Comparative Analysis of Microstructure and Properties of Wear-Resistant Structural Steels

Abstract

1. Introduction

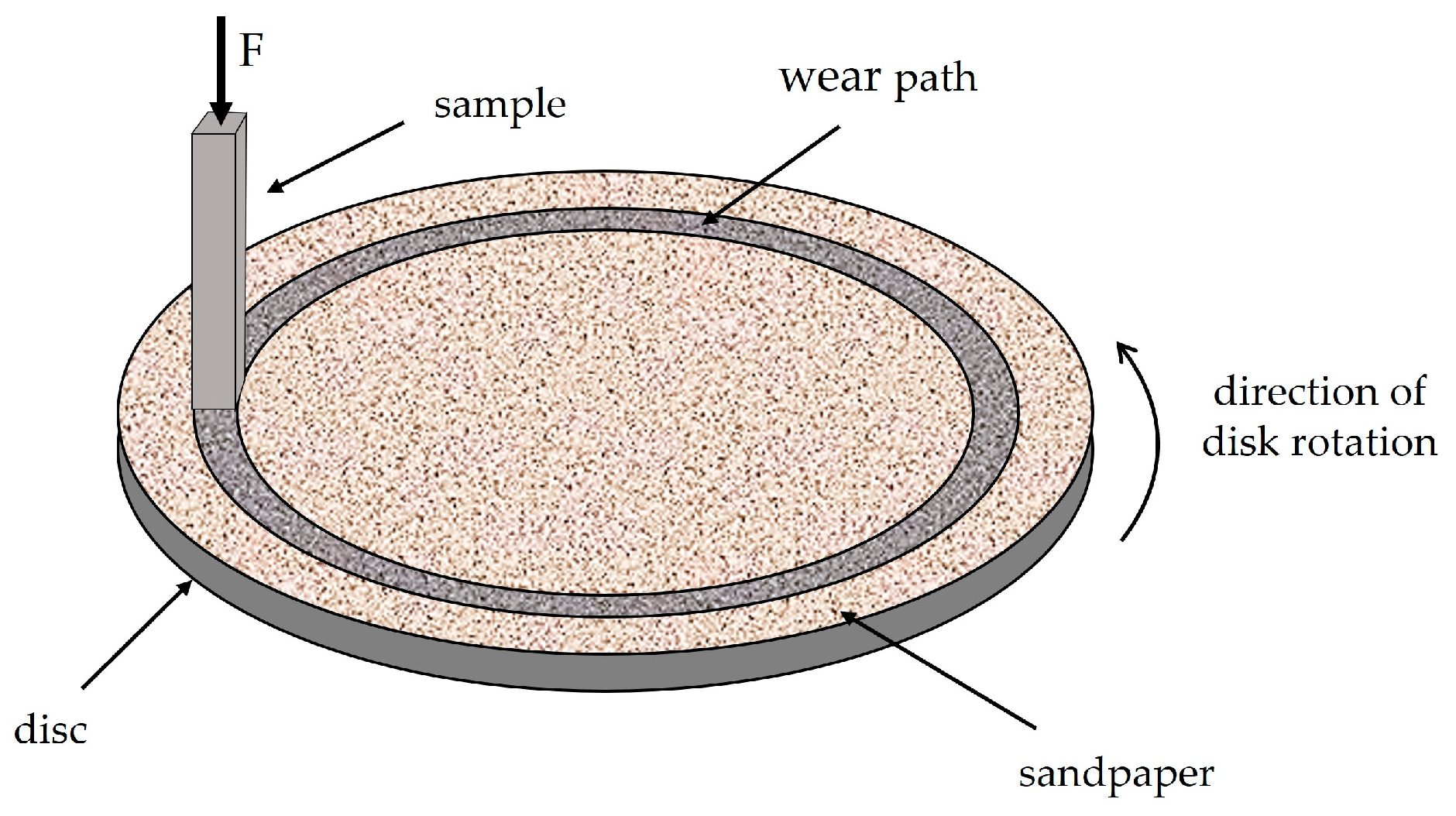

2. Materials and Methods

3. Results and Discussion

