Influence of Plasma Assistance on EB-PVD TBC Coating Thickness Distribution and Morphology

Abstract

1. Introduction

- -

- Enhances ad-atom mobility, suppressing sintering gaps and providing a denser, less porous columnar network;

- -

- Improves bond–coat adhesion and in situ surface cleaning;

- -

- Permits bias-mediated steering of column inclination and crystallographic texture (001 vs. 011 fibres);

- -

- Allows for closed-loop rate/stoichiometry control through optical emission feedback, as shown for plasma-activated YSZ evaporation.

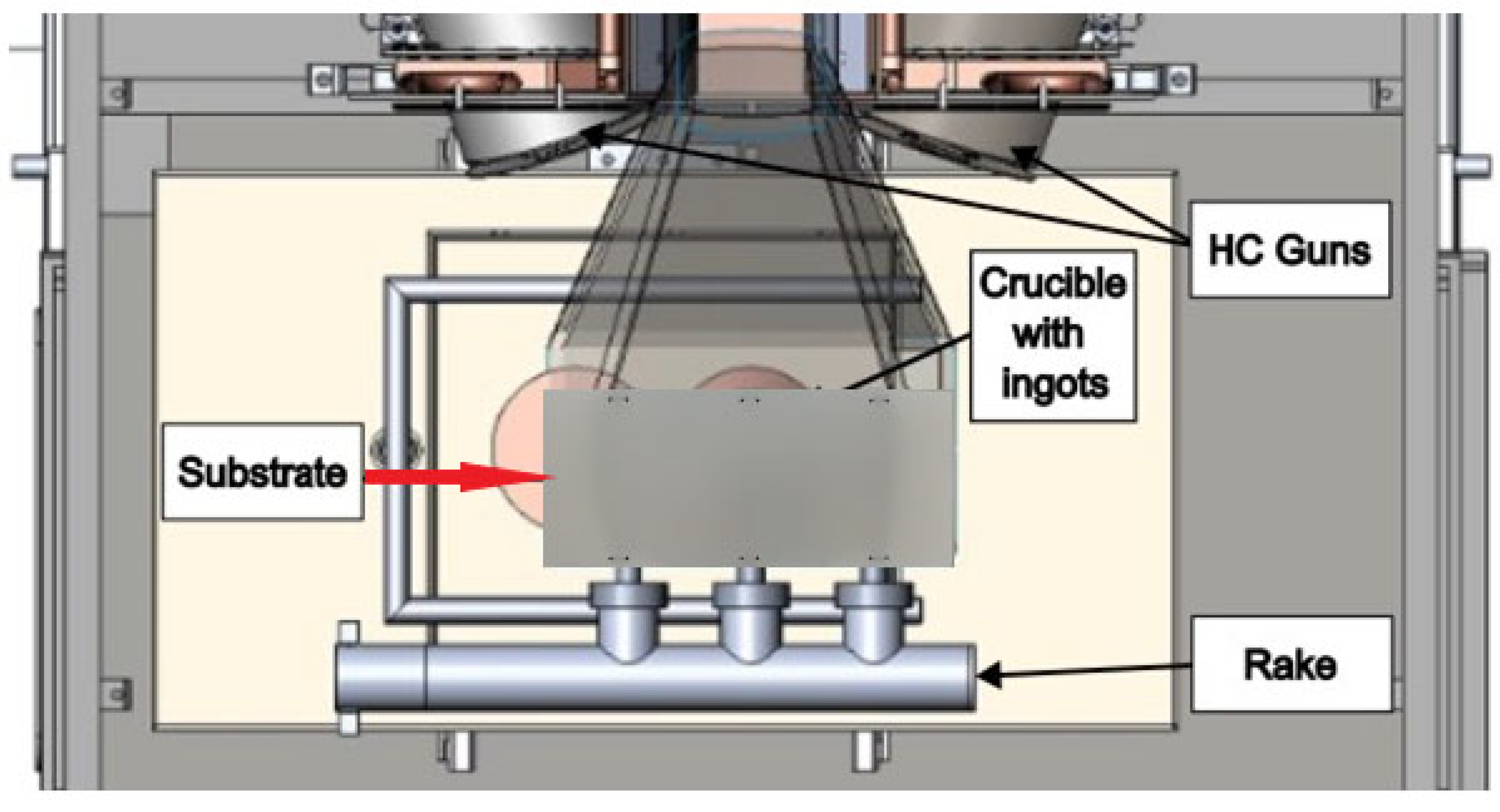

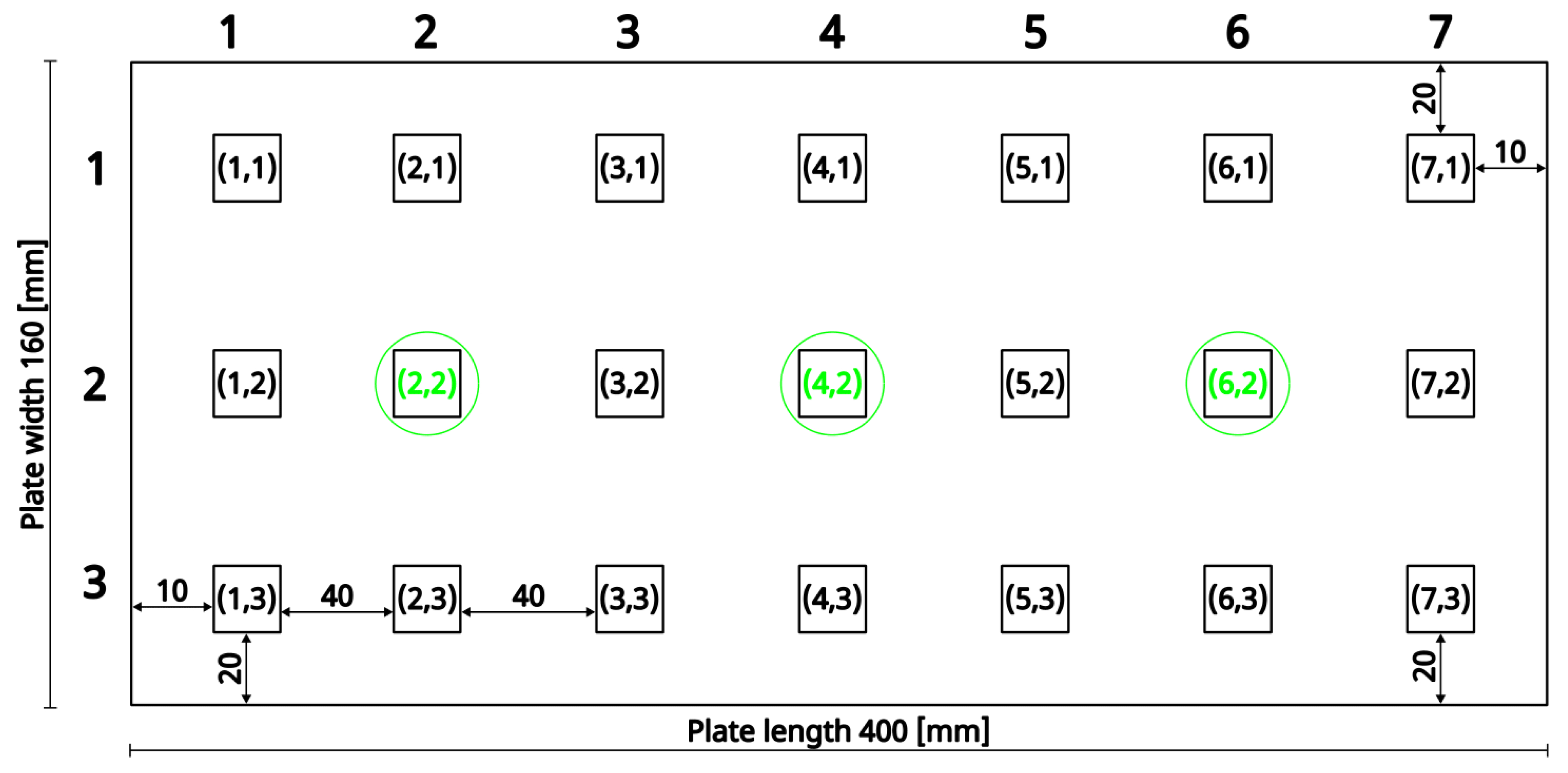

