Optimizing Gun Drilling Parameters for Oxygen-Free Copper Using Response Surface Methodology and Genetic Algorithm

Abstract

1. Introduction

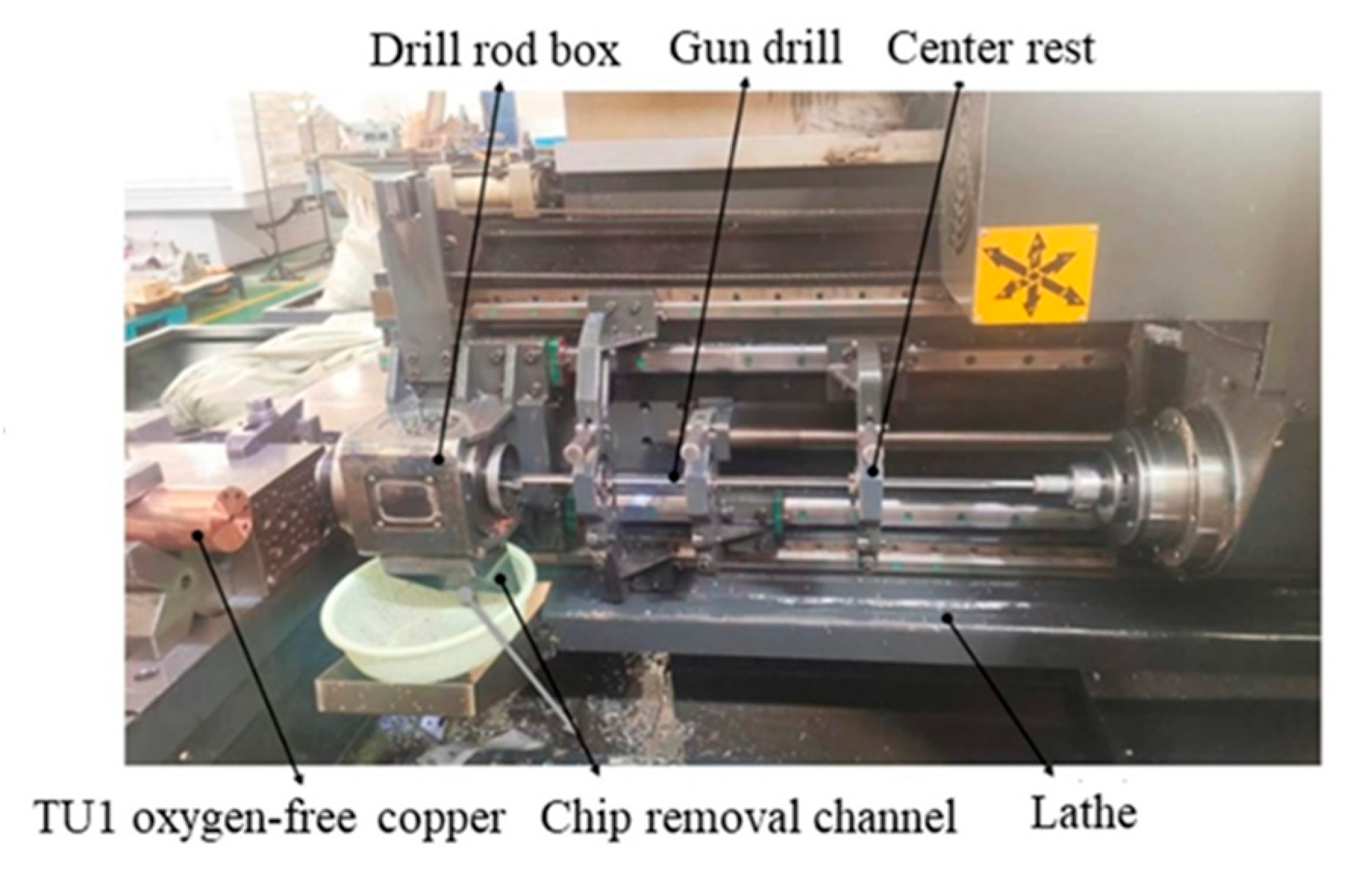

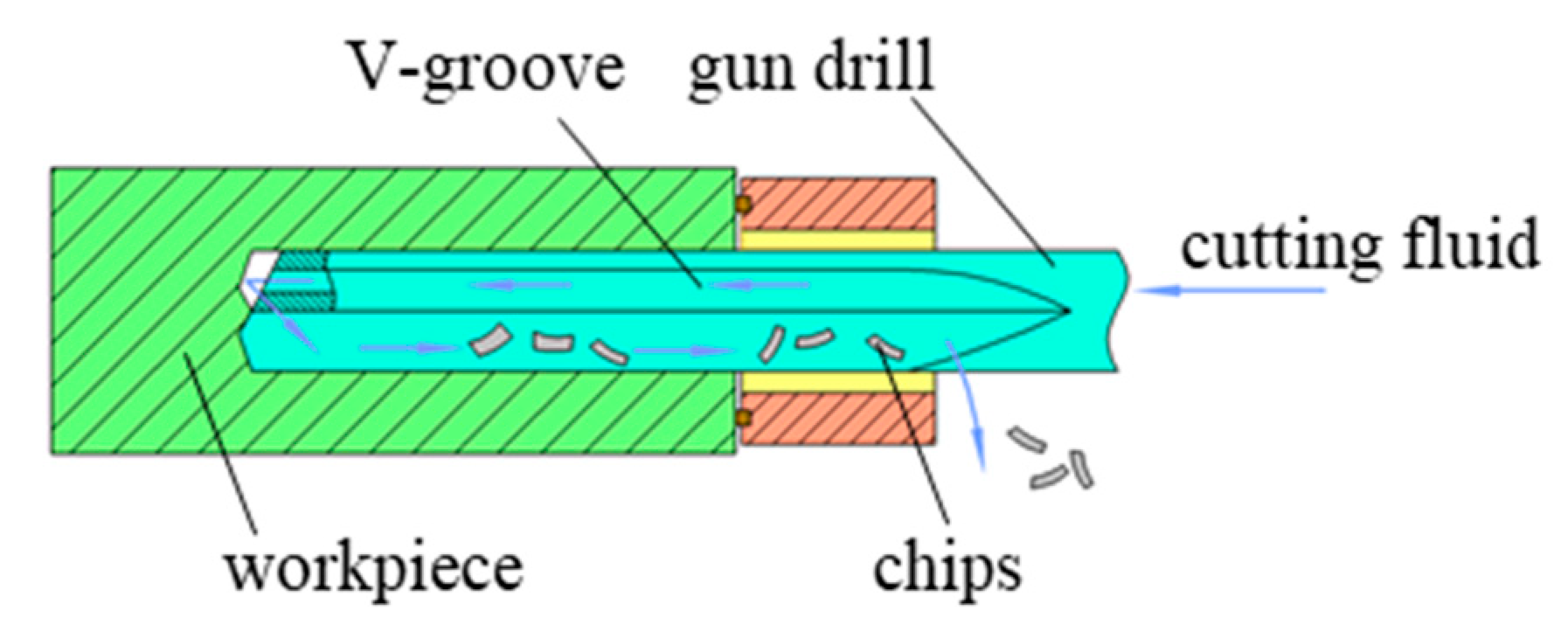

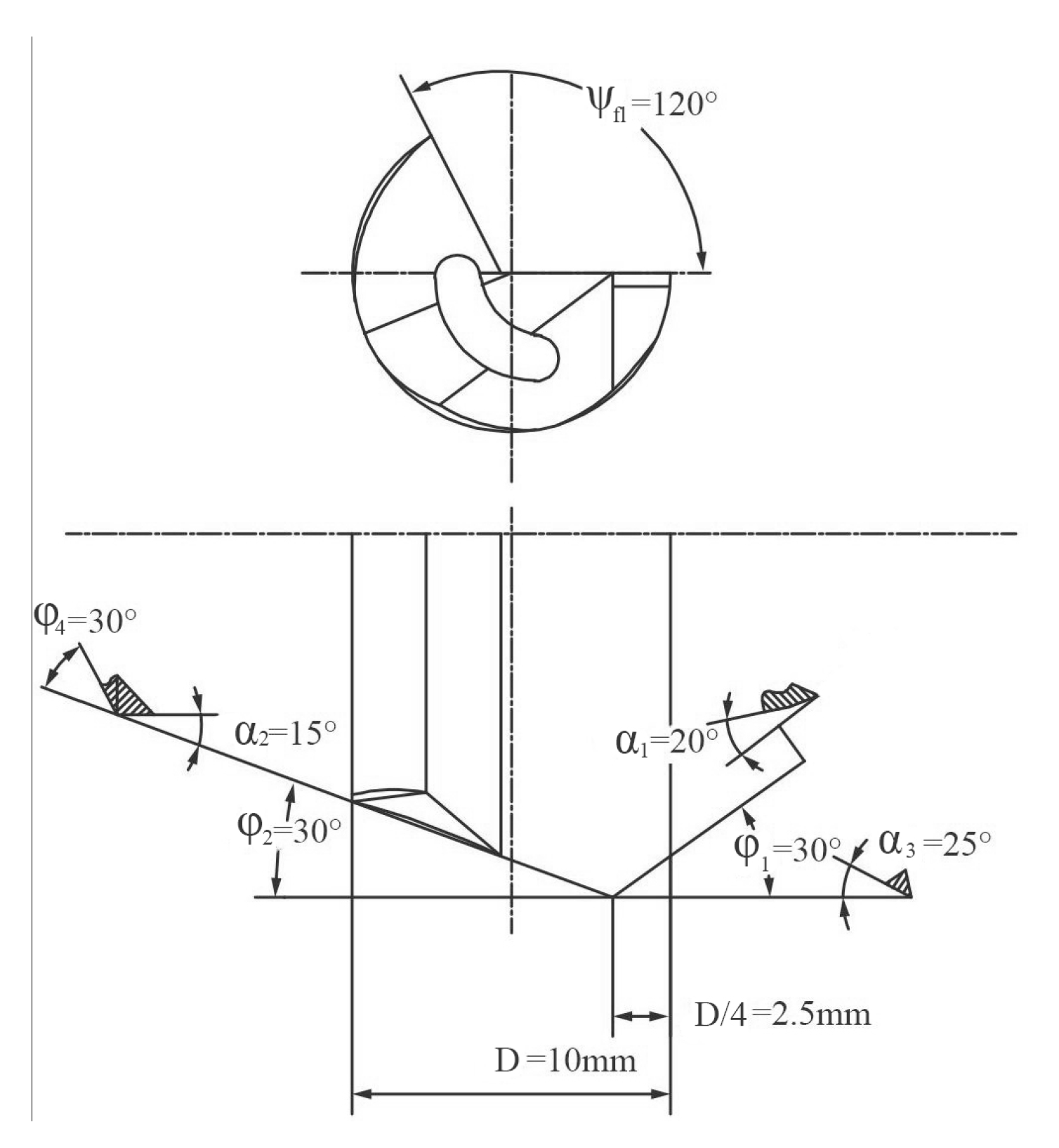

2. Experimental Methods

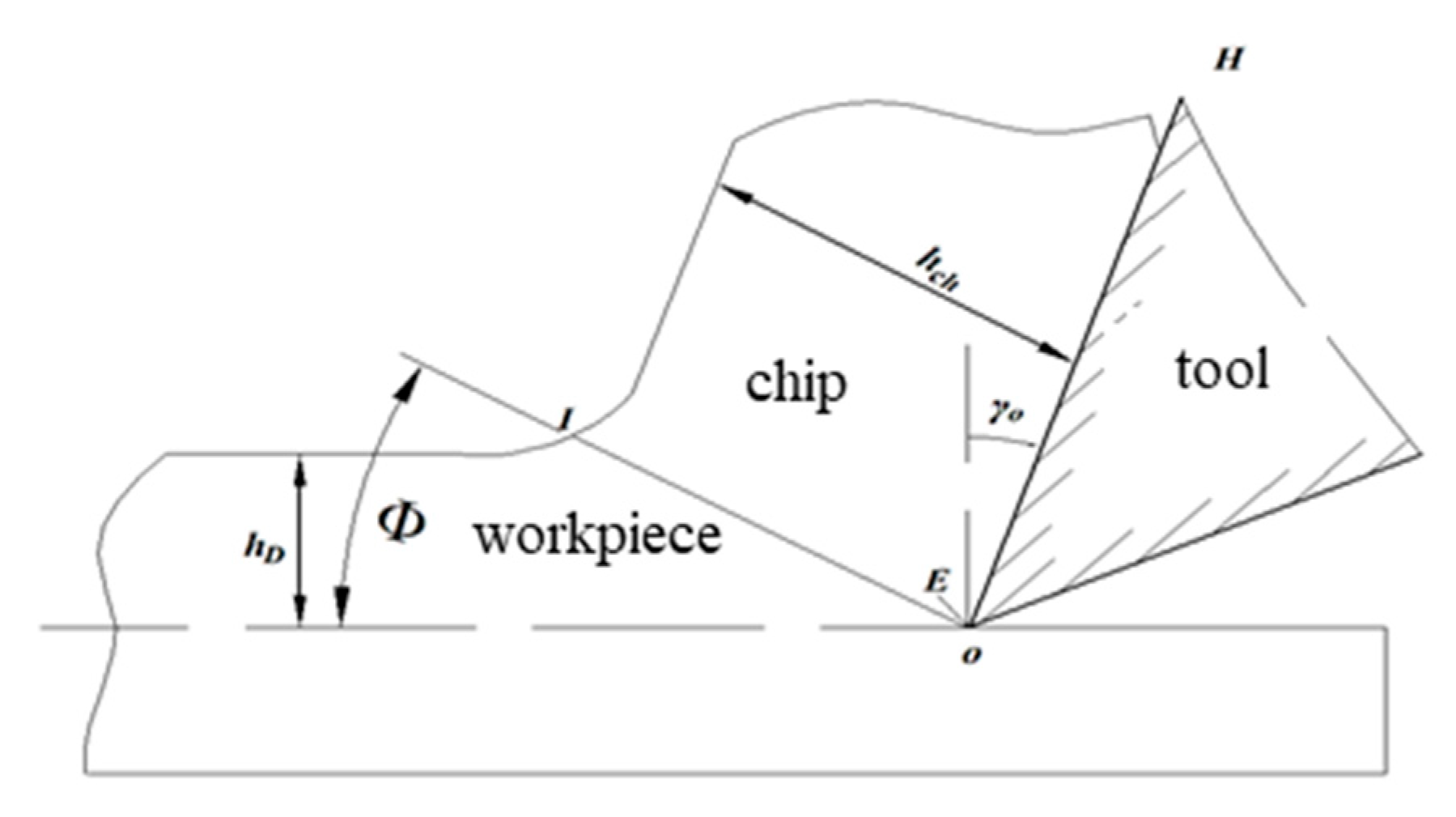

3. Theoretical Calculation of Chip Morphology Indicators

