4.2. Range Analysis and ANOVA

Ki indicates the sum of the test results of a factor at three levels, and

ki = Ki/3, which indicates the average of the single factor test results at three levels; the range,

R = max{

k}-min{

k}, where the larger the R value is, the greater the impact of this factor on the indicator will be. The results of the range analysis are shown in

Table 9 and

Table 10.

The results show that in terms of strength, factor A tops the list, followed by factor C; in terms of workability, factor A also had the greatest impact, followed by factor B; for the residual stability, factor A was the most prominent, but the TSR was most affected by the factor B; the temperature performance was also dominated by the influence of factor A, followed by factor B, and factor C was the smallest. Comprehensive analysis shows that the total filler amount was the core variable that determined the comprehensive performance of CPAM. Factor B had the greatest effect on the TSR, indicating that part of the mineral powder replaced by cement–bentonite can effectively improve the water stability of the material. Factor C was second only to factor A in strength sensitivity, but its influence was weaker than that of factors A and B in all other performance indicators.

When performing ANOVA on factors and levels, a blank column is needed to perform as an error column. When the mean square of one of the three factors is smaller than the error mean square, it is necessary to recalculate the mean square after combining the mean square and the freedom degrees of that factor to the error and then perform the ANOVA again. The effect significance of a factor could be shown by the degree of freedom (

df), mean square deviations (

MS), test statistics (

F), and probability level (

P), as shown in

Table 11.

The results of ANOVA show that factor A significantly affected the construction workability and temperature performance of CPAM and relatively affected the early strength, while factors B and C had no significant effect on the early strength and forming strength. In terms of the high-temperature performance, factor A had a highly significant effect on the dynamic stability, and factors B and C had no significant effect. In terms of water stability and low-temperature cracking resistance, factors A and B had the greatest impact on the residual stability and damage bending and tensile strains. Factor C, the proportion of cement and bentonite replacing the mineral powder, affected the low-temperature breaking bending and tensile strain. The effects of ANOVA on the significance of each factor are shown in

Table 12.

