Wood–Plastic Composites: Manufacturing, Rheology and Processing and Process Modeling

Abstract

1. Introduction

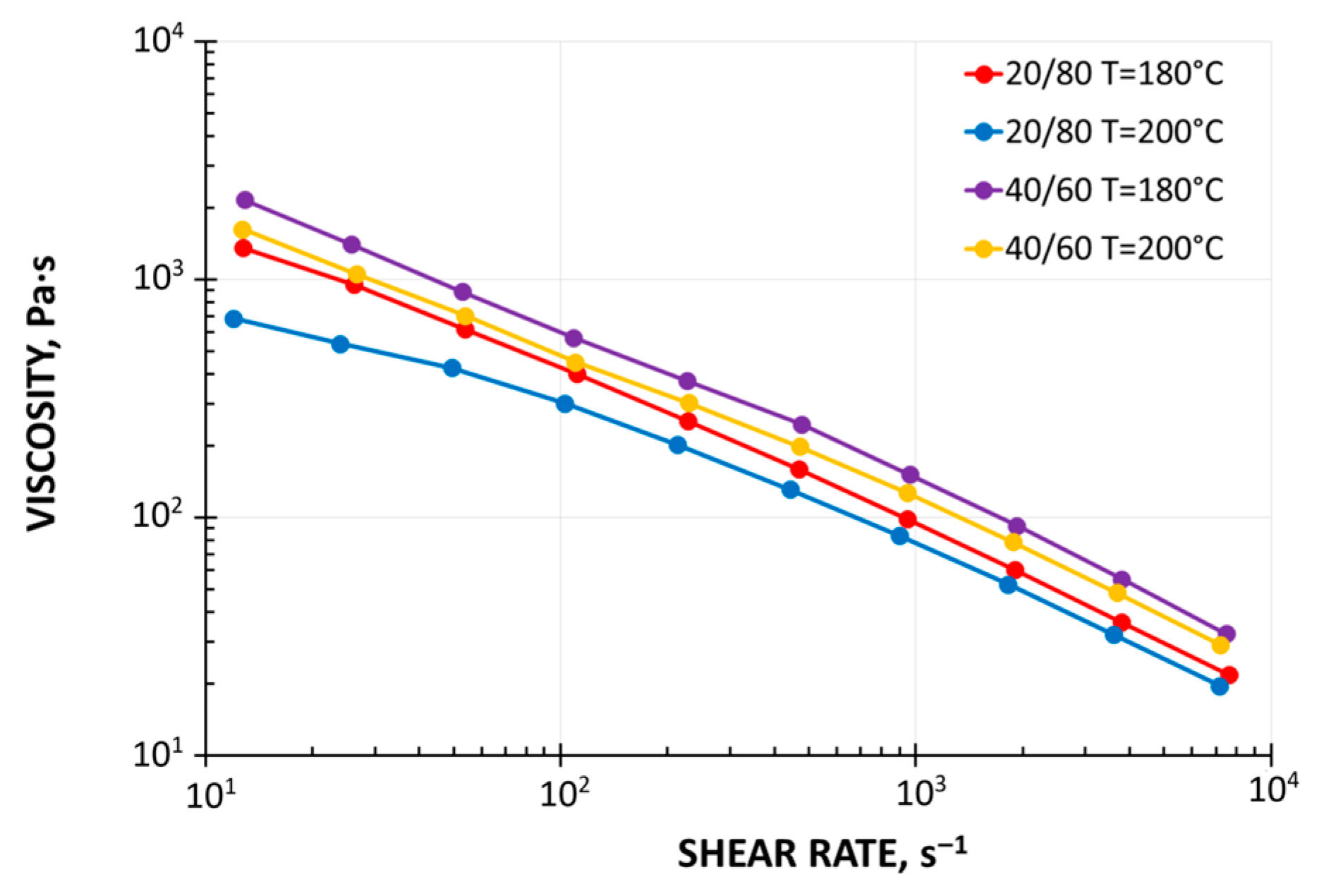

2. Materials, Manufacturing, Processing

3. Rheology

4. Process Modeling

4.1. Polymer Extrusion

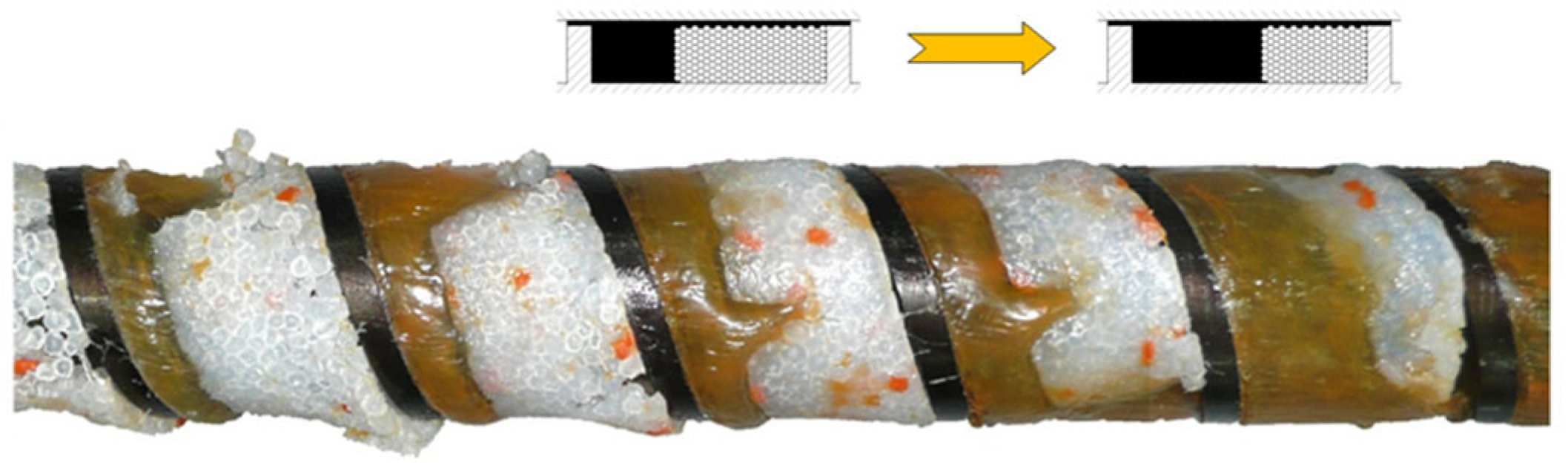

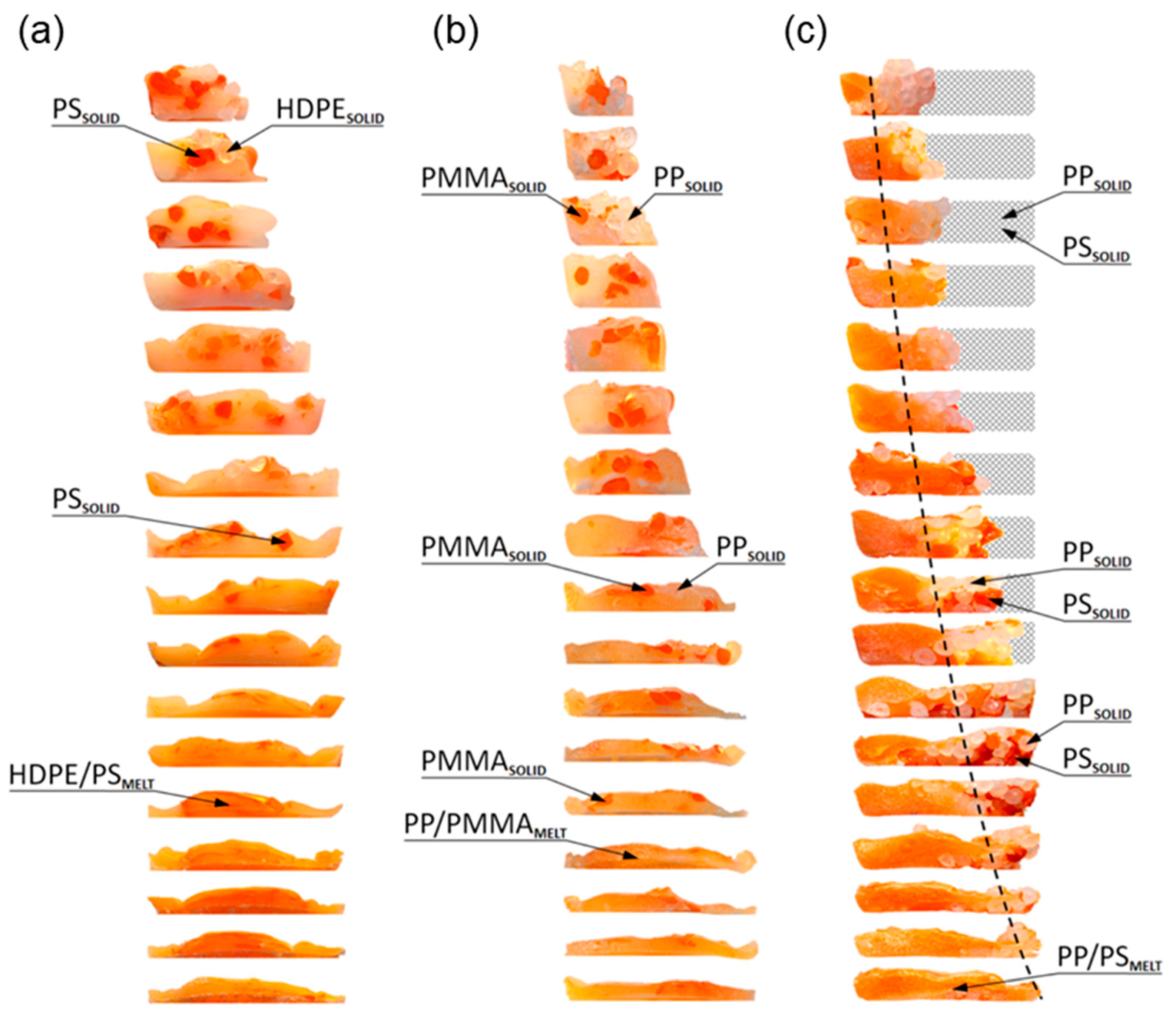

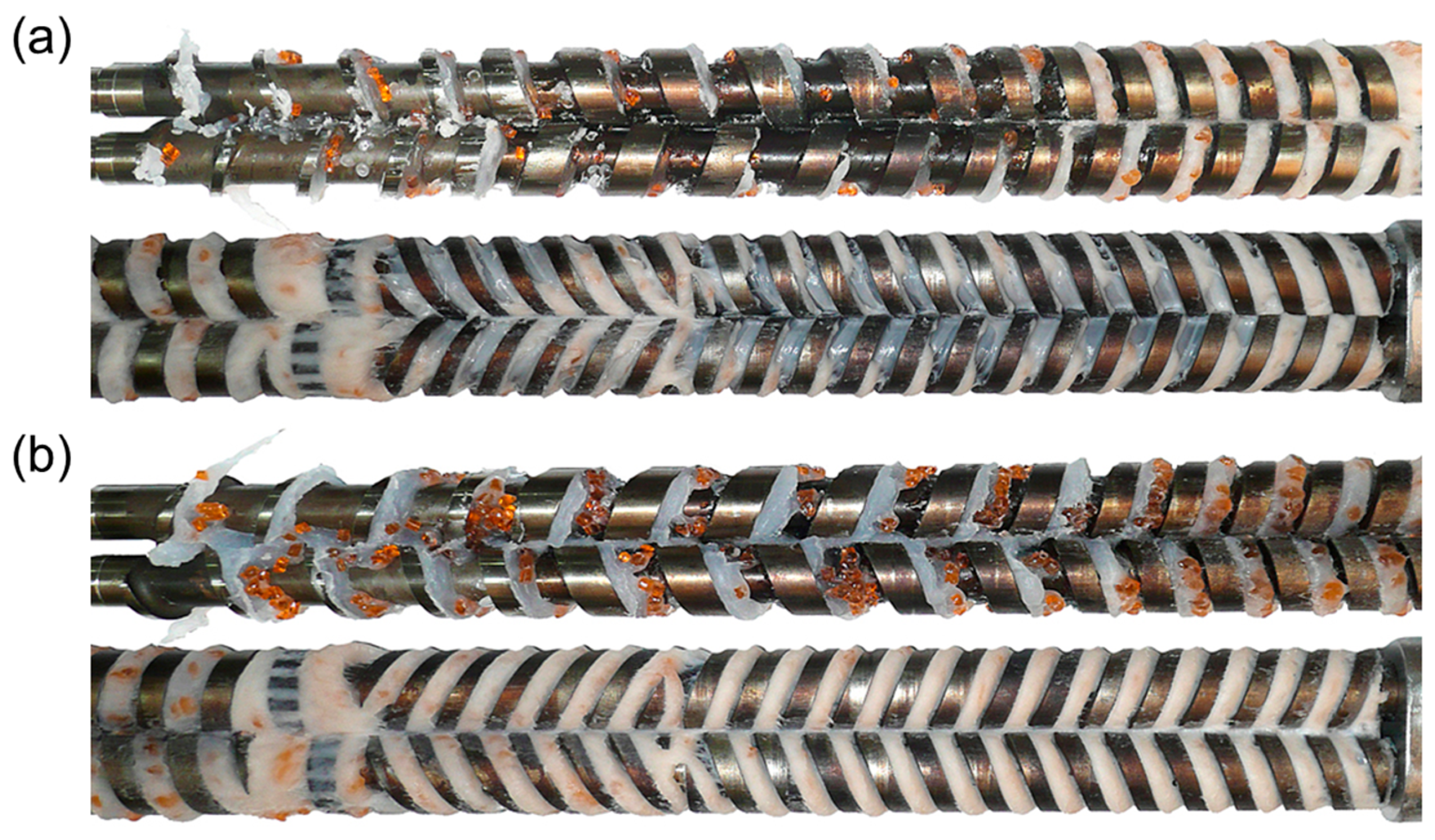

4.2. WPCs Extrusion

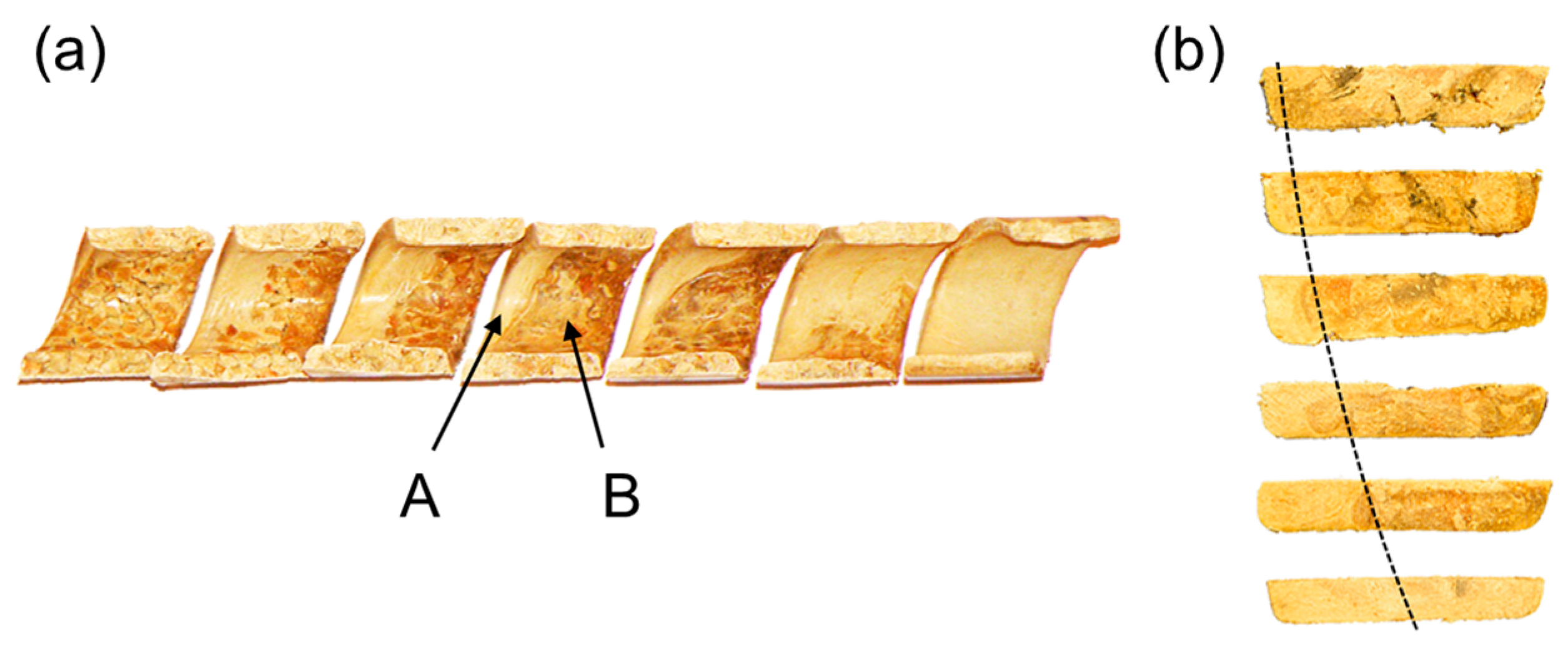

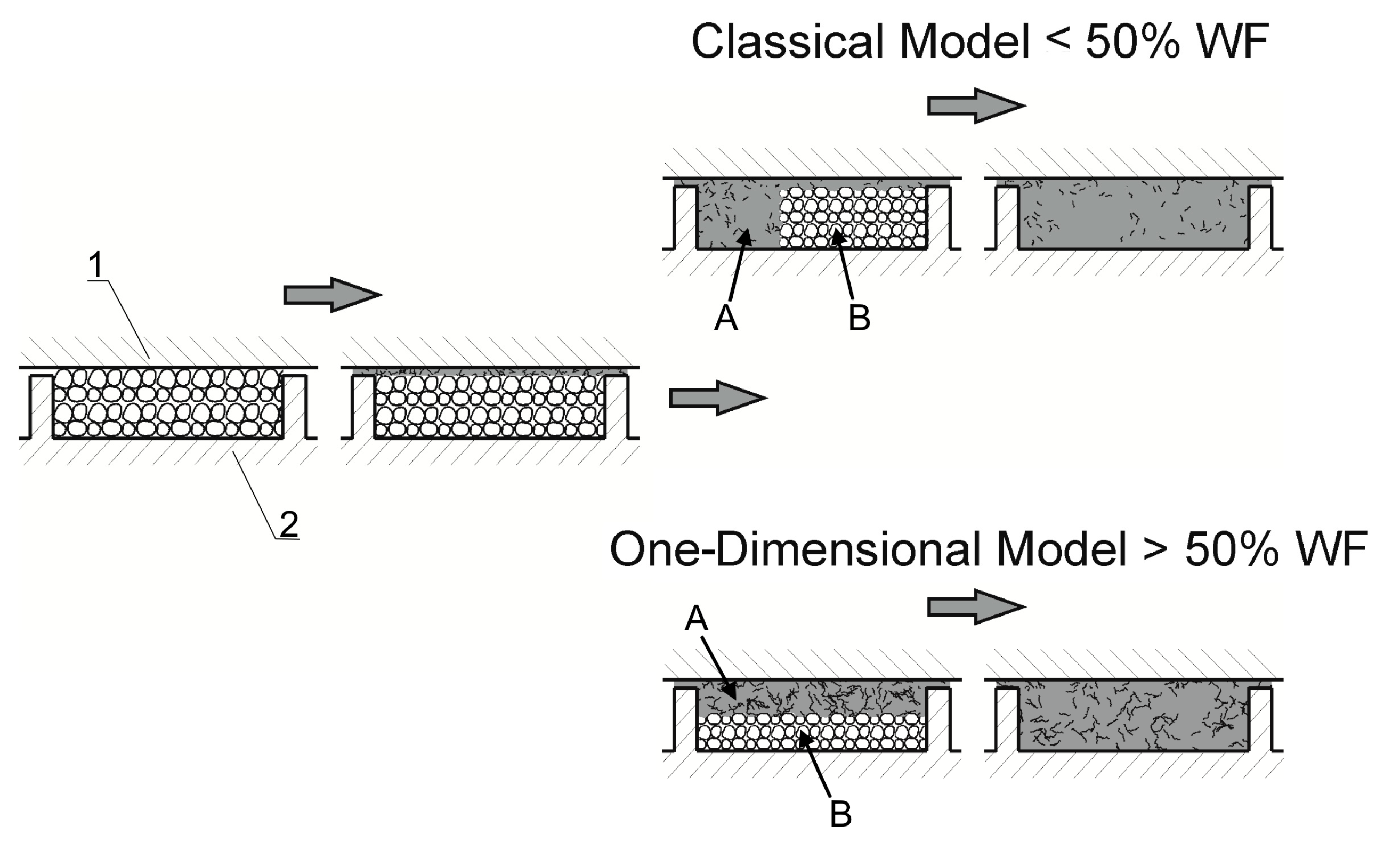

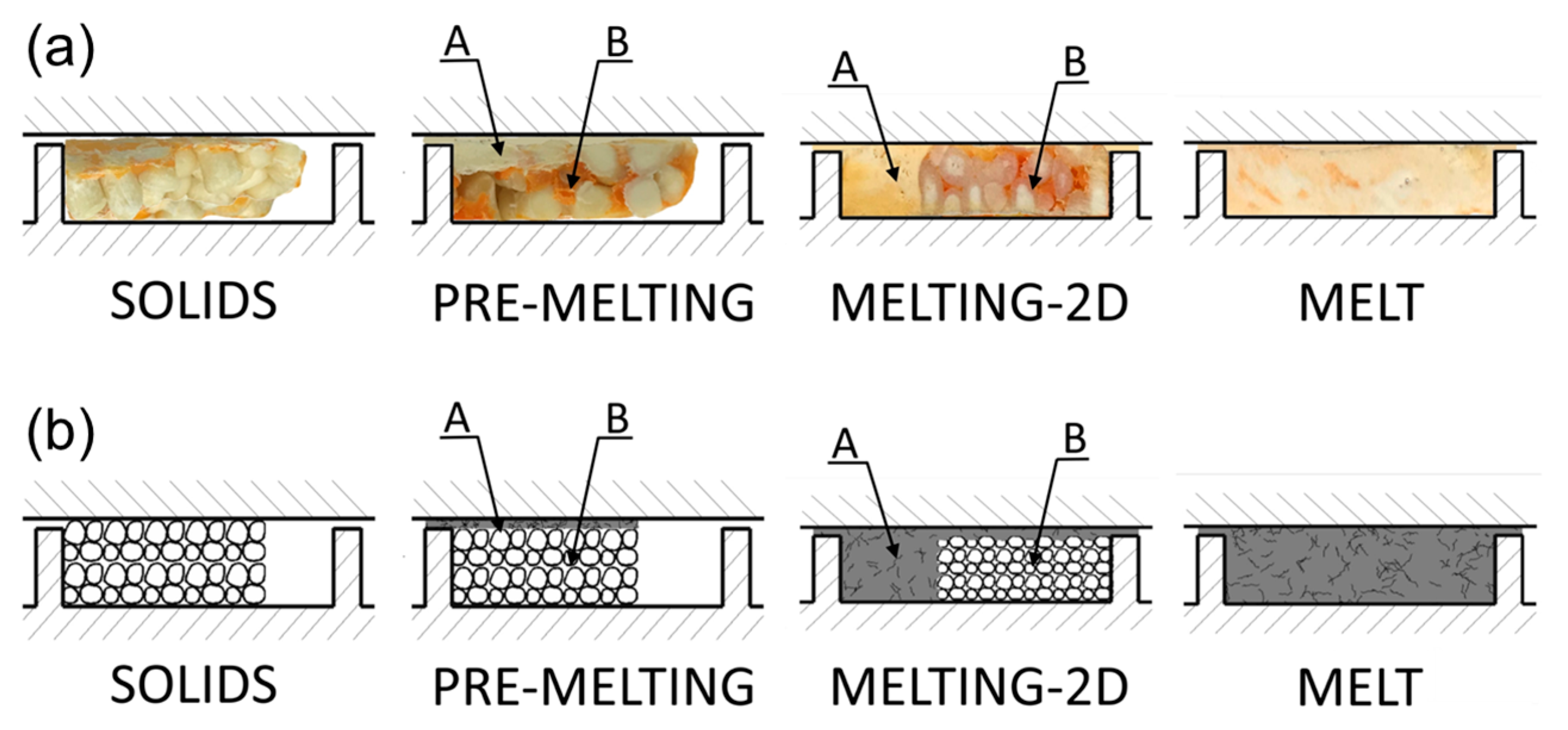

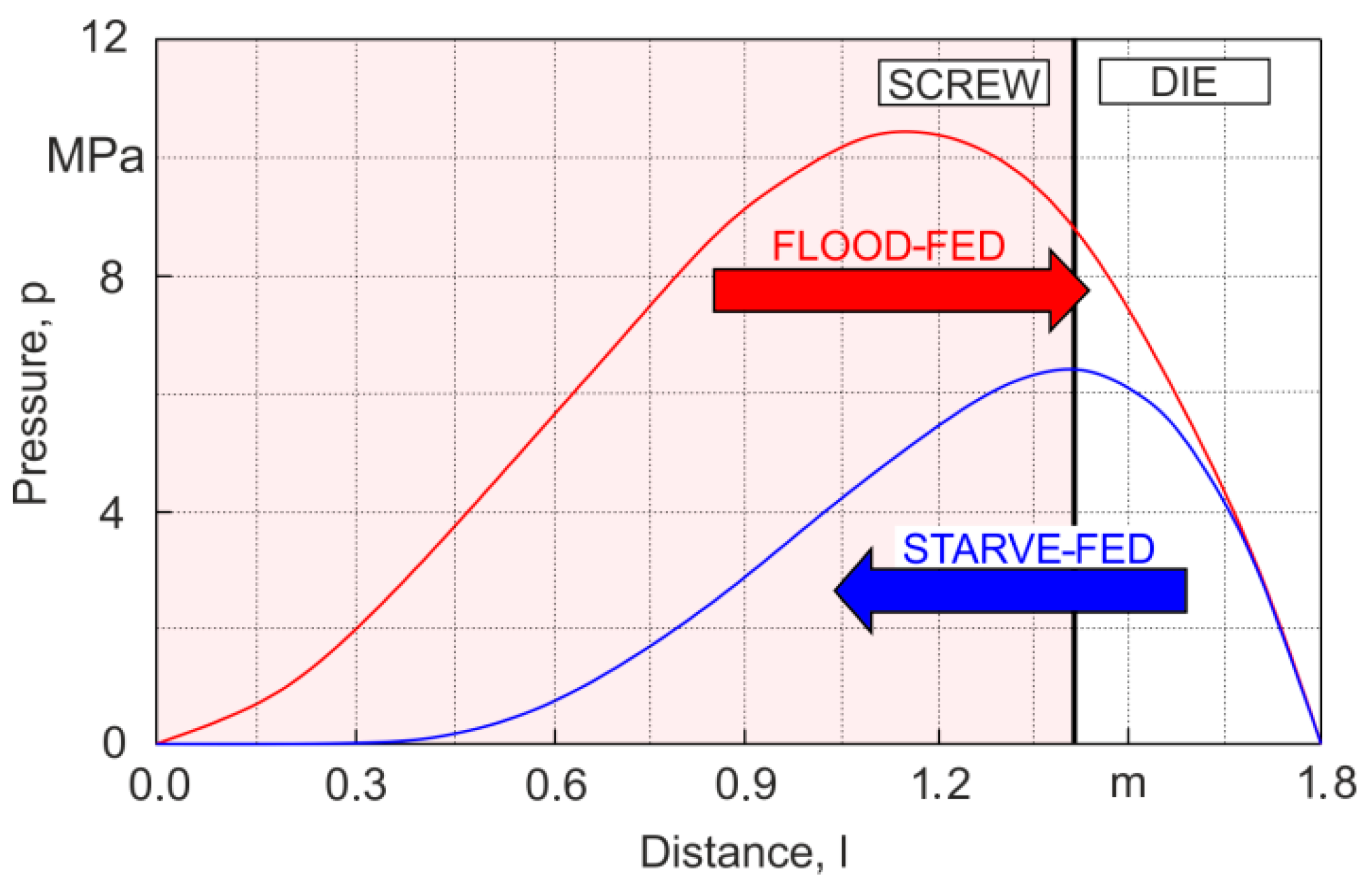

4.2.1. Gravity-Fed Extrusion

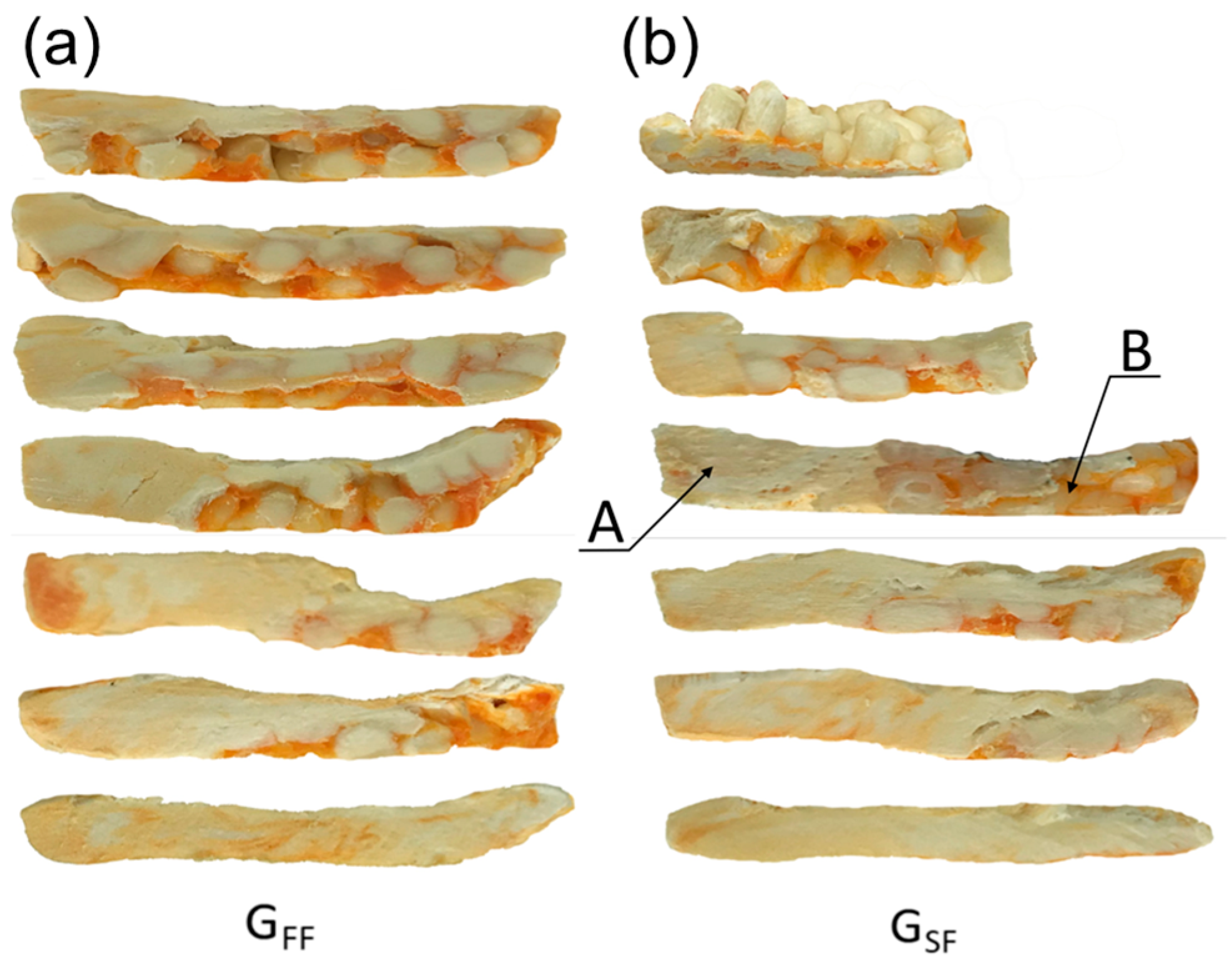

4.2.2. Starve-Fed Extrusion

4.2.3. Extrusion Process Modeling

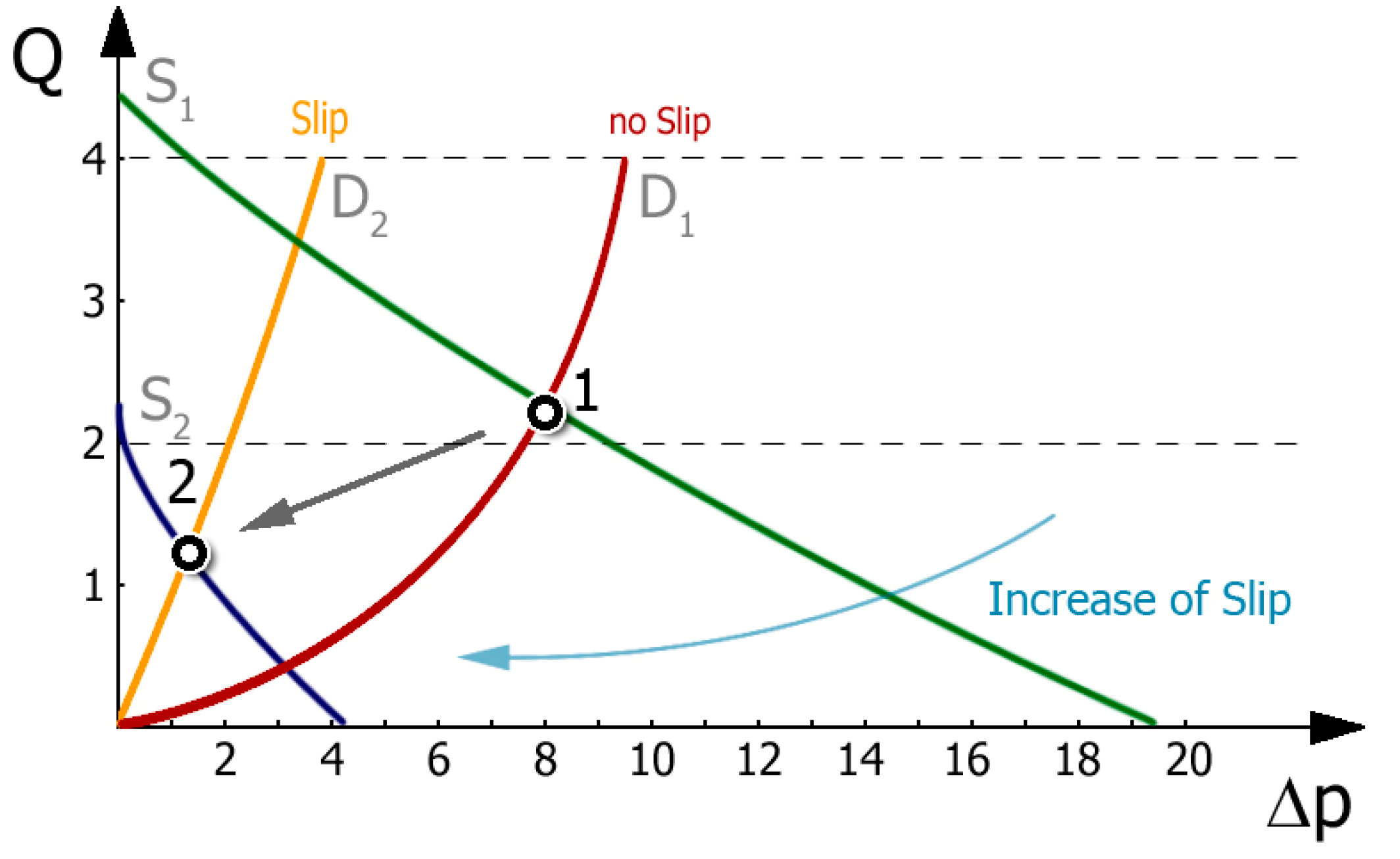

4.2.4. Slip Effects

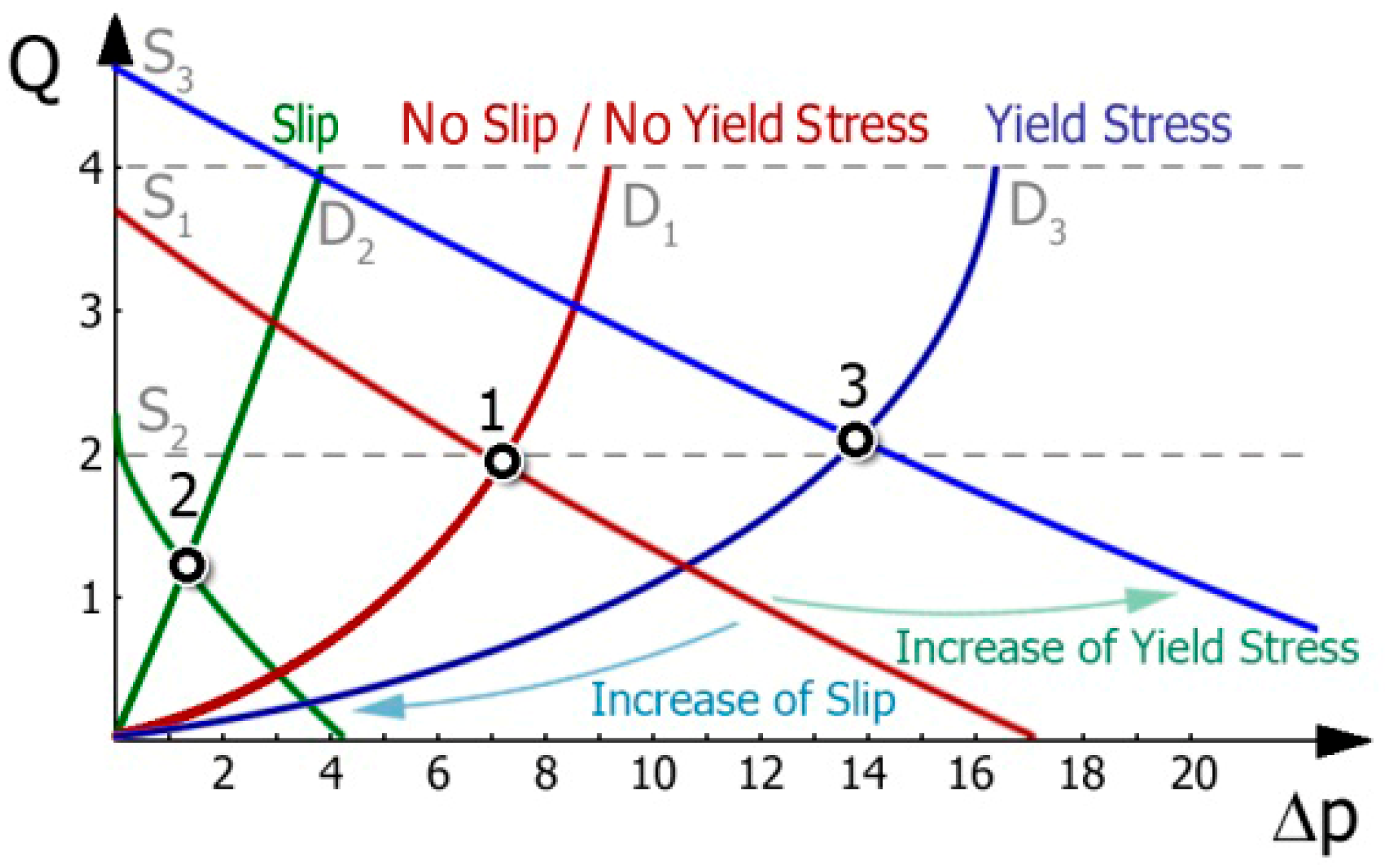

4.2.5. Yield Stress Effects

