Scalable Engineering of Superhydrophobic Copper Surfaces with Enhanced Corrosion Resistance by Combined Nanostructuring and Chemical Vapor Deposition

Abstract

1. Introduction

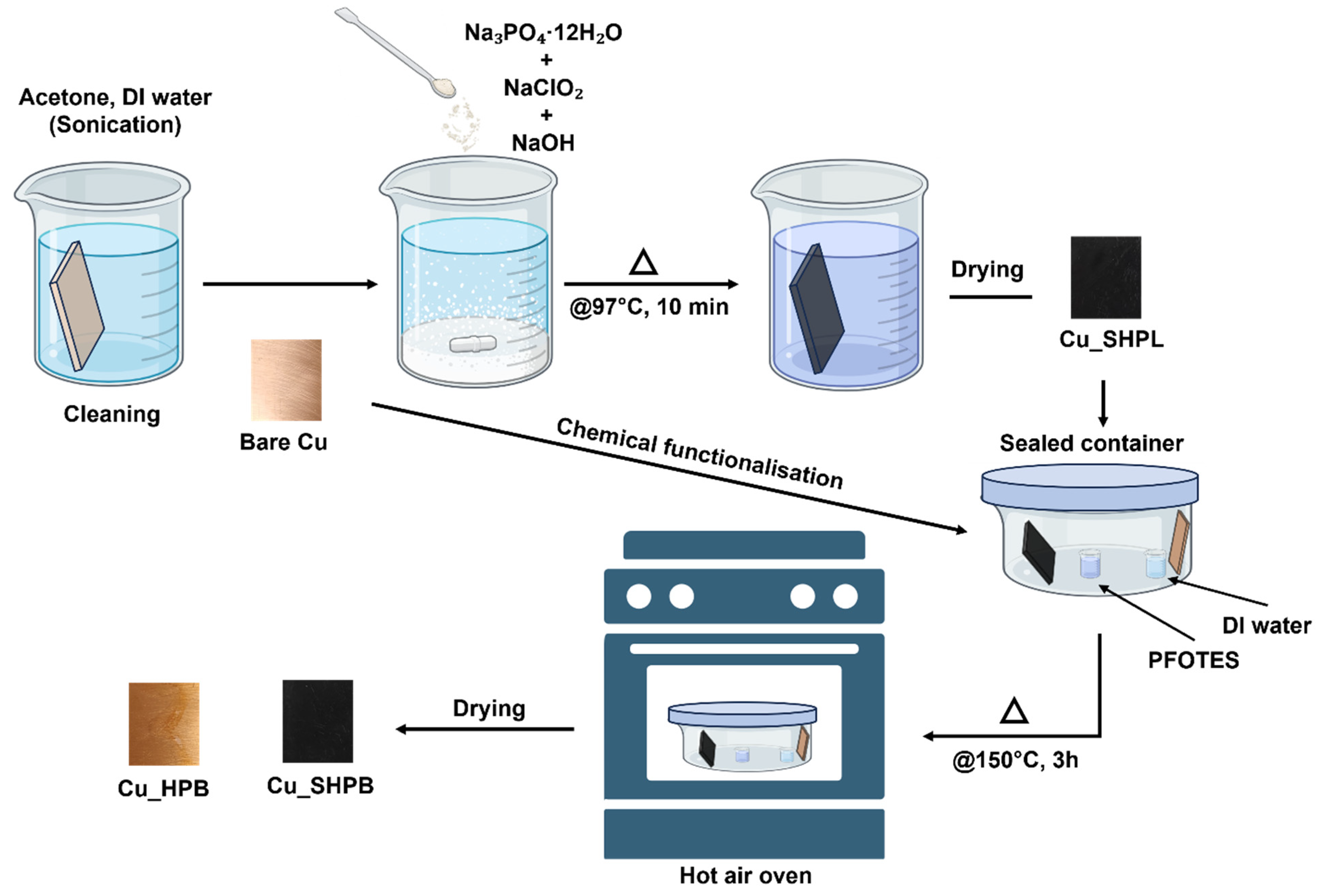

2. Materials and Methods

2.1. Surface Characterization

2.2. Electrochemical Measurements

2.3. Salt Spray Test

3. Results and Discussion

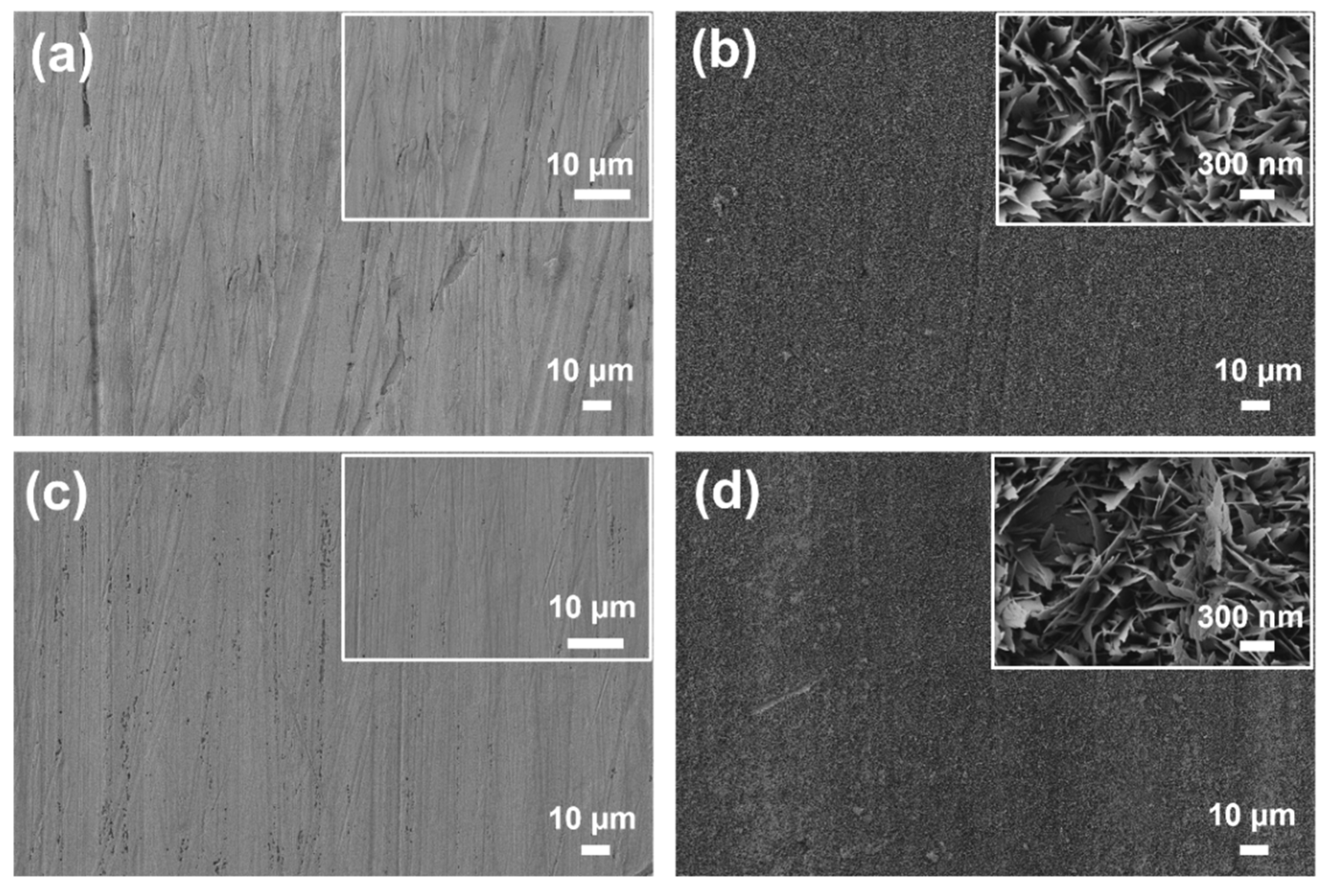

3.1. Surface Characterization

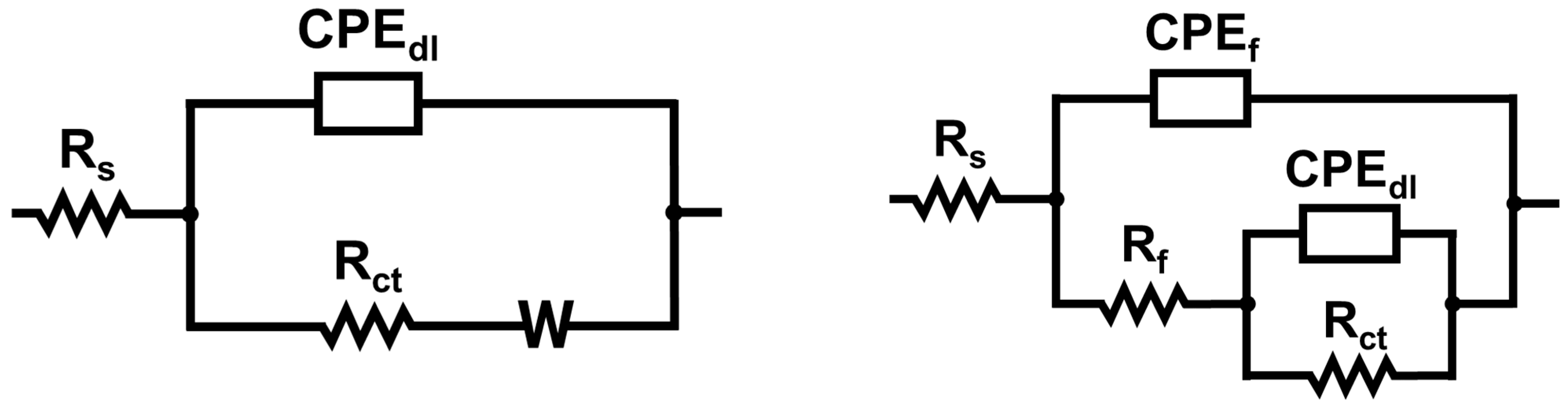

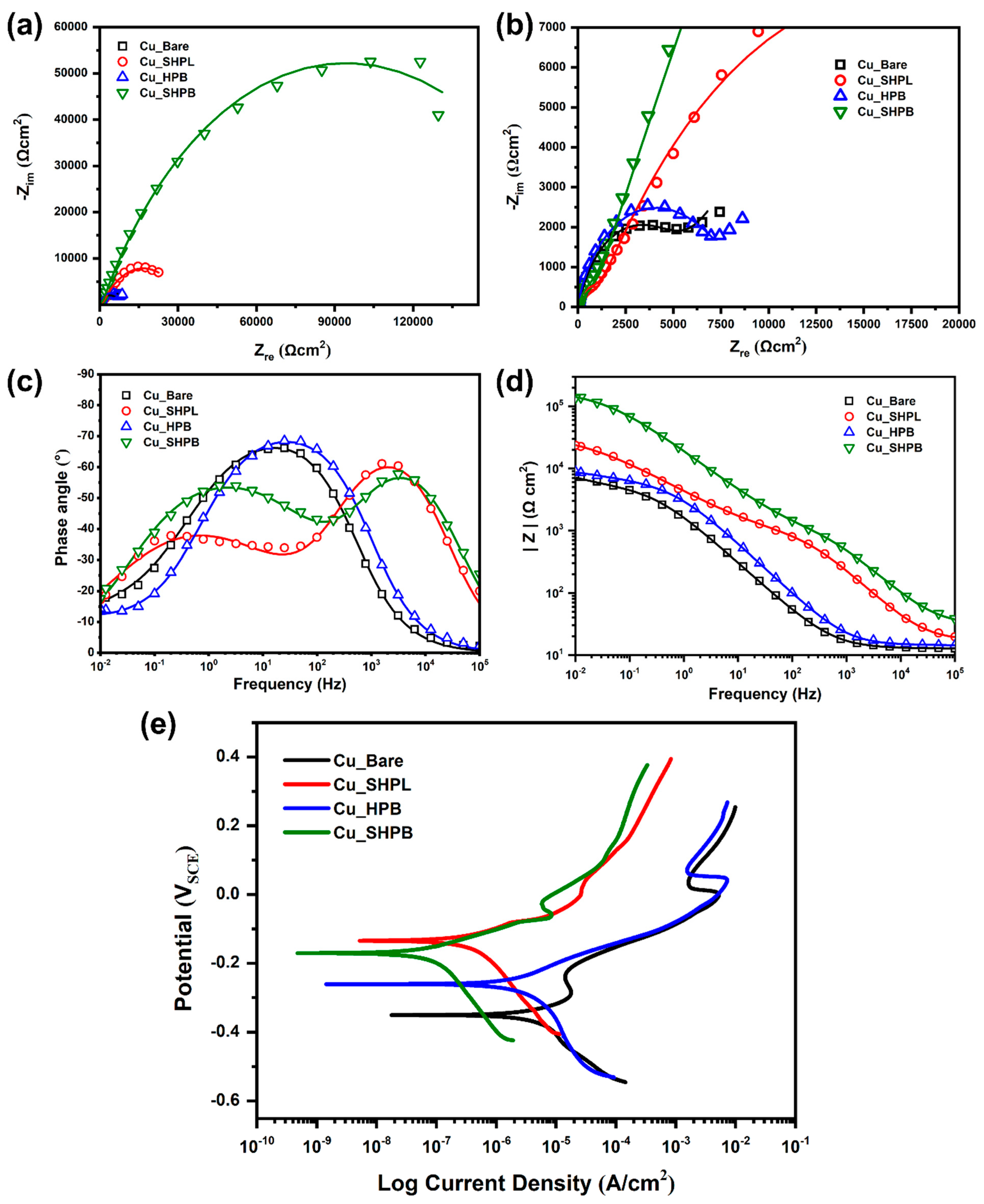

