Welding Technology and Heat Treatment Butt-Welded Joints of Thin-Walled Inconel 718 Alloy Tubes

Abstract

1. Introduction

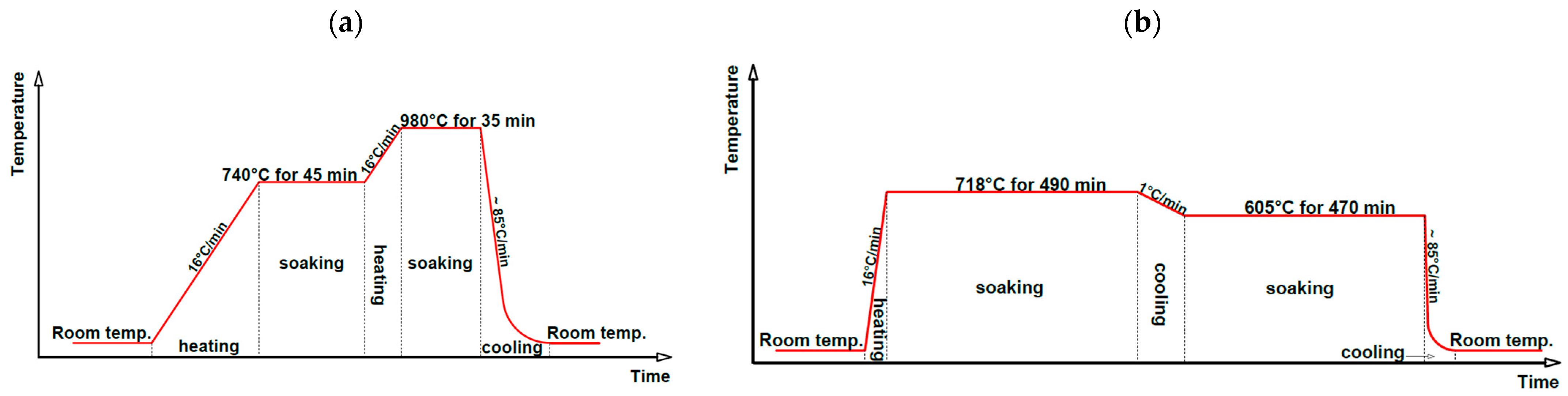

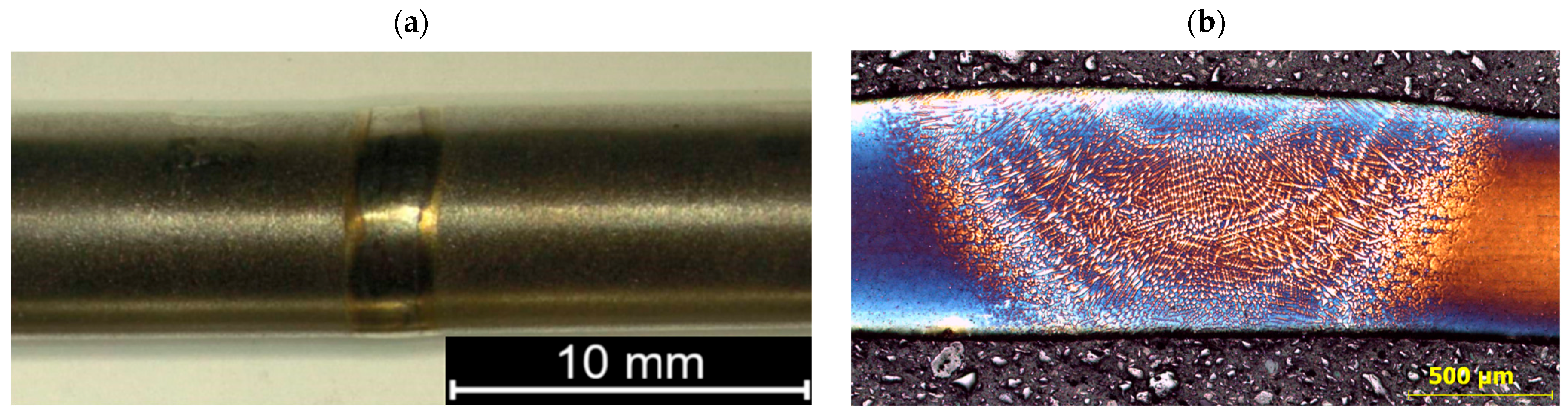

2. Materials and Methods

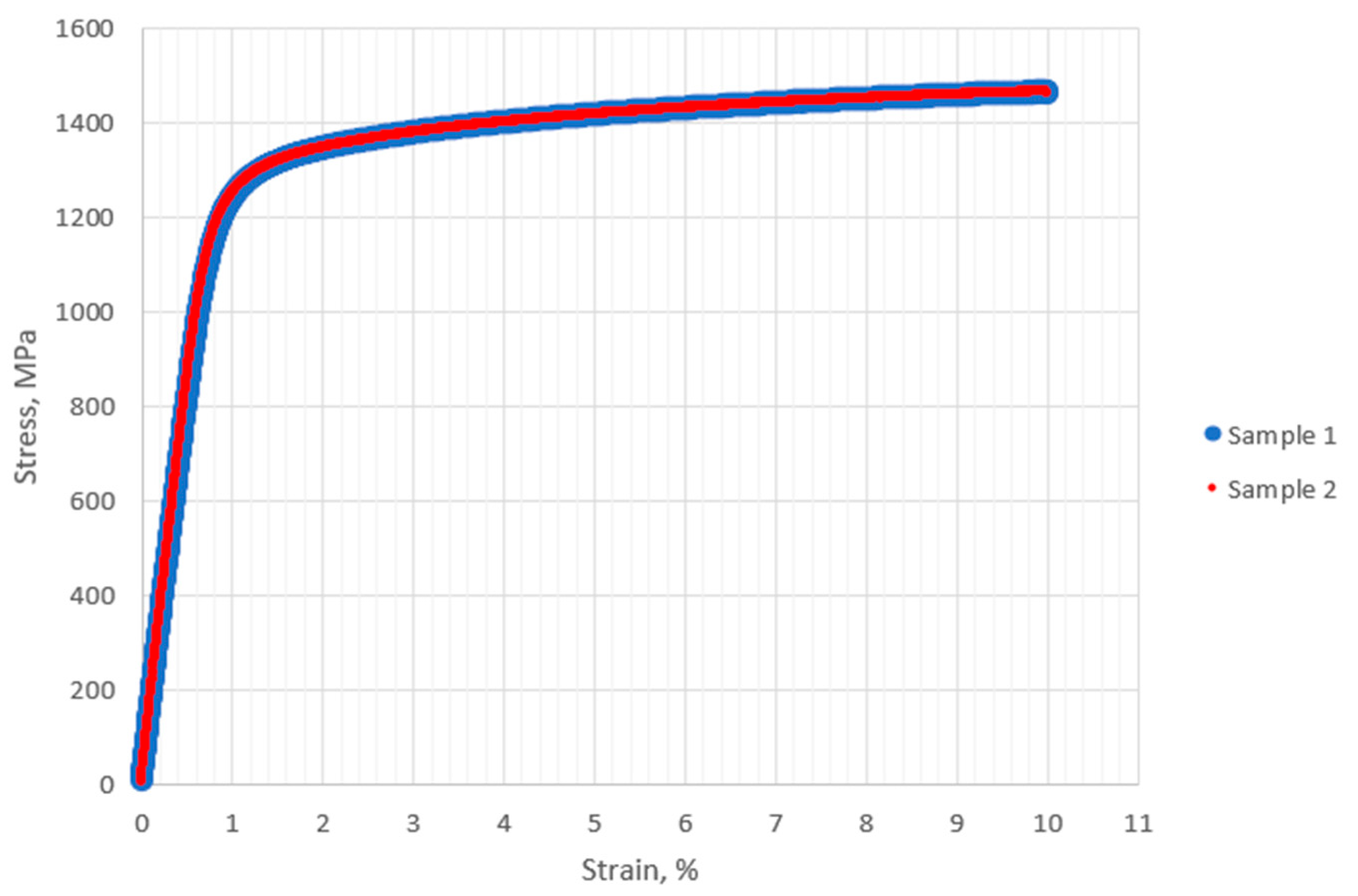

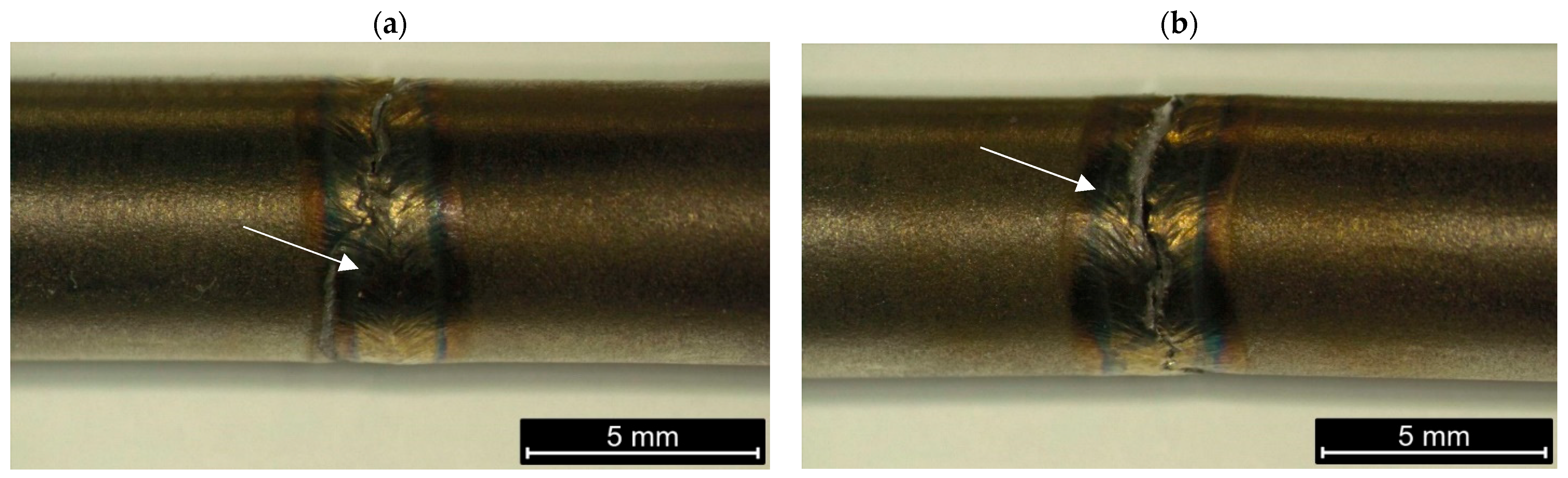

3. Results and Discussion

4. Conclusions

- Correct shape and geometry of the fabricated joints, characterized by the high quality of the face and root;

- Symmetrical fusion zone with a very narrow heat-affected zone. In the various zones of the joint, a typical microstructure of welded joints made of Inconel 718 was observed. The alloy matrix consisted of a γ phase of the FFC structure and precipitations of niobium carbides (NbC) and titanium carbide in it. No microcracks were observed in the HAZ area; however, a change in the morphology of the precipitates from globular to lamellar was evident in this zone. The welds were characterized by a dendritic structure. Thanks to the EDS analysis, a tendency of the niobium was observed to segregate in the interdendritic areas, where there were δ phase (Ni3Nb) with lamellar morphology and Laves phase;

- An increase in hardness after the applied precipitation hardened heat treatment relative to the material under delivery conditions from 240 HV0.3 to 468 HV0.3. The measured microhardness (HV0.3) has met the requirements according to AMS 5589. In all zones of the joints, the hardness was similar (±10 HV0.3);

- The tensile strength (1464 MPa) and yield strength (1277 MPa) met the requirements for welded joints according to AMS 5589. The placement of the fracture was the weld area, which is typical for a girth weld. This placement of crack means that, despite the use of favorable heat treatment, the fatigue resistance of the joints will be limited;

