Analysis of Fatigue and Residual Strength Estimation of Polymer Matrix Composites Using the Theory of the Markov Chain Method

Abstract

1. Introduction

- -

- -

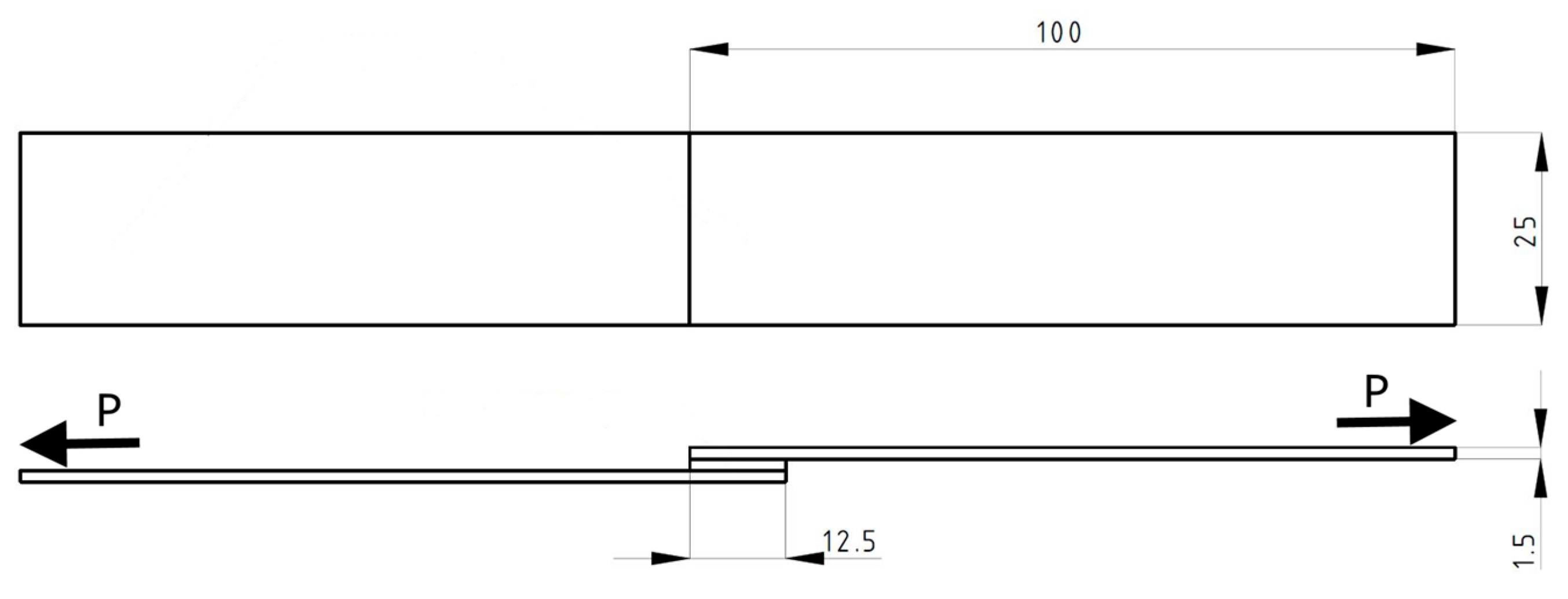

