The Influence of Cyclic Torsion with Application of Current Pulses on the Formability of CuZn30 Brass

Abstract

1. Introduction

2. Experimental Procedure

2.1. Tested Material

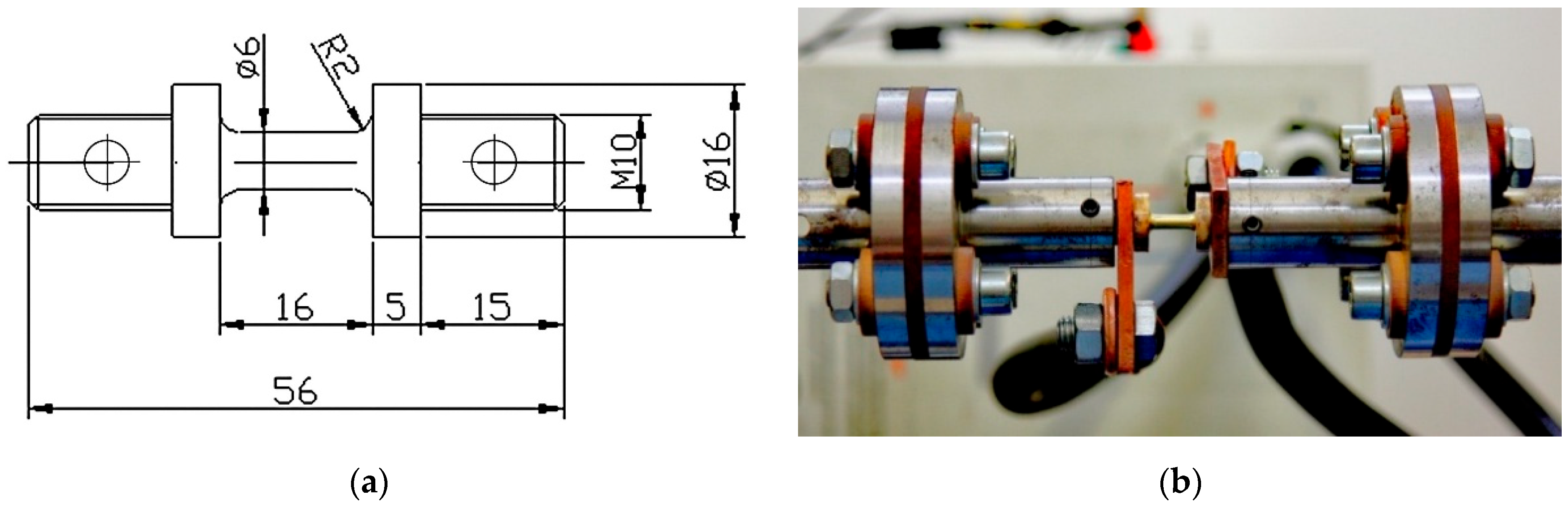

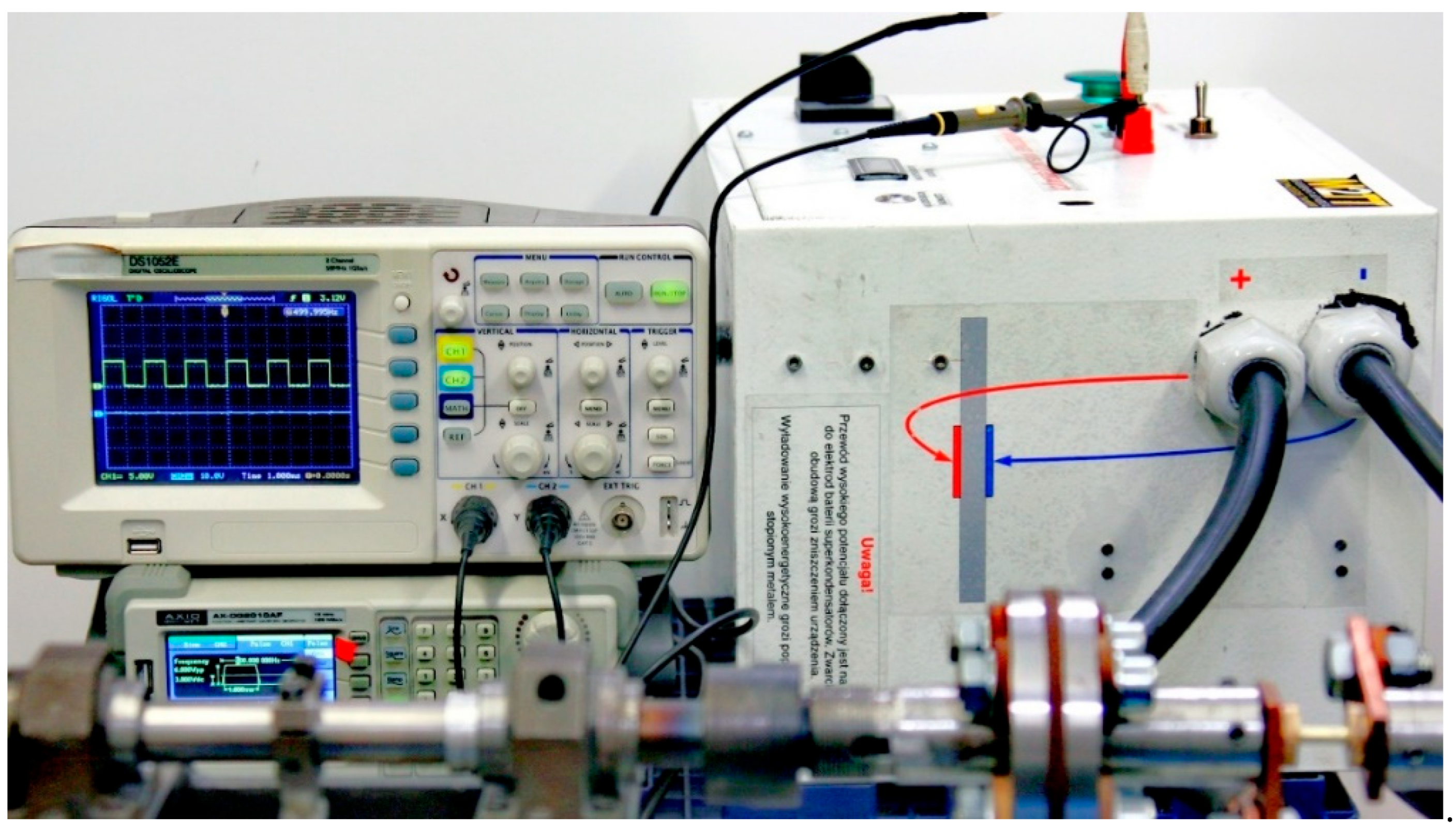

2.2. Research Equipment

2.3. Methodology

- -

- conventional monotonic torsion with a strain rate of = 1 s−1,

- -

- symmetric cyclic torsion with a strain rate of = 1 s−1 and a strain amplitude of A = 0.06,