4.3. Performance Verification of CPAM

4.3.1. Strength

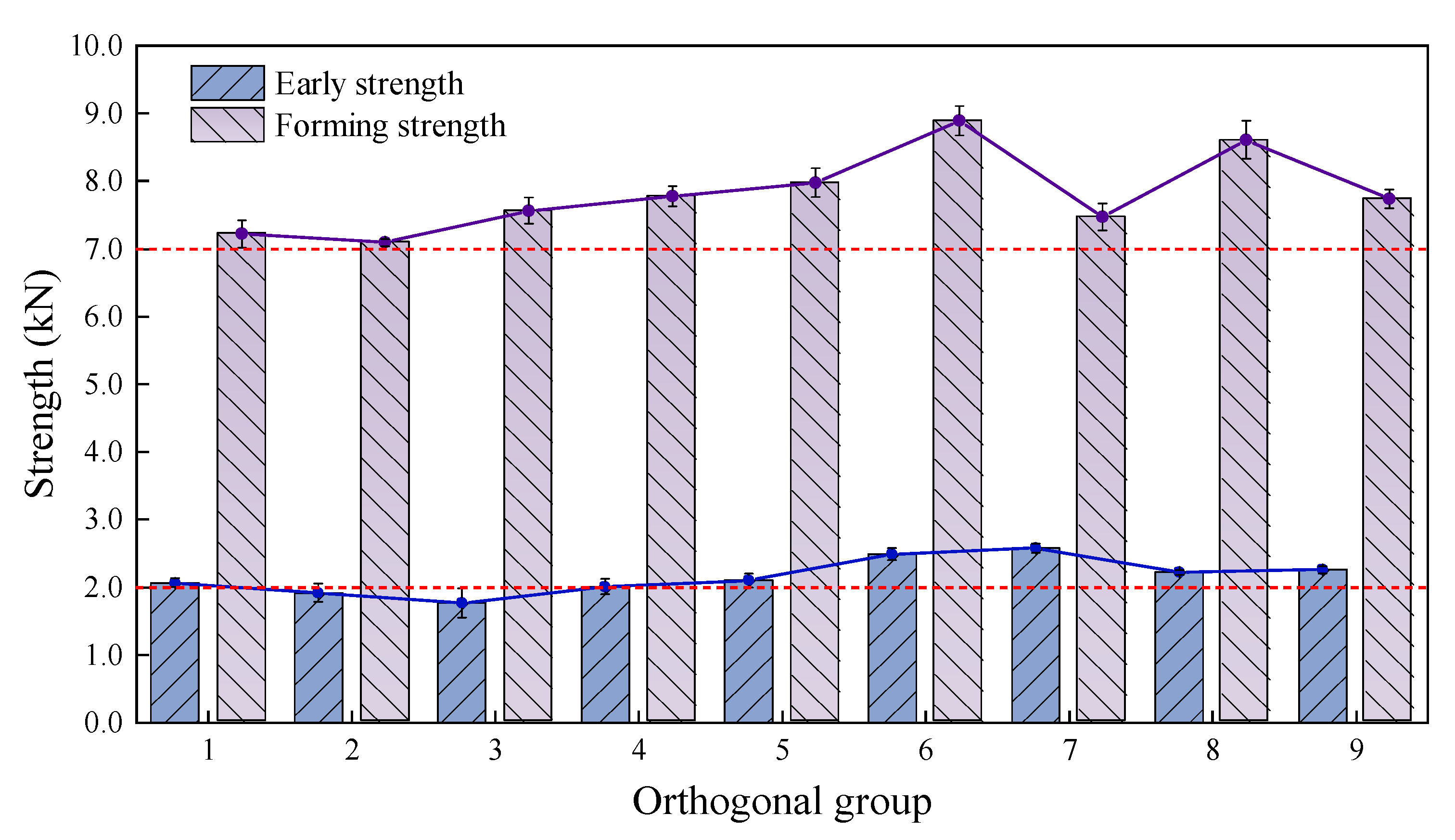

The intuitive analysis of different orthogonal groups’ strengths is shown in

Figure 5.

The red lines in

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9 represent the index requirement specified in the test methods. The results show that only the early strengths of groups 2 and 3 (1.92 kN and 1.77 kN, respectively) did not meet the requirements. Groups 6 and 7 had relatively high early strengths of 2.49 kN and 2.58 kN, respectively. Groups 5, 6, and 8 had greater forming strengths of 7.98 kN, 8.89 kN, and 8.61 kN, respectively. However, the strengths of groups 1, 2, and 3 were relatively low, but the early strength and forming strength of group 1 met the requirements. This is because the total filler amount has a significant impact on the early strength, and a low filler amount will increase the free asphalt content in the CPAM. Therefore, groups 1, 2, and 3, with a filler amount of only 2.3% had relatively low early strengths. Groups 7, 8, and 9 had the highest filler amounts and relatively higher initial strengths, but the forming strengths of groups 7 and 9 were lower.

This indicates that when the total filler amount is the same, the ratio of bentonite and cement replacing mineral powder at 30% and a bentonite/cement ratio of 0.2:1 could achieve higher strength, which was group 8. Meanwhile, group 9 used a ratio of 50% bentonite and cement replacing mineral powder and a bentonite/cement ratio of 1:1, which did not reach the highest strength. This also proves that it is not necessarily true that a higher content of cement and bentonite is better; excessive cement or bentonite may reduce the cohesion of the asphalt binder, and thus, the strength of the CPAM would decrease. Considering all factors, group 6 had the highest initial and forming strengths, followed by groups 8, 5, and 1 with better strength.

