1. Introduction

The application of mechanical multi-pin joints, including bolted joints and riveted joints, in composite materials is a commonly used connection method for engineering structures. This method is particularly prevalent when connecting critical load-bearing composite structures in aircraft. However, this leads to a more complex load distribution near the joints, thereby imposing higher demands on stress analysis and structural design in the connection area [

1].

Owing to the high sensitivity of the ply angle in composite lap joints, this phenomenon will affect the effective stiffness and bearing capacity of riveted composite assemblies [

2]. In a study by Franco [

3], it was shown that angle ply ([0/90/(±45)

2]

s) laminates could nearly double the energy absorption of riveted joints compared to other configurations, and they had a higher ultimate load. Meanwhile, in the work of Seyednourani et al. [

4], a laminate with a cross-ply configuration was found to possess a higher ultimate load than a laminate with an angle ply layup in sequence [45/−45]

4s. Joint testing revealed that the failure modes of the pins included rivet shear, rivet tilt, and rivet pull-out [

5]. Excessive interference in composite riveted joints can result in exceedance of the elastic deformation limit, leading to initial damage. To maintain the integrity of the joint, recommendations specify that the maximum interference size should not exceed 2% [

6]. The effects of ply thickness and ply angle on the ultimate load of bolted joints have also been studied [

7].

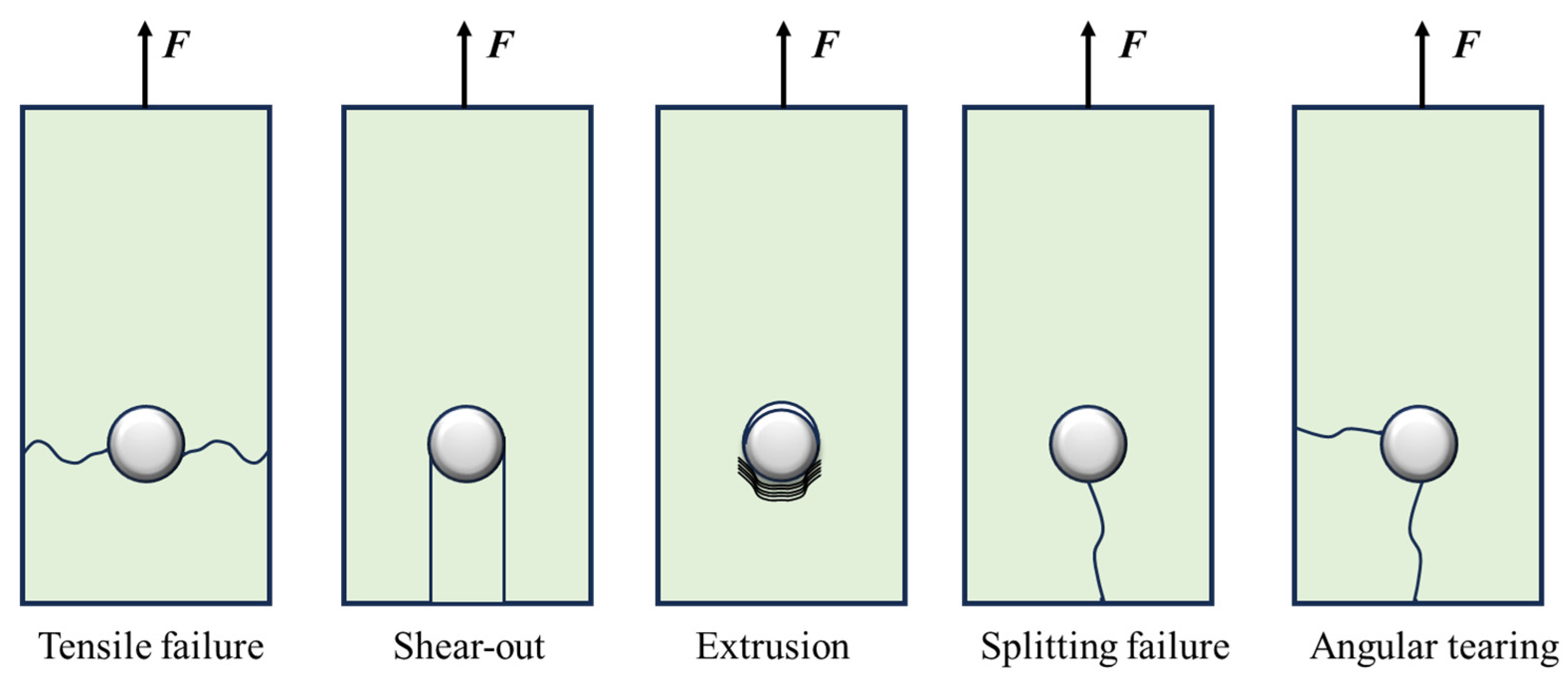

The anisotropy and brittleness of composite materials, coupled with their laminated structures, result in significant stress concentrations in composite bolted joints. These factors lead to complex fracture behaviors and multiple failure modes. As shown in

Figure 1, the primary failure mechanisms of composites in bolted structures can be categorized into tensile failure, shear failure, extrusion failure, and combined failure modes [

8]. In addition, the delamination that occurs on the interface between layers is also considered for bolted joints. Given these failure mechanisms, the reinforcement design of composite bolted joints should focus on two key objectives: (1) increasing tensile strength, for example, by increasing the proportion of 0° fiber layers, and (2) ensuring that extrusion failure remains the dominant failure mode. An optimal reinforcement design should balance enhancing the joint strength while preserving extrusion as the preferred and safer mode of failure.

To address the aforementioned issues, it is essential to model the rivets that serve as the joint connectors. Rivets can be modeled using different methods [

1], such as those using linear springs, nonlinear springs, and nonlinear beam elements. Some finite element programs (such as MSC.NASTRAN) provide bushing elements [

9]. In a study by Pitta [

10], rivets were modeled as point-based fasteners. The properties of the rivets were considered bushing elements with stiffness in six degrees of freedom: three in the translational direction and three in the rotational direction. The stiffness in the translational and rotational directions of bushing elements was calculated using closed-form solutions. Godzimirski [

11] searched for the most effective ways of joining composites, including the use of different fasteners, such as aluminum rivets, Hi-lok, and Jo-Bolt, which differed not only in terms of the materials they were made of but also the pressure forces they exerted on the joined parts. Belardi et al. [

12] evaluated the capabilities of joint elements and a solid model in simulating the multi-column in single-lap composite bolted joints, in which the former showed high efficiency.

In addition to constructing the rivet model, it is also essential to develop an efficient and accurate laminate model to replicate the failure process of composite material joints. From a meso-scale perspective, a composite laminate can be viewed as a three-dimensional structure consisting of multiple stacked layers. Therefore, Camanho and Matthews [

13] proposed a three-dimensional finite element analysis in which the delamination onset criterion was applied at each interface. Djebbar et al. [

14] investigated the effect of beveling a substrate’s geometrical shape on stresses in a bonded single-lap joint. The adhesive mesh consists of a single layer of eight-node three-dimensional cohesive elements, which was proven to be applicable to single-lap joint analysis. In a study by Wang [

15], the general 3D Hashin [

16] failure criterion and the stiffness degradation rule proposed by Tan [

17] were employed to simulate the progressive failure behavior of a glass fiber/polypropylene riveted single-lap joint. Laminates and glass fiber/polypropylene rivets were simulated using linear, eight-node, 3D reduced integration elements. Cohesive elements were inserted into two parts of the model. The detailed intralaminar damage, including matrix cracks and fiber failures, can be predicted using the 3D Hashin criteria, which are generally applied to the material through the coded user-defined material subroutine (VUMAT) in ABAQUS/Explicit. The interlaminar damage (primarily delamination) is simulated using cohesive zone elements [

18,

19]. In the work of Cabrera-González et al. [

20], several finite element analyses and experimental tests were carried out for basic load cases, different materials, and different orientations of the fiber. A tool was provided, thus allowing the users to easily estimate the stress distribution (

,

) along the hole contour and

along the tangential lines to the hole circumference, which can be used for failure predictions. The nonlinear behavior of a single-lap bolted joint of woven glass fiber-reinforced plastic (GFRP) laminates was simulated in the work of Mohapatra et al. [

21]. This nonlinear behavior was caused by shear failure and the damage of woven GFRP laminates. The results of the numerical simulation and experimentation matched well. Shan et al. [

22] proposed a novel numerical prediction method based on a similar model to predict the fatigue failure behavior of a CFRP–aluminum two-bolt, double-lap joint.

In terms of joint modeling, this study focuses on the scarf joint of a helicoidal composite [

23], which has lamination sequences that were inspired by naturally occurring impact-resistant Bouligand structures [

24,

25]. Bouligand-featured structures can be found in a variety of animals, including mantis shrimp [

26], and they can also be found in fish scales [

27] and the exoskeleton of arthropods, such as beetles [

28]. The last segment of the appendage consists of several repetitions of the Bouligand unit stacked up through the thickness [

29]. Each Bouligand unit contains a helicoidal layup with very small pitch angles for a rotation of 180° inside each unit. Research in the field of biomechanics has shown that cracks growing in the matrix of helicoidal composite specimens follow the fiber orientations and lead to the formation of twisted cracks [

25]. A twisted crack growing in the helicoidal architecture amplifies the crack surface per unit volume, thereby enhancing energy dissipation and stress relaxation in the composite without leading to catastrophic failure. Some interlaminar cracks still exist; however, they are regarded as sub-critical delamination rather than the large delamination occurring in ordinary composites. In prior studies, the compressive strength after the impact of helicoidal composites mixed with additional 0° plies and the buckling optimization of curved grid-stiffened panels were investigated [

30,

31]. With their superior impact resistance, helicoidal composite materials may be applied in engineering structures in the future.