2. Materials and Methods

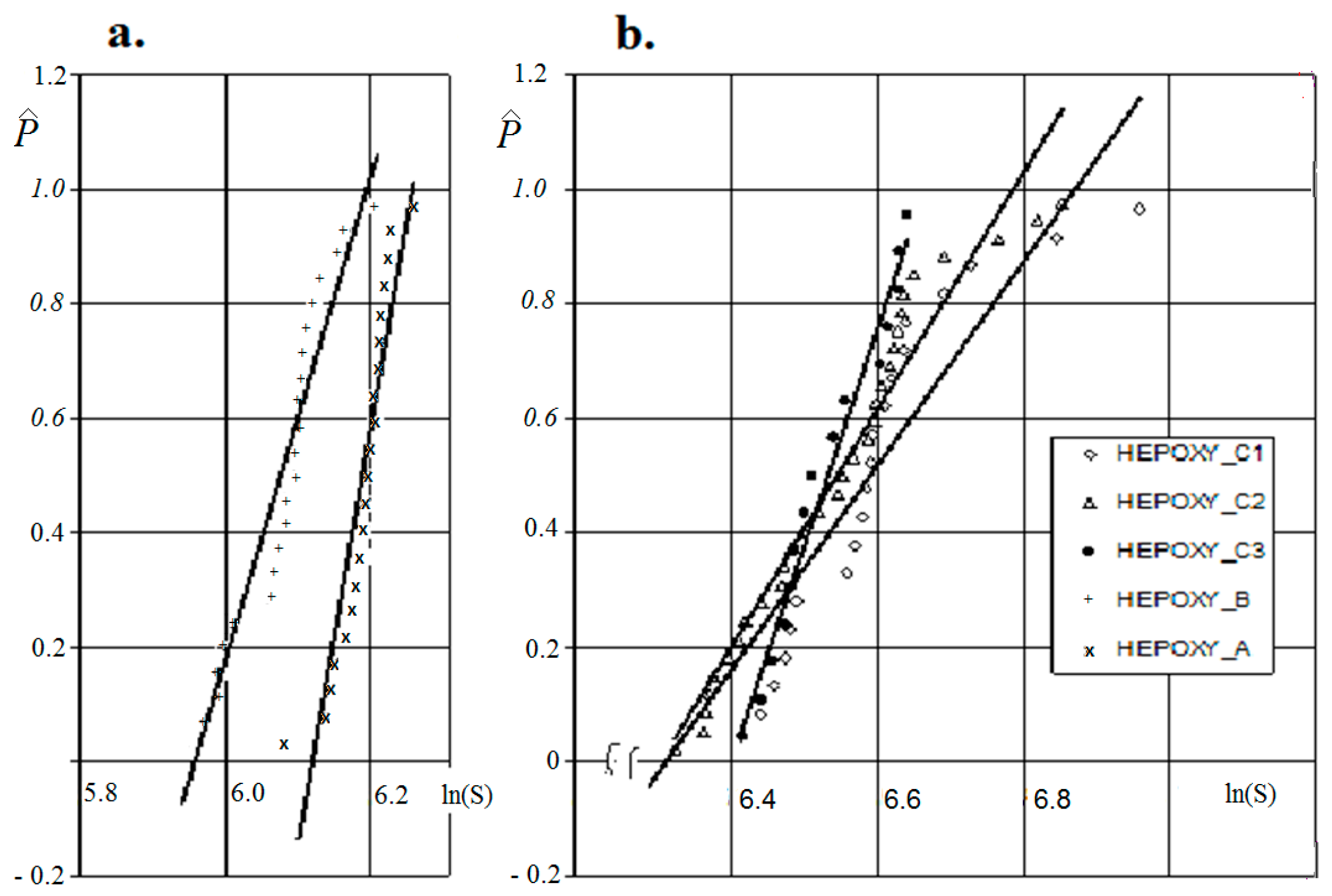

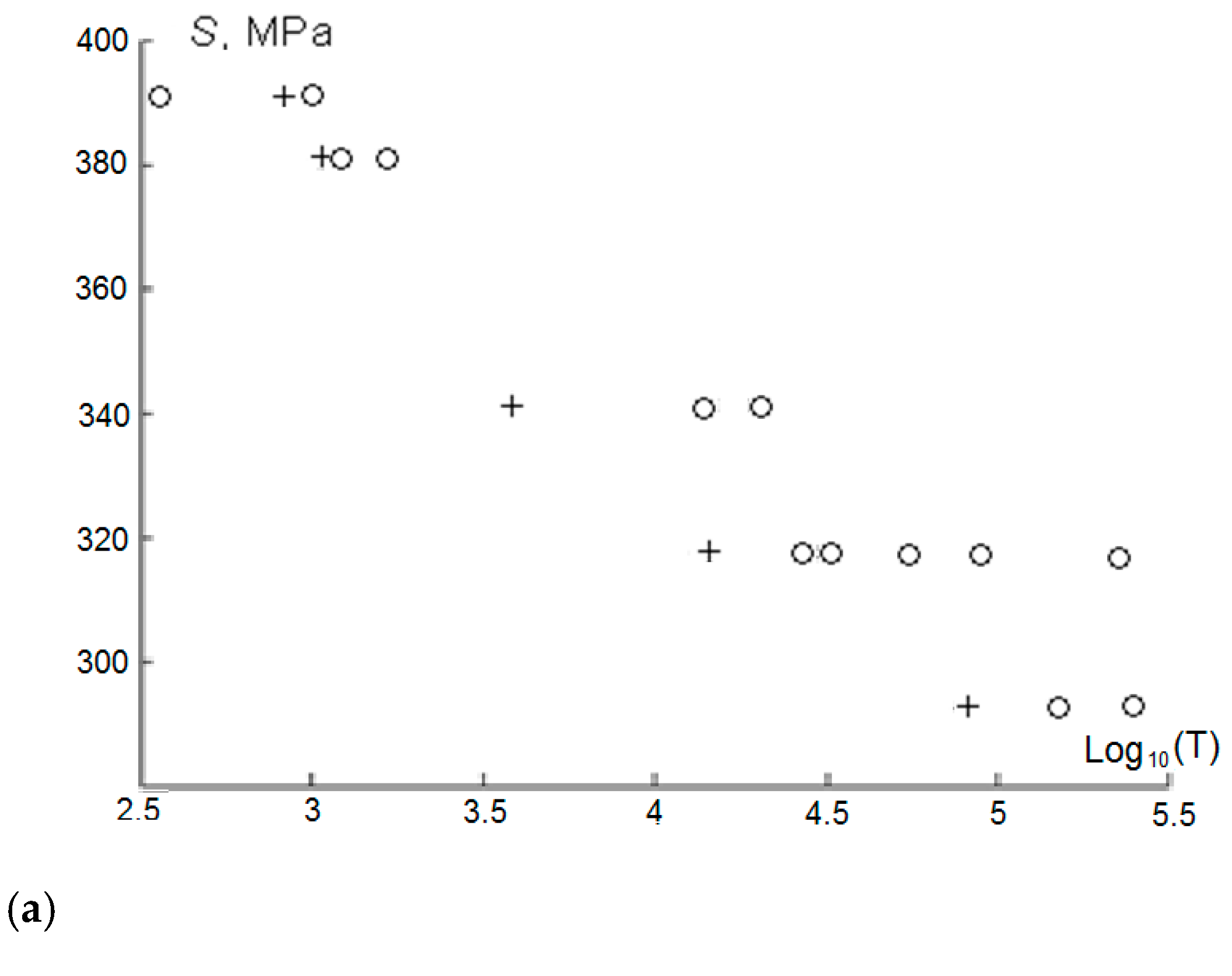

3. Experimental Research Results

- i is the ordinal number of the expected value in the ordered set of samples;

- n is the total set size.

- is the upper limit;

- is the lower limit;

- ni is the number of meanings in the set;

- F(x) is the distribution function.