4.3.2. Construction Workability

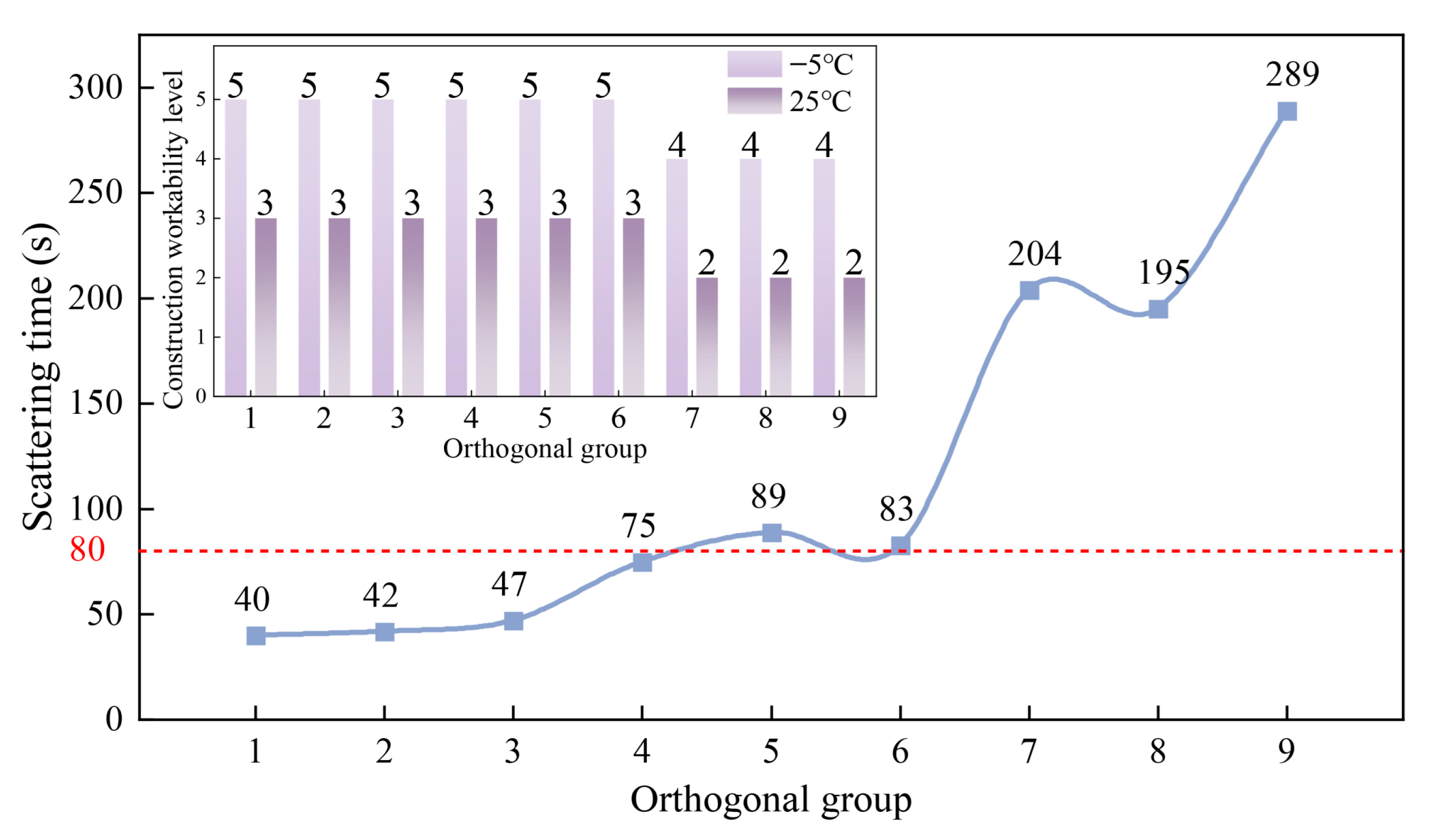

The workability analysis of different orthogonal groups is shown in

Figure 6.

