Influence of Surface Treatments on the Pull-Off Performance of Adhesively Bonded Polylactic Acid (PLA) Specimens Manufactured by Fused Deposition Modeling (FDM)

Abstract

1. Introduction

2. Materials and Methods

2.1. Surface Characterization

- 1.

- Untreated (UT): Specimens used in their original condition, directly after the FDM printing process, without any additional cleaning, surface modification, or post-processing. This condition preserves the native topography and any surface residues generated during printing.

- 2.

- Alcohol Cleaning (AL-C): The bonding surface was cleaned using 99% isopropyl alcohol (IPA) applied with lint-free wipes to remove possible contaminants and surface release agents.

- 3.

- Mechanical Abrasion (MA): The surface was abraded using P240 grit sandpaper applied manually in a circular motion. To minimize variability, all specimens were treated by the same operator using a consistent motion and fixed duration. While manual sanding may introduce some limitations in terms of reproducibility, it reflects a widely used and accessible surface preparation technique in industrial practice (particularly suitable for parts with complex geometries or when automation is not feasible). Therefore, despite its manual nature, this treatment retains practical relevance and offers valuable insights into real-world bonding conditions.

- 4.

- Acetone Cleaning (AC-C): The bonding surface was cleaned using 99% acetone applied with lint-free wipes in a uniform manner.