- -

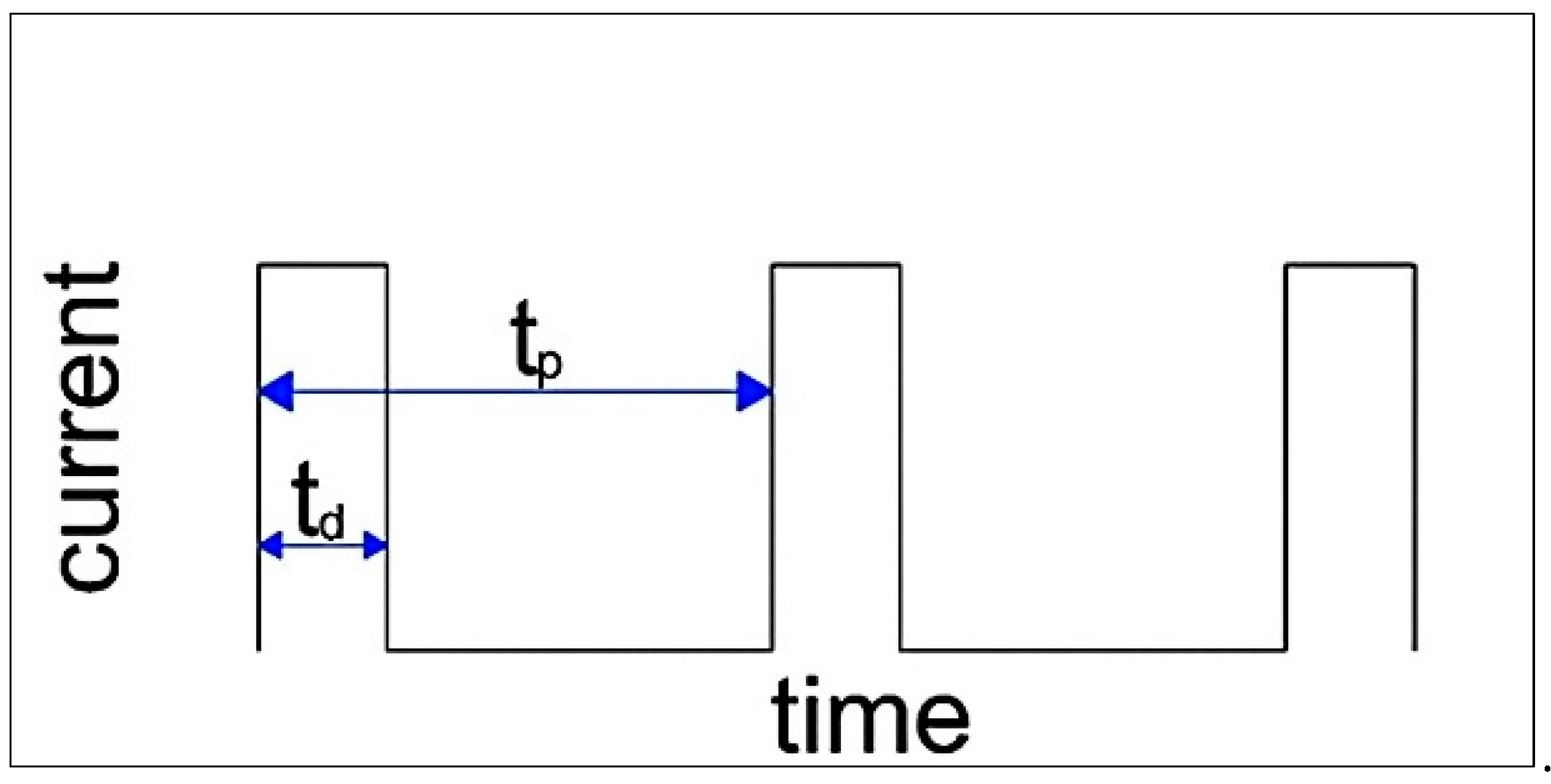

- symmetric cyclic torsion with a strain rate of = 1 s−1 and a strain amplitude of A = 0.06, combined with the application of rectangular electric pulses with pulse duration td and period tp (Figure 3).

- τ—shear stress,

- M—torsional moment,

- n—strain hardening factor,

- m—strain rate sensitivity factor,

- ω—specimen torsional angle,

- rrz—specimen true radius,

- lrz—specimen true length,

- γ—non-dilatational strain.

- M—torsional moment,

- N—number of specimen rotations,

- Ṅ—specimen torsion rate.

