Implementation of Paper-Based Materials in Emergency Architecture: Research and Development of Transportable Emergency Cardboard Houses

Abstract

1. Introduction

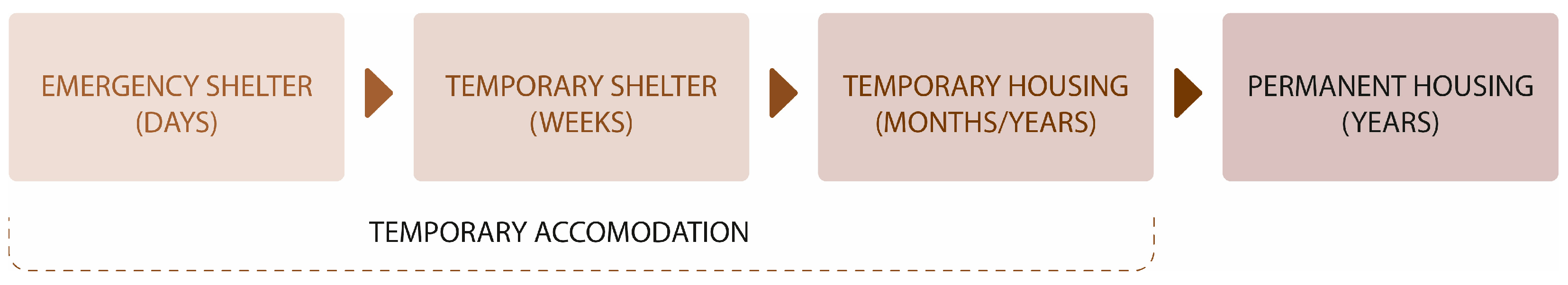

1.1. Shelters

- Emergency shelter: A shelter used at the highest peak of an emergency situation. It can be a private house or a public shelter. This shelter should be used for days as disaster aftermath.

- Temporary shelter: A place accommodated for a short time up to several weeks after the disaster. It can be in the form of gathering in public spaces such as a gymnasium or deployable shelter, e.g., tent.

- Temporary housing: A more durable space, inhabitable, where victims of natural or man-made disasters can experience resilience. This space provides accommodation from 6 months to up to 3 years. It should provide basic comfort, services, and a sense of security.

- Permanent housing: A permanent house where victims of disasters can resettle or return to their original place of stay.

1.2. Environmental Impact of Contemporary Emergency Shelters

1.3. Selected Case Studies of Temporary Housing Solutions

1.3.1. UNHCR Family Tent (FT)

1.3.2. Refugee Housing Unit (RHU)

1.3.3. Paper Log House (PLH)

1.4. Paper as a Building Material

1.5. Objectives of the Study

- (i)

- design and develop paper-based shelters based on varied design criteria and expected lifespans;

- (ii)

- validate the architectural concept through research by prototyping;

- (iii)

- analyze and compare the performance, strengths, and limitations of each design iteration; and

- (iv)

- formulate recommendations for the further development and implementation of paper-based emergency architecture.

2. Materials and Methods

- Material scale, which refers to individual products of cellulosic origin, such as corrugated cardboard, honeycomb panels, paperboard, and paper tubes. These materials are characterized by specific physical and mechanical properties and form the base for further processing.

- Component scale, which includes assembled construction components made from the above-mentioned products, such as wall modules, roof panels, beams, and connectors. This level involves the integration of materials through bonding, lamination, folding, or structural reinforcement.

- Structure scale, which relates to complete architectural prototypes, composed of selected components assembled into a functional shelters.

2.1. Materials’ Properties

2.2. Research Methodology

2.3. Protytyping Process

2.4. Design Evaluation

- In the category of thermal insulations, envelopes were assessed based on the U-value calculated according to the methodology described in the previous paragraph. For U-values lower than 0.5 W/m2K—2 points were assigned, for 0.5 < U < 1.0—1 point, and for U > 1.0—0 pints.

- For R:d (thermal resistance to envelope thickness) ratios, envelopes were assigned 2 points if the ratio was higher than 0.15, 1 point when 0.15 > R:d > 0.10, and 0 point when R:d < 0.10.

- For R:m (thermal resistance to envelope weight) ratios, envelopes were assigned 2 points if the ratio was higher than 0.20, 1 point when 0.20 > R:d > 0.15, and 0 point when R:d < 0.15.

- In the categories of fire, water, and mechanical damage resistance, each envelope was assigned 2 points for high level of resistance on each of its surfaces (external and internal), 1 point for medium resistance, and 0—for low.

- In the categories of price and availability, each envelope was assigned 4 points for good availability, 2 points for medium, and 0—for poor.