4.3. Polymer Injection Molding

4.4. WPC Injection Molding

5. Summary and Conclusions

- -

- There is generally a lack of basic rheological data for wood–plastic composites in the available material databases;

- -

- There is no data at all that takes into account slip and yield stress, and these data should be obtained in-house, preferably in on-line production conditions;

- -

- There is generally no valid thermal data, e.g., melting or softening point or no-flow temperature, heat of fusion etc.

- -

- Global modeling of extrusion (for gravity-fed and starve-fed, separately) including solid conveying, polymer fusion as well as melt flow in a plasticating unit and a die;

- -

- Simultaneous modeling of fusion and melt flow using the CFD concept in extrusion;

- -

- Simultaneous modeling of solid conveying, fusion and melt flow using the DEM/CFD concept in extrusion;

- -

- Global modeling of injection molding which would include modeling of solid transport, polymer fusion and melt flow in the plasticating unit and the mold;

- -

- Holistic modeling of gravity-fed and starve-fed extrusion with a smooth transition between these two feed modes;

- -

- Holistic modeling of extrusion and injection molding with a smooth transition between these two techniques.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rowell, R.M.; Konkol, P. Treatments That Enhance Physical Properties of Wood; General Technical Report FPL-GTR-55; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1987; pp. 1–12. [Google Scholar]

- Nova-Institut GmbH. New Market and Trend Report Published. Available online: http://news.bio-based.eu/new-market-and-trend-report-published (accessed on 11 June 2015).

