Features of the Solid HDDR Process in Sintered (Nd,Pr,Gd)-Fe-B Magnets at Low Hydrogen Pressure and Low Temperature

Abstract

1. Introduction

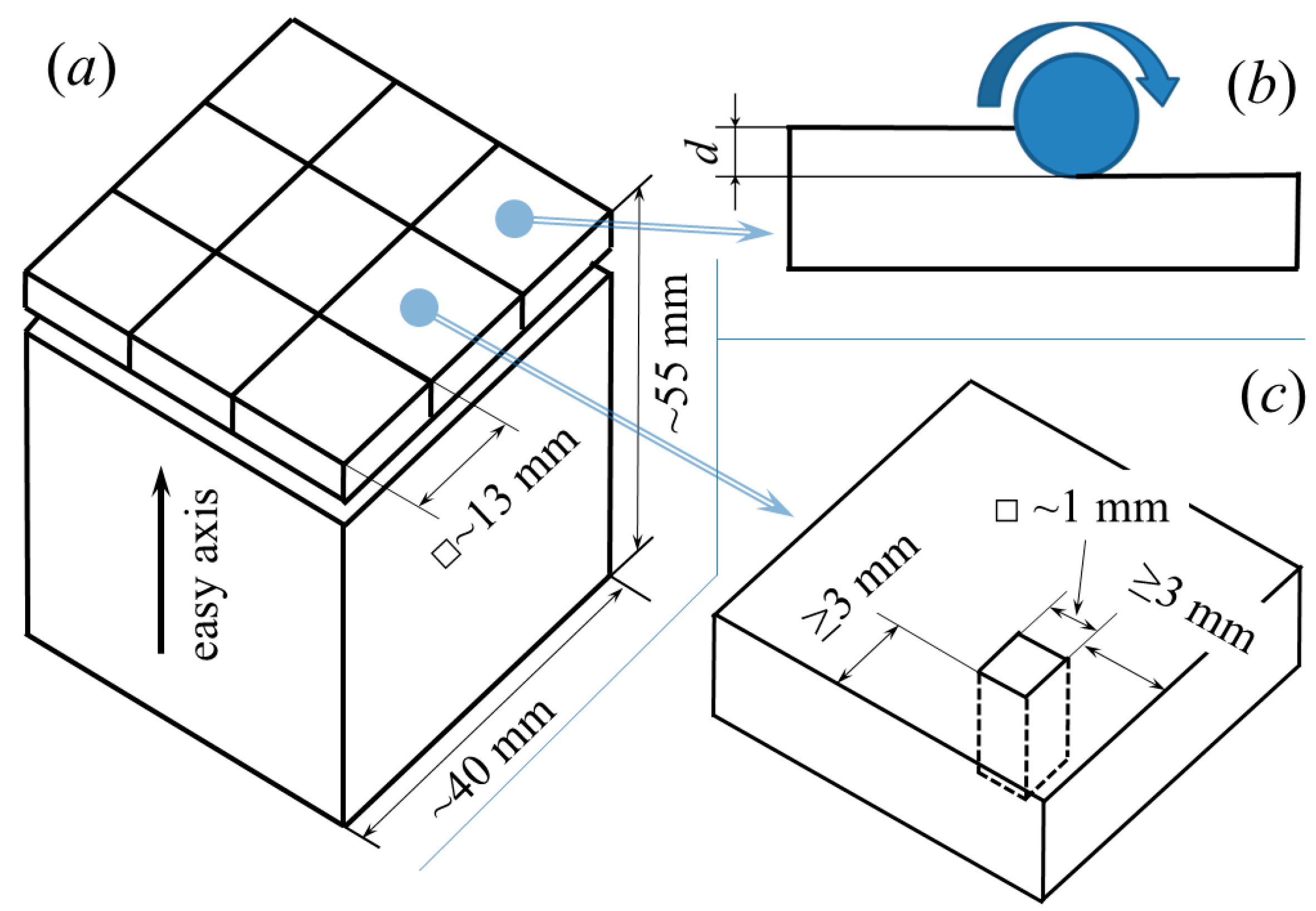

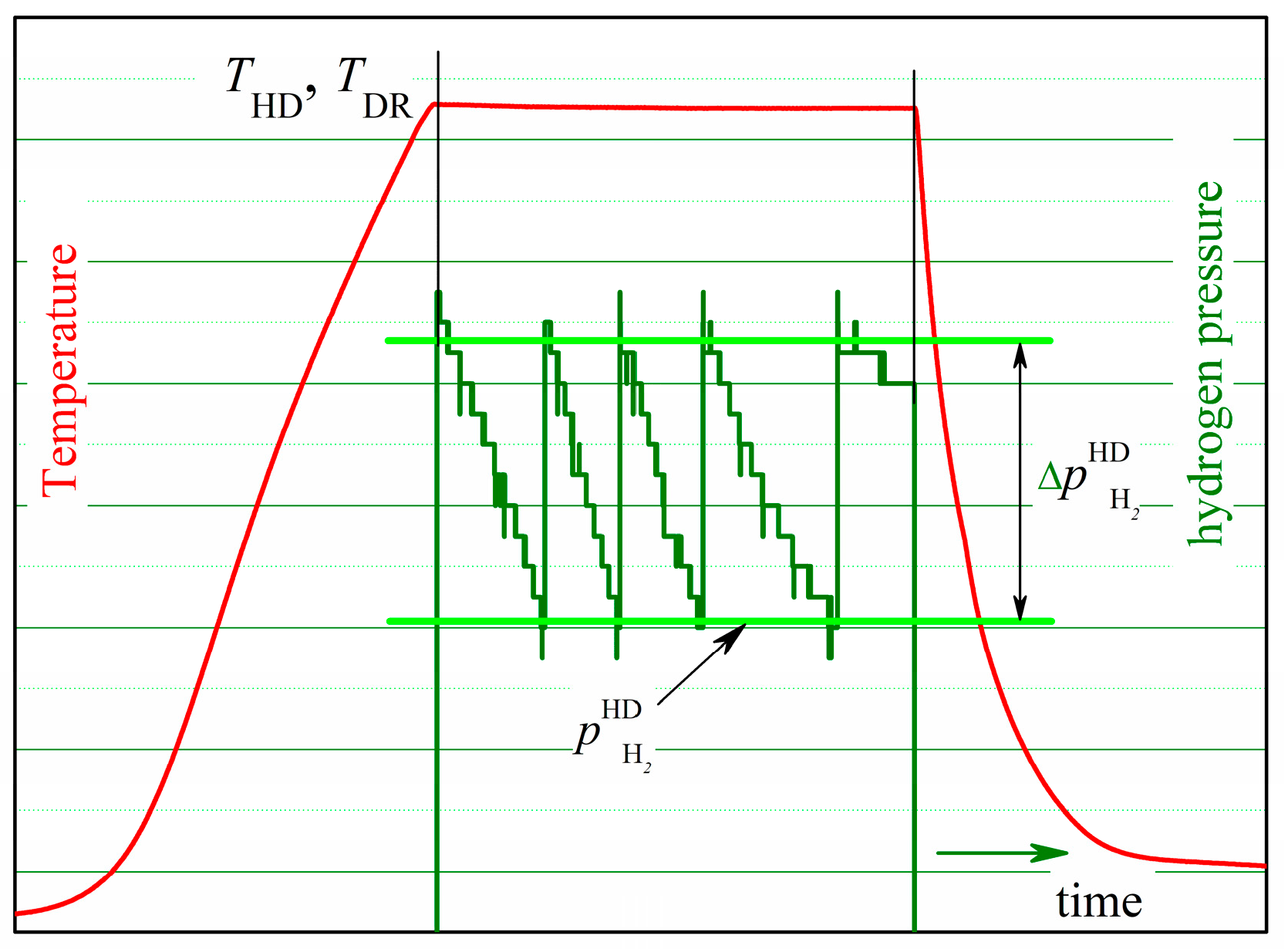

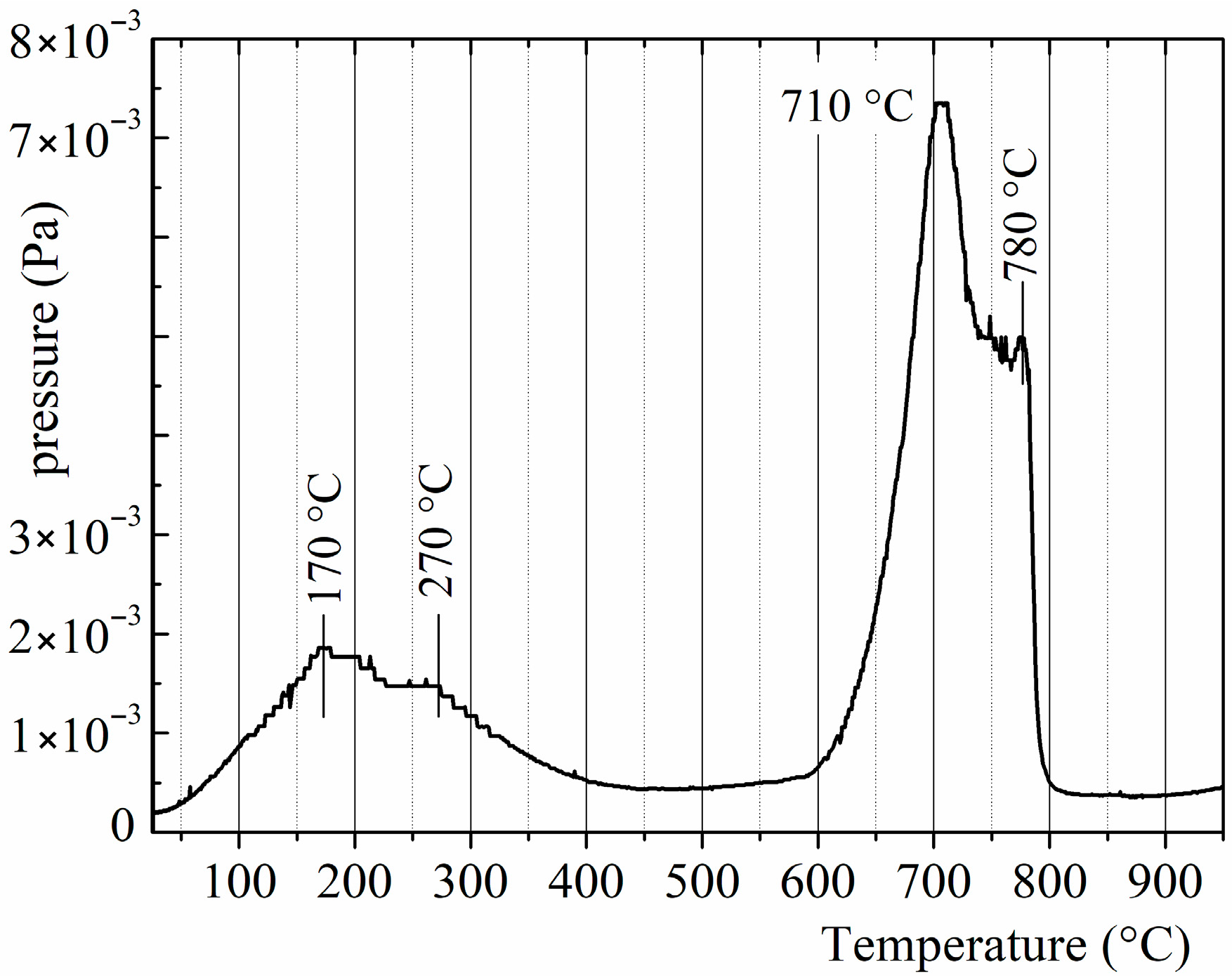

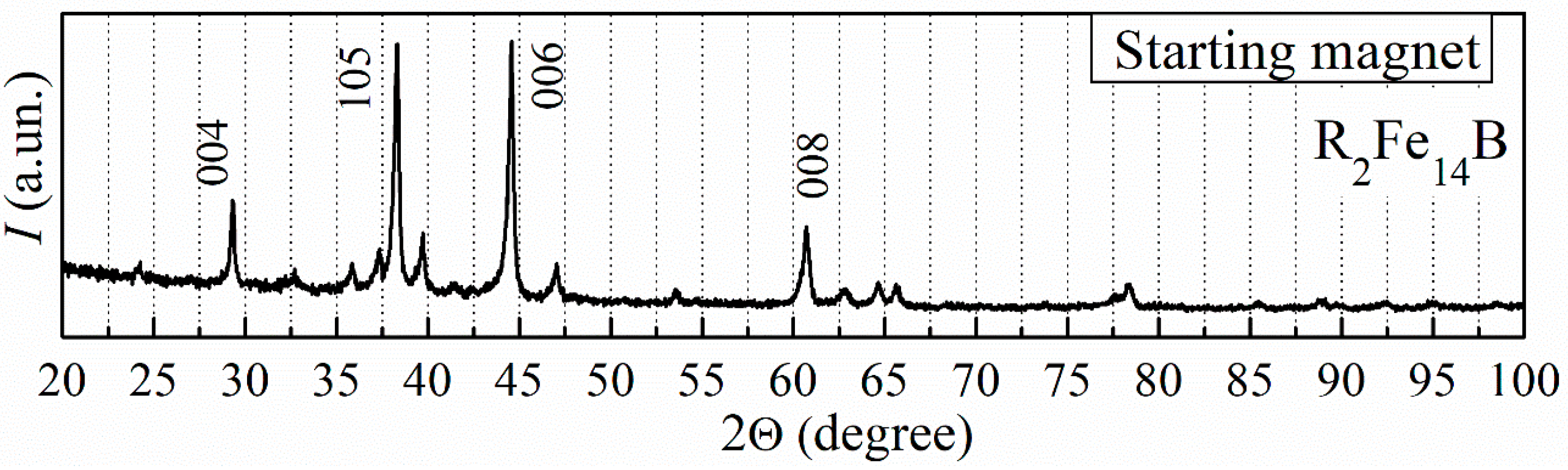

2. Materials and Methods

3. Results