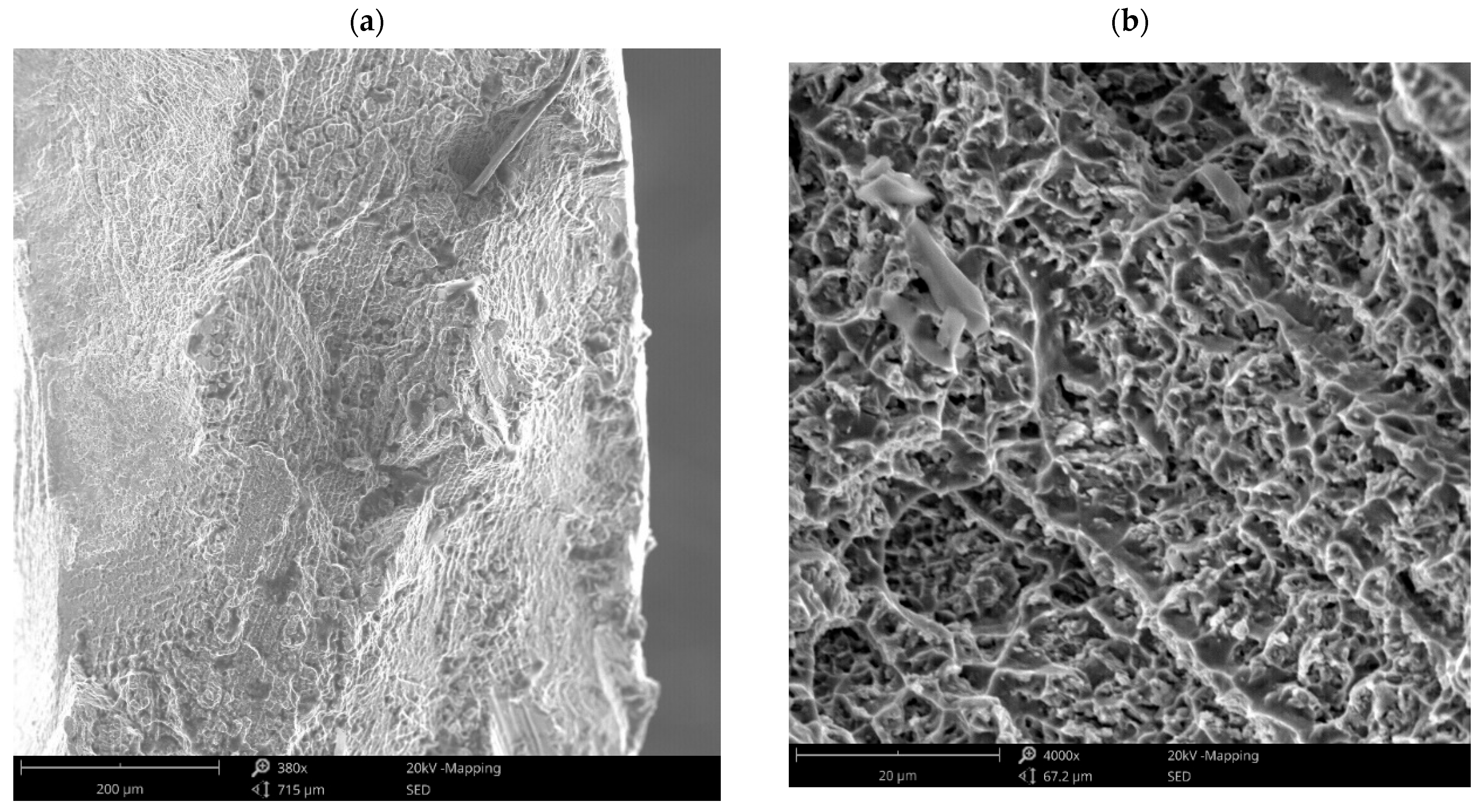

- The ductile fracture of the resulting fractures was observed, on the surface of which a large number of precipitates were observed as well as the inclusion of slags, gas micropores formed during crystallization, and small hot cracks. Despite the local discontinuities, the fractures studied can be assessed as correct.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lippold, J.C.; Kiser, S.D.; DuPont, J.N. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Donachie, M.J.; Donachie, S.J. Superalloys a Technical Guide; ASM International: Almere, The Netherlands, 2002. [Google Scholar]

