Achieving High Specific Strength via Multiple Strengthening Mechanisms in an Fe-Mn-Al-C-Ni-Cr Lightweight Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results

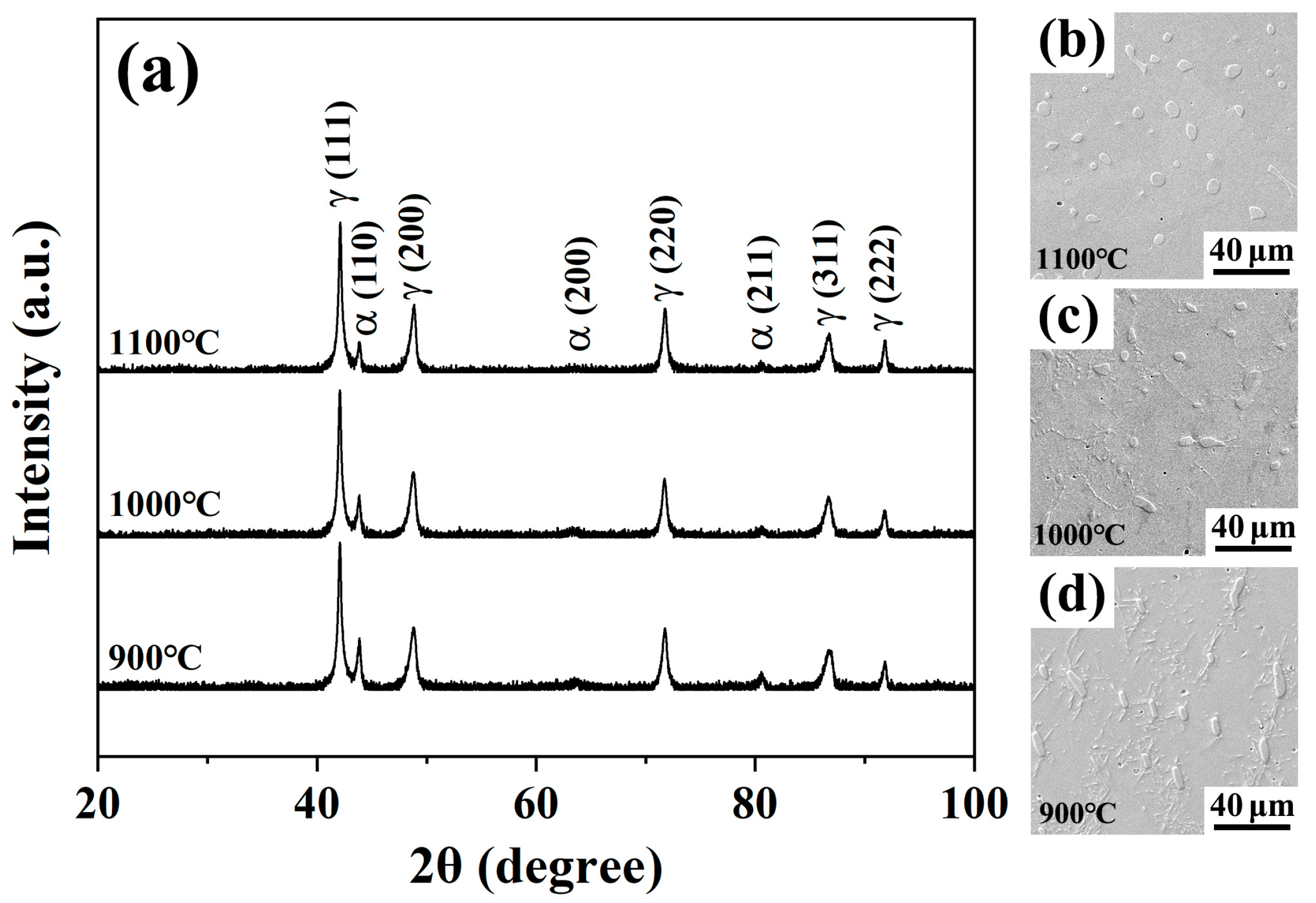

