Assessment of 10CrMo9-10 Power Engineering Steel Degradation State by Using Small Punch Test

Abstract

1. Introduction

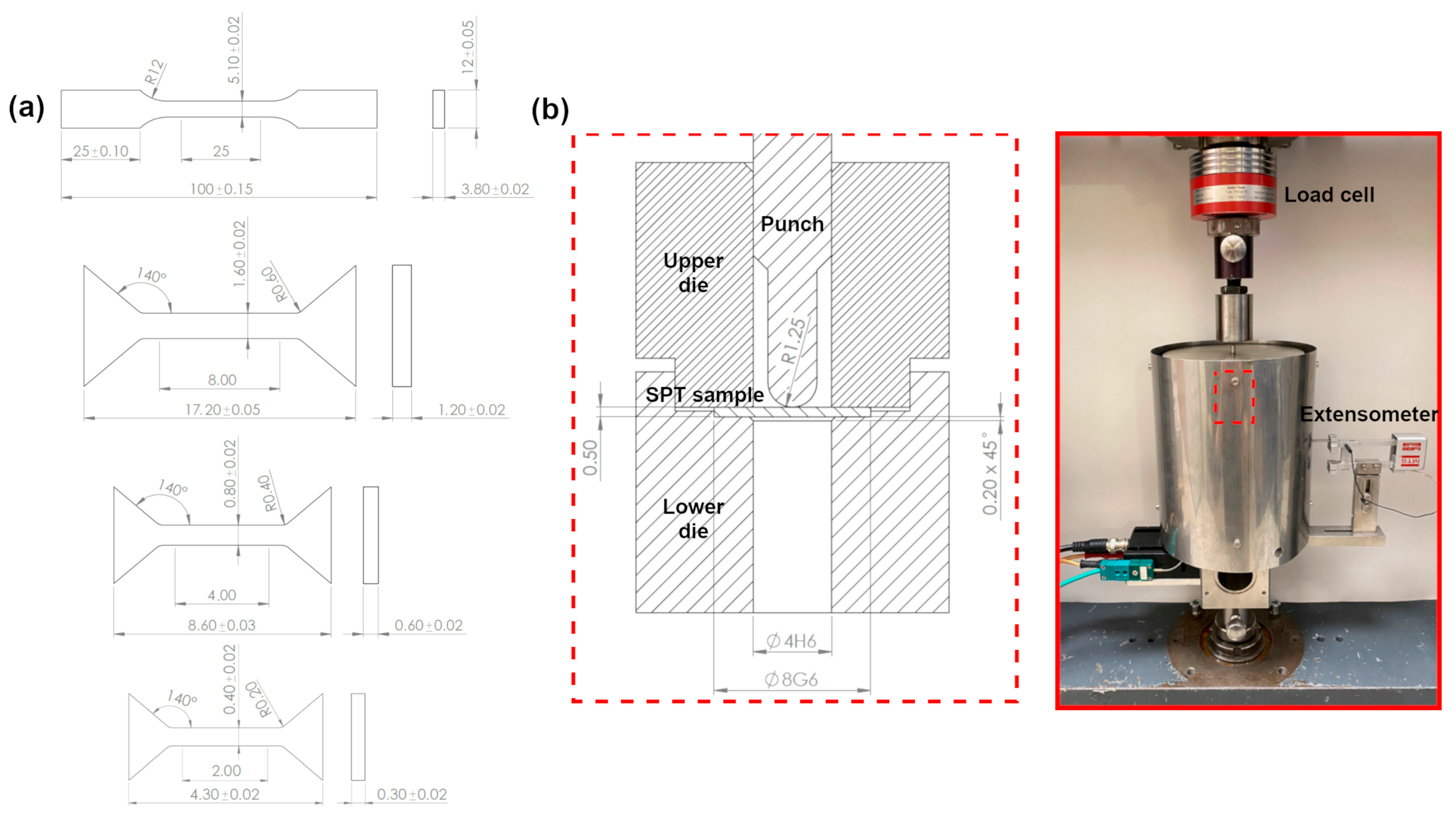

2. Materials and Methods

3. Results and Discussion

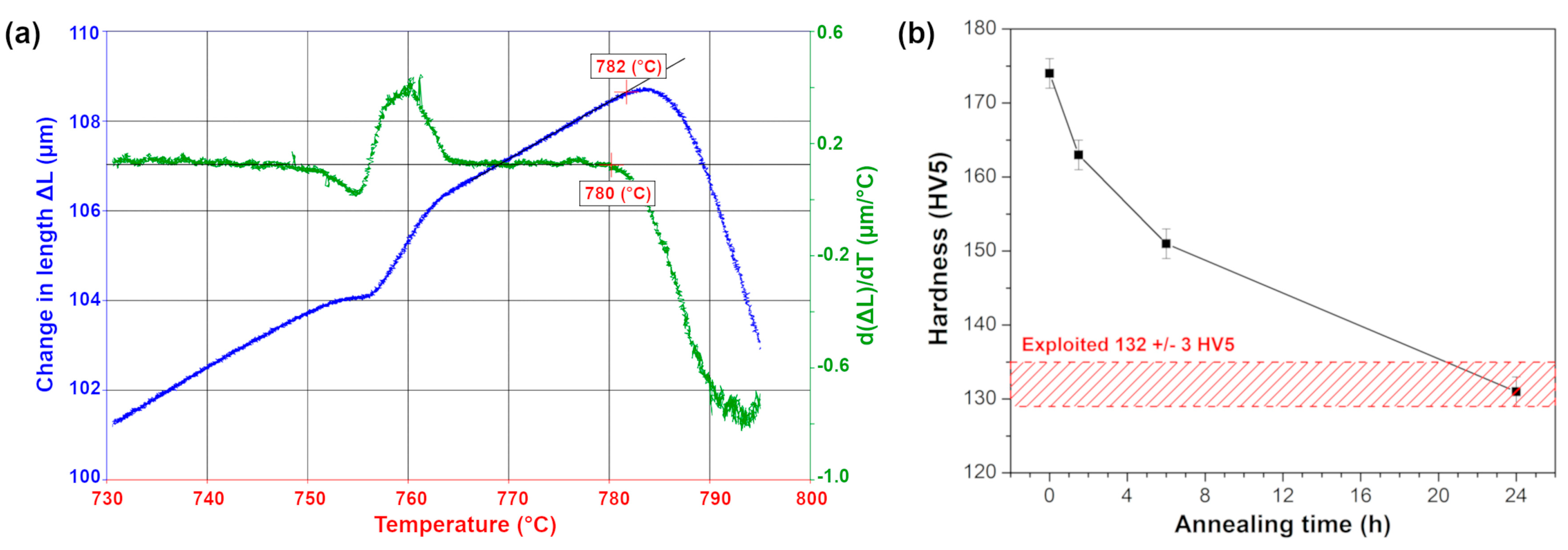

3.1. Heat Treatment

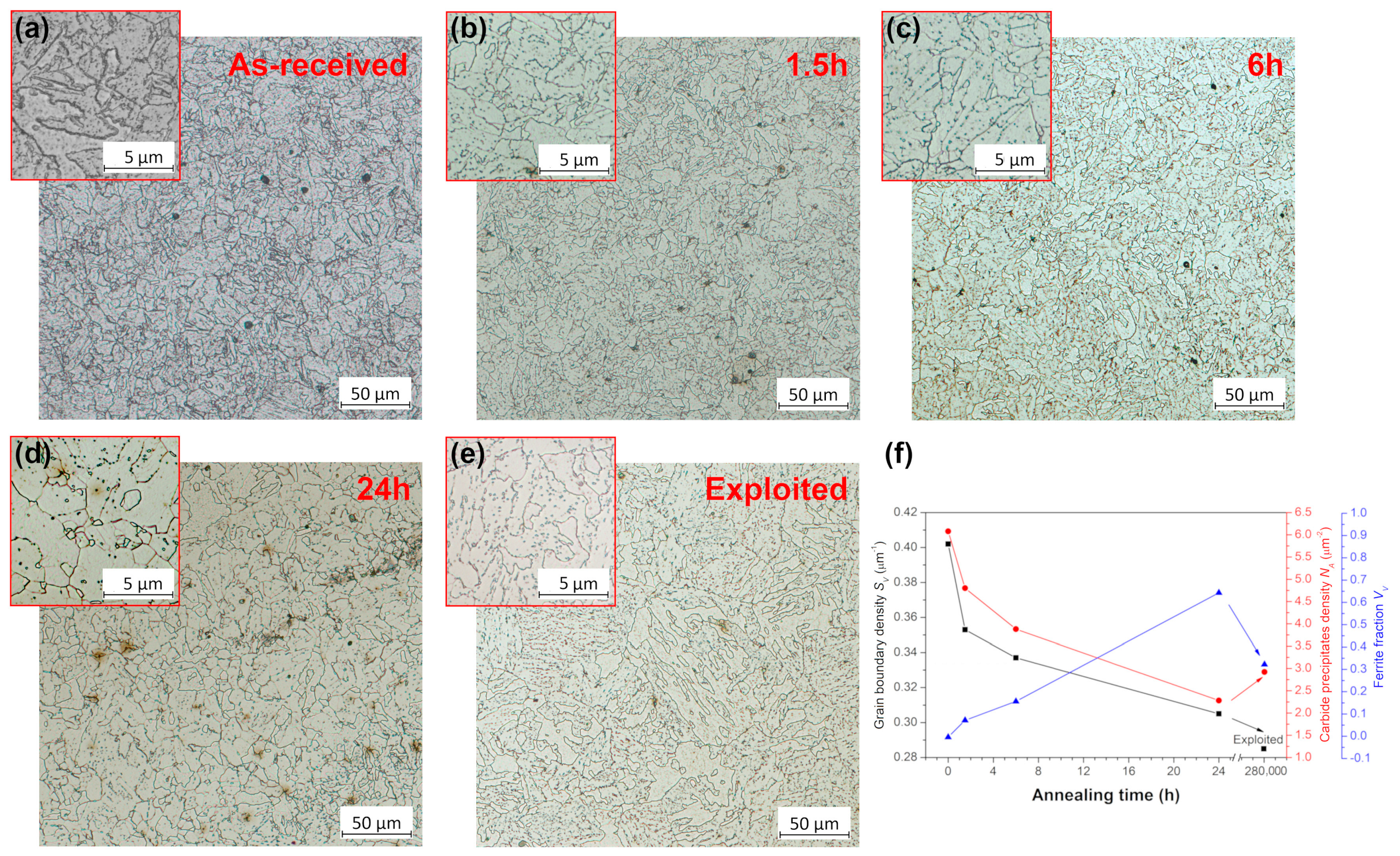