3.2. Electrochemical Corrosion Behavior

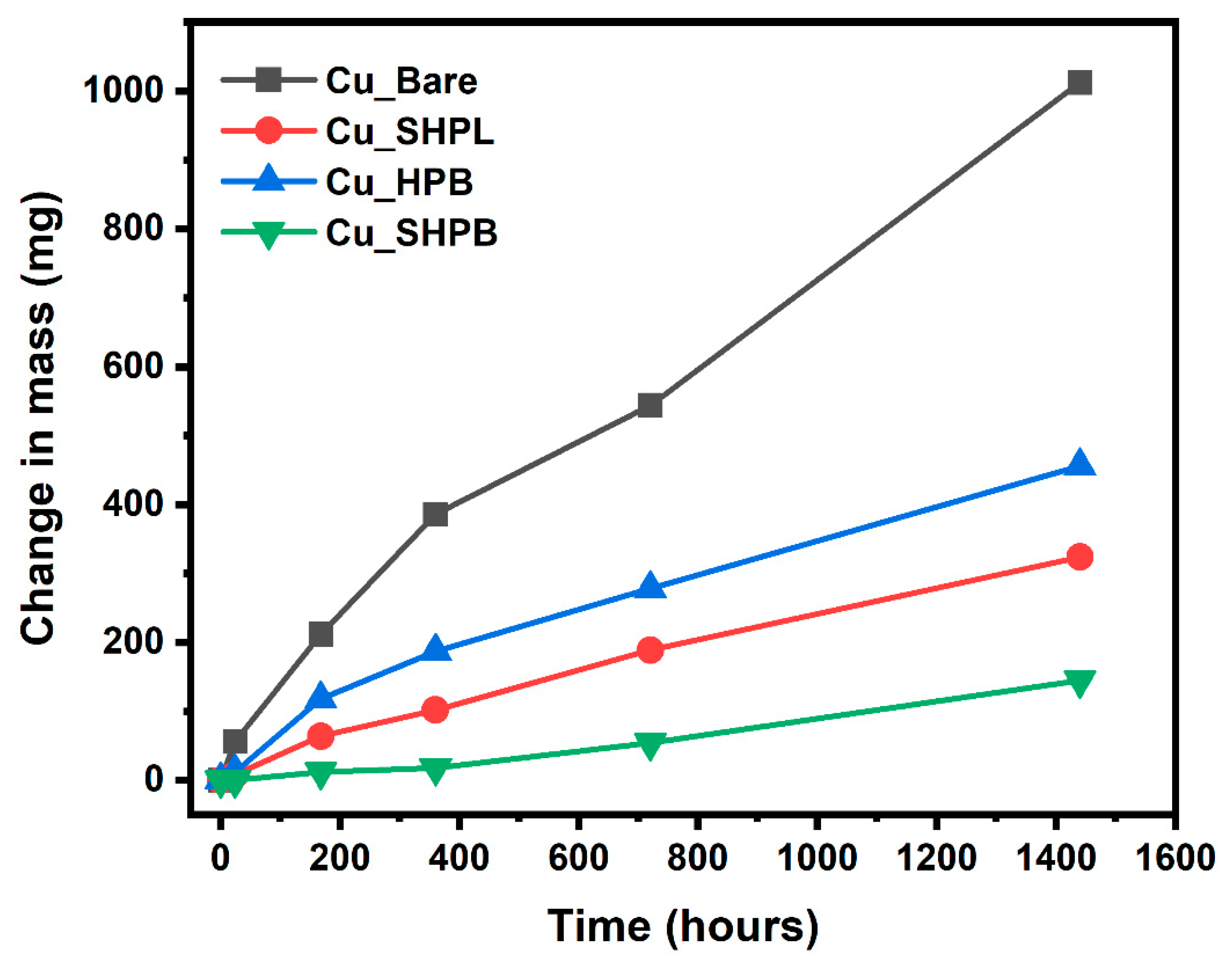

3.3. Corrosion Test (Salt Spray Test)

4. Conclusions

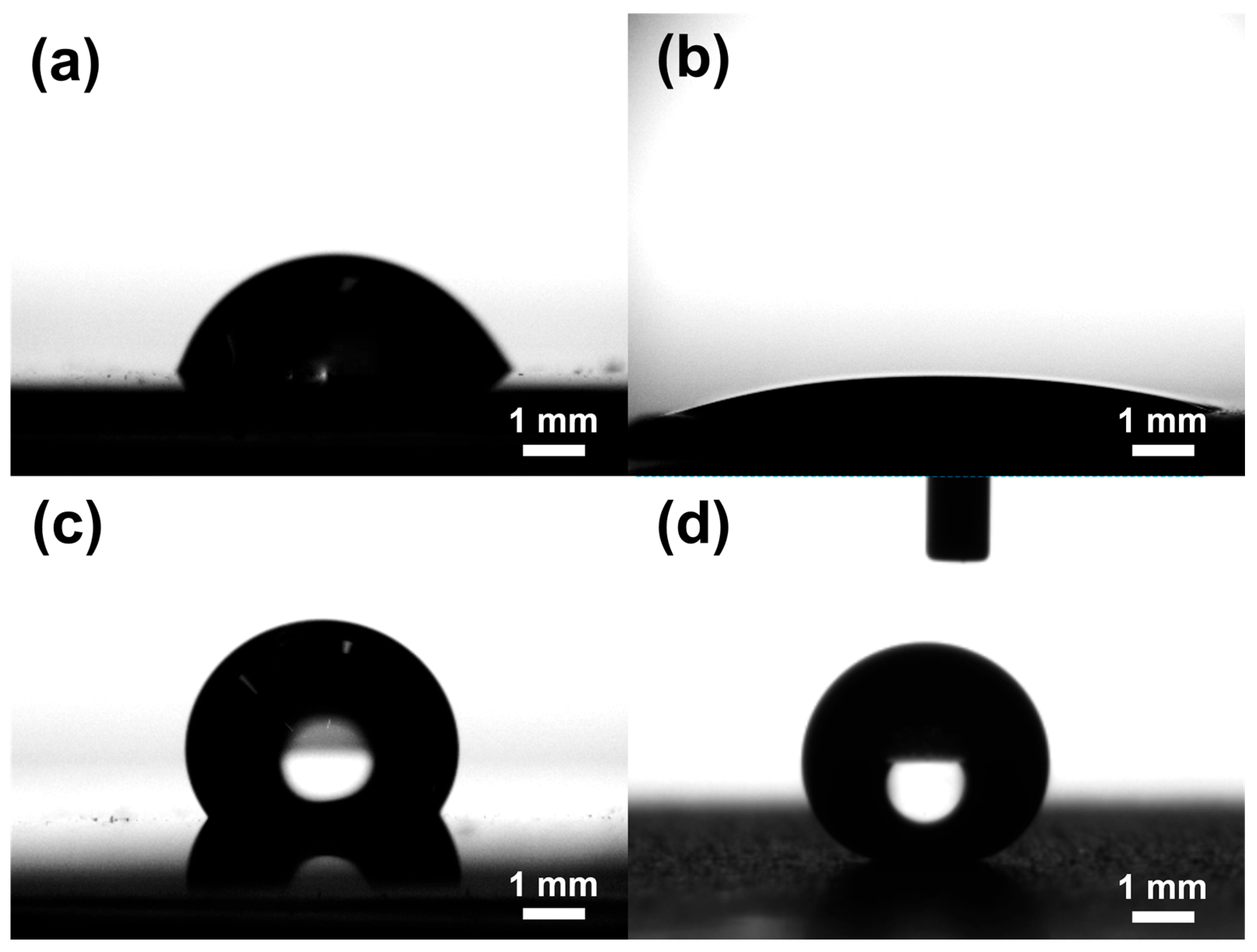

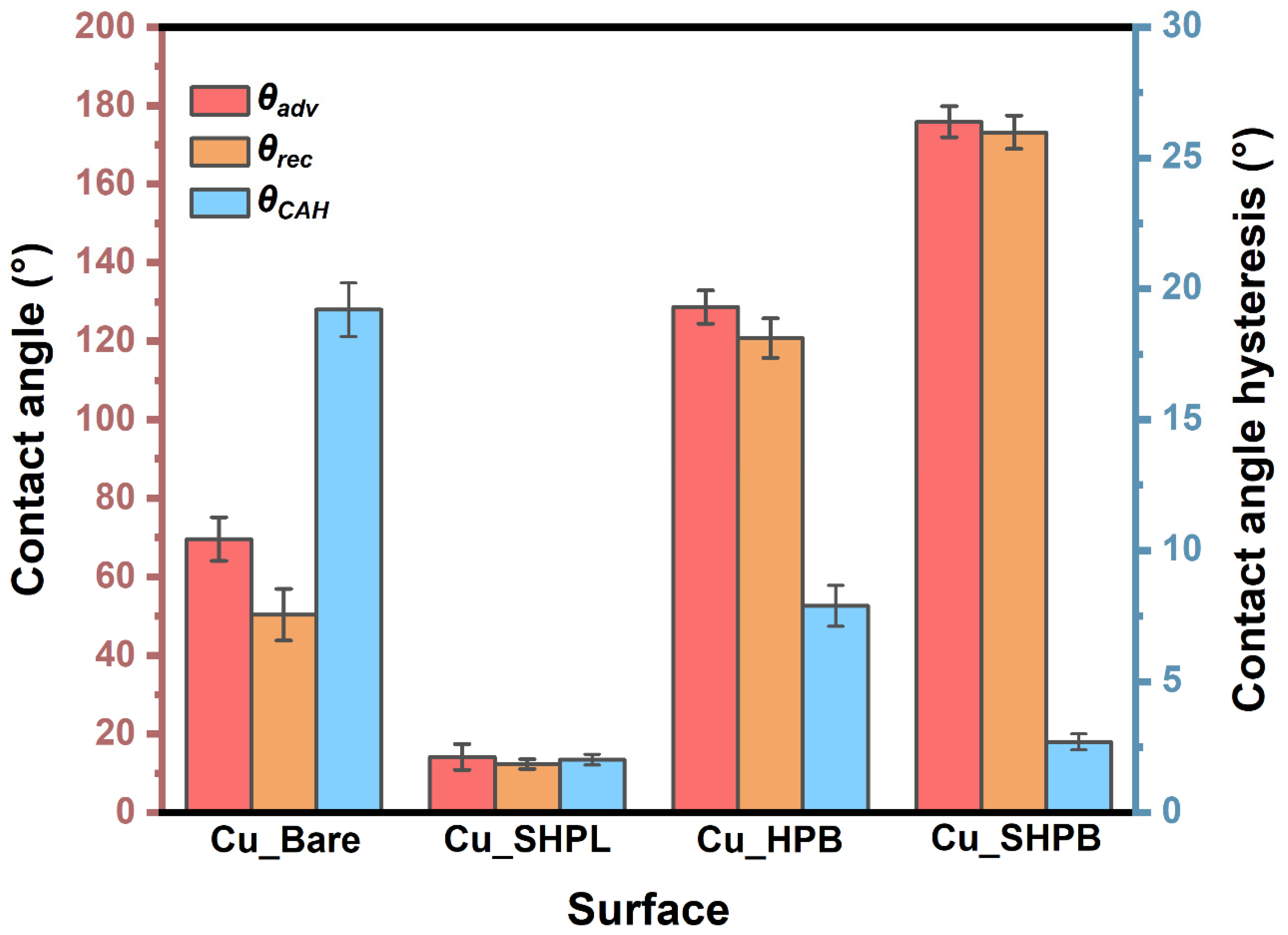

- The resulting surfaces exhibit hierarchical CuO nanostructures conformally coated with a low-surface-energy silane, yielding water repellency with a contact angle of ~170° and a low contact angle hysteresis of ~3°, and robust resistance to salt-induced corrosion. Surface analyses confirm that the hierarchical morphology is preserved throughout the modification process.