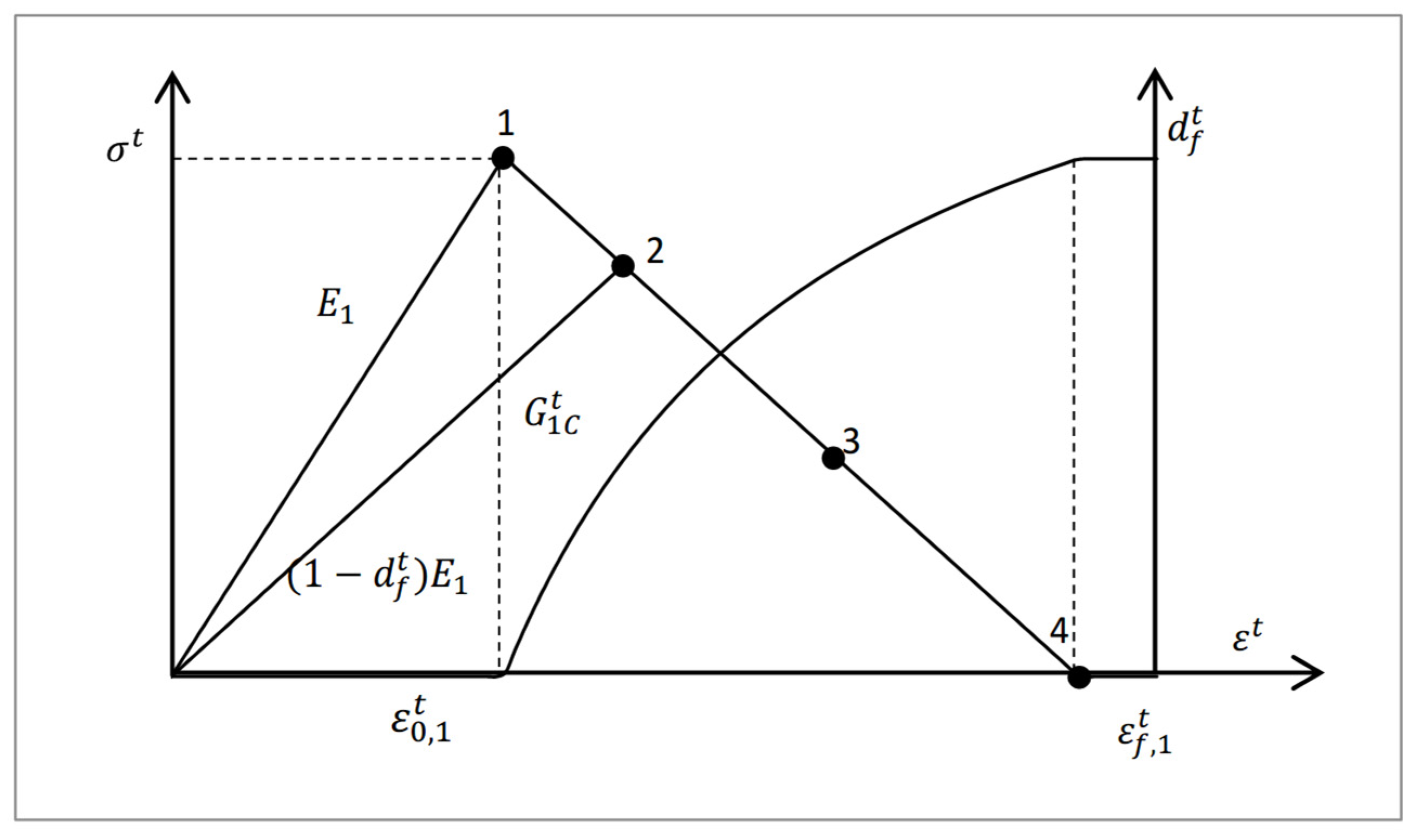

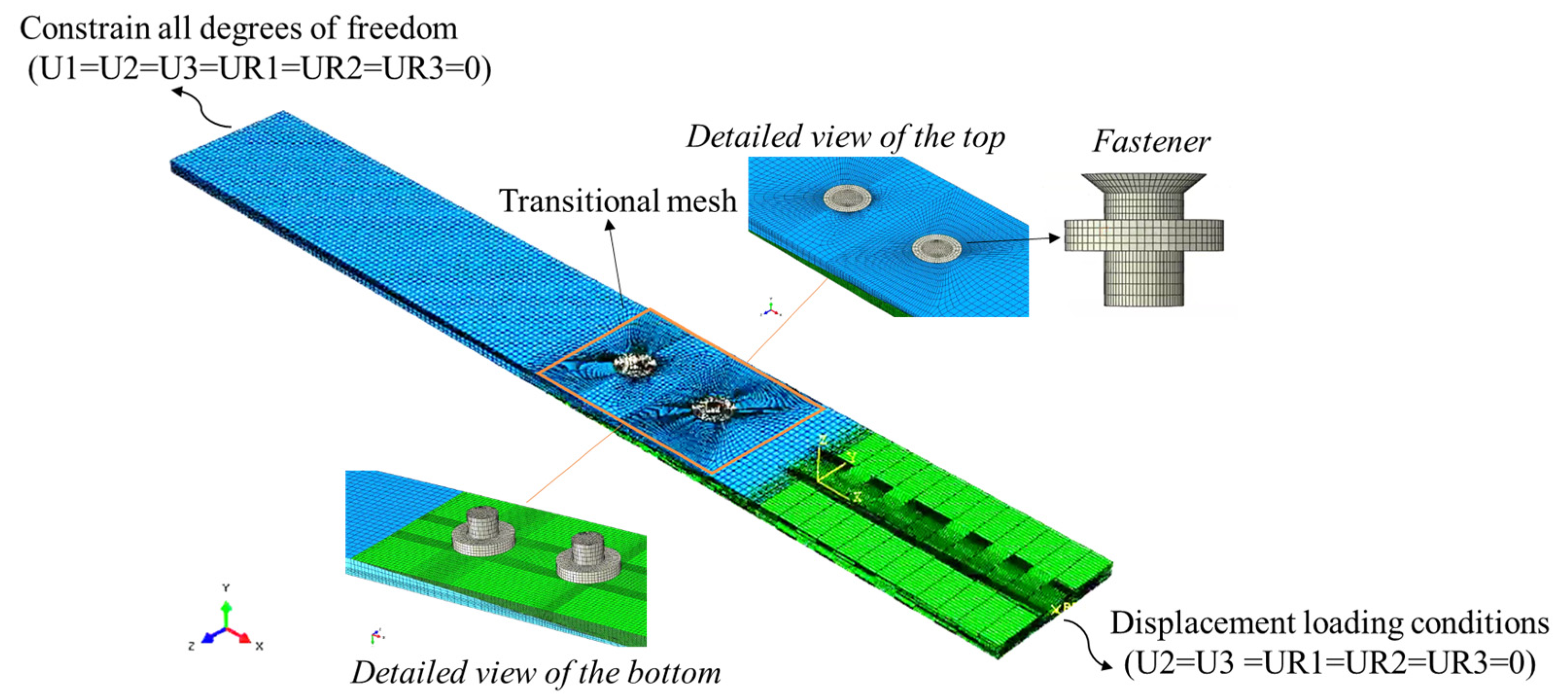

The strength of composite materials after repair is an important performance metric of concern, so the strength of spiral composite materials after repair needs to be studied. Scarf repair plays a significant role in composite laminate repair, and this study focuses on the prediction of the failure mode and failure load of metal/composite scarf joints with double countersunk head bolts. Due to its capabilities in nonlinear analysis, damage definition through the subroutine method, and interlaminar damage simulation, ABAQUS software version 6.14 was employed in the simulation. A progressive damage model, integrated with the enhanced 3D Hashin failure initiation criterion and stiffness degradation, was utilized to analyze the damage evolution in the composite laminate. A normal failure delamination model was developed in the out-of-face direction of the laminate. This approach deviates from the widely used zero-thickness cohesive zone model (CZM), which is typically applied in predicting the failure of carbon fiber-reinforced plastic (CFRP) interfaces and adhesive layer damage. This alternative model enables a more detailed analysis of the mechanical properties of composite laminates through the thickness. The intrinsic properties of the composites were incorporated via the development of a VUMAT subroutine. The progressive damage model was validated with experimental data, and it was utilized to investigate the influence of layup changes on the failure load, particularly in helicoidal laminates.

The remainder of this paper is structured as follows. In

Section 2, the specimen and test setup are presented. The damage initiation criteria, damage evolution model, and the validation of the TC4/CFRP scarf joint are described in

Section 3. In

Section 4, a failure analysis of bolted joints and laminates is presented, and the effect of ply angle is also demonstrated using laminates with a helicoidal layup. Lastly, the key contributions are summarized and potential directions for future work are outlined in

Section 5.

2. Configuration of the Joint Test Schedule

To investigate the damage and failure modes of composite/metal double-bolted, single-shear scarf joints, specimens were designed in accordance with ASTM D5961 standards [