2. Materials and Methods

3. Results and Discussion

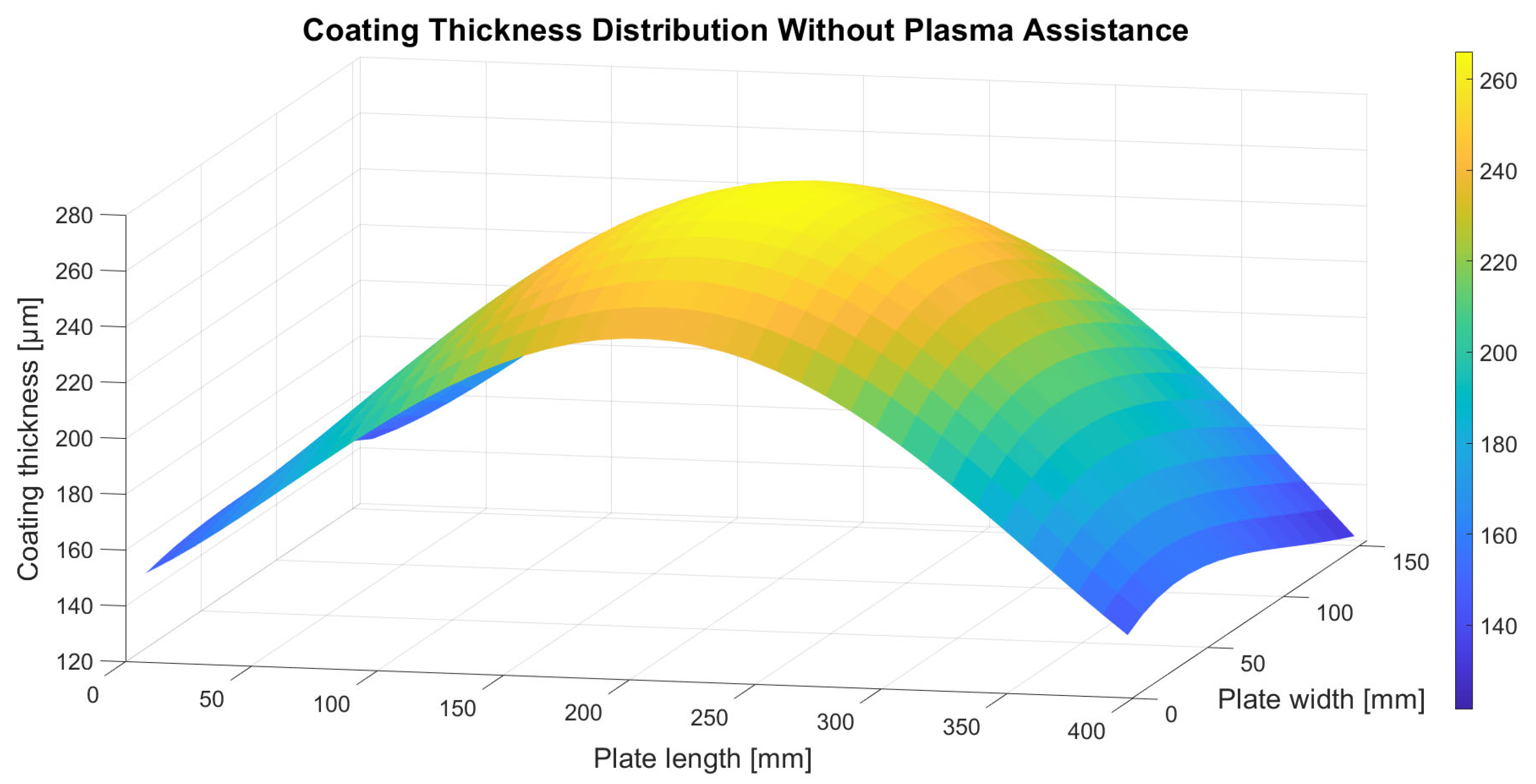

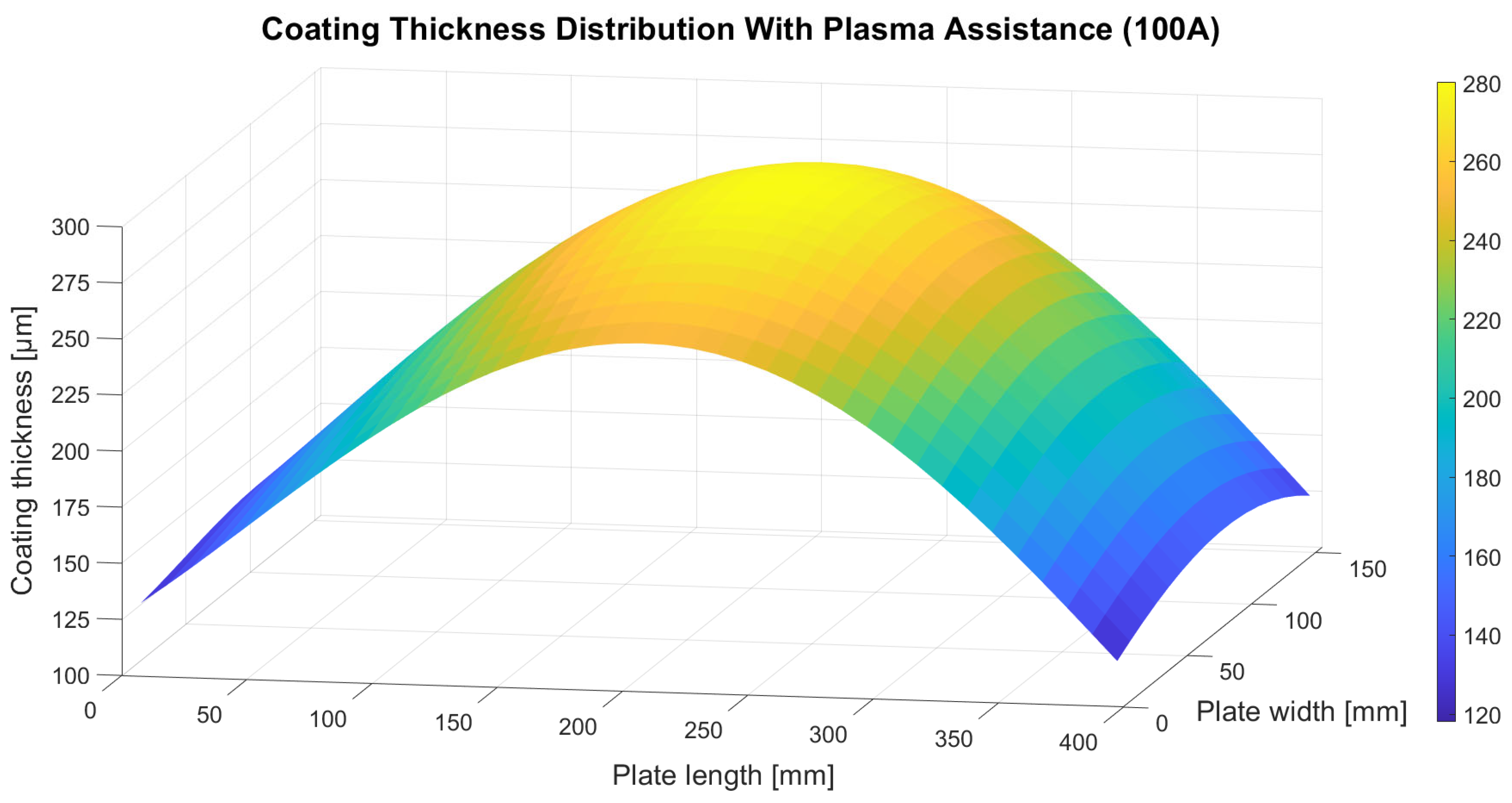

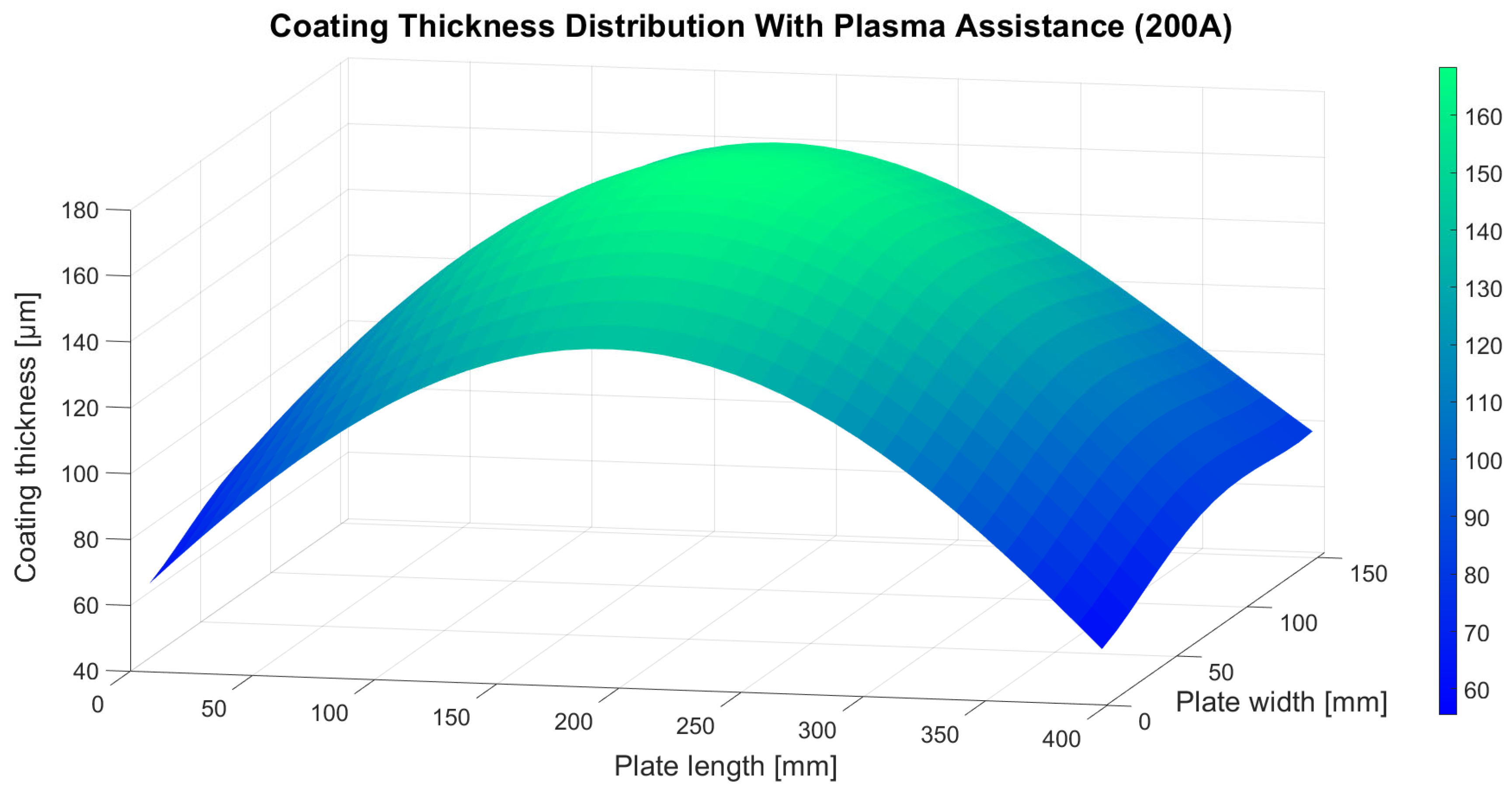

3.1. Coating Thickness Distribution Analysis

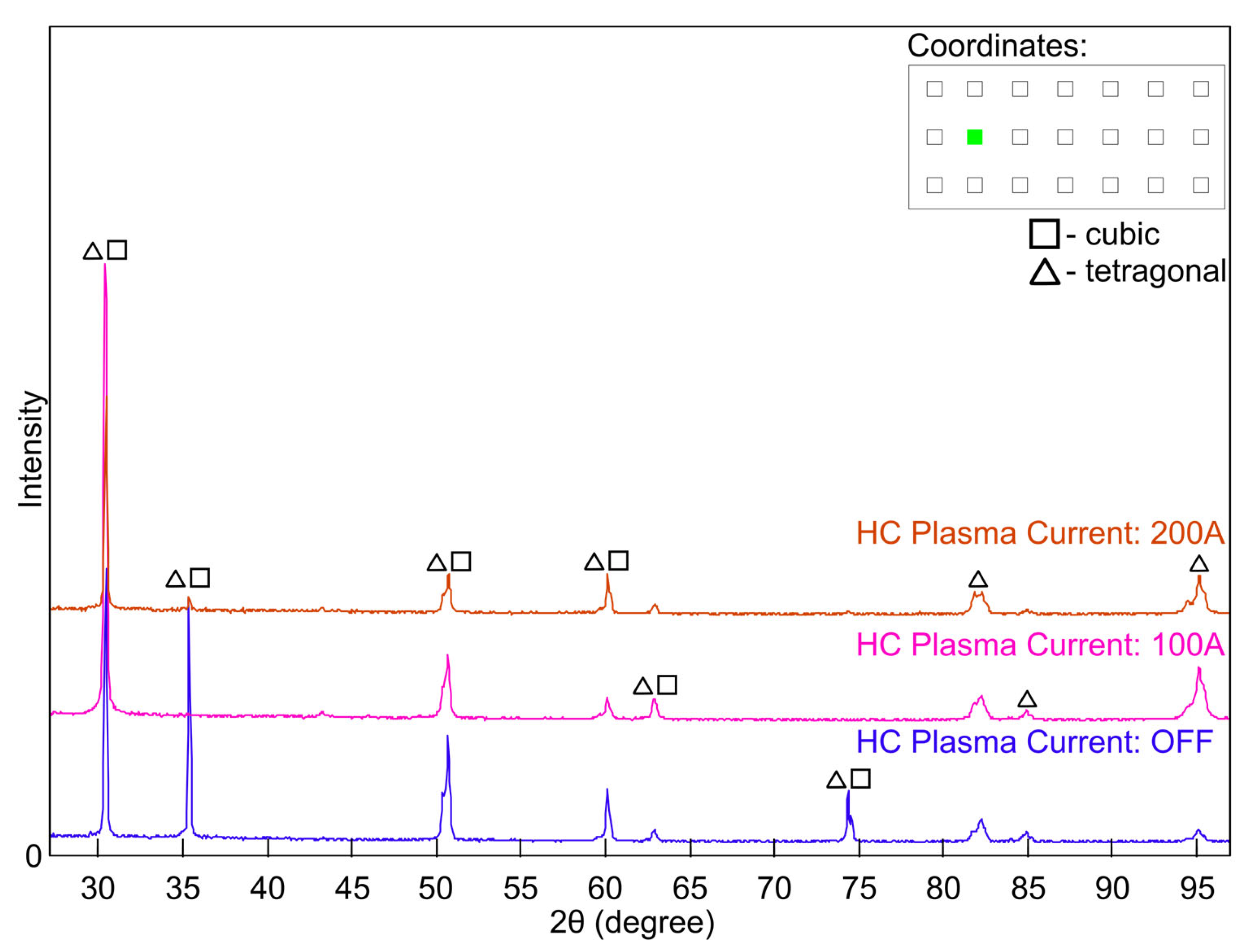

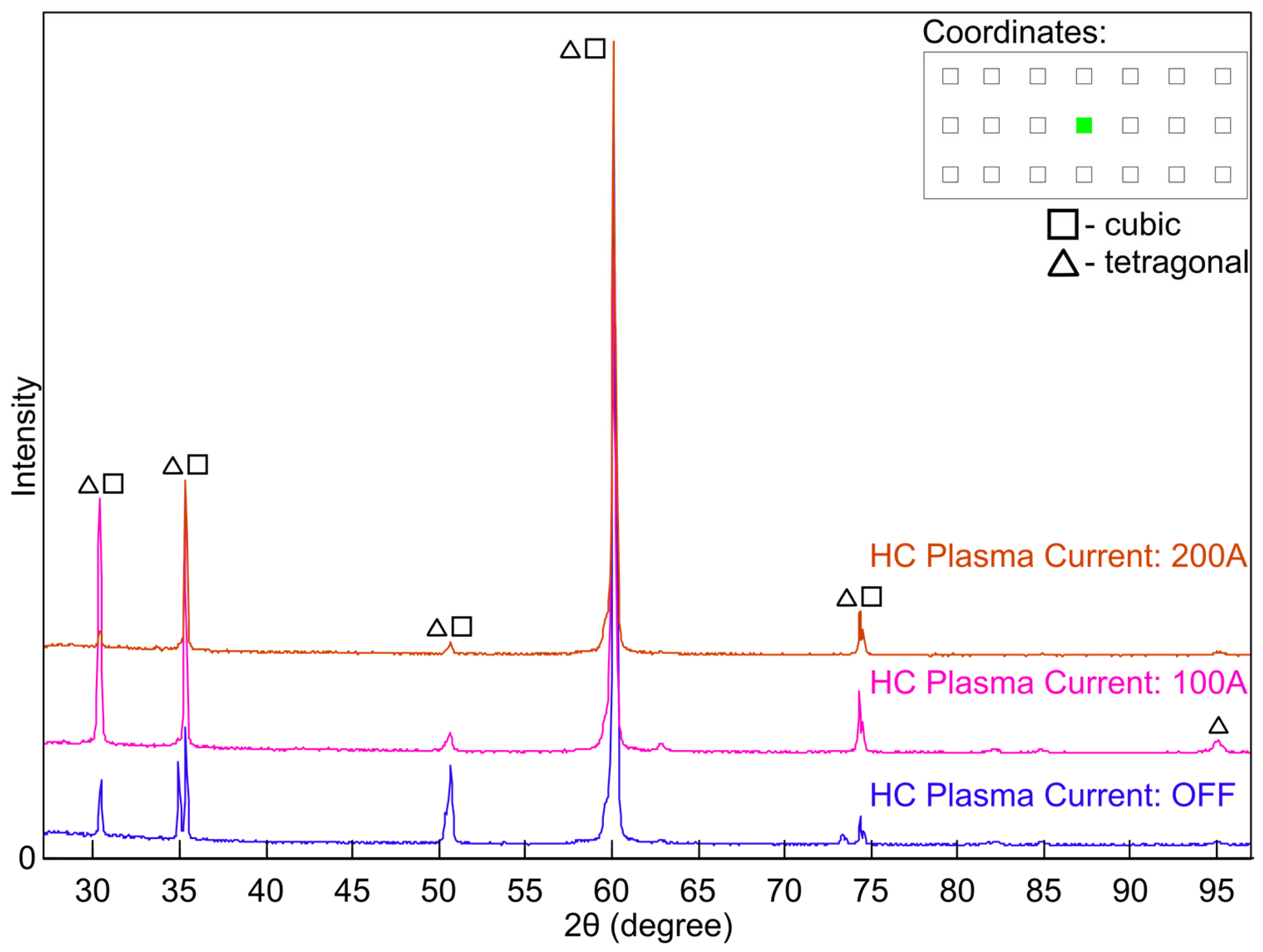