3.1. Chemical Composition Analysis

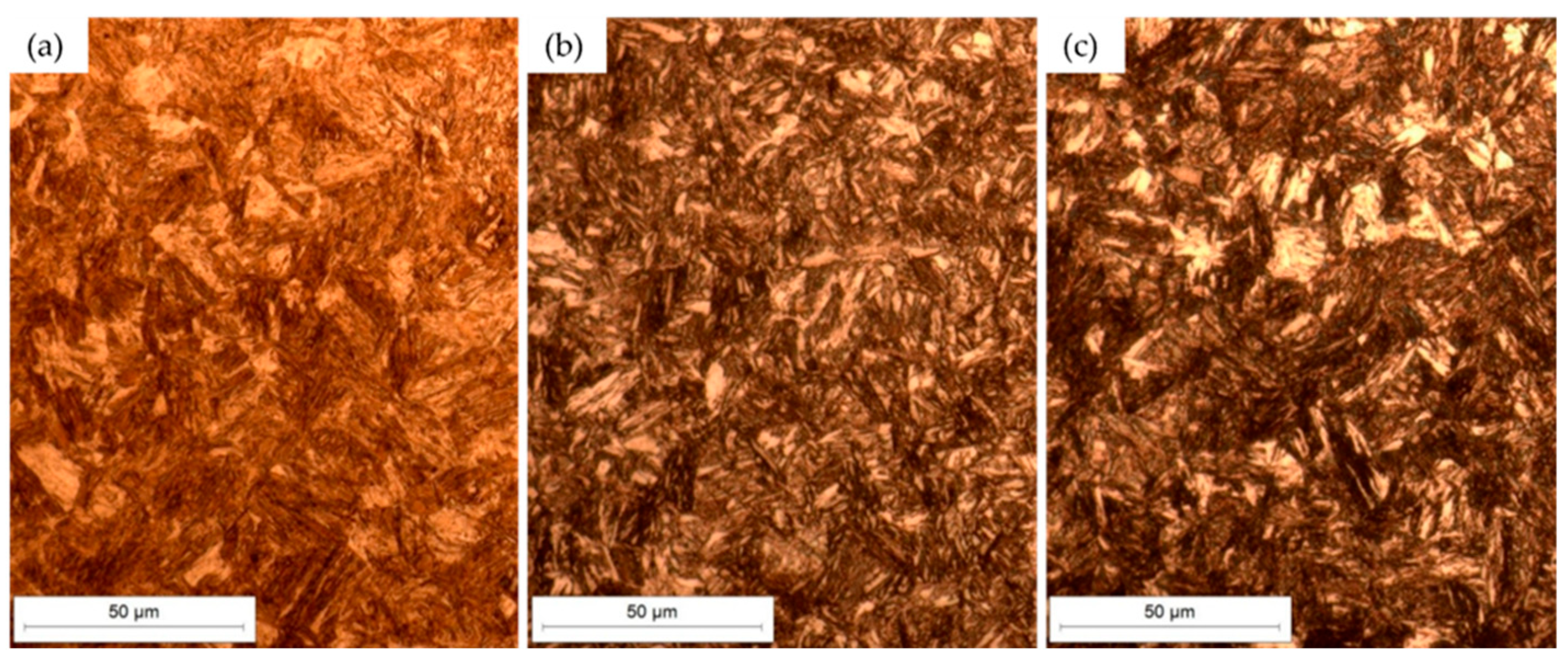

3.2. Microstructural Analysis

- ώ—wear intensity, mm3/mm2,

- X—average of the abrasive grain size, μm.

4. Conclusions

- (i)