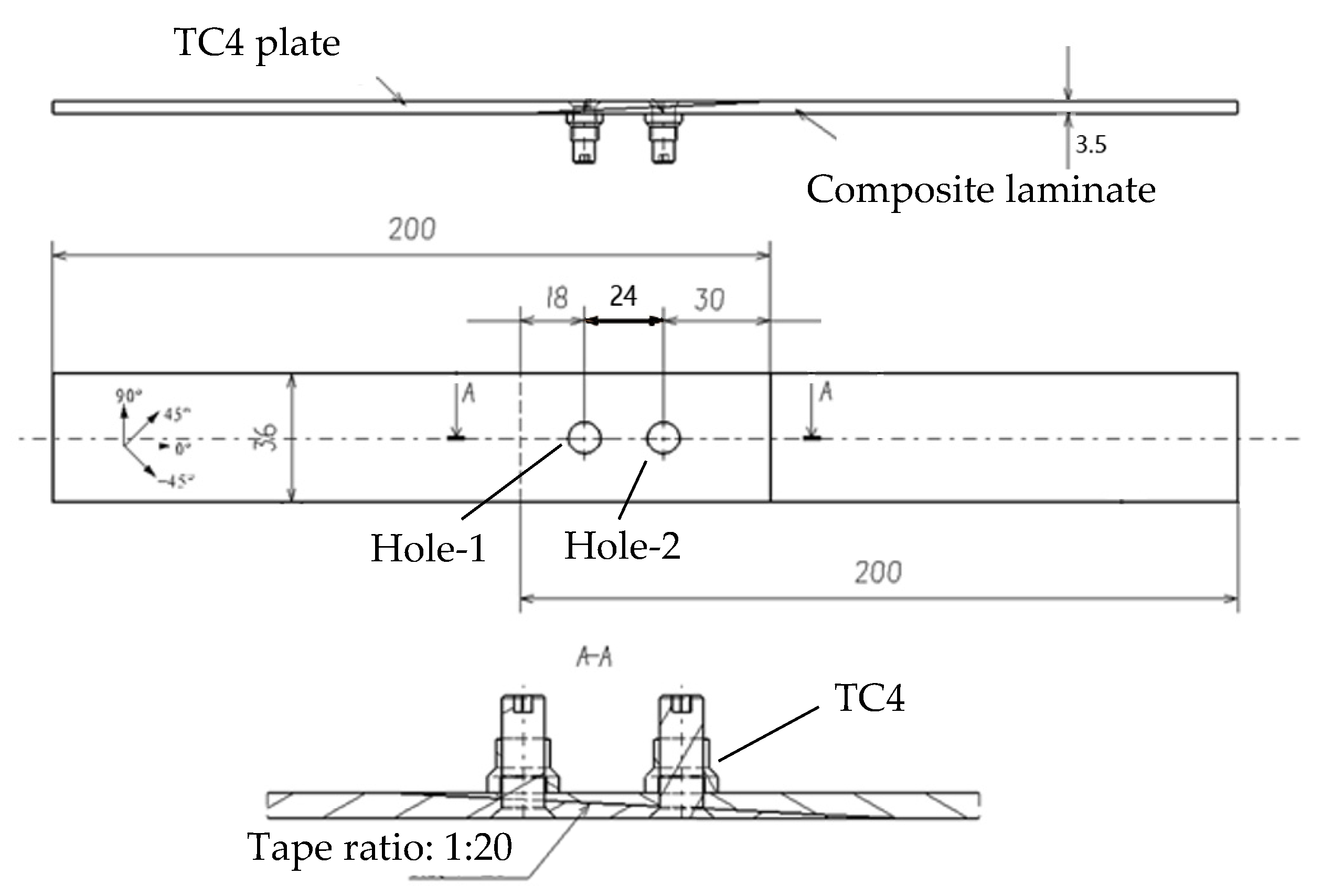

32]. The specimens were fabricated using 5228A/CCF300 CFRP laminates and TC4, as shown in

Figure 2.

The laminate is attached using single-shear, scarf joints. The CFRP laminate has a length of 200 mm and a width of 36 mm, with an edge-to-hole center distance of 18 mm and a spacing of 24 mm between the two holes. The total thickness of the laminate is 3.5 mm, with each layer being 0.125 mm thick. This laminate consists of four distinct ply orientations. Based on principal stress theory, 0° fiber layups are essential for bearing structural tension and compression. To minimize matrix loading in all directions, 90° layups are used sparingly. Additionally, ±45° layups are optimized for the outer surfaces to enhance structural stability and reduce coupling effects. Consequently, the layup sequence is formulated as [45/0/−45/−90/45/03/−45/90/45/02/−45]s.

The metal splice plates are made of a TC4 titanium alloy with a thickness of 3.5 mm. All bolts and gaskets within the joint structure are also constructed using the titanium alloy. The composite laminates and metal plates are joined with countersunk bolts. The shearing bolts, with countersunk heads angled at 100° and a diameter of 6 mm, were designed for precise tightening to ensure an ideal fit between the bolts and holes.

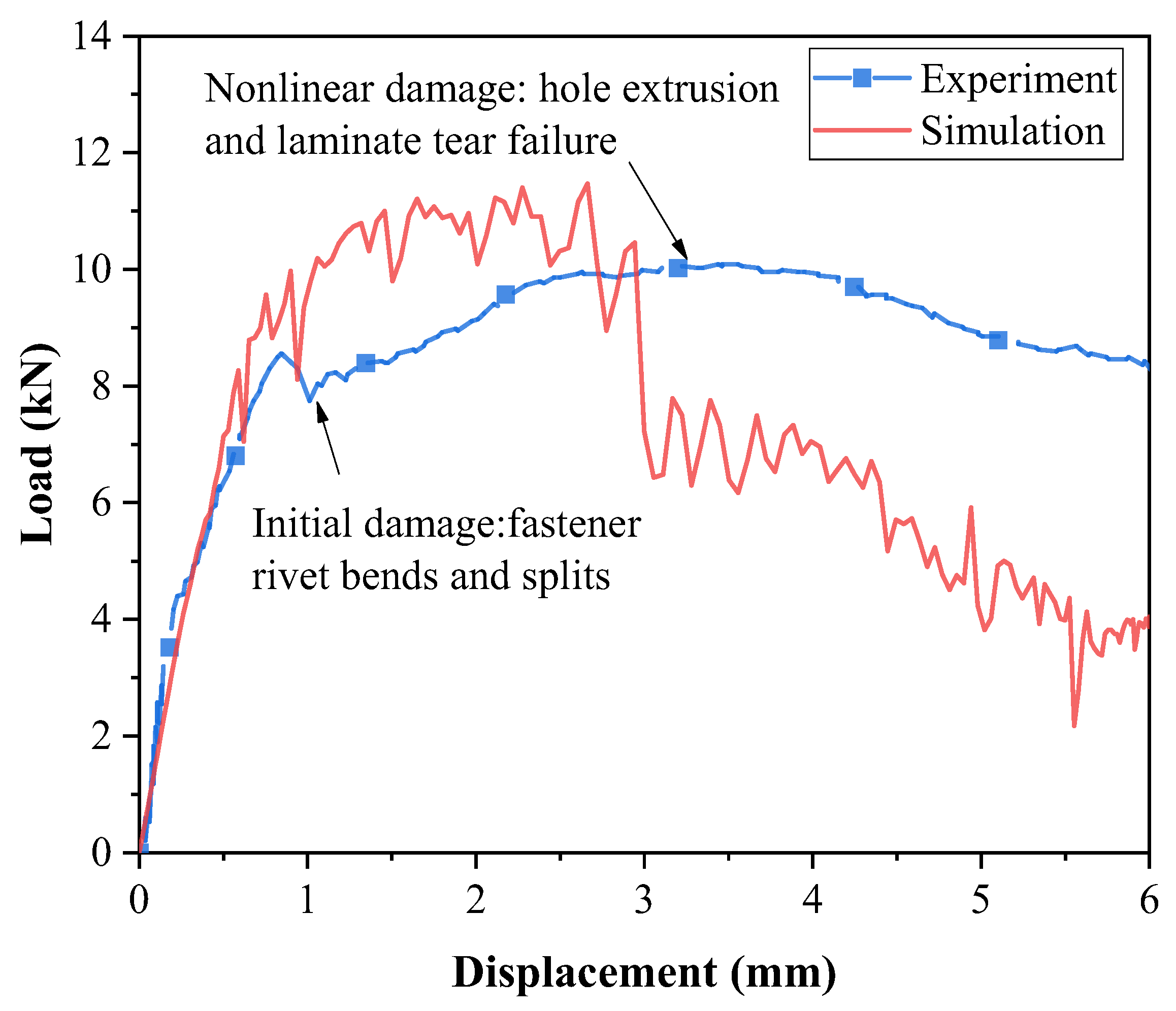

Uniaxial tensile tests were performed in compliance with the ASTM D5961 standard. To prevent slippage during loading, reinforcing plates were installed at both ends of the specimen. The specimen was firmly clamped in the grips of an electronic universal tensile testing machine. The bottom end of the bolted joint specimen was fixed, while a quasi-static displacement load was applied to the upper end. Throughout the testing process, load–displacement data were recorded in real time using a computer.

4. Failure Analysis and Discussion

4.1. Failure Analysis of Bolted Joints

4.1.1. Local Deformation of Scarf Joints

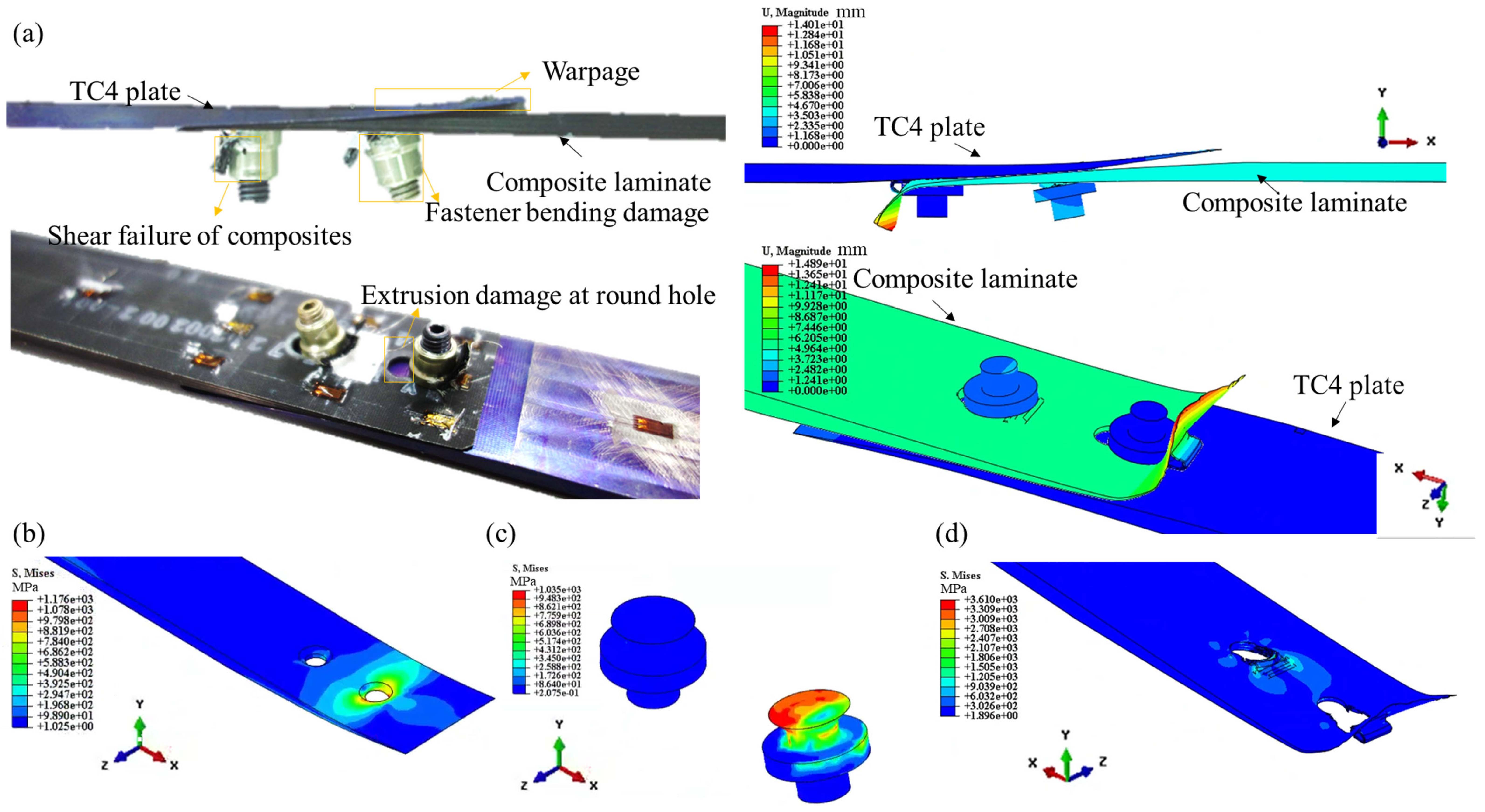

Figure 7a depicts the local deformation and contact area between the fastener holes and bolts in the double-bolt scarf joint.