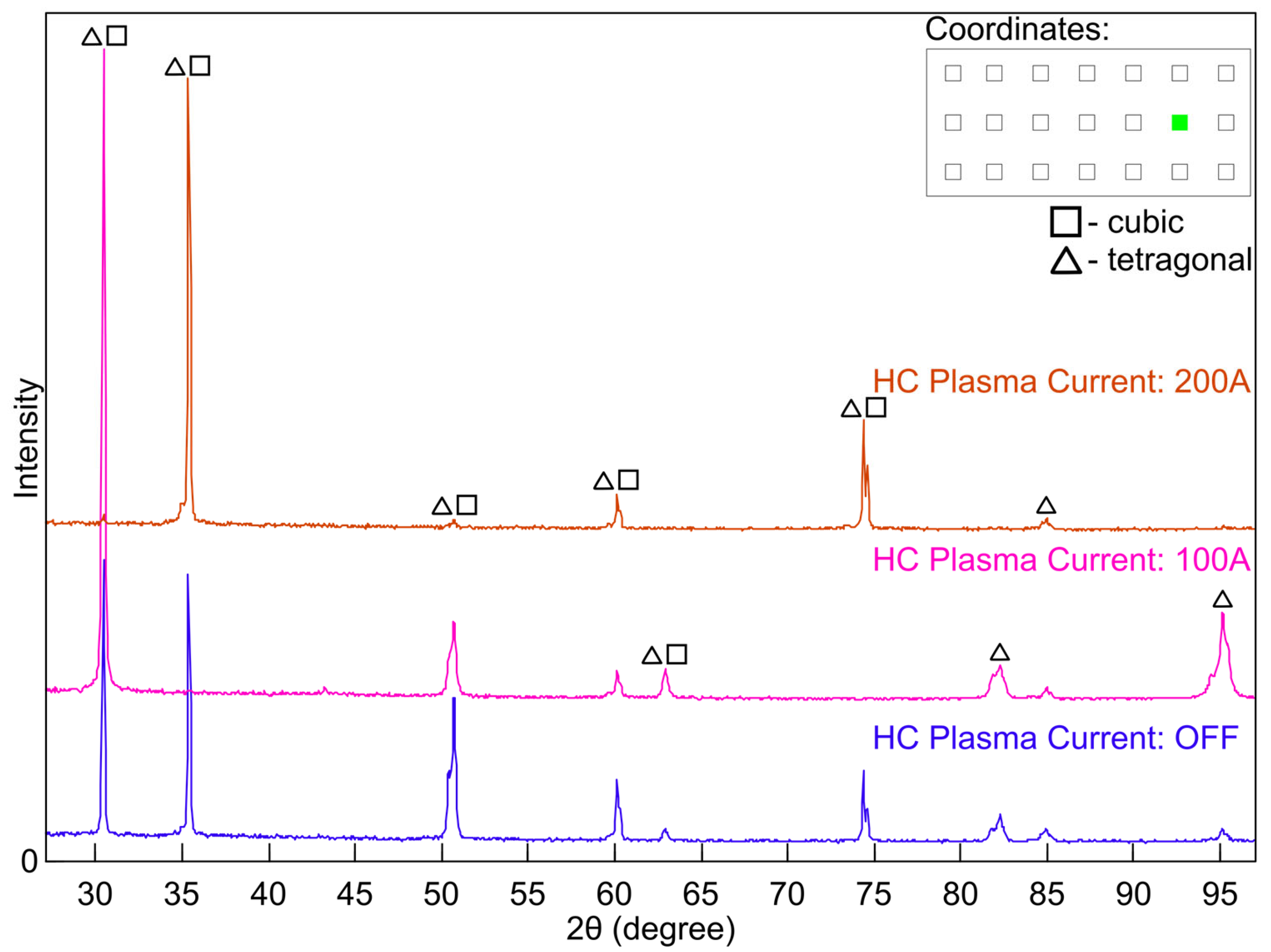

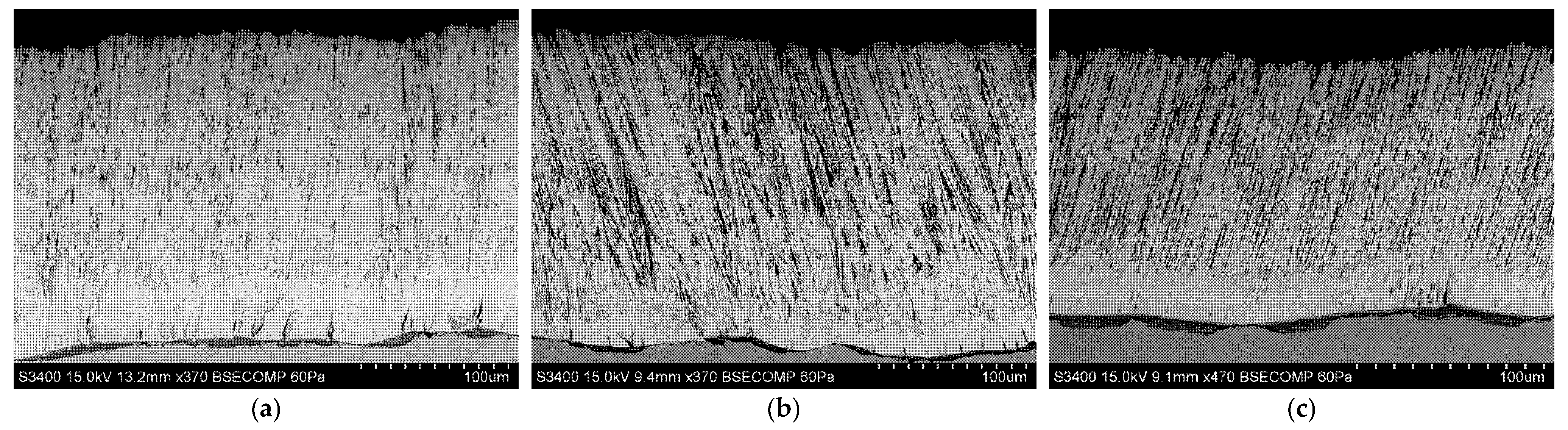

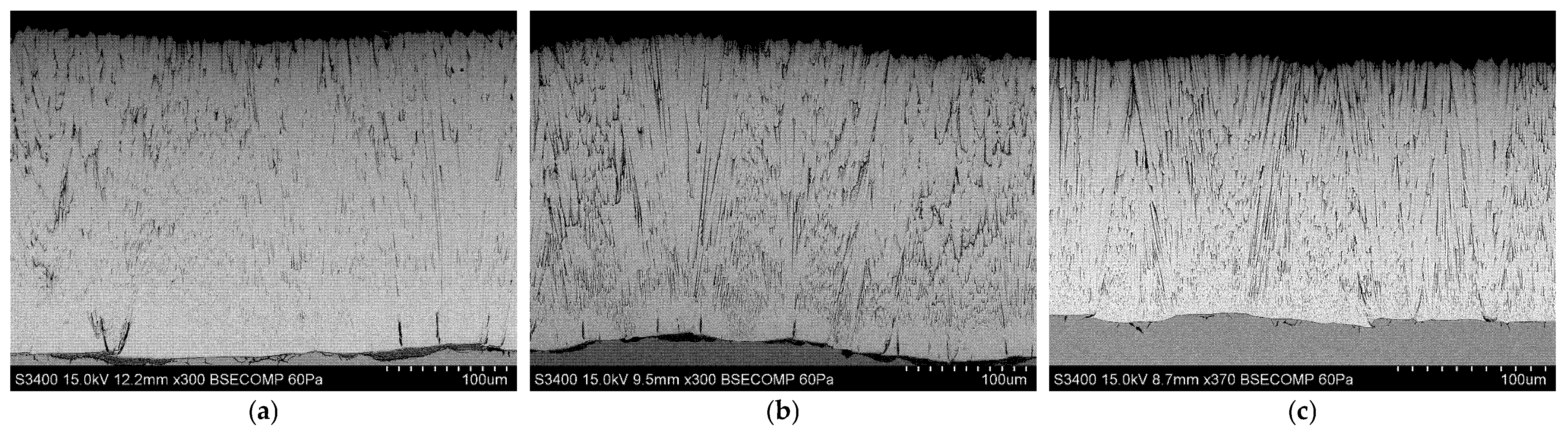

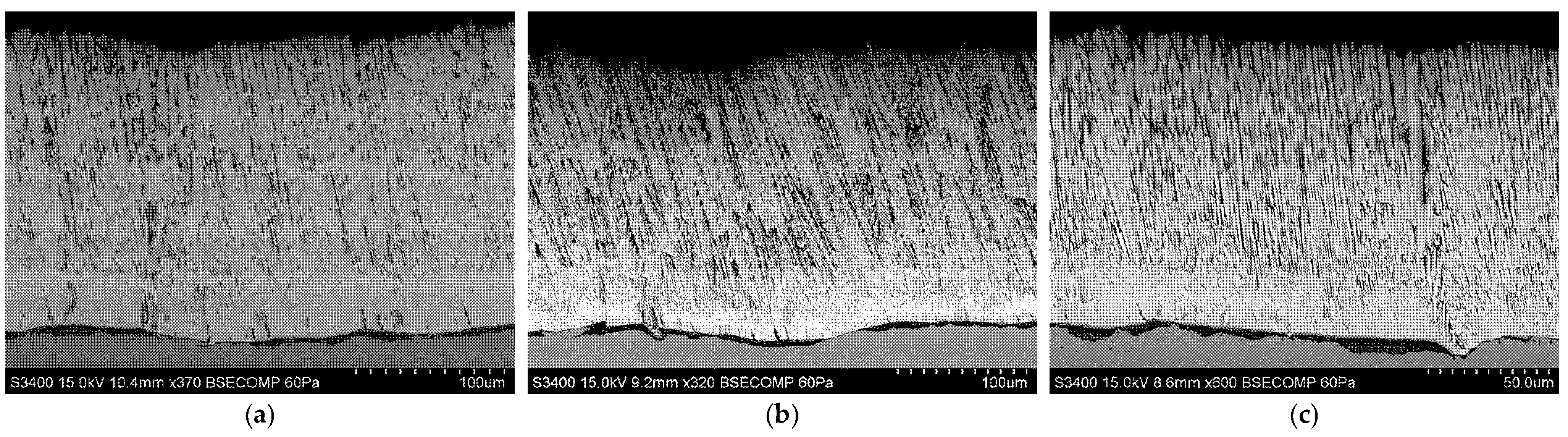

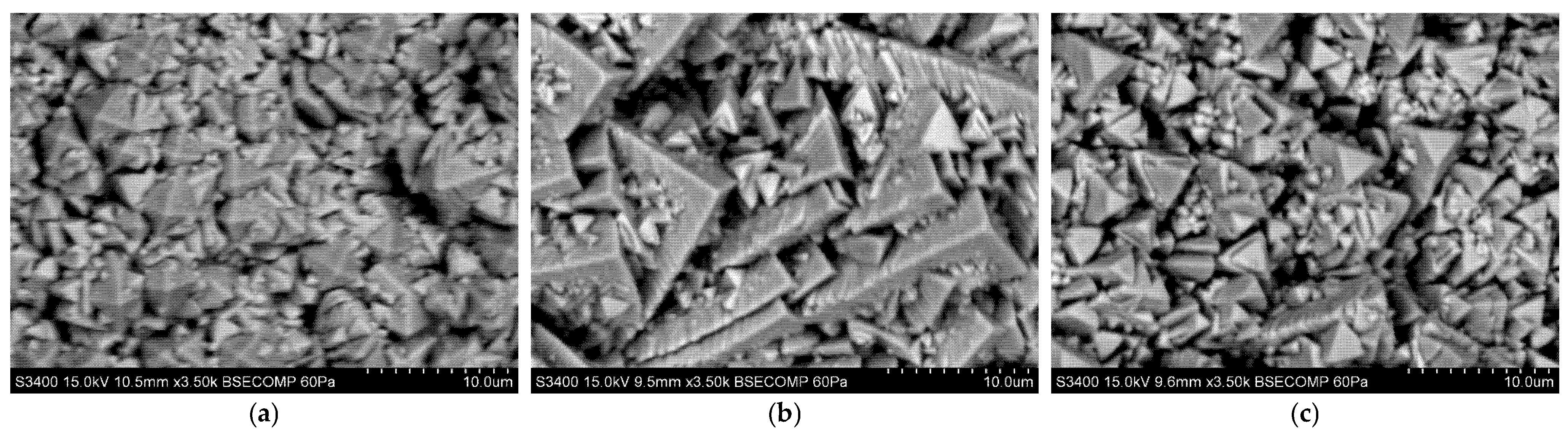

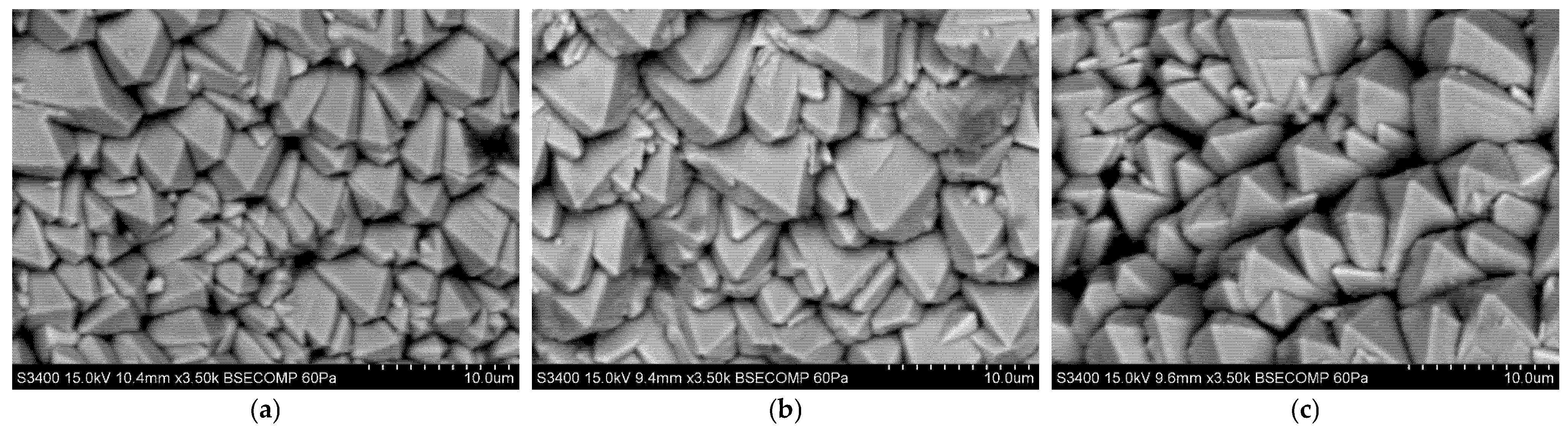

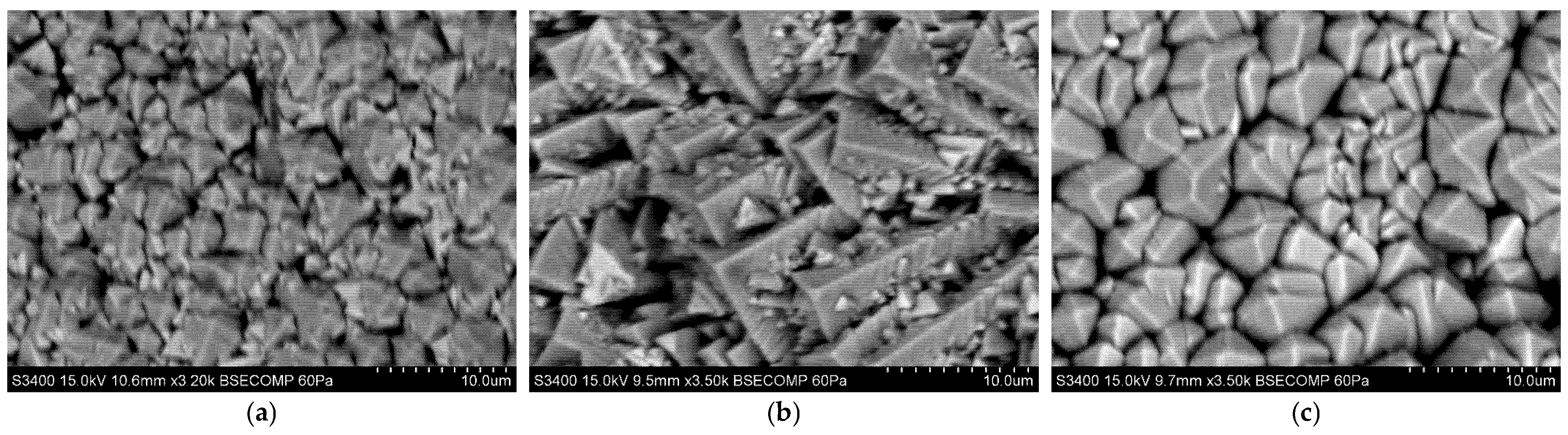

3.2. TBC Coating Morphology Evaluation