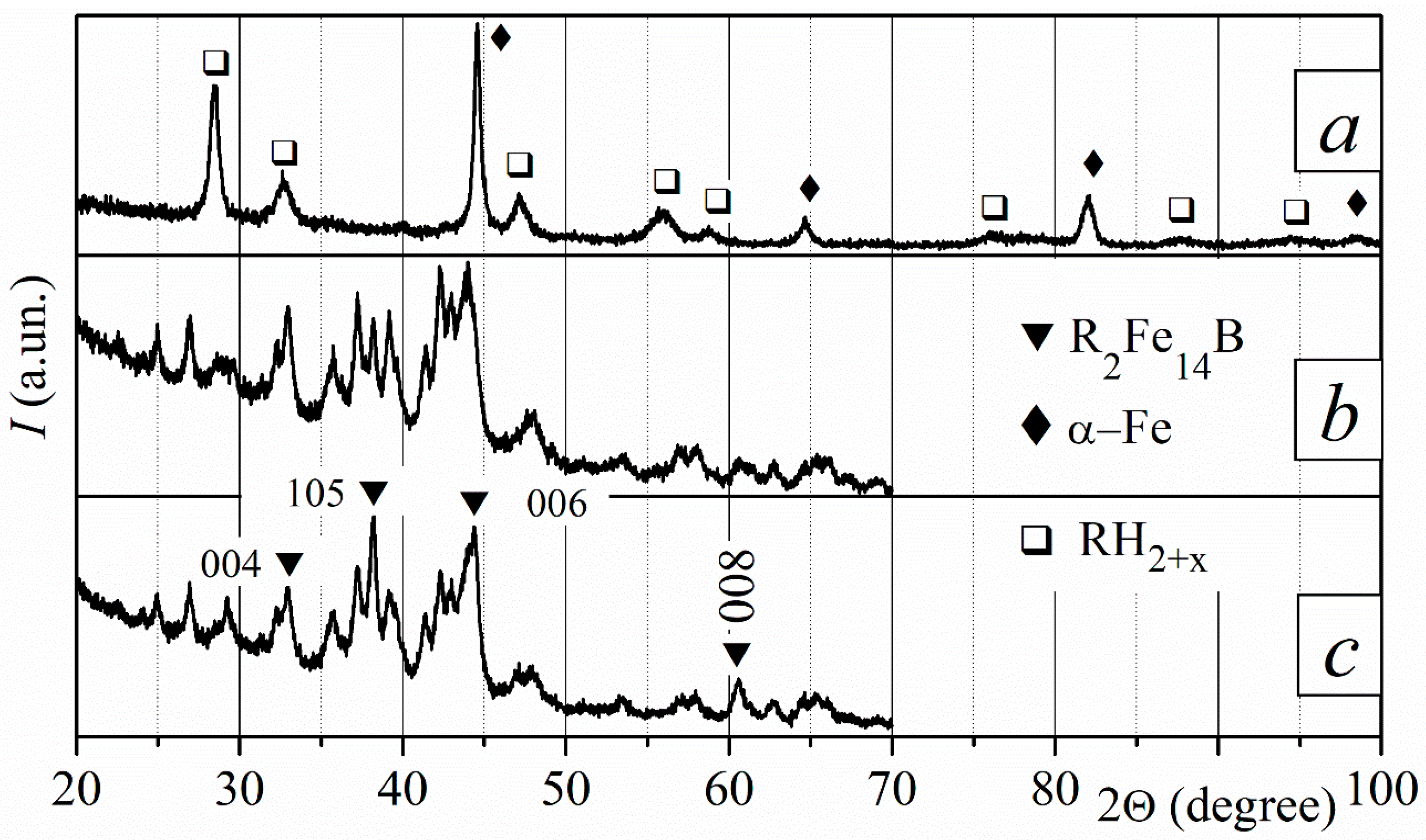

3.1. Phase Composition of Starting Magnets

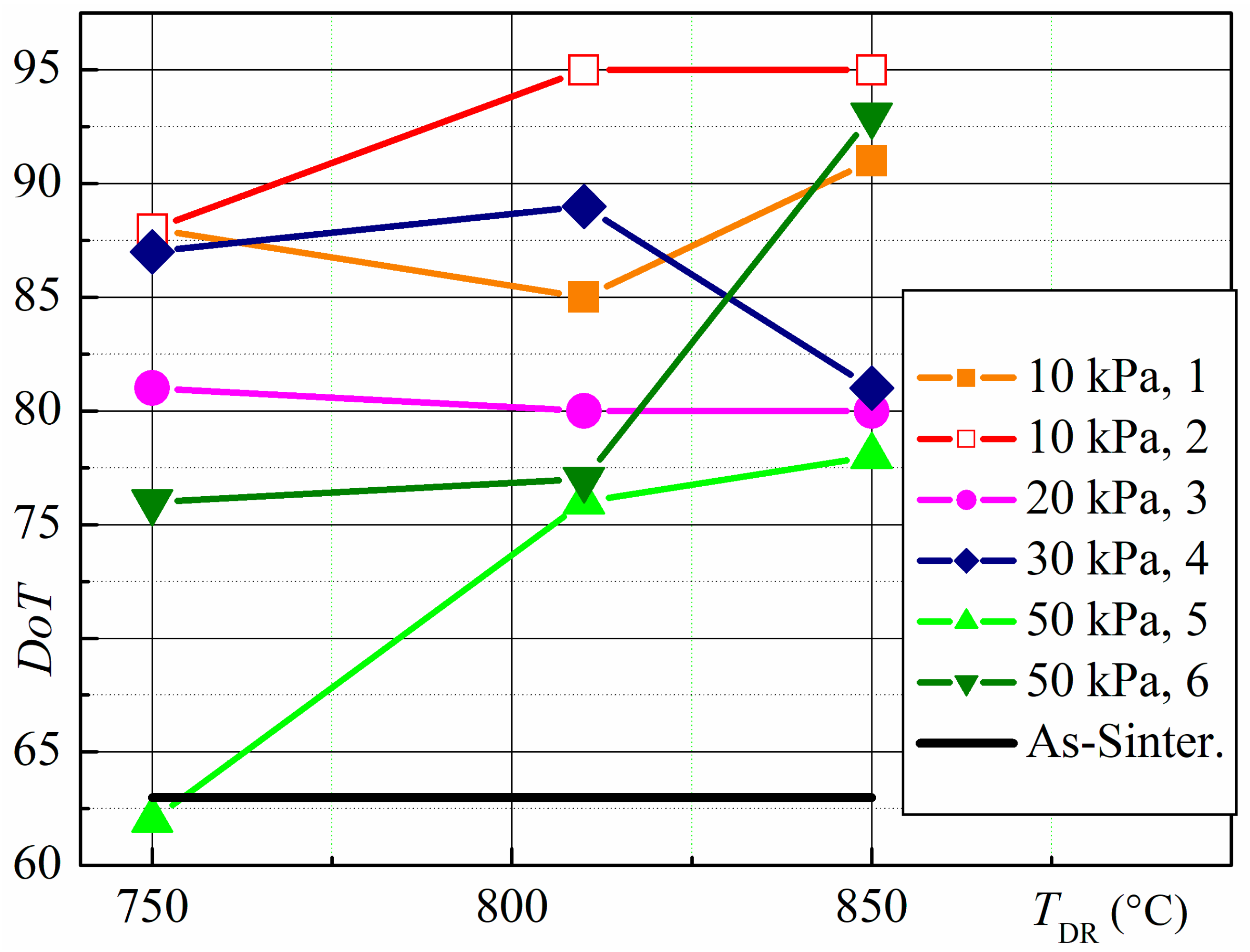

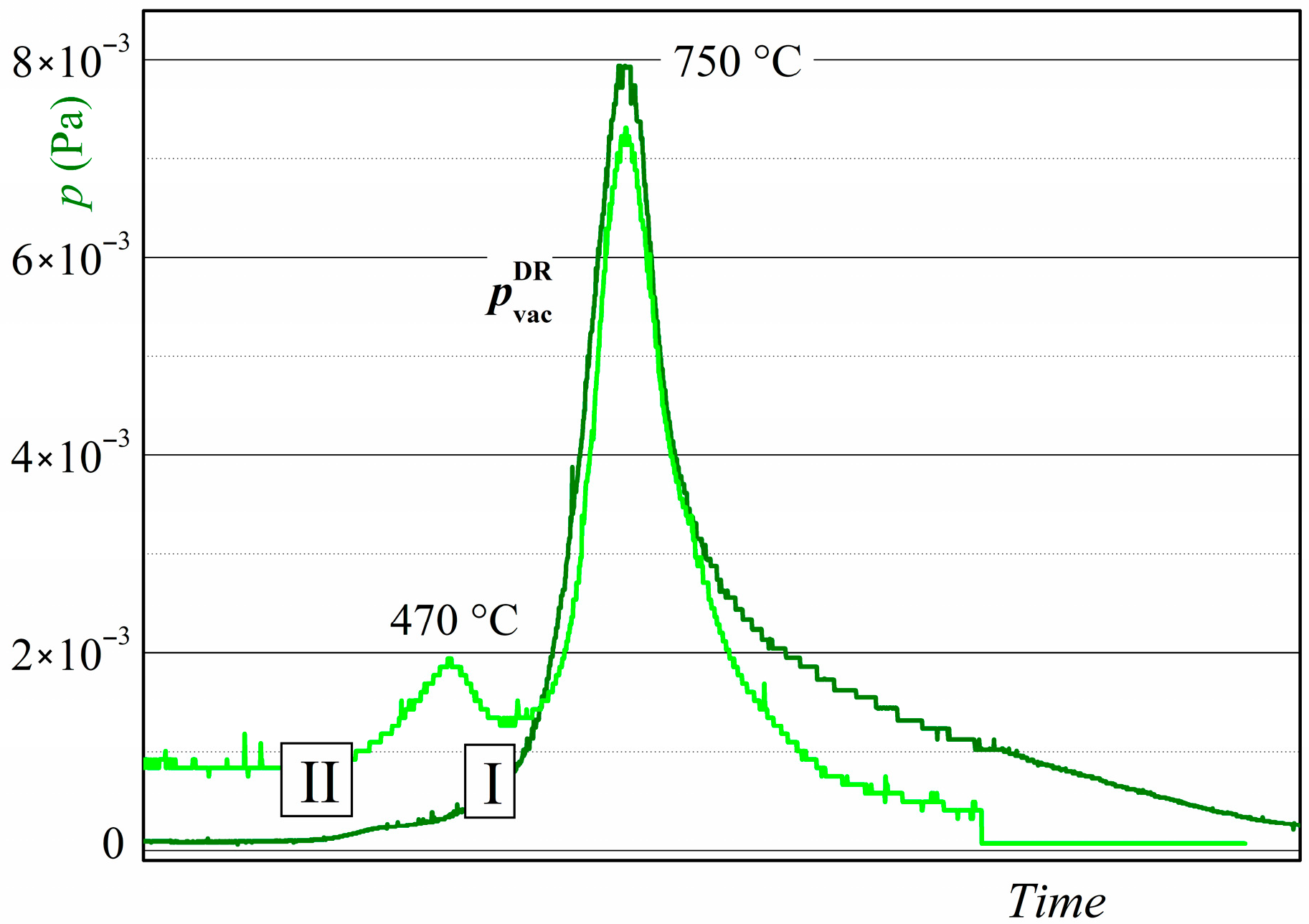

3.2. Interaction of Sintered Magnets with Hydrogen at 10 kPa

3.3. Interaction of Sintered Magnets with Hydrogen at 20 kPa

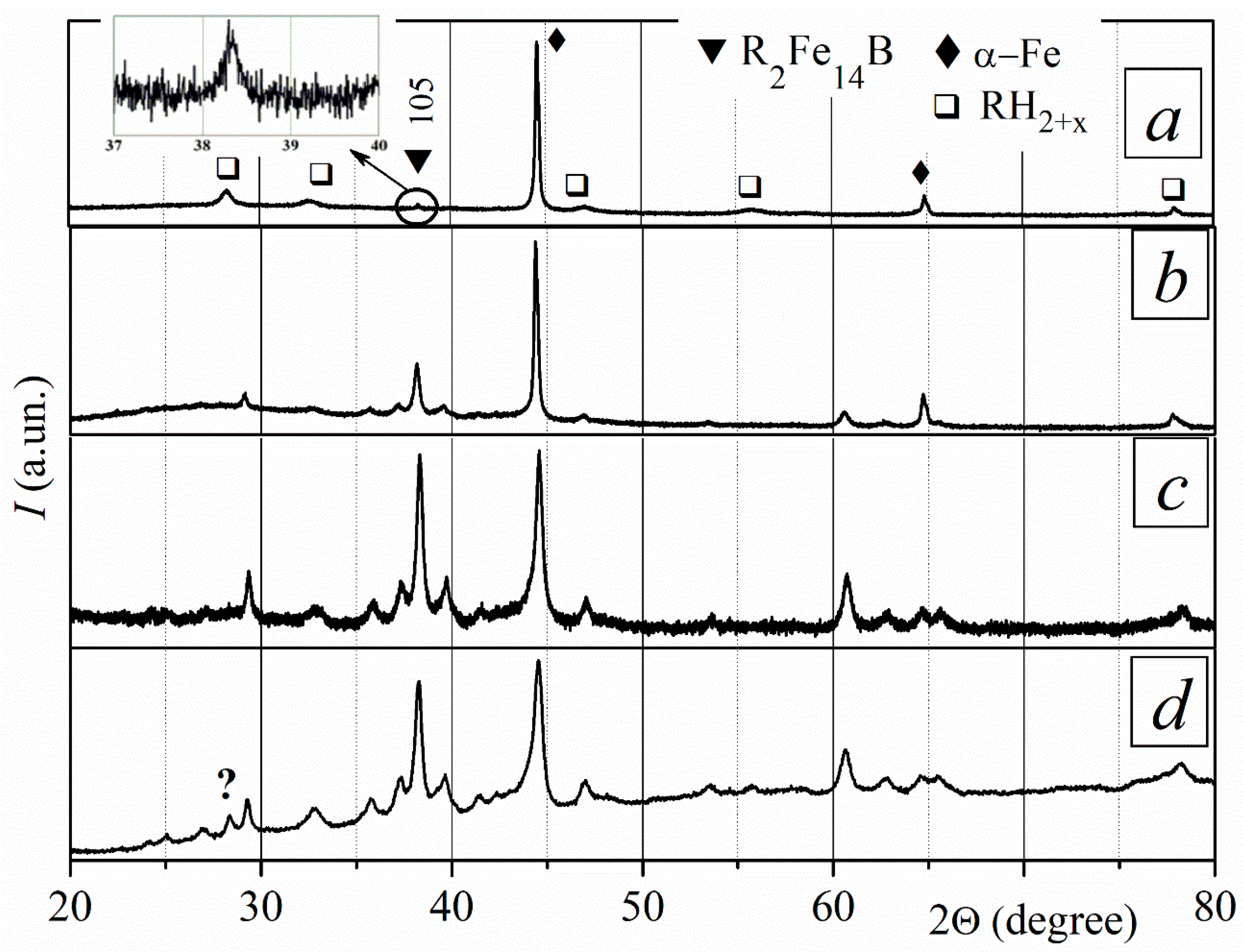

3.4. Interaction of Sintered Magnets with Hydrogen at 30 kPa