3. Results and Discussion

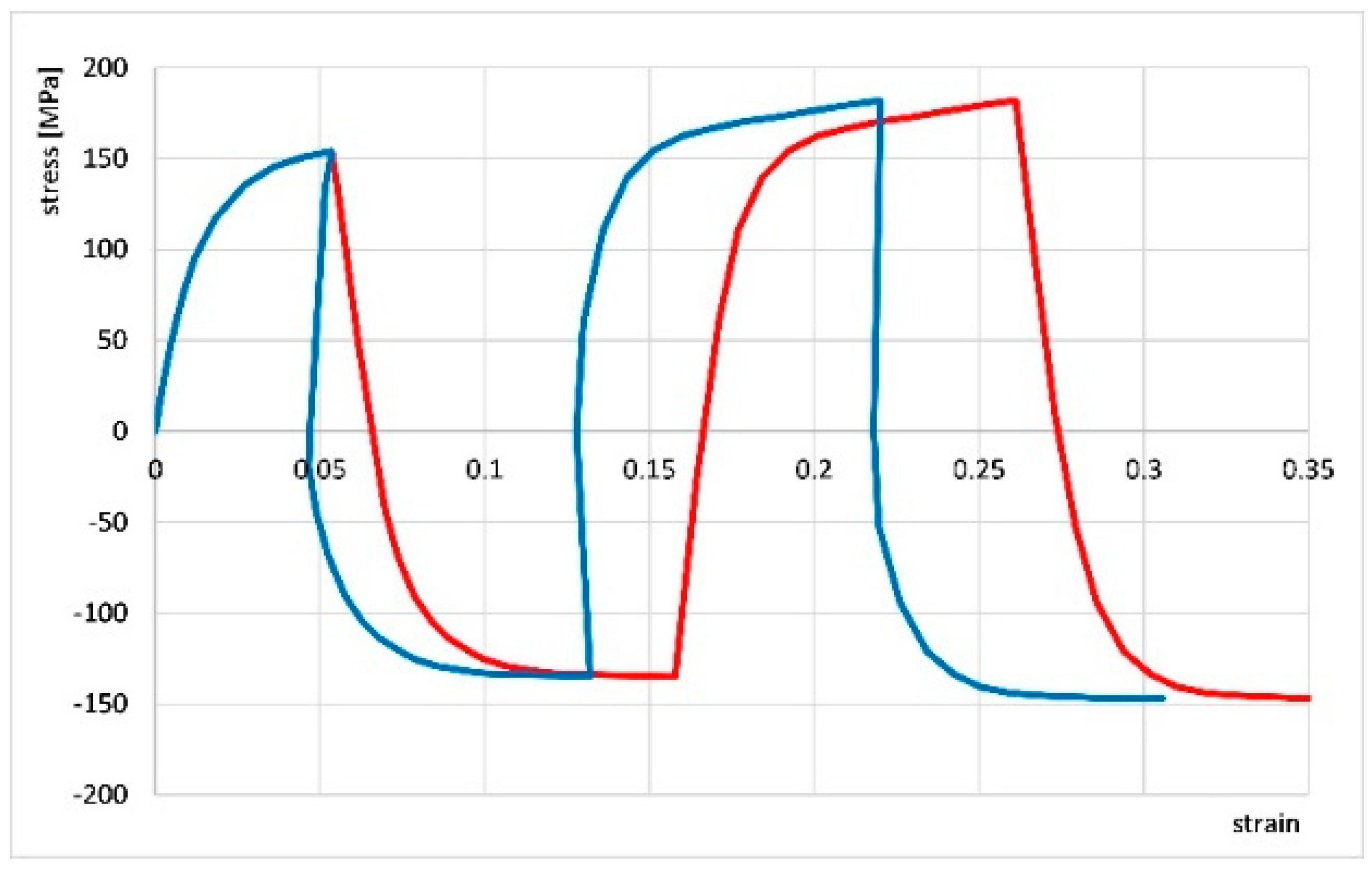

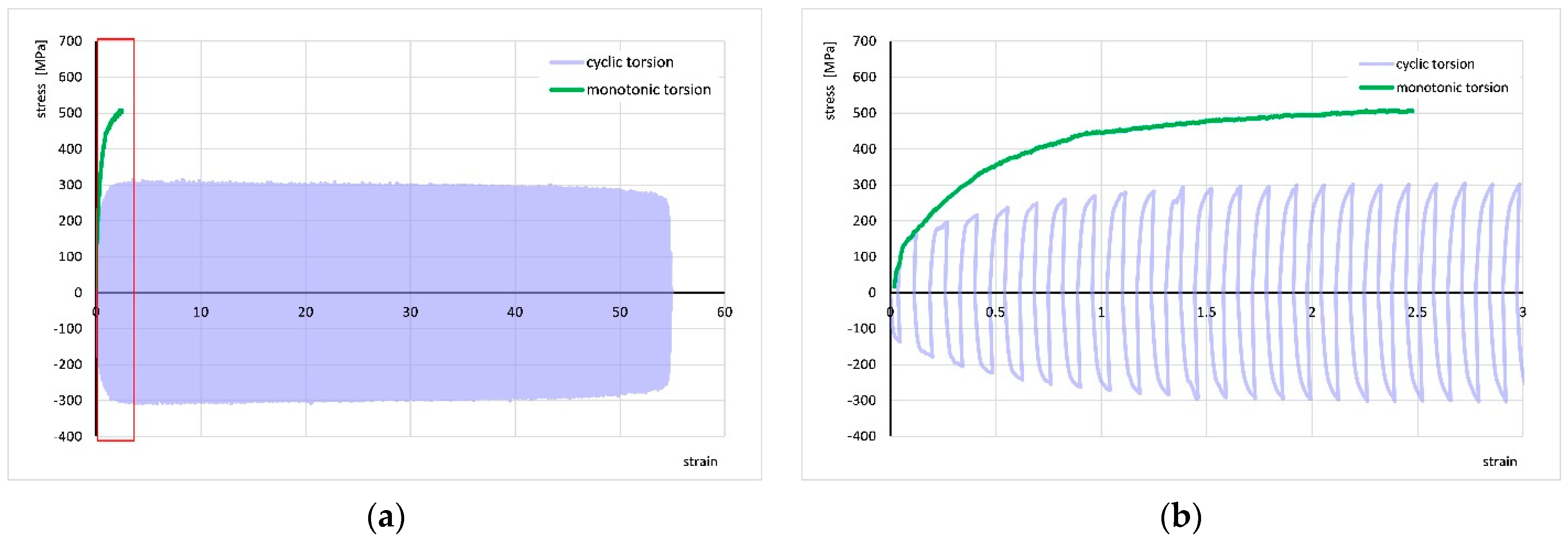

3.1. Results Without Application of Electropulsing

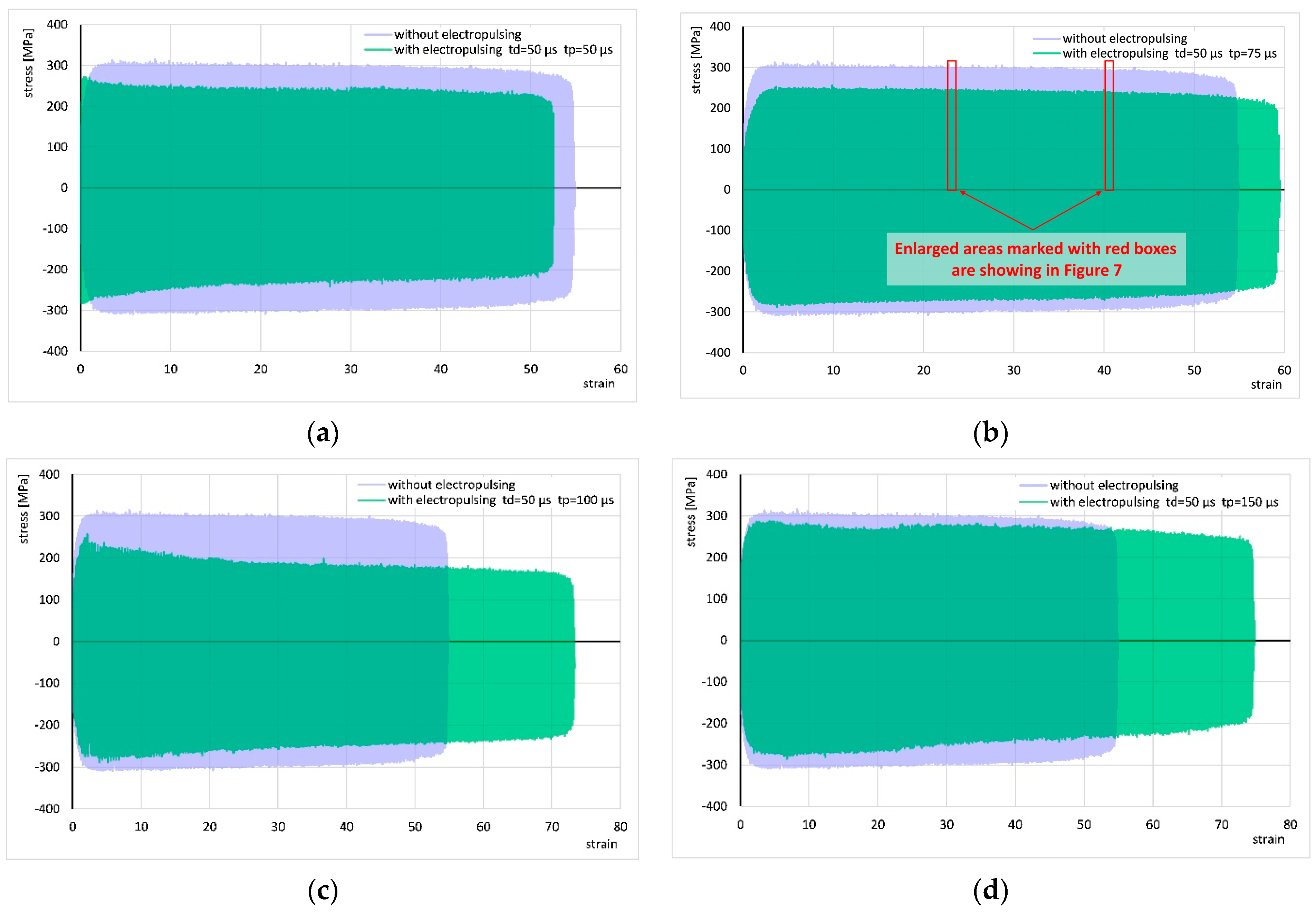