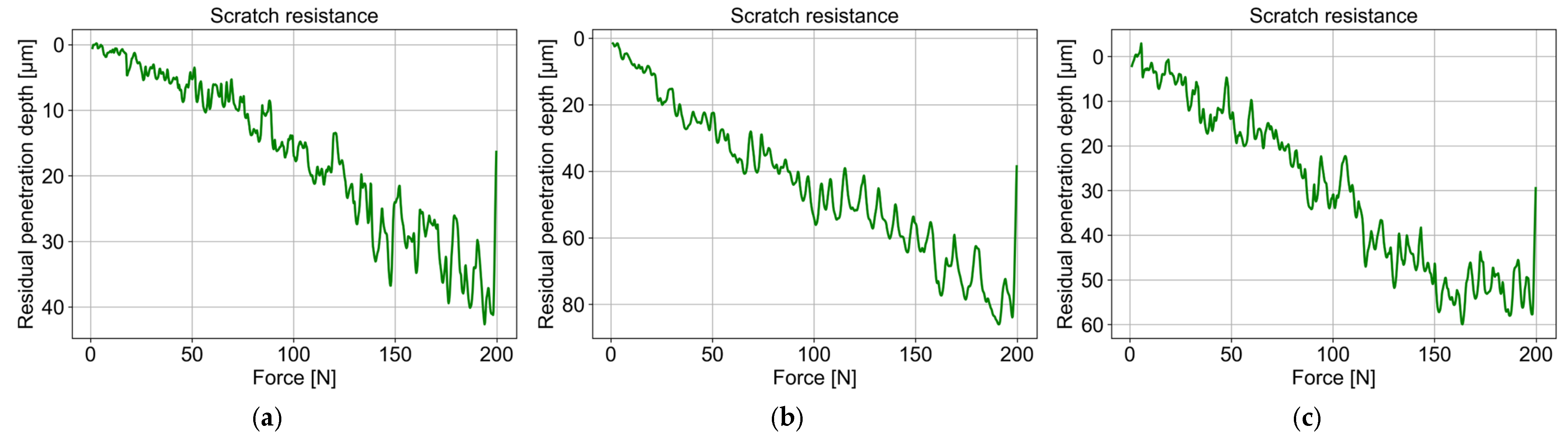

3.3. TBC Coating Scratch Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TBC | Thermal Barrier Coating |

| EB-PVD | Electron Beam-Physical Vapour Deposition |

| HC | Hollow Cathode |

| SEM | Scanning Electron Microscopy |

References

- Mondal, K.; Nuñez, L.; Downey, C.M.; Van Rooyen, I.J. Thermal Barrier Coatings Overview: Design, Manufacturing, and Applications in High-Temperature Industries. Ind. Eng. Chem. Res. 2021, 60, 6061–6077. [Google Scholar] [CrossRef]

- Vaßen, R. Thermal Barrier Coatings. In Ceramics Science and Technology, 1st ed.; Riedel, R., Chen, I.-W., Eds.; Wiley: Hoboken, NJ, USA, 2013; pp. 95–115. [Google Scholar] [CrossRef]

- Ujifusa, K. Electron Beam Physical Vapor Deposition for Thermal Barrier Coatings. Available online: https://www.linkedin.com/pulse/electron-beam-physical-vapor-deposition-thermal-barrier-ujipc/ (accessed on 28 July 2025).

