resins Modified with Boron Compounds. BioResources 2024, 19, 5367–5383. [Google Scholar] [CrossRef]

- Kryńska, K.; Kowaluk, G. Application of Soy Starch as a Binder in HDF Technology. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2023, 123, 41–50. [Google Scholar] [CrossRef]

- Kord, B. Effect of Chemical Modification of Wood Flour on Long-Term Hygroscopic Behavior of Polypropylene Composites. J. Thermoplast. Compos. Mater. 2015, 29, 577–588. [Google Scholar] [CrossRef]

- Li, X.; Cai, Z.; Horn, E.; Winandy, J.E.; Service, U.F. Effect of Oxalic Acid Pretreatment of Wood Chips on Manufacturing Medium-Density Fiberboard. Holzforschung 2011, 65, 737–741. [Google Scholar] [CrossRef]

- Zamani, R.; Najafi, S.K.; Younesi, H. Utilization of Activated Carbon as an Additive for Urea- Formaldehyde Resin in Medium Density Fiberboard (MDF) Manufacturing. J. Adhes. Sci. Technol. 2022, 36, 2285–2296. [Google Scholar] [CrossRef]

- Poblete, H.W.; Vargas, C.R. Relationship between Density and Properties of HDF Manufactured by a Dry Process. Maderas Cienc. Tecnol. 2006, 8, 169–182. [Google Scholar]

- Gupta, A.; Jordan, P.; Pang, S. Modelling of the Development of the Vertical Density Profile of MDF during Hot Pressing. Chem. Prod. Process Model. 2007, 2, 1–16. [Google Scholar] [CrossRef]

- Wang, S.; Winistorfer, P.M.; Young, T.M. Fundamentals of Vertical Density Profile Formation in Wood Composites. Part III. MDF Density Formation during Hot-Pressing. Wood Fiber Sci. 2004, 36, 17–25. [Google Scholar]

- Aguilera, A. Cutting Energy and Surface Roughness in Medium Density Fiberboard Rip Sawing. Eur. J. Wood Wood Prod. 2011, 69, 11–18. [Google Scholar] [CrossRef]

- Hiziroglu, S.; Kosonkorn, P. Evaluation of Surface Roughness of Thai Medium Density Fiberboard (MDF). Build. Environ. 2006, 41, 527–533. [Google Scholar] [CrossRef]

- Ayrilmis, N. Effect of Panel Density on Dimensional Stability of Medium and High Density Fiberboards. J. Mater. Sci. 2007, 42, 8551–8557. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D.; Kuliński, M.; Derkowski, A. Lightweight Insulation Boards Based on Lignocellulosic Particles Glued with Agents of Natural Origin. Materials 2021, 14, 3219. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dasiewicz, J.; Wronka, A.; Rizikovs, J.; Kowaluk, G. Utilization of Birch Bark-Derived Suberinic Acid Residues as Additives in High-Density Fiberboard Production. Materials 2025, 18, 4171. https://doi.org/10.3390/ma18174171

Dasiewicz J, Wronka A, Rizikovs J, Kowaluk G. Utilization of Birch Bark-Derived Suberinic Acid Residues as Additives in High-Density Fiberboard Production. Materials. 2025; 18(17):4171. https://doi.org/10.3390/ma18174171

Chicago/Turabian StyleDasiewicz, Julia, Anita Wronka, Janis Rizikovs, and Grzegorz Kowaluk. 2025. "Utilization of Birch Bark-Derived Suberinic Acid Residues as Additives in High-Density Fiberboard Production" Materials 18, no. 17: 4171. https://doi.org/10.3390/ma18174171

APA StyleDasiewicz, J., Wronka, A., Rizikovs, J., & Kowaluk, G. (2025). Utilization of Birch Bark-Derived Suberinic Acid Residues as Additives in High-Density Fiberboard Production. Materials, 18(17), 4171. https://doi.org/10.3390/ma18174171