3.2. Microstructure

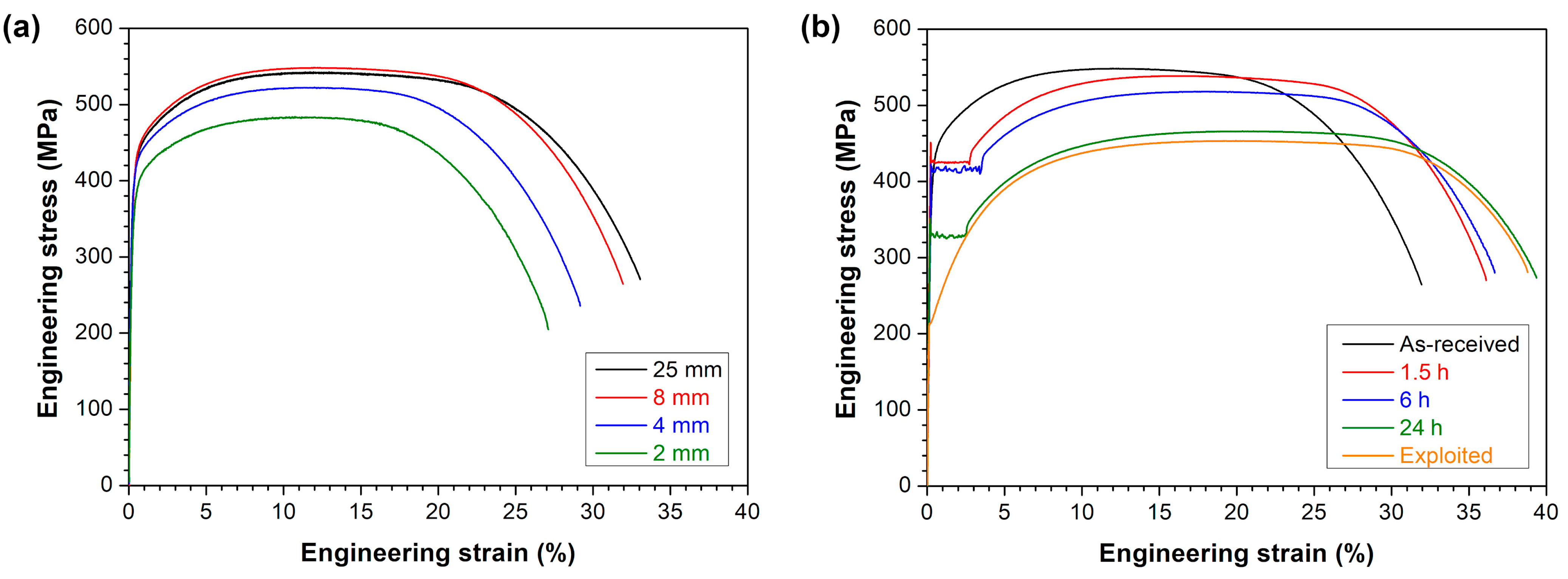

3.3. Tensile Properties

3.4. SPT Results

4. Conclusions

- The annealing of the as-received 10CrMo9-10 steel (Rm = 544 MPa) at 770 °C for 1.5, 6 and 24 h allowed its strength to gradually decrease to Rm = 539, 517 and 467 MPa, respectively, i.e., to