3. Results and Discussion

3.1. TECH 01

3.1.1. TECH 01—Design and Materials

3.1.2. TECH 01—Prototyping and Assembly

3.1.3. TECH 01—Evaluation

3.2. TECH 02

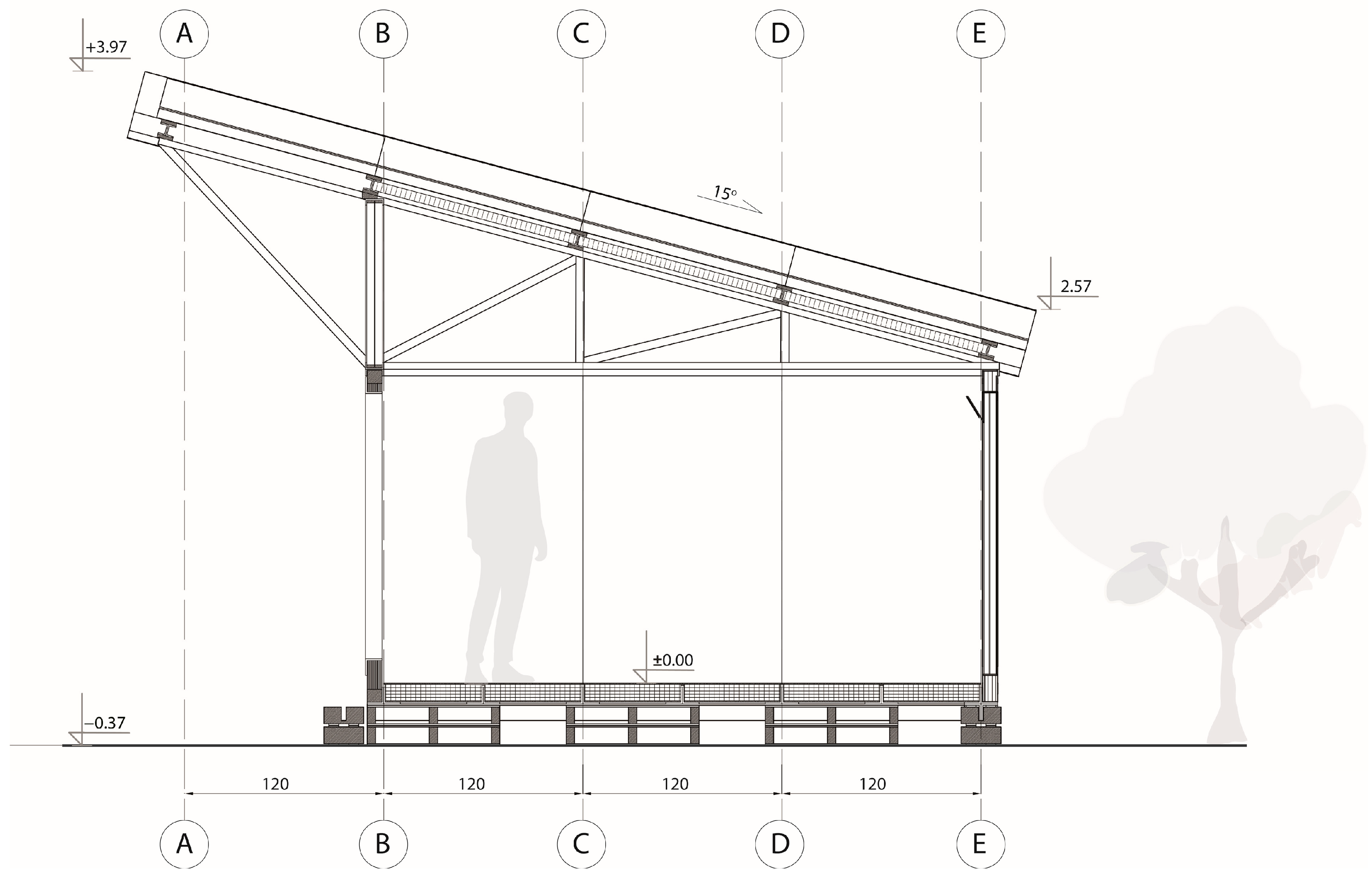

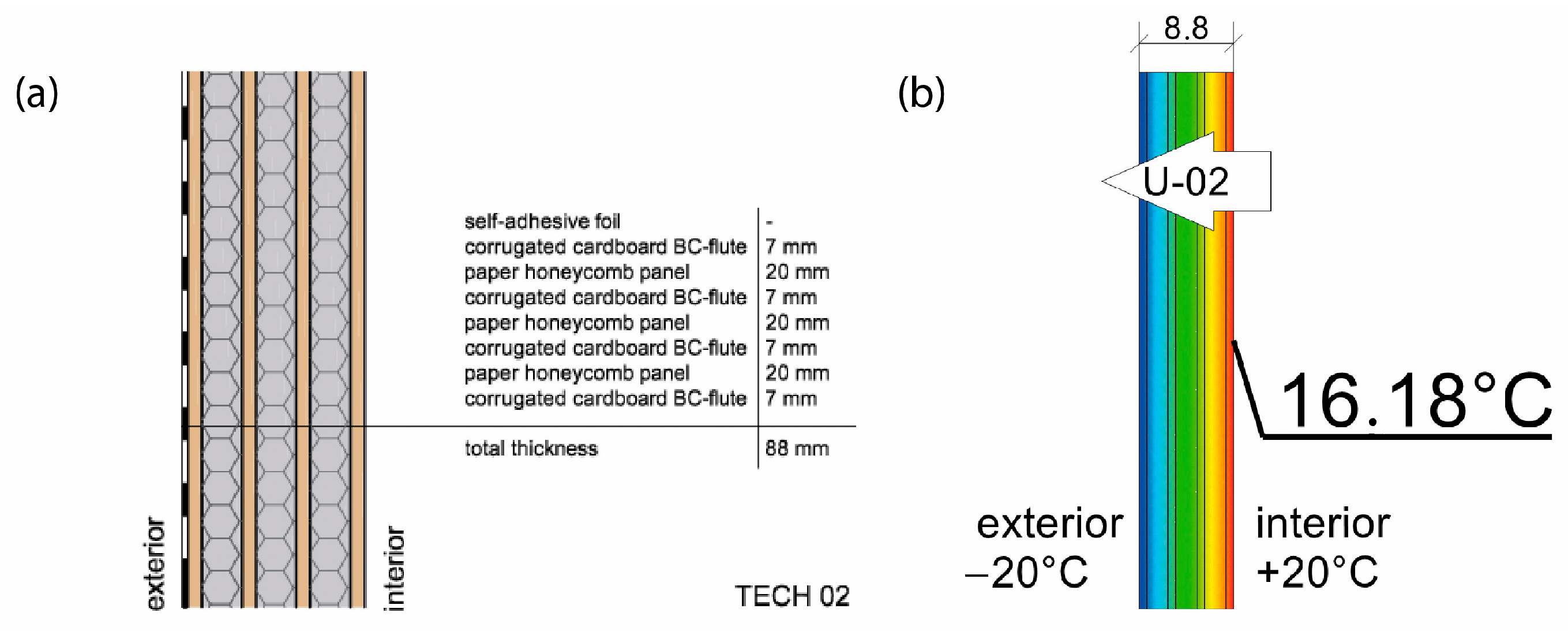

3.2.1. TECH 02—Design and Materials

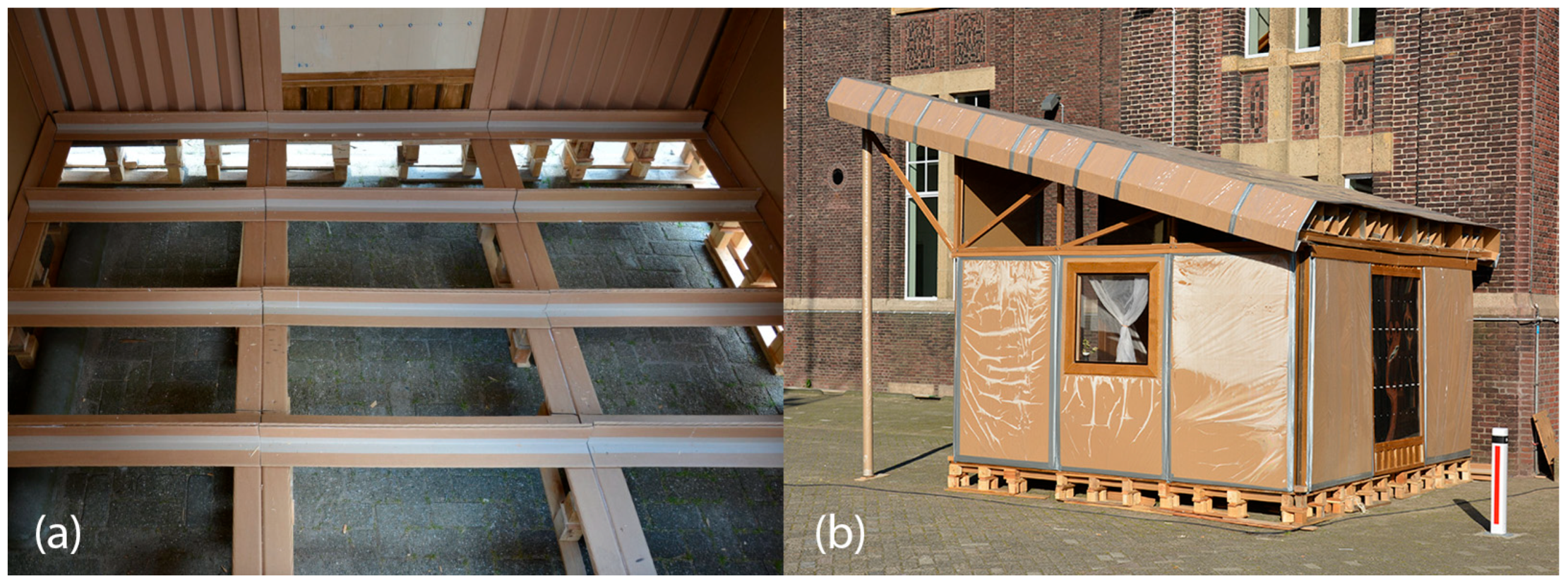

3.2.2. TECH 02—Prototyping and Assembly

3.2.3. TECH 02—Evaluation

3.3. TECH 03

3.3.1. TECH 03—Design and Materials

3.3.2. TECH 03—Prototyping and Assembly

3.3.3. TECH 03—Evaluation

3.4. TECH 04

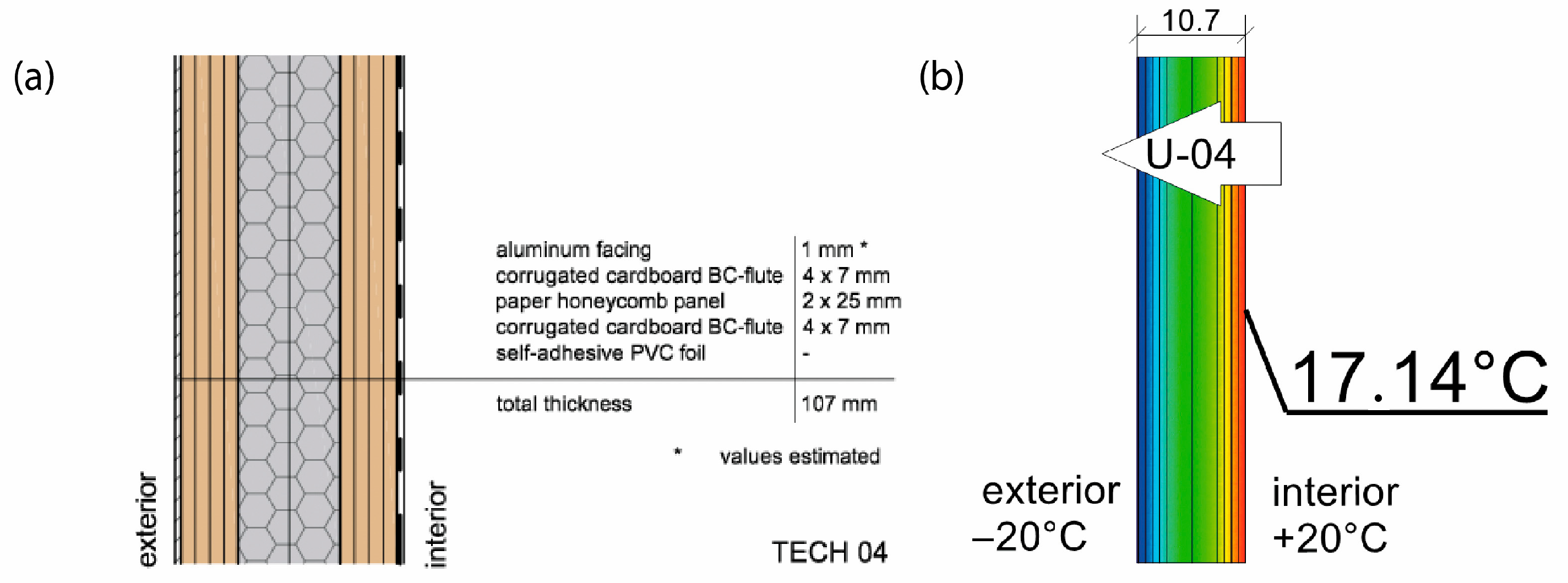

3.4.1. TECH 04—Design and Materials

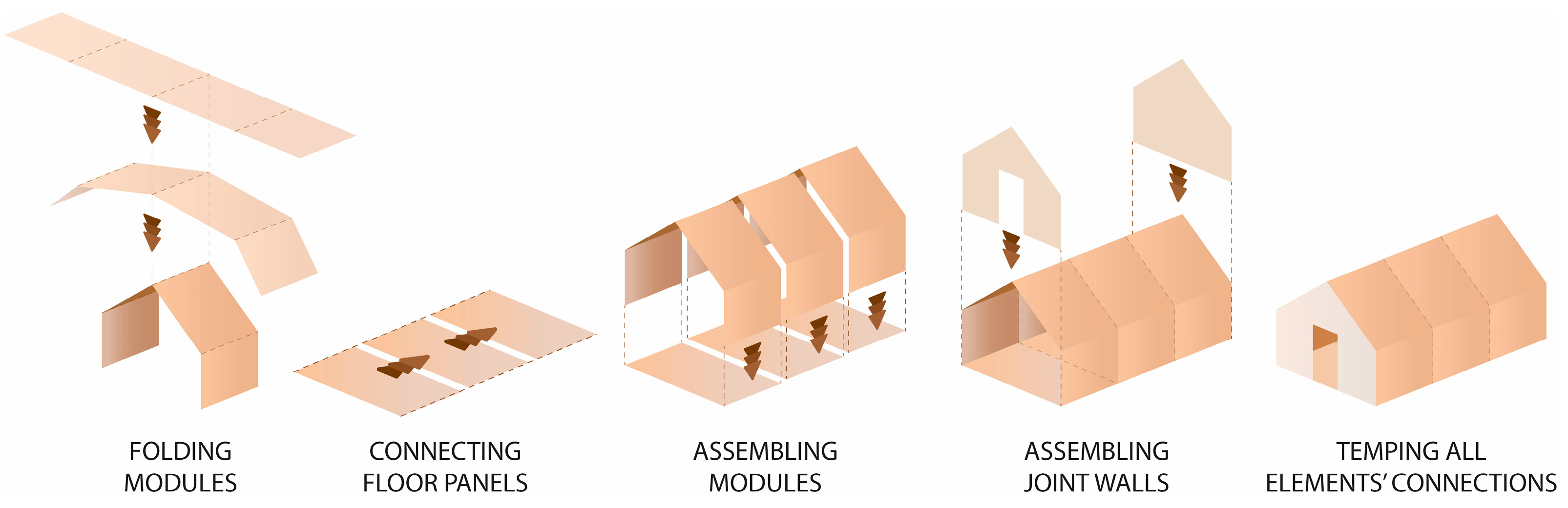

3.4.2. TECH 04—Prototyping and Assembly

3.4.3. TECH 04—Evaluation

3.5. TECH 05

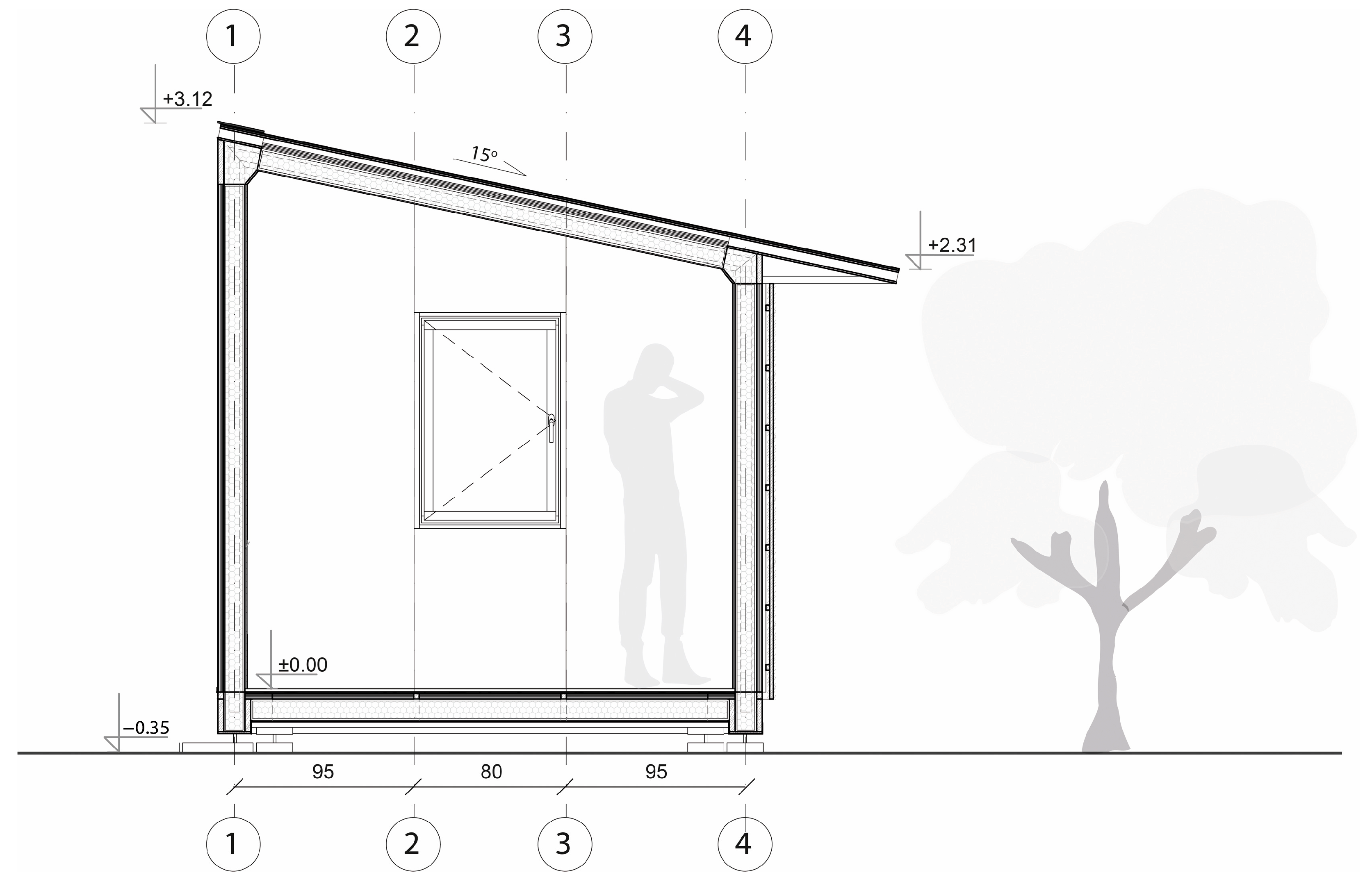

3.5.1. TECH 05—Design and Materials

3.5.2. TECH 05—Prototyping and Assembly

3.5.3. TECH 05—Evaluation

3.6. Design and Prototype Evaluation

3.6.1. Prototyping Evaluation

3.6.2. Envelopes Evaluation

4. Conclusions