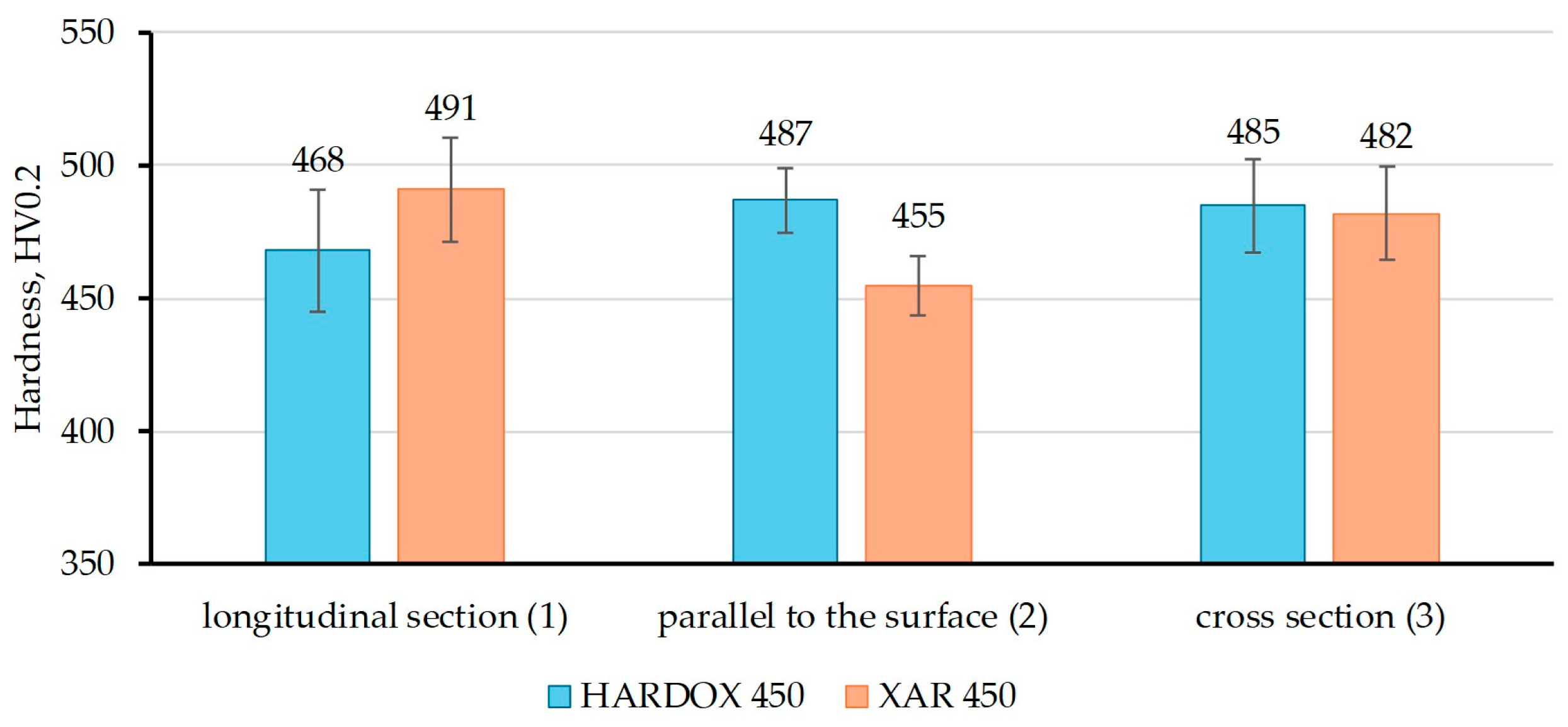

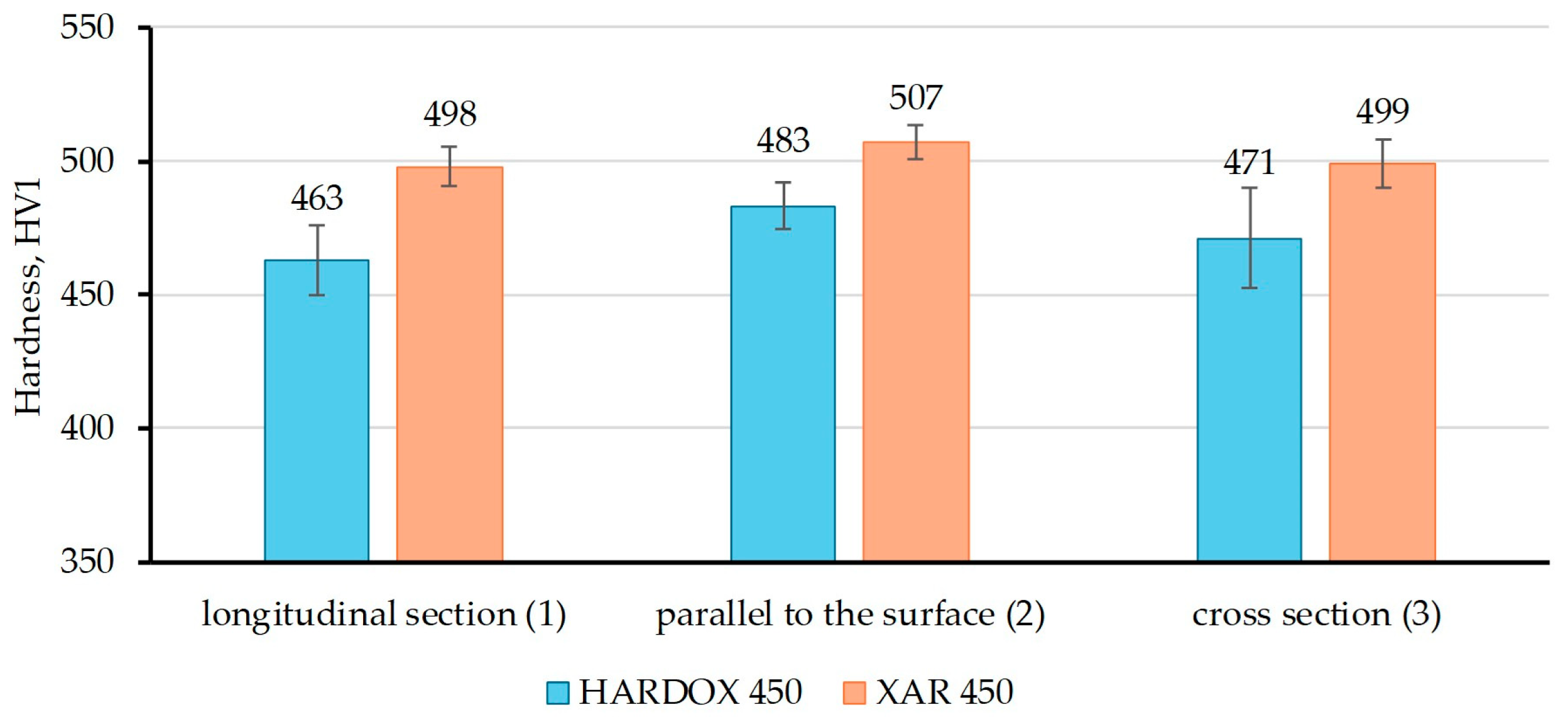

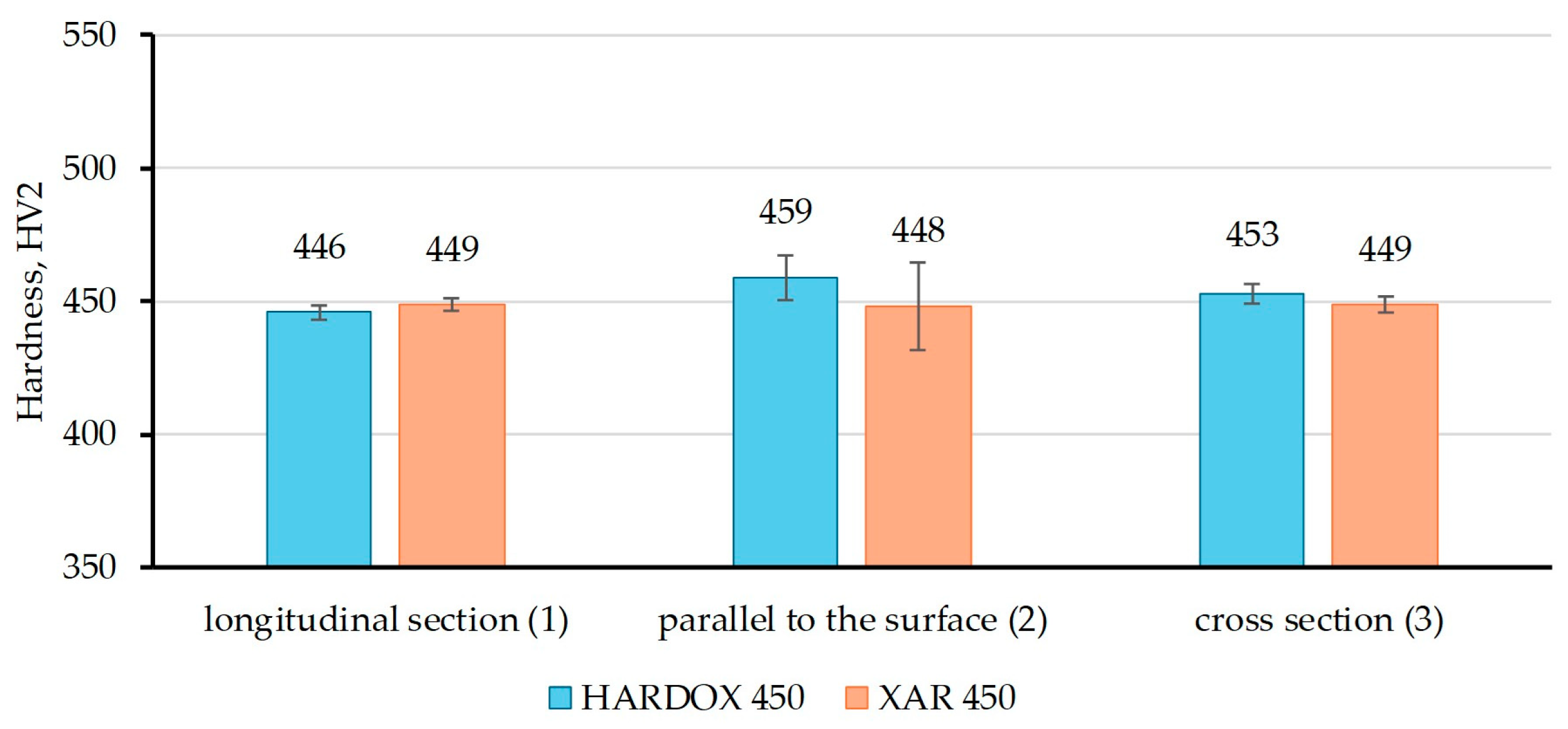

- Both steels have high hardness, approximately 450 HV2, measured on all three characteristic sections and meet the hardness class 450,

- (ii)

- The high hardness of wear-resistant steels is the result of the presence of the fine-grained martensitic microstructure,

- (iii)