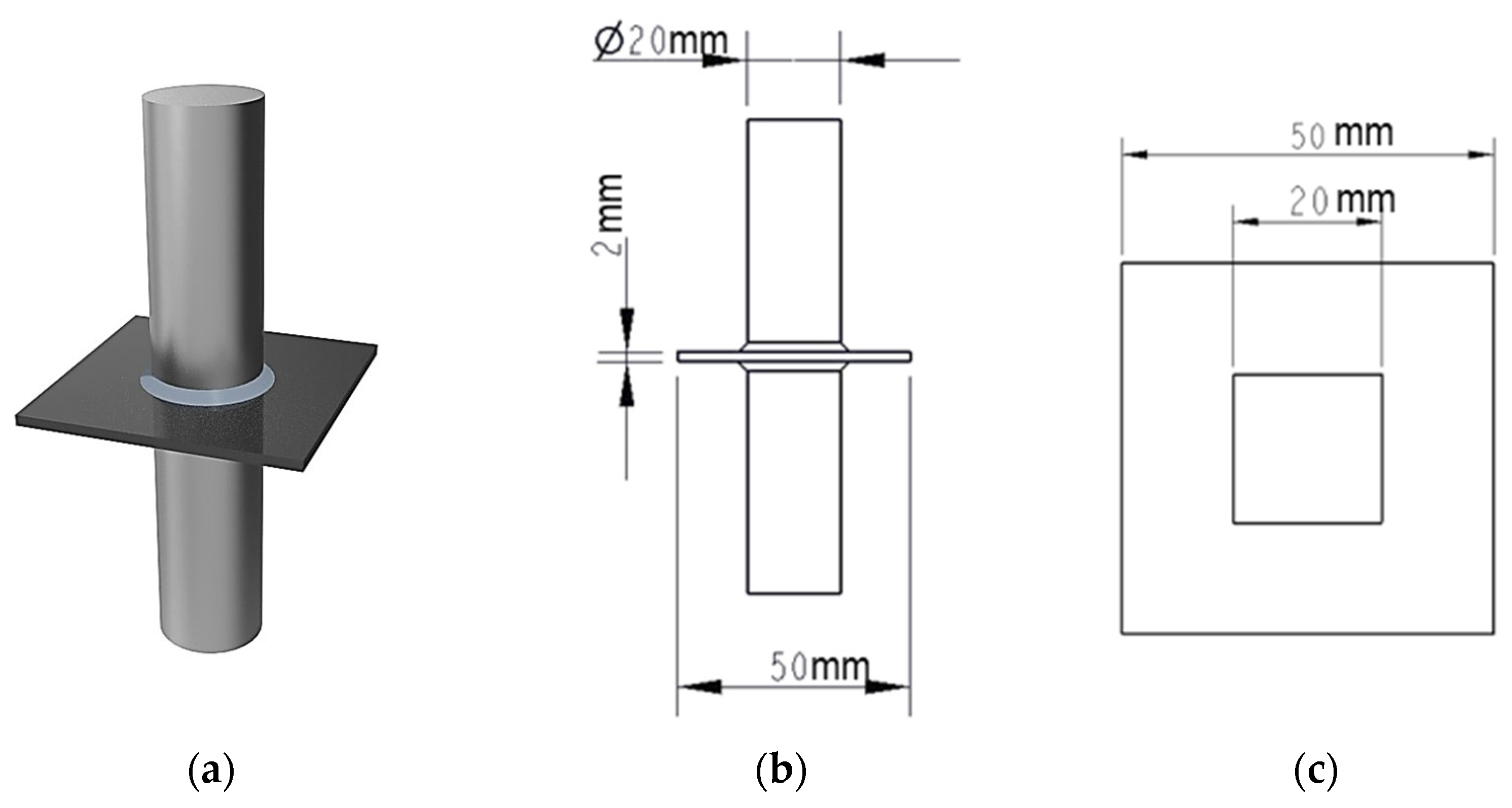

2.2. Adhesion Tests

3. Results and Discussion

