1. Introduction

With the ongoing improvement of the highway network, advancements in the transportation industry, and growing traffic volume, asphalt pavements in many regions worldwide have been increasingly damaged. While road construction is being strengthened, the rehabilitation of existing pavements has gained increasing significance. Given the extensive highway maintenance mileage, a large amount of recycled asphalt mixture (RAP) is generated after milling old asphalt pavements [

1,

2]. The heat recovery process of RAP not only reuses existing materials, thereby reducing landfill waste, but also decreases waste compared to traditional asphalt production methods [

3,

4]. In addition, incorporating RAP into asphalt mixtures can reduce energy consumption during production, lower the overall demand for raw aggregates, and promote energy conservation, emission reduction, and effective high-volume reuse, which represent future development trends [

5,

6,

7].

At present, Chinese pavement engineering construction and maintenance require billions of tons of sand and gravel materials annually, among which the consumption of asphalt pavement mixtures alone reaches 500 million tons [

8]. The energy consumption and emission problems associated with this have become increasingly significant [

9]. Meanwhile, annual generation of reclaimed asphalt pavement (RAP) reaches tens of billions of tons. However, despite its value as a recyclable resource, the comprehensive recycling rate is only about 30% [

8]. Most of the RAP is disposed of primarily through piling and landfilling [

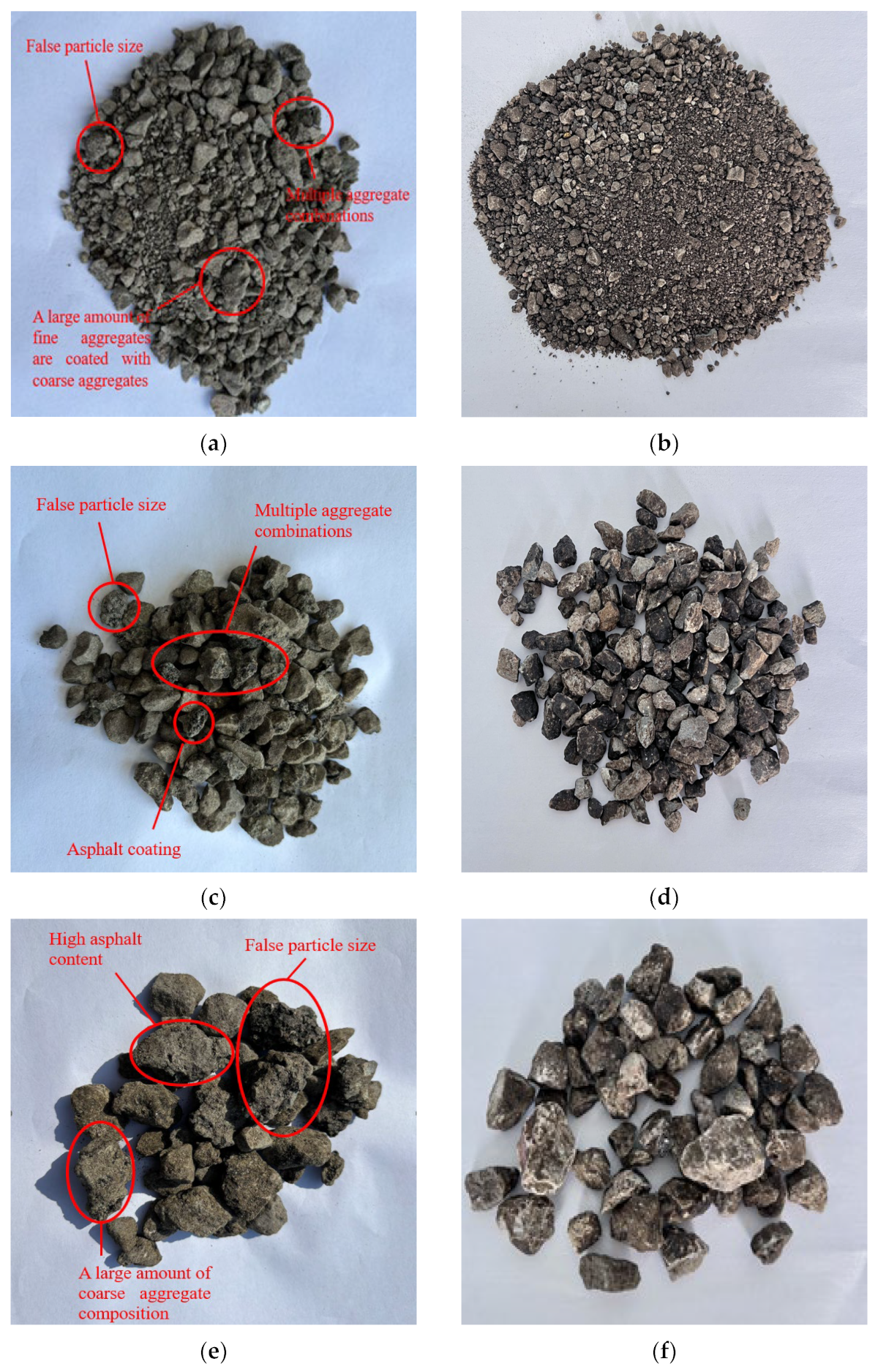

10]. RAP is a multiphase composite material consisting of aged asphalt, reclaimed aggregates, mineral filler, and admixtures. The phenomenon of particle agglomeration represents one of the most notable characteristics of RAP materials. Traditional crushing and screening methods struggle to address the “black stone” phenomenon in RAP [

11]. These clumps hinder the effective blending of new asphalt with aged asphalt, resulting in only partial activation of the aged asphalt [

12,

13,

14]. Excessive variability in these RAPs may cause substantial variations in the gradation of recycled asphalt mixtures, complicate mix design, degrade recycling performance, and impair road functionality.