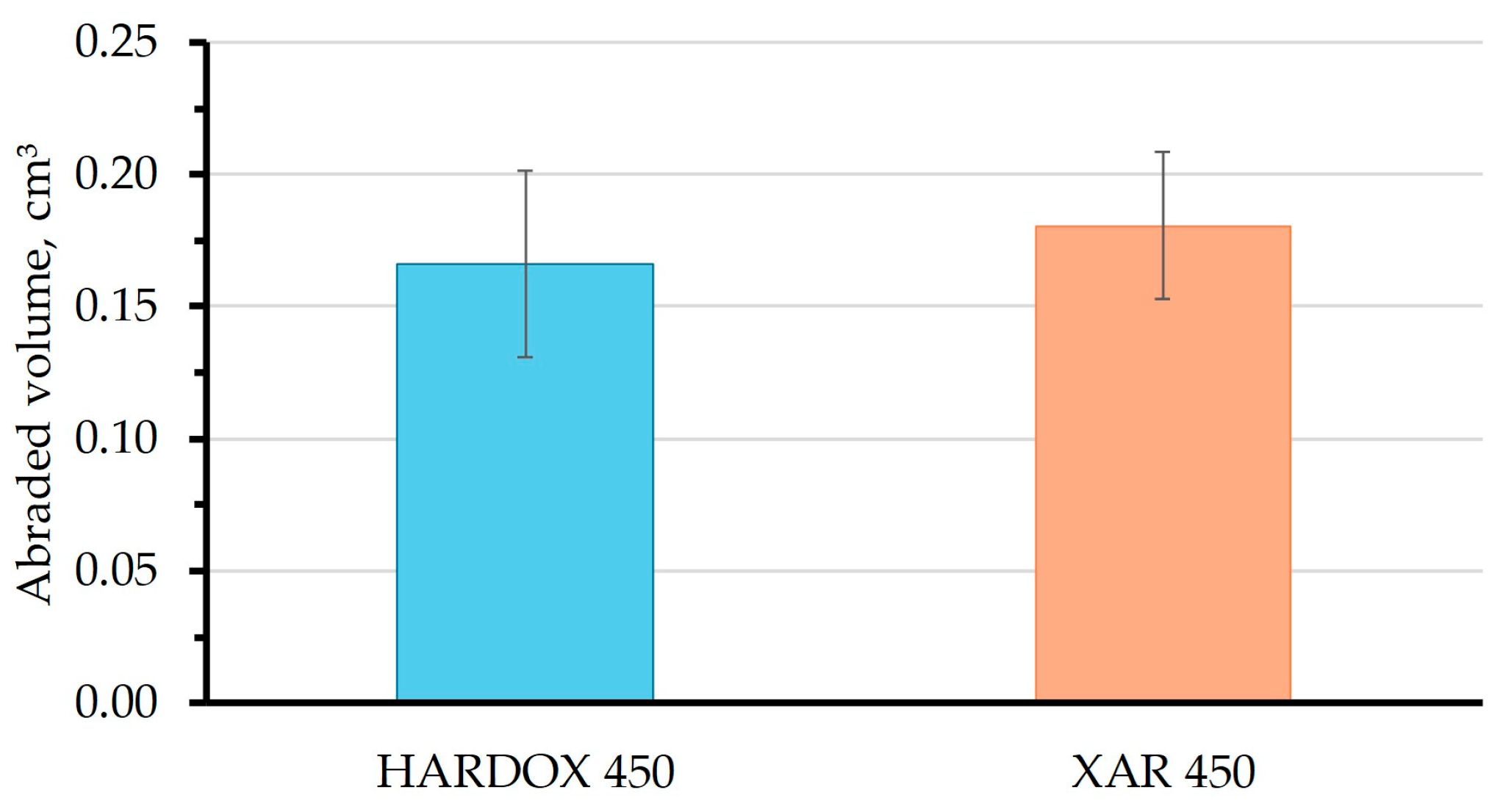

- Hardox 450 steel shows slightly higher wear resistance for both tested methods, which makes it a more appropriate choice for the manufacture of machine components exposed to intensive abrasive wear,

- (iv)

- The wear regression equations allow for a reliable assessment of the wear intensity concerning the abrasive grain size. These results can serve as a guideline for steel selection in abrasive wear applications with different sizes of particles,

- (v)

- A critical abrasive grain size was observed, between 21.8 and 30.2 μm, after which wear intensity does not change with an increase in abrasive grain size.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zemlik, M.; Białobrzeska, B.; Stachowicz, M.; Hanszke, J. The Influence of Grain Size on the Abrasive Wear Resistance of Hardox 500 Steel. Appl. Sci. 2024, 14, 11490. [Google Scholar] [CrossRef]

- Dzioba, I.; Pala, R. Strength and Fracture Toughness of Hardox-400 Steel. Metals 2019, 9, 508. [Google Scholar] [CrossRef]