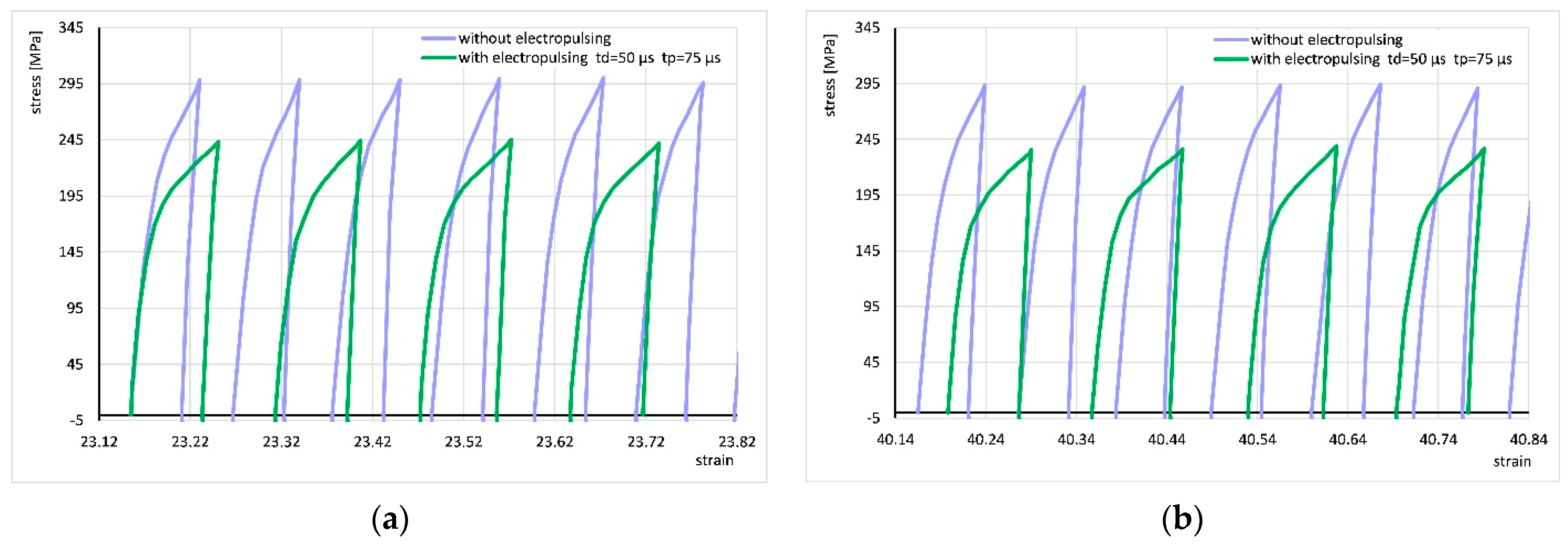

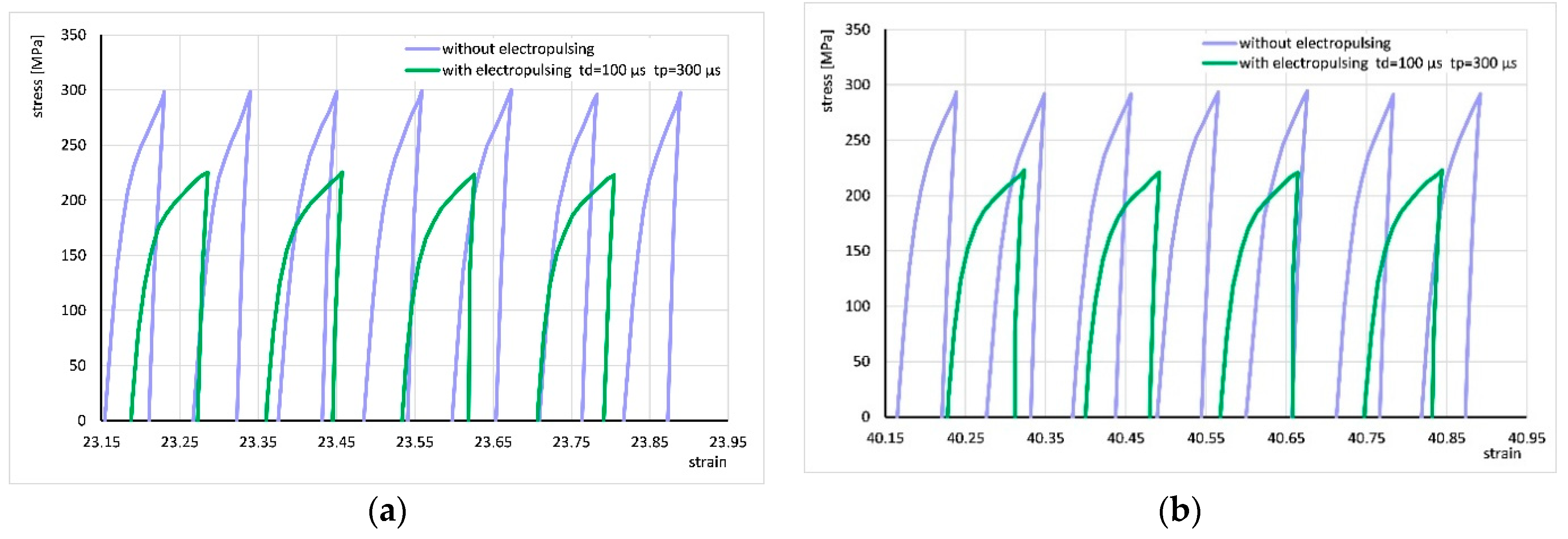

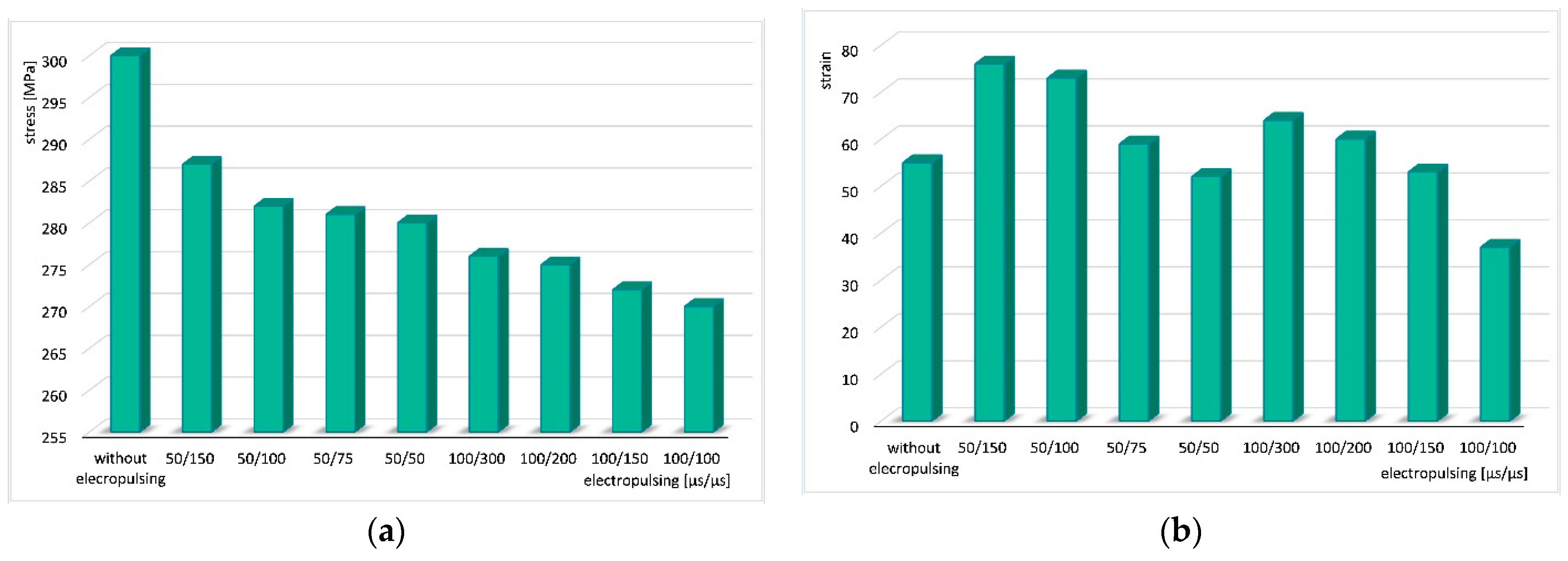

3.2. Results with Application of Electropulsing

3.3. Microstructural Studies