the level similar to the exploited condition (Rm = 454 MPa).

- The lowered strength resulted from the gradually reduced grain boundary and carbide precipitates densities and the increased fraction of equiaxed ferrite grains after prolonged annealing.

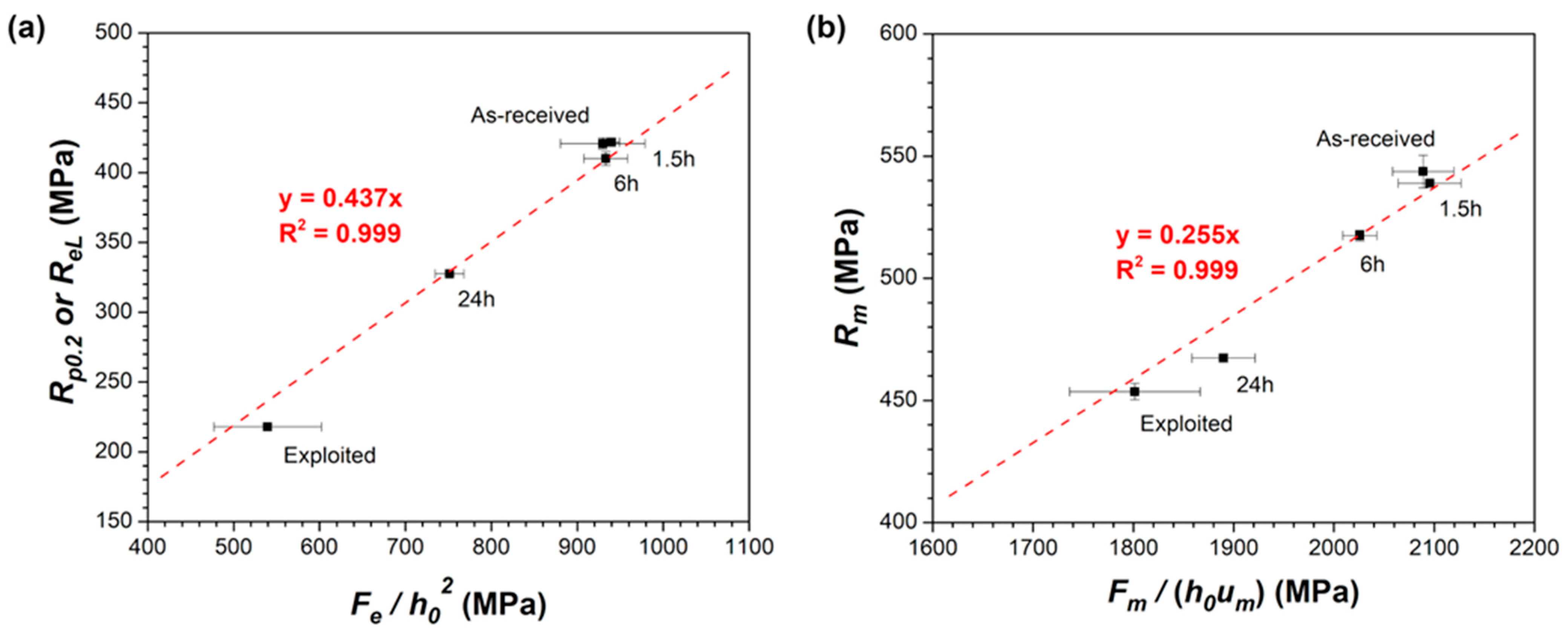

- The obtained SPT parameters for the as-received, annealed and exploited conditions (i.e., Fe, Fm, um) exhibited the same tendencies as the Rp0.2 (or ReL), Rm and Au during tensile tests. The following correlation factors were determined βRp0.2 = 0.437 and βRm = 0.255 for the estimation of Rp0.2 and Rm, respectively.