- Ratia, V.; Rojacz, H.; Terva, J.; Valtonen, K.; Badisch, E.; Kuokkala, V.T. Effect of Multiple Impacts on the Deformation of Wear-Resistant Steels. Tribol. Lett. 2015, 57, 15. [Google Scholar] [CrossRef]

- Bhakat, A.K.; Mishra, A.K.; Mishra, N.S. Characterization of Wear and Metallurgical Properties for Devel-opment of Agricultural Grade Steel Suitable in Specific Soil Conditions. Wear 2007, 263, 228–233. [Google Scholar] [CrossRef]

- Jirková, H.; Rubešová, K.; Jeníček, Š.; Hradil, D.; Kučerová, L. Improving the Wear Resistance of Ledeburitic Tool Steels by a Combination of Semi-Solid and Cryogenic Processing. Metals 2022, 12, 1869. [Google Scholar] [CrossRef]

- Adamiak, M.; Górka, J.; Kik, T. Comparison of Abrasion Resistance of Selected Constructional Materials. J. Achiev. Mater. Manuf. Eng. 2009, 37, 375–380. [Google Scholar]

- Pawlak, K.; Białobrzeska, B.; Konat, Ł. The Influence of Austenitizing Temperature on Prior Austenite Grain Size and Resistance to Abrasion Wear of Selected Low-Alloy Boron Steel. Arch. Civ. Mech. Eng. 2016, 16, 913–926. [Google Scholar] [CrossRef]

- Zemlik, M.; Konat, Ł.; Napiórkowski, J. Comparative Analysis of the Influence of Chemical Composition and Microstructure on the Abrasive Wear of High-Strength Steels. Materials 2022, 15, 5083. [Google Scholar] [CrossRef] [PubMed]

- Haiko, O.; Somani, M.; Porter, D.; Kantanen, P.; Kömi, J.; Ojala, N.; Heino, V. Comparison of Impact-Abrasive Wear Characteristics and Performance of Direct Quenched (DQ) and Direct Quenched and Partitioned (DQ&P) Steels. Wear 2018, 400–401, 21–30. [Google Scholar] [CrossRef]

- Pawar, S.; Jha, A.K.; Mukhopadhyay, G. Effect of Different Carbides on the Wear Resistance of Fe-Based Hardfacing Alloys. Int. J. Refract. Met. Hard Mater. 2019, 78, 288–295. [Google Scholar] [CrossRef]

- Machado, P.C.; Pereira, J.I.; Sinatora, A. Abrasion Wear of Austenitic Manganese Steels via Jaw Crusher Test. Wear 2021, 476, 203726. [Google Scholar] [CrossRef]

- Białobrzeska, B.; Jasiński, R.; Konat, Ł.; Szczepański, Ł. Analysis of the Properties of Hardox Extreme Steel and Possibilities of Its Applications in Machinery. Metals 2021, 11, 162. [Google Scholar] [CrossRef]

- Konat, Ł.; Zemlik, M.; Jasiński, R.; Grygier, D. Austenite Grain Growth Analysis in a Welded Joint of High-Strength Martensitic Abrasion-Resistant Steel Hardox 450. Materials 2021, 14, 2850. [Google Scholar] [CrossRef]

- Ratia, V. Behavior of Martensitic Wear Resistant Steels in Abrasion and Impact Wear Testing Conditions. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, November 2015. [Google Scholar]

- Białobrzeska, B.; Konat, Ł. Comparative Analysis of Abrasive-Wear Resistance of Brinar and Hardox Steels. Tribologia 2017, 272, 7–16. [Google Scholar] [CrossRef]

- Haiko, O.; Heino, V.; Porter, D.A.; Uusitalo, J.; Kömi, J. Effect of Microstructure on the Abrasive Wear Resistance of Steels with Hardness 450 HV. Tribologia 2019, 36, 54–57. [Google Scholar] [CrossRef]

- Szala, M.; Szafran, M.; Macek, W.; Marchenko, S.; Hejwowski, T. Abrasion Resistance of S235, S355, C45, AISI 304 and Hardox 500 Steels with Usage of Garnet, Corundum and Carborundum Abrasives. Adv. Sci. Technol. Res. J. 2019, 13, 151–161. [Google Scholar] [CrossRef] [PubMed]

- ASTM G65-16; Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 6344-3:2021; Coated Abrasives—Determination and Designation of Grain Size Distribution—Part 3: Microgrit Sizes P240 to P5000. ISO: Geneva, Switzerland, 2021.

