Effect of Ultrasonic Rolling on the Surface Integrity and High Temperature Oxidation Properties of Laser Melted NiCrAl Coatings

Abstract

1. Introduction

2. Experimental Details

2.1. Preparation of Materials

2.2. Experimental Procedures

3. Coating Organizational Properties Testing

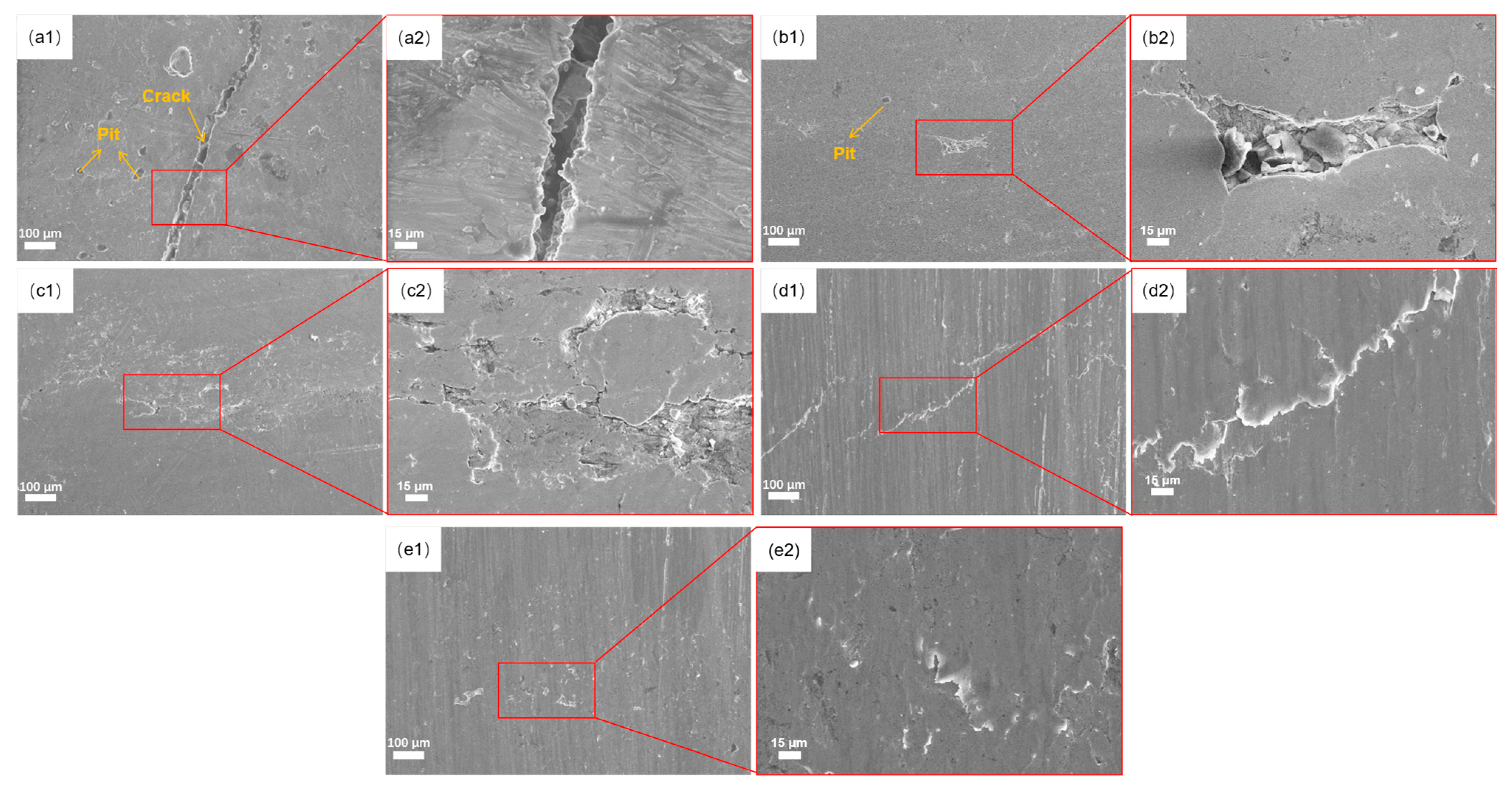

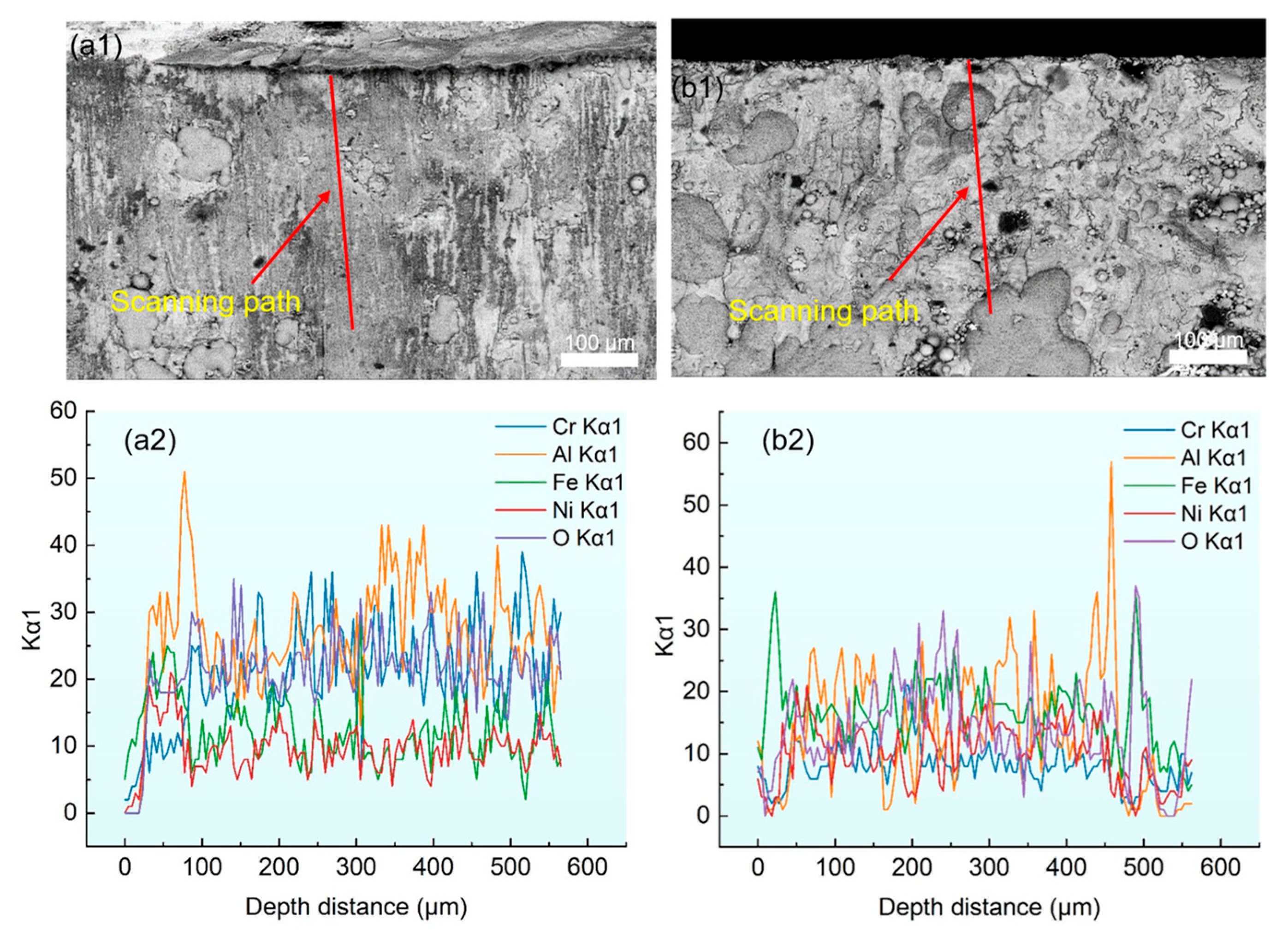

3.1. Microstructure Analysis

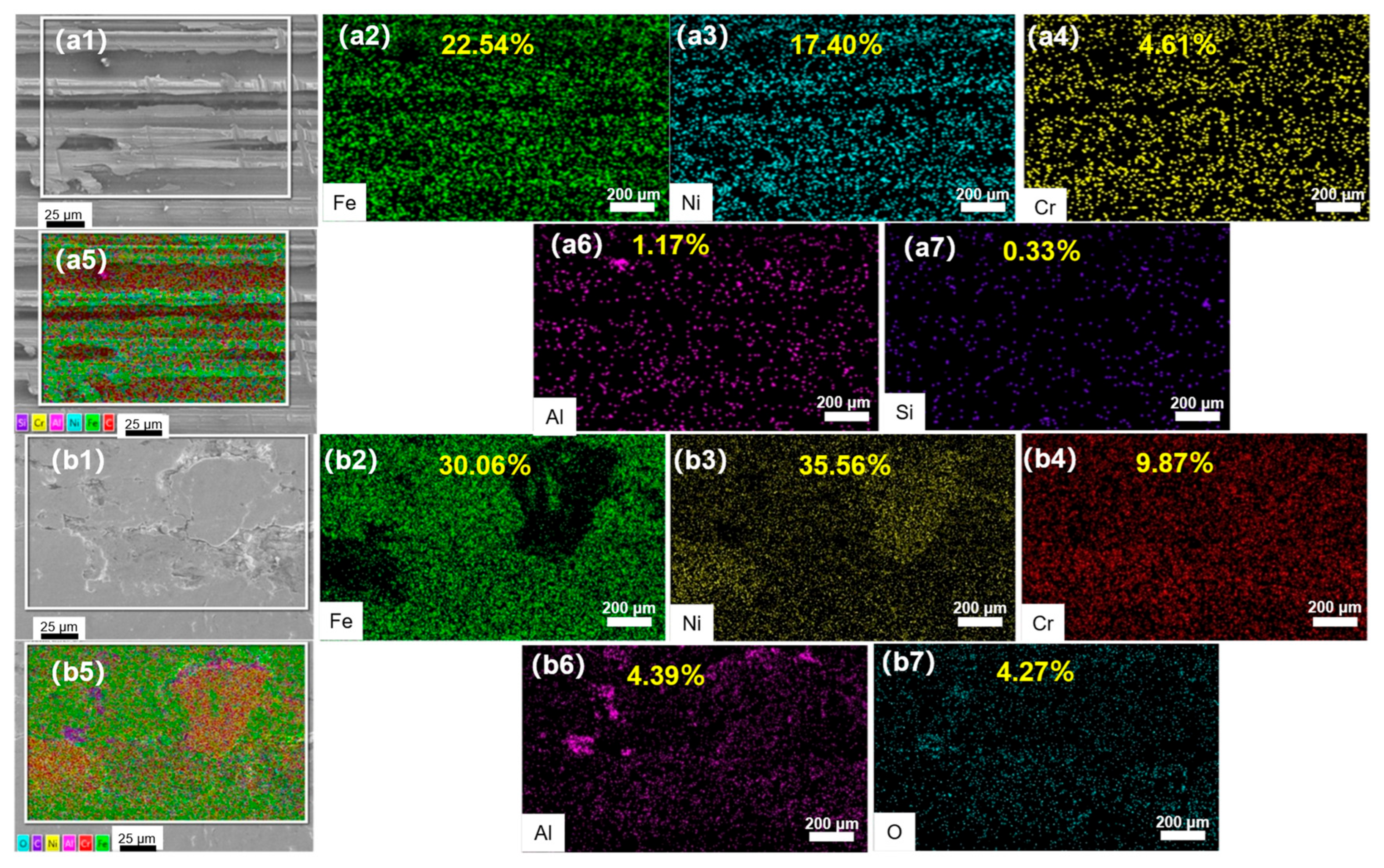

3.2. Surface Elemental Analysis

4. Results and Discussion

4.1. Effect of Rolling Depth on Microhardness

4.2. Effect of Rolling Depth on Residual Stress

4.3. Effect of Rolling Depth on Surface Roughness

4.4. Effect of Rolling on High Temperature Oxidation Resistance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Duan, J.; An, T.; Gu, Y.; Yu, H.; Gan, B.; Lv, X.; Qu, J.; Du, J.; Bi, Z. Effect of gamma’ phase and microtwins on the microstructural evolution and mechanical properties of a novel Ni-Co base superalloy. Mater. Sci. Eng. A 2023, 865, 144323. [Google Scholar] [CrossRef]

