Microstructure Evolution and Constitutive Model of Spray-Formed 7055 Forging Aluminum Alloy

Abstract

1. Introduction

2. Materials and Experimental Method

2.1. Experimental Materials and Methods

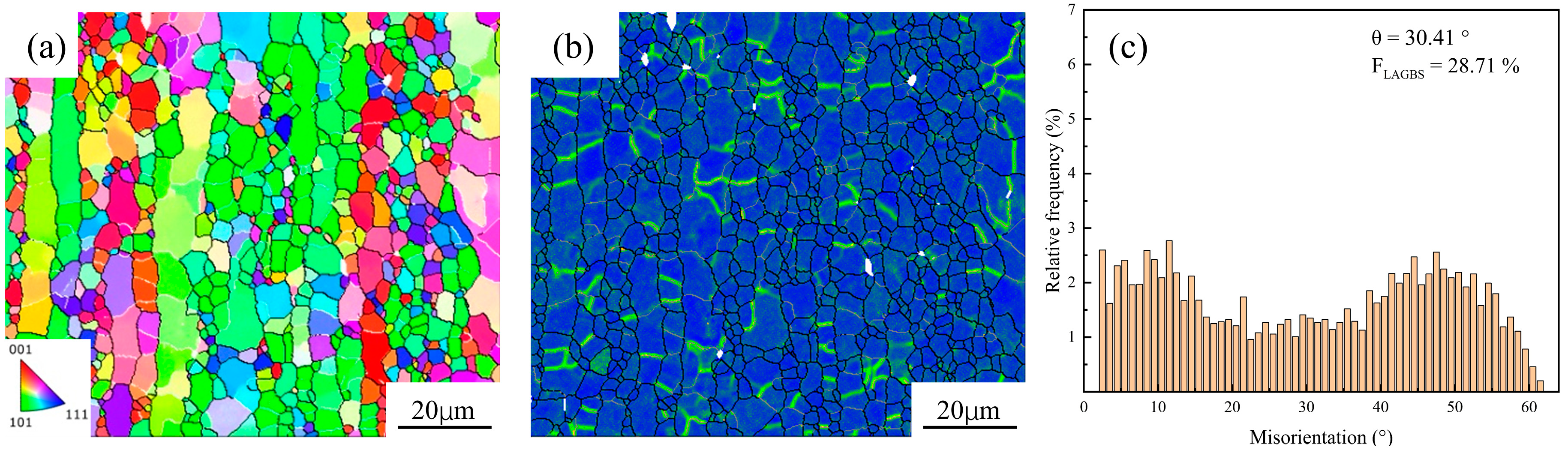

2.2. Microstructure Observation

3. Results and Discussion

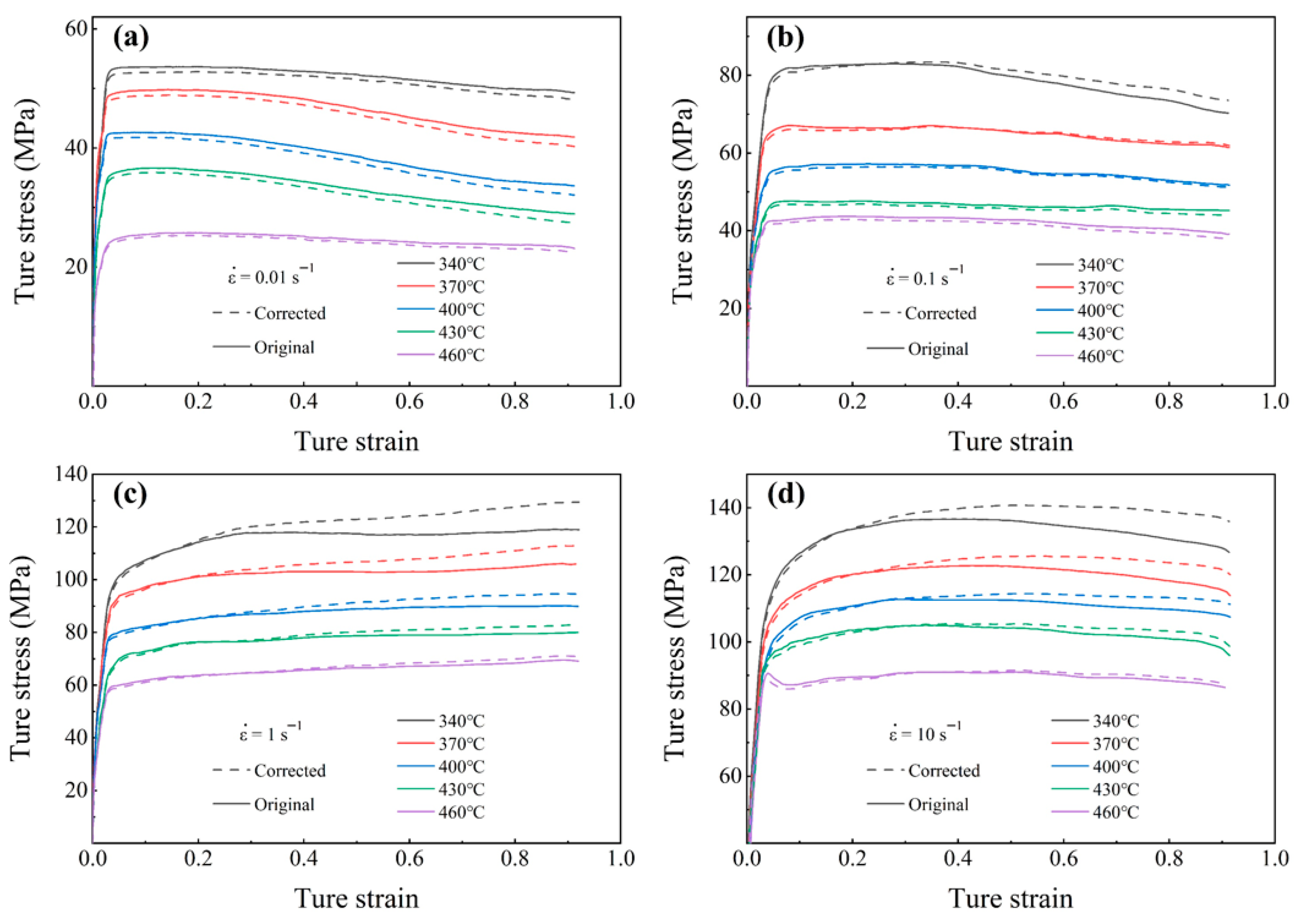