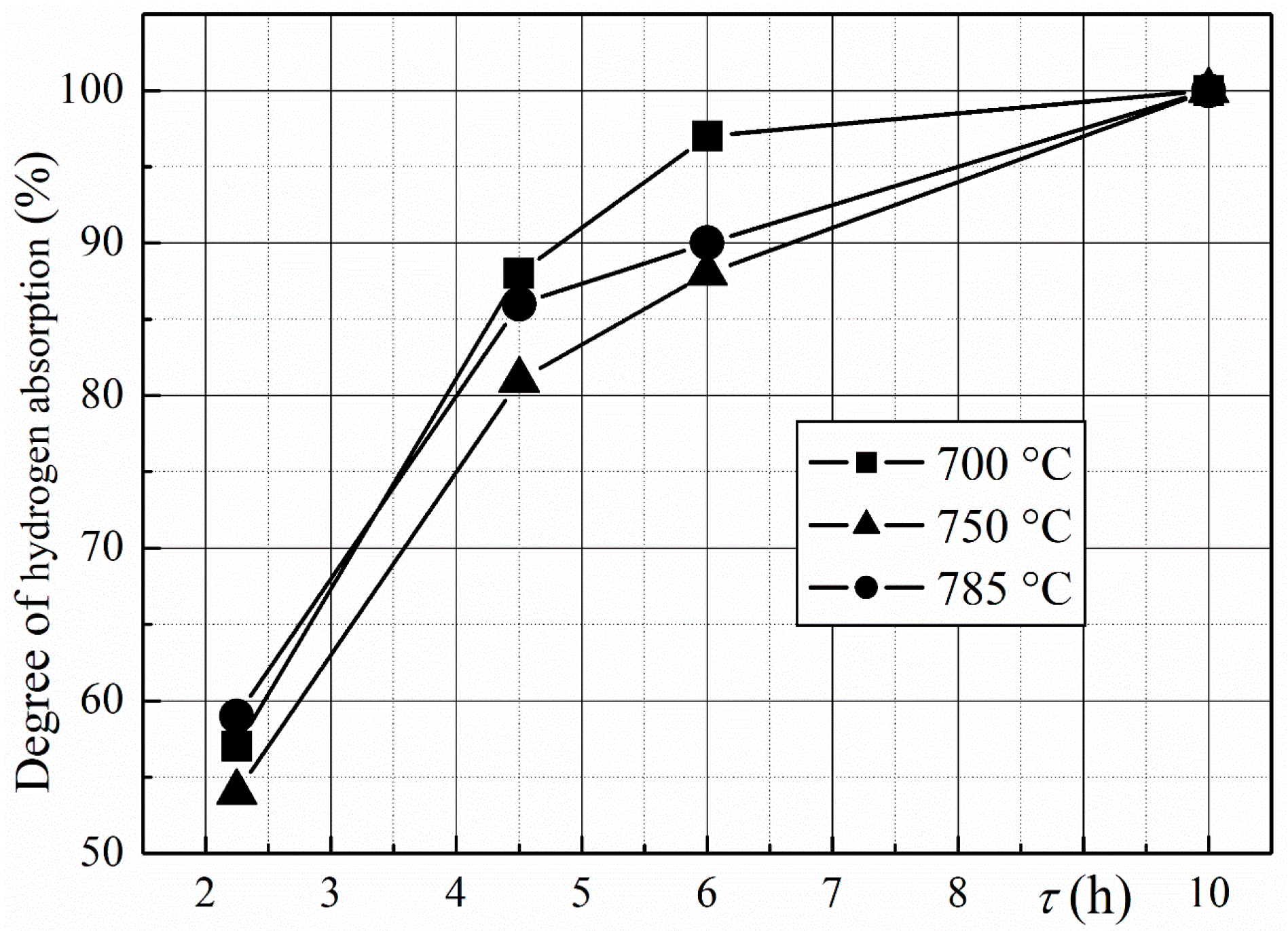

3.5. Peculiarities of the HDDR Process in Sintered Magnets at Hydrogen Pressure of 50 kPa—The Dependence of the Phase—Structure State of the Materials at the Different Depths in the Samples on the Disproportionation Temperature and Reaction Time

3.5.1. Disproportionation Temperature of 700 °C