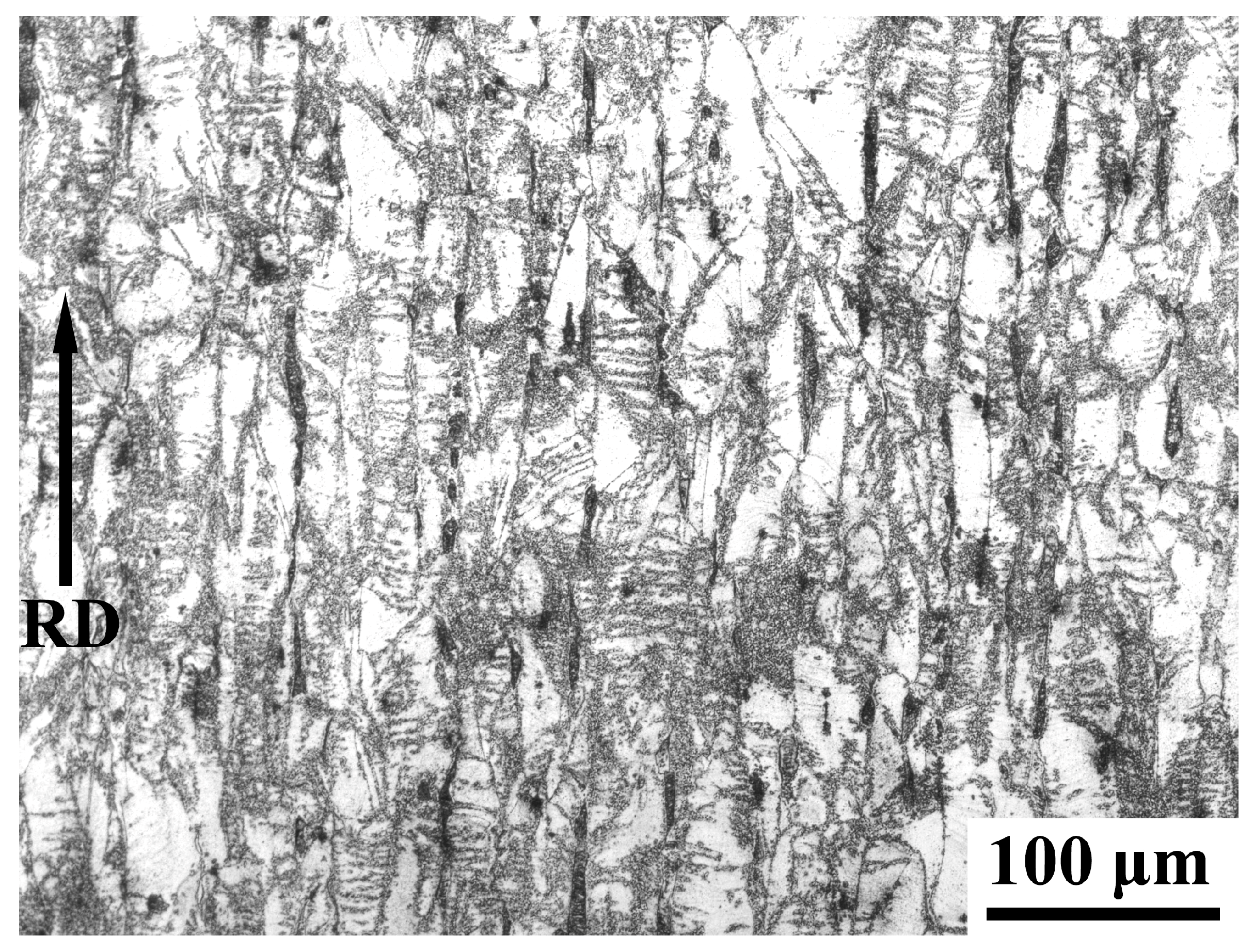

3.1. Microstructure of As-Solutionized Sample After Hot-Rolling

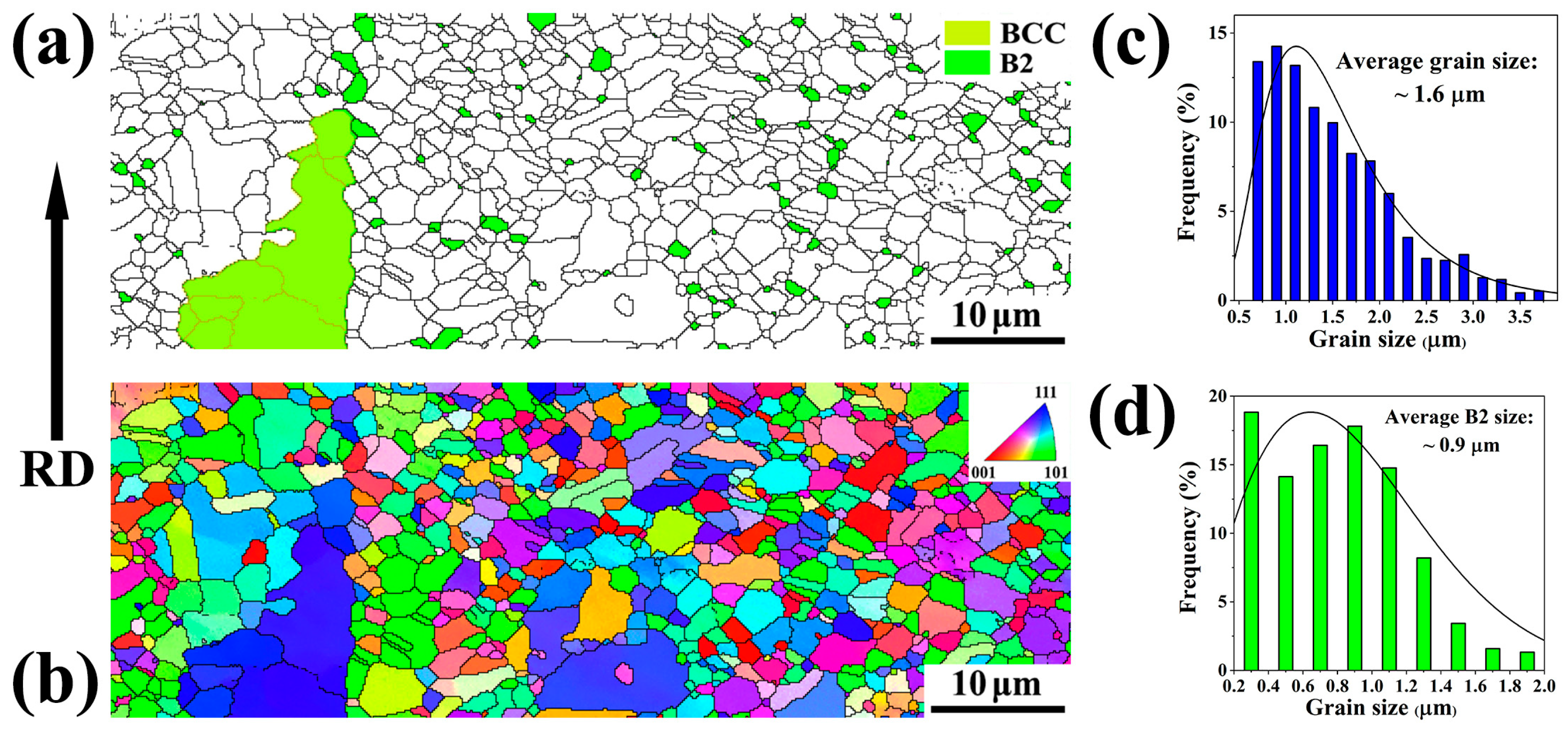

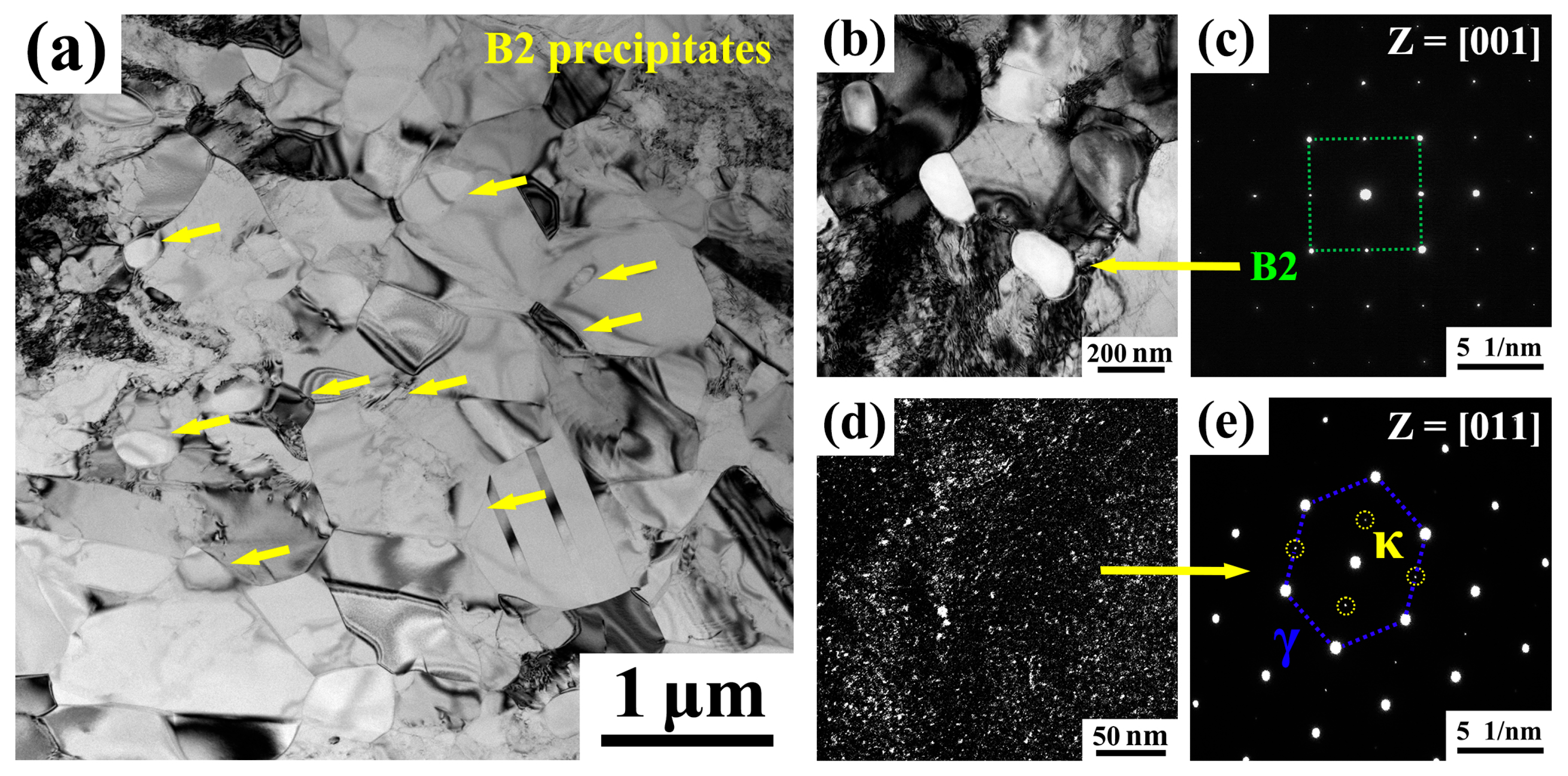