- Partanen, A.; Carus, M. Wood and natural fiber composites current trend in consumer goods and automotive parts. Reinf. Plast. 2016, 60, 170–173. [Google Scholar] [CrossRef]

- Grand View Research 2019, Wood Plastic Composite Market Size, Share & Trends Analysis Report by Type (PE, PP, PVC), Application, Region, Segment Forecasts, 2020–2027. Available online: https://www.grandviewresearch.com/industry-analysis/wood-plastic-composites-market (accessed on 1 February 2020).

- Partanen, A.; Carus, M. Biocomposites, find the real alternative to plastic—An examination of biocomposites in the market. Reinf. Plast. 2019, 63, 317–321. [Google Scholar] [CrossRef]

- Friedrich, D. Success factors of Wood-Plastic Composites (WPC) as sustainable packaging material: A cross-sector expert study. Sustain. Prod. Consum. 2022, 30, 506–517. [Google Scholar] [CrossRef]

- Khoaele, K.K.; Gbadeyan, O.J.; Chunilall, V.; Sithole, B. A review on waste wood reinforced polymer composites and their processing for construction materials. Int. J. Sustain. Eng. 2023, 16, 104–116. [Google Scholar] [CrossRef]

- Khoaele, K.K.; Gbadeyan, O.J.; Chunilall, V.; Sithole, B. The Devastation of Waste Plastic on the Environment and Remediation Processes: A Critical Review. Sustainability 2023, 15, 5233. [Google Scholar] [CrossRef]

- Teuber, L.; Osburg, V.S.; Toporowski, W.; Militz, H.; Krause, A. Wood polymer composites and their contribution to cascading utilisation. J. Clean. Prod. 2016, 110, 9–15. [Google Scholar] [CrossRef]

- Ribeiro, L.S.; Stolz, C.M.; Amario, M.; da Silva, A.L.N.; Haddad, A.N. Use of Post-Consumer Plastics in the Production of Wood-Plastic Composites for Building Components: A Systematic Review. Energies 2023, 16, 6549. [Google Scholar] [CrossRef]

- Anonymous. Wood Plastic Composites Market Size, Share & Trends Analysis Report by Product (Polyethylene, Polypropylene), by Application (Automotive Components), by Region, and Segment Forecasts, 2022–2030; Grand View Research, Report ID: 978-1-68038-849-7. 2023. Available online: https://www.grandviewresearch.com/industry-analysis/wood-plastic-composites-market (accessed on 4 April 2025).

- Anonymous. Wood-Plastic Composites Market Report by Type (Polyethylene, Polyvinylchloride, Polypropylene, and Others), Application (Building and Construction, Automotive, Industrial and Consumer Goods, and Others), and Region 2025–2033. IMARC Group. 2025. Available online: https://www.imarcgroup.com/wood-plastic-composites-market (accessed on 4 April 2025).

- Anonymous. Wood Plastic Composites Market Size, by Product Type (Polyethylene, Polypropylene, Polyvinylchloride), Application (Building & Construction, Automotive Components, Industrial & Consumer Goods)—Growth Trends, Regional Share, Competitive Intelligence, Forecast Report 2025–2037. Research Nester. 2025. Available online: https://www.researchnester.com/reports/wood-plastic-composites-market/5159 (accessed on 4 April 2025).

- Bogoeva-Gaceva, G.; Avella, M.; Malinconico, M.; Buzarovska, A.; Grozdanov, A.; Gentile, G.; Errico, M.E. Natural fiber eco-composites. Polym. Compos. 2007, 28, 98–107. [Google Scholar] [CrossRef]

- Nassar, M.M.A.; Alzebdeh, K.I.; Pervez, T.; Al-Hinai, N.; Munam, A. Progress and challenges in sustainability, compatibility, and production of eco-composites: A state-of-art review. J. Appl. Polym. Sci. 2021, 138, e51284. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; Taylor & Francis: Boca Raton, FL, USA, 2005; ISBN 978-084-931-741-5. [Google Scholar]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007; ISBN 978-047-014-891-4. [Google Scholar]

- Oksman Niska, K.; Sain, M. Wood-Polymer Composites; Woodhead Publishing Ltd.: Cambridge, UK, 2008; ISBN 978-184-569-272-8. [Google Scholar]

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Thermoplastics Reinforced with Wood Fillers: A Literature Review. Polym. Plast. Technol. Eng. 1998, 37, 451–468. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–273. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Zajchowski, S.; Ryszkowska, J. Kompozyty polimerowo-drzewne—Charakterystyka ogólna oraz ich otrzymywanie z materiałów odpadowych. Polimery 2009, 10, 674–682. [Google Scholar] [CrossRef][Green Version]

- Stewart, R. Wood Fiber Composites. Plast. Eng. 2007, 63, 20–26. [Google Scholar] [CrossRef]

- Chan, C.M.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Composites of wood and biodegradable thermoplastics: A review. Polym. Rev. 2018, 58, 444–494. [Google Scholar] [CrossRef]

- Khan, M.Z.; Srivastava, S.K.; Gupta, M.K. A state-of-the-art review on particulate wood polymer composites: Processing, properties and applications. Polym. Test. 2020, 89, 106721. [Google Scholar] [CrossRef]

- Yadav, S.M.; Lubis, M.A.R.; Sihag, K. A Comprehensive Review on Process and Technological Aspects of Wood-Plastic Composites. J. Sylva Lestari 2021, 9, 329–356. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Sasikala, G.; Balaji, D.; Saravanakumar, A.; Bhuvaneswari, V.; Bhoopathi, R. A Critical Review on Wood-Based Polymer Composites: Processing, Properties, and Prospects. Polymers 2022, 14, 589. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Sun, Z.; Duan, Y.; An, H.; Wang, X.; Liang, S.; Li, N. Research Progress and Application of Natural Fiber Composites. J. Nat. Fibers 2023, 20, 2206591. [Google Scholar] [CrossRef]

- Mital’ová, Z.; Mital’, D.; Berladir, K. A Concise Review of the Components and Properties of Wood–Plastic Composites. Polymers 2024, 16, 1556. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Strydom, M.J. Critical Materials and Processing Challenges Affecting the Interface and Functional Performance of Wood Polymer Composites (WPCs). Mater. Chem. Phys. 2016, 171, 290–302. [Google Scholar] [CrossRef]

- Yam, K.L.; Gogoi, B.K.; Lai, C.C.; Selke, S.E. Composites from Compounding Wood Fibers with Recycled High Density Polyethylene. Polym. Eng. Sci. 1990, 30, 693–699. [Google Scholar] [CrossRef]

- Clemons, C. Raw Materials for Wood–Polymer Composites. In Wood–Polymer Composites; Woodhead Publishing Ltd.: Cambridge, UK, 2008; pp. 1–22. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T.K. Study on the Properties of Nanocomposite Based on High Density Polyethylene, Polypropylene, Polyvinyl Chloride and Wood. Compos. Part A Appl. Sci. Manuf. 2011, 42, 686–693. [Google Scholar] [CrossRef]

- Martins, G.; Antunes, F.; Mateus, A.; Malça, C. Optimization of a Wood Plastic Composite for Architectural Applications. Procedia Manuf. 2017, 12, 203–220. [Google Scholar] [CrossRef]

- Krause, K.C.; Sauerbier, P.; Koddenberg, T.; Krause, A. Utilization of Recycled Material Sources for Wood-Polypropylene Composites: Effect on Internal Composite Structure, Particle Characteristics and Physico-Mechanical Properties. Fibers 2018, 6, 86. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal Stability of Natural Fibers and Their Polymer Composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Bollakayala, V.L.; Vuba, K.K.; Uttaravalli, A.N.; Boppena, K.; Bethi, B.; Ganta, H. Compatibility studies of in-house prepared sustainable wood-plastic composites with commercial composites. Mater. Today Process. 2023. [Google Scholar] [CrossRef]

- Leao, A.L.; Cesarino, I.; de Souza, M.C.; Moroz, I.; Dias, O.T.; Jawaid, M. Present Scenario and Future Scope of the Use of Wood Waste in Wood Plastic Composites. In Wood Waste Management and Products; Springer: Singapore, 2023. [Google Scholar] [CrossRef]

- Han, X.; Wan, Z.; Ding, L.; Chen, L.; Wang, F.; Pu, J.; Jiang, S. Water molecule-induced hydrogen bonding between cellulose nanofibers toward highly strong and tough materials from wood aerogel. Chin. Chem. Lett. 2021, 32, 3105–3108. [Google Scholar] [CrossRef]

- Han, X.; Wu, W.; Wang, J.; Tian, Z.; Jiang, S. Hydrogen-Bonding Aided Fabrication of Wood Derived Cellulose Scaffold/Aramid Nanofiber into High-Performance Bulk Material. Materials 2021, 14, 5444. [Google Scholar] [CrossRef]

- Gonzalez, C.; Myers, G.E. Thermal Degradation of Wood Fillers at the Melt-Processing Temperatures of Wood-Plastic Composites: Effects on Wood Mechanical Properties and Production of Volatiles. Int. J. Polym. Mater. 1993, 23, 67–85. [Google Scholar] [CrossRef]

- Clemons, C.; Ibach, R.E. Effects of Processing Method and Moisture History on Laboratory Fungal Resistance of Wood-HDPE Composites. For. Prod. J. 2004, 54, 50–57. [Google Scholar]

- Błędzki, A.K.; Faruk, O. Extrusion and Injection Moulded Microcellular Wood Fibre Reinforced Polypropylene Composites. Cell. Polym. 2004, 23, 211–227. [Google Scholar] [CrossRef]

- Błędzki, A.K.; Faruk, O. Influence of Processing Temperature on Microcellular Injection-Moulded Wood–Polypropylene Composites. Macromol. Mater. Eng. 2006, 291, 1226–1232. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M.; Clemons, C.M. Effect of processing method on surface and weathering characteristics of wood–flour/HDPE composites. J. Appl. Polym. Sci. 2004, 93, 1021–1030. [Google Scholar] [CrossRef]

- Burgstaller, C. Processing of Thermal Sensitive Materials—A Case Study for Wood Plastic Composites. Monatshefte Chem. 2007, 138, 343–346. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A. Fundamental Studies on Wood–Plastic Composites: Effects of Fiber Concentration and Mixing Temperature on the Mechanical Properties of Poplar/PP Composite. Polym. Compos. 2008, 29, 569–573. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Effects of processing method and fiber size on the structure and properties of wood–plastic composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 80–85. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Perré, P. Effect of fiber origin, proportion, and chemical composition on the mechanical and physical properties of wood-plastic composites. J. Wood Chem. Technol. 2014, 34, 241–261. [Google Scholar] [CrossRef]