3.5.2. Disproportionation Temperature of 750 °C

3.5.3. Disproportionation Temperature of 785 °C

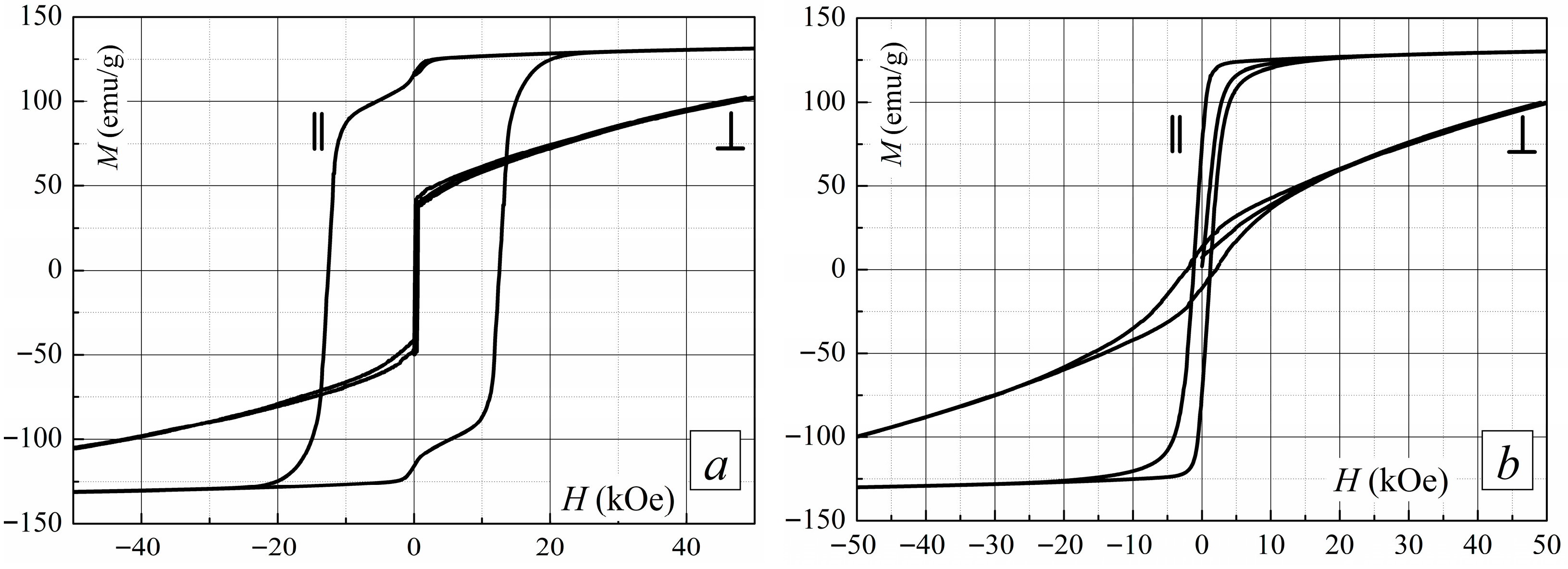

3.6. Magnetic Properties of Sintered R-Fe-B Magnet and Magnet After HDDR

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sagawa, M.; Fujimura, S.; Togawa, N.; Yamamoto, H.; Matsuura, Y. New material for permanent magnets on a base of Nd and Fe (invited). J. Appl. Phys. 1984, 55, 2083–2087. [Google Scholar] [CrossRef]

- Constantinides, S. Permanent Magnets in a Changing World Market. Magnetics Magazine: Business and Technology (Spring 2016, 26 February 2016). Available online: http://www.magneticsmagazine.com/main/articles/permanent-magnets-in-a-changing-world-market (accessed on 21 November 2022).