3.2. The Microstructure of As-Annealed Samples After Cold-Rolling

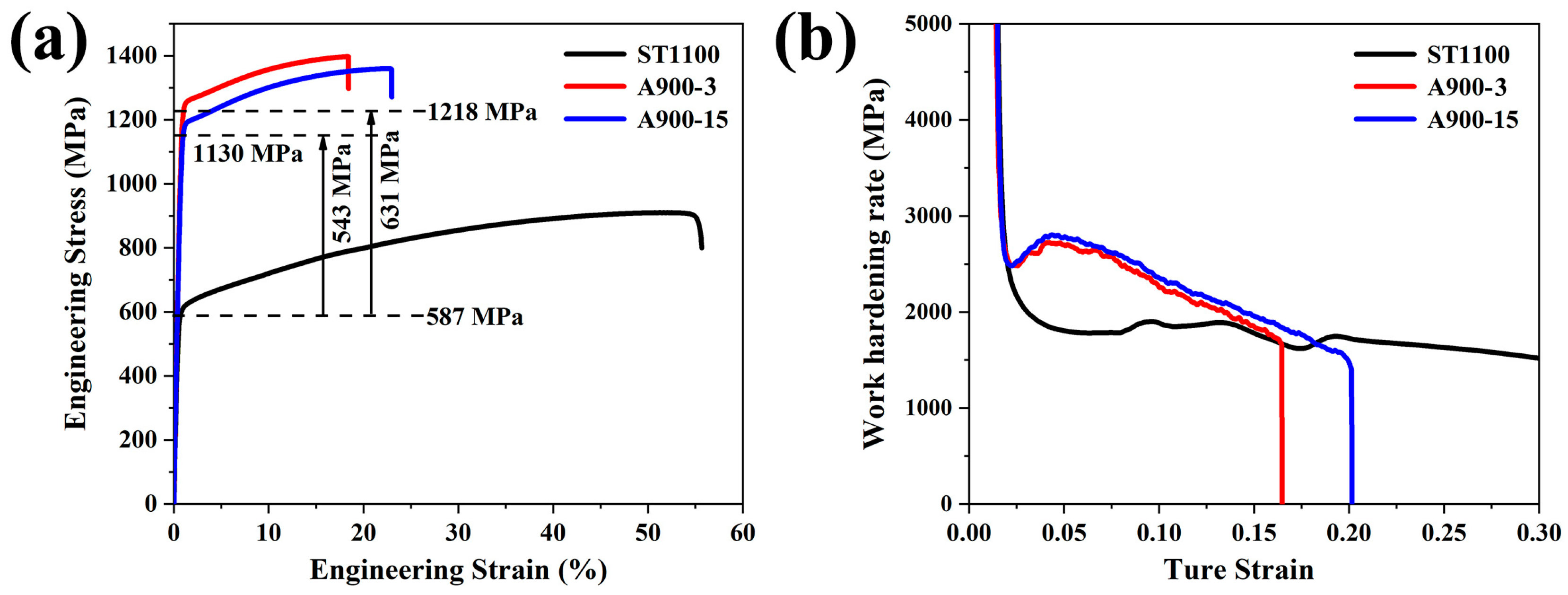

3.3. Mechanical Properties and Strain Hardening Behavior

3.4. The Deformation Microstructure

4. Discussion

4.1. The Role of Alloying Elements

4.2. Precipitation of B2 Phase and Recrystallization Behavior

4.3. The Strengthening Mechanism

4.4. A Comparison of Mechanical Properties

5. Conclusions

- (1)