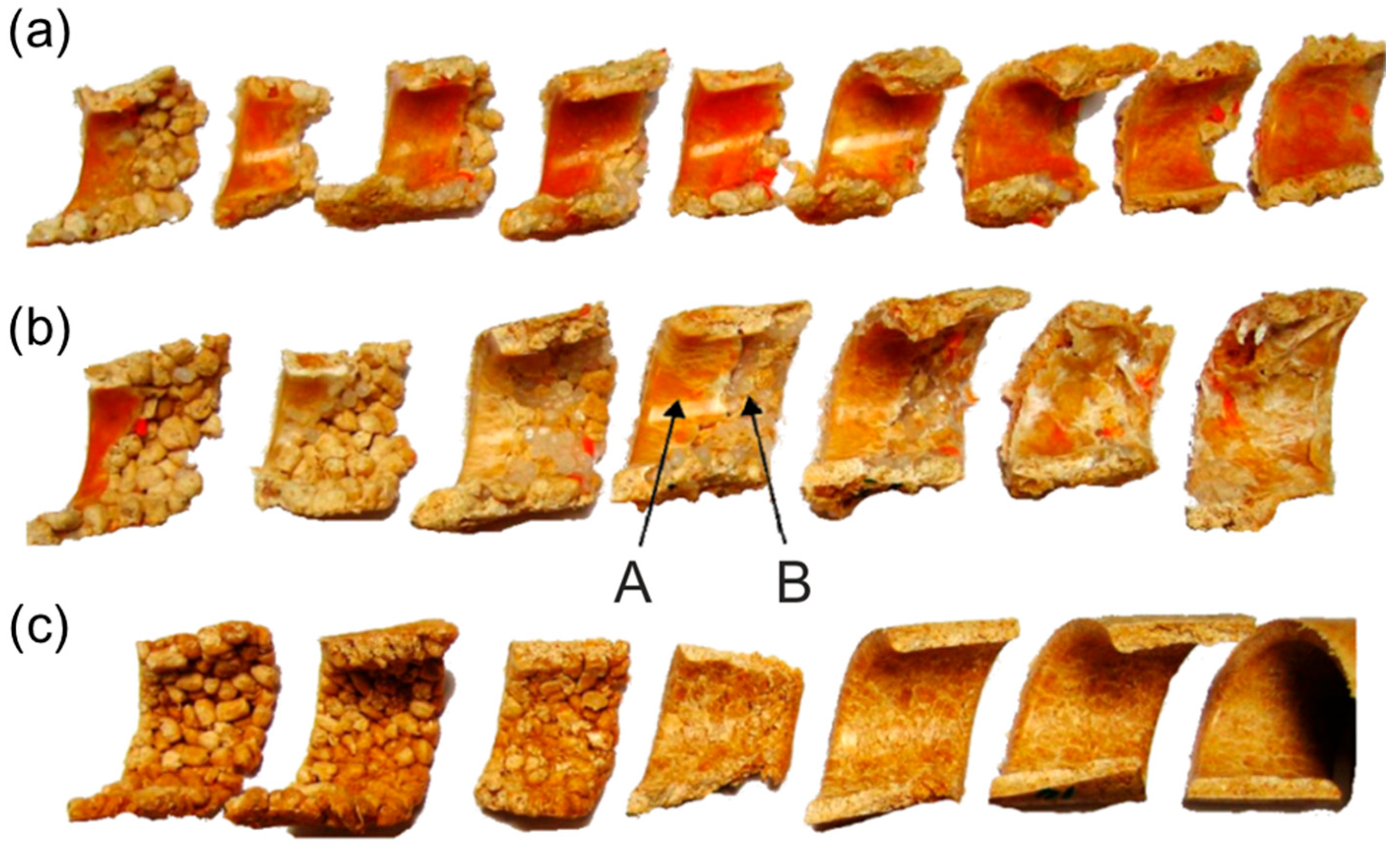

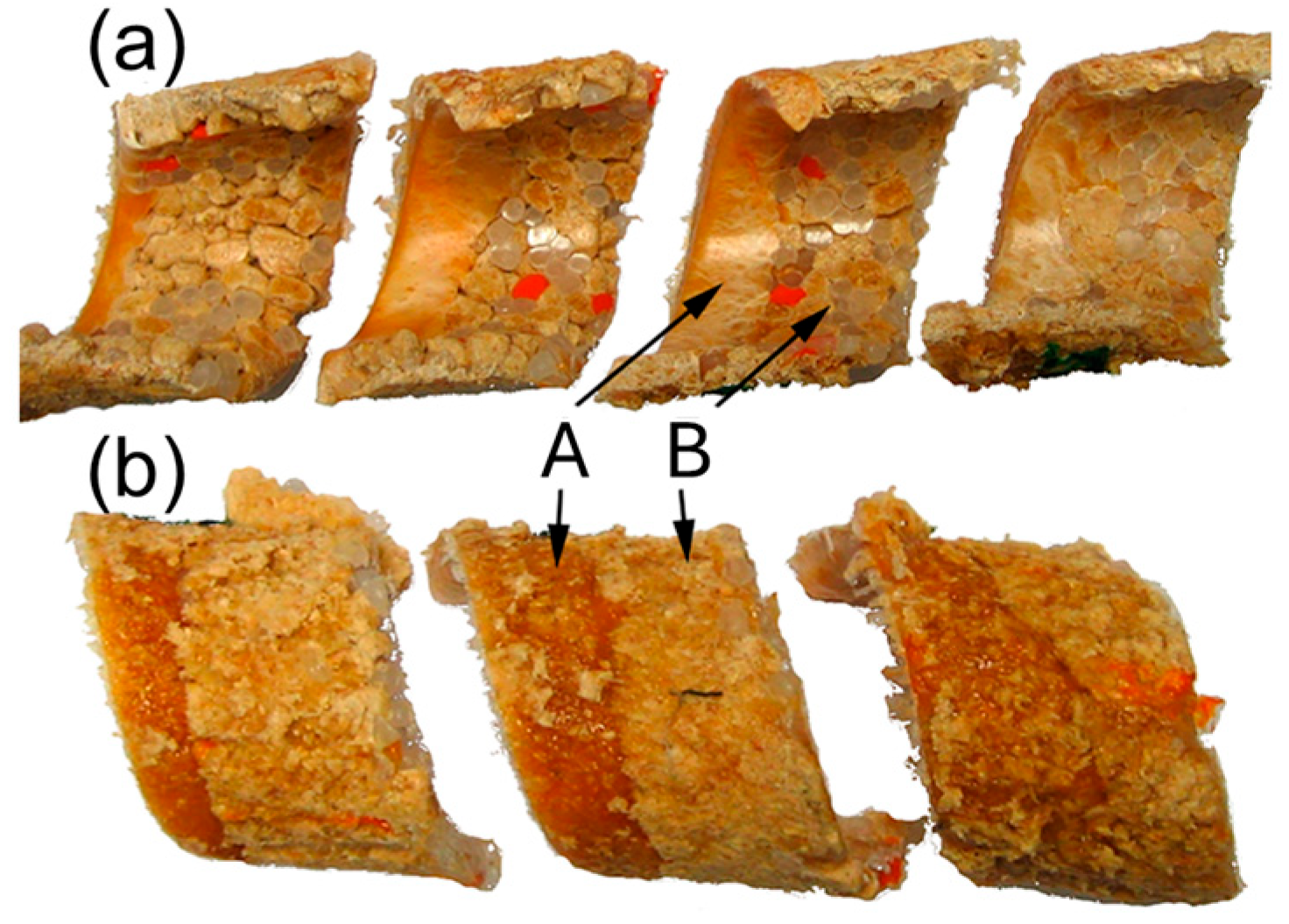

- Gacitua, W.; Bahr, D.; Wolcott, M. Damage of the cell wall during extrusion and injection molding of wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1454–1460. [Google Scholar] [CrossRef]

- Peltola, H.; Laatikainen, E.; Jetsu, P. Effects of Physical Treatment of Wood Fibres on Fibre Morphology and Biocomposite Properties. Plast. Rubber Compos. 2011, 40, 86–92. [Google Scholar] [CrossRef]

- Shahi, P.; Behravesh, A.H.; Daryabari, S.Y.; Lotfi, M. Experimental Investigation on Reprocessing of Extruded Wood Flour/HDPE Composites. Polym. Compos. 2012, 33, 753–763. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood–Plastic Composite Technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef]

- Teuber, L.; Militz, H.; Krause, A. Processing of wood plastic composites: The influence of feeding method and polymer melt flow rate on particle degradation. J. Appl. Polym. Sci. 2015, 133, 43231. [Google Scholar] [CrossRef]

- Wiedl, S.; Karlinger, P.; Schemme, M.; List, M.; Ruckdäschel, H. Comparison of Melting Processes for WPC and the Resulting Differences in Thermal Damage, Emissions and Mechanics. Materials 2022, 15, 3393. [Google Scholar] [CrossRef] [PubMed]

- Raj, S.S. Wood-Plastic Composite Processing and Mechanical Characteristics—A Brief Literature Review. In Recent Advances in Manufacturing, Automation, Design and Energy Technologies; Natarajan, S.K., Prakash, R., Sankaranarayanasamy, K., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2022; pp. 269–276. [Google Scholar] [CrossRef]

- Nygård, P.; Tanem, B.S.; Karlsen, T.; Brachet, P.; Leinsvang, B. Extrusion-Based Wood Fibre–PP Composites: Wood Powder and Pelletized Wood Fibres–A Comparative Study. Compos. Sci. Technol. 2008, 68, 3418–3424. [Google Scholar] [CrossRef]

- Guo, G.; Lee, Y.H.; Rizvi, G.M.; Park, C.B. Influence of wood fiber size on extrusion foaming of wood fiber/HDPE composites. J. Appl. Polym. Sci. 2008, 107, 3505–3511. [Google Scholar] [CrossRef]

- Crookston, K.A.; Young, T.M.; Harper, D.; Guess, F.M. Statistical reliability analyses of two wood plastic composite extrusion processes. Reliab. Eng. Syst. Saf. 2011, 96, 172–177. [Google Scholar] [CrossRef]

- Vandi, L.J.; Chan, C.M.; Werker, A.; Richardson, D.; Laycock, B.; Pratt, S. Extrusion of wood fibre reinforced poly(hydroxybutyrate-co-hydroxyvalerate) (PHBV) biocomposites: Statistical analysis of the effect of processing conditions on mechanical performance. Polym. Degrad. Stab. 2019, 159, 1–14. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Guo, S.; Liu, T. A review of coextruded wood–plastic composites. Polym. Compos. 2021, 42, 4174. [Google Scholar] [CrossRef]

- Moriwaki, T. Mechanical property enhancement of glass fibre-reinforced polyamide composite made by direct injection moulding process. Compos. Part A Appl. Sci. Manuf. 1996, 27, 379–384. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O. Wood fiber reinforced polypropylene composites: Compression and injection molding process. Polym. Plast. Technol. Eng. 2004, 43, 871–888. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O. Effects of the chemical foaming agents, injection parameters, and melt-flow index on the microstructure and mechanical properties of microcellular injection-molded wood-fiber/polypropylene composites. J. App. Polym. Sci. 2005, 97, 1090–1096. [Google Scholar] [CrossRef]

- Yoon, J.D.; Kuboki, T.; Jung, P.U.; Wang, J.; Park, C.B. Injection molding of wood–fiber/plastic composite foams. Compos. Interfaces 2009, 16, 797–811. [Google Scholar] [CrossRef]

- Behravesh, A.H.; Zohdi Aghdam, A.; Soury, E. Experimental Investigation of Injection Molding of Wood/Plastics Composites. J. Reinf. Plast. Compos. 2010, 29, 456–465. [Google Scholar] [CrossRef]

- Azaman, M.D.; Sapuan, S.M.; Sulaiman, S.; Zainudin, E.S.; Abdan, K. An investigation of the processability of natural fibre reinforced polymer composites on shallow and flat thin-walled parts by injection moulding process. Mater. Des. 2013, 50, 451–456. [Google Scholar] [CrossRef]

- Gong, G.; Chen, J.C.; Guo, G. Enhancing tensile strength of injection molded fiber reinforced composites using the Taguchi-based six sigma approach. Int. J. Adv. Manuf. Technol. 2017, 91, 3385–3393. [Google Scholar] [CrossRef]

- Ansari, F.; Granda, L.A.; Joffe, R.; Berglund, L.A.; Vilaseca, F. Experimental evaluation of anisotropy in injection molded polypropylene/wood fiber biocomposites. Compos. Part A Appl. Sci. Manuf. 2017, 96, 147–154. [Google Scholar] [CrossRef]

- Azad, R.; Shahrajabian, H. Experimental study of warpage and shrinkage in injection molding of HDPE/rPET/wood composites with multiobjective optimization. Mater. Manuf. Process. 2018, 34, 274–282. [Google Scholar] [CrossRef]

- Guo, G.; Chen, J.C.; Gong, G. Injection molding of polypropylene hybrid composites reinforced with carbon fiber and wood fiber. Polym. Compos. 2018, 39, 3329–3335. [Google Scholar] [CrossRef]

- Guo, G.; Finkenstadt, V.L.; Nimmagadda, Y. Mechanical properties and water absorption behavior of injection-molded wood fiber/carbon fiber high-density polyethylene hybrid composites. Adv. Compos. Hybrid Mater. 2019, 2, 690–700. [Google Scholar] [CrossRef]

- Guo, G.; Li, Y.; Zhao, X.; Rizvi, R. Tensile and longitudinal shrinkage behaviors of polylactide/wood-fiber composites via direct injection molding. Polym. Compos. 2020, 41, 4663–4677. [Google Scholar] [CrossRef]

- Guo, G.; Kethineni, C. Direct injection molding of hybrid polypropylene/wood-fiber composites reinforced with glass fiber and carbon fiber. Int. J. Adv. Manuf. Technol. 2020, 106, 201–209. [Google Scholar] [CrossRef]

- Moritzer, E.; Richters, M. Injection Molding of Wood-Filled Thermoplastic Polyurethane. J. Compos. Sci. 2021, 5, 316. [Google Scholar] [CrossRef]

- Rabbi, M.S.; Islam, T.; Islam, G.M.S. Injection-molded natural fiber-reinforced polymer composites—A review. Int. J. Mech. Mater. Eng. 2021, 16, 15. [Google Scholar] [CrossRef]

- Li, T.Q.; Wolcott, M.P. Rheology of Wood Plastics Melt. Part 1. Capillary Rheometry of HDPE Filled with Maple. Polym. Eng. Sci. 2005, 45, 549–559. [Google Scholar] [CrossRef]

- Li, T.Q.; Wolcott, M.P. Rheology of Wood Plastics Melt, Part 2: Effects of Lubricating Systems in HDPE/Maple Composites. Polym. Eng. Sci. 2006, 46, 464–473. [Google Scholar] [CrossRef]

- Li, T.Q.; Wolcott, M.P. Rheology of Wood Plastics Melt, Part 3: NonLinear Nature of the Flow. Polym. Eng. Sci. 2006, 46, 114–121. [Google Scholar] [CrossRef]

- Xiao, K.; Tzoganakis, C. Rheological Properties and Their Influence on Extrusion Characteristics of HDPE-Wood Composite Resins. SPE ANTEC 2002, 39, 252–257. [Google Scholar]

- Hristov, V.; Takács, E.; Vlachopoulos, J. Surface tearing and wall slip phenomena in extrusion of highly filled HDPE/wood flour composites. Polym. Eng. Sci. 2006, 46, 1204–1214. [Google Scholar] [CrossRef]

- Vlachopoulos, J.; Hristov, V. Rheology of Wood Polymer Composites. In Proceedings of the Regional PPS Meeting, Pretoria, South Africa, 9–13 October 2006. [Google Scholar]

- Zolfaghari, A.; Behravesh, A.H.; Shakouri, E.; Soury, E. Flow balancing in die design of wood flour/HDPE composite extrusion profiles with consideration of rheological effect. Polym. Eng. Sci. 2010, 50, 543–549. [Google Scholar] [CrossRef]

- Lewandowski, A.; Wilczyński, K. Global Modeling of Single Screw Extrusion with Slip Effects. Int. Polym. Process. 2019, 34, 81–90. [Google Scholar] [CrossRef]

- Lewandowski, A.; Wilczyński, K. Global Modeling for Single Screw Extrusion of Viscoplastics. Int. Polym. Process. 2020, 35, 26–36. [Google Scholar] [CrossRef]