- Wettability measurements reveal that both roughness and chemical functionalization are essential for achieving the Cassie–Baxter wetting regime and droplet mobility.

- Salt spray testing further validates the enhanced durability and protective performance of the fabricated surfaces.

- The approach outlined here provides a scalable and reproducible platform for the development of advanced copper interfaces with applications in self-cleaning, anti-fouling, and long-lasting protective coatings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mamgain, H.P.; Pati, P.R.; Samanta, K.K.; Brajpuriya, R.; Gupta, R.; Pandey, J.K.; Giri, J.; Sathish, T.; Kanan, M. A review on bio-inspired corrosion resistant superhydrophobic coating on copper substrate: Recent advances, mechanisms, constraints, and future prospects. Results Eng. 2024, 25, 103868. [Google Scholar] [CrossRef]

- Mousavi, S.M.A.; Pitchumani, R. A study of corrosion on electrodeposited superhydrophobic copper surfaces. Corros. Sci. 2021, 186, 109420. [Google Scholar] [CrossRef]

- Yao, C.W.; Sebastian, D.; Lian, I.; Günaydın-Şen, Ö.; Clarke, R.; Clayton, K.; Chen, C.Y.; Kharel, K.; Chen, Y.; Li, Q. Corrosion resistance and durability of superhydrophobic copper surface in corrosive NaCl aqueous solution. Coatings 2018, 8, 70. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Abdullah, A.M.; Younan, N.A. Corrosion behavior of superhydrophobic surfaces: A review. Arab. J. Chem. 2015, 8, 749–765. [Google Scholar] [CrossRef]

- Parvate, S.; Dixit, P.; Chattopadhyay, S. Superhydrophobic surfaces: Insights from theory and experiment. J. Phys. Chem. B 2020, 124, 1323–1360. [Google Scholar] [CrossRef]

- Wang, N.; Wang, Q.; Xu, S.; Zheng, X.; Zhang, M. Facile fabrication of amphiphobic surfaces on copper substrates with a mixed modified solution. RSC Adv. 2019, 9, 17366–17372. [Google Scholar] [CrossRef]

- Liu, K.; Vuckovac, M.; Latikka, M.; Huhtamäki, T.; Ras, R.H. Improving surface-wetting characterization. Science 2019, 363, 1147–1148. [Google Scholar] [CrossRef]