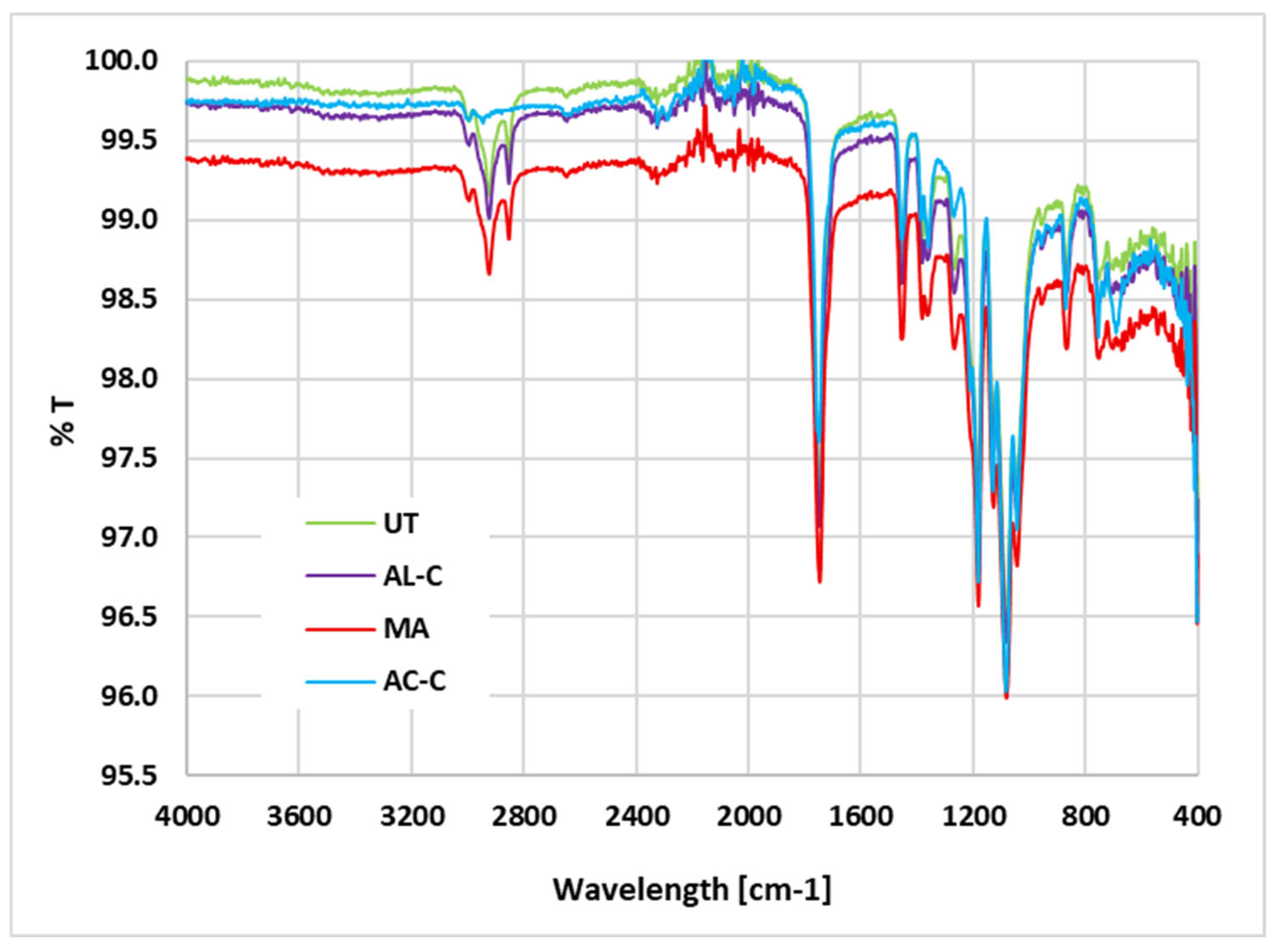

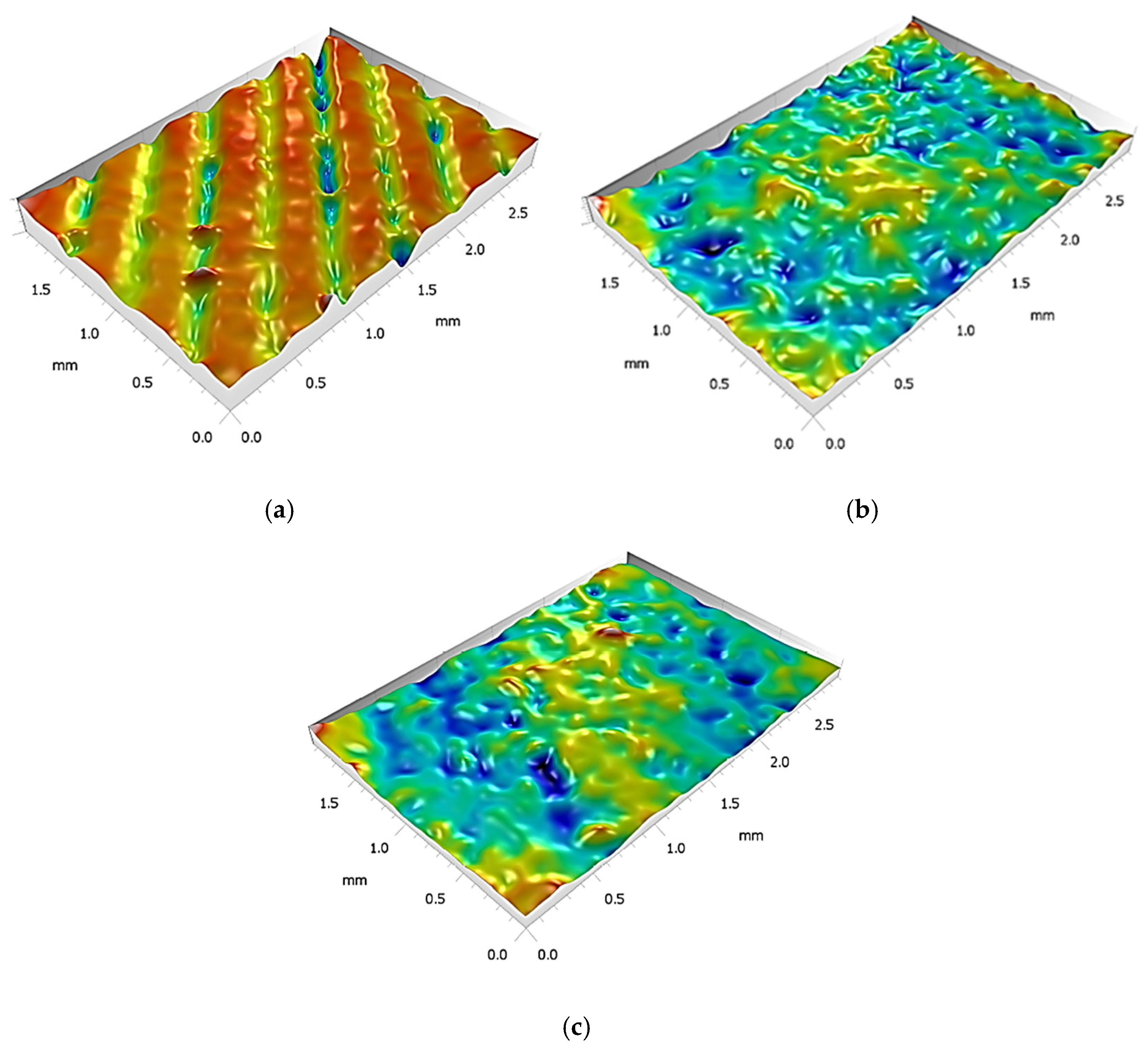

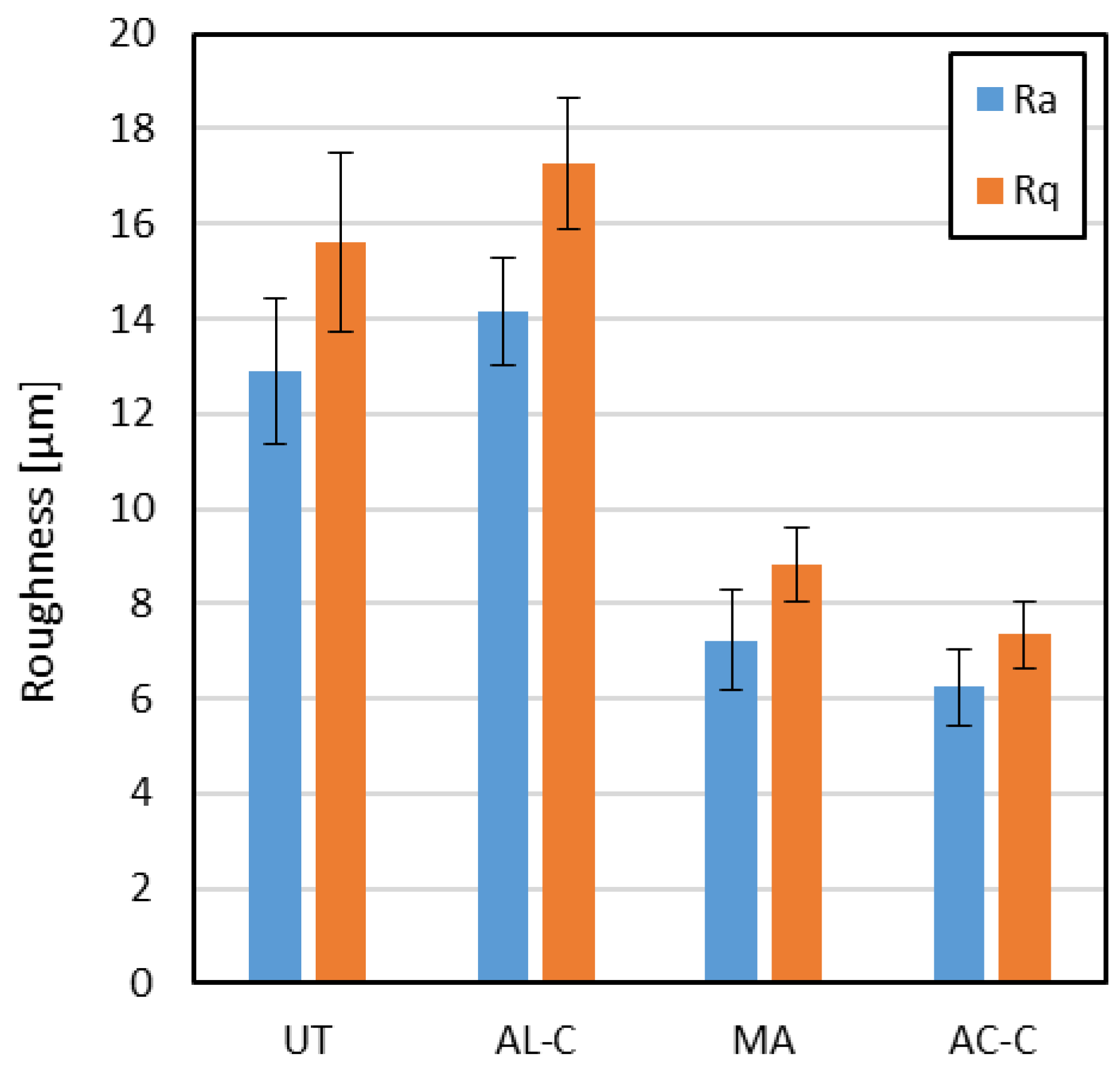