Based on the construction workability and scattering time, the lowest filler amount of groups 1, 2, 3 had the shortest scattering time of only 40 s, 42 s, and 47 s, which were far better than the stipulated scattering time of less than 80 s. Groups 4, 5, and 6 had 4.3% moderate, and the scattering time was approximately 80 s, which barely met the requirements. While when the filler amount reached 6.3%, the scattering time of groups 7, 8, and 9 increased sharply, reaching 204 s, 195 s, and 289 s. The low-temperature construction workability grades of these three groups were only grade 2, which did not meet the basic requirements for low-temperature construction. The construction workability at room temperature grade was only grade 4, which did not meet the requirements of grade 5. This indicates that the more filler used, the longer the scattering time, and the worse the workability. Among all groups, group 9 had the longest scattering time and the worst workability. The reason might be that the proportion of bentonite and cement replacing the mineral powder in group 9 was the largest, and the amount of bentonite was the most. Therefore, it is concluded that when the total filler amount is the same, the larger the proportion of bentonite and cement replacing the mineral powder, the worse the workability will be.

4.3.3. Water Stability

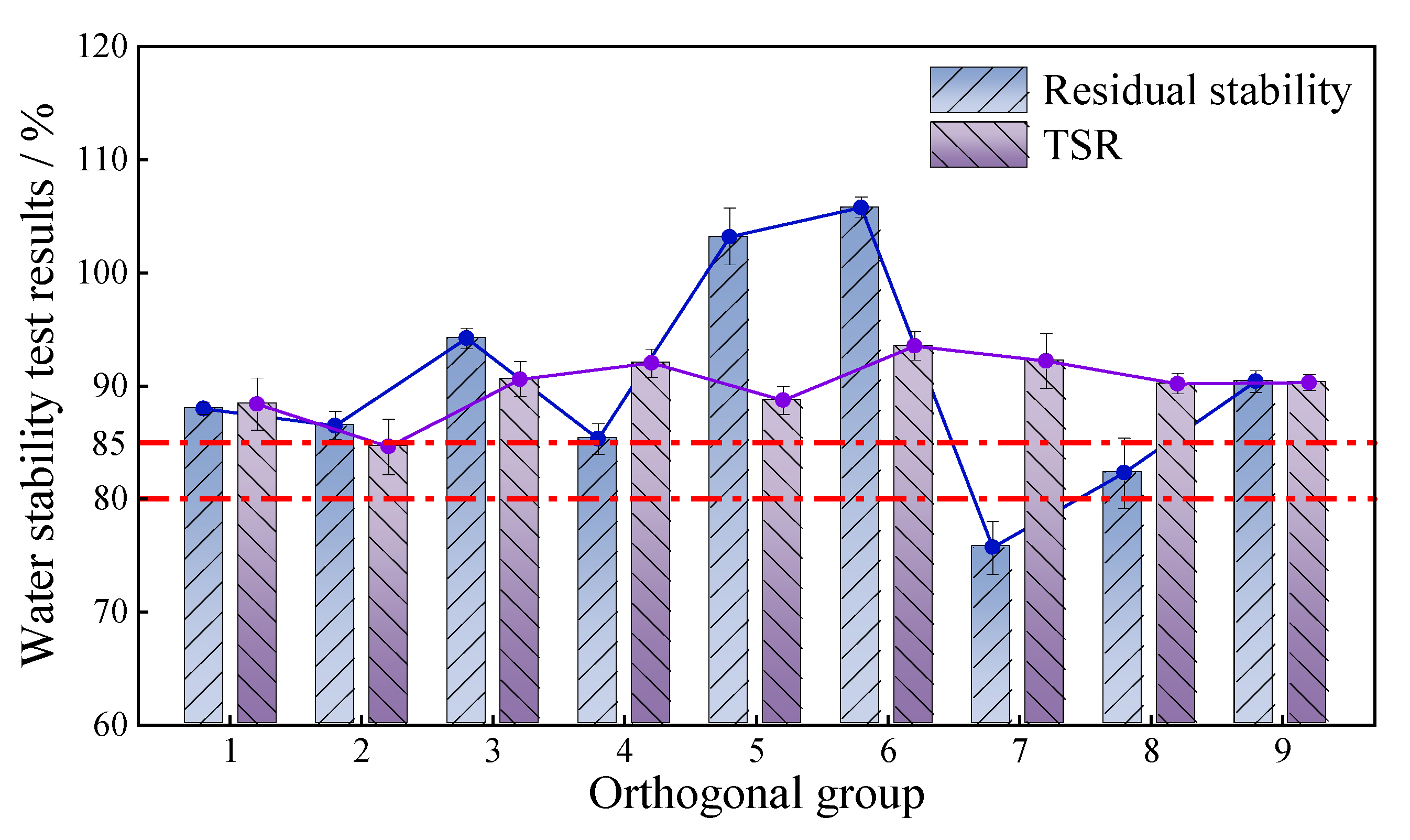

The analysis of the immersion Marshall test and freeze–thaw splitting test results is shown in

Figure 7.

From the test results, it was seen that except for group 7 and group 8, all other groups met the requirement of residual stability (≥85%). Group 5 and 6 showed a residual stability greater than 100%, indicating that hydration of cement took place during the immersion of the specimen, thus increasing the strength. Group 7 had the worst residual stabilization at a filler amount of 6.3%. This suggests that excessive filler content and too thin an asphalt film led to a decrease in the internal cohesion of the mixture, making the mixture more susceptible to water erosion. Group 8 and 9 both showed a significant improvement in residual stability compared to group 7, with group 9 achieving a residual stability of 90.4%. This indicates that increasing the proportion of cement and bentonite could significantly improve the water stability of CPAM, and