- Li, H.; Sun, Y.; Wang, Z.; Wang, S. Constructing superhydrophobic surface on copper substrate with dealloying-forming and solution-immersion method. Materials 2022, 15, 4816. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, F.; Niu, J.; Jiang, Y.; Wang, Z. Superhydrophobic surfaces: From structural control to functional application. J. Mater. Chem. 2008, 18, 621–633. [Google Scholar] [CrossRef]

- Azar, S.; Ali, B. Effects of Hierarchical Surface Roughness on Droplet Contact Angle. Langmuir 2015, 31, 6752–6762. [Google Scholar] [CrossRef]

- Devra, R.S.; Gupta, R.; Rahul, N.; Sett, S.; Vadali, M. Transitioning Surface Wettability of Ti6Al4V via Laser Ablation and Post-processing Methods. J. Bio-Tribo-Corros. 2025, 11, 39. [Google Scholar] [CrossRef]

- Taliantzis, K.; Ellinas, K. Green hydrophobic and superhydrophobic coatings and surfaces for water related applications: A review. Adv. Colloid Interface Sci. 2025, 343, 103566. [Google Scholar] [CrossRef]

- Mirmohammadi, S.M.; Savijoki, K.; Hoshian, S.; Varmanen, P.; Yli-Kauhaluoma, J.; Jokinen, V.; Franssila, S. Superhydrophobic Copper-Composite Surfaces Exert Antibacterial Effects against Gram-Negative and-Positive Bacteria. Adv. Mater. Interfaces 2023, 10, 2300121. [Google Scholar] [CrossRef]

- Jain, R.; Pitchumani, R. Facile fabrication of durable copper-based superhydrophobic surfaces via electrodeposition. Langmuir 2017, 34, 3159–3169. [Google Scholar] [CrossRef]

- Su, F.; Yao, K. Facile fabrication of superhydrophobic surface with excellent mechanical abrasion and corrosion resistance on copper substrate by a novel method. ACS Appl. Mater. Interfaces 2014, 6, 8762–8770. [Google Scholar] [CrossRef]

- Vilaró, I.; Yagüe, J.L.; Borrós, S. Superhydrophobic copper surfaces with anticorrosion properties fabricated by solventless CVD methods. ACS Appl. Mater. Interfaces 2017, 9, 1057–1065. [Google Scholar] [CrossRef]

- Chokshi, A.; Devra, R.S.; Rahul, N.; Vadali, M.; Sett, S. Wettability patterning of titanium surfaces through pulsed laser melting for enhanced condensation heat transfer. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2024; Volume 2766, p. 012144. [Google Scholar]

- Ma, R.; Li, R.; Niu, Q.; Zeng, Y.; Li, J.; Bai, S.; Cheng, Y. Preparation of Superhydrophobic Surfaces Based on Copper Mesh Substrates and Its Application Performance. ACS Omega 2023, 8, 45616–45625. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Wang, F.; Xu, J.; Jin, W. Wear-resistant superhydrophobic and high oleophobic copper surface constructed by tin soldering rod-like copper particles inside protective structure. Surf. Coat. Technol. 2025, 511, 132266. [Google Scholar] [CrossRef]

- Cao, J.; Lv, Z.; Liao, B.; Chen, D.; Tong, W.; Zong, Z.; Li, C.; Xiang, T. In-situ fabrication of superhydrophobic surface on copper with excellent anti-icing and anti-corrosion properties. Mater. Today Commun. 2022, 33, 104633. [Google Scholar] [CrossRef]

- Sasmal, A.K.; Mondal, C.; Sinha, A.K.; Gauri, S.S.; Pal, J.; Aditya, T.; Ganguly, M.; Dey, S.; Pal, T. Fabrication of superhydrophobic copper surface on various substrates for roll-off, self-cleaning, and water/oil separation. ACS Appl. Mater. Interfaces 2014, 6, 22034–22043. [Google Scholar] [CrossRef]

- Zhou, H.; Ning, L.; Luo, W.; Liu, H. Self-assembled superhydrophobic coating on the beryllium copper surface with a micro–nano dual-scale structure for anti-icing. Langmuir 2025, 41, 4806–4816. [Google Scholar] [CrossRef]

- ASTM B117-19; Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International: West Conshohocken, PA, USA, 2019.