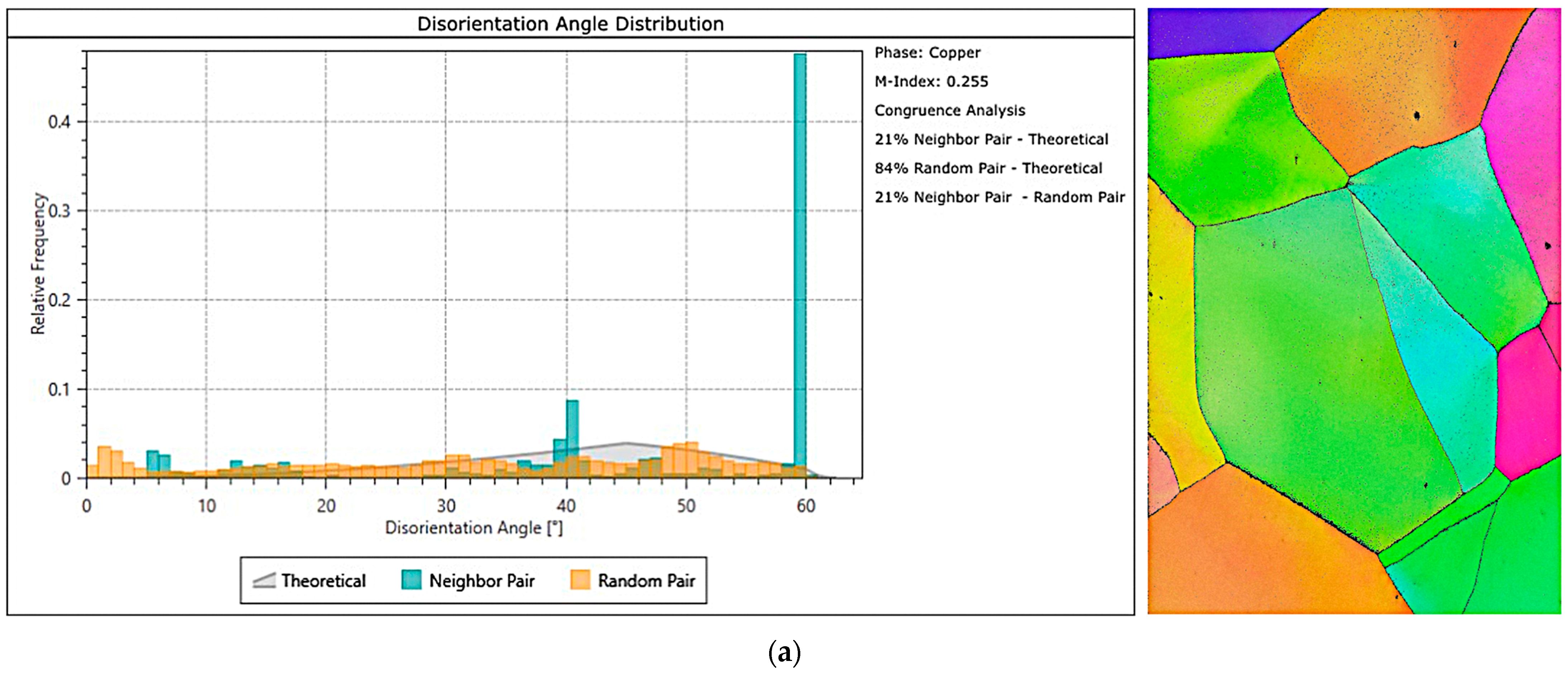

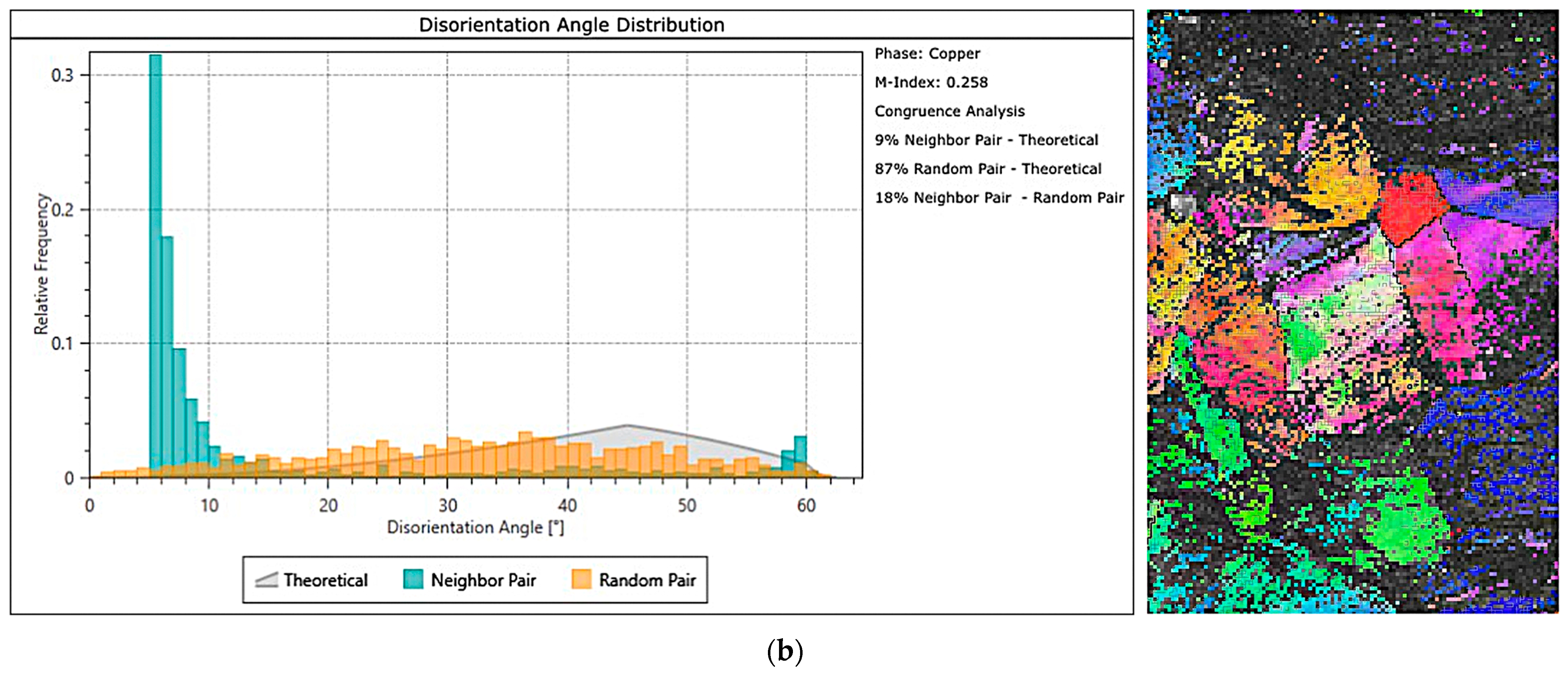

3.4. Microstructure Analysis by EBSD

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dimitrov, N.K.; Liu, Y.; Horstemeyer, M.F. Electroplasticity: A review of mechanisms in electro-mechanical coupling of ductile metals. Mech. Adv. Mater. Struct. 2020, 29, 705–716. [Google Scholar] [CrossRef]