- Laufer, N.; Hansmann, H.; Koch, M. Rheological Characterisation of the Flow Behaviour of Wood Plastic Composites in Consideration of Different Volume Fractions of Wood. J. Phys. Conf. Ser. 2017, 790, 012017. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Buziak, K. A Computer Model of Starve Fed Single Screw Extrusion of Wood Plastic Composites. Polymers 2021, 13, 1252. [Google Scholar] [CrossRef]

- Mazzanti, V.; Mollica, F.; El Kissi, N. Rheological and mechanical characterization of polypropylene-based wood plastic composites. Polym. Compos. 2016, 37, 3460–3473. [Google Scholar] [CrossRef]

- Mazzanti, V.; Mollica, F. A review of wood polymer composites rheology and its implications for processing. Polymers 2020, 12, 2304. [Google Scholar] [CrossRef]

- Li, T.Q.; Wolcott, M.P. Rheology of HDPE–wood composites. I. Steady state shear and extensional flow. Compos. Part. A 2004, 35, 303–311. [Google Scholar] [CrossRef]

- Santi, C.R.; Hage, E.; Vlachopoulos, J.; Correa, C.A. Rheology and processing of HDPE/wood flour composites. Int. Polym. Process. 2009, 24, 346–353. [Google Scholar] [CrossRef]

- Carrino, L.; Ciliberto, S.; Giorleo, G.; Prisco, U. Effect of filler content and temperature on steady-state shear flow of wood/high density polyethylene composites. Polym. Compos. 2011, 32, 796–809. [Google Scholar] [CrossRef]

- He, P.; Bai, S.; Wang, Q. Structure and performance of poly(vinyl alcohol)/wood powder composite prepared by thermal processing and solid state shear milling technology. Compos. Part B 2016, 99, 373–380. [Google Scholar] [CrossRef]

- Kaseem, M.; Hamad, K.; Deri, F.; Ko, Y.G. Effect of wood fibers on the rheological and mechanical properties of polystyrene/wood composites. J. Wood Chem. Technol. 2017, 37, 251–260. [Google Scholar] [CrossRef]

- Hong, H.; Guo, Q.; Zhang, H.; He, H. Effect of interfacial modifiers and wood flour treatment on the rheological properties of recycled polyethylene/wood flour composites. Prog. Rubber Plast. Recycl. Technol. 2019, 36, 31–46. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Improving the properties of polypropylene–wood flour composites by utilization of maleated adhesion promoters. Compos. Interfaces 2007, 14, 685–698. [Google Scholar] [CrossRef]

- Hristov, V.; Vlachopoulos, J. Influence of coupling agents on melt flow behavior of natural fiber composites. Macromol. Mater. Eng. 2007, 292, 608–619. [Google Scholar] [CrossRef]

- Hristov, V.; Vlachopoulos, J. A study of viscoelasticity and extrudate distortions of wood polymer composites. Rheol. Acta 2007, 46, 773–783. [Google Scholar] [CrossRef]

- Hristov, V.; Valchopoulos, J. Effects of polymer molecular weight and filler particle size on flow behavior of wood polymer composites. Polym. Compos. 2008, 29, 831–839. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Park, C.B.; Islam, M.R.; Rizvi, G.M. Effects of lubricant content on extrusion processing and mechanical properties of wood flour–high density polyethylene composites. J. Thermoplast. Compos. Mater. 2011, 24, 155–171. [Google Scholar] [CrossRef]

- Intawong, N.; Kantala, C.; Lotaisong, W.; Sombatsompop, N. A die rotating system for moderations of extrusion load and pressure drop profiles for molten PP and wood/polypropylene composites in extrusion processes. J. Appl. Polym. Sci. 2011, 120, 1006–1016. [Google Scholar] [CrossRef]

- Duretek, I.; Schuschnigg, S.; Gooneie, A.; Langecker, G.R.; Holzer, C. Rheological properties of wood polymer composites and their role in extrusion. J. Phys. Conf. Ser. 2015, 602, 012014. [Google Scholar] [CrossRef]

- Lewandowski, K.; Piszczek, K.; Zajchowski, S.; Mirowski, J. Rheological properties of wood polymer composites at high shear rates. Polym. Test. 2016, 51, 58–62. [Google Scholar] [CrossRef]

- Li, J.; Li, D.; Song, Z.; Shang, S.; Guo, Y. Preparation and properties of wood plastic composite reinforced by ultralong cellulose nanofibers. Polym. Compos. 2016, 37, 1206–1215. [Google Scholar] [CrossRef]

- Hristov, V. Melt flow instabilities of wood polymer composites. Compos. Interfaces 2009, 16, 731–750. [Google Scholar] [CrossRef]

- Hristov, V.; Vlachopoulos, J. Thermoplastic silicone elastomer lubricant in extrusion of polypropylene wood f lour composites. Adv. Polym. Technol. 2007, 26, 100–108. [Google Scholar] [CrossRef]

- Ares, A.; Bouza, R.; Pardo, S.G.; Abbad, M.J.; Barral, L. Rheological, Mechanical and Thermal Behaviour of Wood Polymer Composites Based on Recycled Polypropylene. J. Polym. Environ. 2010, 18, 318–325. [Google Scholar] [CrossRef]

- Ewurum, L.I.; Jokic, D.; Bar-Ziv, E.; McDonald, A.G. Evaluation of the rheological and mechanical properties of mixed plastic waste-based composites. Waste Biomass Valorization 2022, 13, 4625–4637. [Google Scholar] [CrossRef]

- Talcott, S.; Uptmor, B.; McDonald, A.G. Evaluation of the Mechanical, Thermal and Rheological Properties of Hop, Hemp and Wood Fiber Plastic Composites. Materials 2023, 16, 4187. [Google Scholar] [CrossRef]

- Feng, C.; Li, Z.; Wang, Z.; Wang, B.; Wang, Z. Optimizing torque rheometry parameters for assessing the rheological characteristics and extrusion processability of wood plastic composites. J. Thermoplast. Compos. Mater. 2019, 32, 123–140. [Google Scholar] [CrossRef]

- Wilczyński, K. Rheology in Polymer Processing: Modeling and Simulation; Carl Hanser Verlag: Munich, Germany, 2021; ISBN 978-1-56990-660-6. [Google Scholar]

- Tadmor, Z.; Klein, I. Engineering Principles of Plasticating Extrusion; Van Nostrand Reinhold, Co.: New York, NY, USA, 1970; ISBN 978-044-215-635-0. [Google Scholar]

- Ariffin, A.; Ahmad, M.S.B. Review: Single Screw Extruder in Particulate Filler Composite. Polym. Plast. Technol. Eng. 2011, 50, 395–403. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J. Multipurpose Computer Model for Screw Processing of Plastics. Polym. Plast. Technol. Eng. 2012, 51, 626–633. [Google Scholar] [CrossRef]

- Potente, H.; Ridder, H.; Cunha, R.V. Global Concept for Describing and Investigation of Wall Slip Effects in the Extrusion Process. Macromol. Mater. Eng. 2002, 287, 836–842. [Google Scholar] [CrossRef]

- Malik, M.; Kalyon, D.M.; Golba, J.C. Simulation of Co-Rotating Twin Screw Extrusion Process Subject to Pressure-Dependent Wall Slip at Barrel and Screw Surfaces: 3D FEM Analysis for Combinations of Forward- and Reverse-Conveying Screw Elements. Int. Polym. Process. 2014, 29, 51–62. [Google Scholar] [CrossRef]

- Gooneie, A.; Schuschnigg, S.; Duretek, I.; Holzer, C. In Numerical simulations of the flow of wood polypropylene composites with wall slipping in a profile die: The significance of material data. AIP Conf. Proc. 2015, 1664, 050014. [Google Scholar] [CrossRef]

- Maddock, B.H. A Visual Analysis of Flow and Mixing in Extruder Screws. Soc. Plast. Eng. 1959, 15, 383–389. [Google Scholar]

- Street, L.F. Plastifying Extrusion. Int. Plast. Eng. 1959, 1, 289–296. [Google Scholar]

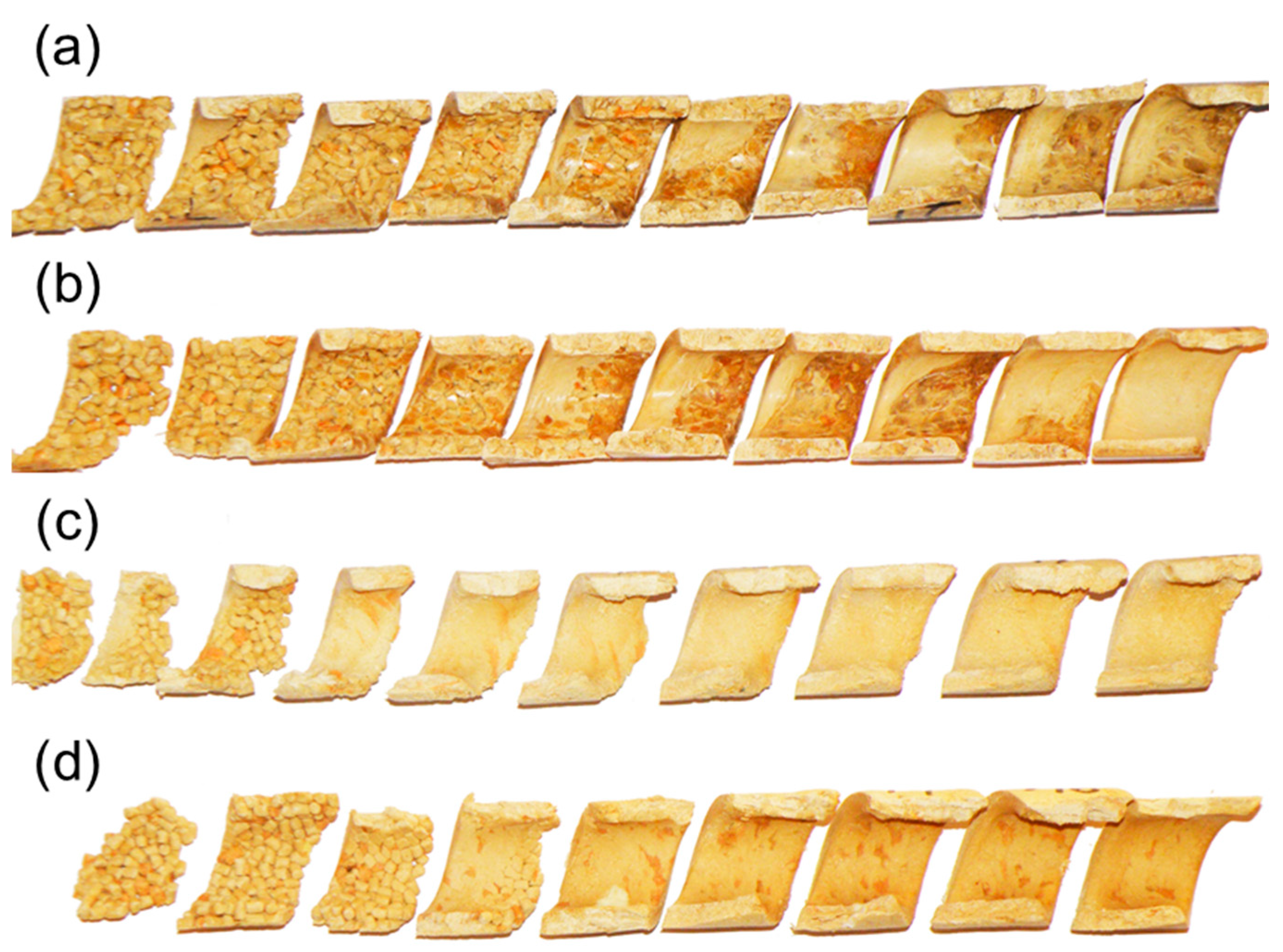

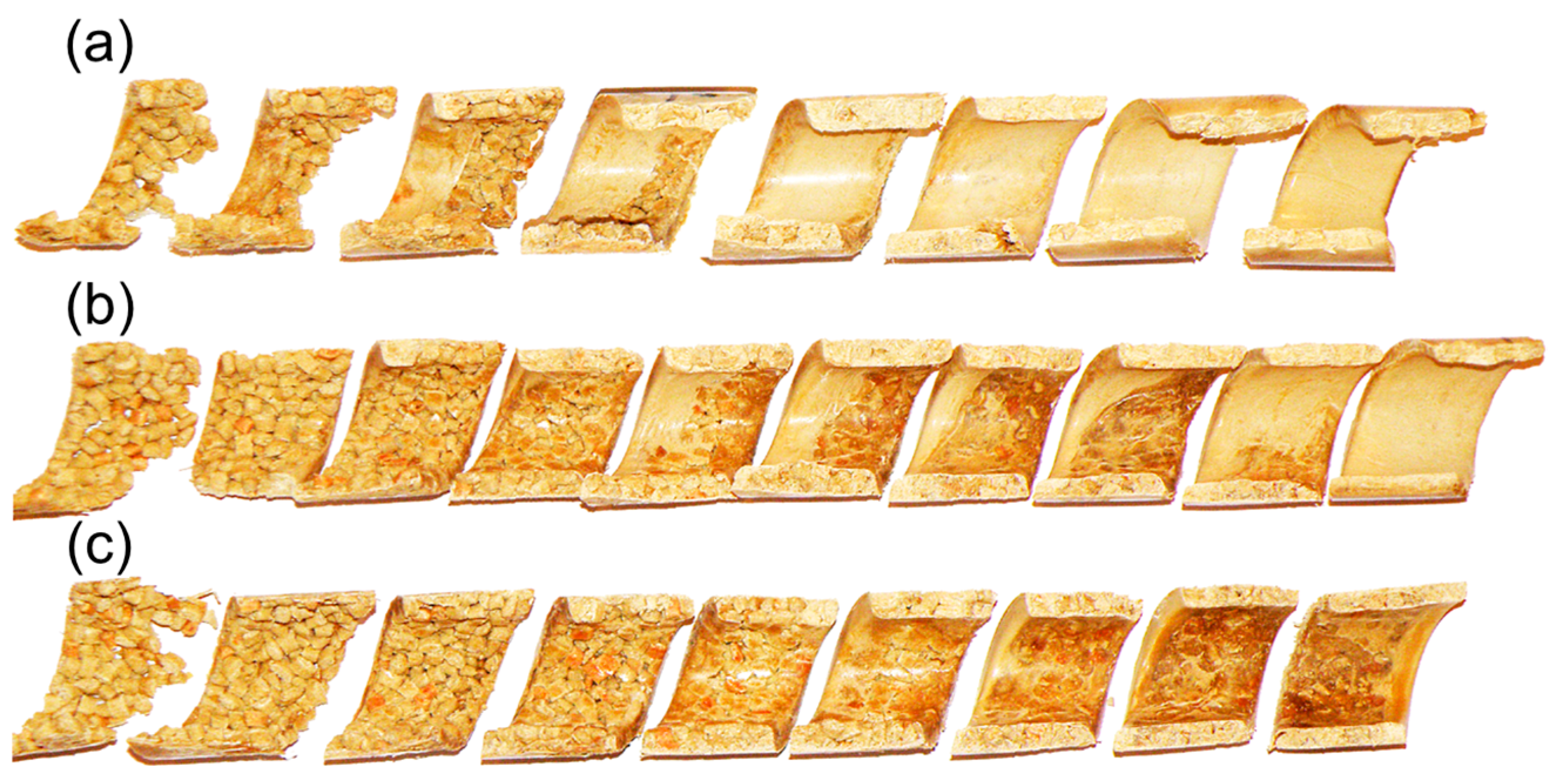

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental study for starve-fed single screw extrusion of thermoplastics. Polym. Eng. Sci. 2012, 52, 1258–1270. [Google Scholar] [CrossRef]