- Frame or hybrid frame-panel structural system enhance rigid and lightweight structure. Hybrid system consists of fewer components, and hence improves the assembly process, while frame system allows for replacing damaged panels during the use of the house.

- Building envelope composed of corrugated cardboard and thin honeycomb panels shows the most optimal thermal insulation and weight ratio, while maintaining structural properties of the panel.

- Thermal insulation as additive element, added to previously erected structure minimizes the weight and hence operability of the structure during transportation and assembly. This can be done as an extra outer layer or as a thermal insulation material that is inserted into the building envelope box, for example, cellulose fiber.

- Prefabrication of building components in indoor controlled conditions ensures precise manufacturing where the paper materials are not exposed to water and high humidity.

- Component sizes and weights should allow them to be comfortably handled by two people to ensure smooth assembly process.

- Use of mass-produced paper and other industries produce sub-components that are combined into building components ensures higher reproducibility and hence reduces costs.

- Water and humidity protection is crucial for paper-based structures for short lifespan foil lamination may be sufficient; however, for longer lifespans, a double-layer protection with non-paper material is recommended.

- Fire protection can be combined with the waterproof layers into a single element, made from different material.

- Building envelope ventilation—in the case of long-lasting temporary houses, the system of walls and roof ventilation is required to prevent damage caused by moisture.

- Recyclability analysis and Life Cycle Assessment, that embraces all used materials should be a part of design process, reduce environmental impact of shelters.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UNHCR. Global Trends: Forced Displacement in 2024 Report; UNHCR: Geneva, Switzerland, 2025.

- Internal Displacement Monitoring Centre Global Report on Internal Displacement 2025; IIDMC: Geneva, Switzerland, 2025.