3.1. Calculation of R

3.2. Calculation of CCR

4. Experimental Results and Analysis

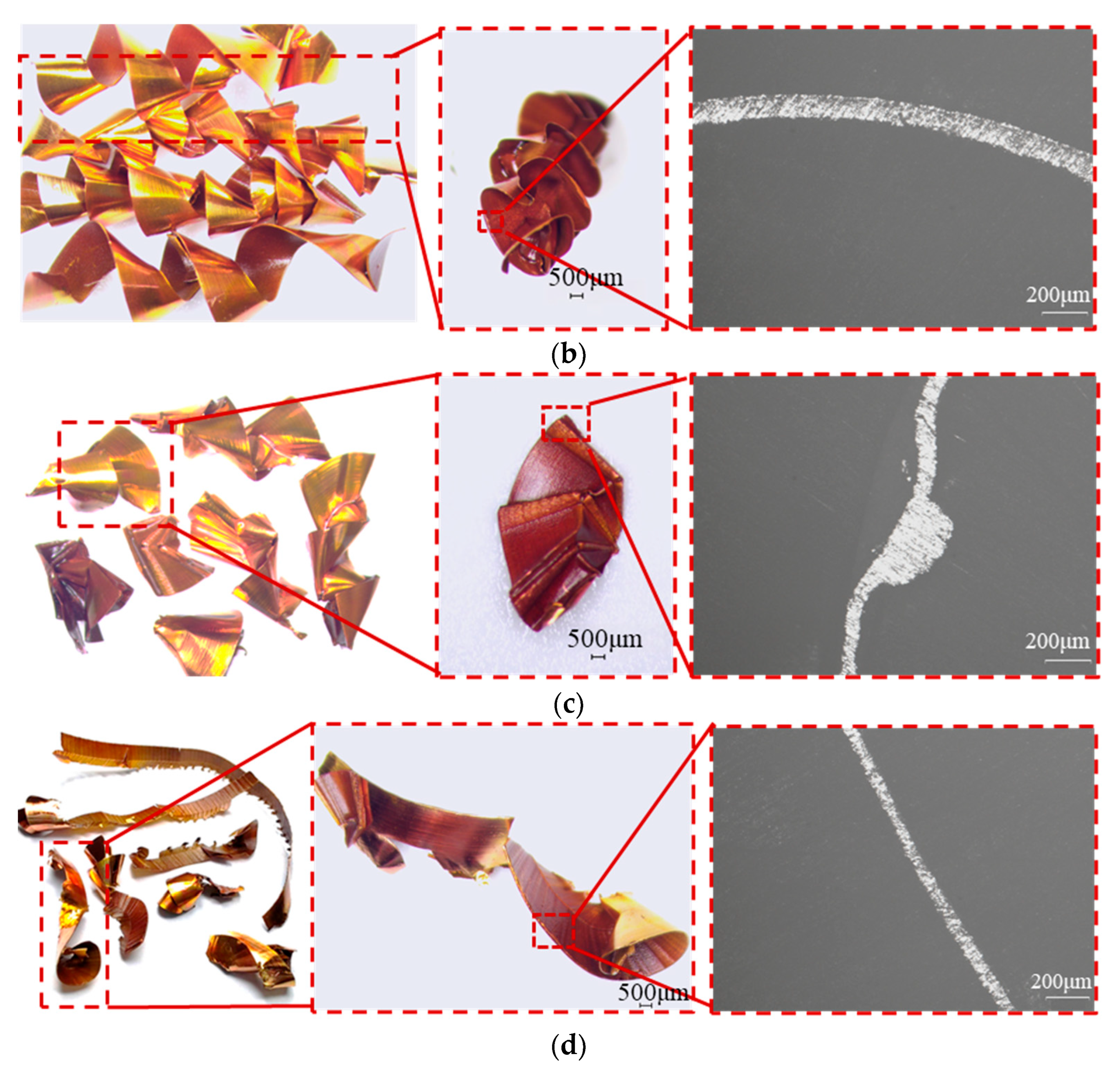

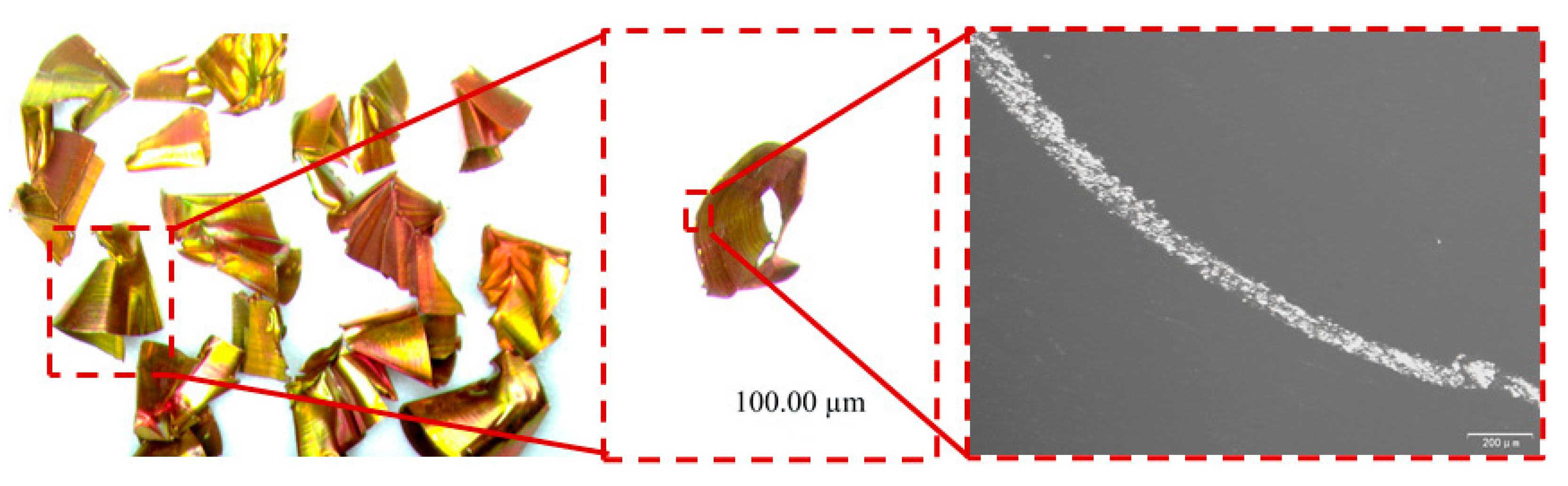

4.1. Analysis of Chip Morphology

4.2. Development of Regression Models

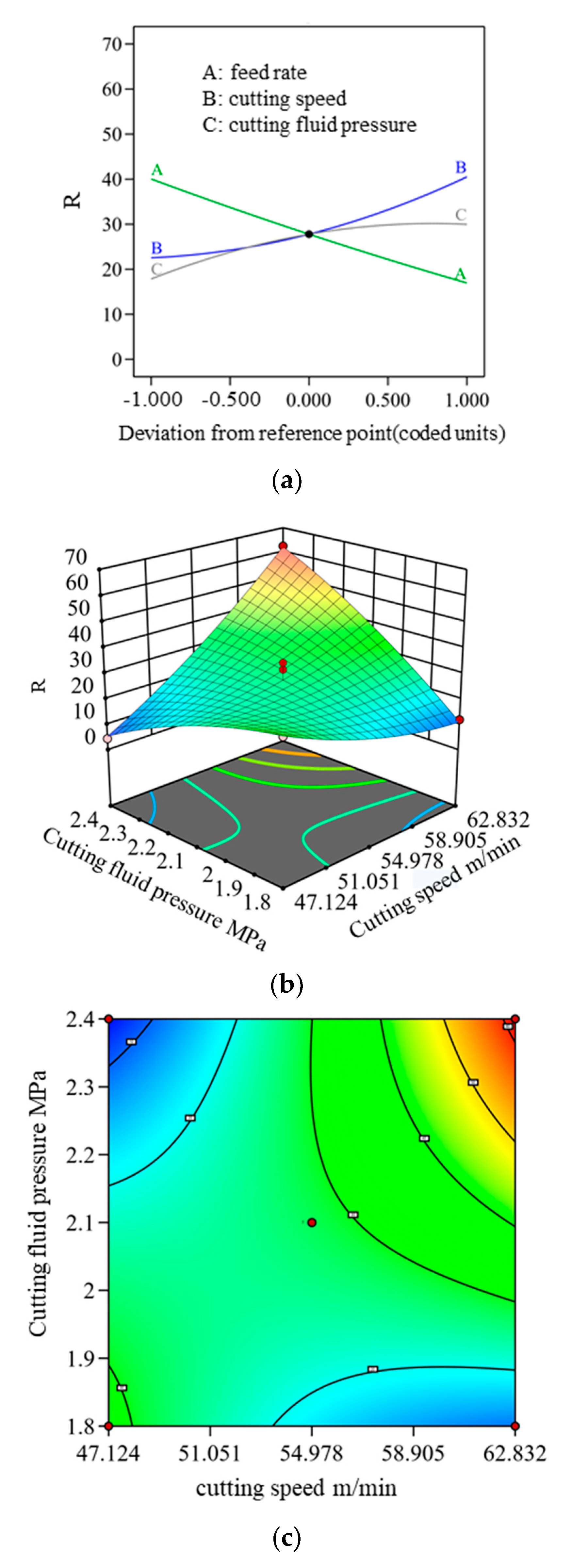

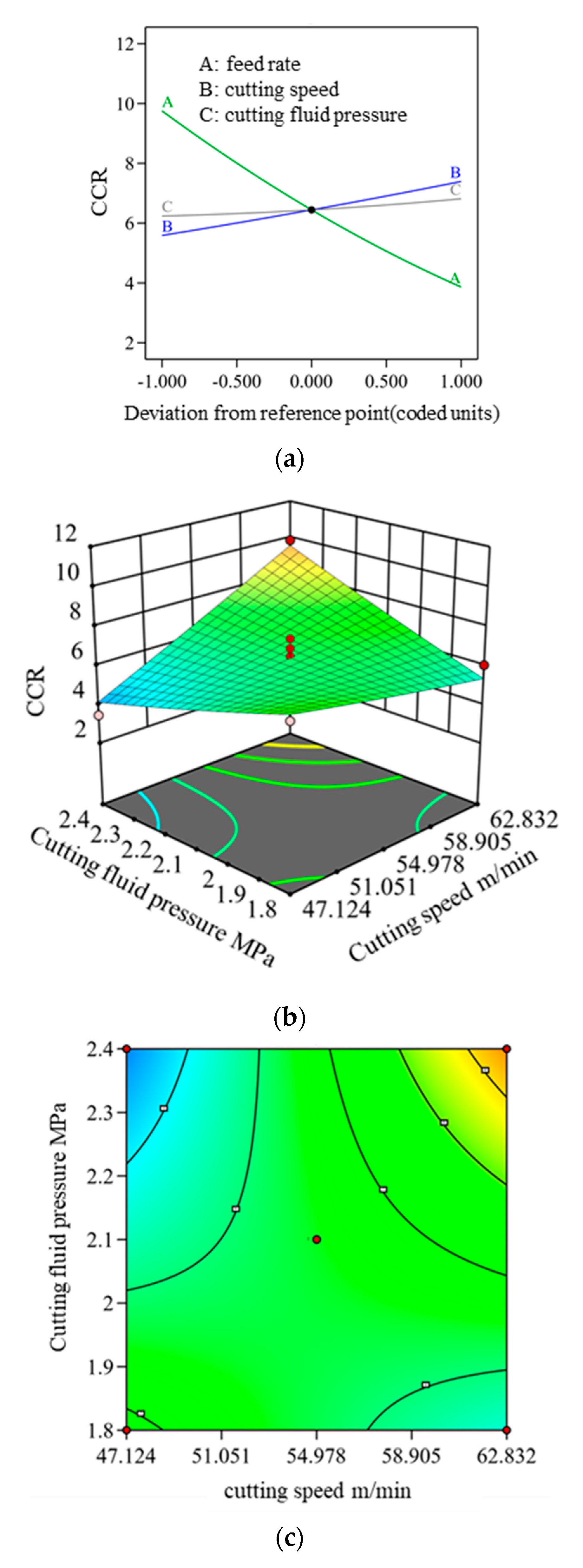

4.3. Analysis of Single and Interactive Effects of Process Parameters on CCR and R