- SSAB. Hardox® 450 Steel Product Data Sheet. Available online: https://www.ssab.com/en/brands-and-products/hardox/product-program/450?gad_source=1&gad_campaignid=19576720931&gbraid=0AAAAApD_yEegyy9fIzYFz_k1PB1ROm6LV&gclid=EAIaIQobChMItuGXiejXjQMV84KDBx1P0CNOEAAYASABEgKGXfD_BwE (accessed on 4 June 2025).

- Thyssenkrupp. Perdur® 450 Steel Product Data Sheet. Available online: https://www.thyssenkrupp-steel.com/en/products/cut-to-length-sheet-products/perdur/perdur.html (accessed on 4 June 2025).

- Mohapatra, S.; Satpathy, B.; Sarkar, A.; Kumar, S.; Aich, S.; Oh, M.-S. Recent Advances in Medium-Manganese Steel: A Review of Key Findings, Challenges, and Future Perspectives. J. Mater. Sci. 2025, 60, 9447–9528. [Google Scholar] [CrossRef]

- Jahn, A.; Kovalev, A.; Weiß, A.; Scheller, P.R. Influence of Manganese and Nickel on the α’ Martensite Transformation Temperatures of High Alloyed Cr-Mn-Ni Steels. Steel Res. Int. 2011, 82, 1108–1112. [Google Scholar] [CrossRef]

- Białobrzeska, B. The Influence of Boron on the Resistance to Abrasion of Quenched Low-Alloy Steels. Wear 2022, 500–501, 204345. [Google Scholar] [CrossRef]

- Ishikawa, K.; Nakamura, H.; Homma, R.; Fujioka, M.; Hoshino, M. Effect of Molybdenum Content on the Combined Effect of Boron and Molybdenum on Hardenability of Low-Carbon Boron-Added Steels. ISIJ Int. 2018, 58, 551–560. [Google Scholar] [CrossRef]

- Luo, Q.; Kitchen, M. Microhardness, Indentation Size Effect and Real Hardness of Plastically Deformed Austenitic Hadfield Steel. Materials 2023, 16, 1117. [Google Scholar] [CrossRef]

- Muslić, M.; Rede, V.; Maksimović, V.; Ćorić, D. Hardness and Microstructural Characterization of Al/FA Composites Fabricated by Compo Casting and the Equal Channel Angular Extrusion. Processes 2025, 13, 928. [Google Scholar] [CrossRef]

- Sin, H.; Saka, N.; Suh, N.P. Abrasive Wear Mechanisms and the Grit Size Effect. Wear 1979, 55, 163–190. [Google Scholar] [CrossRef]

- Coronado, J.J.; Sinatora, A. Effect of Abrasive Size on Wear of Metallic Materials and Its Relationship with Microchips Morphology and Wear Micromechanisms: Part 1. Wear 2011, 271, 1794–1803. [Google Scholar] [CrossRef]

- Coronado, J.J.; Sinatora, A. Effect of Abrasive Size on Wear of Metallic Materials and Its Relationship with Microchips Morphology and Wear Micromechanisms: Part 2. Wear 2011, 271, 1804–1812. [Google Scholar] [CrossRef]

- Coronado, J.J. Effect of Abrasive Size on Wear. In Abrasion Resistance of Materials; Adamiak, M., Ed.; InTech: Rijeka, Croatia, 2012; pp. 167–184. [Google Scholar]

- Rodinger, T.; Lukšić, H.; Ćorić, D.; Rede, V. Abrasion Wear Resistance of Precipitation-Hardened Al-Zn-Mg Alloy. Materials 2024, 17, 2446. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Zhang, G.; Ren, L.; Yang, Z. Analysis of Abrasive Grain Size Effect of Abrasive Belt on Material Removal Performance of GCr15 Bearing Steel. Tribol. Int. 2022, 171, 107536. [Google Scholar] [CrossRef]

- Essert, S.; Rede, V.; Barišić, J. Effect of Abrasive Grain Size on the Abrasion Volume Loss of Subfossil and Recent Oak Wood in Three Characteristic Sections. Materials 2023, 16, 432. [Google Scholar] [CrossRef]