The introduction of countersunk holes leads to a local reduction in stiffness around the fastener holes in the composite plate. This stiffness disparity is further amplified by the thickness difference caused by the scarf angle, in which the bearing deformation at the upper plate holes is significantly larger than that at the lower plate holes. As a result, the countersunk bolts experience rotation, thus leading to the asymmetric bending of the bolt shanks and radial deformation along the through-thickness path.

As the load increases, the contact area between the upper plate and the bolt shank progressively shifts to the cylindrical section of the hole. This transition enhances the contact area on the upper plate, thus enabling it to more effectively resist the bearing load. Consequently, the localized deformation near the countersunk holes is reduced. Over time, this process mitigates the asymmetry in the bending of the countersunk bolts, thereby delaying structural failure until the ultimate load capacity is exceeded.

As shown in

Figure 8, the loading process induces both damage and plastic deformation in the countersunk bolts.

For bolt 1, in which the laminate is thinner, the contact area is mainly confined to the cylindrical holes. This leads to laminate extrusion and shear damage concentrated along the loading direction. In contrast, at bolt 2, the thicker laminate with greater load-bearing capacity primarily exhibits laminate extrusion damage, accompanied by bolt bending failure.

Throughout the loading process, bolt 2 plays a more significant role in the overall structural response due to its greater load-bearing capacity. This highlights the critical influence of laminate thickness and bolt interaction on structural performance and failure mechanisms.

4.1.2. Stress Distribution Around Fastener Holes

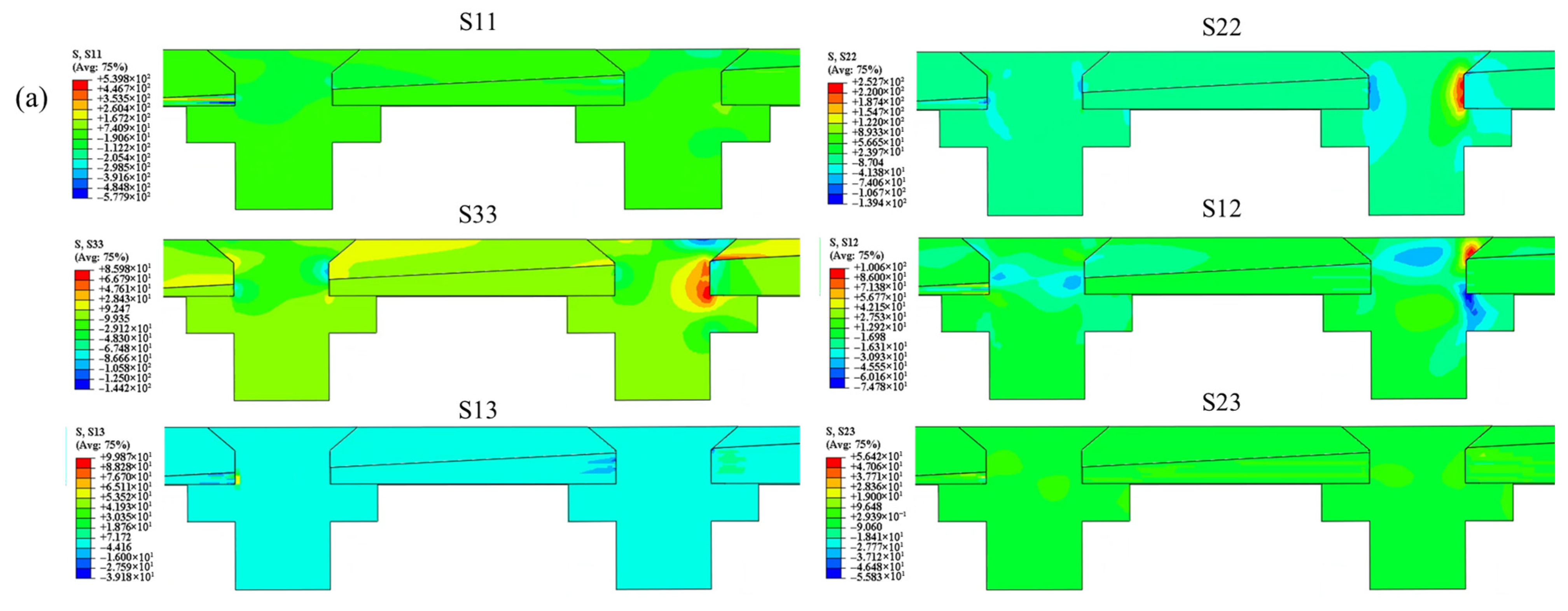

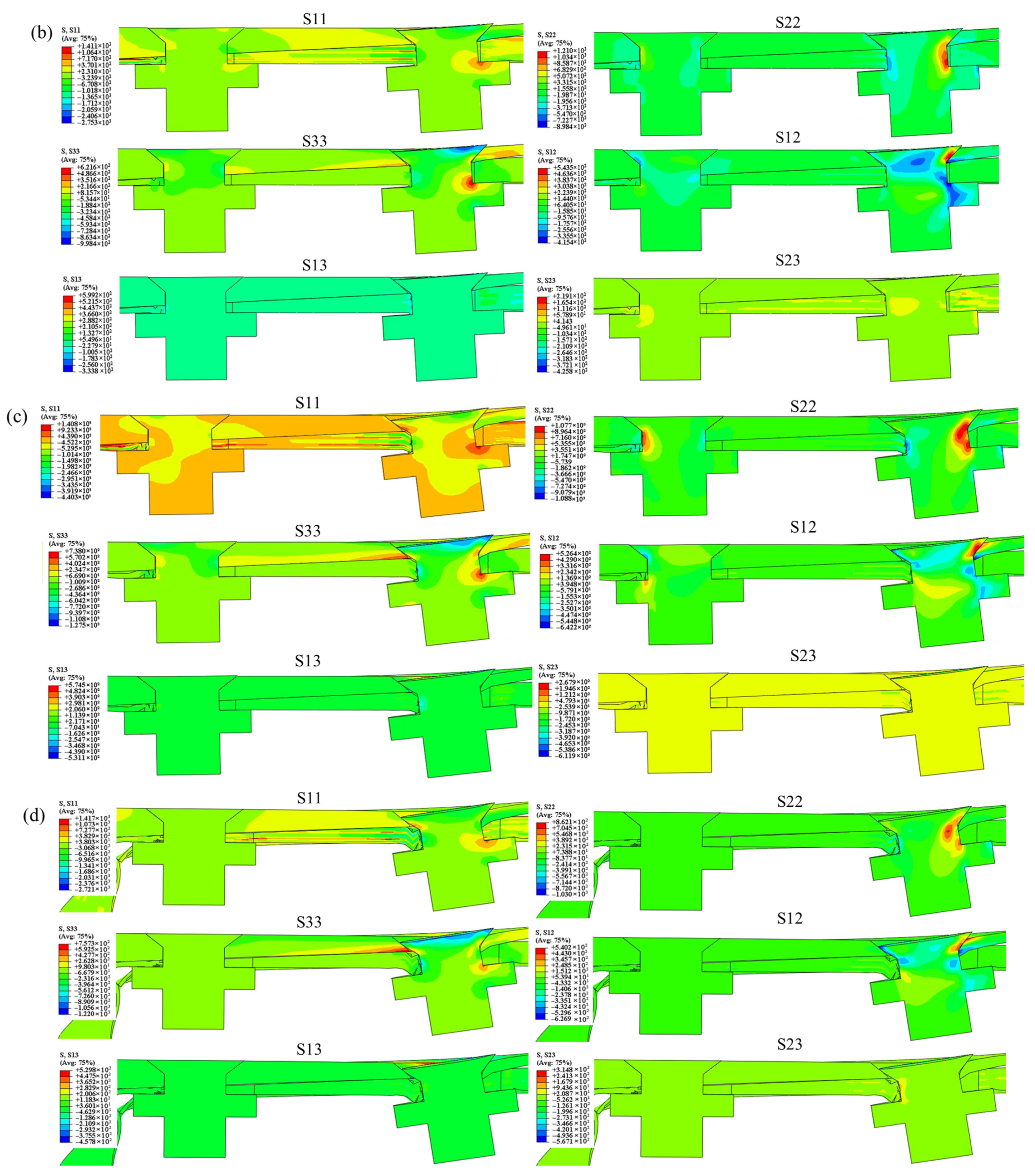

Typical stress contours around fastener holes in the double-bolt joints, as shown in

Figure 9, reveal that critical stress zones for all components are concentrated either on the upper or lower side of the midplane.

In countersunk hole joints, stress components such as S11, S22, S12, and S33 are similarly distributed on the upper or lower side of the center plate. A key observation is that critical stress regions S33 and S13 are particularly located at the start of the countersunk hole in the upper plate, thus illustrating that countersunk holes introduce significant stress concentration in this region. This stress concentration may induce warpage in the upper plate (TC4).

For scarf joints with countersunk head bolts, stress concentrations are primarily found at the countersunk head end and near the threads. In contrast, the tapered portion near the nail experiences only minimal stress concentration. This creates a pronounced stress gradient between the screw and the countersunk head, making the top of the screw prone to significant deformation.

Additionally, the extrusion effect generated by the beveled surface of the countersunk head section may cause delamination damage in the composite plate. This delamination can intensify the sub-buckling phenomenon observed in the scarf joint structure, thus further affecting the joint performance and load-bearing capacity.