5. GA Optimization and Validation

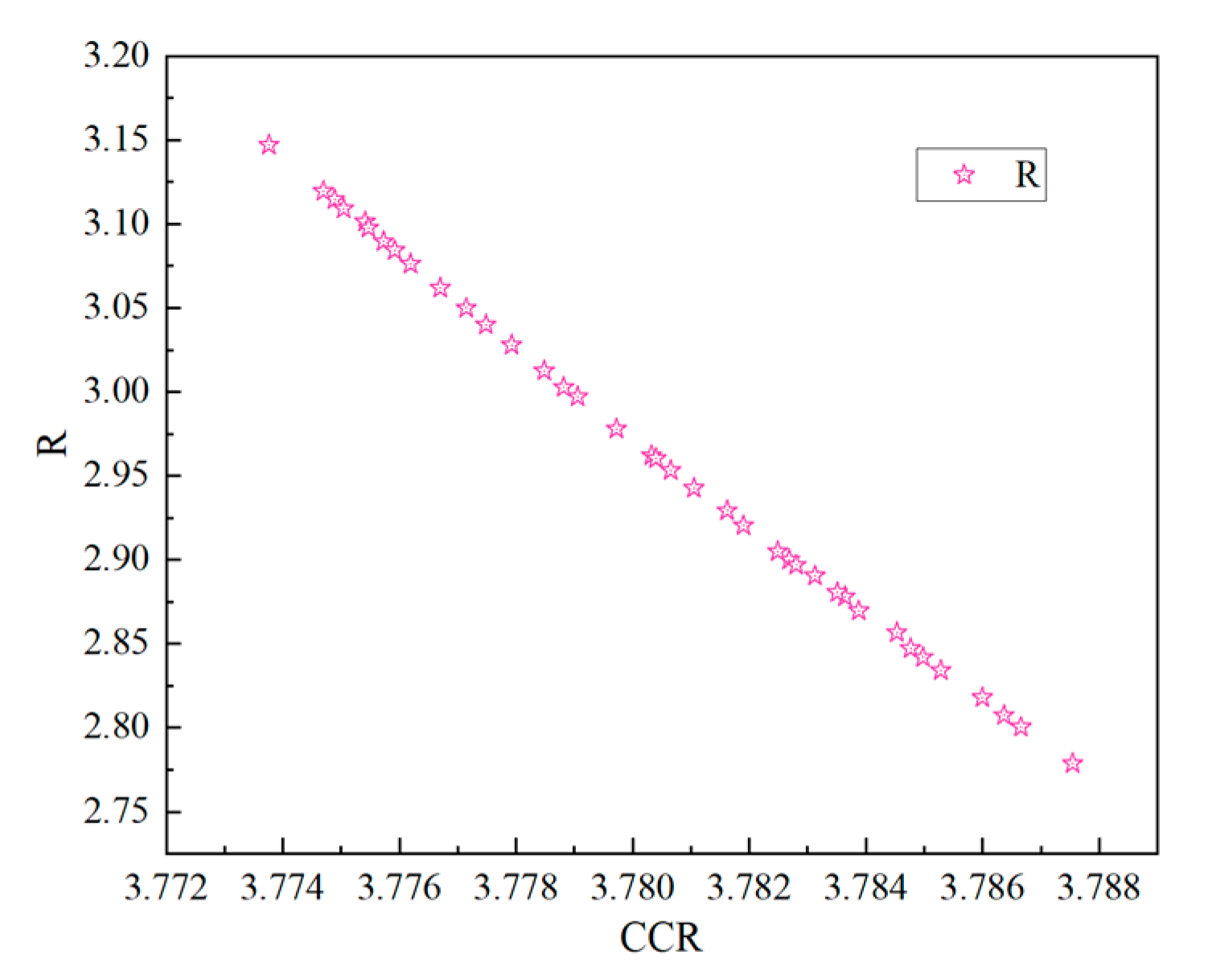

5.1. GA Optimization

5.2. Experimental Validation

6. Conclusions

- (1)

- Response surface variance analysis revealed that, in single-factor influence assessments, feed rate had the most significant effect on R and CCR, followed by cutting speed, with cutting fluid pressure exerting the least influence. In multi-factor