- Lu, H.-H.; Han, J.-S.; Li, G.; Zhang, Y.-D.; Du, L.-Y.; Li, Y.-L.; Chen, D.-H. Effect of ultrasonic surface rolling processing on surface integrity and mechanical properties of ZL205A alloy. J. Mater. Res. Technol. 2025, 37, 470–483. [Google Scholar] [CrossRef]

- Tan, L.; Tang, W.; Wang, M.; Zhang, Y.; Yao, C. Studies on surface integrity and fatigue performance of Ti-17 alloy induced by ultrasonic surface rolling process. Surf. Coat. Technol. 2025, 512, 132336. [Google Scholar] [CrossRef]

- Cui, G.; Yang, C. Microstructure evolution and grain refinement mechanism of ultrasonic-assisted low-frequency pulse VPPA welded joint of AA2195-T8 Al-Cu-Li alloy. J. Manuf. Process. 2025, 141, 679–693. [Google Scholar] [CrossRef]

- Guo, W.; Zhang, H.; Li, Y.; Li, Z. Fabrication of high-performance Ti–6Al–4V laser cladding layer on low carbon steel using Ni/Cu as interlayers. Mater. Chem. Phys. 2025, 345, 131280. [Google Scholar] [CrossRef]

- van Dam, J.P.B.; Tiringer, U.; Abrahami, S.T.; Milošev, I.; Terryn, H.; Kovač, J.; Mol, J.M.C. Surface engineering of aerospace aluminium alloys: Understanding alloying effects on chemical pre-treatment and sol-gel coating adhesion. Surf. Coat. Technol. 2024, 485, 130901. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, Y.; Liu, J.; Cai, Z.; Du, X.; Wang, H. Study on the enhancement of surface integrity and wear resistance of iron-based coatings by ultrasonic surface rolling process. J. Mater. Res. Technol. 2025, 36, 4898–4912. [Google Scholar] [CrossRef]

- Odabas, O.; Karaoglanli, A.C.; Ozgurluk, Y.; Binal, G. Evaluation of high-temperature oxidation resistance of AlCoCrFeNiZr high-entropy alloy (HEA) coating system at 1000 °C and 1100 °C. Surf. Coat. Technol. 2025, 512, 132439. [Google Scholar] [CrossRef]

- Xiao, L.; Deng, G.; Zhao, X.; Jiang, Y.; Chen, H.; Yu, Q.; Dong, H.; Li, J.; Liu, S.; Cai, Z. Preparation and oxidation properties of tantalum-based Yb2O3 modified MoSi2 ceramic coating. J. Eur. Ceram. Soc. 2025, 45, 117546. [Google Scholar] [CrossRef]

- Zhu, X.; Li, X.; Ma, Y.; Zhang, C.; Tang, P.; Fu, Z.; Shi, Q.; Lin, S. Effect of Zr/Dy doping on the high-temperature oxidation resistance of NiCrAlY coatings. Mater. Today 2025, 47, 113168. [Google Scholar] [CrossRef]

- Henao, J.; Rivera-Gil, M.A.; Poblano-Salas, C.A.; Espinosa-Arbelaez, D.G.; Trapaga-Martinez, L.G.; Mazon, O.S.; Castuera, J.C. Multilayered coatings by thermal spray for high-temperature applications. In Ceramic Coatings for High-Temperature Environments; Schneider, M., Ed.; Springer: Cham, Switzerland, 2024; pp. 123–145. [Google Scholar] [CrossRef]