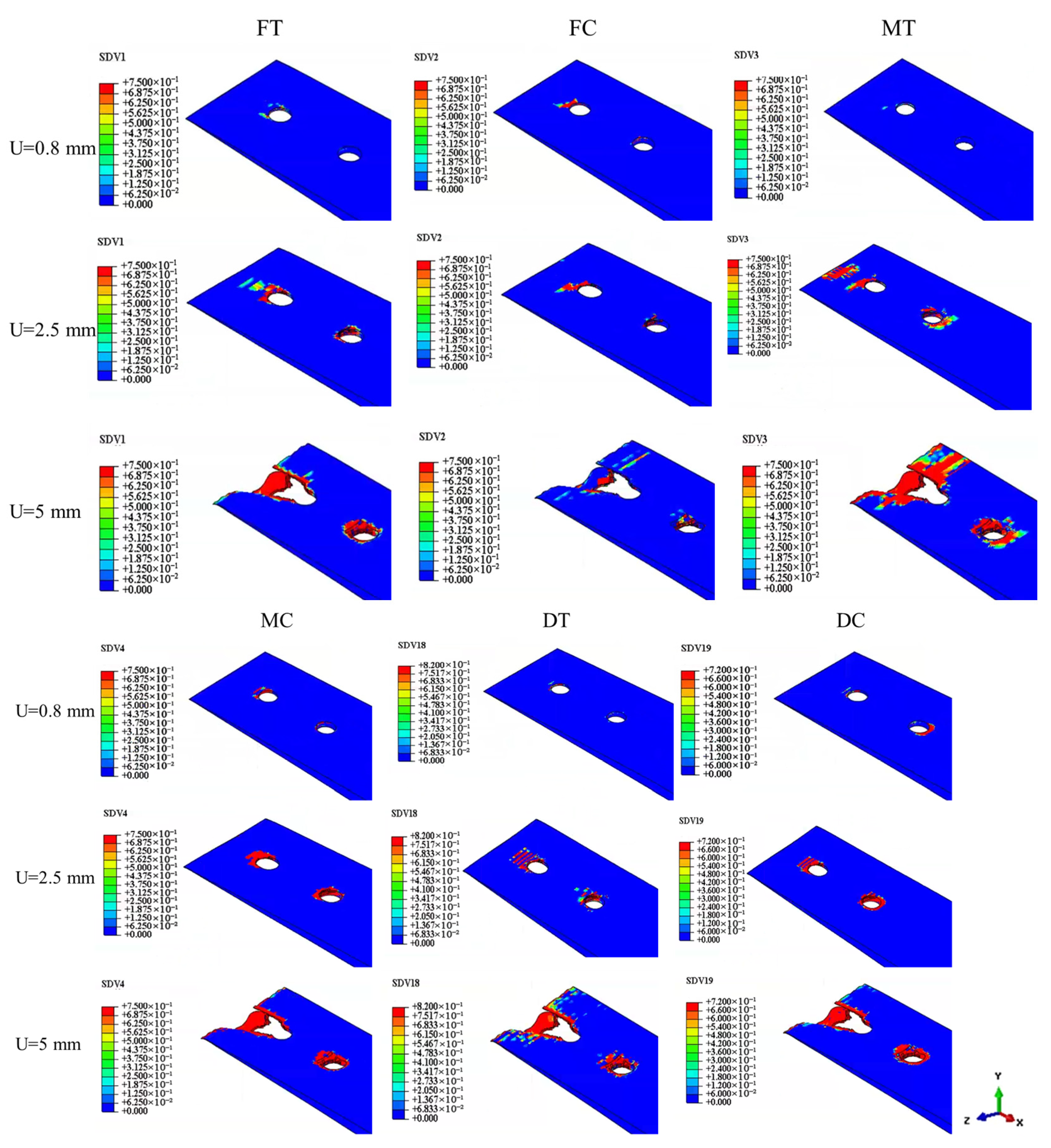

4.2. Failure Analysis of Plates

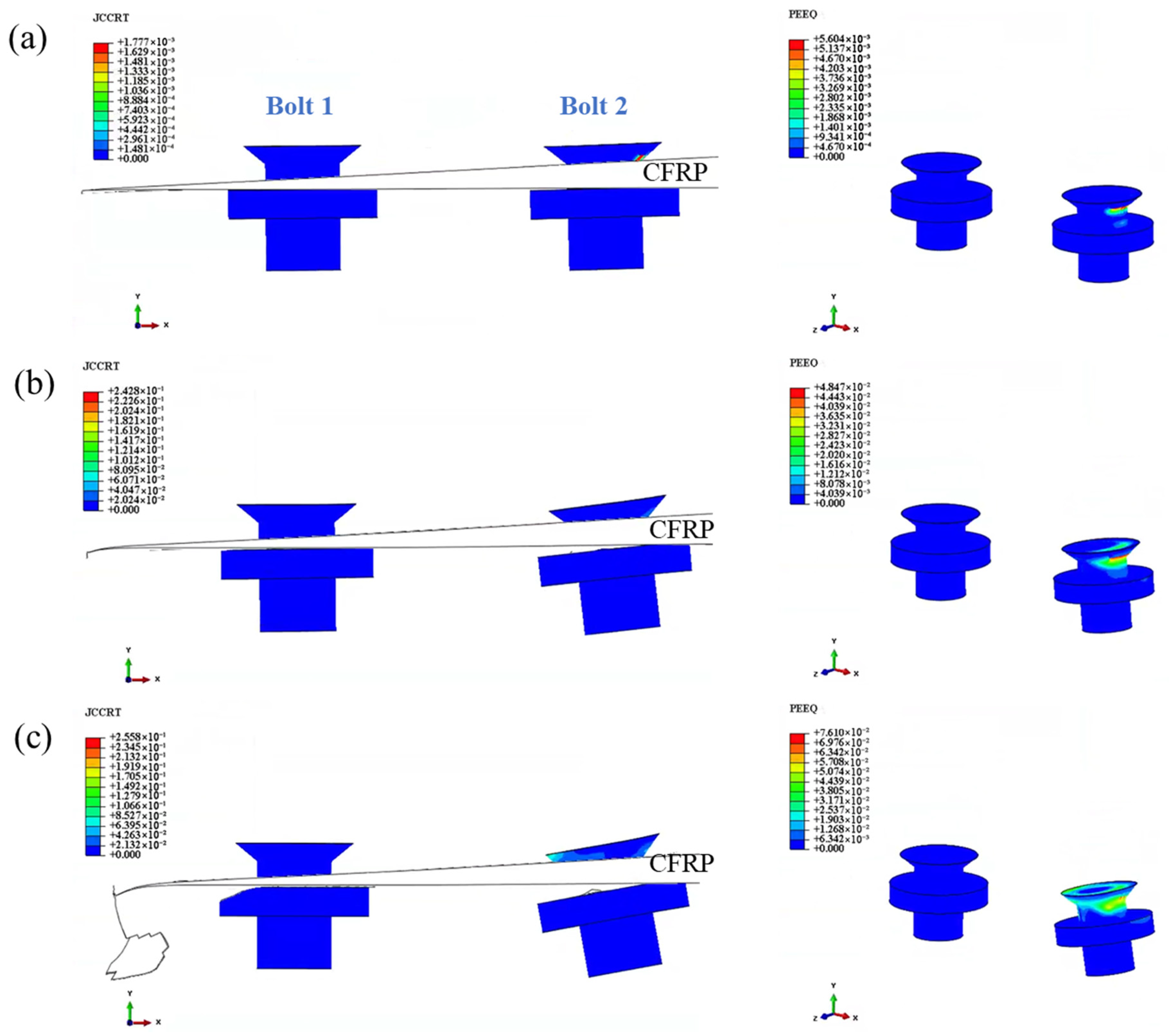

Based on the output variables, the progression of different damage modes in the composite plate can be systematically monitored. Initially, matrix compression and fiber compression damage are the primary damage modes, typically initiating at the 90° layer of the composite lap plate (hole 1), which is the closest to the lap surface. As loading increases, this damage gradually propagates to the inner layers of the lap plate. Subsequently, matrix tensile damage and fiber tensile damage also become evident.

Once the damage progression accelerates, the damage variables in the composite laminate quickly reach their maximum values, and damage extends outward toward the periphery. Simultaneously, the state variable JCCRT (Johnson–Cook damage initiation criterion) of the bolt begins to show positive values, which steadily increase during loading. At the ultimate load stage, the overall damage states, as illustrated in

Figure 10, identify key damage areas, including extrusion and shear-out damage at hole 1 and extrusion damage at hole 2. Furthermore, due to the deflection of bolt 2 during loading, Z-direction damage appears at hole 2.

A comparison of the simulated damage distributions with experimental damage photographs demonstrates strong agreement between the simulation results and test observations. This confirms the accuracy of the model in capturing the primary damage mechanisms, including extrusion, shear-out, and Z-direction damage, along with their propagation during the loading process.