- Tadmor, Z. Fundamentals of plasticating extrusion. I. A theoretical model for melting. Polym. Eng. Sci. 1966, 6, 185–190. [Google Scholar] [CrossRef]

- Tadmor, Z.; Duvdevani, I.; Klein, I. Melting in plasticating extuders theory and experiments. Polym. Eng. Sci. 1967, 7, 198–217. [Google Scholar] [CrossRef]

- Altınkaynak, A.; Gupta, M.; Spalding, M.A.; Crabtree, S.L. Melting in a Single Screw Extruder: Experiments and 3D Finite Element Simulations. Int. Polym. Process. 2011, 26, 182–196. [Google Scholar] [CrossRef]

- Agur, E.E.; Vlachopoulos, J. Numerical simulation of a single-screw plasticating extruder. Polym. Eng. Sci. 1982, 22, 1084–1094. [Google Scholar] [CrossRef]

- Vincelette, A.R.; Guerrero, C.S.; Carreau, P.J.; Lafleur, P.G. A Model for Single-screw Plasticating Extruders. Int. Polym. Process. 1989, 4, 232–241. [Google Scholar] [CrossRef]

- Potente, H.; Hanhart, W.; Schöppner, V. Potential Applications for Computer-aided Extruder Design. Int. Polym. Process. 1993, 8, 335–344. [Google Scholar] [CrossRef]

- Wilczyński, K. Single Screw Extrusion Model for Plasticating Extruders. Polym. Plast. Techol. Eng. 1999, 4, 581–608. [Google Scholar] [CrossRef]

- Bawiskar, S.; White, J.L. Solids Conveying and Melting in a Starve Fed Self-wiping Co-rotating Twin Screw Extruder. Int. Polym. Process. 1995, 10, 105–110. [Google Scholar] [CrossRef]

- Bawiskar, S.; White, J.L. Melting model for modular self wiping co-rotating twin screw extruders. Polym. Eng. Sci. 1998, 38, 727–740. [Google Scholar] [CrossRef]

- Sakai, T. The development of on-line techniques and novel processing systems for the monitoring and handling of the evolution of microstructure in nonreactive and reactive polymer systems. Adv. Polym. Technol. 1995, 14, 277–290. [Google Scholar] [CrossRef]

- Potente, H.; Melisch, U. Theoretical and Experimental Investigations of the Melting of Pellets in Co-Rotating Twin-Screw Extruders. Int. Polym. Process. 1996, 11, 101–108. [Google Scholar] [CrossRef]

- Gogos, C.C.; Tadmor, Z.; Kim, M.H. Melting phenomena and mechanisms in polymer processing equipment. Adv. Polym. Technol. 1998, 17, 285–305. [Google Scholar] [CrossRef]

- Vergnes, B.; Delacour, M.L.; Souveton, G.; Bouvier, J.M. A Study of Polymer Melting in a Co-Rotating Twin Screw Extruder. In Proceedings of the International Polymer Processing Society Annual Meeting PPS-15’s Hertogenbosch, Hertogenbosch, The Netherlands, 31 May–4 June 1999. [Google Scholar]

- Vergnes, B.; Souveton, G.; Delacour, M.L.; Ainser, A. Experimental and Theoretical Study of Polymer Melting in a Co-rotating Twin Screw Extruder. Int. Polym. Process. 2001, 16, 351–362. [Google Scholar] [CrossRef]

- Bawiskar, S.; White, J.L. A Composite Model for Solid Conveying, Melting, Pressure and Fill Factor Profiles in Modular Co -Rotating Twin Screw Extruders. Int. Polym. Process. 1997, 12, 331–340. [Google Scholar] [CrossRef]

- Vergnes, B.; Valle, G.D.; Delamare, L. A global computer software for polymer flows in corotating twin screw extruders. Polym. Eng. Sci. 1998, 38, 1781–1792. [Google Scholar] [CrossRef]

- Potente, H.; Bastian, M.; Flecke, J. Design of a compounding extruder by means of the SIGMA simulation software. Adv. Polym. Technol. 1999, 18, 147–170. [Google Scholar] [CrossRef]

- Wilczyński, K.; White, J.L. Experimental Study of Melting in an Intermeshing Counter-Rotating Twin Screw Extruder. Int. Polym. Process. 2001, 16, 257–262. [Google Scholar] [CrossRef]

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental study of melting of LDPE/PS polyblend in an intermeshing counter-rotating twin screw extruder. Polym. Eng. Sci. 2012, 52, 449–458. [Google Scholar] [CrossRef]

- Wilczyński, K.; White, J.L. Melting model for intermeshing counter-rotating twin-screw extruders. Polym. Eng. Sci. 2003, 43, 1715–1726. [Google Scholar] [CrossRef]

- Wilczyński, K.; Jiang, Q.; White, J.L. A Composite Model for Melting, Pressure and Fill Factor Profiles in a Metered Fed Closely Intermeshing Counter-rotating Twin Screw Extruder. Int. Polym. Process. 2007, 22, 198–203. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J. Modelowanie przepływu tworzyw w procesie wytłaczania dwuślimakowego przeciwbieżnego, Cz.2. Badania symulacyjne i doświadczalne. Polimery 2011, 56, 45–50. [Google Scholar]

- Wilczyński, K.; Lewandowski, A. Study on the Polymer Melt Flow in a Closely Intermeshing Counter-Rotating Twin Screw Extruder. Int. Polym. Process. 2014, 29, 649–659. [Google Scholar] [CrossRef]

- Lewandowski, A.; Wilczyński, K.J.; Nastaj, A.; Wilczyński, K. A composite model for an intermeshing counter-rotating twin-screw extruder and its experimental verification. Polym. Eng. Sci. 2015, 55, 2838–2848. [Google Scholar] [CrossRef]

- Jiang, Q.; White, J.L.; Yang, J. A Global Model for Closely Intermeshing Counter-rotating Twin Screw Extruders with Flood Feeding. Internl Polym. Process. 2010, 25, 223–235. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Wilczyński, K.J. Melting Model for Starve Fed Single Screw Extrusion of Thermoplastics. Int. Polym. Process. 2013, 28, 34–42. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A.; Lewandowski, A.; Wilczyński, K. A composite model for starve fed single screw extrusion of thermoplastics. Polym. Eng. Sci. 2014, 54, 2362–2374. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Nastaj, A.; Wilczyński, K. Modeling for Starve Fed/Flood Fed Mixing Single-Screw Extruders. Int. Polym. Process. 2016, 31, 82–91. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Nastaj, A.; Wilczyński, K. A Global Model for Starve-Fed Nonconventional Single-Screw Extrusion of Thermoplastics. Adv. Polym. Technol. 2017, 36, 23–35. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Wilczyński, K. Experimental Study of Melting of Polymer Blends in a Starve Fed Single Screw Extruder. Polym. Eng. Sci. 2016, 56, 1349–1356. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A.; Wilczyński, K. A Computer Model for Starve-Fed Single-Screw Extrusion of Polymer Blends. Adv. Polym. Technol. 2018, 37, 2142–2151. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A. Modelowanie procesu wytaczania jednoœlimakowego z dozowanym zasilaniem mieszanin tworzyw termoplastycznych. Polimery 2015, 60, 199–208. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A. Modelowanie procesu wytłaczania jednoślimakowego mieszanin polimerów z zastosowaniem ślimaków mieszających i dozowanego zasilania wytłaczarki. Polimery 2016, 61, 279–285. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A. Modelowanie procesu wytłaczania jednoślimakowego mieszanin polimerów z zastosowaniem ślimaków niekonwencjonalnych i dozowanego zasilania wytłaczarki. Polimery 2016, 61, 357–362. [Google Scholar] [CrossRef]

- Ilinca, F.; Hétu, J.F. Three-dimensional Finite Element Solution of the Flow in Single and Twin-Screw Extruders. Int. Polym. Process. 2010, 25, 275–286. [Google Scholar] [CrossRef]

- Teixeira, C.; Gaspar-Cunha, A.; Covas, J.A. Flow and Heat Transfer Along the Length of a Co-rotating Twin Screw Extruder. Polym. Plast. Technol. Eng. 2012, 51, 1567–1577. [Google Scholar] [CrossRef]

- White, J.L.; Potente, H. Screw Extrusion; Carl Hanser Verlag: Munich, Germany, 2003; ISBN 344-619-624-2. [Google Scholar]

- Tadmor, Z.; Gogos, C. Principles of Polymer Processing; Wiley & Sons: New York, NY, USA, 2006; ISBN 047-138-770-3. [Google Scholar]

- Rauwendaal, C. Polymer Extrusion; Hanser: Munich, Germany, 2014; ISBN 978-156-990-516-6. [Google Scholar]

- Xiao, K.; Tzoganakis, C. Extrusion Characteristic of HDPE-Wood Composites. SPE ANTEC 2003, 39, 197–201. [Google Scholar]

- Xiao, K.; Tzoganakis, C. Rheological Properties of HDPE-Wood Composites. SPE ANTEC 2003, 39, 975–979. [Google Scholar]

- Xiao, K.; Tzoganakis, C. Extrusion of HDPE-Wood Blends. SPE ANTEC 2004, 40, 448–453. [Google Scholar]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Experimental Study for Extrusion of Polypropylene/Wood Flour Composites. Int. Polym. Process. 2015, 30, 113–120. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Buziak, K. Study on the Flow of Wood Plastic Composites in the Starve Fed Single Screw Extrusion. Polimery 2017, 62, 680–685. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Fundamentals of Global Modeling for Polymer Extrusion. Polymers 2019, 11, 2106. [Google Scholar] [CrossRef]

- Wilczyński, K.; Buziak, K.; Wilczyński, K.J.; Lewandowski, A.; Nastaj, A. Computer Modeling for Single-Screw Extrusion of Wood–Plastic Composites. Polymers 2018, 10, 295. [Google Scholar] [CrossRef]

- Campbell, G.A.; Spalding, M.A. One Dimensional Melting in Single-Screw Extruders. SPE ANTEC 2011, 47, 1367–1373. [Google Scholar]

- Wilczyński, K.J.; Nastaj, A.; Buziak, K. Modelowanie procesu wytłaczania jednoślimakowego z dozowanym zasilaniem polimerowych kompozytów drzewnych. Polimery 2018, 63, 542–548. [Google Scholar] [CrossRef]

- Mooney, M. Explicit Formulas for Slip and Fluidity. J. Rheol. 1931, 2, 210–222. [Google Scholar] [CrossRef]

- Potente, H.; Bornemann, M.; Kurte-Jardin, M. Analytical Model for the Throughput and Drive Power Calculation in the Melting Section of Single Screw Plasticizing Units Considering Wall-Slippage. Int. Polym. Process. 2009, 24, 23–30. [Google Scholar] [CrossRef]

- Worth, R.A.; Parnaby, J.; Helmy, H.A. Wall Slip and its Implications in the Design of Single Screw Melt-Fed Extruders. Polym. Eng. Sci. 1977, 17, 257–265. [Google Scholar] [CrossRef]

- Meijer, H.E.H.; Verbraak, C.P.J.M. Modeling of Extrusion with Slip Boundary Conditions. Polym. Eng. Sci. 1988, 28, 758–771. [Google Scholar] [CrossRef]

- Lawal, A.; Kalyon, D.M.; Yilmazer, U. Extrusion and Lubrication Flows of Viscoplastic Fluids with Wall Slip. Chem. Eng. Commun. 1993, 122, 127–150. [Google Scholar] [CrossRef]

- Lawal, A.; Kalyon, D.M. Single Screw Extrusion of Viscoplastic Fluids Subject to Different Slip Coefficients at Screw and Barrel Surfaces. Polym. Eng. Sci. 1994, 34, 1471–1479. [Google Scholar] [CrossRef]

- Kalyon, D.M.; Lawal, A.; Yazici, R.; Yaras, P.; Railkar, S. Mathematical Modeling and Experimental Studies of Twin-Screw Extrusion of Filled Polymers. Polym. Eng. Sci. 1999, 39, 1139–1151. [Google Scholar] [CrossRef]