At present, extensive research has primarily focused on the performance of high-content recycled asphalt mixtures. At present, the road industry mostly downgrades the use of recycled asphalt mixtures, applying RAP from the upper asphalt layer to the middle and lower asphalt layers, and the RAP content is usually less than 50%, making it difficult to achieve in situ ultra-high proportion regeneration with RAP content higher than 50% [

15,

16]. Since the aged asphalt in RAP becomes increasingly brittle with aging, the mixture is prone to cracking in low-temperature environments. Additionally, poor bonding between the original asphalt and aged asphalt results in inadequate toughness and structural strength in the recycled mixture. Moreover, as RAP content increases, the low-temperature performance of the recycled mixture correspondingly declines [

17,

18]. Li et al. [

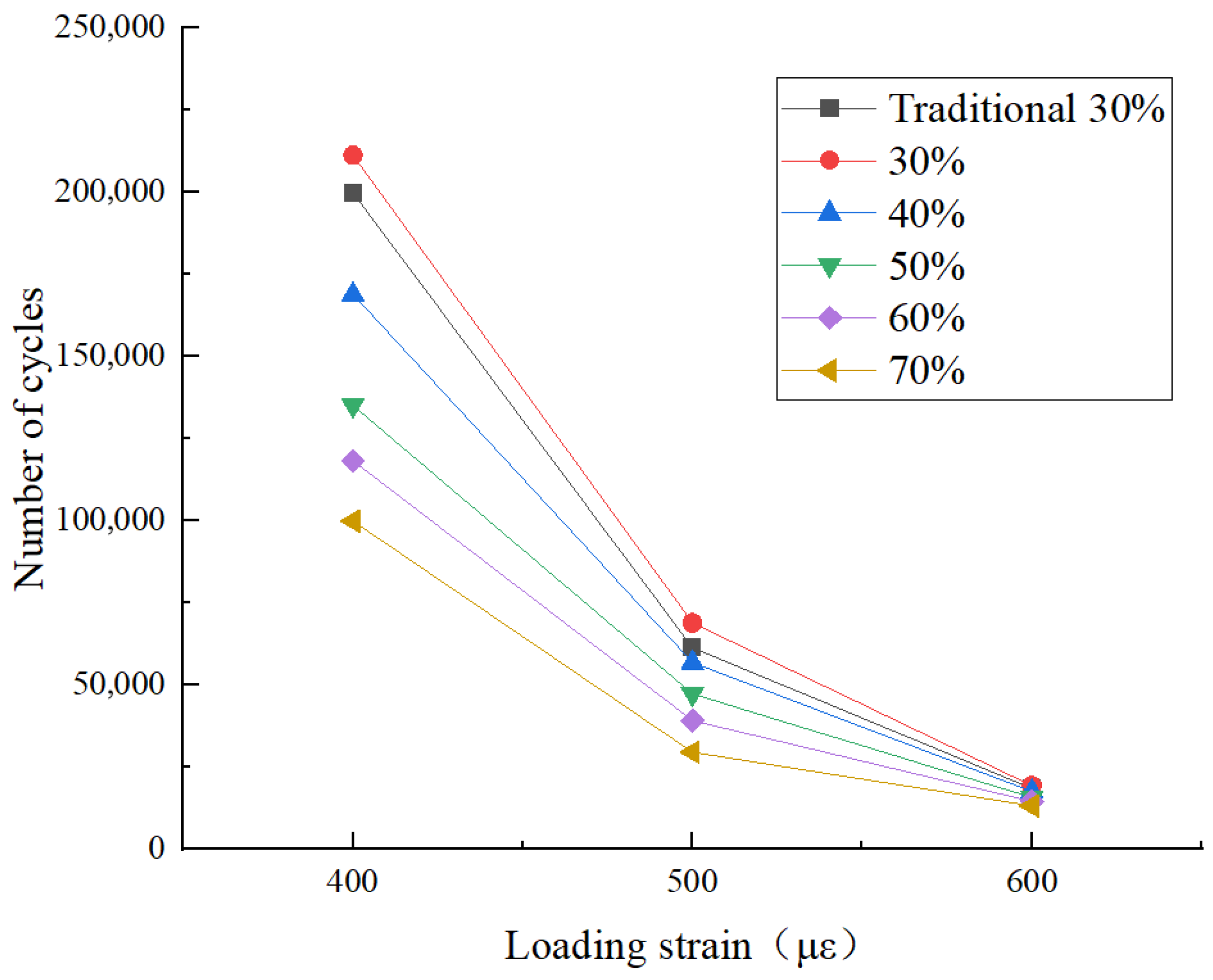

19] investigated the fatigue damage evolution of high-RAP thermal cycling asphalt mixtures considering creep effects and examined the impact of temperature and stress levels on fatigue life. Their findings indicated that the fatigue life of the mixtures decreased progressively with increasing RAP content. At present, there are different and even contradictory conclusions regarding the performance research of hot-recycled mixtures. Hao et al. [

20] compared the mechanical properties of recycled asphalt mixtures under different mixing methods and found that while the high-temperature rutting resistance was diminished by the pre-mixing of new and aged asphalt, water stability and low-temperature performance were improved. Furthermore, the water stability performance of mixtures deteriorates as RAP content increases, although both high-temperature rutting performance and Marshall stability are significantly enhanced [

21,

22,

23,

24]. The main reason for the difference in results is that there are many factors that affect the road performance of recycled asphalt mixtures, especially the RAP properties and their variability with different degrees of aging, RAP dosage, and the design of recycled asphalt mixture mix proportions [

25,

26]. Due to the multiple effects of these factors, it is currently unclear how RAP affects the performance of the final designed recycled asphalt mixture.