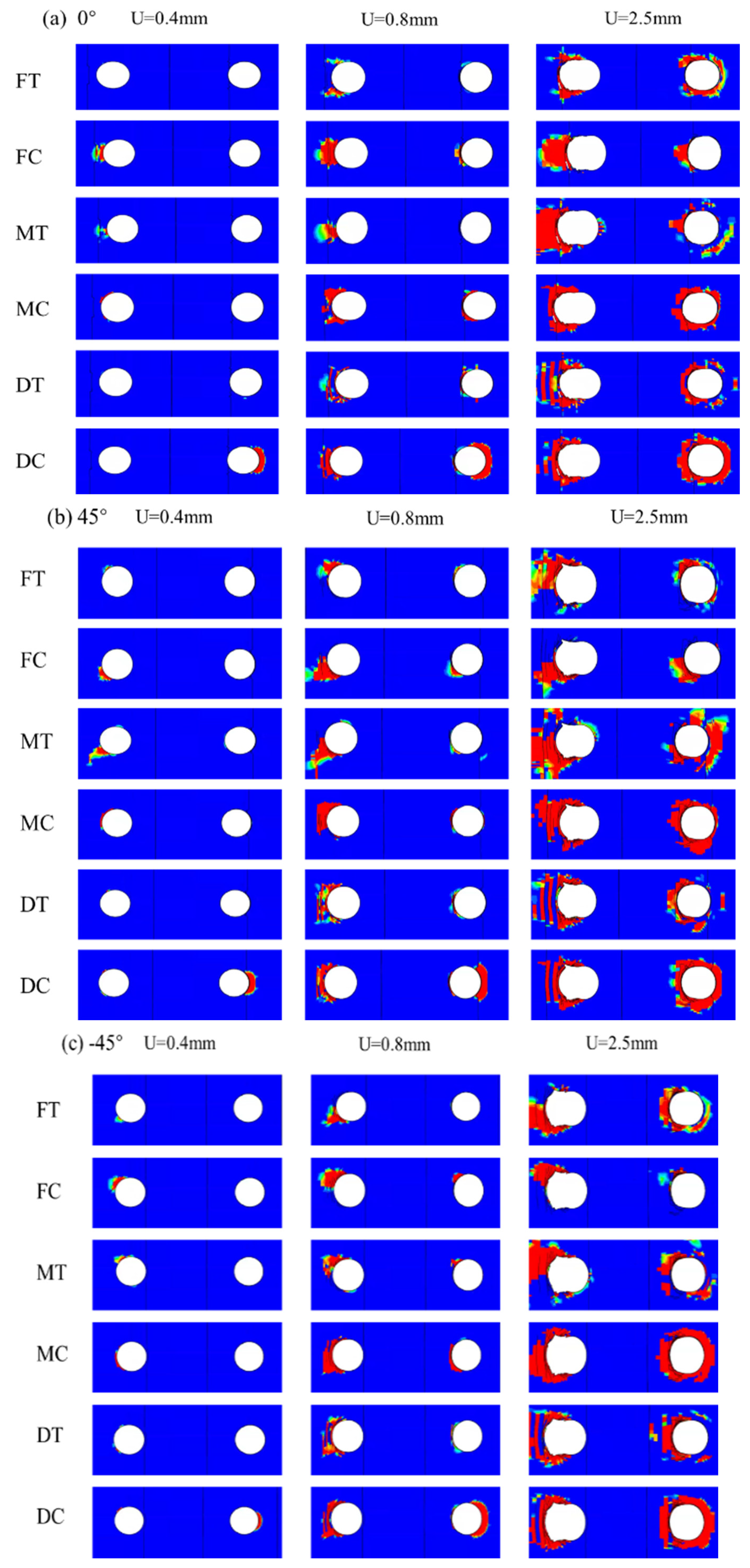

To understand the failure mechanism and guide structural optimization, analyzing the failure mode of individual layers within the connection structure is essential. Since tensile forces in the 0° direction dominate the radial connection, the 0° ply of the composite laminate plays a pivotal role in load-bearing.

Figure 11 displays the failure modes for each laminate ply angle, with the progression of damage indicated by the damage variable

d.

Areas shaded in red, representing the largest values of d, correspond to zones of the most severe damage, which align with stress concentrations near the hole perimeter.

At a displacement of 0.4 mm, fiber compression and matrix tensile damage begin to develop in localized regions around bolt 1. Initial tensile damage appears in the ±45° plies, while the 90° plies exhibit the lowest load-bearing capacity. This discrepancy reflects different load transmission mechanisms in various ply orientations. Specifically, the 0° plies are primarily loaded via the fibers, while the ±45° plies transmit loads through both the fibers and the matrix. Because the matrix has a considerably lower load-bearing capacity than the fibers, it is the first to fail. As displacement increases, fiber tensile damage emerges in the 0° ply, leading to the immediate loss of load-bearing capacity in the affected element and intensifying local stress concentrations. Since the fibers bear most of the tensile load, their failure significantly undermines structural reliability.

At a displacement of 0.8 mm, laminate delamination occurs due to bolt failure caused by bending. The bolts apply compressive forces to the screw holes, resulting in localized compressive collapse near the bolt holes. However, tensile damage remains the primary failure mechanism in the laminate. Matrix tensile failure precedes fiber tensile failure, with the damage propagating sequentially from the ±45° plies to the 90° plies, while fiber tensile damage spreads from the 0° plies to the ±45° plies. Since the fibers offer significantly higher load-bearing capacity than the matrix, their failure results in an immediate and substantial reduction in load-carrying capacity, thus critically impacting structural reliability.

As the displacement increases further, the damage zone continues to grow toward the laminate edges. This progressive expansion of the damage ultimately leads to a complete loss of structural load-bearing capacity, thus signifying total failure. By observing these failure patterns, it becomes evident that preventing fiber tensile failure is crucial to maintaining structural integrity and optimizing the connection design.

4.3. Effects of Helicoidal Layup

The potential application of helicoidal composites in engineering structures underscores the critical need to investigate and optimize their joint strength. By appropriately adjusting the orientation of the fiber layup, the superior mechanical properties of the fibers can be leveraged more effectively, thus enhancing the overall load-bearing capacity of the structure.

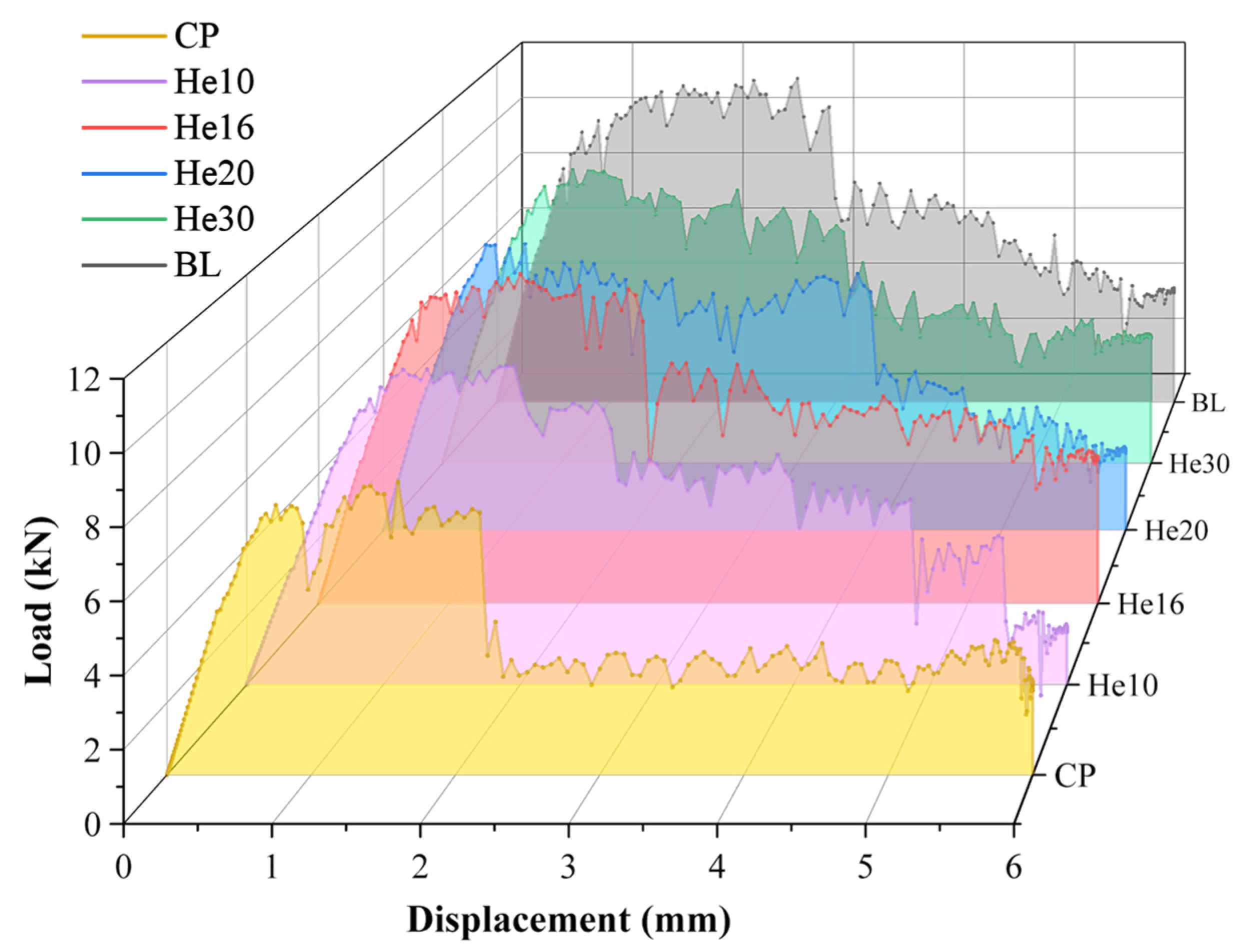

This subsection introduces an exploratory study focused on optimizing helicoidal layup angles for improved performance. The above specimen plays a role of a baseline (BL) in evaluating the impact of fiber layup orientations on the mechanical behavior and joint strength of helicoidal composites, as listed in

Table 3. The laminate thickness for each specimen is 3.5 mm, and each specimen is composed of 28 layers, which are 0.125 mm thick. The composite material layering scheme was selected to ensure that the number of layers in each test piece is equal and the layering is symmetrical. For helicoidal composite laminates, a 180° layup is maintained in the center. An exception is made for specimen He16, which features a 45/−45 layup on the surface of the helicoidal layer to examine the protective effect of this conventional layer. The simulation results indicate that this configuration exhibits a relatively high ultimate load.