- Mechanical parameters of the exploited 10CrMo9-10 estimated based on the SPT results (Rp0.2 = 236 ± 27 MPa and Rm = 459 ± 17 MPa) were in a good agreement with those assessed during the uniaxial tensile tests (218 ± 3 MPa and Rm = 454 ± 4 MPa).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Hao, X.J.; Zhou, L.; Strangwood, M.; Davis, C.L.; Peyton, A.J. Measurement of microstructure changes in 9Cr-1Mo and 2.25Cr-1Mo steels using an electromagnetic sensor. Scr. Mater. 2012, 66, 367–370. [Google Scholar] [CrossRef]

- Brodecki, A.; Kopec, M.; Kowalewski, Z.L. Monitoring of fatigue damage development in as-received and exploited 10CrMo9-10 power engineering steel supported by Digital Image Correlation. Int. J. Press. Vessel. Pip. 2023, 202, 104889. [Google Scholar] [CrossRef]

- Ławrynowicz, Z. Bainitic reaction and microstructure evolution in two normalized and tempered steels designed for service at elevated temperatures. Adv. Mater. Sci. 2017, 17, 22–36. [Google Scholar] [CrossRef]

- Sirohi, S.; Kumar, S.; Bhanu, V.; Pandey, C.; Gupta, A. Study on the Variation in Mechanical Properties along the Dissimilar Weldments of P22 and P91 Steel. J. Mater. Eng. Perform. 2022, 31, 2281–2296. [Google Scholar] [CrossRef]

- Fadel, A.; Gliŝić, D.; Radović, N.; Drobnjak, D. Influence of Cr, Mn and Mo Addition on Structure and Properties of V Microalloyed Medium Carbon Steels. J. Mater. Sci. Technol. 2012, 28, 1053–1058. [Google Scholar] [CrossRef]

- Xia, T.; Ma, Y.; Zhang, Y.; Li, J.; Xu, H. Effect of Mo and Cr on the Microstructure and Properties of Low-Alloy Wear-Resistant Steels. Materials 2024, 17, 2408. [Google Scholar] [CrossRef] [PubMed]

- Gwoździk, M.; Motylenko, M.; Rafaja, D. Microstructure changes responsible for the degradation of the 10CrMo9-10 and 13CrMo4-5 steels during long-term operation. Mater. Res. Express 2020, 7, 016515. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Li, H.; Lin, S.; Ren, Y. Effect of long-term aging on the microstructure and mechanical properties of T23 steel weld metal without post-weld heat treatment. J. Mater. Process. Technol. 2018, 252, 618–627. [Google Scholar] [CrossRef]

- Furtado, H.C.; May, I. Le High temperature degradation in power plants and refineries. Mater. Res. 2004, 7, 103–110. [Google Scholar] [CrossRef]

- Watanabe, Y.; Shoji, T. The evaluation of in-service materials degradation of low-alloy steels by the electrochemical method. Metall. Trans. A 1991, 22, 2097–2106. [Google Scholar] [CrossRef]

- Sharma, T.; Bonagani, S.K.; Naveen Kumar, N.; Harish, D.; Mani Krishna, K.V.; Samajdar, I.; Kain, V. Effect of thermal aging on embrittlement of Cr–Mo–V pressure vessel steel. J. Nucl. Mater. 2019, 527, 151817. [Google Scholar] [CrossRef]

- Golański, G.; Pietryka, I.; Jasak, J.; Słania, J.; Urbańczyk, P.; Wieczorek, P. Degradation of Microstructure and Mechanical Properties of 15HM Steel after 420 000 Hours of Service. Adv. Mater. Sci. 2014, 14, 5–11. [Google Scholar] [CrossRef]

- Kopec, M.; Brodecki, A.; Kowalewski, Z.L. Fatigue damage development in 10CrMo9-10 steel for power plant pipes in as-received state and after 280,000 h of exploitation. Arch. Civ. Mech. Eng. 2023, 23, 98. [Google Scholar] [CrossRef]

- Singh, K.; Kamaraj, M. Microstructural degradation in power plant steels and life assessment of power plant components. Procedia Eng. 2013, 55, 394–401. [Google Scholar] [CrossRef]

- Arunkumar, S. Overview of Small Punch Test. Met. Mater. Int. 2020, 26, 719–738. [Google Scholar] [CrossRef]

- Romelczyk-Baishya, B.; Łęczycki, K.; Płocińska, M.; Kulczyk, M.; Molak, R.; Pakieła, Z. The effect of microstructure anisotropy on low temperature fracture of ultrafine-grained iron. Arch. Civ. Mech. Eng. 2018, 18, 1166–1182. [Google Scholar] [CrossRef]