3.1. Surface Characterization

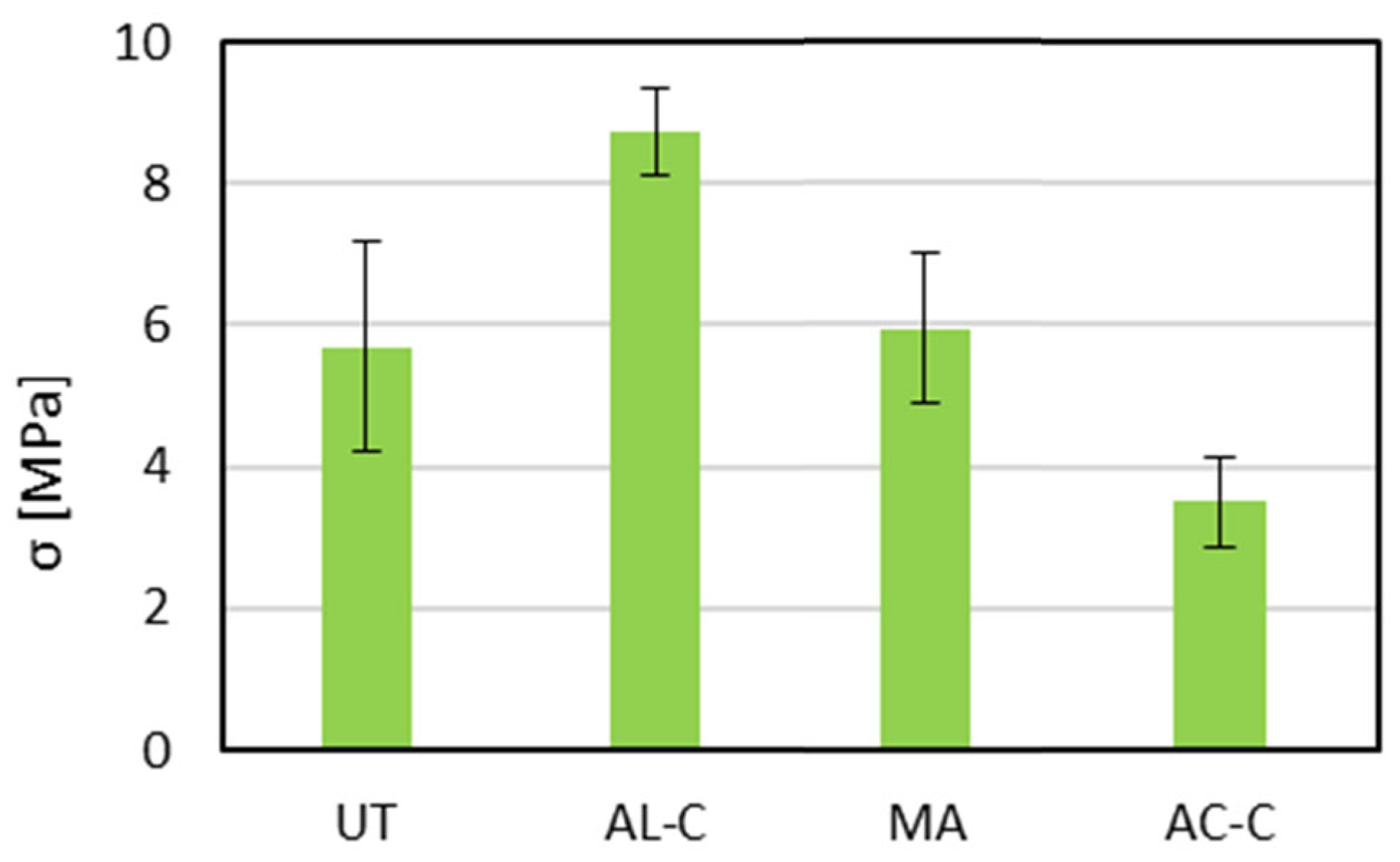