- Annealing at 900 °C significantly influences the microstructure evolution of the steel. Short-time annealing results in a microstructure characterized by ultrafine recrystallized austenite grains (1.1 μm), fine B2 precipitates (0.18 μm in matrix and 0.4 μm at grain boundaries) with a relatively high volume fraction (9.5%), and uniformly dispersed nanoscale κ-carbides (<10 nm). Long-time annealing (15 min) leads to the coarsening of austenite grains (1.6 μm) and grain boundary B2 particles (0.9 μm), along with a reduction in B2 volume fraction (8.9%).

- (2)

- The steel achieves an exceptional strength–ductility balance (YS: 1130~1218 MPa; UTS: 1360~1397 MPa; elongation: 18~23%). Quantitative strengthening analysis reveals dominant contributions from solid solution strengthening (326~328 MPa) and grain boundary strengthening (227~289 MPa), with additional precipitation hardening (126~167 MPa) from B2 phases and dislocation strengthening. The 260 MPa difference between the calculated and experimental yield stresses is attributed to the contributions of ferrite and κ-carbide strengthening.

- (3)

- The developed steel exhibits excellent mechanical properties, achieving specific yield strengths of 171~185 MPa·g−1·cm3 and specific ultimate tensile strengths of 206~212 MPa·g−1·cm3. This superior performance is achieved through innovative compositional design and the optimization of the hot-rolling, cold-rolling, and annealing process to control recrystallization kinetics and precipitate distribution.

- (4)

- This work provides a new strategy for developing low-Ni lightweight steels through Cr addition and microstructural optimization, enriching the understanding of multiple strengthening mechanisms in Fe-Mn-Al-C steels. The high specific strength of the developed steel can contribute to automotive lightweighting, reducing energy consumption and carbon emissions, which aligns with global sustainability goals.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Frommeyer, G.; Brüx, U. Microstructures and mechanical properties of high-strength Fe-Mn-Al-C light-weight TRIPLEX steels. Steel Res. Int. 2006, 77, 627–633. [Google Scholar] [CrossRef]

- Wu, H.; Tan, Y.; Malik, A.; Wang, Y.W.; Naqvi, S.Z.H.; Cheng, H.W.; Tian, J.B.; Meng, X.M. Dynamic Compressive Mechanical Behavior and Microstructure Evolution of Rolled Fe-28Mn-10Al-1.2C Low-Density Steel. Material 2022, 15, 3550. [Google Scholar] [CrossRef] [PubMed]

- Ding, H.; Liu, D.; Cai, M.; Zhang, Y. Austenite-based Fe-Mn-Al-C lightweight steels: Research and prospective. Metals 2022, 12, 1572. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I. Low Density Fe–Mn–Al–C Steels: Phase Structures, Mechanisms and Properties. ISIJ Int. 2021, 61, 16–25. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Kazakova, A.A.; Pozdniakov, A.V.; Churyumova, T.A.; Prosviryakov, A.S. Investigation of Hot Deformation Behavior and Microstructure Evolution of Lightweight Fe-35Mn-10Al-1C Steel. Metals 2022, 12, 831. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Kazakova, A.A. Prediction of True Stress at Hot Deformation of High Manganese Steel by Artificial Neural Network Modeling. Materials 2023, 16, 1083. [Google Scholar] [CrossRef]

- Kazakova, A.A.; Churyumov, A.Y. Microstructure and Mechanical Properties of Fe-30Mn-10Al-3.3Si-1C Light-Weight Steel. Materials 2025, 18, 1258. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez-Urrutia, I.; Raabe, D. Influence of Al content and precipitation state on the mechanical behavior of austenitic high-Mn low-density steels. Scr. Mater. 2013, 68, 343–347. [Google Scholar] [CrossRef]

- Yao, M.J.; Dey, P.; Seol, J.B.; Choi, P.; Raabe, D. Combined atom probe tomography and density functional theory investigation of the Al off-stoichiometry of κ-carbides in an austenitic Fe-Mn-Al-C low density steel. Acta Mater. 2016, 106, 229–238. [Google Scholar] [CrossRef]