- Félix, D.; Monteiro, D.; Branco, J.M.; Bologna, R.; Feio, A. The Role of Temporary Accommodation Buildings for Post-Disaster Housing Reconstruction. J. Hous. Built Environ. 2015, 30, 683–699. [Google Scholar] [CrossRef]

- Ashmore, J.; Treherne, C. Post-Disaster Shelter: Ten Designs; International Federation of Red Cross and Red Crescent Societies, Ed.; International Federation of Red Cross and Red Crescent Societies: Geneva, Switzerland, 2013. [Google Scholar]

- Szmigiera, M. Distribution of Total Refugee Population Worldwide in 2017, by Housing Type. Available online: https://www.statista.com/statistics/742574/percentage-distribution-of-refuges-worldwide-by-accommodation-type/#statisticContainer (accessed on 24 September 2021).

- Corsellis, T.; Vitale, A. Transitional Settlement: Displaced Populations; Oxfam-University of Cambridge: Cambridge, UK, 2005; p. 464. [Google Scholar]

- Turner, S. What Is a Refugee Camp? Explorations of the Limits and Effects of the Camp. J. Refug. Stud. 2016, 29, 139–148. [Google Scholar] [CrossRef]

- Hosseini, S.M.A.; Farahzadi, L.; Pons, O. Assessing the Sustainability Index of Different Post-Disaster Temporary Housing Unit Configuration Types. J. Build. Eng. 2021, 42, 102806. [Google Scholar] [CrossRef]

- Bellomo, M.; Colajanni, S.; Saeli, M. Emergency Architecture: Application of the Active House Protocol for the Indoor Comfort Prediction in Post-Disaster Shelters. Sustainability 2025, 17, 2290. [Google Scholar] [CrossRef]

- Pinto, D.; Firmino, B.; Santos, M.; Carvalho, W.; Oliveira, L. The Emergency Architecture—Reuse and Recycle Material After Disasters. J. Eng. Technol. Ind. Appl. 2020, 6, 31–40. [Google Scholar]

- Karimi, R.; Shirowzhan, S.; Sepasgozar, S.M.E. Architectural Design Criteria Considering the Circular Economy and Buildability for Smart Disaster Relief Shelter Prototyping. Buildings 2023, 13, 1777. [Google Scholar] [CrossRef]

- Paparella, R.; Caini, M. Sustainable Design of Temporary Buildings in Emergency Situations. Sustainability 2022, 14, 8010. [Google Scholar] [CrossRef]

- Kahvecioğlu, B.; Selçuk, S.A. Review of Sustainable Temporary Housing and Reuse Strategy for Post-Disaster Architectures: Current Trends and Strategic Gaps. J. Eng. Appl. Sci. 2025, 72, 8. [Google Scholar] [CrossRef]

- Conzatti, A.; Kershaw, T.; Copping, A.; Coley, D. A Review of the Impact of Shelter Design on the Health of Displaced Populations. J. Int. Humanit. Action 2022, 7, 18. [Google Scholar] [CrossRef]

- Kuchai, N.; Albadra, D.; Lo, S.; Saied, S.; Paszkiewicz, N.; Shepherd, P.; Natarajan, S.; Orr, J.; Hart, J.; Adeyeye, K.; et al. Improving the Shelter Design Process via a Shelter Assessment Matrix. Prog. Disaster Sci. 2024, 23, 100354. [Google Scholar] [CrossRef]

- IFRC. Transitional Shelters Eight Designs; IFRC: Geneva, Switzerland, 2011; p. 96. [Google Scholar]

- UNHCR. Shelter and Settlement Section Shelter Design Catalogue; UNHCR: Geneva, Switzerland, 2016.

- UNHCR Item No 05353; United Nation High Commisioner for Refugees UNHCR Family Tent. UNHCR: Geneva, Switzerland, 2014.

- Ashmore, J. A Guide to the Use and Logistics of Family Tents in Humanitarian Relief; United Nations: Manhattan, NY, USA, 2004.

- UNHCR. The Refugee Housing Unit; Creating Better Homes for Emergency Relief and Beyond; UNHCR: Geneva, Switzerland, 2018.

- Christian, M.; Ban, S.; Bruderlein, C.; Kimmelman, M.; Kitayama, K.; Pitt, B.; Pollock, N.; Weizman, E.; Zuckerman Jackobson, H. Shigeru Ban: Humanitarian Architecture: [Published on the Occasion of the Exhibition Shigeru Ban: Humanitarian Architecture, on View at the Aspen Art Museum August 9–October 5, 2014]; Aspen Art Press: Aspen, CO, USA, 2014; ISBN 978-0-934324-64-9. [Google Scholar]

- Miyake, R.; Luna, I.; Gould, L.A. Shigeru Ban: Paper in Architecture; Rizzoli International Publications: New York, NY, USA, 2012; ISBN 0847829251. [Google Scholar]

- Shigeru Ban Architects Disaster Relief Works. Available online: https://shigerubanarchitects.com/works/?_work=disaster-relief (accessed on 15 June 2025).

- Alshawawreh, L.; Pomponi, F.; D’Amico, B.; Snaddon, S.; Guthrie, P. Qualifying the Sustainability of Novel Designs and Existing Solutions for Post-Disaster and Post-Conflict Sheltering. Sustainability 2020, 12, 890. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Eekhout, M.; Verheijen, F.; Visser, R. Cardboard in Architecture; IOS Press: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Diarte, J.; Shaffer, M. Cardboard Architecture: Eight Decades of Exploration in Academic Research and Professional Practice 1940–2019. Enq. ARCC J. Archit. Res. 2021, 18, 17–40. [Google Scholar] [CrossRef]

- The Hyatt Foundation Announcement: Shigeru Ban Lauraete of the Pritzker Prize. Available online: https://www.pritzkerprize.com/announcement-shigeru-ban (accessed on 21 September 2021).

- McQuaid, M. Shigeru Ban; Phaidon: London, UK, 2003; ISBN 0714841943. [Google Scholar]

- Fiction Factory Wikkel House. Available online: https://wikkelhouse.com (accessed on 20 June 2025).

- Knaack, U.; Bach, R.; Schabel, S. (Eds.) Building with Paper: Architecture and Construction; Birkhäuser: Basel, Switzerland, 2022. [Google Scholar]

- Bach, R.; Wolf, A.; Wilfinger, M.; Kiziltoprak, N.; Knaack, U. A Full Performance Paper House. J. Facade Des. Eng. 2021, 9, 117–130. [Google Scholar] [CrossRef]

- Diarte, J.; Vazquez, E. Building from Waste Cardboard: A Grammar for the Design and Fabrication of a Customized Modular House with Waste Cardboard and Wood-Framed Panels. In RE: Anthropocene, Design in the Age of Humans, Proceedings of the 25th International Conference on Computer-Aided Architectural Design Research in Asia, CAADRIA, Bangkok, Thailand, 5–6 August 2020; Volume 1, pp. 465–474. [CrossRef]

- Diarte, J.; Vazquez, E.; Shaffer, M. Tooling Cardboard for Smart Reuse: A Digital and Analog Workflow for Upcycling Waste Corrugated Cardboard as a Building Material; Springer: Berlin/Heidelberg, Germany, 2019; pp. 384–398. [Google Scholar] [CrossRef]