- Moosavy, H.N.; Aboutalebi, M.R.; Seyedein, S.H.; Mapelli, C. Microstructural, mechanical and weldability assessments of the dissimilar weld between γ’- and γ”-strengthened nickel-based superalloys. Mater. Charact. 2013, 82, 41–49. [Google Scholar] [CrossRef]

- Ghaffari, R.; Naffakh-Moosavy, H. Investigation of macrostructure, microstructure, and hot cracking susceptibility of laser-welded Inconel-718 superalloy under various post- cold treatment environments. CIRP J. Manuf. Sci. Technol. 2022, 37, 110–124. [Google Scholar] [CrossRef]

- Keivanloo, A.; Naffakh-Moosavy, H.; Miresmaeili, R. The effect of pulsed laser welding on hot cracking susceptible region size and weld pool internal geometry of Inconel 718: Numerical and experimental approaches. CIRP J. Manuf. Sci. Technol. 2021, 35, 787–794. [Google Scholar] [CrossRef]

- Rahul, M.R.; Agilan, M.; Mohan, D.; Phanikumar, G. Integrated experimental and simulation approach to establish the effect of elemental segregation in Inconel 718 welds. Materialia 2022, 26, 101593. [Google Scholar] [CrossRef]

- Liu, F.; Lyu, F.; Liu, F.; Lin, X.; Huang, C. Laves phase control of Inconel 718 superalloy fabricated by laser direct energy deposition via δ aging and solution treatment. J. Mater. Res. Technol. 2020, 9, 9753–9765. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: Sample orientation dependence and effects of post heat treatments. Mater. Sci. Eng. 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Rezaei, M.A.; Naffakh-Moosavy, H. The effect of pre-cold treatment on microstructure, weldability and mechanical properties in laser welding of superalloys. J. Manuf. Process. 2018, 34, 339–348. [Google Scholar] [CrossRef]

- Watring, D.S.; Benzing, J.T.; Hrabe, N.; Spear, A.D. Effects of laser-energy density and build orientation on the structure–property relationships in as-built Inconel 718 manufactured by laser powder bed fusion. Addit. Manuf. 2020, 36, 101425. [Google Scholar] [CrossRef] [PubMed]

- Mahadevan, S.; Nalawade, S.; Singh, J.B.; Verma, A.; Paul, B.; Ramaswamy, K. Evolution of δ phase microstructure in alloy 718. In Proceedings of the 7th International Symposium on Superalloy 718 and Dervivates, Pittsburgh, PA, USA, 10–13 October 2010; pp. 737–750. [Google Scholar]

- Wang, Z.; Zhou, D.; Deng, Q.; Chen, G.; Xie, W. The Microstructure and Mechanical Properties of Inconel 718 Fine Grain Ring Forging. In Proceedings of the 7th International Symposium on Superalloy 718 and Dervivates, Pittsburgh, PA, USA, 10–13 October 2010; pp. 343–349. [Google Scholar]

- Sonar, T.; Balasubramanian, V.; Malarvizhi, S.; Venkateswaran, T.; Sivakumar, D. An overview on welding of Inconel 718 alloy—Effect of welding processes on microstructural evolution and mechanical properties of joints. Mater. Charact. 2021, 174, 110997. [Google Scholar] [CrossRef]

- Kulawik, K.; Buffat, P.A.; Kruk, A.; Wusatowska-Sarnek, A.M.; Czyrska-Filemonowicz, A. Imaging and characterization of γ’ and γ” nanoparticles in Inconel 718 by EDX elemental mapping and FIB-SEM tomography. Mater. Charact. 2015, 100, 74–80. [Google Scholar] [CrossRef]

- Chang, L.; Sun, W.; Cui, Y.; Zhang, F.; Yang, R. Effect of heat treatment on microstructure and mechanical properties of the hot-isostatic-pressed Inconel 718 powder compact. J. Alloys Compd. 2014, 590, 227–232. [Google Scholar] [CrossRef]