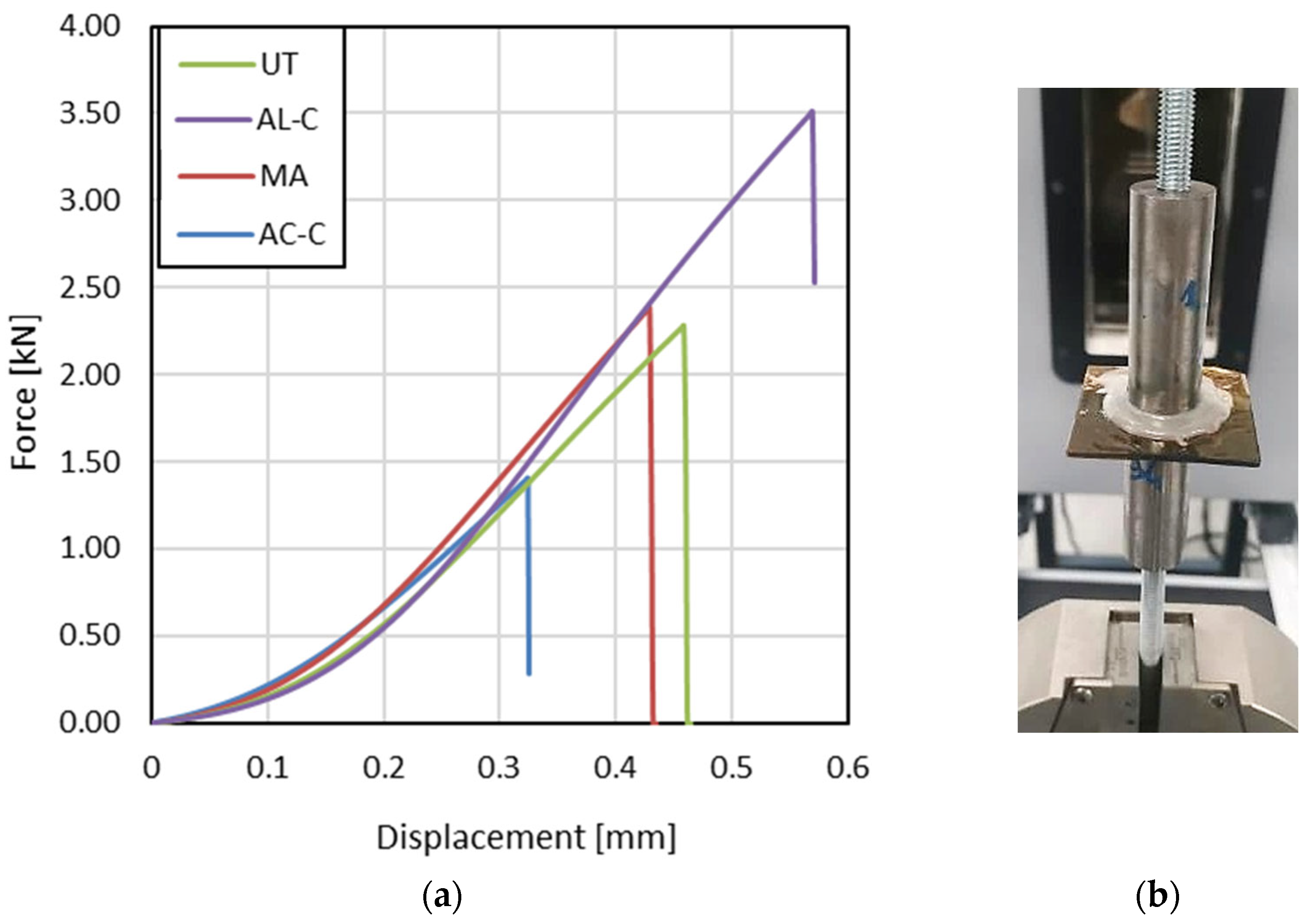

3.2. Adhesion Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baldan, A. Adhesion Phenomena in Bonded Joints. Int. J. Adhes. Adhes. 2012, 38, 95–116. [Google Scholar] [CrossRef]