- Potente, H.; Ridder, H. Pressure/Throughput Behavior of a Single-Screw Plasticising Unit in Consideration of Wall Slippage. Int. Polym. Process. 2002, 17, 102–107. [Google Scholar] [CrossRef]

- Potente, H.; Kurte, M.; Ridder, H. Influence of Non-Newtonian Behaviour on the Processing Characteristics of Wall-Slipping Materials. Int. Polym. Process. 2003, 18, 115–121. [Google Scholar] [CrossRef]

- Potente, H.; Kurte–Jardin, M.; Klus, S.; Timmermann, K. Two Dimensional Description of Pressure-Throughput Behaviour of Newtonian Materials Considering Wall Slippage Effects. Int. Polym. Process. 2005, 20, 312–321. [Google Scholar] [CrossRef]

- Potente, H.; Timmermann, K.; Kurte-Jardin, M. Description of the Pressure/Throughput Behavior of a Single-Screw Plasticating Unit in Consideration of Wall Slippage Effects for Non-Newtonian Material and 1-D Flow. Int. Polym. Process. 2006, 21, 272–282. [Google Scholar] [CrossRef]

- Ferras, L.L.; Nobrega, J.M.; Pinho, F.T.; Carneiro, O.S. Profile Extrusion Die Design: The Effect of Wall Slip. In Proceedings of the Polymer Processing Society 23rd Annual Meeting (PPS-23), Salvador, Brazil, 27–31 May 2007. [Google Scholar]

- Hatzikiriakos, S.G.; Mitsoulis, E. Slip Effects in Tapered Dies. Polym. Eng. Sci. 2009, 49, 1960–1969. [Google Scholar] [CrossRef]

- Gupta, M. Effect of Wall Slip on the Flow in a Flat Die for Sheet Extrusion. SPE ANTEC Techol. Pap. 2011, 57, 1191–1196. [Google Scholar]

- Wilczyński, K.; Buziak, K.; Lewandowski, A.; Wilczyński, K.J.; Nastaj, A. In Proceedings of the AIP 35th International Conference of the Polymer Processing Society. Izmir-Cesma, Turkey, 26–30 May 2019. [Google Scholar]

- Ansys Polyflow, v. 17. Available online: www.ansys.com (accessed on 4 April 2025).

- Bingham, E.C. Fluidity and Plasticity; McGraw-Hill: New York, NY, USA, 1922. [Google Scholar]

- Bird, R.B.; Dai, G.C.; Yarusso, B.J. The Rheology and Flow of Viscoplastic Materials. Rev. Chem. Eng. 1983, 1, 1–70. [Google Scholar] [CrossRef]

- Mitsoulis, E. Flows of Viscoplastic Materials: Models and Computations. In Rheology Reviews 2007; Binding, D.M., Hudson, N.E., Keunings, R., Eds.; The British Society of Rheology: London, UK, 2007; pp. 135–178. [Google Scholar]

- Manzione, L.T. (Ed.) Applications of Computer Aided Engineering in Injection Molding; Carl Hanser Verlag: Munich, Germany, 1992; ISBN 978-0-195-20752-1. [Google Scholar]

- Isayev, A.I.; Liu, S.J.; Kamal, M.R. Injection Molding: Technology and Fundamentals; Carl Hanser Verlag: Munich, Germany, 2009; ISBN 978-3-446-41685-7. [Google Scholar]

- Osswald, T.; Turng, L.S.; Gramman, P. Injection Molding Handbook; Carl Hanser Verlag: Munich, Germany, 2009; ISBN 978-3-446-40781-7. [Google Scholar]

- Kennedy, P.; Zheng, R. Flow Analysis of Injection Molds, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2013; ISBN 978-1-569-90512-8. [Google Scholar]

- Wang, M.; Chang, R.; Hsu, C. Molding Simulation. Theory and Practice; Carl Hanser Verlag: Munich, Germany, 2018; ISBN 978-1-569-90619-4. [Google Scholar]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Modeling and Optimization of the Injection-Molding Process: A Review. Adv. Polym. Technol. 2016, 37, 429–449. [Google Scholar] [CrossRef]

- MOLDFLOW Plastic Injection and Compression Mold Simulation. Available online: www.autodesk.com/products/moldflow (accessed on 17 May 2025).

- Moldex3D Plastic Injection Molding Simulation Software. Available online: www.moldex3d.com (accessed on 17 May 2025).

- CADMOULD Plastic Injection Molding Simulation. Available online: www.simcon.com/cadmould (accessed on 17 May 2025).

- Wilczyński, K.; Narowski, P. Simulation Studies on the Effect of Material Characteristics and Runners Layout Geometry on the Filling Imbalance in Geometrically Balanced Injection Molds. Polymers 2019, 11, 639. [Google Scholar] [CrossRef]

- Wilczyński, K.; Narowski, P. A Strategy for Problem Solving of Filling Imbalance in Geometrically Balanced Injection Molds. Polymers 2020, 12, 805. [Google Scholar] [CrossRef]

- COMSOL Multiphysics Simulation Software. Available online: www.comsol.com/comsol-multiphysics (accessed on 17 May 2025).

- Sullivan, A.; Saigal, A.; Zimmerman, M.A. Practical Simulation and Experimental Measurement of Liquid Crystal Polymer Directionality During Injection Molding. Polym. Eng. Sci. 2019, 59, E414–E424. [Google Scholar] [CrossRef]

- Donovan, R.C.; Thomas, D.E.; Leversen, L.D. An Experimental Study of Plasticating in a Reciprocating-Screw Injection Molding Machine. Polym. Eng. Sci. 1971, 11, 353–360. [Google Scholar] [CrossRef]

- Gao, F.; Jin, Z.; Chen, X. A Visual Barrel System for Study of Reciprocating Screw Injection Molding. Polym. Eng. Sci. 2000, 40, 1334–1343. [Google Scholar] [CrossRef]

- Jin, Z.; Gao, F.; Zhu, F. An Experimental Study of Solid-Bed Break-up in Plasticization of a Reciprocating-Screw Injection Molding. Polym. Eng. Sci. 2004, 44, 1313–1318. [Google Scholar] [CrossRef]

- Pham, T.L.; Balcaen, J.; Charmeau, J.Y.; Bereaux, Y. In-Line Visualisation of Polymer Plastication in an Injection Molding Screw. Key Eng. Mater. 2013, 554, 1683–1691. [Google Scholar] [CrossRef]

- Donovan, R.C. A Theoretical Melting Model for a Reciprocating-Screw Injection Molding Machine. Polym. Eng. Sci. 1971, 11, 361–368. [Google Scholar] [CrossRef]

- Donovan, R.C. The Plasticating Process in Injection Molding. Polym. Eng. Sci. 1974, 14, 101–111. [Google Scholar] [CrossRef]

- Donovan, R.C. A Theoretical Melting Model for Plasticating Extruders. Polym. Eng. Sci. 1971, 11, 247–257. [Google Scholar] [CrossRef]

- Lipshitz, S.D.; Lavie, R.; Tadmor, Z. A Melting Model for Reciprocating Screw Injection-Molding Machines. Polym. Eng. Sci. 1974, 14, 553–559. [Google Scholar] [CrossRef]

- Rauwendaal, C. Melt Conveying in Reciprocating extruders. SPE-ANTEC Tech. Pap. 1991, 36, 433–435. [Google Scholar]

- Rauwendaal, C. Conveying and Melting in Screw Extruders with Axial Movement. Int. Polym. Process. 1992, 7, 26–31. [Google Scholar] [CrossRef]

- Dormeier, S.; Panreck, K. Dynamic behavior of temperature during extrusion. Kunststoffe 1990, 11, 32–33. [Google Scholar]

- Rao, N.S.; Schumacher, G.; Schott, N.R.; Edwards, R. Calculations of Melting Performance of Injection Molding Screws by an Easily Applicable Model. SPE-ANTEC Tech. Pap. 2001, 59, 651–655. [Google Scholar]

- Potente, H.; Schulte, H.; Effen, N. Simulation of Injection Molding and Comparison with Experimental Values. Int. Polym. Process. 1993, 8, 224–235. [Google Scholar] [CrossRef]

- Potente, H.; Bornemann, M. Non-isothermal Model for the Drive Power Calculation of Single-Screw Plasticating Units. Int. Polym. Process. 2008, 23, 345–350. [Google Scholar] [CrossRef]

- Bereaux, Y.; Charmeau, J.-Y.; Moguedet, M. A simple model of throughput and pressure development for single screw. J. Mater. Process. Technol. 2009, 209, 611–618. [Google Scholar] [CrossRef]

- Yung, K.L.; Yan, X. Analysis of a melting model for an extruder with reciprocation. J. Mater. Process. Technol. 2001, 117, 21–27. [Google Scholar] [CrossRef]

- Yung, K.L.; Yan, X.; Lau, K.H. Simulation of transient process in melting section of reciprocating extruder. Polymer 2002, 3, 983–988. [Google Scholar] [CrossRef]

- Yung, K.L.; Yan, X. Transient melting models for the three stages of reciprocating extrusion. J. Mater. Process. Technol. 2003, 139, 170–177. [Google Scholar] [CrossRef]

- Steller, R.; Iwko, J. Polymer Plastication during Injection Molding. Part 1. Mathematical model. Int. Polym. Process. 2008, 23, 252–262. [Google Scholar] [CrossRef]

- Iwko, J.; Steller, R. Polymer Plastication during Injection Molding. Part 2. Simulations and Experiments. Int. Polym. Process. 2008, 23, 263–269. [Google Scholar] [CrossRef]

- Iwko, J.; Steller, R.; Wróblewski, R. Experimentally Verified Mathematical Model of Polymer Plasticization Process in Injection Molding. Polymers 2018, 10, 968. [Google Scholar] [CrossRef]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Nóbrega, J.M.; Gaspar-Cunha, A. Modeling of Plasticating Injection Molding-Experimental Assessment. Int. Polym. Process. 2014, 29, 558–569. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A. Modeling and Optimization of Single Screw Extrusion. PhD. Thesis, University of Minho, Braga, Portugal, 2000. [Google Scholar]

- PSI—Paderborner Spritzgießsimulation. Available online: www.ktp.uni-paderborn.de/en/foerderverein/software/psi (accessed on 17 May 2025).

- Wilczyński, K.; Wilczyński, K.J.; Buziak, K. Modeling and Experimental Studies on Polymer Melting and Flow in Injection Molding. Polymers 2022, 14, 2106. [Google Scholar] [CrossRef] [PubMed]

- Narowski, P.; Wilczyński, K. A Global Approach to Modeling Injection Molding. Polymers 2024, 16, 147. [Google Scholar] [CrossRef] [PubMed]

- Duretek, I.; Lucyshyn, T.; Holzer, C. Filling Behaviour of Wood Plastic Composites. J. Phys. Conf. Ser. 2017, 790, 012006. [Google Scholar] [CrossRef]

- Azaman, M.D.; Sapuan, S.M.; Sulaiman, S.; Zainudin, E.S.; Khalina, A. Numerical Simulation Analysis of the In-Cavity Residual Stress Distribution of Lignocellulosic (Wood) Polymer Composites Used in Shallow Thin-Walled Parts Formed by the Injection Moulding. Process. Mater. Des. 2014, 55, 381–386. [Google Scholar] [CrossRef]

- Azaman, M.D.; Sapuan, S.M.; Sulaiman, S.; Zainudin, E.S.; Khalina, A. Optimization and Numerical Simulation Analysis for Molded Thin-Walled Parts Fabricated Using Wood-Filled Polypropylene Composites via Plastic Injection Molding. Polym. Eng. Sci. 2015, 55, 1082–1095. [Google Scholar] [CrossRef]

- Rahman, W.A.W.A.; Sin, L.T.; Rahmat, A.R. Injection Moulding Simulation Analysis of Natural Fiber Composite Window Frame. J. Mater. Process. Technol. 2008, 197, 22–30. [Google Scholar] [CrossRef]

- Zhan, J.; Li, J.; Wang, G.; Guan, Y.; Zhao, G.; Lin, J.; Coutellier, D. Review on the Performances, Foaming and Injection Molding Simulation of Natural Fiber Composites. Polym. Compos. 2021, 42, 1305–1324. [Google Scholar] [CrossRef]

- Liese, F.; Wünsch, O. Modeling and Numerical Simulation of Flow Processes of Wood-Polymer Composites. Process. Appl. Math. Mech. 2023, 23, e202200199. [Google Scholar] [CrossRef]

- Pashazadeh, S.; SeshadriSuresh, A.; Ghai, V.; Moberg, T.; Brolin, A.; Kadar, R. Predicting orientation in extruded wood polymer composites. Phys. Fluids 2024, 36, 093109. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilczyński, K.; Buziak, K.; Wilczyński, A. Wood–Plastic Composites: Manufacturing, Rheology and Processing and Process Modeling. Materials 2025, 18, 4042. https://doi.org/10.3390/ma18174042

Wilczyński K, Buziak K, Wilczyński A. Wood–Plastic Composites: Manufacturing, Rheology and Processing and Process Modeling. Materials. 2025; 18(17):4042. https://doi.org/10.3390/ma18174042

Chicago/Turabian StyleWilczyński, Krzysztof, Kamila Buziak, and Adam Wilczyński. 2025. "Wood–Plastic Composites: Manufacturing, Rheology and Processing and Process Modeling" Materials 18, no. 17: 4042. https://doi.org/10.3390/ma18174042

APA StyleWilczyński, K., Buziak, K., & Wilczyński, A. (2025). Wood–Plastic Composites: Manufacturing, Rheology and Processing and Process Modeling. Materials, 18(17), 4042. https://doi.org/10.3390/ma18174042