- REN21. Renewables 2022 Global Status Report (Paris: REN21 Secretariat), 50, 65, 68. 2022. Available online: https://www.ren21.net/wp-content/uploads/2019/05/GSR2022_Full_Report.pdf (accessed on 21 November 2022).

- Cui, J.; Kramer, M.; Zhou, L.; Liu, F.; Gabay, A.; Hadjipanayis, G.; Balasubramanian, B.; Sellmyer, D. Current progress and future challenges in rare-earth-free permanent magnets. Acta Mater. 2018, 158, 118–137. [Google Scholar] [CrossRef]

- Nieves, P.; Arapan, S.; Maudes-Raedo, J.; Marticorena-Sánchez, R.; Del Brío, N.L.; Kovacs, A.; Echevarria-Bonet, C.; Salazar, D.; Weischenberg, J.; Zhang, H.; et al. Database of novel magnetic materials for high-performance permanent magnet development. Comput. Mater. Sci. 2019, 168, 188–202. [Google Scholar] [CrossRef]

- Coey, J.M.D. Perspective and Prospects for Rare Earth Permanent Magnets. Engineering 2020, 6, 119–131. [Google Scholar] [CrossRef]

- Liu, J.P. Exchange-Coupled Nanocomposite Permanent Magnets. In Nanoscale Magnetic Materials and Applications; Liu, J.P., Fullerton, E., Gutfleisch, O., Sellmyer, D.J., Eds.; Springer: London, UK, 2009; pp. 309–336. [Google Scholar]

- Poudyal, N.; Liu, J.P. Advances in nanostructured permanent magnets research. J. Phys. D Appl. Phys. 2013, 46, 043001. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Hirosawa, S.; Hono, K. Advances in Nd-Fe-B Based Permanent Magnets. In Handbook of Magnetic Materials; Brück, E., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 27, pp. 269–372. [Google Scholar]

- Gutfleisch, O.; Harris, I.R. Fundamental and practical aspects of the hydrogenation, disproportionation, desorption and recombination process. J. Phys. D: Appl. Phys. 1996, 29, 2255–2265. [Google Scholar] [CrossRef]

- Cannesan, N.; Harris, I.R. Aspects of NdFeB HDDR Powders: Fundamentals and Processing. In Proceedings of the NATO Advanced Research Workshop on Science and Technology of Bonded Magnets, Newark, NJ, USA, 22–25 August 2002; Series II; Mathematics, Physics and Chemistry. Hadjipanayis, G.C., Ed.; Springer: Berlin/Heidelberg, Germany, 2002; Volume 118, pp. 13–36. [Google Scholar]

- Tao, S.; Tian, J.; Lu, X.; Qu, X.; Honkura, Y.; Mitarai, H.; Noguchi, K. Anisotropic bonded NdFeB magnets with radial oriented magnetization by 2-step warm compaction process. J. Alloys Compd. 2009, 477, 510–514. [Google Scholar] [CrossRef]

- Yang, Y.; Walton, A.; Sheridan, R.; Güth, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.-M.; Van Gerven, T.; Jones, P.T.; et al. REE Recovery from End-of-Life NdFeB Permanent Magnet Scrap: A Critical Review. J. Sustain. Metall. 2017, 3, 122–149. [Google Scholar] [CrossRef]

- Bulyk, I.I.; Burkhovetskyy, V.V. Variation in microstructure of ground SmCo5 alloy during disproportionation in hydrogen and recombination. Powder Metall. Met. Ceram. 2016, 54, 614–623. [Google Scholar] [CrossRef]

- Bulyk, I.I. Application of hydrogen in the production of sintered anisotropic nanostructured magnets from alloys of rare-earth and transition metals. Mater. Sci. 2019, 54, 761–775. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Dirba, I.; Tang, X.; Ohkubo, T.; Schrefl, T.; Gutfleisch, O.; Hono, K. Development of high coercivity anisotropic Nd-Fe-B/Fe nanocomposite powder using hydrogenation disproportionation desorption recombination process. Acta Mater. 2019, 175, 276–285. [Google Scholar] [CrossRef]

- Ikram, A.; Mehmood, M.F.; Samardžija, Z.; Sheridan, R.S.; Awais, M.; Walton, A.; Sturm, S.; Kobe, S.; Žužek Rožman, K. Coercivity increase of the recycled HDDR Nd–Fe–B powders doped with DyF3 and processed via spark plasma sintering & the effect of thermal treatments. Materials 2019, 12, 1498. [Google Scholar]

- Trostianchyn, A.; Bulyk, I.; Duriagina, Z. The influence of iron content on the phase structural state of the alloy based on Sm2Co17 compound during hydrogen vacuum treatment. Function. Mater. 2021, 28, 497–504. [Google Scholar]

- Bulyk, I.I.; Kononiuk, O.P. Sintering of ferromagnetic materials at lower temperatures in hydrogen I. Sm2Co17 alloys. Powder Metall. Met. Ceram. 2023, 61, 548–559. [Google Scholar] [CrossRef]

- Bulyk, I.I.; Borukh, I.V. Sintering of ferromagnetic materials at lower temperatures in hydrogen. II. Nd–Fe–B alloys. Powder Metall. Met. Ceram. 2023, 61, 657–669. [Google Scholar] [CrossRef]

- Kubis, M.; Handstein, A.; Gebel, B.; Gutfleisch, O.; Muller, K.-H.; Schultz, L. Highly coercive SmCo5 magnets prepared by a modified hydrogenation-disproportionation-desorption-recombination process. J. Appl. Phys. 1999, 85, 5666–5668. [Google Scholar] [CrossRef]

- Bulyk, I.I.; Chabanenko, V.V.; Nabiałek, A.; Zajarniuk, T.; Szewczyk, A.; Puz’niak, R.; Burkhovetskyi, V.V.; Tarenkov, V.Y.; Wr’obel, J.; Borukh, I.V. Enhanced coercivity in SmCo5 magnet subjected to hydrogen treatment. J. Alloys Compd. 2021, 866, 158272. [Google Scholar] [CrossRef]

- Hono, K.; Sepehri-Amin, H. Strategy for high-coercivity Nd–Fe–B magnets. Scr. Mater. 2012, 67, 530–535. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Martinez, N.; Verdier, M.; Harris, I.R. Phase transformations during the disproportionation stage in the solid HDDR process in a Nd16Fe76B8 alloy. J. Alloys Compd. 1994, 215, 227–233. [Google Scholar] [CrossRef]

- Bulyk, I.I.; Luo, S.; Ur Rehman, S.; Zhong, S.; Yang, M. Peculiarities of conventional HDDR process in R-Fe-B alloy powders under low hydrogen pressure. Intermetallics 2022, 148, 107621. [Google Scholar] [CrossRef]

- Available online: http://www.ccp14.cryst.bbk.ac.uk/ccp/web-mirrors/powdcell/a_v/v_1/powder/e_cell.html (accessed on 14 August 2025).