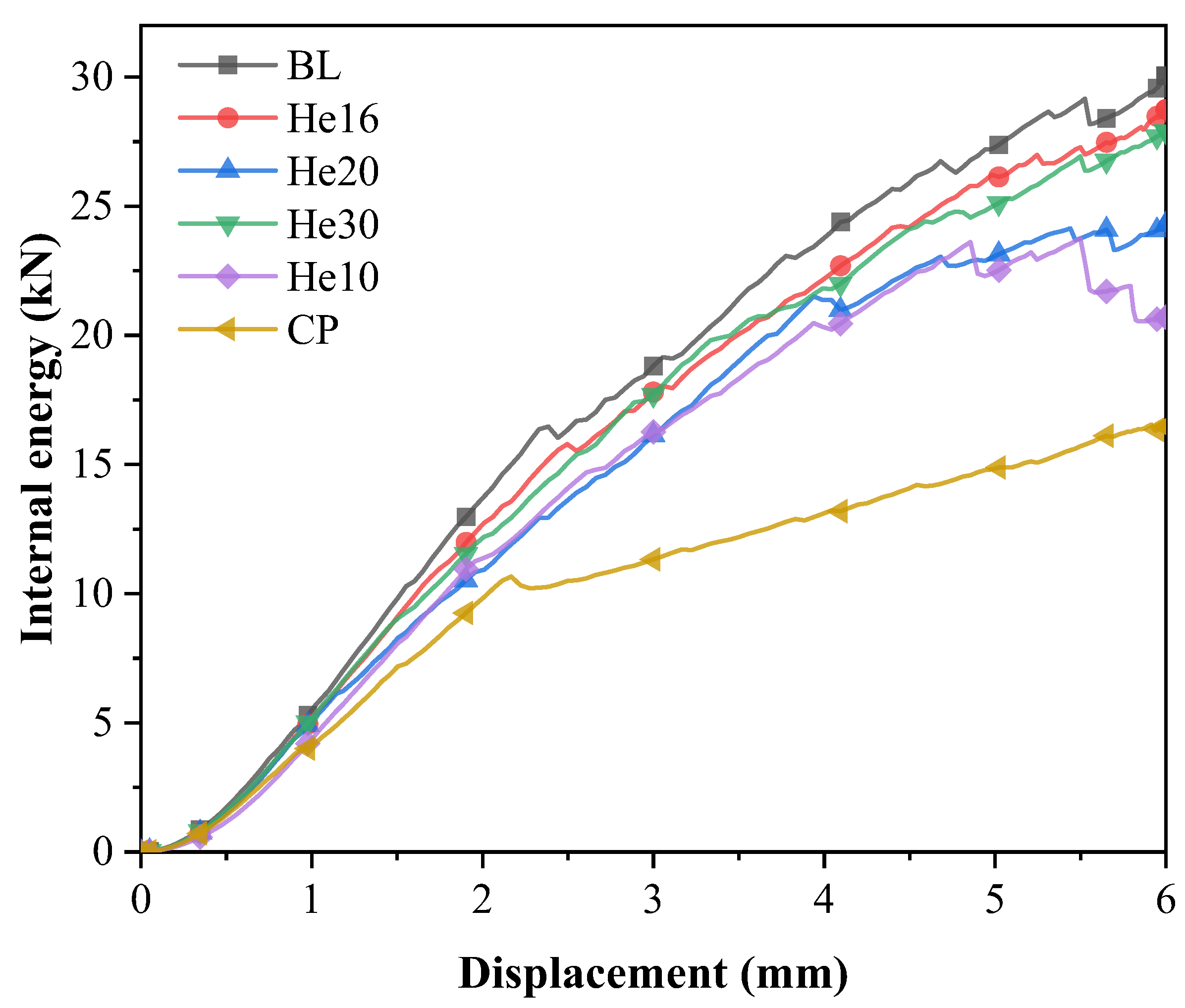

The load curves for specimens of different layup configurations, which are presented in

Figure 12, are compared to those of the benchmark test specimens discussed previously.

These load–displacement curves display a notable progression: an initial linear increase in load, which is followed by a load decline as the bending failure of the bolt occurs. The load then continues to increase but at a reduced rate. Ultimately, a series of load drops leads to structural failure. Insights into the tensile damage process within the scarf joint model are further provided by the internal energy variations during the simulation, as shown in

Figure 13.

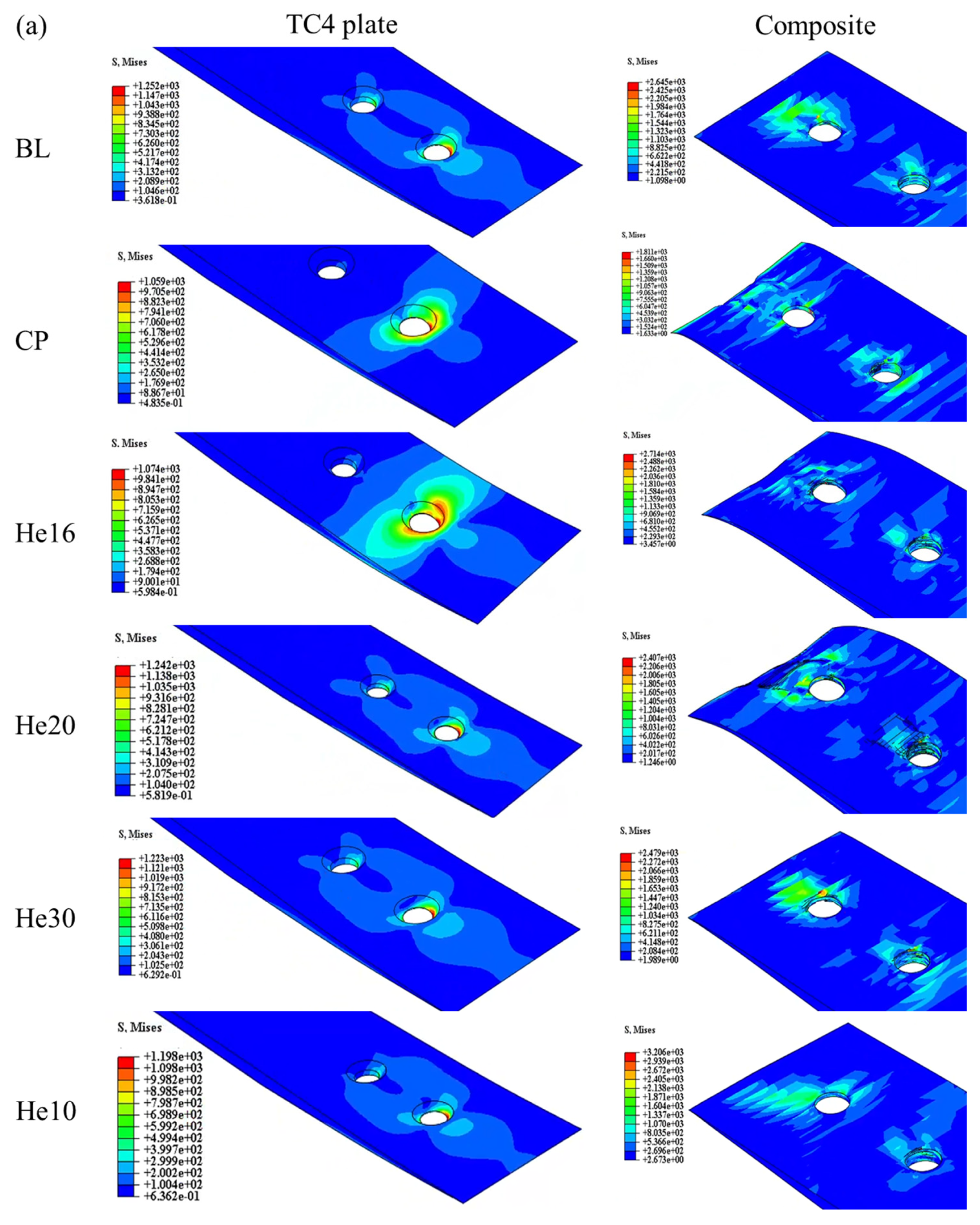

As shown in

Figure 14, the stress distribution in the lap model at peak load reveals key areas of stress concentration. In the metal plate, stress concentrations are primarily localized around the bolt holes, whereas in the composite plate, stress concentrations occur both around the holes and in the wedge transition region. These regions are subjected to the highest mechanical demands during loading, thus making them critical to the structural integrity of the joint.

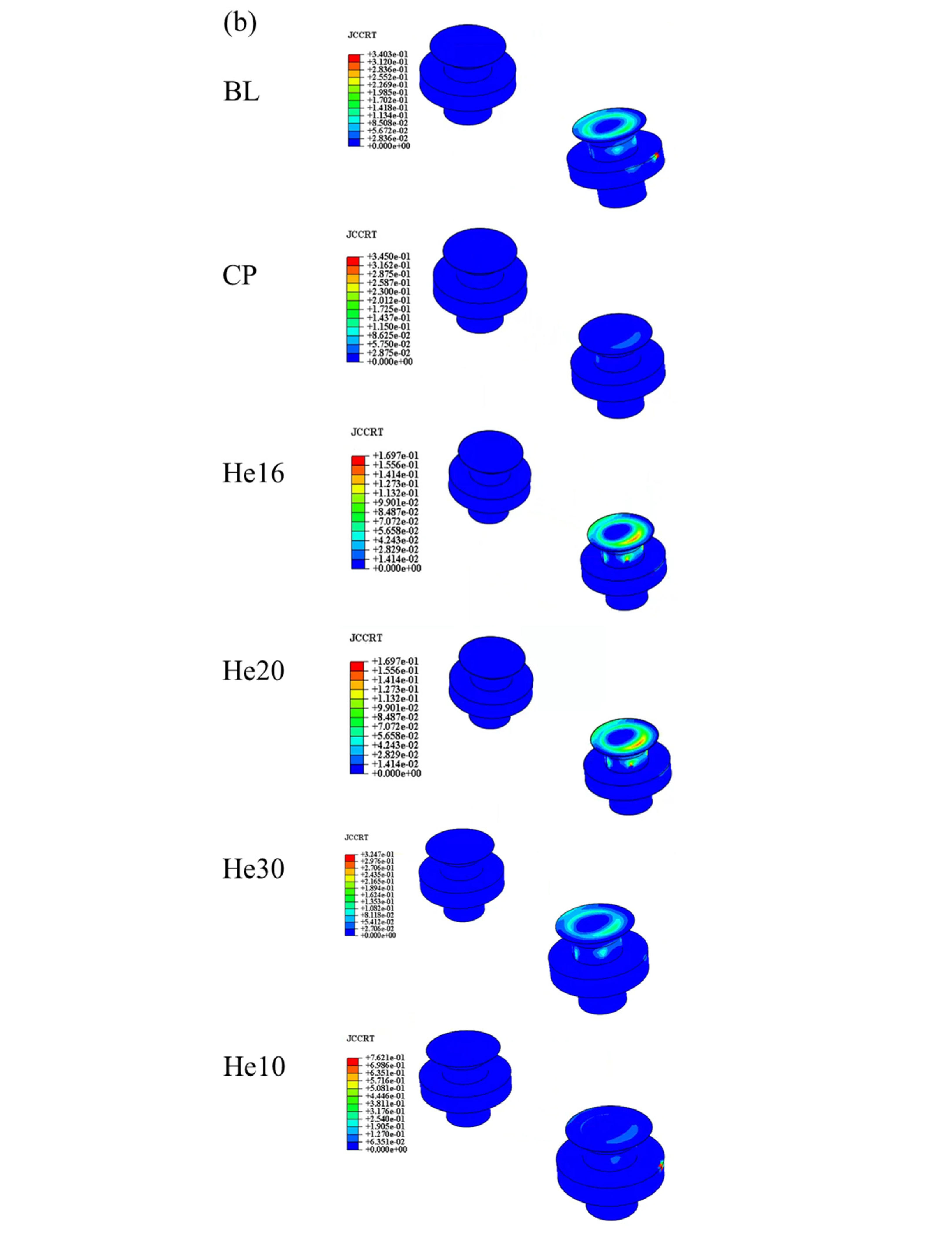

For the bolts, the stress concentrations are primarily associated with bending and extrusion damage, as illustrated in

Figure 14b. The form of bolt damage in the He16 specimen closely resembles that of the BL specimen, indicating a similar load transfer and damage mechanism. Conversely, the He10 and CP specimens experience significantly less bolt damage due to the lower tensile loads borne by these configurations. This reduced tensile load prevents substantial stress accumulation in the bolts, thus limiting the extent of bending and extrusion damage in these specimens.