- Chao, C.Y.; Liu, C.H. Effects of Mn contents on the microstructure and mechanical properties of the Fe-10Al-xMn-1.0C alloy. Mater. Trans. 2002, 43, 2635–2642. [Google Scholar] [CrossRef]

- Park, S.W.; Park, J.Y.; Cho, K.M.; Jang, J.H.; Park, S.J.; Moon, J.; Lee, T.H.; Shin, J.H. Effect of Mn and C on Age Hardening of Fe-Mn-Al-C Lightweight Steels. Met. Mater. Int. 2019, 25, 683–696. [Google Scholar] [CrossRef]

- Zargaran, A.; Trang, T.T.T.; Park, G.; Kim, N.J. κ-Carbide assisted nucleation of B2: A novel pathway to develop high specific strength steels. Acta Mater. 2021, 220, 117349. [Google Scholar] [CrossRef]

- Mishra, B.; Sarkar, R.; Singh, V.; Mukhopadhyay, A.; Mathew, R.T.; Madhu, V.; Prasad, M.J.N.V. Microstructure and deformation behaviour of austenitic low-density steels: The defining role of B2 intermetallic phase. Materialia 2021, 20, 101198. [Google Scholar] [CrossRef]

- Yang, M.X.; Yuan, F.P.; Xie, Q.G.; Wang, Y.D.; Ma, E.; Wu, X.L. Strain hardening in Fe-16Mn-10Al-0.86C-5Ni high specific strength steel. Acta Mater. 2016, 109, 213–222. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, K.; Zhang, X.; Liu, H.; Zhang, W.; Wang, J. Microstructure Characteristics, Mechanical Properties and Strain Hardening Behavior of B2 Intermetallic Compound-Strengthening Fe-16Mn-9Al-0.8C-3Ni Steel Fabricated by Twin-Roll Strip Casting, Cold Rolling and Annealing. Materials 2023, 16, 5417. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, H.; Kim, N.J. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature 2015, 518, 77–79. [Google Scholar] [CrossRef]

- Park, G.; Nam, C.H.; Zargaran, A.; Kim, N.J. Effect of B2 morphology on the mechanical properties of B2-strengthened lightweight steels. Scr. Mater. 2019, 165, 68–72. [Google Scholar] [CrossRef]

- Hwang, J.; Trang, T.; Lee, O.; Park, G.; Zargaran, A.; Kim, N.J. Improvement of strength–ductility balance of B2-strengthened lightweight steel. Acta Mater. 2020, 191, 1–12. [Google Scholar] [CrossRef]

- Piston, M.; Bartlett, L.; Limmer, K.R.; Field, D.M. Microstructural Influence on Mechanical Properties of a Lightweight Ultrahigh Strength Fe-18Mn-10Al-0.9C-5Ni (wt%) Steel. Metals 2020, 10, 1305. [Google Scholar] [CrossRef]

- Lv, X.; Wang, X.; Lan, A.; Qiao, J. Synergistic Effect of Al and Ni on Microstructure Evolutions and Mechanical Properties of Fe-Mn-Al-C Low-Density Steels. Metals 2024, 14, 495. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, W.; Zhao, H.; Liebscher, C.H.; He, J.; Ponge, D.; Raabe, D.; Li, Z. Ultrastrong lightweight compositionally complex steels via dual-nanoprecipitation. Sci. Adv. 2020, 6, 9543. [Google Scholar] [CrossRef]

- Wang, J.; Yang, M.; Wu, X.; Yuan, F. Achieving better synergy of strength and ductility by adjusting size and volume fraction of coherent κ′–carbides in a lightweight steel. Mater. Sci. Eng. A 2022, 857, 144085. [Google Scholar] [CrossRef]

- Mishra, B.; Singh, V.; Sarkar, R.; Mukhopadhyay, A.; Gopinath, K.; Madhu, V.; Prasad, M. Dynamic recovery and recrystallization mechanisms in secondary B2 phase and austenite matrix during hot deformation of Fe-Mn-Al-C-(Ni) based austenitic low-density steels. Mater. Sci. Eng. A 2022, 842, 143095. [Google Scholar] [CrossRef]

- Geng, X.; Gao, J.; Huang, Y.; Wang, S.; Zhang, Y.; Wu, G.; Zhao, H.; Wu, H.; Mao, X. A novel dual-heterogeneous-structure ultralight steel with high strength and large ductility. Acta Mater. 2023, 252, 118925. [Google Scholar] [CrossRef]