- Fang, L.; Zhang, T.; Wang, H.; Jiang, C.; Liu, J. Effect of ball milling process on coercivity of nanocrystalline SmCo5 magnets. J. Magn. Magn. Mater. 2018, 446, 200–205. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Matzinger, M.; Fidler, J.; Harris, I.R. Characterisation of solid-HDDR processed Nd16Fe76B8 alloys by means of electron microscopy. J. Magn. Magn. Mater. 1995, 147, 320–330. [Google Scholar] [CrossRef]

- Didus, V.A.; Rybalka, S.B.; Dodonova, E.V.; Goltsov, V.A. The effect of hydrogen pressure and temperature on kinetics of hydrogen-induced direct phase transformation in hard magnetic alloy. J. Alloys Compd. 2005, 404–406, 351–354. [Google Scholar] [CrossRef]

- Bulyk, I.I.; Trostianchyn, A.M.; Lyutyy, P.Y. Influence of the time of interaction of an alloy based on SmCo5 with low-pressure hydrogen on the phase composition. Mater. Sci. 2012, 48, 316–322. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Ohkubo, T.; Hono, K.; Güth, K.; Gutfleisch, O. Mechanism of the texture development in hydrogen-disproportionation–desorption-recombination (HDDR) processed Nd–Fe–B powders. Acta Mater. 2015, 85, 42–52. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Li, W.F.; Ohkubo, T.; Nishiuchi, T.; Hirosawa, S.; Hono, K. Effect of Ga addition on the microstructure and magnetic properties of hydrogenation–disproportionation–desorption–recombination processed Nd–Fe–B powder. Acta Mater. 2010, 58, 1309–1316. [Google Scholar] [CrossRef]

- Lixandru, A.; Poenaru, I.; Güth, K.; Gauß, R.; Gutfleisch, O. A systematic study of HDDR processing conditions for the recycling of end-of-life Nd-Fe-B magnets. J. Alloys Compd. 2017, 724, 51–61. [Google Scholar] [CrossRef]

- Gűth, K.; Woodcock, T.G.; Schultz, L.; Gutfleisch, O. Comparison of local and global texture in HDDR processed Nd–Fe–B magnets. Acta Mater. 2011, 59, 2029–2034. [Google Scholar] [CrossRef]

- Song, T.; Tang, X.; Yin, W.; Chen, R.; Yan, A. Coercivity enhancement of hot-pressed magnet prepared by HDDR Nd-Fe-B powders using Pr-Cu eutectic alloys diffusion. J. Magn. Magn. Mater. 2019, 471, 105–109. [Google Scholar] [CrossRef]

- Morimoto, K.; Katayama, N.; Akamine, H.; Itakura, M. Coercivity enhancement of anisotropic Dy-free Nd–Fe–B powders by conventional HDDR process. J. Magn. Magn. Mater. 2012, 324, 3723–3726. [Google Scholar] [CrossRef]

- Song, T.; Wang, H.; Tang, X.; Yin, W.; Wang, Z.; Ju, J.; Chen, R.; Yan, A. The effects of Nd-rich phase distribution on deformation ability of hydrogenation-disproportionation-desorption-recombination powders and magnetic properties of the final die-upset Nd-Fe-B magnets. J. Magn. Magn. Mater. 2019, 476, 194–198. [Google Scholar] [CrossRef]

- Zeng, J.; Wang, H.; Guo, S.; Chen, R.; Yang, X.; Di, J.; Ding, G.; Yan, A. Surface nanocrystallization of sintered Nd-Fe-B magnet by HDDR process. Mater. Design. 2019, 180, 107938. [Google Scholar] [CrossRef]

- Wan, F.; Han, J.; Zhang, Y.; Wang, C.; Liu, S.; Yang, J.; Yang, Y.; Sun, A.; Yang, F.; Song, R. Coercivity enhancement in HDDR near-stoichiometric ternary Nd–Fe–B powders. J. Magn. Magn. Mater. 2014, 360, 48–51. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Khlopkov, K.; Teresiak, A.; Müller, K.-H.; Drazic, G.; Mishima, C.; Honkura, Y. Memory of Texture During HDDR Processing of NdFeB. IEEE Trans. Magn. 2003, 39, 2926–2931. [Google Scholar] [CrossRef]

- Honkura, Y.; Mishima, C.; Hamada, N.; Drazic, G.; Gutfleisch, O. Texture memory effect of Nd–Fe–B during hydrogen treatment. J. Magn. Magn. Mater. 2005, 290–291, 1282–1285. [Google Scholar] [CrossRef]

- Kwon, H.-W.; Kim, J.-H. Effect of hydrogen pressure on anisotropy of HDDR-treated Nd–Fe–B-type powder. J. Magn. Magn. Mater. 2006, 304, e222–e224. [Google Scholar] [CrossRef]

- Horikawa, T.; Yamazaki, M.; Mishima, C.; Matsuura, M.; Sugimoto, S. Magnetic anisotropy and crystallographic alignment in Fe and NdH2 during d-HDDR process of Nd-Fe-B-Ga-Nb powders. AIP Adv. 2019, 9, 035244. [Google Scholar] [CrossRef]

- Horikawa, T.; Matsuura, M.; Sugimoto, S.; Yamazaki, M.; Mishima, C. Crystallographic alignment in the recombination stage in d-HDDR process of Nd-Fe-B-Ga-Nb powders. AIP Adv. 2016, 6, 056017. [Google Scholar] [CrossRef]

- Szymanski, M.; Michalski, B.; Jezierska, E.; Leonowicz, M.; Miazga, Z. Hydrogen disproportionation phase diagram and magnetic properties for Nd15Fe79B6 alloy. J. Rare Earths 2016, 34, 843–849. [Google Scholar] [CrossRef]

- Liu, M.; Han, G.B.; Gao, R.W. Anisotropic HDDR Nd–Fe–B magnetic powders prepared directly from strip casting alloy flakes. J. Alloys Compd. 2009, 488, 310–313. [Google Scholar] [CrossRef]

- Liu, M.; Xiao, R.; Gao, R.W.; Han, G.B. Origin of anisotropy for the HDDR Nd13.5Fe79.5B7 magnetic powders. Phys. B Condens. Matter 2011, 406, 3534–3537. [Google Scholar] [CrossRef]

- Kim, T.-H.; Oh, J.-S.; Cha, H.-R.; Lee, J.-G.; Kwon, H.-W.; Yang, C.-W. Direct observation of texture memory in hydrogenation–disproportionation–desorption–recombination processed Nd-Fe-B magnets using electron backscatter diffraction. Scr. Mater. 2016, 115, 6–9. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kang, M.-C.; Lee, J.-G.; Kwon, H.-W.; Kim, D.S.; Yang, C.-W. Crystallographic alignment of Fe2B and Nd2Fe14B for texture memory in hydrogenation-disproportionation-desorption-recombination processed Nd-Fe-B powders. J. Alloys Compd. 2018, 732, 32–42. [Google Scholar] [CrossRef]

- Poenaru, I.; Lixandru, A.; Güth, K.; Malfliet, A.; Yoon, S.; Skulj, I.; Gutfleisch, O. HDDR treatment of Ce-substituted Nd2Fe14B-based permanent magnet alloys-phase structure evolution, intergranular processes and magnetic property development. J. Alloys Compd. 2020, 814, 152215. [Google Scholar] [CrossRef]