- Diarte, J.; Vazquez, E.; Shaffer, M. Tooling Cardboard for Smart Reuse—Testing a Parametric Tool for Adapting Waste Corrugated Cardboard to Fabricate Acoustic Panels and Concrete Formwork. In Proceedings of the 37th International Conference on Education and Research in Computer Aided Architectural Design in Europe (eCAADe) & 23rd Conference of the Iberoamerican Society Digital Graphics, Porto, Portugal, 11–13 September 2019; Volume 2, pp. 769–778. [Google Scholar] [CrossRef]

- Sapienza, V.; Rodonò, G.; Monteleone, A.; Calvagna, S. ICARO—Innovative Cardboard ARchitecture Object: Sustainable Building Technology for Multipurpose Micro-Architecture. Sustainability 2022, 14, 16099. [Google Scholar] [CrossRef]

- Łątka, J.F.; Jasiołek, A.; Karolak, A.; Niewiadomski, P.; Noszczyk, P.; Klimek, A.; Zielińska, S.; Misiurka, S.; Jezierska, D. Properties of Paper-Based Products as a Building Material in Architecture—An Interdisciplinary Review. J. Build. Eng. 2022, 50, 104135. [Google Scholar] [CrossRef]

- Shenoy, P.; Aithal, P. A Study on History of Paper and Possible Paper Free World. Int. J. Manag. 2016, 6, 337–355. [Google Scholar] [CrossRef]

- Bank, L.C.; Gerhardt, T.D. Paperboard Tubes in Structural and Construction Engineering. Nonconv. Vernac. Constr. Mater. 2016, 453–480. [Google Scholar]

- Correa, C. Designing with Paper Tubes. Struct. Eng. Int. 2004, 14, 277–281. [Google Scholar] [CrossRef]

- Pflug, J.; Verpoest, I.; Vandepitte, D. Folded honeycomb cardboard and core material for structural applications. In Proceedings of the 5th International Conference on Sandwich Construction, Zürich, Switzerland, 5–7 September 2000. [Google Scholar]

- Cripps, A. Cardboard as a Construction Material: A Case Study. Build. Res. Inf. 2004, 32, 207–219. [Google Scholar] [CrossRef]

- Abdel-Mohsen, M.A.; Faggal, A.A.; El-Metwally, Y.S. Efficiency of Corrugated Cardboard as a Building Material. 2012; 1–19. [Google Scholar] [CrossRef]

- Pohl, A.; Fontana, M. The Mechanical and Thermal Properties of Corrugated Paper Honeycomb. Part 2—Analytical Determination. Nord. Pulp Pap. Res. J. 2010, 25, 522–535. [Google Scholar] [CrossRef]

- Bank, L.C.; Gerhardt, T.D.; Gordis, J.H. Dynamic Mechanical Properties of Spirally Wound Paper Tubes. J. Vib. Acoust. Stress Reliab. Des. 1989, 111, 489–490. [Google Scholar] [CrossRef]

- Bank, L.C.; Cofie, E.; Gerhardt, T.D. A New Test Method for the Determination of the Flexural Modulus of Spirally Wound Paper Tubes. J. Eng. Mater. Technol. 1992, 114, 84–89. [Google Scholar] [CrossRef]

- Schönwälder, J.; Jan, R. Mechanical Behaviour of Cardboard in Construction. In Cardboard in Architecture; IOS Press: Amsterdam, The Netherlands, 2008; pp. 131–1146. ISBN 978-1-58603-820-5. [Google Scholar]

- Ayan, O. Cardboard in Architectural Technology and Structural Engineering a Conceptual Approach to Cardboard Buildings in Architecture. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2009. [Google Scholar]

- Block, K. The Structural Behavior of the Load Carrying Paper Made for the Japanese Pavilion at the EXPO 2000; Technische Universität Dortmund: Dortmund, Germany, 1999; p. 1. [Google Scholar]

- von der Heyden, A.; Lange, J. 07.25: Assessment of the Utilisation of Corrugated Cardboard as a Core Material for Sandwich Panels. Ce/Papers 2017, 1, 1716–1725. [Google Scholar] [CrossRef]

- Asdrubali, F.; Pisello, A.L.; D’Alessandro, F.; Bianchi, F.; Fabiani, C.; Cornicchia, M.; Rotili, A. Experimental and Numerical Characterization of Innovative Cardboard Based Panels: Thermal and Acoustic Performance Analysis and Life Cycle Assessment. Build. Environ. 2016, 95, 145–159. [Google Scholar] [CrossRef]

- Čekon, M.; Struhala, K.; Slávik, R. Cardboard-Based Packaging Materials as Renewable Thermal Insulation of Buildings: Thermal and Life-Cycle Performance. J. Renew. Mater. 2017, 5, 84–93. [Google Scholar] [CrossRef]

- Salavatian, S.; D’Orazio, M.; Di Perna, C.; Di Giuseppe, E. Assessment of Cardboard as an Environment-Friendly Wall Thermal Insulation for Low-Energy Prefabricated Buildings BT—Sustainable Building for a Cleaner Environment: Selected Papers from the World Renewable Energy Network’s Med Green Forum 2017; Sayigh, A., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 463–470. ISBN 978-3-319-94595-8. [Google Scholar]

- Gaudelas, A.; Blanchet, P.; Gosselin, L.; Cabral, M.R. Physical Characterization of Biobased Corrugated Panels, an Innovative Material. Bioresources 2023, 18, 5838–5858. [Google Scholar] [CrossRef]

- Gray-Stuart, E.M.; Bronlund, J.E.; Navaranjan, N.; Redding, G.P. Measurement of Thermal Conductivity of Paper and Corrugated Fibreboard with Prediction of Thermal Performance for Design Applications. Cellulose 2019, 26, 5695–5705. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, C.S.; Wang, D.Q.; Han, W.J. Preparation of Refractory Fiber Cardboard for Building Insulation. Appl. Mech. Mater. 2013, 357-360, 1295–1299. [Google Scholar] [CrossRef]

- Lavrykov, S.A.; Ramarao, B.V. Thermal Properties of Copy Paper Sheets. Dry. Technol. 2012, 30, 297–311. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Ramarao, B.V.; Ramaswamy, S. Transient Moisture Diffusion through Paperboard Materials. Colloids Surf. A Physicochem. Eng. Asp. 2002, 206, 455–467. [Google Scholar] [CrossRef]

- Lyngå, H.; Sikö, G. Moisture Dynamics in Corrugated Board Boxes. Master’s Thesis, Mahidol University International College (MUIC), Salaya, Thailand, 2003. [Google Scholar]

- Gimåker, M. Influence of Fibre Modification on Moisture Sorption and the Mechanical Properties of Paper. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2010. [Google Scholar]