- An, Y.F.; Chen, X.P.; Ren, P.; Cao, W.Q. Ultrastrong and ductile austenitic lightweight steel via ultra-fine grains and heterogeneous B2 precipitates. Mater. Sci. Eng. A 2022, 860, 144330. [Google Scholar] [CrossRef]

- Zhang, G.F.; Shi, H.Y.; Wang, S.T.; Tang, Y.H.; Zhang, X.Y.; Jing, Q.; Liu, R.P. Ultrahigh strength and high ductility lightweight steel achieved by dual nanoprecipitate strengthening and dynamic slip refinement. Mater. Lett. 2023, 330, 133366. [Google Scholar] [CrossRef]

- Zhang, B.G.; Zhang, X.M.; Liu, H.T. Precipitation behavior of B2 and κ-carbide during aging and its effect on mechanical properties in Al-containing high strength steel. Mater. Charact. 2021, 178, 111291. [Google Scholar] [CrossRef]

- Kies, F.; Wu, X.; Hallstedt, B.; Li, Z.; Haase, C. Enhanced precipitation strengthening of multi-principal element alloys by κ- and B2-phases. Mater. Des. 2021, 198, 109315. [Google Scholar] [CrossRef]

- He, C.; Shen, Y.; Xue, W.; Fan, Z.; Zhou, Y. Nanosized κ-Carbide and B2 Boosting Strength Without Sacrificing Ductility in a Low-Density Fe-32Mn-11Al Steel. Nanomaterials 2025, 15, 48. [Google Scholar] [CrossRef]

- Bai, R.; Du, Y.; He, X.; Zhang, Y. The Influence of Cr Addition on the Microstructure and Mechanical Properties of Fe-25Mn-10Al-1.2C Lightweight Steel. Metals 2024, 14, 687. [Google Scholar] [CrossRef]

- An, Y.F.; Chen, X.P.; Mei, L.; Qiu, Y.C.; Li, Y.Z.; Cao, W.Q. Enhancing strength-ductility balance in Fe-Mn-Al-C-Ni austenitic low-density steel via intragranular dual-nanoprecipitation. J. Mater. Sci. Technol. 2024, 200, 38–51. [Google Scholar] [CrossRef]

- An, Y.F.; Chen, X.P.; Mei, L.; Ren, P.; Wei, D.; Cao, W.Q. Precipitation transformation pathway and mechanical behavior of nanoprecipitation strengthened Fe-Mn-Al-C-Ni austenitic low-density steel. J. Mater. Sci. Technol. 2023, 174, 157–167. [Google Scholar] [CrossRef]

- Piston, M.; Bartlett, L.; Limmer, K.R.; Field, D.M.; Hornbuckle, B.C. Formation of Heterogeneous Nucleation of B2-NiAl in Hot Rolled Fe-Mn-Al-C Plate: A Novel Composition and Processing Route for Lightweight High Strength Steel Containing Nickel. Metals 2024, 14, 1342. [Google Scholar] [CrossRef]

- Ren, X.; Li, Y.; Qi, Y.; Wang, C. Effect of Micro-Alloyed/Alloyed Elements on Microstructure and Properties of Fe-Mn-Al-C Lightweight Steel. Metals 2022, 12, 695. [Google Scholar] [CrossRef]

- Liu, M.; Zhou, J.; Zhang, J.; Song, C.; Zhai, Q. Ultra-high strength medium-Mn lightweight steel by dislocation slip band refinement and suppressed intergranular κ-carbide with Cr addition. Mater. Charact. 2022, 190, 112042. [Google Scholar] [CrossRef]

- Choi, W.S.; De Cooman, B.C.; Sandlöbes, S.; Raabe, D. Size and orientation effects in partial dislocation-mediated deformation of twinning-induced plasticity steel micro-pillars. Acta Mater. 2015, 98, 391–404. [Google Scholar] [CrossRef]

- Bouaziz, O.; Zurob, H.; Chehab, B.; Embury, J.; Allain, S.; Huang, M. Effect of chemical composition on work hardening of Fe-Mn-C TWIP steels. Mater. Sci. Technol. 2011, 27, 707–709. [Google Scholar] [CrossRef]

- Jung, I.-C.; De Cooman, B.C. Temperature dependence of the flow stress of Fe-18Mn-0.6C-xAl twinning-induced plasticity steel. Acta Mater. 2013, 61, 6724–6735. [Google Scholar] [CrossRef]

- Sieurin, H.; Zander, J.; Sandström, R. Modelling solid solution hardening in stainless steels. Mater. Sci. Eng. A 2006, 415, 66–71. [Google Scholar] [CrossRef]