- Chen, C.; Wei, M.; Zhu, X.; Wang, J.; Lu, X. Microstructure and corrosion resistance of c-BN/NiCrAl coatings synthesized by laser cladding. Mater. Today 2025, 46, 112827. [Google Scholar] [CrossRef]

- Yu, T.; Tang, H.Y. Effect of Ta on oxidation behavior of laser clad NiCrAl coating at 950 °C and 1050 °C in air. Surf. Coat. Technol. 2025, 496, 131713. [Google Scholar] [CrossRef]

- Ji, H.; Liu, Y.; Wang, T.; Yuan, Q.; Chen, H.; Wang, P.; Janković, N.; Zhu, X.; Chen, X. Isothermal oxidation behaviors of NiCrAlY coatings at 1100 °C. Mater. Today 2025, 46, 112902. [Google Scholar] [CrossRef]

- Tator, K.B. ASM Handbook, 5B; ASM International: Materials Park, OH, USA, 2015. [Google Scholar]

- Huang, W.; Hu, H.; Li, L.; Yan, H.; Li, C.; Liu, W.; Li, J. Effects of ultrasonic surface rolling process on the mechanical properties and corrosion resistance of Ni50(AlNbTiV)50 high-entropy alloy laser cladding layer. Mater. Today Commun. 2025, 47, 113194. [Google Scholar] [CrossRef]

- Gao, W.; Wang, S.-C.; Hu, K.-K.; Jiang, X.-Z.; Yu, H.-Y.; Sun, D.-B. Effect of laser cladding speed on microstructure and properties of titanium alloy coating on low carbon steel. Surf. Coating. Technol. 2025, 451, 129029. [Google Scholar] [CrossRef]

- Chen, Q.H.; Wei, L.; Long, J.M.; Li, J.C. Microstructure study of laser melted NiCrAl-ceramic coatings. Eng. Sci. 2001, 3, 64–71. [Google Scholar]

- Unal, O.; Varol, R. Surface severe plastic deformation of AISI 304 via conventional shot peening, severe shot peening, and repeening. Appl. Surf. Sci. 2015, 351, 289–295. [Google Scholar] [CrossRef]

- Wong, C.C.; Hartawan, A.; Teo, W.K. Deep cold rolling of features on aero-engine components. Procedia CIRP 2014, 13, 350–354. [Google Scholar] [CrossRef]

- Li, W.L.; Tao, N.R.; Lu, K. Fabrication of gradient nanostructured surface layer on bulk metallic materials via surface mechanical attrition treatment. Scr. Mater. 2008, 59, 546–549. [Google Scholar] [CrossRef]

- Bozdana, A.T.; Gindy, N.N.Z.; Li, H. Experimental and numerical analysis of tool wear in high-speed machining of nickel-based superalloys. Int. J. Mach. Tools Manuf. 2005, 45, 713–718. [Google Scholar]

- Teimouri, R.; Amini, S.; Guagliano, M. Mechanical characterization and modeling of additive manufactured Ti-6Al-4V under cyclic loading: A microstructure-sensitive approach. Mater. Sci. Eng. A 2019, 747, 208–224. [Google Scholar] [CrossRef]

- Lopes, K.S.S.; Sales, W.F.; Palma, E.S. The effect of cutting parameters on surface roughness and tool wear in hard turning of AISI H13 steel with mixed ceramic tools. J. Braz. Soc. Mech. Sci. Eng. 2008, 30, 77–83. [Google Scholar] [CrossRef]

- Yao, C.; Zhou, Z.; Zhao, Y.; Tan, L.; Cui, M.; Wang, Y. Investigation of surface quality and wear behavior of coated tools in high-speed milling of titanium alloy Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2021, 112, 1359–1371. [Google Scholar] [CrossRef]