- Wang, Z.; Gui, Z.; Wu, J.; Zhang, Q.; Wu, X.; Lin, S.; Tian, J.; Guo, C. Microstructure and high-temperature mechanical properties of Inconel 718 superalloy weldment affected by fast-frequency pulsed TIG welding. J. Manuf. Process. 2023, 89, 338–348. [Google Scholar] [CrossRef]

- Anuradha, M.; Vemulapalli, C.D.; Cheepu, M. Effect of filler materials on dissimilar TIG welding of Inconel 718 to high strength steel. Mater. Today Proc. 2022, 52, 1314–1320. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Microstructural study of weld fusion zone of TIG welded IN 738LC nickel-based superalloy. Scr. Mater. 2004, 51, 683–688. [Google Scholar] [CrossRef]

- Yelamasetti, B.; Adithya, G.S.; Ramadevi, R.S.; Sonia, P.; Saxena, K.K.; Kumar, N.; Eldin, S.M.; Al-kafaji, F.H. Metallurgical, mechanical and corrosion behavior of pulsed and constant current TIG dissimilar welds of AISI 430 and Inconel 718. J. Mater. Res. Technol. 2023, 24, e6664. [Google Scholar] [CrossRef]

- Górka, J.; Jamrozik, W.; Kiel-Jamrozik, M. The effect of TIG welding on the structure and hardness of butt joints made of Inconel 718. Heliyon 2023, 9, e13175. [Google Scholar] [CrossRef]

- Janaki Ram, G.D.; Venugopal Reddy, A.; Prasad Rao, K.; Reddy, G.M.; Sarin Sundar, J.K. Microstructure and tensile properties of Inconel 718 pulsed Nd-YAG laser welds. J. Mater. Process. Technol. 2005, 167, 73–82. [Google Scholar] [CrossRef]

- Tuz, L.; Sokołowski, Ł.; Stano, S. Effect of Post-Weld Heat Treatment on Microstructure and Hardness of Laser Beam Welded 17-4 PH Stainless Steel. Materials 2023, 16, 1334. [Google Scholar] [CrossRef]

- Chen, J.; Chang, Y.; Wei, Y. Building ultra-thin Inconel 718 sheet joints using low-frequency PLBW scheme: Weld bead quality, keyhole dynamics, and solidification characteristics. J. Mater. Res. Technol. 2023, 27, 4145–4156. [Google Scholar] [CrossRef]

- Sharma, S.K.; Biswas, K.; Nath, A.K.; Manna, I.; Majumdar, J.D. Microstructural change during laser welding of Inconel 718. Opt.—Int. J. Light Electron Opt. 2020, 218, 165029. [Google Scholar] [CrossRef]

- Brunner-Schwer, C.; Simón-Muzásb, J.; Biegler, M.; Hilgenberg, K.; Rethmeier, M. Laser Welding of L-PBF AM components out of inconel 718. Procedia CIRP 2022, 111, 92–96. [Google Scholar] [CrossRef]

- Thejasree, P.; Manikandan, N.; Raju, R.; Narasimhamu, K.L.; Surendranatha, G.M.; Damodaram, A.K. Investigations on laser beam welded Inconel 718 weldments. Mater. Today Proc. 2022, 68, 1757–1761. [Google Scholar] [CrossRef]

- Ai, Y.; Yan, Y.; Dong, G.; Han, S. Investigation of microstructure evolution process in circular shaped oscillating laser welding of Inconel 718 superalloy. Int. J. Heat Mass Transf. 2023, 216, 124522. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Xiong, H.; Wang, X.; Guo, M.; Zhang, B. Influence of assembly gap on microstructural evolution in electron beam lap welding of Inconel 718 and electroformed nickel. Mater. Today Commun. 2023, 37, 107111. [Google Scholar] [CrossRef]

- Tuz, L.; Kąc, S.; Sierakowski, D. Technology of electron beam welding of 10CrMo9-10 steel with the specific quality requirements. Manuf. Lett. 2023, 35, 53–57. [Google Scholar] [CrossRef]

- Dan, Z.; Fei, L.; Yuan-Biao, T.; Wei, S.; Song, X. Improving the strength-ductility synergy and corrosion resistance of Inconel 718/316L dissimilar laser beam welding joint via post-weld heat treatment. J. Mater. Res. Technol. 2023, 26, 71–87. [Google Scholar] [CrossRef]