- Etienne, A.; Massardier-Jourdan, V.; Cazottes, S.; Garat, X.; Soler, M.; Zuazo, I.; Kleber, X. Ferrite effects in Fe-Mn-Al-C triplex steels. Metall. Mater. Trans. A 2014, 45, 324–334. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

- Crimp, M.A.; Vedula, K.M. The relationship between cooling rate, grain size and the mechanical behavior of B2 Fe-Al alloys. Mater. Sci. Eng. A 1993, 165, 29–34. [Google Scholar] [CrossRef]

- Welsch, E.; Ponge, D.; Haghighat, S.H.; Sandlöbes, S.; Choi, P.; Herbig, M.; Zaefferer, S.; Raabe, D. Strain hardening by dynamic slip band refinement in a high-Mn lightweight steel. Acta Mater. 2016, 116, 188–199. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- He, J.; Wang, H.; Huang, H.; Xu, X.; Chen, M.; Wu, Y.; Liu, X.; Nieh, T.; An, K.; Lu, Z. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Song, H.; Yoo, J.; Kim, S.-H.; Sohn, S.S.; Koo, M.; Kim, N.J.; Lee, S. Novel ultra-high-strength Cu-containing medium-Mn duplex lightweight steels. Acta Mater. 2017, 135, 215–225. [Google Scholar] [CrossRef]

- Li, P.; Sun, H.L.; Xiao, N.; Ding, H.; Guo, X.F. Optimizing the synergy of strength and ductility in a Fe-18Mn-8Al-1C-5Ni lightweight steel by adjusting the distribution, volume fraction and size of B2 phases and κ-carbides. J. Mater. Res. Technol. 2025, 34, 501–510. [Google Scholar] [CrossRef]

- Mishra, B.; Sarkar, R.; Singh, V.; Kumar, D.; Mukhopadhyay, A.; Madhu, V.; Prasad, M. Effect of cold rolling and subsequent heat treatment on microstructural evolution and mechanical properties of Fe-Mn-Al-C-(Ni) based austenitic low-density steels. Mater. Sci. Eng. A 2022, 861, 144324. [Google Scholar] [CrossRef]

- Zhang, G.; Ma, W.; Tang, Y.; Wang, F.; Zhang, X.; Wang, Q.; Liu, R. Investigation on the microstructural evolution and mechanical properties of partially recrystallized Fe-27Mn-10Al-1.4C steel. Mater. Sci. Eng. A 2022, 833, 142545. [Google Scholar] [CrossRef]

| Sample | RC | B2 | |||

|---|---|---|---|---|---|

| Austenite | Ferrite | GB | Matrix | ||

| A900-3 | Fraction (%) | 51.7 | 6.8 | 4.5 | 5.0 |

| Size (μm) | 1.1 | 2.7 | 0.41 | 0.18 | |

| A900-15 | Fraction (%) | 79.3 | 6.8 | 5.3 | 3.6 |

| Size (μm) | 1.6 | 3.2 | 0.88 | 0.33 | |

| Sample | σ0 (MPa) | σs (MPa) | σg (MPa) | σp (MPa) | σd (MPa) | σYS (MPa) (Est.) | σYS (MPa) (Exp.) |

|---|---|---|---|---|---|---|---|

| A900-3 | 97 | 326 | 227 | 167 | 144 | 961 | 1218 |

| A900-15 | 97 | 328 | 289 | 126 | 23 | 863 | 1130 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, R.; Li, Y.; Du, Y.; Zhang, Y.; He, X.; Liang, H. Achieving High Specific Strength via Multiple Strengthening Mechanisms in an Fe-Mn-Al-C-Ni-Cr Lightweight Steel. Materials 2025, 18, 4023. https://doi.org/10.3390/ma18174023

Bai R, Li Y, Du Y, Zhang Y, He X, Liang H. Achieving High Specific Strength via Multiple Strengthening Mechanisms in an Fe-Mn-Al-C-Ni-Cr Lightweight Steel. Materials. 2025; 18(17):4023. https://doi.org/10.3390/ma18174023

Chicago/Turabian StyleBai, Rui, Ying Li, Yunfei Du, Yaqin Zhang, Xiuli He, and Hongyu Liang. 2025. "Achieving High Specific Strength via Multiple Strengthening Mechanisms in an Fe-Mn-Al-C-Ni-Cr Lightweight Steel" Materials 18, no. 17: 4023. https://doi.org/10.3390/ma18174023

APA StyleBai, R., Li, Y., Du, Y., Zhang, Y., He, X., & Liang, H. (2025). Achieving High Specific Strength via Multiple Strengthening Mechanisms in an Fe-Mn-Al-C-Ni-Cr Lightweight Steel. Materials, 18(17), 4023. https://doi.org/10.3390/ma18174023