Overall, the He16 specimen stands out since it achieved a damage pattern comparable to that of the BL specimen, while the weaker tensile response of the He10 and CP configurations underscores their limited structural performance and reduced susceptibility to bolt damage. These insights highlight the critical role of joint configuration in distributing stress and influencing damage mechanisms within the scarf joint system.

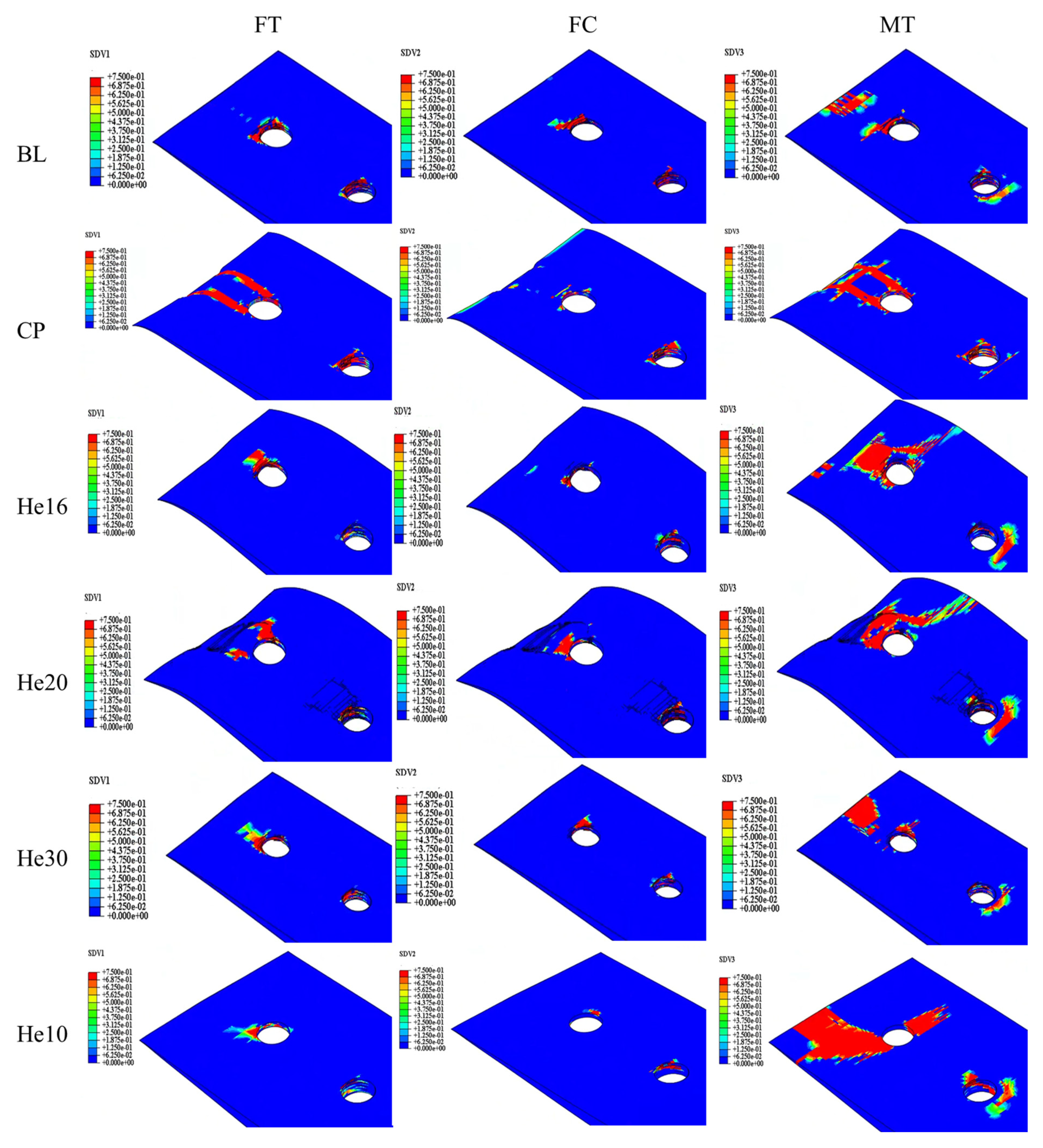

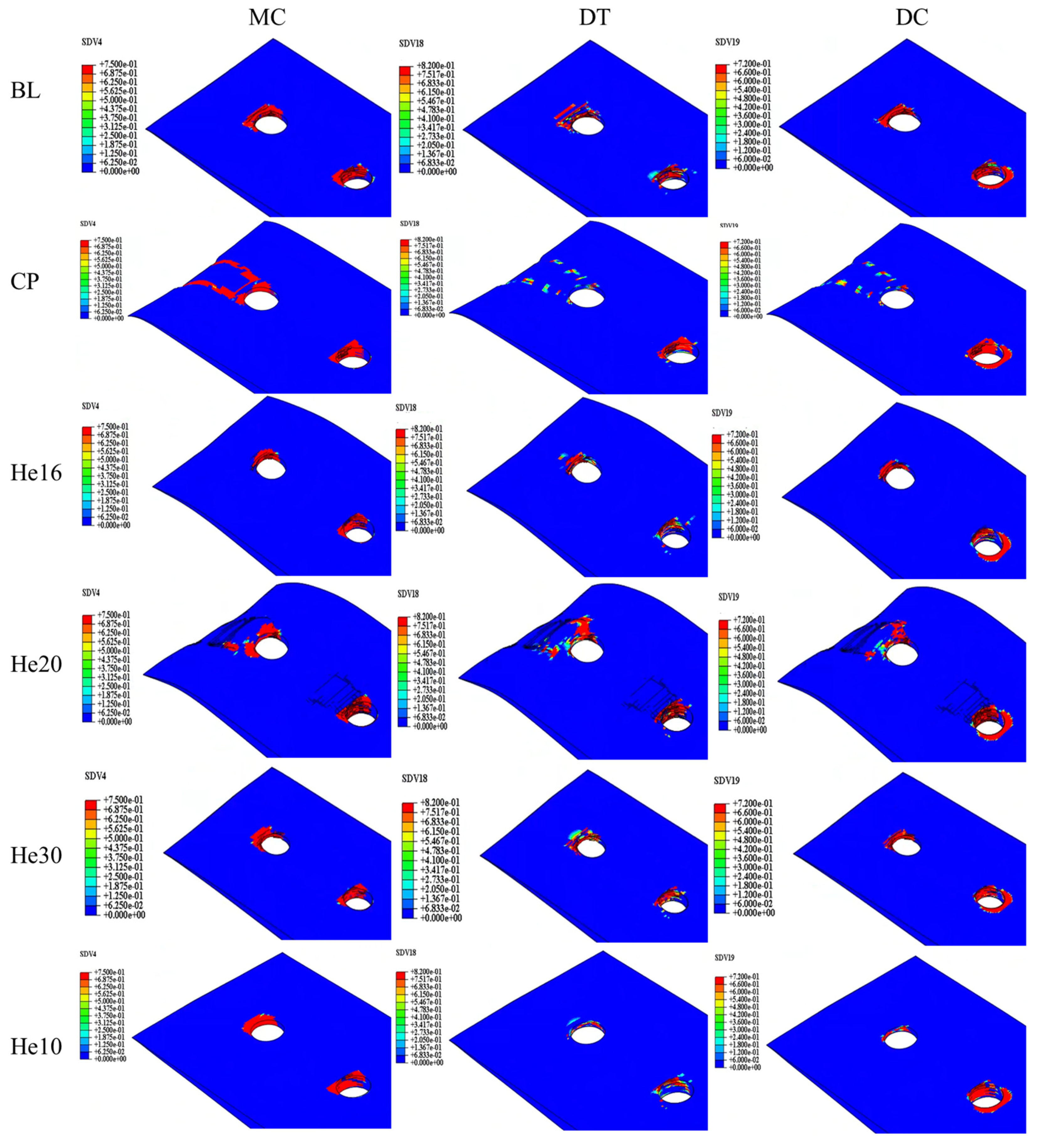

The failure modes of each specimen are shown in

Figure 15. The damage of shear-out is shown in hole 1 of the CP specimen, which exhibits the lowest peak load. The larger matrix tensile damage is shown in the helicoidal composite specimen. The peak load, displacement at peak load, and energy absorption at 6 mm are listed in

Table 4.

The orthogonal layup CP configuration exhibits the lowest peak load, which is primarily due to the increase in transverse crack formation between the fibers oriented at a 90° angle during tensile loading. This susceptibility significantly reduces the load-carrying capacity of the structure. In the work of Seyednourani et al. [

4], the laminate with a cross-ply possess a higher ultimate load than the one with an angle ply layup with the sequence [45/−45]

4s because shear failure between the plies of the latter easily occurs. The stress of composite bolted joints is very complex, and only when each layer can bear complex loads in multiple directions can a higher bearing capacity be achieved. As shown in the simulation results, the baseline model has the best performance. The BL specimen, however, achieves the highest peak load, the greatest elastic stiffness, and the most efficient energy absorption. This superior performance is directly linked to its fiber composition, which features approximately 42.9% fiber alignment in the 0° direction. This alignment optimally reinforces the structure and maximizes load-bearing efficiency, thus making the BL specimen the standout configuration in terms of mechanical performance.

Among the helicoidal configurations, He16 demonstrates a load-bearing capacity similar to that of the baseline specimen. This performance is attributed to its uniform 16° helix angle throughout a symmetric 28-layer design, supplemented by the 45°/-45° layup in the outermost layers, which enhances structural stability. Specimen He30 displays suboptimal mechanical properties, as its layup configuration is similar to that of the BL specimen. The peak loads of He10 and He20 are slightly lower. Helicoidal specimens perform better than CP specimens. These helicoidal configurations may mitigate substrate delamination, thereby preserving structural integrity by requiring more force to induce transverse cracking, which subsequently results in a higher peak force.

From these observations, it can be concluded that optimizing the interlayer angle has the potential to improve the overall structural performance, thus reducing fiber fracture to a secondary damage mode. Furthermore, no substantial differences in delamination damage were observed across the various ply types. The delamination observed was predominantly caused by bolt bending and the extrusion of screw holes, leading to localized failure.