- Foulds, J.; Viswanathan, R. Small Punch Testing for Determining the Material Toughness of Low Alloy Steel Components in Service. J. Eng. Mater. Technol. 1994, 116, 457–464. [Google Scholar] [CrossRef]

- Bruchhausen, M.; Holmström, S.; Simonovski, I.; Austin, T.; Lapetite, J.M.; Ripplinger, S.; de Haan, F. Recent developments in small punch testing: Tensile properties and DBTT. Theor. Appl. Fract. Mech. 2016, 86, 2–10. [Google Scholar] [CrossRef]

- Romelczyk-Baishya, B.; Lumelskyj, D.; Stępniewska, M.; Giżyński, M.; Pakieła, Z. The mechanical properties at room and low temperature of P110 steel characterised by means of small punch test. Arch. Metall. Mater. 2019, 64, 159–165. [Google Scholar] [CrossRef]

- Wang, Z.X.; Shi, H.J.; Lu, J.; Shi, P.; Ma, X.F. Small punch testing for assessing the fracture properties of the reactor vessel steel with different thicknesses. Nucl. Eng. Des. 2008, 238, 3186–3193. [Google Scholar] [CrossRef]

- Alegre, J.M.; Lacalle, R.; Cuesta, I.I.; Álvarez, J.A. Different methodologies to obtain the fracture properties of metallic materials using pre-notched small punch test specimens. Theor. Appl. Fract. Mech. 2016, 86, 11–18. [Google Scholar] [CrossRef]

- Majchrowicz, K.; Romelczyk-Baishya, B.; Wieczorek-Czarnocka, M.; Dobkowska, A.; Raga, K.; Filip, R.; Pakieła, Z. Determination of the fracture toughness of carburized Pyrowear 53 steel for planetary gears by the small punch test method. Arch. Civ. Mech. Eng. 2024, 24, 177. [Google Scholar] [CrossRef]

- Bruchhausen, M.; Holmström, S.; Lapetite, J.M.; Ripplinger, S. On the determination of the ductile to brittle transition temperature from small punch tests on Grade 91 ferritic-martensitic steel. Int. J. Press. Vessel. Pip. 2017, 155, 27–34. [Google Scholar] [CrossRef]

- Stępniewska, M.; Romelczyk-Baishya, B.; Brynk, T.; Giżyński, M.; Pakieła, Z. Influence of low temperature on mechanical properties of carbon steel P110 estimated by means of small punch test. In Proceedings of the 7th International Conference on Fracture Fatigue and Wear, FFW 2018, Ghent, Belgium, 9–10 July 2018; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2019; pp. 151–163. [Google Scholar]

- Dobeš, F.; Milička, K. Comparison of conventional and small punch creep tests of mechanically alloyed Al-C-O alloys. Mater. Charact. 2008, 59, 961–964. [Google Scholar] [CrossRef]

- Rouse, J.P.; Cortellino, F.; Sun, W.; Hyde, T.H.; Shingledecker, J. Small punch creep testing: Review on modelling and data interpretation. Mater. Sci. Technol. 2013, 29, 1328–1345. [Google Scholar] [CrossRef]

- EN 10371:2021; Metallic Materials—Small Punch Test Method. European Commission: Brussels, Belgium, 2021.

- Kumar, K.; Pooleery, A.; Madhusoodanan, K.; Singh, R.N.; Chakravartty, J.K.; Shriwastaw, R.S.; Dutta, B.K.; Sinha, R.K. Evaluation of ultimate tensile strength using Miniature Disk Bend Test. J. Nucl. Mater. 2015, 461, 100–111. [Google Scholar] [CrossRef]

- García, T.E.; Rodríguez, C.; Belzunce, F.J.; Suárez, C. Estimation of the mechanical properties of metallic materials by means of the small punch test. J. Alloys Compd. 2014, 582, 708–717. [Google Scholar] [CrossRef]

- Altstadt, E.; Houska, M.; Simonovski, I.; Bruchhausen, M.; Holmström, S.; Lacalle, R. On the estimation of ultimate tensile stress from small punch testing. Int. J. Mech. Sci. 2018, 136, 85–93. [Google Scholar] [CrossRef]

- Altstadt, E.; Ge, H.E.; Kuksenko, V.; Serrano, M.; Houska, M.; Lasan, M.; Bruchhausen, M.; Lapetite, J.M.; Dai, Y. Critical evaluation of the small punch test as a screening procedure for mechanical properties. J. Nucl. Mater. 2016, 472, 186–195. [Google Scholar] [CrossRef]