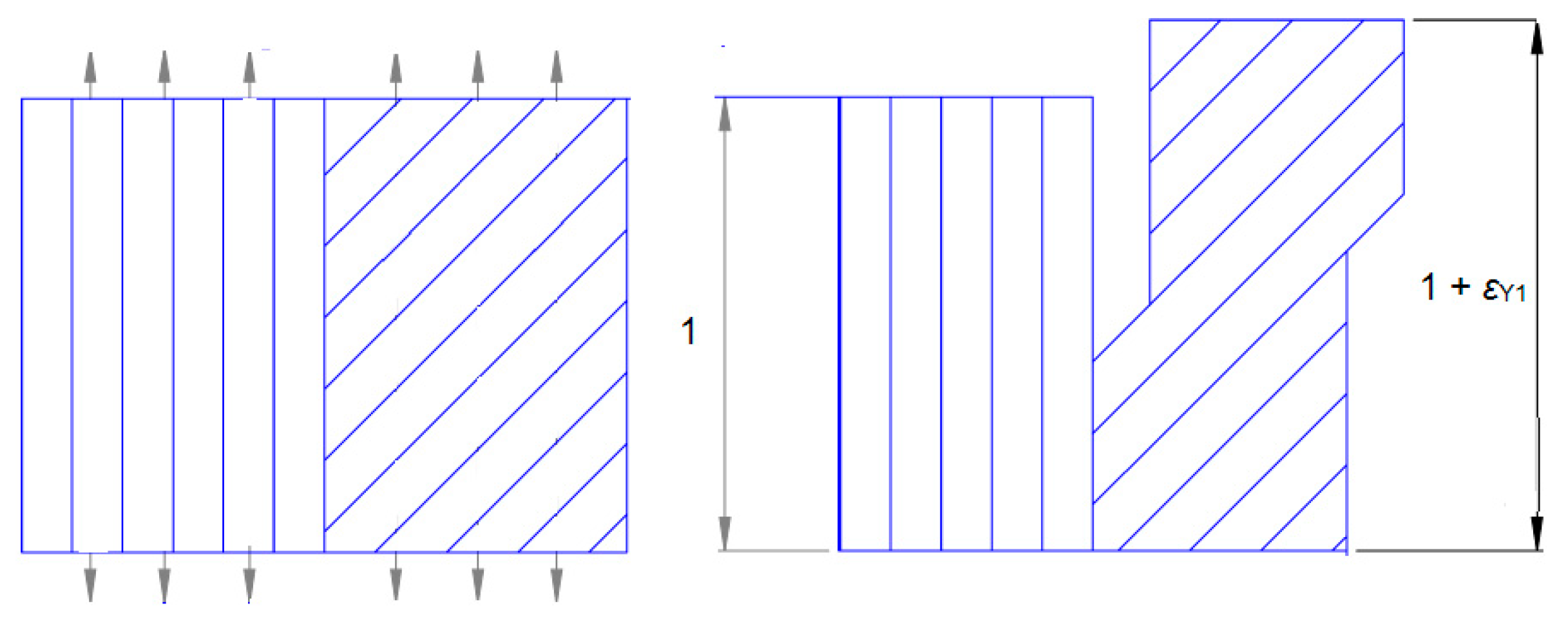

4. Modelling the Fatigue Strength of a Laminate, Taking Markov Chain Theory into Account

4.1. Fatigue Model Assumptions

- , , at , ;

- is the cumulative distribution function (cdf—random numbers) of the strength of the elements working in the elastic range and SR (iR, iY) is the stress in the working part in the elastic range when the process is in a state of i.

- , 1 at , ;

- is the cdf distribution function of the relevant element numbers where the yield point was reached;

- is the critical number of elements in which the yield point has been reached;

- is the number of elements where the yield point has been reached;

- (jY − 1) is the number identifying Case B;

- is the stress in the plastic range, with a specified number of elements that have reached their yield point (jY − 1) and have been destroyed in the plastic range (jR − 1).

- X, Y are the strength limit of elements working in the elastic range and yield strength limit of elements working in the plastic range (on logarithmic scales);

- are the strength distribution parameters (mean and standard deviation);

- (.) is the function with a standard normal distribution.

4.2. Distribution of Fatigue Limits with a Limited Number of Cycles

- R is the initial number of elements, i is the number of damaged components and si is the stress (loading) corresponding to a uniform distribution of load within the other (R-i) elements.

- S is the initial (in the first step of the process) load in each element;

- Sf is the mean stress value which may still carry the load (at least at the start of the working composite components—the cumulative failure of the component that occurs in different sections).

- , k = 1,…, m* are the vector components ;

- m*= (rY + 1)(rR + 1) − (rY + 1 + rR) are the total number of unabsorbed (irreversible) states.

4.3. Local Stress with the Estimated Fatigue Curve Equation and Residual Strength

- S is the average normal stress;

- E is the modulus of elasticity, where the subscripts R and Y represent the elastic and plastic working parts, respectively.

- Q is a stochastic matrix describing the probability of transformation only within transients;

- I is a unity matrix;

- 0 is a matrix containing zeros (r-s) through s;

- R is a matrix describing the probability of transformation from transition states to absorbing states within a single step.

4.4. Determination of Residual Strength

- , and IA is a sequence of indices of irreversible states.

- Bij is the probability in the absorbing state of the process at the j-th transformation state if the initial state is the i-th irreversible state.

- m*= (rY + 1)(rR + 1) − (rY + 1 + rR) is the total number of unabsorbed (irreversible) states.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lakho, D.A.; Yao, D.; Cho, K.; Ishaq, M.; Wang, Y. Study of the Curing Kinetics toward Development of Fast-Curing Epoxy Resins. Polym. Plast. Technol. Eng. 2017, 56, 161–170. [Google Scholar] [CrossRef]

- Bereska, B.; Iłowska, J.; Czaja, K.; Bereska, A. Hardeners for epoxy resins. Chem. Ind. 2014, 4, 443–448. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, Y.C.; Huang, P. Effect of cure cycle on curing process and hardness for epoxy resin. Polymer 2009, 3, 534–541. [Google Scholar] [CrossRef]

- Ren, R.; Chen, P.; Lu, S.; Xiong, X.; Liu, S. The curing kinetics and thermal properties of epoxy resins cured by aromatic diamine with hetero-cyclic side chain structure. Thermochim. Acta 2014, 595, 22–27. [Google Scholar]

- Heneczkowski, M.; Oleksy, M. Plastics processing technology with elements of laboratory exercises. The script prepared under the project “Extension and enrichment of the educational offer and improvement of the quality of education at the Faculty of Chemistry of Rzeszów University of Technology”, Human Capital Operational Programme. 2020. [Google Scholar]