3.1. Analysis of Stress–Strain Curves During Thermal Deformation Processes

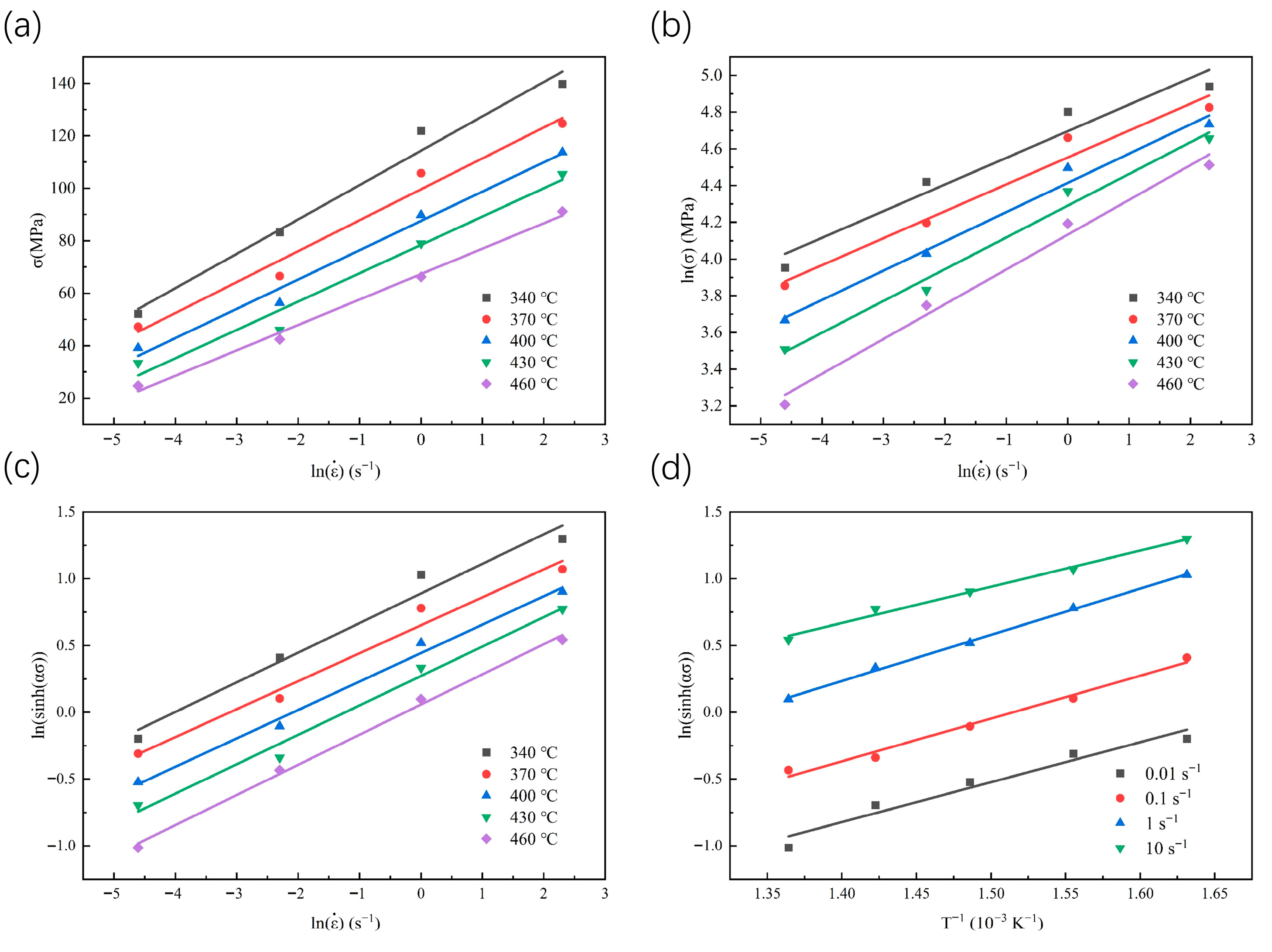

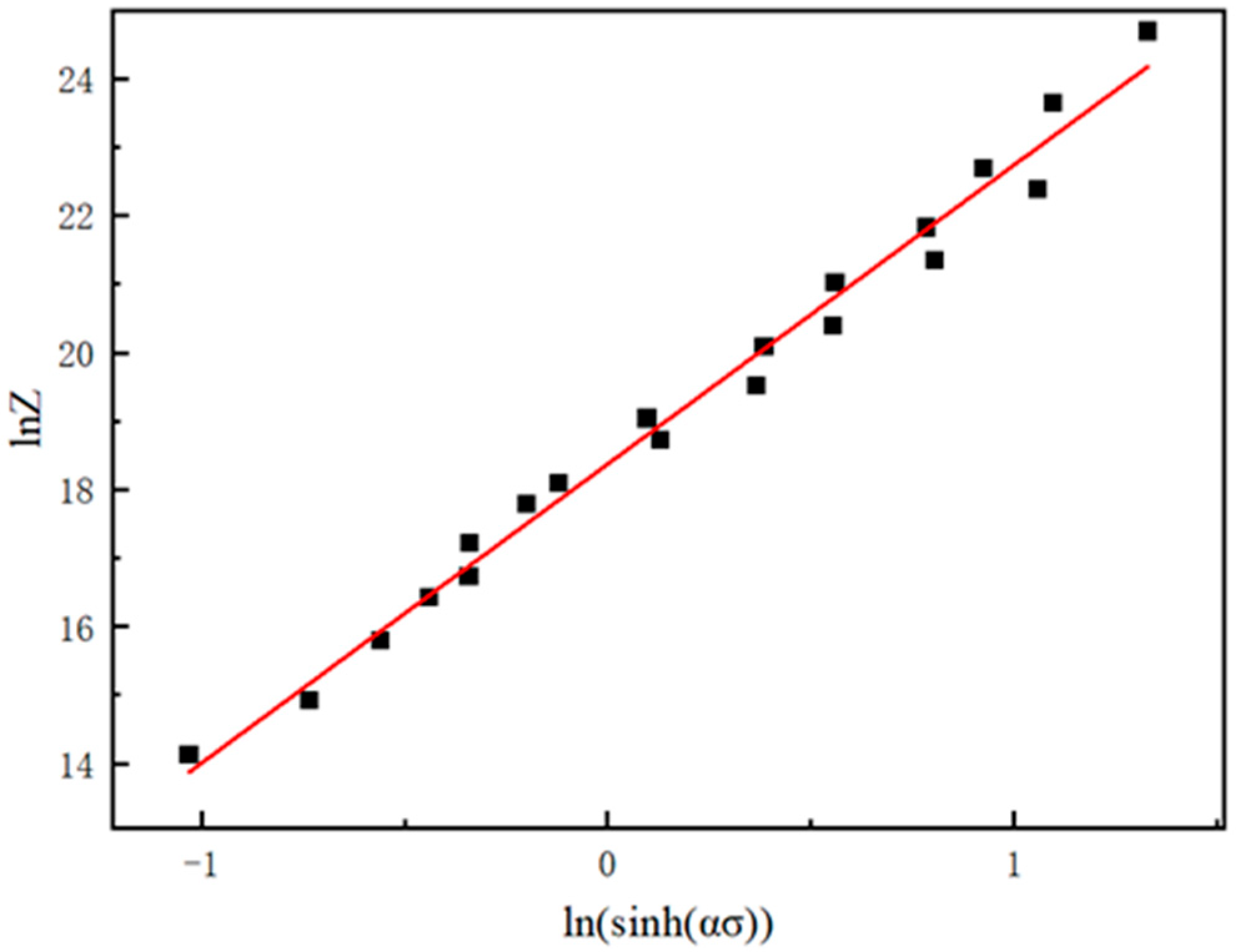

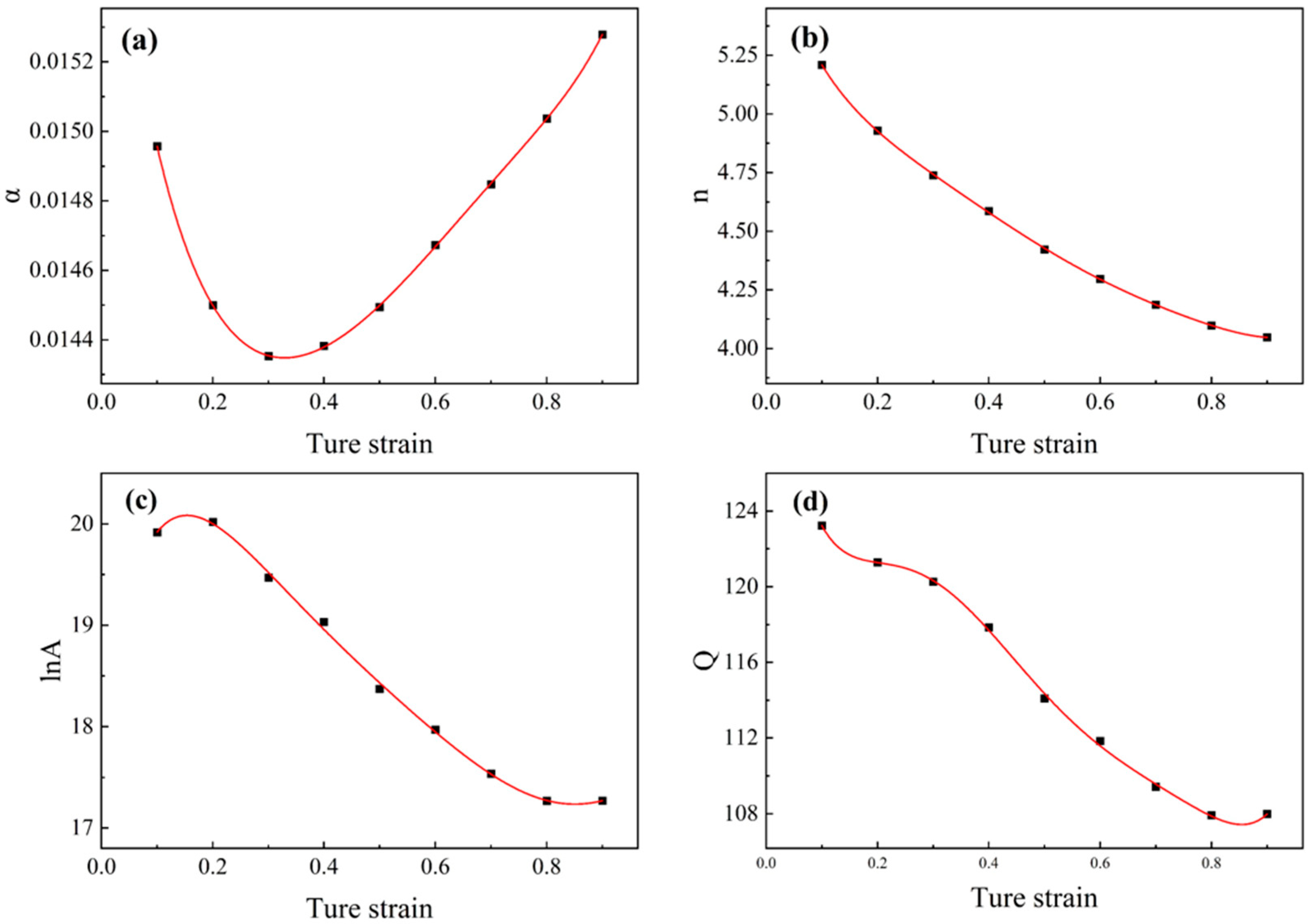

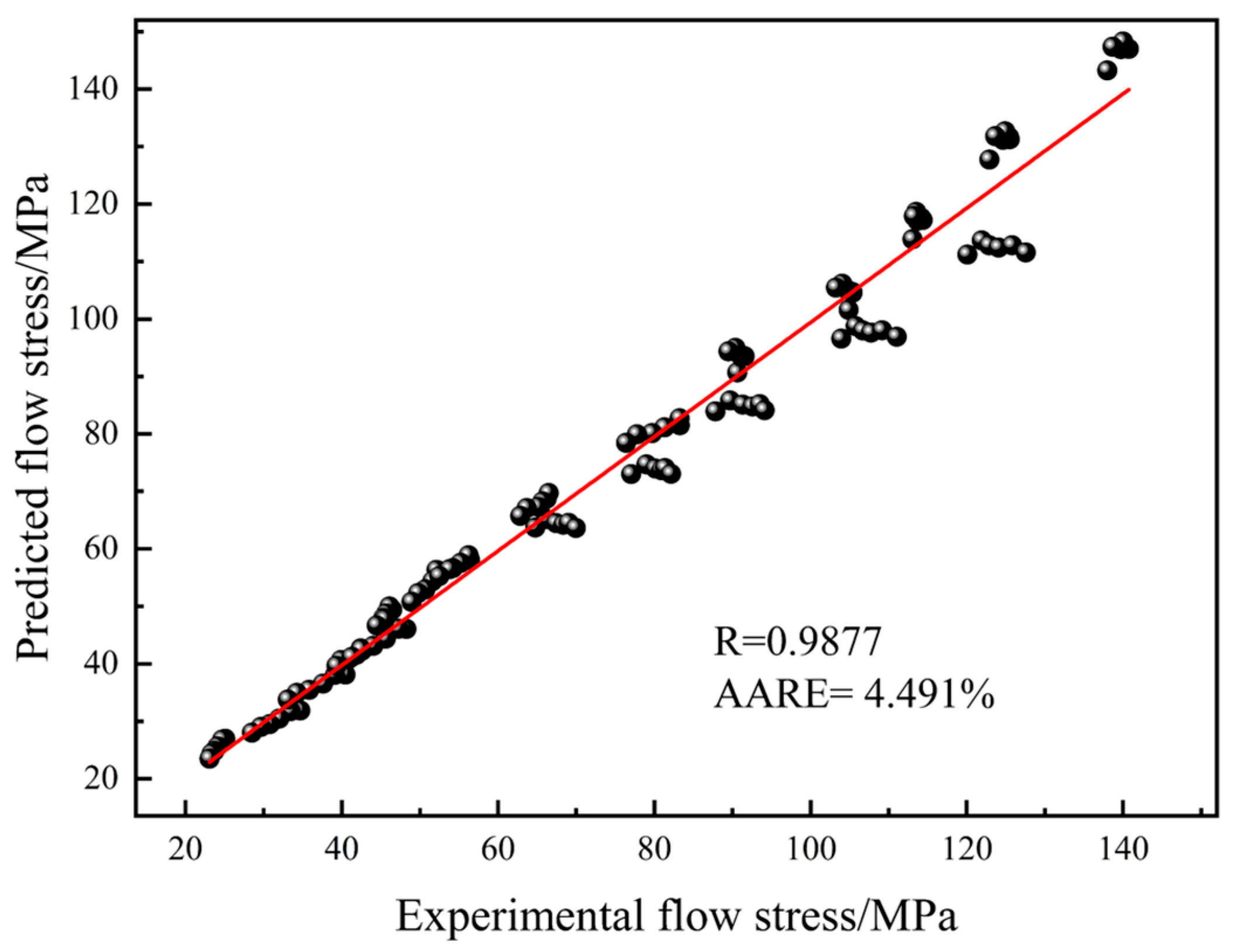

3.2. Constitutive Equation Establishment

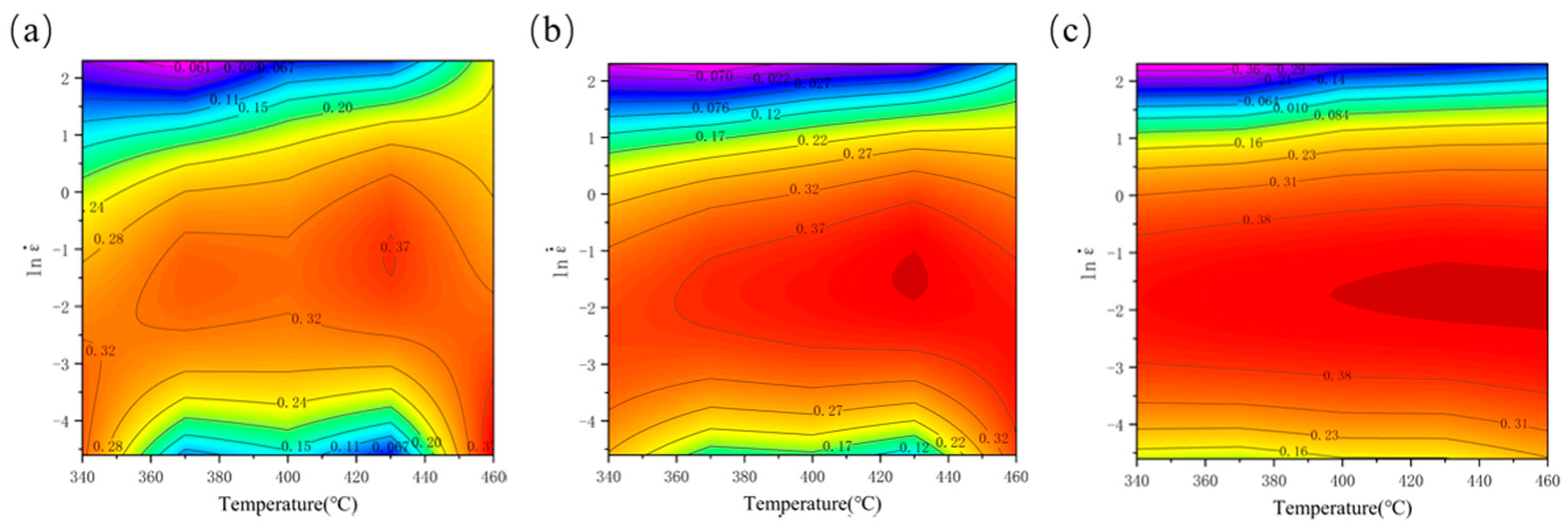