- Nguyen-Tran, H.D.; Oh, H.S.; Hong, S.T.; Han, H.N.; Cao, J.; Ahn, S.H.; Chun, D.M. A review of electrically-assisted manufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 2015, 2, 365–376. [Google Scholar] [CrossRef]

- Roth, J.T.; Loker, I.; Mauck, D.; Warner, M.; Golovashchenko, S.F.; Krause, A. Enhanced formability of 5754 aluminum sheet metal using electric pulsing. In Transactions of the North American Manufacturing Research Institution of SME; NAMRC 36; North American Manufacturing Research Institution: Monterrey, Mexico, 2008. [Google Scholar]

- Ruszkiewicz, B.J.; Grimm, T.; Ragai, I.; Mears, L.; Roth, J.T. A Review of Electrically-Assisted Manufacturing with Emphasis on Modeling and Understanding of the Electroplastic Effect. J. Manuf. Sci. Eng. 2017, 139, 110801. [Google Scholar] [CrossRef]

- Kravchenko, V.Y. Effect of Directed Electron Beam on Moving Dislocations. J. Exp. Theor. Phys. 1967, 24, 1135–1142. [Google Scholar]

- Golovin, Y.I. Magnetoplastic effects in solids. Physic Solid State 2004, 46, 789–824. [Google Scholar] [CrossRef]

- Molotskii, M.I.; Fleurov, V. Magnetic effects in electroplasticity of metals. Phys. Rev. 1995, 52, 15829–15834. [Google Scholar] [CrossRef]

- Molotskii, M.I. Theoretical basis for electro- and magnetoplasticity. Mater. Sci. Eng. 2000, 287, 248–258. [Google Scholar] [CrossRef]

- Li, D.; Yu, E. An approach based on the classical free-electron theory to study electroplastic effect. Adv. Mater. Res. 2011, 148–149, 71–74. [Google Scholar] [CrossRef]

- Li, D.; Yu, E.; Liu, Z. Mechanism research and progress of metal’s pure electroplastic effect. Appl. Mech. Mater. 2012, 184–185, 1060–1063. [Google Scholar] [CrossRef]

- Ruszkiewicz, B.J.; Mears, L.; Roth, J.T. Investigation of Heterogeneous Joule Heating as the Explanation for the Transient Electroplastic Stress Drop in Pulsed Tension of 7075-T6 Aluminum. J. Manuf. Sci. Eng. 2018, 140, 091014. [Google Scholar] [CrossRef]

- Wang, X.L.; Guo, J.D.; Wang, Y.M.; Wu, X.Y.; Wang, B.Q. Segregation of lead in Cu-Zn alloy under electric current pulses. Appl. Phys. Lett. 2006, 89, 061910. [Google Scholar] [CrossRef]

- Shang, H.; Wang, S.; Lou, Y. Modeling and characterization on electroplastic effect during dynamic deformation of 5182-O aluminium alloy. Trans. Nonferrous Met. Soc. China 2024, 24, 2455–2475. [Google Scholar] [CrossRef]

- Dobras, D.; Zimniak, Z.; Zwierzchowski, M.; Dziubek, M.A. Effect of strain rate on the mechanical behavior of Al-Mg alloy under a pulsed electric current. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2024, 55, 1284–1294. [Google Scholar] [CrossRef]

- Farkhondeh, A.; Bakhshi-Jooybari, M.; Gorji, H.; Mirnia, M. Electroplastic Effect on Plastic Behavior of AA6061 Sheet in T6 and Annealed States. Int. J. Eng. 2025, 38, 986–996. [Google Scholar] [CrossRef]

- Shasha, D.; Zhuang, L.; Zhijun, L.; Haojie, S.; Kang, Z.; Jiansheng, X. Mechanical Properties of 7075-T6 Aluminum Alloy in Electrically Assisted Forming. Metals 2025, 15, 117. [Google Scholar] [CrossRef]

- Zimniak, Z.; Dobras, D. Electroplastic effect of high manganese austenitic steel. Arch. Metall. Mater. 2019, 64, 431–436. [Google Scholar] [CrossRef]

- Korolkov, O.E.; Pakhomov, M.A.; Stolyarov, V.V. Electroplastic Effect in Titanium Alloys Under Tension. Inorg. Mater. Appl. Res. 2023, 59, 1581–1589. [Google Scholar] [CrossRef]

- Kinsey, B.; Cullen, G.; Jordan, A.; Mates, S. Investigation of electroplastic effect at high deformation rates for 304SS and Ti-6Al-4V. CIRP Ann. Manuf. Technol. 2013, 62, 279–282. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, R.; Chong, Y.; Li, X.; Abu-Odeh, A.; Rothchild, E.; Chrzan, D.C.; Asta, M.; Morris, J.W.; Minor, A.M. Defect reconfiguration in a Ti–Al alloy via electroplasticity. Nat. Mater. 2021, 20, 468–472. [Google Scholar] [CrossRef]

- Zhu, Y.H.; To, S.; Lee, W.B.; Liu, X.M.; Jiang, Y.B.; Tang, G.Y. Effects of dynamic electropulsing on microstructure and elongation of a Zn-Al alloy. Mater. Sci. Eng. 2009, 501, 125–132. [Google Scholar] [CrossRef]