- Kłonica, M.; Kuczmaszewski, J.; Samborski, S. Effect of a notch on impact resistance of the epidian 57/Z1 epoxy material after “Thermal Shock”. Solid State Phenom. 2016, 240, 161–167. [Google Scholar] [CrossRef]

- Gnatowski, A. The influence of filler type on the properties of selected polymer mixtures. Composites 2005, 2, 63–68. [Google Scholar]

- Wang, X.X.; Zhao, Y.R.; Su, H.; Jia, Y.X. Curing process-induced internal stress and deformation of fiber reinforced resin matrix composites: Numerical comparison between elastic and viscoelastic models. Polym. Polym. Compos. 2016, 24, 155–160. [Google Scholar] [CrossRef]

- White, S.R.; Hahn, H.T. Process modeling of composites materials: Residual stress development during cure. Part I. Model formulation. J. Compos. Mater. 1992, 26, 2402–2422. [Google Scholar] [CrossRef]

- Ciriscioli, P.R.; Wang, Q.; Springer, G.S. Autoclave curing—Comparisons of model and test results. J. Compos. Mater. 1992, 26, 90–102. [Google Scholar] [CrossRef]

- Kusyi, Y.; Stupnytsky, V.; Kostiuk, O.; Onysko, O.; Dragašius, E.; Baskutis, S.; Chatys, R. Control of the parameters of the surface layer of steel parts during their processing applying the material homogeneity criterion. Eksploat. I Niezawodn. Maint. Reliab. 2024, 26, 187794. [Google Scholar] [CrossRef]

- Smit, D.A.; Lahuerta, F.; Borst, M.; Nijssen, R.P.L. The Influence of Uneven Temperature Distributions on Local Shear and Interlaminar Fracture Toughness Properties of a Thick Composite Laminate. Mater. Perform. Charact. 2018, 7, 969–983. [Google Scholar] [CrossRef]

- Lahuerta, F.; Nijssen, R.P.L.; van der Meer, F.P.; Sluys, L.J. The influence of curing cycle and through thickness variability of properties in thick laminates. J. Compos. Mater. 2017, 51, 563–575. [Google Scholar] [CrossRef]

- George, S. Springer, Resin Flow During the Cure of Fiber Reinforced Composites. J. Compos. Mater. 1982, 16, 400–410. [Google Scholar]

- Deléglise, M.; Binétruy, C.; Castaing, P.; Krawczak, P. Use of non local equilibrium theory to predict transient temperature during non-isothermal resin flow in a fibrous porous medium. Int. J. Heat Mass Transf. 2007, 50, 2317–2324. [Google Scholar] [CrossRef]

- Hsiao, K.; Laudorn, H.; Advani, S.G. Experimental investigation of heat dispersion due to impregnation of viscous fluids in heated fibrous porous during composites processing. ASME J. Heat Transf. 2001, 123, 178–187. [Google Scholar] [CrossRef]

- Chiu, H.; Yu, B.; Chen, S.C.; Lee, L.J. Heat transfer during flow and resin reaction through fiber reinforcement. Chem. Eng. Sci. 2000, 55, 3365–3376. [Google Scholar] [CrossRef]

- Szymczak, T.; Kowalewski, Z.L. Strength tests of polymer-glass composite to evaluate its operational suitability for ballistic shield plates. Eksploat. I Niezawodn. Maint. Reliab. 2020, 22, 592–600. [Google Scholar] [CrossRef]

- Henne, M.; Ermanni, P.; Deleglise, M.; Krawczak, P. Heat Transfer of Fiber Beds in Resin Transfer Molding: An Experimental Approach. Compos. Sci. Technol. 2014, 64, 1191–1202. [Google Scholar] [CrossRef]

- Ganapathi, A.S.; Joshi, S.C.; Chen, Z. Simulation of Bleeder flow and curing of thick composites with pressure and temperature dependent properties. Simul. Model. Pract. Theory 2013, 32, 64–82. [Google Scholar] [CrossRef]

- Choi, M.A.; Lee, M.H.; Chang, J.; Lee, S.J. Permeability modeling of fibrous media in composite processing. J. Non-Newton. Fluid Mech. 1998, 79, 585–598. [Google Scholar] [CrossRef]

- Starov, V.M.; Zhdanov, V.G. Effective viscosity and permeability of porous media. Colloids Surf. 2001, 192, 363–375. [Google Scholar] [CrossRef]