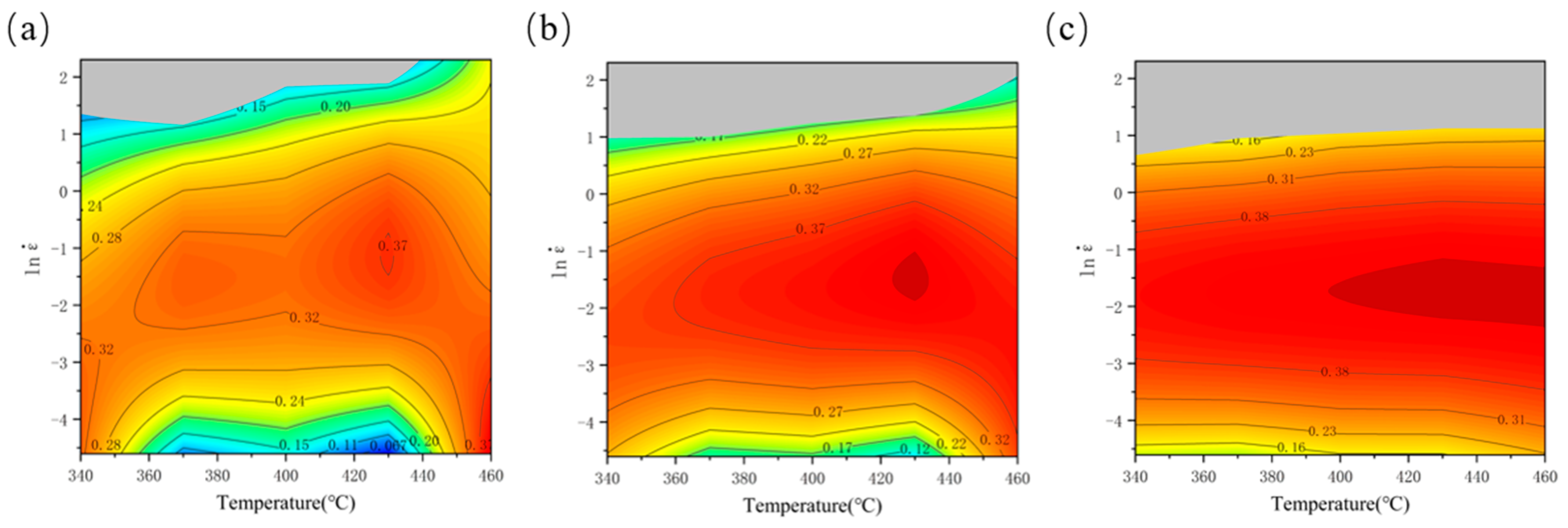

3.3. Hot Processing Map

3.4. Microstructure Evolution

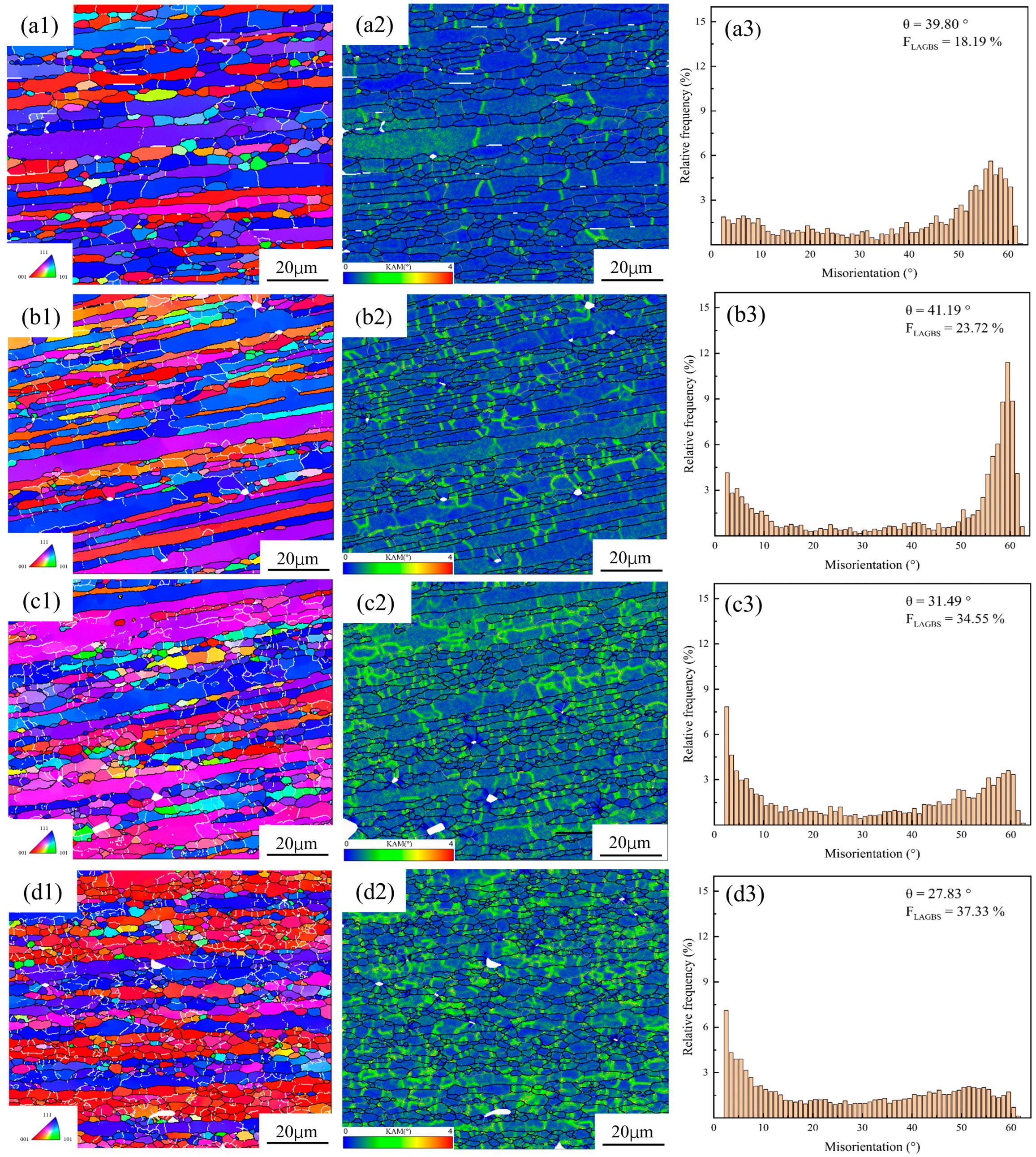

3.4.1. Microstructural Evolution with Strain Rate

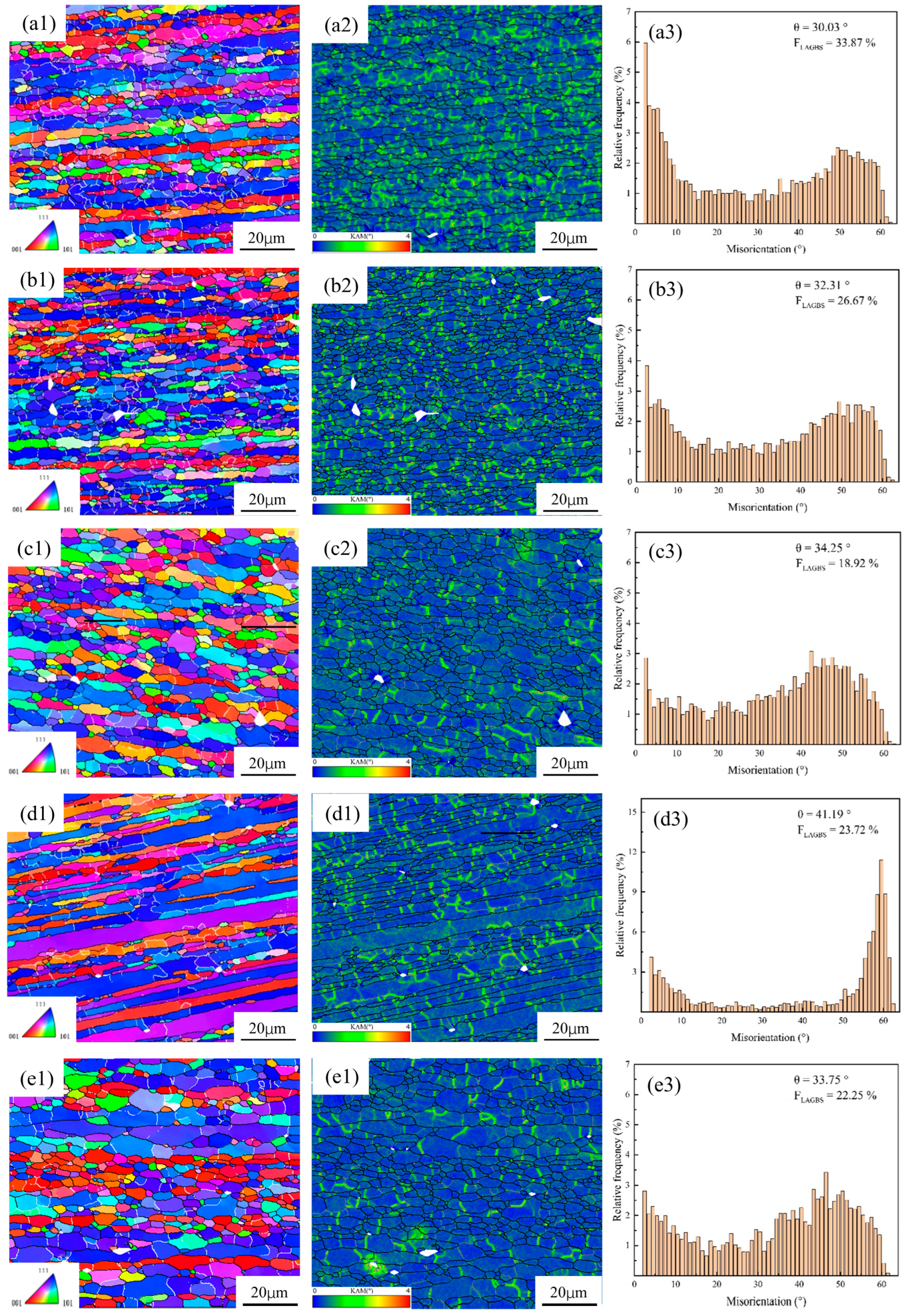

3.4.2. Microstructural Evolution with Deformation Temperature

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bai, P.; Shang