- Bach, R. Papier Fassaden: Entwicklung Konstruktiver Prinzipien Für Fassaden Aus Papierwerkstoffen Mit Fokus Auf Brandschutz, Wärmedämmung, Feuchteschutz Und Ökologische Eigenschaften. Ph.D. Thesis, RWTH Aachen University, Aachen, Deutschland, 2020. [Google Scholar]

- Noszczyk, P.; Łątka, J.; Jasiołek, A. Termoizolacyjność Materiałów Pochodzenia Celulozowego—Tektura Falista i Plaster Miodu. Mater. Bud. 2022, nr 11, 158–160. [Google Scholar] [CrossRef]

- EN 12667:2002; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- Karolak, A.; Niewiadomski, P.; Szymanowski, J.; Zielonka, P.; Duda, S.; Łątka, J. Paper-Based Products as a Building Material for a Small Residential Unit: Testing of the Mechanical Properties. J. Struct. Des. Constr. Pr. 2024, 30, 04024087. [Google Scholar] [CrossRef]

- Latka, J.F. Paper in Architecture: Research by Design, Engineering and Prototyping. Arch. Built Environ. 2017, 19, 1–532. [Google Scholar] [CrossRef]

- ISO 10456:2007/Cor 1:2009; Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values—Technical Corrigendum 1. ISO: Geneva, Switzerland, 2009. Available online: https://www.iso.org/standard/55597.html (accessed on 6 July 2025).

- Mathews, J.M.; Vivek, B.; Charde, M. Thermal Insulation Panels for Buildings Using Recycled Cardboard: Experimental Characterization and Optimum Selection. Energy Build 2023, 281, 112747. [Google Scholar] [CrossRef]

- Li, Y.; Yang, J.; Chen, J.; Yin, J.; Li, Y.; Yang, J.; Chen, J.; Yin, J. Study of the Heat Transfer Performance of Laminated Paper Honeycomb Panels. Biomimetics 2023, 8, 46. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, J.; Pan, L.; Qiu, X. Experimental, Numerical and Theoretical Study on Heat Transfer in Paper Honeycomb Structure. Int. J. Therm. Sci. 2023, 186, 108108. [Google Scholar] [CrossRef]

- Mick, E. Methodology for Product Development in Architecture; IOS Press: Amsterdam, The Netherlands, 2008; p. 230. [Google Scholar]

- EN 1991-1-2:2002; Eurocode 1: Actions on Structures—Part 1–2: General Actions—Actions On. European Committee for Standardization: Brussels, Belgium, 2002. Available online: https://standards.iteh.ai/catalog/standards/cen/5bdb5478-f413-4f23-a3e2-2eba83dc303f/en-1991-1-2-2002?srsltid=AfmBOooNs2HjpoyLPbsWxhvbr-Qd0Q8NrjCfcPFcqCs_Wxeknety52WG (accessed on 6 July 2025).

- Jasiolek, A. Paper-Based Building Envelopes—Environmental and Performance Assessment of Original and Literature-Based Designs. Build. Environ. 2023, 244, 110755. [Google Scholar] [CrossRef]

- Latka, J.F. TECH Transportable Emergency Cardboard House. In Proceedings of the IASS 2016: Spatial Structures in the 21st Century, Tokyo, Japan, 26–30 September 2016; Kawaguchi, K.T., Takeuchi, M.O., Eds.; IASS: Tokyo, Japan, 2016. [Google Scholar]

- Latka, J.F. House of Cards-Design and Implementation of a Paper House Prototype. In Proceedings of the IASS Annual Symposia, Hamburg, Germany, 25–28 September 2017; pp. 1–10. [Google Scholar]

| Paper-Based Product | Description | Mechanical Parameters from Tests—Mean Values | |

|---|---|---|---|

Paper tube 60 | outer diameter 60 mm wall thickness 4 mm material density 650 kg/m3 | fc | 9.9 MPa |

| ft | 12.8 MPa | ||

| fm,3 | 11.7 MPa | ||

| fm,4 | 14.8 MPa | ||

| Et | 2.49 GPa | ||

| Em | 0.82 GPa | ||

Paper tube 115 | outer diameter 115 mm wall thickness 7 mm material density 650 kg/m3 | fc | 11.0 MPa |

| ft | 12.3 MPa | ||

| fm,3 | 12.9 MPa | ||

| fm,4 | 11.6 MPa | ||

| Et | 11.07 GPa | ||

| Em | 0.58 GPa | ||

Paper tube 170 | outer diameter 170 mm wall thickness 10 mm material density 650 kg/m3 | fc | 5.7 MPa |

| ft | 8.7 MPa | ||

| fm,3 | 5.8 MPa | ||

| fm,4 | 6.4 MPa | ||

| Et | 5.56 GPa | ||

| Em | 0.40 GPa | ||

Corrugated cardboard BC flute | 5 layers paper thickness 6.01 mm density 573 g/m2 | ft,par | 14.0 MPa |

| ft,per | 16.7 MPa | ||

Honeycomb panel | thickness 25 mm | ft | 7.5 MPa |

Honeycomb panel | thickness 50 mm | ft | 2.2 MPa |

Rectangular paper tubes from two U-shape elements glued together | section dimensions: 58 mm × 68.5 mm wall thickness 5.5 mm element length 1080 mm | fm,4 | 6.6 MPa |