- Zhou, L.; Xu, P.; Lin, T.; Zhu, X.; Liang, Y.; Liang, Y. Outstanding ductility of flash-butt welded Inconel 718 joints after post-weld heat treatment. Mater. Sci. Eng. A 2022, 843, 143132. [Google Scholar] [CrossRef]

- Devendranath Ramkumar, K.; Vishnu Arvind, A.; Rama Aravinth, K.V.; Srivatson, E.; Ganguly, S. Effect of solutionizing and double ageing treatments on the microstructural characteristics and tensile properties of Inconel 718 welds. J. Mater. Res. Technol. 2023, 26, 6255–6265. [Google Scholar] [CrossRef]

- EN ISO 4063:2011; Welding and Allied Processes—Nomenclature of Processes and Reference Numbers. Comite Europeen de Normalisation: Brussels, Belgium, 2011.

- EN ISO 17637:2008; Non-Destructive Testing of Welds—Visual Testing of Fusion-Welded Joints. Comite Europeen de Normalisation: Brussels, Belgium, 2016.

- EN ISO 5817:2023-08; Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (Beam Welding Excluded)—Quality Levels for Imperfections. Comite Europeen de Normalisation: Brussels, Belgium, 2023.

| Wt.% | C | Mn | Si | Cr | Ni | Mo | Nb | Ti | Al | Co | Ta | B | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | 0 | 0 | 0 | 17 | 50 | 2.8 | 4.75 | 0.65 | 0.2 | 0 | 0 | 0 | 0 |

| Max | 0.08 | 0.35 | 0.35 | 21 | 55 | 3.3 | 5.5 | 1.15 | 0.8 | 1.0 | 0.02 | 0.006 | 0.3 |

| Mechanical Properties | Delivery Conditions | After Precipitation Heat Treatment |

|---|---|---|

| Tensile strength, max | 1069 MPa | 1276 MPa |

| Yield strength, max | 655 MPa | 1034 MPa |

| Elongation 50 mm, min | 30% | 12% |

| Parameters | Sectors | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Welding current HP [A] | 18.2 | 17.6 | 16.7 | 15.4 | 14.5 |

| Welding current LP [A] | 6.3 | 6.1 | 5.8 | 5.4 | 5.0 |

| Welding average voltage [V] | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 |

| Travel speed HP [mm/min] | 100 | 100 | 100 | 100.0 | 100 |

| Travel speed LP [mm/min] | 100 | 100 | 100 | 100 | 100 |

| Argon flow [l/min] | 5.6 | 6.0 | 6.0 | 6.0 | 6.0 |

| Condition | Base Metal | Heat-Affected Zone | Weld Metal |

|---|---|---|---|

| Delivery conditions | 242 | - | - |

| After welding and heat treatment | 478 | 439 | 465 |

| Sample No. | Fracture Locations | Tensile Strength [MPa] | Yield Strength [MPa] | Elongation [%] |

|---|---|---|---|---|

| 1 | Weld metal | 1465 | 1278 | 10 |

| 2 | Weld metal | 1464 | 1277 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warchoł, P.; Tuz, L. Welding Technology and Heat Treatment Butt-Welded Joints of Thin-Walled Inconel 718 Alloy Tubes. Materials 2025, 18, 3896. https://doi.org/10.3390/ma18163896

Warchoł P, Tuz L. Welding Technology and Heat Treatment Butt-Welded Joints of Thin-Walled Inconel 718 Alloy Tubes. Materials. 2025; 18(16):3896. https://doi.org/10.3390/ma18163896

Chicago/Turabian StyleWarchoł, Patryk, and Lechosław Tuz. 2025. "Welding Technology and Heat Treatment Butt-Welded Joints of Thin-Walled Inconel 718 Alloy Tubes" Materials 18, no. 16: 3896. https://doi.org/10.3390/ma18163896

APA StyleWarchoł, P., & Tuz, L. (2025). Welding Technology and Heat Treatment Butt-Welded Joints of Thin-Walled Inconel 718 Alloy Tubes. Materials, 18(16), 3896. https://doi.org/10.3390/ma18163896