However, as discussed, previous studies have been limited by the high variability and agglomeration issues inherent in traditionally processed RAP, which restricts its dosage and compromises mixture performance. To overcome these limitations, this study introduces and evaluates an advanced pre-treatment method: fine separation and screening technology. The primary objectives of this work are threefold: (1) to quantify the effectiveness of this technology in minimizing RAP variability (in asphalt content and gradation) and reducing false particle content; (2) to utilize Response Surface Methodology (RSM) for optimizing the mix design of ultra-high-content RAP mixtures (50–70%); and (3) to comprehensively evaluate the influence of this technology and RAP dosage on the road performance and mechanical properties of the resulting recycled asphalt mixtures.

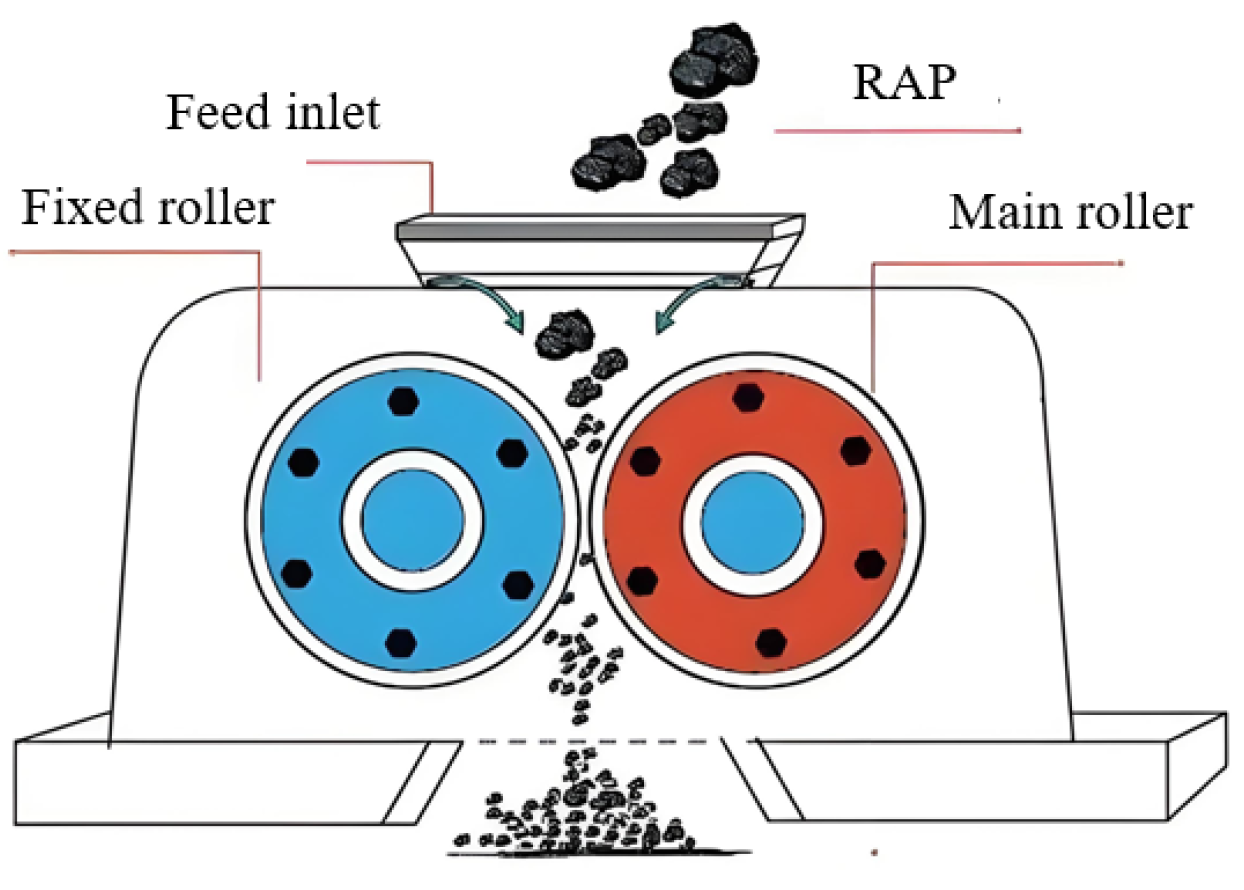

The RAP oil–stone separation was accomplished using fine separation technology, which effectively separates aged asphalt from aggregates, ensures the ultra-high proportion of RAP usage, and resolves critical issues limiting RAP dosage while enhancing the road performance of plant-mixed recycled mixtures. Secondly, the mix ratios of various RAP recycled asphalt mixtures were optimized using the response surface methodology to determine the optimal oil–stone ratio and regenerant dosage for recycled asphalt mixtures with varying RAP contents. Finally, the road performance and mechanical properties of recycled asphalt mixtures with different RAP contents were evaluated to assess the impact of fine separation technology on their performance.

5. Conclusions

5.1. Conclusions

To address the challenges of high variability and false particle content in RAP, which hinder its large-scale, high-value utilization, this study investigated the application of fine separation technology for RAP pre-treatment. The primary objectives were to minimize RAP variability, optimize the mix design for ultra-high-content RAP mixtures (30–70%) using RSM, and comprehensively evaluate the resulting performance. The following key conclusions were drawn:

(1) Pre-treatment Efficacy: Fine separation technology successfully mitigated the key challenges of RAP variability, reducing the coefficients of variation for asphalt content and gradation to below 5% and 10%, respectively. This process is essential for ensuring consistent quality in high-RAP mixtures.