- Macek, W.; Kopec, M.; Laska, A.; Kowalewski, Z.L. Entire fracture surface topography parameters for fatigue life assessment of 10H2M steel. J. Constr. Steel Res. 2024, 221, 108890. [Google Scholar] [CrossRef]

- Andrés, D.; Dymáček, P. Study of the upper die clamping conditions in the small punch test. Theor. Appl. Fract. Mech. 2016, 86, 117–123. [Google Scholar] [CrossRef]

- Dymáček, P.; Milička, K. Small punch testing and its numerical simulations under constant deflection force conditions. Strength Mater. 2008, 40, 24–27. [Google Scholar] [CrossRef]

- Kaliciak, M.; Uhl, T.; Nowak, M. Statistical analysis and correlation of small punch test. In Proceedings of the SPIE 12488, Health Monitoring of Structural and Biological Systems XVII, Long Beach, CA, USA, 13–16 March 2023; Volume 12488, p. 65. [Google Scholar]

- EN 10028-2:2017; Flat Products Made of Steels for Pressure Purposes—Part 2: Non-Alloy and Alloy Steels with Specified Elevated Temperature Properties. European Commission: Brussels, Belgium, 2017.

- ISO 6892-1:2019; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- Petzova, J.; Brezina, M.; Kapusnak, M.; Kupca, L. Application of Small Punch Testing Methods for Thermal Ageing Monitoring at Primary Circuit Components in Nuclear Power Plant. In Proceedings of the ASME 2015 Pressure Vessels and Piping Conference, Boston, MA, USA, 19–23 July 2015; p. 45539. [Google Scholar]

- Molak, R.M.; Kartal, M.E.; Pakiela, Z.; Kurzydlowski, K.J. The effect of specimen size and surface conditions on the local mechanical properties of 14MoV6 ferritic-pearlitic steel. Mater. Sci. Eng. A 2016, 651, 810–821. [Google Scholar] [CrossRef]

- Sitek, R.; Puchlerska, S.; Nejman, I.; Majchrowicz, K.; Pakieła, Z.; Żaba, K.; Mizera, J. The Impact of Plastic Deformation on the Microstructure and Tensile Strength of Haynes 282 Nickel Superalloy Produced by DMLS and Casting. Materials 2022, 15, 7545. [Google Scholar] [CrossRef]

- Kopec, M.; Brodecki, A.; Kowalewski, Z.L. Quantitative digital image correlation approach for the monitoring of fatigue damage development in 10CrMo9-10 steel in the as-received state and after extended service. Measurement 2024, 234, 114926. [Google Scholar] [CrossRef]

- Kals, R.; Vollertsen, F.; Geiger, M. Scaling effects in sheet metal forming. In Proceedings of the Fourth Conference of Sheet Metal, Enschede, The Netherlands, 1996. [Google Scholar]

- Fleury, E.; Ha, J.S. Small punch tests to estimate the mechanical properties of steels for steam power plant: I. Mechanical strength. Int. J. Press. Vessel. Pip. 1998, 75, 699–706. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Zhong, J.; He, Z.; Guan, K.; Jiang, T. Investigation on regression model for the force of small punch test using machine learning. Int. J. Press. Vessel. Pip. 2023, 206, 105031. [Google Scholar] [CrossRef]

- Pan, H.; Peng, J.; Geng, X.; Gao, M.; Miao, X. Prediction of mechanical properties for typical pressure vessel steels by small punch test combined with machine learning. Int. J. Press. Vessel. Pip. 2023, 206, 105060. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | Cr | Mo | Fe |

|---|---|---|---|---|---|---|

| As-received | 0.12 | 0.37 | 0.42 | 2.00 | 0.90 | Balanced |

| Exploited | 0.16 | 0.44 | 0.61 | 2.51 | 0.98 | Balanced |

| EN 10028-2 | 0.08–0.14 | ≤0.50 | 0.40–0.80 | 2.00–2.50 | 0.90–1.10 | Balanced |

| Material | Rp0.2 or ReH/ReL (MPa) | Rm (MPa) | Au (%) | A (%) | Fe (N) | Fm (N) | um (mm) |

|---|---|---|---|---|---|---|---|

| As-received (25 mm) | 407 ± 11 | 538 ± 6 | 11.7 ± 0.2 | 32.1 ± 1.9 | 234 ± 13 | 1607 ± 28 | 1.53 ± 0.02 |