- Yu, W.; Wu, J.; Li, Y.; An, Q.; Ming, W.; Chen, D.; Wang, H.; Chen, M. Study on tool wear mechanisms and surface integrity in high-speed milling of additive manufactured Ti6Al4V. Int. J. Adv. Manuf. Technol. 2023, 129, 1473–1488. [Google Scholar] [CrossRef]

- Dang, J.; Wang, H.; Wang, C.; An, Q.; Li, Y.; Wang, H.; Chen, M. Microstructure evolution and surface strengthening behavior of 300 M ultrahigh strength steel under engineered surface treatments. Mater. Charact. 2024, 215, 114127. [Google Scholar] [CrossRef]

- Dang, J.; Li, Y.; Zhang, X.; Wang, Q.; An, Q.; Ming, W.; Chen, M. Surface modification and its effect on the tensile and fatigue properties of 300M steel subjected to ultrasonic surface rolling process. Surf. Coatings Technol. 2021, 422, 127566. [Google Scholar] [CrossRef]

- HB 5258-2000; Test Method for Determination of Oxidation Resistance of Steel and Superalloys. China National Aviation Industry Standard: Beijing, China, 2000.

- Niidam, T.J.; van der Pers, N.M.; Sloof, W.G. High Temperature Oxidation of γ-NiCrAl: Modelling and Experiments. In Novel Approaches to Improving High Temperature Corrosion Resistance; Schütze, M., Quadakkers, W.J., Eds.; Elsevier Science: Burlington, VT, USA, 2008; pp. 582–598. [Google Scholar] [CrossRef]

- Platonenko, A.; Gryaznov, D.; Popov, A.I.; Dovesi, R.; Kotomin, E.A. First principles calculations of the vibrational properties of single and dimer F-type centers in corundum crystals. J. Chem. Phys. 2020, 153, 134107. [Google Scholar] [CrossRef] [PubMed]

| Element | Cr | Al | Ni |

|---|---|---|---|

| percentage | 17 | 5 | Bal. |

| Laser Power (W) | Scanning Speed (mm/s) | Laser Spot Straight (mm) | Shield Gas Flow Rate (L/min) | Overlap Rate (%) |

|---|---|---|---|---|

| 800–1300 | 5 | 3.5 | 15 | 50 |

| Time (h) | 25 | 50 | 75 | 100 |

|---|---|---|---|---|

| No ultrasonic rolling | 0.628 mg/cm2 | 0.832 mg/cm2 | 0.982 mg/cm2 | 1.055 mg/cm2 |

| Rolling depth of 0.05 mm | 0.589 mg/cm2 | 0.785 mg/cm2 | 0.889 mg/cm2 | 0.946 mg/cm2 |

| Rolling depth of 0.085 mm | 0.578 mg/cm2 | 0.762 mg/cm2 | 0.862 mg/cm2 | 0.926 mg/cm2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Hu, C.; Liu, X.; Hu, D.; Yu, T.; Zhan, J. Effect of Ultrasonic Rolling on the Surface Integrity and High Temperature Oxidation Properties of Laser Melted NiCrAl Coatings. Materials 2025, 18, 4119. https://doi.org/10.3390/ma18174119

Zhang D, Hu C, Liu X, Hu D, Yu T, Zhan J. Effect of Ultrasonic Rolling on the Surface Integrity and High Temperature Oxidation Properties of Laser Melted NiCrAl Coatings. Materials. 2025; 18(17):4119. https://doi.org/10.3390/ma18174119

Chicago/Turabian StyleZhang, Dejiang, Chengchao Hu, Xubo Liu, Dewei Hu, Ting Yu, and Jiaming Zhan. 2025. "Effect of Ultrasonic Rolling on the Surface Integrity and High Temperature Oxidation Properties of Laser Melted NiCrAl Coatings" Materials 18, no. 17: 4119. https://doi.org/10.3390/ma18174119

APA StyleZhang, D., Hu, C., Liu, X., Hu, D., Yu, T., & Zhan, J. (2025). Effect of Ultrasonic Rolling on the Surface Integrity and High Temperature Oxidation Properties of Laser Melted NiCrAl Coatings. Materials, 18(17), 4119. https://doi.org/10.3390/ma18174119