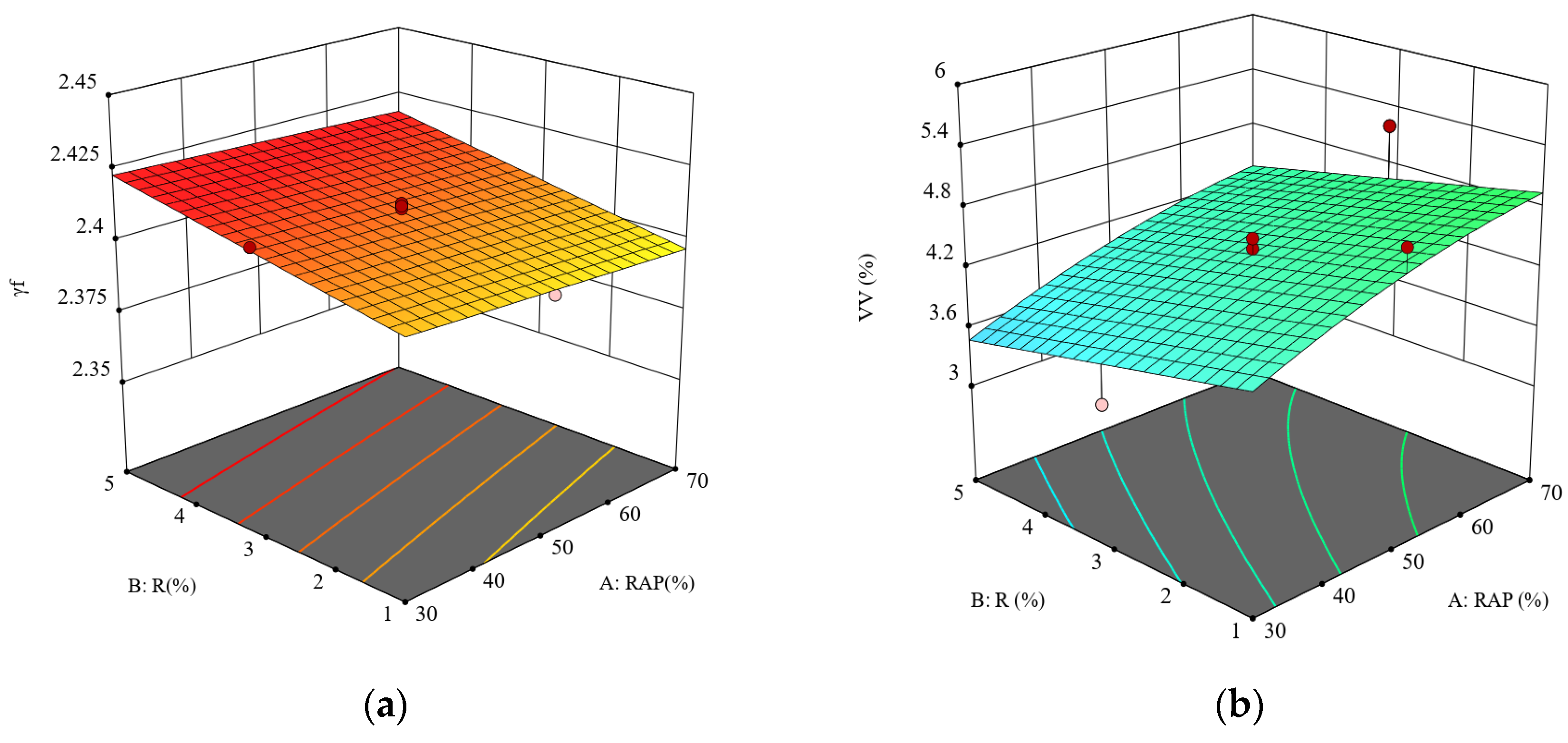

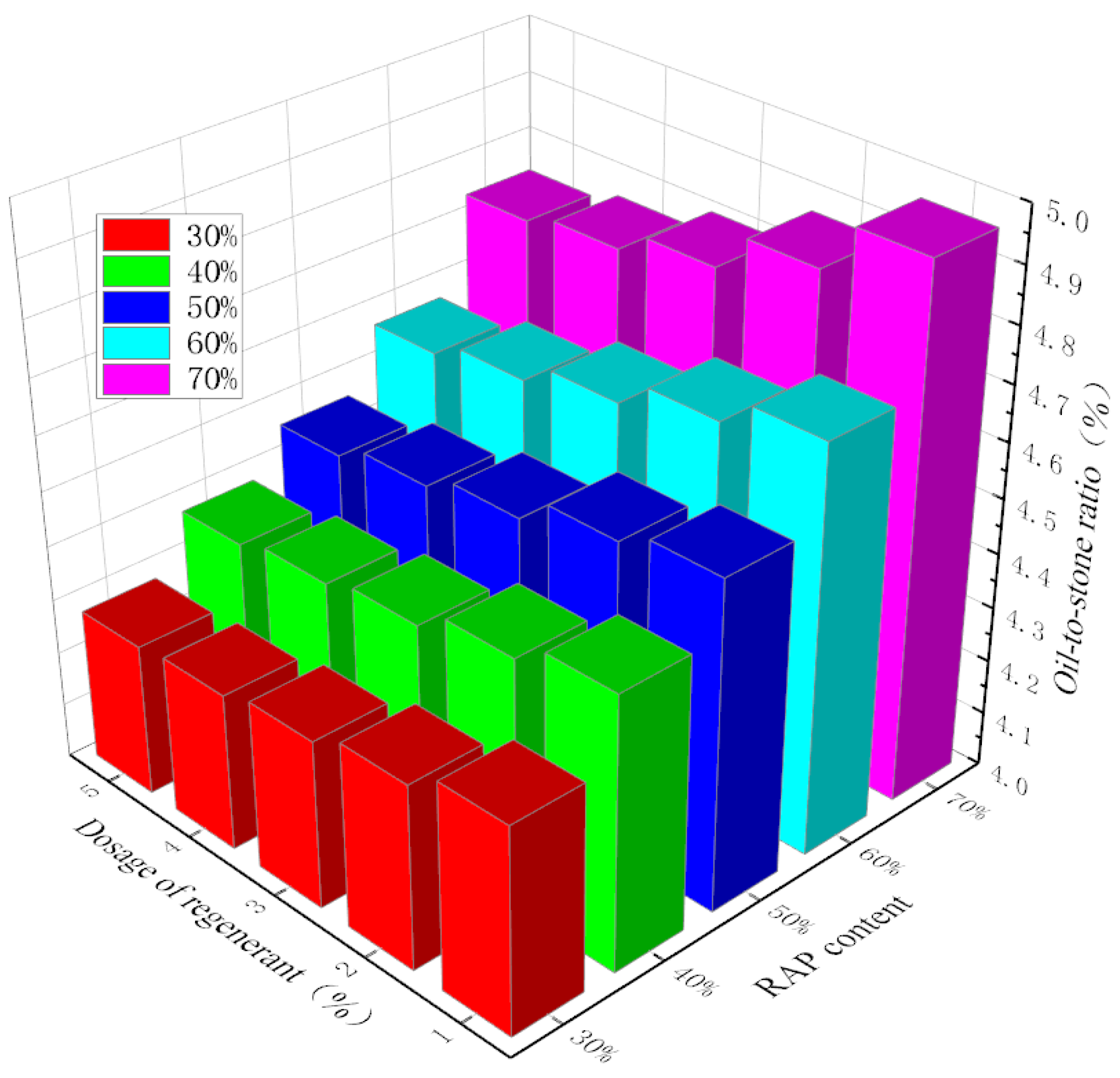

(2) Optimized Mix Design: The RSM-based model proved reliable for optimizing the oil–stone ratio across a wide range of RAP (30–70%) and regenerant (1–5%) dosages, providing a practical tool for mix design.