interactions, the combination of cutting speed and cutting fluid pressure had the most substantial impact on CCR and R.

- (2)

- Considering actual machining conditions and the genetic algorithm optimization results, the optimal drilling process parameters were determined to be a feed rate of 0.019 mm/r, a spindle speed of 47.1 m/min, and a cutting fluid pressure of 2.4 MPa. Under these conditions, the CCR was 3.2951, and R was 3.3345, with chips primarily exhibiting a C-shaped morphology and smooth chip evacuation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Emami, S.; Aghajani, H.; Tabrizi, A.T. Sustainable Oxygen-Free Copper Powder Production Method from Wastes. J. Sustain. Metall. 2023, 9, 1803–1809. [Google Scholar] [CrossRef]

- Kočiško, M.; Pollák, M.; Grozav, S.D.; Ceclan, V. Influence of Coolant Properties and Chip Former Geometry on Tool Life in Deep Drilling. Appl. Sci. 2023, 13, 8360. [Google Scholar] [CrossRef]

- Naruki, T.; Suzuki, K.; Kato, H.; Sakamoto, S.; Seto, M.; Katayama, J.; Oka, T. Effect of Different Feed Rates on Chip Evacuation in Drilling of Lead-Free Brass with a Small-Diameter Drill. Int. J. Autom. Technol. 2024, 18, 503–512. [Google Scholar] [CrossRef]