- Bose, S. High Temperature Coatings; Elsevier Science & Technology Books: Amsterdam, The Netherlands, 2011. [Google Scholar] [CrossRef]

- Schulz, U.; Fritscher, K.; Leyens, C.; Peters, M. Influence of Processing on Microstructure and Performance of Electron Beam Physical Vapor Deposition (EB-PVD) Thermal Barrier Coatings. J. Eng. Gas Turbines Power 2002, 124, 229–234. [Google Scholar] [CrossRef]

- Arustamov, V.N.; Rotchtein, V.M.; Ashurov, K.B.; Khudaykulov, I.K. Cleaning the surface of products with glow discharge plasma. J. Phys. Conf. Ser. 2020, 1686, 012013. [Google Scholar] [CrossRef]

- Reinhold, E.; Faber, J. Large area electron beam physical vapor deposition (EB-PVD) and plasma activated electron beam (EB) evaporation—Status and prospects. Surf. Coat. Technol. 2011, 206, 1653–1659. [Google Scholar] [CrossRef]

- Fietzke, F.; Zimmermann, B. Plasma characterization and technological application of a hollow cathode plasma source with an axial magnetic field. Surf. Coat. Technol. 2010, 205, 1491–1496. [Google Scholar] [CrossRef]

- Zimmermann, B.; Mattausch, G.; Fietzke, F.; Scheffel, B.; Heinß, J.-P.; Top, M.; Metzner, C. Gas Discharge Electron Sources—Powerful Tools for Thin-Film Technologies. Available online: https://www.svc.org/clientuploads/directory/resource_library/2021_EB_02_Zimmermann_docx.pdf (accessed on 28 July 2025).

- Zimmermann, B.; Fietzke, F.; Möller, W. Spatially resolved Langmuir probe measurements of a magnetically enhanced hollow cathode arc plasma. Surf. Coat. Technol. 2011, 205, S393–S396. [Google Scholar] [CrossRef]

- de Amorim Filho, J. (Ed.) Gas Discharges: Fundamentals & Applications; Trivandrum: Kerala, India, 2007. [Google Scholar]

- Gudmundsson, J.T.; Anders, A.; Von Keudell, A. Foundations of physical vapor deposition with plasma assistance. Plasma Sources Sci. Technol. 2022, 31, 083001. [Google Scholar] [CrossRef]

- Mishra, S.K.; Pandey, S.; Mahato, P.; Kumar, K.S.; Bysakh, S.; Sreemany, M.; Pathak, L.C. Microstructural studies on EB-PVD deposited NiCrAlY, YSZ and lanthanum zirconate for thermal barrier applications. Surf. Coat. Technol. 2012, 207, 143–148. [Google Scholar] [CrossRef]

- Doleker, K.M.; Ozgurluk, Y.; Ahlatci, H.; Karaoglanli, A.C. Evaluation of oxidation and thermal cyclic behavior of YSZ, Gd2Zr2O7 and YSZ/Gd2Zr2O7 TBCs. Surf. Coat. Technol. 2019, 371, 262–275. [Google Scholar] [CrossRef]

- Jiang, S.L.; Huang, X.; He, Z. Phase Transformation and Lattice Parameter Changes of Trivalent Rare Earth Doped YSZ as a Function of Temperature. J. Mater. Eng. Perform. 2016, 25, 4686–4694. [Google Scholar] [CrossRef]

- Guo, L.; Li, M.; Ye, F. Phase stability and thermal conductivity of RE2O3 (RE = La, Nd, Gd, Yb) and Yb2O3 co-doped Y2O3 stabilized ZrO2 ceramics. Ceram. Int. 2016, 42, 7360–7365. [Google Scholar] [CrossRef]

- Ozgurluk, Y.; Karaoglanli, A.C.; Ahlatci, H. Comparison of calcium—Magnesium-alumina-silicate (CMAS) resistance behavior of produced with electron beam physical vapor deposition (EB-PVD) method YSZ and Gd2Zr2O7/YSZ thermal barrier coatings systems. Vacuum 2021, 194, 110576. [Google Scholar] [CrossRef]

| Trial Number | Hollow-Cathode Plasma Current [A] | Emission Current [A] | Pressure [mbar] | Temperature [°C] | Feed Rate [mm/min] | Duration [s] |

|---|---|---|---|---|---|---|

| 01 | 100 | 1.82 | 0.00991 | 841 | 1.5 | 1200 |

| 02 | 200 | 1.62 | 0.00969 | 858 | 1.5 | 1200 |

| 03 | 0 | 2.32 | 0.00997 | 947 | 1.5 | 1200 |

| Location of Measurement * | Thickness of the Coating [µm] Deposited Without Plasma Assistance Measured By | Thickness of the Coating [µm] Deposited with Plasma Assistance (100 A) Measured By | Thickness of the Coating [µm] Deposited with Plasma Assistance (200 A) Measured By | |||

|---|---|---|---|---|---|---|

| Non-Destructive Method | SEM Cross-Section Analysis | Non-Destructive Method | SEM Cross-Section Analysis | Non-Destructive Method | SEM Cross-Section Analysis | |

| (1,1) | 164 | 162 | 147 | 144 | 85 | 84 |

| (1,2) | 166 | 163 | 155 | 158 | 94 | 94 |

| (1,3) | 159 | 158 | 153 | 158 | 97 | 97 |

| (2,1) | 192 | 188 | 200 | 213 | 120 | 118 |

| (2,2) | 203 | 204 | 214 | 213 | 138 | 133 |

| (2,3) | 189 | 187 | 209 | 200 | 137 | 132 |

| (3,1) | 245 | 233 | 231 | 230 | 144 | 154 |

| (3,2) | 249 | 235 | 258 | 240 | 162 | 168 |

| (3,3) | 236 | 225 | 252 | 249 | 161 | 169 |

| (4,1) | 256 | 254 | 245 | 233 | 151 | 156 |

| (4,2) | 265 | 257 | 265 | 248 | 165 | 170 |

| (4,3) | 252 | 238 | 261 | 243 | 163 | 160 |

| (5,1) | 241 | 235 | 240 | 239 | 138 | 146 |

| (5,2) | 244 | 241 | 265 | 249 | 153 | 160 |

| (5,3) | 238 | 224 | 262 | 250 | 150 | 156 |

| (6,1) | 206 | 193 | 195 | 201 | 111 | 113 |

| (6,2) | 214 | 200 | 210 | 211 | 125 | 118 |

| (6,3) | 199 | 185 | 206 | 198 | 122 | 119 |

| (7,1) | 156 | 157 | 145 | 151 | 72 | 74 |

| (7,2) | 153 | 156 | 157 | 167 | 86 | 89 |

| (7,3) | 146 | 151 | 155 | 158 | 85 | 87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maciaszek, G.; Cioch, K.; Nowotnik, A.; Nabel, D. Influence of Plasma Assistance on EB-PVD TBC Coating Thickness Distribution and Morphology. Materials 2025, 18, 4109. https://doi.org/10.3390/ma18174109

Maciaszek G, Cioch K, Nowotnik A, Nabel D. Influence of Plasma Assistance on EB-PVD TBC Coating Thickness Distribution and Morphology. Materials. 2025; 18(17):4109. https://doi.org/10.3390/ma18174109

Chicago/Turabian StyleMaciaszek, Grzegorz, Krzysztof Cioch, Andrzej Nowotnik, and Damian Nabel. 2025. "Influence of Plasma Assistance on EB-PVD TBC Coating Thickness Distribution and Morphology" Materials 18, no. 17: 4109. https://doi.org/10.3390/ma18174109

APA StyleMaciaszek, G., Cioch, K., Nowotnik, A., & Nabel, D. (2025). Influence of Plasma Assistance on EB-PVD TBC Coating Thickness Distribution and Morphology. Materials, 18(17), 4109. https://doi.org/10.3390/ma18174109