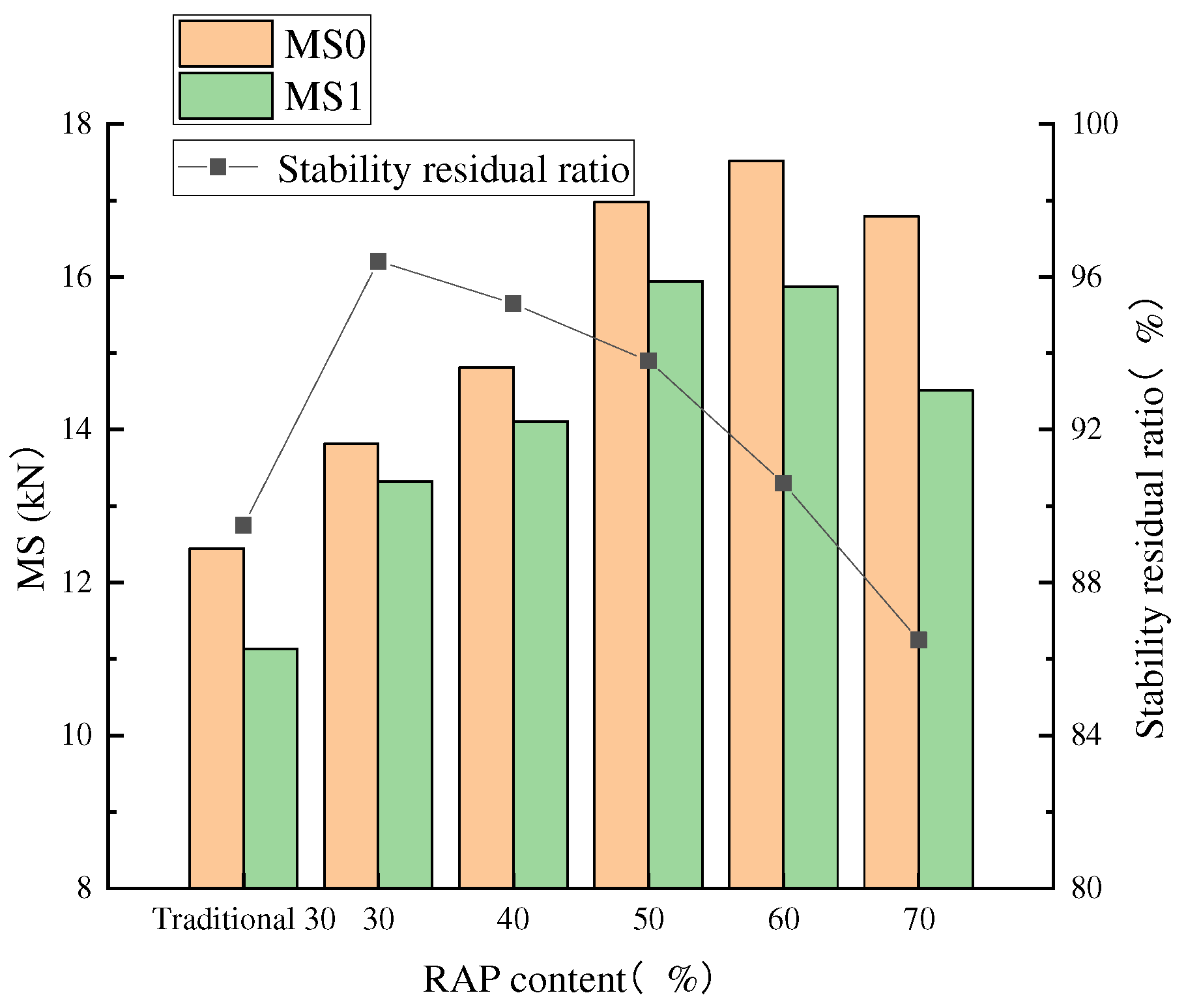

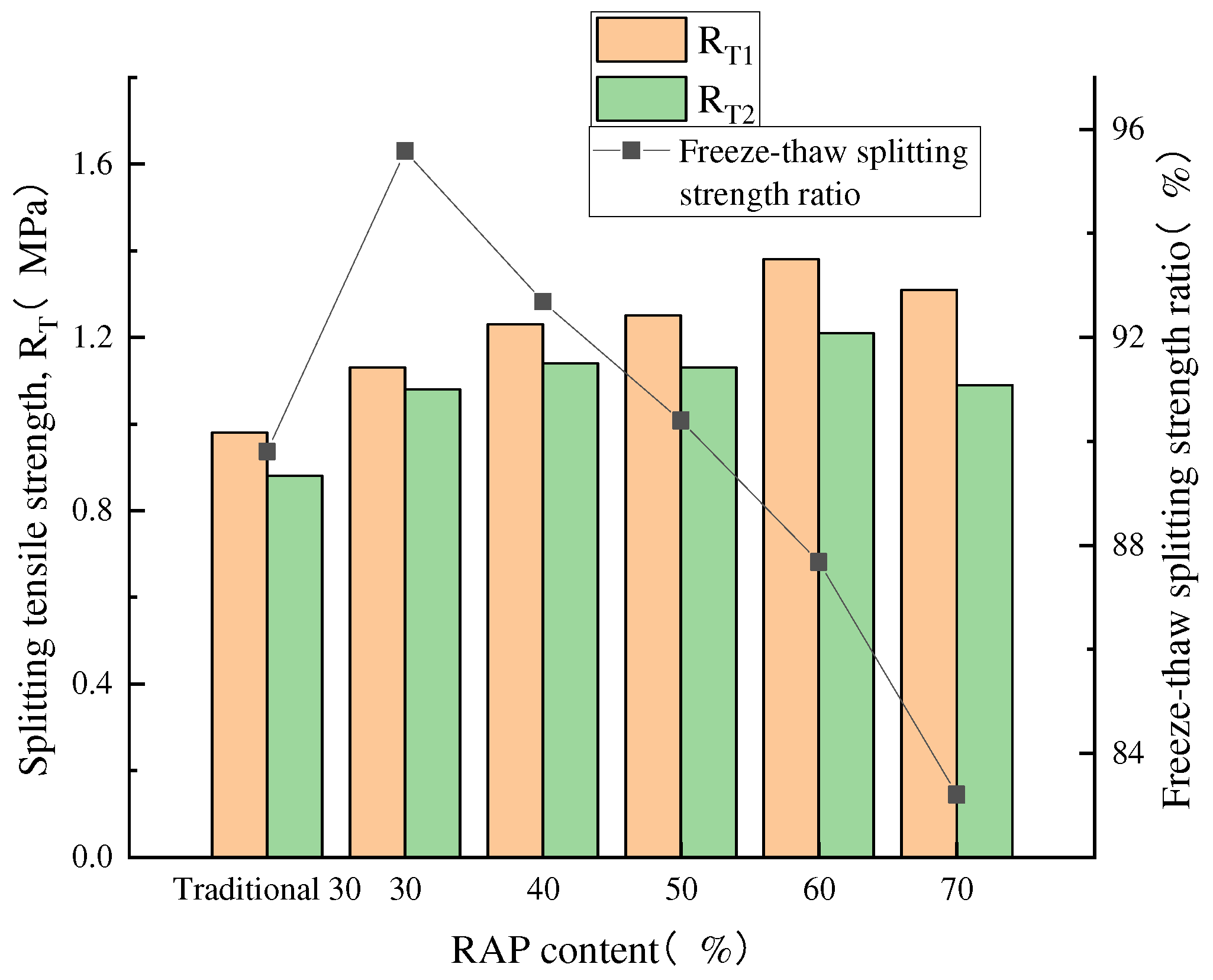

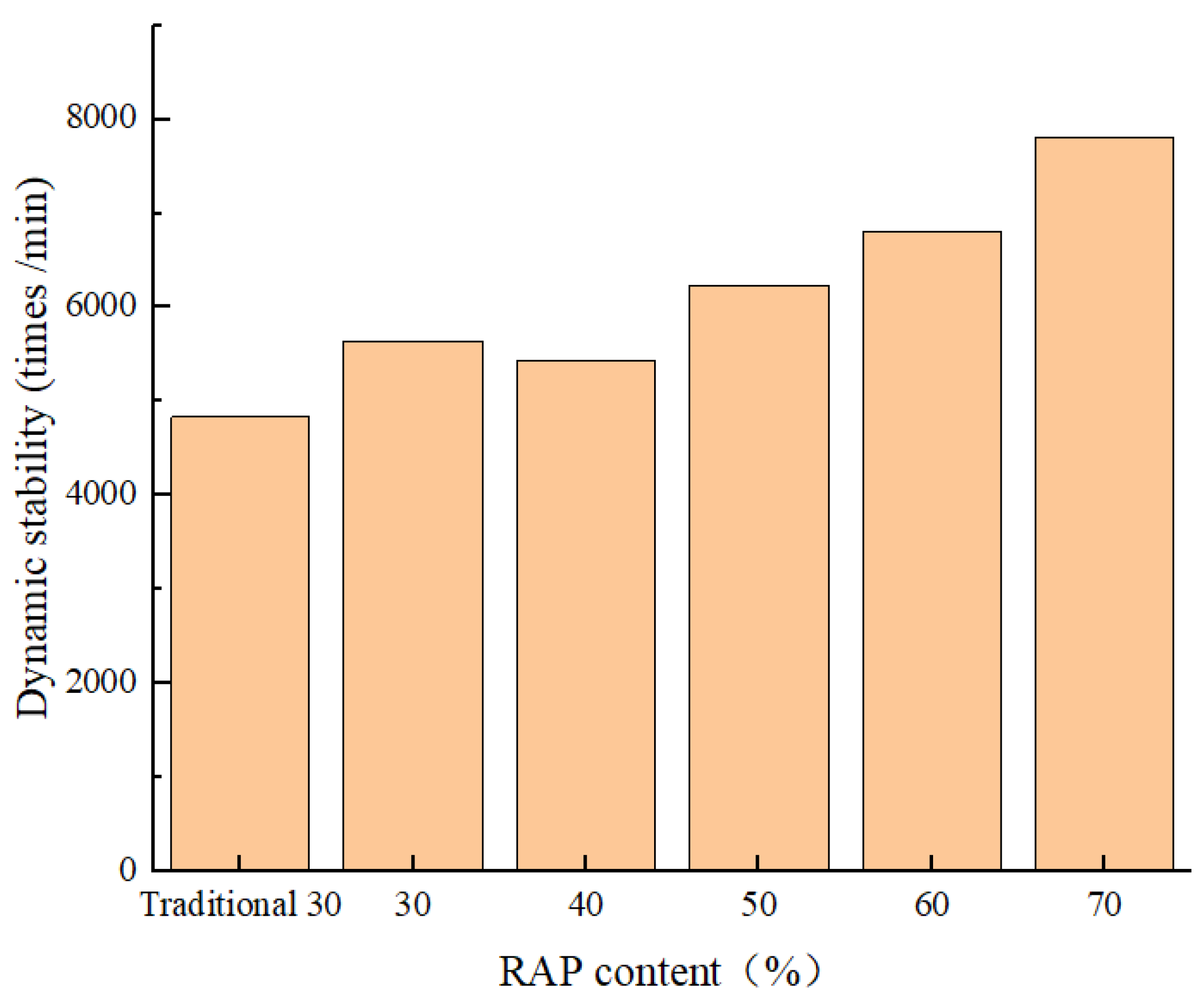

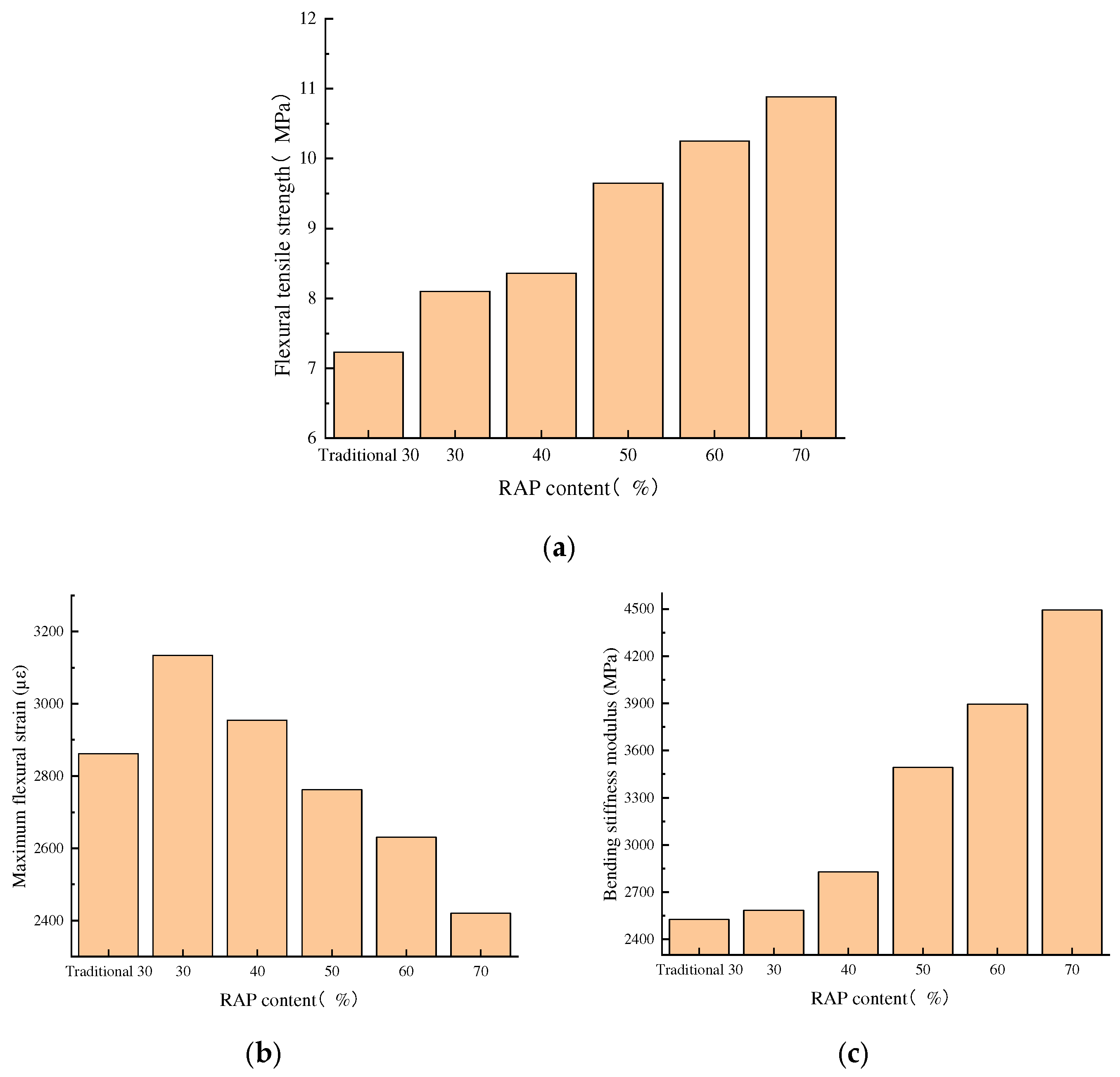

(3) Performance Trade-off: The technology significantly improved mixture uniformity and blending, enhancing overall road performance. A clear performance trade-off was observed: high-temperature stability improved with RAP content, but low-temperature performance and fatigue resistance gradually declined. All performance metrics for the 60% RAP mixture met specifications; however, the 70% RAP mixture failed low-temperature requirements. Therefore, 60% is identified as the optimal and practical maximum RAP content for balanced performance.