- Kim, S.K.; Opperer, J.G.; Daniel, I.M. Determination of permeability of fibrous medium considering inertial effects. Int. Comm. Heat Mass Transf. 2002, 29, 879–885. [Google Scholar] [CrossRef]

- Scendo, M.; Żórawski, W.; Staszewska, K.; Makrenek, M.; Góral, A. Influence of Surface Pretreatment on the Corrosion Resistance of Cold Sprayed Nickel Coatings in Acid Chloride Solution. J. Mater. Eng. Perform. 2018, 27, 1725–1737. [Google Scholar] [CrossRef]

- Sienicki, J.; Żórawski, W.; Dworak, A.; Koruba, P.; Jurewicz, P.; Reiner, J. Cold spraying and laser cladding in the aircraft coating production as an alternative to harmful cadmium and chromium electroplating processes. Aircr. Eng. Aerosp. Technol. 2019, 91, 205–215. [Google Scholar] [CrossRef]

- Godzimirski, J. Structural Bonding Problems. Assem. Tech. Technol. 2009, 1, 25–31. [Google Scholar]

- Sadowski, T.; Balawender, T.; Śliwa, R.; Golewski, P.; Kneć, M. Modern hybrid joints in aerospace: Modeling and testing. Arch. Metall. Mater. 2013, 58, 163–169. [Google Scholar] [CrossRef]

- Jansen, K.M.B.; De Vreugd, J.; Ernst, L.J. Analytical estimate for curing-induced stress and warpage in coating layers. J. Appl. Polym. Sci. 2012, 126, 1623–1630. [Google Scholar] [CrossRef]

- Paramonov, Y.M.; Kleinhof, M.A.; Paramonova, A.Y. Markov Model of Connection Between the istribution of Static Strength and Fatigue Life of a Fibrous Composite. Mech. Compos. Mater. 2006, 42, 615–630. [Google Scholar] [CrossRef]

- Chatys, R.; Kłonica, M. Influence of the Curing Process on the Fatigue Strength and Residual Strength of a Fiber Composite Estimation Using the Theory of Markov Chains. Adv. Sci. Technol. Res. J. 2023, 17, 53–62. [Google Scholar] [CrossRef]

- Radek, N.; Pietraszek, J.; Gądek-Moszczak, A.; Orman, Ł.J.; Szczotok, A. The Morphology and Mechanical Properties of ESD Coatings before and after Laser Beam Machining. Materials 2020, 13, 2331. [Google Scholar] [CrossRef]

- Ropyak, L.Y.; Makoviichuk, M.V.; Shatskyi, I.P.; Pritula, I.M.; Gryn, L.O.; Belyakovskyi, V.O. Stressed state of laminated interference-absorption filter under local loading. Funct. Mater. 2020, 27, 638–642. [Google Scholar] [CrossRef]

- Vidinejevs, S.; Chatys, R.; Aniskevich, A.; Jamroziak, K. Prompt Determination of Mechanical Properties of Industrial Polypropylene Sandwich Pipes. Materials 2021, 14, 2128. [Google Scholar] [CrossRef]

- Dekker, R.; Nicolai, R.P.; Kallenberg, L.C.M. Maintenance and Markov decision models. In Wiley StatsRef: Statistics Reference Online; Balakrishnan, N., Colton, T., Everitt, B., Piegorsch, W., Ruggeri, F., Teugels, J.L., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Found, M.S.; Quaresimin, M. Two–stage fatigue loading of woven carbon fiber reinforced laminates. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 17–26. [Google Scholar] [CrossRef]

- Wu, X.; Zou, X.; Guo, X. First passage Markov decision processes with constraints and varying discount factors. Front. Math. China 2015, 10, 1005–1023. [Google Scholar] [CrossRef]

- Chatys, R. Application of the Markov Chain Theory in Estimating the Strength of Fiber-Layered Composite Structures With Regard to Manufacturing Aspects (ASTRJ-01435-2020-01). Adv. Sci. Technol. Res. J. 2020, 4, 64–71. [Google Scholar]

- Philippidis, T.P.; Assimakopoulou, T.T.; Passipoularidis, V.A.; Antoniou, A.E. Static and Fatigue Tests on ISO Standard ±45_ Coupons, OB_TG2_R020_UP. August 2004. Available online: https://www.kcwmc.nl/optimatblades/Publications (accessed on 20 April 2020).