- He, Q.; Sun, F.; Zhang, S.; Zou, Z.; Pang, K.; Che, H.; Zhang, L. Experimental Study on the Fracture Morphology of Chips in 50# Steel Internal Chip Removal Deep Hole Drilling. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 81. [Google Scholar] [CrossRef]

- Habib, N.; Sharif, A.; Hussain, A.; Aamir, M.; Giasin, K.; Pimenov, D.Y.; Ali, U. Analysis of Hole Quality and Chips Formation in the Dry Drilling Process of Al7075-T6. Metals 2021, 11, 891. [Google Scholar] [CrossRef]

- Lou, J.; Li, L.; Dong, X.; Cao, M.; Jiang, J.; Zhang, Y. Research on the Influencing Factors of Chip Forming in 304 Stainless Steel Deep Hole Gun Drilling. Int. J. Adv. Manuf. Technol. 2024, 134, 1447–1461. [Google Scholar] [CrossRef]

- Oezkaya, E.; Michel, S.; Biermann, D. Chip Formation Simulation and Analysis of the Mechanical Loads during Micro Single-Lip Deep Hole Drilling of Inconel 718 with Varying Cooling Lubricant Pressure. Prod. Eng. 2021, 15, 299–309. [Google Scholar] [CrossRef]

- Liu, H.; Peng, B.; Meurer, M.; Schraknepper, D.; Bergs, T. Three-Dimensional Multi-Physical Modelling of the Influence of the Cutting Fluid on the Chip Formation Process. Procedia CIRP 2021, 102, 216–221. [Google Scholar] [CrossRef]

- Makhesana, M.A.; Patel, K.M.; Bagga, P.J. Evaluation of Surface Roughness, Tool Wear and Chip Morphology during Machining of Nickel-Based Alloy under Sustainable Hybrid Nanofluid-MQL Strategy. Lubricants 2022, 10, 315. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; Sandua, X.; Rivero, P.J.; De Lacalle, L.N.L.; Wretland, A. Machinability of Waspaloy: An Investigation of Cutting Forces and Tool Wear in Turning. Int. J. Adv. Manuf. Technol. 2025, 139, 3159–3172. [Google Scholar] [CrossRef]

- Al-kahtani, M.S.M.; Zhu, H.; Ibrahim, Y.E.; Haruna, S.I.; Al-qahtani, S.S.M. Study on the Mechanical Properties of Polyurethane-Cement Mortar Containing Nanosilica: RSM and Machine Learning Approach. Appl. Sci. 2023, 13, 13348. [Google Scholar] [CrossRef]

- Bousnina, K.; Hamza, A.; Ben Yahia, N. Predictive Optimization of Surface Quality, Cost, and Energy Consumption during Milling Alloy 2017A: An Approach Integrating GA-ANN and RSM Models. Int. J. Interact. Des. Manuf. IJIDeM 2024, 18, 5177–5196. [Google Scholar] [CrossRef]

- Leliso, B.; Sinha, D.K.; Magami, I.A.B.; Gupta, G. Optimization of Process Parameters for Synthesis of High Entropy Shape Memory Alloys Using Hybrid ANN-GA Approach. Int. J. Inf. Technol. 2025, 1–15. [Google Scholar] [CrossRef]

- Alam, S.T.; Tomal, A.N.M.A.; Nayeem, M.K. High-Speed Machining of Ti–6Al–4V: RSM-GA Based Optimization of Surface Roughness and MRR. Results Eng. 2023, 17, 100873. [Google Scholar] [CrossRef]

- Zhao, Y.; Cui, L.; Sivalingam, V.; Sun, J. Understanding Machining Process Parameters and Optimization of High-Speed Turning of NiTi SMA Using Response Surface Method (RSM) and Genetic Algorithm (GA). Materials 2023, 16, 5786. [Google Scholar] [CrossRef]

- Kesireddy, A.; Medrano, F.A. Elite Multi-Criteria Decision Making—Pareto Front Optimization in Multi-Objective Optimization. Algorithms 2024, 17, 206. [Google Scholar] [CrossRef]

- GB/T 5231-2022; Designation and Chemical Composition of Wrought Copper and Copper Alloys. Standards Press of China: Beijing, China, 2022.

- Kolesnyk, V.; Peterka, J.; Alekseev, O.; Neshta, A.; Xu, J.; Lysenko, B.; Sahul, M.; Martinovič, J.; Hrbal, J. Application of ANN for Analysis of Hole Accuracy and Drilling Temperature When Drilling CFRP/Ti Alloy Stacks. Materials 2022, 15, 1940. [Google Scholar] [CrossRef]

- Lu, M.; Qiao, Z.; Chen, S.; Lin, J.; Zhai, S.; Gong, H. Analytical Modeling of Cutting Force in Pulsed Laser–Assisted Turnings of SiCp/Al Composites. Int. J. Adv. Manuf. Technol. 2025, 137, 4839–4852. [Google Scholar] [CrossRef]

- Ali, S. Performance Evaluation of Minimum Quantity Lubrication (MQL) When Machining High-Performance Materials; Rochester Institute of Technology: Rochester, NY, USA, 2022. [Google Scholar]