- Anaç, N. Assessment of Adhesively Bonded Joints of Similar and Dissimilar Materials: Industrial Case Study. Processes 2023, 11, 1312. [Google Scholar] [CrossRef]

- Karthikeyan, N.; Naveen, J. Progress in Adhesive-Bonded Composite Joints: A Comprehensive Review. J. Reinf. Plast. Compos. 2024. [Google Scholar] [CrossRef]

- Sorrentino, L.; Parodo, G.; Giuliano, G. Lightweight Structures: An Innovative Method to Uniform the Thickness of Metal Sheets by Patchwork Blanks. Int. J. Lightweight Mater. Manuf. 2022, 5, 20–28. [Google Scholar] [CrossRef]

- Li, C.; Viswanathan-Chettiar, S.; Sun, F.; Shi, Z.; Blackman, B. Effect of CFRP Surface Topography on the Adhesion and Strength of Composite-Composite and Composite-Metal Joints. Compos. Part A Appl. Sci. Manuf. 2023, 164, 107275. [Google Scholar] [CrossRef]

- Sorrentino, L.; Polini, W.; Bellini, C.; Parodo, G. Surface Treatment of CFRP: Influence on Single Lap Joint Performances. Int. J. Adhes. Adhes. 2018, 85, 225–233. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

- Kaščak, J.; Gašpár, Š.; Paško, J.; Husár, J.; Knapčíková, L. Polylactic Acid and Its Cellulose Based Composite as a Significant Tool for the Production of Optimized Models Modified for Additive Manufacturing. Sustainability 2021, 13, 1256. [Google Scholar] [CrossRef]

- Daly, M.; Tarfaoui, M.; Chihi, M.; Bouraoui, C. FDM Technology and the Effect of Printing Parameters on the Tensile Strength of ABS Parts. Int. J. Adv. Manuf. Technol. 2023, 126, 5307–5323. [Google Scholar] [CrossRef]

- Palmieri, F.L.; Belcher, M.A.; Wohl, C.J.; Blohowiak, K.Y.; Connell, J.W. Laser Ablation Surface Preparation for Adhesive Bonding of Carbon Fiber Reinforced Epoxy Composites. Int. J. Adhes. Adhes. 2016, 68, 95–101. [Google Scholar] [CrossRef]

- Parodo, G.; Sorrentino, L.; Turchetta, S.; Moffa, G. Evaluation of the Accuracy of a Fused Deposition Modeling Process in the Production of Low-Density ABS Lattice Structures. Materials 2025, 18, 1679. [Google Scholar] [CrossRef]

- Vorkapić, M.; Mladenović, I.; Pergal, M.; Ivanov, T.; Baltić, M. Optimisation of Tensile Stress of Poly(Lactic Acid) 3D Printed Materials Using Response Surface Methodology. Tribol. Mater. 2022, 1, 70–80. [Google Scholar] [CrossRef]

- Gajjar, T.; Yang, R.; Ye, L.; Zhang, Y.X. Effects of Key Process Parameters on Tensile Properties and Interlayer Bonding Behavior of 3D Printed PLA Using Fused Filament Fabrication. Prog. Addit. Manuf. 2025, 10, 1261–1280. [Google Scholar] [CrossRef]

- Kamer, M.S. Investigation of the Effects of Different Curing Methods on the Adhesion Strength of Single-Lap Joints Produced by Bonding 3D-Printed ABS and PLA Plates with Different Epoxy Adhesives. Polymers 2025, 17, 768. [Google Scholar] [CrossRef] [PubMed]