- Philippidis, T.P.; Assimakopoulou, T.T.; Antoniou, A.E.; Passipoularidis, V.A. Residual Strength 31.Tests on ISO Standard ± 45_ Coupons, OB_TG5_R008_UP. July 2005. Available online: https://www.kcwmc.nl/optimatblades/Publications (accessed on 20 April 2020).

- Koszkul, J.; Mazur, P. Poly(ethylene terephthalate) recycled short glass fibre composites. Composites 2003, 8, 348–352. [Google Scholar]

- Wilczyński, A.P.; Klasztorny, M. Determination of complex compliances of fibrous polymeric composites. J. Compos. Mater. 2000, 34, 2–26. [Google Scholar] [CrossRef]

- Ciecieląg, K.; Kęcik, K.; Skoczylas, A.; Matuszak, J.; Korzec, I.; Zaleski, R. Non-Destructive Detection of Real Defects in Polymer Composites by Ultrasonic Testing and Recurrence Analysis. Materials 2022, 15, 7335. [Google Scholar] [CrossRef]

- Paramonov, Y.M. Methods of Mathematical Statistics in Problems on the Estimation and Maintenance of Fatigue Life of Aircraft Structures; RIIGA: Riga, Latvia, 1992. (In Russian) [Google Scholar]

| Designation of Sample Series | P1 | P2 | P3 | P4 |

|---|---|---|---|---|

| Sample type |

|

|

|

|

| Mechanical Properties of the Composite Components with Different LBP | Type Criterion OSPPt | Calfa | Average Sstati. | Standard Deviation | Nspecimens |

|---|---|---|---|---|---|

| Log-normal distribution Sstat., MPa | |||||

| SEPOXY_C1 | 0.27439 | 0.31162 | 6.590 | 0.14987 | 20 |

| SEPOXY_C2 | 0.18322 | 0.26505 | 6.544 | 0.13653 | 31 |

| SEPOXY_C3 | 0.24046 | 0.34601 | 6.411 | 0.076333 | 15 |

| SEPOXY_A | 0.21924 | 0.29487 | 6.076 | 0.065701 | 23 |

| SEPOXY_B | 0.14194 | 0.30321 | 6.189 | 0.059936 | 21 |

| Normal distribution Sstat., MPa | |||||

| SEPOXY_C1 | 0.33237 | 0.33977 | 573.017 | 89.3891 | 20 |

| SEPOXY_C2 | 0.23027 | 0.26217 | 621.303 | 86.9879 | 31 |

| SEPOXY_C3 | 0.25157 | 0.34707 | 610.233 | 46.797 | 15 |

| SEPOXY_A | 0.20613 | 0.30016 | 436.071 | 28.3748 | 23 |

| SEPOXY_B | 0.1553 | 0.30878 | 487.561 | 29.4538 | 21 |

| Mechanical Properties of the Composite’s Components with Different LBP Values | Type criterion OSPPt | Calfa | AverageE | Standard Deviation | Nspecimens |

| Log-normal distribution E, GPa | |||||

| EEPOXY_C1 | 0.30161 | 0.31136 | 2.681 | 0.051224 | 20 |

| EEPOXY_C2 | 0.34004 | 0.26276 | 3.337 | 0.032427 | 31 |

| EEPOXY_C3 | 0.36118 | 0.34924 | 3.328 | 0.025142 | 15 |

| EEPOXY_A | 0.21243 | 0.29428 | 3.119 | 0.050672 | 23 |

| EEPOXY_B | 0.23458 | 0.30164 | 3.085 | 0.072699 | 21 |

| Normal distribution E, GPa | |||||

| EEPOXY_C1 | 0.27588 | 0.31267 | 17.854 | 0.89356 | 20 |

| EEPOXY_C2 | 0.32463 | 0.26123 | 28.139 | 0.89524 | 31 |

| EEPOXY_C3 | 0.37838 | 0.34558 | 27.906 | 0.71101 | 15 |

| EEPOXY_A | 0.20497 | 0.29609 | 22.645 | 1.1382 | 23 |

| EEPOXY_B | 0.22871 | 0.30602 | 21.929 | 1.5821 | 21 |

| Specimens Sstat. with Different LBP Values | D* | Average, Sstat., MPa | Dispersion | Standard Deviation | The Criterion S-K [43] |