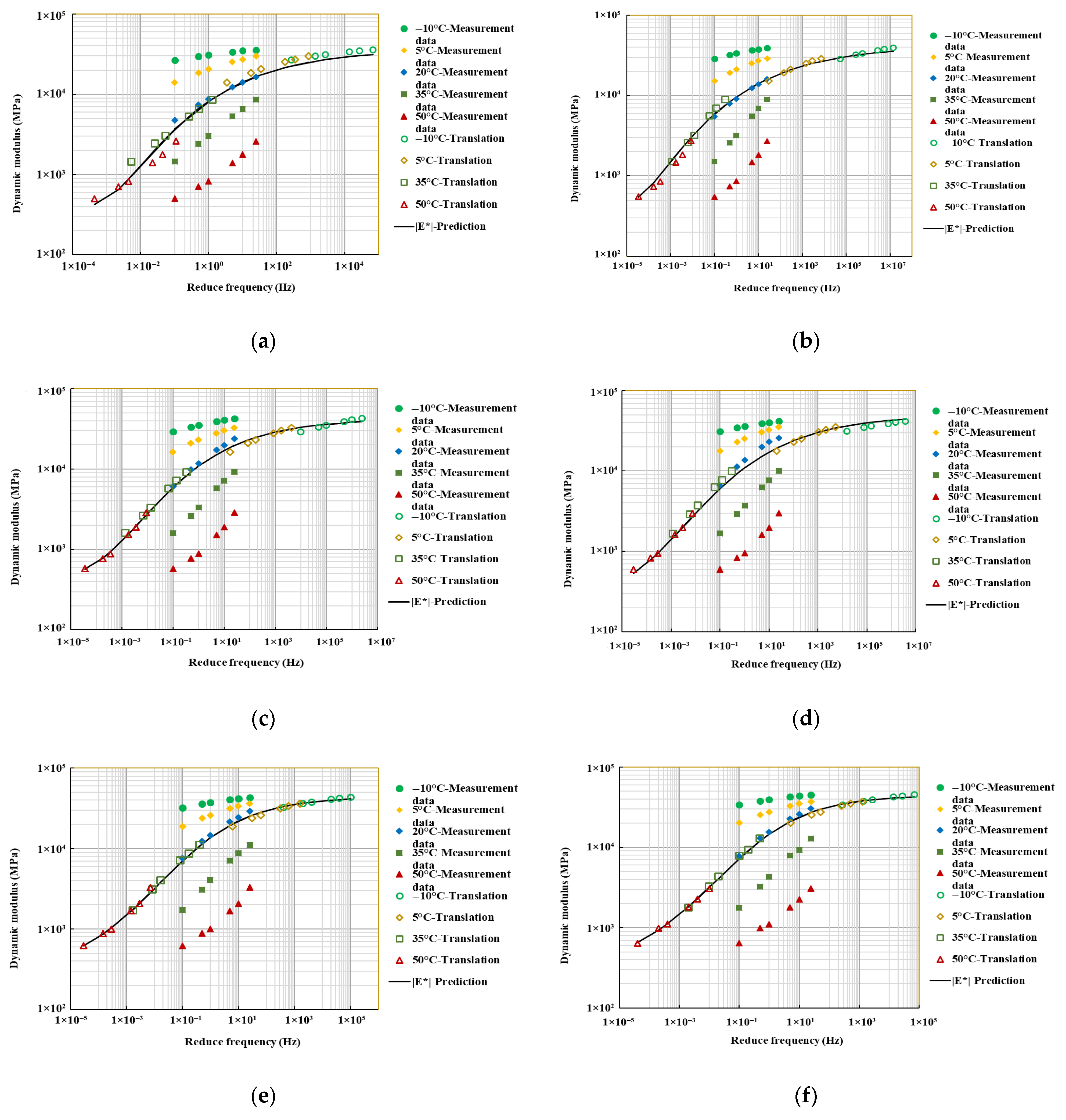

(4) Predictive Modeling: The generalized sigmoidal model accurately characterized the viscoelastic properties and constructed master curves, confirming its utility for modeling high-RAP mixtures.

(5) Economic and Environmental Benefits: The ability to reliably incorporate 60% RAP represents a significant economic advantage by drastically reducing the demand for virgin aggregates and asphalt binder. Furthermore, this high-rate recycling offers substantial environmental benefits, including reduced landfill waste, lower energy consumption associated with quarrying and binder production, and a corresponding decrease in the carbon footprint of pavement construction and rehabilitation projects.

5.2. Limitations and Future Work

This article successfully proves that fine peeling and screening technology is not only a process but also a necessary condition for achieving high-quality RAP. It can technically achieve a RAP content of 60% and is the best choice for asphalt surface layer. By using RSM, a strong scientific basis can be provided for engineering practice, and high-content RAP asphalt mixtures can be reliably designed based on specific material characteristics and performance goals.

However, in terms of limitations, the long-term aging behavior of ultra-high-RAP mixtures (especially with a 70% content), particularly the possibility of further embrittlement within 5–10 years, requires further research through accelerated aging tests or long-term pavement performance monitoring. Meanwhile, research data shows that a 70% RAP content significantly reduces the water stability and low-temperature performance of asphalt mixtures, making it unsuitable for use in the upper layer of asphalt.