- Rahul, N.; Kalita, S.; Sen, P.; Shil, B.; Sen, D. Enhanced pool boiling heat transfer characteristics on microstructured copper surfaces coated with hybrid nanofluid. J. Therm. Anal. Calorim. 2024, 149, 6281–6293. [Google Scholar] [CrossRef]

- Kumar, R.; Kumari, P.; Rahul, N.; Sen, D.; Mandal, S.K. Experimental comparison of pool boiling characteristics between CNT, GO, and CNT+ GO-coated copper substrate. Heat Transf. 2024, 53, 2809–2825. [Google Scholar] [CrossRef]

- Rahul, N.; Kumar, N.; Sett, S. Delayed Condensation on Nanoparticle Coated Transparent Lubricant-Infused Surfaces. In Proceedings of the 27th National and 5th International ISHMT-ASTFE Heat and Mass Transfer Conference December 14–17, 2023, IIT Patna, Patna-801106, Bihar, India; Begel House Inc.: Danbury, CT, USA, 2024. [Google Scholar]

- Xiong, X.L.; Tao, X.; Zhou, Q.J.; Li, J.X.; Volinsky, A.A.; Su, Y.J. Hydrostatic pressure effects on hydrogen permeation in A514 steel during galvanostatic hydrogen charging. Corros. Sci. 2016, 112, 86–93. [Google Scholar] [CrossRef]

- Barenji, A.B.; Eivani, A.R.; Hasheminiasari, M.; Park, N.; Jafarian, H.R. Application of hot forming cold die quenching for facilitating equal channel angular pressing of AA2024 aluminum alloy. J. Alloys Compd. 2019, 791, 265–277. [Google Scholar] [CrossRef]

- Liu, R.; Pan, S.; Liu, M.; Huang, W.; Lv, Z.; He, A. A label-free electrochemical biosensor with magnetically induced self-assembly for the detection of CYP2C9* 3 gene. Appl. Surf. Sci. 2021, 537, 147868. [Google Scholar] [CrossRef]

- Qi, K.; Zhou, Q.; Yang, W. Impact contact mechanical performance evaluation of coated medium by semi-analytical method. Surf. Coat. Technol. 2022, 444, 128689. [Google Scholar] [CrossRef]

| Sample | Rs | Rf | Rct | CPEf | CPEdl | m | n | Rp (Ω cm2) | IE (%) |

|---|---|---|---|---|---|---|---|---|---|

| (Ω cm2) | (F/cm2) | ||||||||

| UC | 12.77 | - | 5421 | - | 1.13 × 10−4 | - | 0.76 | 5421 | - |

| SHPL | 16.7 | 1125 | 31,240 | 3.87 × 10−6 | 8.54 × 10−5 | 0.80 | 0.59 | 32,365 | 82.6 |

| HPB | 13.57 | 755 | 8776 | 1.32 × 10−4 | 1.46 × 10−4 | 0.89 | 0.45 | 9531 | 38.2 |

| SHPB | 32.1 | 1226 | 187,204 | 1.46 × 10−6 | 1.58 × 10−5 | 0.81 | 0.64 | 188,430 | 97.1 |

| Sample | Ecorr (V) | icorr (µA/cm2) | Corrosion Rate (MPY) | IE (%) |

|---|---|---|---|---|

| UC | −0.350 | 5.900 | 2.720 | - |

| SHPL | −0.134 | 0.560 | 0.258 | 90.5 |

| HPB | −0.261 | 1.290 | 0.595 | 78.1 |

| SHPB | −0.171 | 0.082 | 0.038 | 98.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahul, N.; Park, B.; Pradhan, S.K.; Sung, H.-E.; Jeong, I.-H.; Yun, Y.-S.; Oh, M.-S. Scalable Engineering of Superhydrophobic Copper Surfaces with Enhanced Corrosion Resistance by Combined Nanostructuring and Chemical Vapor Deposition. Materials 2025, 18, 3981. https://doi.org/10.3390/ma18173981

Rahul N, Park B, Pradhan SK, Sung H-E, Jeong I-H, Yun Y-S, Oh M-S. Scalable Engineering of Superhydrophobic Copper Surfaces with Enhanced Corrosion Resistance by Combined Nanostructuring and Chemical Vapor Deposition. Materials. 2025; 18(17):3981. https://doi.org/10.3390/ma18173981

Chicago/Turabian StyleRahul, N., Beomguk Park, Sanjaya Kumar Pradhan, Ho-Eon Sung, Inn-Hyup Jeong, Yong-Sup Yun, and Min-Suk Oh. 2025. "Scalable Engineering of Superhydrophobic Copper Surfaces with Enhanced Corrosion Resistance by Combined Nanostructuring and Chemical Vapor Deposition" Materials 18, no. 17: 3981. https://doi.org/10.3390/ma18173981

APA StyleRahul, N., Park, B., Pradhan, S. K., Sung, H.-E., Jeong, I.-H., Yun, Y.-S., & Oh, M.-S. (2025). Scalable Engineering of Superhydrophobic Copper Surfaces with Enhanced Corrosion Resistance by Combined Nanostructuring and Chemical Vapor Deposition. Materials, 18(17), 3981. https://doi.org/10.3390/ma18173981