- Olevsky, E.A.; Jiang, R.; Xu, W.; Maximenko, A.; Grippi, T.; Torresani, E. Quasi-instantaneous materials processing technology via high-intensity electrical nano pulsing. Nat. Sci. Rep. 2024, 14, 434. [Google Scholar] [CrossRef]

- Fan, R.; Magargee, J.; Hu, P.; Cao, J. Influence of grain size and grain boundaries on the thermal and mechanical behavior of 70/30 brass under electrically-assisted deformation. Mater. Sci. Eng. 2013, 574, 218–225. [Google Scholar] [CrossRef]

- Majumdar, A.; Carrejo, J.P.; Lai, J. Thermal imaging using the atomic force microscope. Appl. Phys. Lett. 1993, 62, 2501–2503. [Google Scholar] [CrossRef]

- Dobras, D.; Zimniak, Z.; Zwierzchowski, M.; Dziubek, M.A. Electrically-assisted deep drawing of 5754 aluminium alloy sheet. In Proceedings of the 26th International ESAFORM Conference on Material Forming, Kraków, Poland, 19–21 April 2023; Materials Research Forum LLC: Millersville, PA, USA, 2023; pp. 997–1006. [Google Scholar]

- Valoppi, B.; Sánchez Egea, A.J.; Zhang, Z.; González Rojas, H.A.; Ghiotti, A.; Bruschi, S.; Cao, J. A hybrid mixed double-sided incremental forming method for forming Ti6Al4V alloy. CIRP Ann. Manuf. Technol. 2016, 65, 309–312. [Google Scholar] [CrossRef]

- Lv, Z.; Zhou, Y.; Zhan, L.; Zang, Z.; Zhou, B.; Qin, S. Electrically assisted deep drawing on high-strength steel sheet. Int. J. Adv. Manuf. Technol. 2021, 112, 763–773. [Google Scholar] [CrossRef]

- Wang, D.; Qin, S.; Guo, C.; Chen, H.; Xiao, L.; Ren, W.; Sun, J.; Wang, P.; Hao, L.; Huang, H. Deformability enhancement of rare earth magnesium alloy during electroplastic rolling. Mater. Sci. Eng. A 2025, 934, 148325. [Google Scholar] [CrossRef]

- Zhang, T.; An, X.; Wang, Y.; Bian, G.; Wang, T. Coordinated Regulation of Bonding Interfacial Structure and Mechanical Properties of Al/Mg Alloy Composite Plates by Electrically Assisted Rolling. Chin. J. Mech. Eng. 2025, 38, 22. [Google Scholar] [CrossRef]

- Liu, K.; Dong, X.; Shi, W.; Wang, X.; Wu, G. Investigation on Two Electrically-Assisted Forming Processes of AZ31B Magnesium Alloy Sheets. J. Shanghai Jiaotong Univ. 2019, 24, 409–416. [Google Scholar] [CrossRef]

- Zimniak, Z.; Radkiewicz, G. The electroplastic effect in the cold-drawing of copper wires for the automotive industry. Arch. Civ. Mech. Eng. 2008, 8, 173–179. [Google Scholar] [CrossRef]

- Tang, G.; Zhang, J.; Zheng, M.; Zhang, J.; Fang, W.; Li, Q. Experimental study of electroplastic effect on stainless steel wire 304L. Mater. Sci. Eng. 2000, 281, 263–267. [Google Scholar] [CrossRef]

- Jones, J.J.; Mears, L.; Roth, J.T. Electrically-assisted forming of magnesium AZ31: Effect of current magnitude and deformation rate on forgeability. J. Manuf. Sci. Eng. 2012, 134, 034504. [Google Scholar] [CrossRef]

- Perkins, T.A.; Kronenberger, T.J.; Roth, J.T. Metallic forging using electrical flow as an alternative to warm/hot working. J. Manuf. Sci. Eng. 2007, 129, 84–94. [Google Scholar] [CrossRef]

- Korolkov, O.E.; Misochenko, A.A.; Stolyarov, V.V. Electroplastic Effect in Titanium Under Compression. Inorg. Mater. Appl. Res. 2024, 15, 1863–1868. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, B.; Zhao, R.; Wan, M.; Chen, L. Design and Validation of a Novel Process Solution for Electrically Assisted Superalloy Capillary Microforming. Int. J. Precis. Eng. Manuf.-Green Technol. 2025. [Google Scholar] [CrossRef]

- Lv, Y.; Chen, G.; ·Zhang, B.; Li, H.J. Application of electroplastic effect in mechanical processing. Int. J. Adv. Manuf. Technol. 2024, 135, 25–48. [Google Scholar] [CrossRef]

- Kim, M.-J.; Bui-Thi, T.-A.; Kang, S.-G.; Hong, S.-T.; Han, H.N. Electric current-induced phenomena in metallic materials. Curr. Opin. Solid State Mater. Sci. 2024, 32, 101190. [Google Scholar] [CrossRef]

- ASTM E112-13; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2021.

| Material | Cu | Zn | Fe | Ni | As | Mn |

| CuZn30 | 70.1 | residue | 0.01 | 0.001 | 0.001 | 0.004 |

| Bi | Sn | Al | Si | Cd | Sb | |

| 0.001 | 0.03 | 0.001 | 0.001 | 0.001 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zimniak, Z.; Weiler, W.; Jaśkiewicz, K. The Influence of Cyclic Torsion with Application of Current Pulses on the Formability of CuZn30 Brass. Materials 2025, 18, 3912. https://doi.org/10.3390/ma18163912

Zimniak Z, Weiler W, Jaśkiewicz K. The Influence of Cyclic Torsion with Application of Current Pulses on the Formability of CuZn30 Brass. Materials. 2025; 18(16):3912. https://doi.org/10.3390/ma18163912

Chicago/Turabian StyleZimniak, Zbigniew, Wojciech Weiler, and Karol Jaśkiewicz. 2025. "The Influence of Cyclic Torsion with Application of Current Pulses on the Formability of CuZn30 Brass" Materials 18, no. 16: 3912. https://doi.org/10.3390/ma18163912

APA StyleZimniak, Z., Weiler, W., & Jaśkiewicz, K. (2025). The Influence of Cyclic Torsion with Application of Current Pulses on the Formability of CuZn30 Brass. Materials, 18(16), 3912. https://doi.org/10.3390/ma18163912