| Hardox 450 | XAR 450 | |||

|---|---|---|---|---|

| Element | MD | OR | MD | OR |

| C | ≤0.26 | 0.18 ± 0.010 | ≤0.22 | 0.17 ± 0.010 |

| Mn | ≤0.70 | 1.03 ± 0.011 | ≤0.80 | 0.97 ± 0.004 |

| Si | ≤1.60 | 0.26 ± 0.003 | ≤1.50 | 0.23 ± 0.002 |

| P | ≤0.025 | 0.007 ± 0.010 | ≤0.020 | 0.007 ± 0.003 |

| S | ≤0.010 | 0.002 ± 0.000 | ≤0.010 | 0.001 ± 0.001 |

| Cr | ≤1.400 | 0.001 ± 0.001 | ≤1.300 | 0.188 ± 0.001 |

| Ni | ≤1.500 | 0.024 ± 0.000 | ≤1.500 | 0.001 ± 0.000 |

| Mo | ≤0.60 | 0.02 ± 0.001 | ≤0.50 | 0.01 ± 0.001 |

| B | ≤0.005 | 0.001 ± 0.000 | ≤0.005 | 0.001 ± 0.000 |

| Fe | balance | Balance | balance | balance |

| Sample | Mass Loss, g | |

|---|---|---|

| HARDOX 450 | XAR 450 | |

| 1 | 0.7728 | 1.6555 |

| 2 | 1.1608 | 1.5091 |

| 3 | 1.2169 | 1.5045 |

| 4 | 1.5655 | 1.3733 |

| 5 | 1.6340 | 1.2642 |

| 6 | 1.3735 | 1.4571 |

| 7 | 1.2493 | 1.4773 |

| 8 | 1.4444 | 1.4227 |

| 9 | 0.9316 | 1.0347 |

| 10 | 1.3577 | 0.9966 |

| Mean value | 1.2707 | 1.3695 |

| Standard deviation | 0.2541 | 0.2010 |

| Coefficient of variation | 20% | 15% |

| Average Abrasive Grain Size, μm | Mass Loss, mg | |

|---|---|---|

| HARDOX 450 | XAR 450 | |

| 15.3 | 1.60 ± 0.21 | 1.50 ± 0.56 |

| 21.8 | 6.78 ± 0.49 | 6.44 ± 0.36 |

| 30.2 | 8.50 ± 0.56 | 8.48 ± 0.61 |

| 35.0 | 8.52 ± 0.45 | 8.84 ± 1.55 |

| 46.2 | 9.18 ± 0.79 | 8.82 ± 0.44 |

| Regression Statistics | |||||

| Multiple R | 0.95476 | ||||

| R2 | 0.91158 | ||||

| Adjusted R2 | 0.90354 | ||||

| Standard Error | 0.00590 | ||||

| Observations | 25 | ||||

| ANOVA | |||||

| DF | SS | MS | F-value | Significance F | |

| Regression | 2 | 0.00790 | 0.00395 | 113.40006 | 2.584 × 10−12 |

| Residual | 22 | 0.00077 | 3.482 × 10−5 | ||

| Total | 24 | 0.00866 | |||

| Coefficients | Standard Error | t Stat | p-value | ||

| Intercept | −0.06787 | 0.01000 | −6.78405 | 8.124 × 10−7 | |

| Grain size | 0.00669 | 0.00070 | 9.50461 | 3.018 × 10−9 | |

| Grain size2 | −8.548 × 10−5 | 1.132 × 10−5 | −7.55335 | 1.512 × 10−7 | |

| Regression Statistics | |||||

| Multiple R | 0.94530 | ||||

| R2 | 0.89360 | ||||

| Adjusted R2 | 0.88392 | ||||

| Standard Error | 0.00835 | ||||

| Observations | 25 | ||||

| ANOVA | |||||

| DF | SS | MS | F-value | Significance F | |

| Regression | 2 | 0.01289 | 0.00644 | 92.38004 | 1.979 × 10−11 |

| Residual | 22 | 0.00153 | 6.975 × 10−5 | ||

| Total | 24 | 0.01442 | |||

| Coefficients | Standard Error | t Stat | p-value | ||

| Intercept | −0.09457 | 0.01416 | −6.67915 | 1.028 × 10−6 | |

| Grain size | 0.00902 | 0.00099 | 9.05286 | 7.146 × 10−9 | |

| Grain size2 | −1.177 × 10−4 | 1.602 × 10−5 | −7.34928 | 2.343 × 10−7 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lukšić, H.; Rodinger, T.; Rede, V.; Švagelj, Z.; Ćorić, D. Comparative Analysis of Microstructure and Properties of Wear-Resistant Structural Steels. Materials 2025, 18, 4002. https://doi.org/10.3390/ma18174002

Lukšić H, Rodinger T, Rede V, Švagelj Z, Ćorić D. Comparative Analysis of Microstructure and Properties of Wear-Resistant Structural Steels. Materials. 2025; 18(17):4002. https://doi.org/10.3390/ma18174002

Chicago/Turabian StyleLukšić, Helena, Tomislav Rodinger, Vera Rede, Zrinka Švagelj, and Danko Ćorić. 2025. "Comparative Analysis of Microstructure and Properties of Wear-Resistant Structural Steels" Materials 18, no. 17: 4002. https://doi.org/10.3390/ma18174002

APA StyleLukšić, H., Rodinger, T., Rede, V., Švagelj, Z., & Ćorić, D. (2025). Comparative Analysis of Microstructure and Properties of Wear-Resistant Structural Steels. Materials, 18(17), 4002. https://doi.org/10.3390/ma18174002