- Baran, E.H.; Erbil, H.Y. Surface Modification of 3D Printed PLA Objects by Fused Deposition Modeling: A Review. Colloids and Interfaces 2019, 3, 43. [Google Scholar] [CrossRef]

- Kariž, M.; Tomec, D.K.; Dahle, S.; Kuzman, M.K.; Šernek, M.; Žigon, J. Effect of Sanding and Plasma Treatment of 3D-Printed Parts on Bonding to Wood with PVAc Adhesive. Polymers 2021, 13, 1211. [Google Scholar] [CrossRef]

- Mashayekhi, F.; Bardon, J.; Westermann, S.; Addiego, F. Adhesion Optimization between Incompatible Polymers through Interfacial Engineering. Polymers 2021, 13, 4273. [Google Scholar] [CrossRef]

- Valerga Puerta, A.P.; Fernandez-Vidal, S.R.; Batista, M.; Girot, F. Fused Deposition Modelling Interfacial and Interlayer Bonding in PLA Post-Processed Parts. Rapid Prototyp. J. 2019, 26, 585–592. [Google Scholar] [CrossRef]

- Alsoufi, M.S.; Alhazmi, M.W.; Suker, D.K.; Yunus, M.; Malibari, R.O. From 3D Models to FDM 3D Prints: Experimental Study of Chemical Treatment to Reduce Stairs-Stepping of Semi-Sphere Profile. AIMS Mater. Sci. 2019, 6, 1086–1106. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Gache, C.C.L.; Cascolan, H.M.S.; Cancino, L.T.; Advincula, R.C. Post-Processing of 3D-Printed Polymers. Technologies 2021, 9, 61. [Google Scholar] [CrossRef]

- Chueca de Bruijn, A.; Gómez-Gras, G.; Pérez, M.A. A Comparative Analysis of Chemical, Thermal, and Mechanical Post-Process of Fused Filament Fabricated Polyetherimide Parts for Surface Quality Enhancement. Materials 2021, 14, 5880. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications—A Comprehensive Review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Nozzle temperature | 220 °C |

| Bed temperature | 60 °C |

| Layer height | 0.1 mm |

| Infill density | 100% |

| Printing speed | 60 mm/s |

| Nozzle diameter | 0.4 mm |

| Raster orientation | ±45° |

| Surface Preparation | Label | Number of Specimens |

|---|---|---|

| Untreated | UT | 5 |

| Isopropyl Alcohol Cleaning | AL-C | 5 |

| Mechanical Abrasion | MA | 5 |

| Acetone Cleaning | AC-C | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parodo, G.; Moffa, G.; Silvestri, A.; Sorrentino, L.; Testa, G.; Turchetta, S. Influence of Surface Treatments on the Pull-Off Performance of Adhesively Bonded Polylactic Acid (PLA) Specimens Manufactured by Fused Deposition Modeling (FDM). Materials 2025, 18, 3965. https://doi.org/10.3390/ma18173965

Parodo G, Moffa G, Silvestri A, Sorrentino L, Testa G, Turchetta S. Influence of Surface Treatments on the Pull-Off Performance of Adhesively Bonded Polylactic Acid (PLA) Specimens Manufactured by Fused Deposition Modeling (FDM). Materials. 2025; 18(17):3965. https://doi.org/10.3390/ma18173965

Chicago/Turabian StyleParodo, Gianluca, Giuseppe Moffa, Alessandro Silvestri, Luca Sorrentino, Gabriel Testa, and Sandro Turchetta. 2025. "Influence of Surface Treatments on the Pull-Off Performance of Adhesively Bonded Polylactic Acid (PLA) Specimens Manufactured by Fused Deposition Modeling (FDM)" Materials 18, no. 17: 3965. https://doi.org/10.3390/ma18173965

APA StyleParodo, G., Moffa, G., Silvestri, A., Sorrentino, L., Testa, G., & Turchetta, S. (2025). Influence of Surface Treatments on the Pull-Off Performance of Adhesively Bonded Polylactic Acid (PLA) Specimens Manufactured by Fused Deposition Modeling (FDM). Materials, 18(17), 3965. https://doi.org/10.3390/ma18173965