|---|---|---|---|---|---|

| SHEPOXY_A | 0.113879 | 6.0758 | 0.003421 | 0.065701 | 0.516735 < 0.99 |

| SHEPOXY_B | 0.135569 | 6.1891 | 0.004986 | 0.059936 | 0.60825 < 0.99 |

| SHEPOXY_B (R = 0,1), MPa | N, Cycles |

|---|---|

| 292.535 | 147.000; 241.000 |

| 317.36 | 28.500; 31.000; 36.800; 56.000; 92.000; 222.000 |

| 341.29 | 13.700; 14.600; 19.650 |

| 380.78 | 300; 450; 1100; 1200; 1650; 1700 |

| 390.05 | 350; 1000 |

| SHEPOXY_A (R = 0,1), MPa | N, Cycles | SR, MPa | Average SR, MPa |

|---|---|---|---|

| 243.78 | 265.000 | 399.8 | 399.8 |

| 292.53 | 60.000 | 465.84; 432.04; 425.13; 414.73; 408.84; 387.55 | 422 |

| 390.05 | 900 | 481.58; 478.39; 477.78; 474.16; 456.54; 451.85 | 470 |

| 1 | 2 | 3 | |||||||||

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

| 1 | 1 | 1 | |||||||||

| 2 | 2 | 0 | 0 | 0 | 0 | ||||||

| 3 | 3 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 2 | 1 | 4 | 0 | 0 | 0 | ||||||

| 2 | 5 | 0 | 0 | 0 | 0 | 0 | |||||

| 3 | 6 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | |

| 3 | 1 | 7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 2 | 8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 3 | 9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | |

| Characteristics | Dependencies |

|---|---|

| Fatigue strength (time to absorption) | T = X1 + X2 +...+ Xr (8) where: Xi, i = 1; r—destruction time (is) in an i-m state |

| Random variable Xi in a geometric distribution | P(Xi = n) = (1 − p)n−1pi (9) |

| Expected value | E(Xi) = 1/pi (10) |

| Dispersion | V(Xi) = (1 − pi)/pi2 (11) |

| Random variable |

(12) (13) |

| Function which produces the probabilities of the random variable T | |

| Function of cumulative distribution | FT(t) = p1 r+1(t), t = 1, 2, 3 (14) where: p1 r+1(t) is (1, r +1)—matrix element |

| Function of fatigue strength distribution | P(t) = Pt described as: FT(t) = a Pt b (15) where: a = (100....); b = (0.0,…0.1)T- column vector |

| Model Conditions |

|---|

| basic matrix of the different initial states. where ξ = [1,…,1] is a columnar unit vector. probability matrix in the absorbing state. where: Tij is the number of visits to state j, starting from state i; Ti is the time of absorption (considering also the initial state) starting from state i; E(Ti), Var(Ti) are the average and variance of the absorption time if i is the initial state; τ = {E(Ti}), τ2 = {Var(Ti)} are the corresponding column vectors, i is the transition state index; B = {bij} is the probability matrix of absorption; bij is the probability that the process will be absorbed in state j if the initial state is i. |

| Model Parameters | Parameter Values |

|---|---|

| Number of working elements in the critical micro-volume, rY | 5 |

| Average strength value for longitudinal components operating in the elastic range, QOR(exp(QOR)) | 6.1883 (487.56 MPa) * |

| Standard deviation of the element’s longitudinal strength, | 0.15 |

| Standard deviation in the critical plastic part of micro-volumes, | 0.2 |

| Number of cycles equivalent to a single step in the Markov chain, kM | 227 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chatys, R.; Kłonica, M.; Blumbergs, I. Analysis of Fatigue and Residual Strength Estimation of Polymer Matrix Composites Using the Theory of the Markov Chain Method. Materials 2025, 18, 3229. https://doi.org/10.3390/ma18143229

Chatys R, Kłonica M, Blumbergs I. Analysis of Fatigue and Residual Strength Estimation of Polymer Matrix Composites Using the Theory of the Markov Chain Method. Materials. 2025; 18(14):3229. https://doi.org/10.3390/ma18143229

Chicago/Turabian StyleChatys, Rafał, Mariusz Kłonica, and Ilmars Blumbergs. 2025. "Analysis of Fatigue and Residual Strength Estimation of Polymer Matrix Composites Using the Theory of the Markov Chain Method" Materials 18, no. 14: 3229. https://doi.org/10.3390/ma18143229

APA StyleChatys, R., Kłonica, M., & Blumbergs, I. (2025). Analysis of Fatigue and Residual Strength Estimation of Polymer Matrix Composites Using the Theory of the Markov Chain Method. Materials, 18(14), 3229. https://doi.org/10.3390/ma18143229