, C.; Zhu, D.; Zhao, H.; Liu, Y.; Kuang, J.; Li, F.; Ji, J.; Wang, S.; Wu, G. The interpretable descriptors for fatigue performance of wrought aluminum alloys. J. Mater. Res. Technol. 2024, 32, 3423–3431. [Google Scholar] [CrossRef]

- Zhou, T.; Wang, Y.; Bao, J.; Khan, M.A.; Zhao, P.; An, R.; Zhang, H.; Afifi, M.A. Effects of hot extrusion texture on anisotropy in microstructure and mechanical properties of spray formed Al–Zn–Mg–Cu 7055 aluminum alloy. J. Mater. Res. Technol. 2024, 30, 7295–7307. [Google Scholar] [CrossRef]

- Luo, R.; Cao, Y.; Bian, H.; Chen, L.; Peng, C.-T.; Cao, F.; Ouyang, L.; Qiu, Y.; Xu, Y.; Chiba, A. Hot workability and dynamic recrystallization behavior of a spray formed 7055 aluminum alloy. Mater. Charact. 2021, 178, 111203. [Google Scholar] [CrossRef]

- Lm, Y.; Shen, J.; Zb, L.; Jp, L. Effect of deformation temperature on microstructure and mechanical properties of 7055 aluminum alloy after heat treatment. Trans. Nonferrous Met. Soc. China 2013, 3, 625–630. [Google Scholar] [CrossRef]