- Savkovic, B.; Kovac, P.; Sidjanin, L.; Rajnovic, D. The Chip Formation Process When Cutting High-Speed Steels and Ti3SiC2 Ceramics. J. Manuf. Mater. Process. 2023, 7, 72. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Xu, X.; Qi, Y.; Liu, Z.; Zhao, W. Effects of Dislocation Density Evolution on Mechanical Behavior of OFHC Copper during High-Speed Machining. Materials 2019, 12, 2348. [Google Scholar] [CrossRef]

- Han, X.; Xie, F.; Qiu, L.; Ma, H. Multiobjective Optimization of Chip Removal Performance of Cutting Fluid in Large Diameter Titanium Alloy Deep Hole Trepanning. Proc. Inst. Mech. Eng. PART B-J. Eng. Manuf. 2025, 09544054241310340. [Google Scholar] [CrossRef]

| Cu+Ag | P | Bi | Sb | As | Fe | Ni | Pb | Sn | S | Zn | O |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 99.97 | 0.002 | 0.001 | 0.002 | 0.002 | 0.004 | 0.002 | 0.003 | 0.002 | 0.004 | 0.003 | 0.002 |

| Yield Strength (MPa) | Tensile Strength (MPa) | Thermal Conductivity (W/mK) | Coefficient of Linear Thermal Expansion (°C) |

|---|---|---|---|

| 49–78 | 215–254 | 391 | 18.6 × 10−6 |

| Level | Factors | ||

|---|---|---|---|

| Feed Rate (mm/r) | Cutting Speed (m/min) | Cutting Fluid Pressure (MPa) | |

| −1 | 0.012 | 47.124 | 1.8 |

| 0 | 0.018 | 54.978 | 2.1 |

| 1 | 0.024 | 62.832 | 2.4 |

| No | Feed Rate (mm/r) | Cutting Speed (m/min) | Cutting Fluid Pressure (MPa) | CCR | R |

|---|---|---|---|---|---|

| 1 | 0.018 | 47.124 | 1.8 | 6.8974 | 31.7415 |

| 2 | 0.012 | 47.124 | 2.1 | 9.6923 | 43.1025 |

| 3 | 0.024 | 47.124 | 2.1 | 3.2019 | 4.6235 |

| 4 | 0.018 | 47.124 | 2.4 | 3.4583 | 4.3855 |

| 5 | 0.024 | 54.978 | 1.8 | 3.9211 | 7.9765 |

| 6 | 0.018 | 54.978 | 2.1 | 6.932 | 34.559 |

| 7 | 0.018 | 54.978 | 2.1 | 6.5231 | 31.8955 |

| 8 | 0.024 | 54.978 | 2.4 | 4.1534 | 13.4295 |

| 9 | 0.018 | 54.978 | 2.1 | 7.423 | 26.411 |

| 10 | 0.018 | 54.978 | 2.1 | 6.3675 | 22.8165 |

| 11 | 0.018 | 54.978 | 2.1 | 4.975 | 23.219 |

| 12 | 0.012 | 54.978 | 1.8 | 8.8846 | 28.518 |

| 13 | 0.012 | 54.978 | 2.4 | 10.606 | 48.552 |

| 14 | 0.012 | 62.832 | 2.1 | 10.096 | 39.704 |

| 15 | 0.024 | 62.832 | 2.1 | 4.4369 | 41.5275 |

| 16 | 0.018 | 62.832 | 1.8 | 6.0744 | 12.047 |

| 17 | 0.018 | 62.832 | 2.4 | 9.8633 | 62.412 |

| Source | CCR | R | ||||

|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | |||

| Model | 12.42 | 0.0016 | Significant | 20.01 | 0.0003 | Significant |

| A-f | 85.26 | <0.0001 | Significant | 46.89 | 0.0002 | Significant |

| B-v | 8.01 | 0.0254 | Significant | 28.39 | 0.0011 | Significant |

| C-P | 0.8145 | 0.3968 | 12.94 | 0.0088 | Significant | |

| AB | 0.2121 | 0.6591 | 17.87 | 0.0039 | Significant | |

| AC | 0.6807 | 0.4365 | 2.34 | 0.1700 | ||

| BC | 16.04 | 0.0052 | Significant | 66.46 | <0.0001 | Significant |

| A2 | 0.6901 | 0.4335 | 0.0950 | 0.7669 | ||

| B2 | 0.0116 | 0.9172 | 2.60 | 0.1511 | ||

| C2 | 0.0346 | 0.8577 | 2.79 | 0.1391 | ||

| Residual | ||||||

| Lack of Fit | 0.9237 | 0.5062 | 0.5062 | 0.6529 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Wang, H.; Feng, Y.; Zhao, S. Optimizing Gun Drilling Parameters for Oxygen-Free Copper Using Response Surface Methodology and Genetic Algorithm. Materials 2025, 18, 3913. https://doi.org/10.3390/ma18163913

Han X, Wang H, Feng Y, Zhao S. Optimizing Gun Drilling Parameters for Oxygen-Free Copper Using Response Surface Methodology and Genetic Algorithm. Materials. 2025; 18(16):3913. https://doi.org/10.3390/ma18163913

Chicago/Turabian StyleHan, Xiaolan, Hailong Wang, Yazhou Feng, and Shengdun Zhao. 2025. "Optimizing Gun Drilling Parameters for Oxygen-Free Copper Using Response Surface Methodology and Genetic Algorithm" Materials 18, no. 16: 3913. https://doi.org/10.3390/ma18163913

APA StyleHan, X., Wang, H., Feng, Y., & Zhao, S. (2025). Optimizing Gun Drilling Parameters for Oxygen-Free Copper Using Response Surface Methodology and Genetic Algorithm. Materials, 18(16), 3913. https://doi.org/10.3390/ma18163913