| fc | 8.3 MPa | ||

| Material | Type/Height/Direction | λ [W/mK] | Source |

|---|---|---|---|

| Corrugated cardboard | B—flute/-/Z | 0.039 | Own research |

| Corrugated cardboard | BC—flute/-/Z | 0.044 | Own research |

| Corrugated cardboard | E—flute/-/Z | 0.045 | Own research |

| Corrugated cardboard | EE—flute/-/Z | 0.043 | Own research |

| Corrugated cardboard | BC—flute/-/Y | 0.090 | Own research |

| Corrugated cardboard | BC—flute/-/X | 0.084 | Own research |

| Honeycomb panel | /10 mm/Z | 0.067 | Own research |

| Honeycomb panel | /25 mm/Z | 0.105 | Own research |

| Honeycomb panel | /50 mm/Z | 0.135 | Own research |

| Honeycomb panel | /25 mm/X | 0.083 | Own research |

| Honeycomb panel | /50 mm/X | 0.074 | Own research |

| Cardboard | />1 mm/Z | 0.14 | [66] |

| Copy paper | /<1 mm/Z | 0.25 | [66] |

| Corrugated cardboard | C-flute/-/Z | 0.053 | [51] |

| Corrugated cardboard | E-flute/-/Z | 0.058 | [51] |

| Corrugated cardboard | /19 mm/Z | 0.0902–0.1326 | [54] |

| Recycled cardboard | /-/Z | 0.09 | [67] |

| Corrugated cardboard | B-flute/-/Z | 0.0486 | [52] |

| Honeycomb panel | /70 mm/Z | 0.1167 | [52] |

| Honeycomb panel | /30 mm/Z | 0.0899 | [52] |

| Honeycomb panel | /18 mm/Z | 0.0773 | [52] |

| Honeycomb panel | /13 mm/Z | 0.0706 | [52] |

| Honeycomb panel | /50 mm/Z | 0.125 | [53] |

| Cardboard | /-/Z | 0.065 | [56] |

| Corrugated cardboard | -/20 to 50 mm/Z | 0.0477 to 0.0839 | [61] |

| Honeycomb panel | /10 to 60 mm/Z | 0.06 to 0.165 | [68] |

| Honeycomb panel | /25 mm/Z | 0.0783 to 0.1064 | [69] |

| Prototype Details | Prototype Characteristics | ||

|---|---|---|---|

| version | TECH 01 | usable area | 17.4 m2 |

| designer | (author) | expected lifespan | 18 months |

| year | 2014 | envelope U-value | 1.66 W/m2K |

| place of construction | Delft, NL (only panel prototype) | structural system | hybrid rod-panel |

| Prototype Details | Prototype Characteristics | ||

|---|---|---|---|

| version | TECH 02 | usable area | 13.0 m2 |

| designers | Students of TU Delft | expected lifespan | 3 years |

| year | 2015 | envelope U-value | 0.73 W/m2K |

| place of construction | Delft, NL | structural system | rod |

| Prototype Details | Prototype Characteristics | ||

|---|---|---|---|

| version | TECH 03 | usable area | 12.0; 25.0 m2 |

| designers | Jerzy Łątka, Julia Schönwälder | expected lifespan | 3 years |

| year | 2016 | envelope U-value | 0.73 W/m2K |

| place of construction | Wrocław, PL | structural system | frame |

| Prototype Details | Prototype Characteristics | ||

|---|---|---|---|

| version | TECH 04 | usable area | 13.8 m2 |

| designers | Jerzy Łątka, Agata Jasiołek | expected lifespan | 5 years |

| year | 2018 | envelope U-value | 0.55 W/m2K |

| place of construction | Wrocław, PL | structural system | hybrid frame-panel |

| Prototype Details | Prototype Characteristics | ||

|---|---|---|---|

| version | TECH 05 | usable area | 14 m2 |

| designers | article authors | expected lifespan | 10 years |

| year | 2024 | envelope U-value | 0.27 W/m2K |

| place of construction | Wrocław, PL | structural system | hybrid frame-panel |

| TECH 01 | TECH 02 | TECH 03 | TECH 04 | TECH 05 | ||

|---|---|---|---|---|---|---|

| envelope structure type | sandwich | sandwich | sandwich | sandwich/embedded | sandwich/embedded | |

| expected lifespan | 18 months | 3 years | 3 years | 5 years | 10 years | |

| load-bearing | no | no | no | yes | yes | |

| thickness (d) [cm] | 4.3 | 8.8 | 15.0 | 10.7 | 21.5 | |

| ventilation | no | no | no | no | yes | |

| weight (m) [kg/m2] | 4.93 | 6.09 | 5.83 | 9.91 | 41.28 | |

| heat of combustion [MJ/m2] | 104.95 | 126.85 | 122.95 | 172.35 | 144.65 | |

| thermal transmittance (U) [W/m2K] | 1.66 | 0.73 | 0.73 | 0.55 | 0.27 | |

| thermal resistance (R) [m2K/W] | 0.60 | 1.37 | 1.37 | 1.82 | 3.70 | |

| R:d ratio | 0.14 | 0.16 | 0.09 | 0.17 | 0.17 | |

| R:m ratio | 0.12 | 0.22 | 0.23 | 0.18 | 0.09 | |

| paper share, by weight | 91% | 90% | 93% | 75% | 20% | |

| paper share, by volume | 99% | 98% | 99% | 98% | 76% | |

| insulative core material | HP | CC, HP | HP | CC | CC, CF | |

| internal surface | protection technique | FL | - | 2× FL | FL | AM |

| fire resistance | low | low | low | low | high | |

| water resistance | medium | low | medium | medium | medium | |

| mechanical resistance | low | low | low | low | high | |

| external surface | protection technique | FL | FL | 2× FL | AM | FL, AM |

| fire resistance | low | low | low | medium | high | |

| water resistance | medium | medium | medium | high | high | |

| mechanical resistance | medium | low | low | high | high | |

| price and material availability | good | good | good | medium | poor | |

| TECH 01 | TECH 02 | TECH 03 | TECH 04 | TECH 05 | |

|---|---|---|---|---|---|

| U [W/m2K] | 0 | 1 | 1 | 1 | 2 |

| R:d ratio | 1 | 2 | 0 | 2 | 2 |

| R:m ratio | 0 | 2 | 2 | 1 | 0 |

| fire resistance | 0 | 0 | 0 | 1 | 4 |

| water resistance to water | 2 | 1 | 2 | 3 | 3 |

| mechanical resistance | 1 | 0 | 0 | 2 | 4 |

| price and material availability | 4 | 4 | 4 | 2 | 0 |

| Performance Score | 8 | 10 | 9 | 12 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łątka, J.F.; Jasiołek, A.; Pawłosik, D.; Karolak, A.; Niewiadomski, P.; Noszczyk, P.; Jörgen, A.; Sołowiej, P. Implementation of Paper-Based Materials in Emergency Architecture: Research and Development of Transportable Emergency Cardboard Houses. Materials 2025, 18, 4134. https://doi.org/10.3390/ma18174134

Łątka JF, Jasiołek A, Pawłosik D, Karolak A, Niewiadomski P, Noszczyk P, Jörgen A, Sołowiej P. Implementation of Paper-Based Materials in Emergency Architecture: Research and Development of Transportable Emergency Cardboard Houses. Materials. 2025; 18(17):4134. https://doi.org/10.3390/ma18174134

Chicago/Turabian StyleŁątka, Jerzy F., Agata Jasiołek, Daria Pawłosik, Anna Karolak, Paweł Niewiadomski, Paweł Noszczyk, Artur Jörgen, and Paulina Sołowiej. 2025. "Implementation of Paper-Based Materials in Emergency Architecture: Research and Development of Transportable Emergency Cardboard Houses" Materials 18, no. 17: 4134. https://doi.org/10.3390/ma18174134

APA StyleŁątka, J. F., Jasiołek, A., Pawłosik, D., Karolak, A., Niewiadomski, P., Noszczyk, P., Jörgen, A., & Sołowiej, P. (2025). Implementation of Paper-Based Materials in Emergency Architecture: Research and Development of Transportable Emergency Cardboard Houses. Materials, 18(17), 4134. https://doi.org/10.3390/ma18174134