- Book, D.; Harris, I.R. Hydrogen absorption/desorption and HDDR studies on Nd16Fe76B8 and Nd11.8Fe82.3B5.9. J. Alloys Comp. 1995, 221, 187–192. [Google Scholar] [CrossRef]

- Yartys, V.A.; Gutfleisch, O.; Panasyuk, V.V.; Harris, I.R. Desorption characteristics of rare earth (R) hydrides (R = Y, Ce, Pr, Nd, Sm, Gd and Tb) in relation to the HDDR behaviour of R–Fe-based compounds. J. Alloys Comp. 1997, 253–254, 128–133. [Google Scholar] [CrossRef]

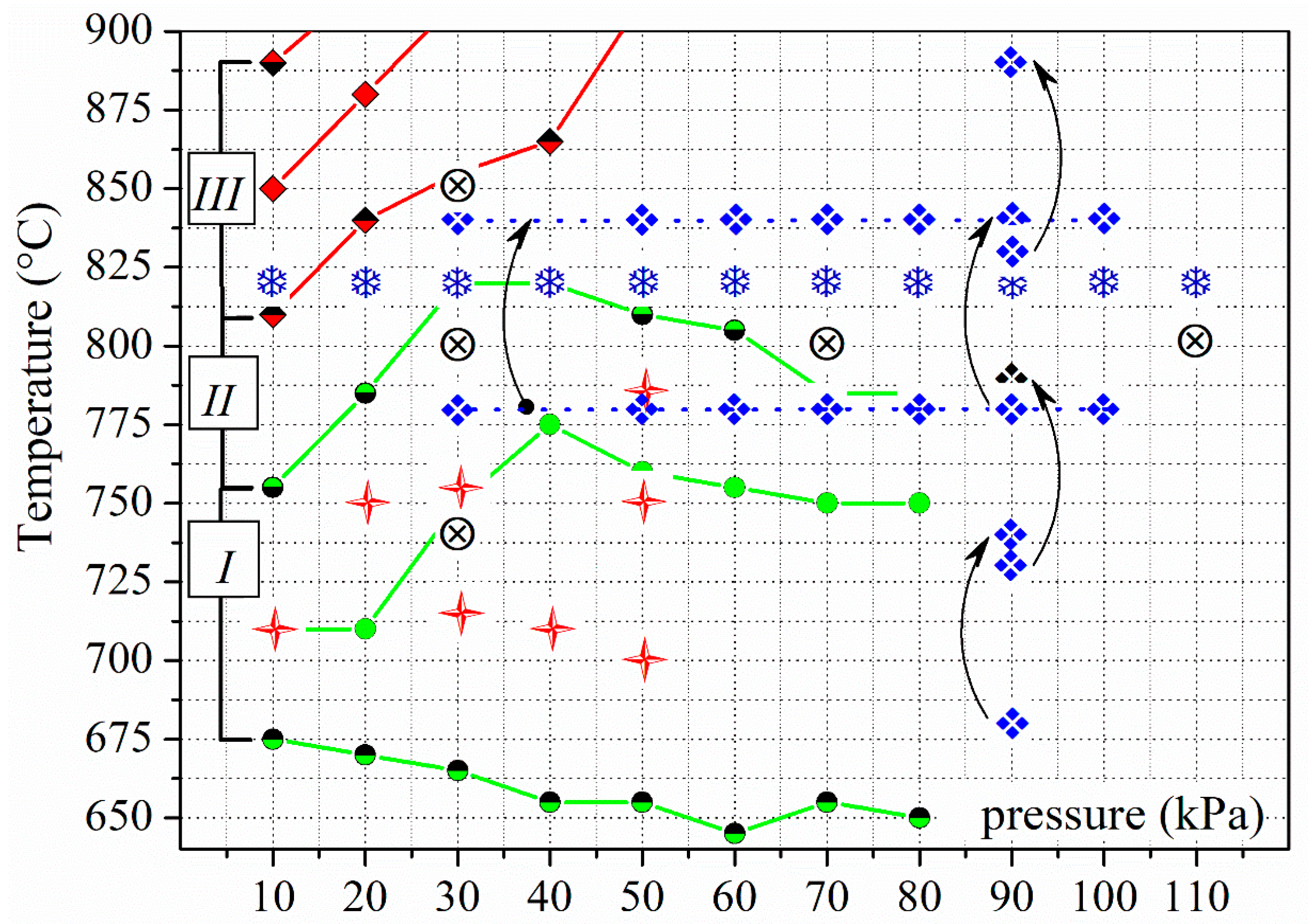

—the transition from low to high temperature during the two-stage treatment.

—the transition from low to high temperature during the two-stage treatment.  —the transition from 780 to 840 °C at specific pressures during the two-stage treatment. The two-stage treatment involves carrying out the disproportionation reaction for a period of time at temperature T1 (the first stage) and then for a period of time at temperature T2 (the second stage). ❄—[40,41,42,43,44]; ⊗—[38,39,40,41,42,43,44,45,46,47,48,49,50];

—the transition from 780 to 840 °C at specific pressures during the two-stage treatment. The two-stage treatment involves carrying out the disproportionation reaction for a period of time at temperature T1 (the first stage) and then for a period of time at temperature T2 (the second stage). ❄—[40,41,42,43,44]; ⊗—[38,39,40,41,42,43,44,45,46,47,48,49,50];  —this work.

—this work.

—the transition from low to high temperature during the two-stage treatment.

—the transition from low to high temperature during the two-stage treatment.  —the transition from 780 to 840 °C at specific pressures during the two-stage treatment. The two-stage treatment involves carrying out the disproportionation reaction for a period of time at temperature T1 (the first stage) and then for a period of time at temperature T2 (the second stage). ❄—[40,41,42,43,44]; ⊗—[38,39,40,41,42,43,44,45,46,47,48,49,50];

—the transition from 780 to 840 °C at specific pressures during the two-stage treatment. The two-stage treatment involves carrying out the disproportionation reaction for a period of time at temperature T1 (the first stage) and then for a period of time at temperature T2 (the second stage). ❄—[40,41,42,43,44]; ⊗—[38,39,40,41,42,43,44,45,46,47,48,49,50];  —this work.

—this work.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Bulyk, I.I.; Yang, M.; Wang, Y.; Wang, H. Features of the Solid HDDR Process in Sintered (Nd,Pr,Gd)-Fe-B Magnets at Low Hydrogen Pressure and Low Temperature. Materials 2025, 18, 4019. https://doi.org/10.3390/ma18174019

Liu R, Bulyk II, Yang M, Wang Y, Wang H. Features of the Solid HDDR Process in Sintered (Nd,Pr,Gd)-Fe-B Magnets at Low Hydrogen Pressure and Low Temperature. Materials. 2025; 18(17):4019. https://doi.org/10.3390/ma18174019

Chicago/Turabian StyleLiu, Renhui, Ihor I. Bulyk, Munan Yang, Yifan Wang, and Hang Wang. 2025. "Features of the Solid HDDR Process in Sintered (Nd,Pr,Gd)-Fe-B Magnets at Low Hydrogen Pressure and Low Temperature" Materials 18, no. 17: 4019. https://doi.org/10.3390/ma18174019

APA StyleLiu, R., Bulyk, I. I., Yang, M., Wang, Y., & Wang, H. (2025). Features of the Solid HDDR Process in Sintered (Nd,Pr,Gd)-Fe-B Magnets at Low Hydrogen Pressure and Low Temperature. Materials, 18(17), 4019. https://doi.org/10.3390/ma18174019