| As-received (8 mm) | 421 ± 6 | 544 ± 7 | 12.0 ± 0.1 | 31.7 ± 0.8 | |||

| As-received (4 mm) | 398 ± 8 | 520 ± 7 | 11.8 ± 0.3 | 29.3 ± 1.3 | |||

| As-received (2 mm) | 375 ± 9 | 484 ± 6 | 11.0 ± 0.5 | 27.8 ± 2.0 | |||

| Annealed 1.5 h | 437 ± 14/422 ± 5 | 539 ± 4 | 16.1 ± 0.3 | 34.3 ± 1.5 | 236 ± 2 | 1634 ± 25 | 1.55 ± 0.01 |

| Annealed 6 h | 430 ± 10/410 ± 7 | 517 ± 4 | 17.4 ± 0.4 | 34.9 ± 1.3 | 234 ± 8 | 1599 ± 13 | 1.58 ± 0.01 |

| Annealed 24 h | 344 ± 7/328 ± 4 | 467 ± 4 | 20.3 ± 0.5 | 37.3 ± 2.1 | 189 ± 5 | 1519 ± 25 | 1.60 ± 0.01 |

| Exploited | 218 ± 3 | 454 ± 4 | 19.1 ± 0.3 | 36.6 ± 1.3 | 135 ± 16 | 1464 ± 47 | 1.62 ± 0.02 |

| βRp0.2 | βRm | Specimen Size (mm) | Receiving Hole Diameter (mm) | Chamfer Size or Edge Radius (mm) | Punch Radius (mm) | Materials Tested | Reference |

|---|---|---|---|---|---|---|---|

| 0.437 | 0.255 | Φ 8 × 0.5 | 4 | 0.2 × 45° | 1.25 | 10CrMo9–10 | This work |

| - | 0.281 | Φ 3 × 0.25 | 1.5 | 0.2 | 0.5 | 20MnMoNi55, CrMoV steel, SS304LN | [28] |

| 0.442 | 0.277 | 10 × 10 × 0.5 | 4 | 0.2 × 45° | 1.25 | 2.25Cr1Mo steels, dual phase steels, AISI 304, D2205, S460, API X70 | [29] |

| - | 0.278 | Φ 8 × 0.5 | 4 | 0.2 × 45° | 1.25 | P91, P92, Eurofer97, 22NiMoCr37, 15Kh2MFA | [30] |

| 0.63 | 0.26 | 3.5 × 3.5 × 0.25 | 1.75 | 0.25 | 0.5 | T91 | [31] |

| 0.49 | 0.26 | 10 × 10 × 0.5 | 4 | 0.5 | 1.25 | T91 | [31] |

| 0.48 | 0.21 | Φ 8 × 0.5 | 4 | 0.2 × 45° | 1.25 | T91 | [31] |

| 0.42 | 0.19 | Φ 3 × 0.25 | 1.5 | 0.2 | 0.5 | T91 | [31] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Majchrowicz, K.; Romelczyk-Baishya, B.; Wieczorek-Czarnocka, M.; Marciniak, S.; Mras, M.; Kukla, D.; Kopec, M.; Pakieła, Z. Assessment of 10CrMo9-10 Power Engineering Steel Degradation State by Using Small Punch Test. Materials 2025, 18, 4133. https://doi.org/10.3390/ma18174133

Majchrowicz K, Romelczyk-Baishya B, Wieczorek-Czarnocka M, Marciniak S, Mras M, Kukla D, Kopec M, Pakieła Z. Assessment of 10CrMo9-10 Power Engineering Steel Degradation State by Using Small Punch Test. Materials. 2025; 18(17):4133. https://doi.org/10.3390/ma18174133

Chicago/Turabian StyleMajchrowicz, Kamil, Barbara Romelczyk-Baishya, Monika Wieczorek-Czarnocka, Szymon Marciniak, Milena Mras, Dominik Kukla, Mateusz Kopec, and Zbigniew Pakieła. 2025. "Assessment of 10CrMo9-10 Power Engineering Steel Degradation State by Using Small Punch Test" Materials 18, no. 17: 4133. https://doi.org/10.3390/ma18174133

APA StyleMajchrowicz, K., Romelczyk-Baishya, B., Wieczorek-Czarnocka, M., Marciniak, S., Mras, M., Kukla, D., Kopec, M., & Pakieła, Z. (2025). Assessment of 10CrMo9-10 Power Engineering Steel Degradation State by Using Small Punch Test. Materials, 18(17), 4133. https://doi.org/10.3390/ma18174133