- Liu, B.; Lei, Q.; Xie, L.; Wang, M.; Li, Z. Microstructure and mechanical properties of high product of strength and elongation Al-Zn-Mg-Cu-Zr alloys fabricated by spray deposition. Mater. Des. 2016, 96, 217–223. [Google Scholar] [CrossRef]

- Jia, Z.; Xie, Z.; Xiang, K.; Ding, L.; Weng, Y.; Liu, Q. Effect of heat treatment and extrusion processing on the microstructure and mechanical properties of spray formed 7055 alloy. Mater. Charact. 2022, 183, 111619. [Google Scholar] [CrossRef]

- Li, L.; Wei, L.; Xu, Y.; Mao, L.; Wu, S. Study on the optimizing mechanisms of superior comprehensive properties of a hot spray formed Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A 2019, 742, 102–108. [Google Scholar] [CrossRef]

- Ditta, A.; Wei, L.; Xu, Y.; Wu, S. Effect of hot extrusion and optimal solution treatment on microstructure and properties of spray-formed Al-11.3 Zn-2.65 Mg-1Cu alloy. J. Alloys Compd. 2019, 797, 558–565. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, Y.; Afifi, M.A.; Malik, A.; Nazeer, F.; Yasin, G.; Bao, J.; Zhang, H. Microstructure and mechanical properties of an Al-Zn-Cu-Mg alloy processed by hot forming processes followed by heat treatments. Mater. Charact. 2019, 157, 109901. [Google Scholar] [CrossRef]

- Schreiber, J.; Omcikus, Z.; Eden, T.; Sharma, M.M.; Champagne, V.; Patankar, S. Combined effect of hot extrusion and heat treatment on the mechanical behavior of 7055 AA processed via spray metal forming. J. Alloys Compd. 2014, 617, 135–139. [Google Scholar] [CrossRef]

- Xia, Y.; Shu, X.; Zhang, Q.; Pater, Z.; Li, Z.; Xu, H.; Ma, Z.; Xu, C. Modified Arrhenius constitutive model and simulation verification of 2A12-T4 aluminum alloy during hot compression. J. Mater. Res. Technol. 2023, 26, 1325–1340. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, G.; Wang, G.; Ma, X.; Yan, Z.; Cao, S. Hot deformation behavior and microstructure evolution model of 7055 aluminum alloy. J. Mater. Res. Technol. 2023, 27, 3191–3213. [Google Scholar] [CrossRef]

- Shao, Y.; Shi, J.; Pan, J.; Liu, Q.; Yan, L.; Guo, P. Influence of thermo-mechanical conditions on the microstructure and mechanical property of spray-formed 7055 aluminum alloy. Mater. Today Commun. 2022, 31, 103593. [Google Scholar] [CrossRef]

- Lin, X.; Wu, X.; Cao, L.; Bai, M.; Meng, Y. Optimization of flow stress model and 3D-processing map for spray-formed aluminum alloy 7055 based on GA-BP artificial neural network. J. Alloys Compd. 2025, 1021, 179743. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, R.; Li, D.; Peng, Y.; Zhou, G.; Jia, Z.; Ma, W. Investigation on deformation behaviors and dynamic recrystallization mechanism of spray formed Al–Zn–Mg–Cu alloy under hot compression. J. Mater. Res. Technol. 2024, 28, 4401–4416. [Google Scholar] [CrossRef]

- Roebuck, B.; Lord, J.; Brooks, M.; Loveday, M.; Sellars, C.; Evans, R. Measurement of flow stress in hot axisymmetric compression tests. Mater. High Temp. 2006, 23, 59–83. [Google Scholar] [CrossRef]

- Ebrahimi, R.; Najafizadeh, A. A new method for evaluation of friction in bulk metal forming. J. Mater. Process. Technol. 2004, 152, 136–143. [Google Scholar] [CrossRef]

- Xiang, S.; Liu, D.-Y.; Zhu, R.-H.; Li, J.-F.; Chen, Y.-L.; Zhang, X.-H. Hot deformation behavior and microstructure evolution of 1460 Al–Li alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 3855–3864. [Google Scholar] [CrossRef]

- Azarbarmas, M.; Aghaie-Khafri, M.; Cabrera, J.; Calvo, J. Dynamic recrystallization mechanisms and twining evolution during hot deformation of Inconel 718. Mater. Sci. Eng. A 2016, 678, 137–152. [Google Scholar] [CrossRef]

- Fereshteh-Saniee, F.; Fatehi-Sichani, F. An investigation on determination of flow curves at room temperature and under forming conditions. J. Mater. Process. Technol. 2006, 177, 478–482. [Google Scholar] [CrossRef]

- Zhang, J.; Yi, Y.; He, H.; Huang, S.; Mao, X.; Guo, W.; You, W.; Guo, Y.; Dong, F.; Tang, J. Kinetic model for describing continuous and discontinuous dynamic recrystallization behaviors of 2195 aluminum alloy during hot deformation. Mater. Charact. 2021, 181, 111492. [Google Scholar] [CrossRef]

- Cram, D.; Zurob, H.S.; Brechet, Y.; Hutchinson, C. Modelling discontinuous dynamic recrystallization using a physically based model for nucleation. Acta Mater. 2009, 57, 5218–5228. [Google Scholar] [CrossRef]

- Sellars, C.; Tegart, W.M. Hot workability. Int. Metall. Rev. 1972, 17, 1–24. [Google Scholar] [CrossRef]

- Sellars, C. Modelling microstructural development during hot rolling. Mater. Sci. Technol. 1990, 6, 1072–1081. [Google Scholar] [CrossRef]

- Jia, Y.; Cao, F.; Guo, S.; Ma, P.; Liu, J.; Sun, J. Hot deformation behavior of spray-deposited Al–Zn–Mg–Cu alloy. Mater. Des. 2014, 53, 79–85. [Google Scholar] [CrossRef]

- Sherby, O.D.; Klundt, R.H.; Miller, A.K. Flow stress, subgrain size, and subgrain stability at elevated temperature. Metall. Trans. A 1977, 8, 843–850. [Google Scholar] [CrossRef]

- Xu, Y.; Ge, C.-C.; Shu, Q. Microstructure, tensile properties and heat treatment process of spray formed FGH95 superalloy. J. Iron Steel Res. Int. 2013, 20, 59–63. [Google Scholar] [CrossRef]

- Martelli, P.; Sabirov, I.; Monclus, M.; Bassini, E.; Marchese, G.; Ugues, D. The effect of temperature and strain rate on the grain boundary sliding in a CM247 LC Ni-based superalloy processed with laser based powder bed fusion. J. Mater. Res. Technol. 2024, 28, 2466–2477. [Google Scholar] [CrossRef]

- Sharma, P.; Das, C.; Sreeramagiri, P.; Balasubramanian, G. Additively manufactured lightweight and hard high-entropy alloys by thermally activated solvent extraction. High Entropy Alloys Mater. 2024, 2, 41–47. [Google Scholar] [CrossRef]

- McDowell, D.L.; Liu, Z.-K. Hierarchical Nonequilibrium Thermodynamics of Thermally Activated Dislocation Plasticity of Metals and Alloys. Int. J. Plast. 2025, 188, 104303. [Google Scholar] [CrossRef]

- Long, S.; Xia, Y.-F.; Wang, P.; Zhou, Y.-T.; Gong-Ye, F.-J.; Zhou, J.; Zhang, J.-S.; Cui, M.-L. Constitutive modelling, dynamic globularization behavior and processing map for Ti-6Cr-5Mo-5V-4Al alloy during hot deformation. J. Alloys Compd. 2019, 796, 65–76. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Z.; Zhang, H.; Ruan, J.; Huang, H.; Zhou, X.; Meng, F.; Zhang, S.; Jiang, L. Hot deformation behavior and new grain size model of hot extruded FGH4096 superalloy during hot compression. J. Alloys Compd. 2023, 938, 168574. [Google Scholar] [CrossRef]

- Guo, S.; Shen, Y.; Guo, J.; Wu, S.; Du, Z.; Li, D. An investigation on the hot workability and microstructural evolution of a novel dual-phase Mg–Li alloy by using 3D processing maps. J. Mater. Res. Technol. 2023, 23, 5486–5501. [Google Scholar] [CrossRef]

- Huang, Y.L.; Wang, J.B.; Ling, X.S.; Zhang, X.Y.; Luan, B.F.; Liu, Q.; Huang, G.J. Research Development of Hot Processing Map Theory. Mater. Rep. 2008, 22, 173–176. [Google Scholar]

- Raj, R. Development of a processing map for use in warm-forming and hot-forming processes. Metall. Trans. A 1981, 12, 1089–1097. [Google Scholar] [CrossRef]

- Prasad, Y.; Sasidhara, S. Hot Working Guide: A Compendium of Processing Maps; Materials Park: Novelty, OH, USA, 1997. [Google Scholar]

- Srinivasan, N.; Prasad, Y. Hot-working characteristics of nichrome and the development of a processing map. J. Mater. Process. Technol. 1994, 41, 409–424. [Google Scholar] [CrossRef]

- Prasad, Y.; Rao, K.; Hort, N.; Kainer, K. Optimum parameters and rate-controlling mechanisms for hot working of extruded Mg–3Sn–1Ca alloy. Mater. Sci. Eng. A 2009, 502, 25–31. [Google Scholar] [CrossRef]

- Huang, L.; LIANG, X.-P. Characterization of hot deformation behavior of AA2014 forging aluminum alloy using processing map. Trans. Nonferrous Met. Soc. China 2017, 27, 1677–1688. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Zhao, X.S.; Xiao, F.Y.; Chun, H.D.; Ming, H.Z. Effect of strain rate on hot deformation characteristics of GH690 superalloy. Trans. Nonferrous Met. Soc. China 2017, 27, 538–550. [Google Scholar] [CrossRef]

- Tan, J.; Tan, M. Dynamic continuous recrystallization characteristics in two stage deformation of Mg–3Al–1Zn alloy sheet. Mater. Sci. Eng. A 2003, 339, 124–132. [Google Scholar] [CrossRef]

- Meng, G.; Li, B.; Li, H.; Huang, H.; Nie, Z. Hot deformation and processing maps of an Al–5.7 wt.% Mg alloy with erbium. Mater. Sci. Eng. A 2009, 517, 132–137. [Google Scholar] [CrossRef]

- Lu, L.; Liu, X.; Shi, D.; Ma, M.; Wang, Z. Effect of Twinning Behavior on Dynamic Recrystallization During Extrusion of AZ31 Mg Alloy. JOM J. Miner. Met. Mater. Soc. 2019, 71, 1566–1573. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

| Zn | Mg | Cu | Zr | Si | Fe | Al |

|---|---|---|---|---|---|---|

| 8.25 | 2.03 | 2.25 | 0.12 | 0.05 | 0.04 | other |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Y.; Zhao, H.; Wang, X.; Cui, M.; Zhao, X.; Zhang, J.; Zhou, J. Microstructure Evolution and Constitutive Model of Spray-Formed 7055 Forging Aluminum Alloy. Materials 2025, 18, 4108. https://doi.org/10.3390/ma18174108

Deng Y, Zhao H, Wang X, Cui M, Zhao X, Zhang J, Zhou J. Microstructure Evolution and Constitutive Model of Spray-Formed 7055 Forging Aluminum Alloy. Materials. 2025; 18(17):4108. https://doi.org/10.3390/ma18174108

Chicago/Turabian StyleDeng, Yu, Huyou Zhao, Xiaolong Wang, Mingliang Cui, Xuanjie Zhao, Jiansheng Zhang, and Jie Zhou. 2025. "Microstructure Evolution and Constitutive Model of Spray-Formed 7055 Forging Aluminum Alloy" Materials 18, no. 17: 4108. https://doi.org/10.3390/ma18174108

APA StyleDeng, Y., Zhao, H., Wang, X., Cui, M., Zhao, X., Zhang, J., & Zhou, J. (2025). Microstructure Evolution and Constitutive Model of Spray-Formed 7055 Forging Aluminum Alloy. Materials, 18(17), 4108. https://doi.org/10.3390/ma18174108