a greater bentonite/cement ratio could gain a more significant performance improvement. Based on the test results, the groups with the best residual stability were groups 5 and 6, followed by groups 3 and 9. The TSR of all orthogonal groups met the requirement of >80%. Similarly, group 6 had the highest TSR, reaching 93.5%, while group 2 had the lowest TSR at 84.6%. The TSR of the other groups also showed significant improvement, and the analysis of variance indicated that the total filler content, the proportion of the two fillers, and the ratio of bentonite to cement all had a significant impact on the TSR. This shows that the addition of cement and bentonite can to some extent improve the water stability of CPAM. However, based on the results of the water immersion Marshall test, the greater addition of cement and bentonite is not necessarily better.

Above all, group 6 had the best water stability, followed by group 3, group 5, and group 9, with good residual stability and TSR.

4.3.4. High-Temperature Stability

The analysis of the high-temperature stability is shown in

Figure 8.

The ANOVA indicates that only the total amount of filler had a significant impact on the dynamic stability; factors B and C had no significant effect. From

Figure 8, it is intuitively seen that the filler amounts in CPAM corresponding to the groups 1, 2, and 3 were the lowest, and the dynamic stability was relatively low. The reason is that less filler and more free asphalt in the mixture would result in a lubricating effect between the mixtures, which makes the surface of the mixture more prone to rutting, and the dynamic stability decreases. When the filler amount was increased to 4.3% and 6.3%, no significant improvement in dynamic stability was observed, and the peak value was concentrated in groups 4, 5, and 6 with a moderate filler amount. This indicates that it is not the case that the higher the filler amount, the better the high-temperature performance of the CPAM. Group 9, with a higher proportion of bentonite and cement, showed a significant improvement in high-temperature performance, indicating that bentonite and cement can conspicuously improve the high-temperature performance of the CPAM. Considering all factors, groups 5, 9, 6, and 4 had the best high-temperature performance.

4.3.5. Low-Temperature Cracking Resistance

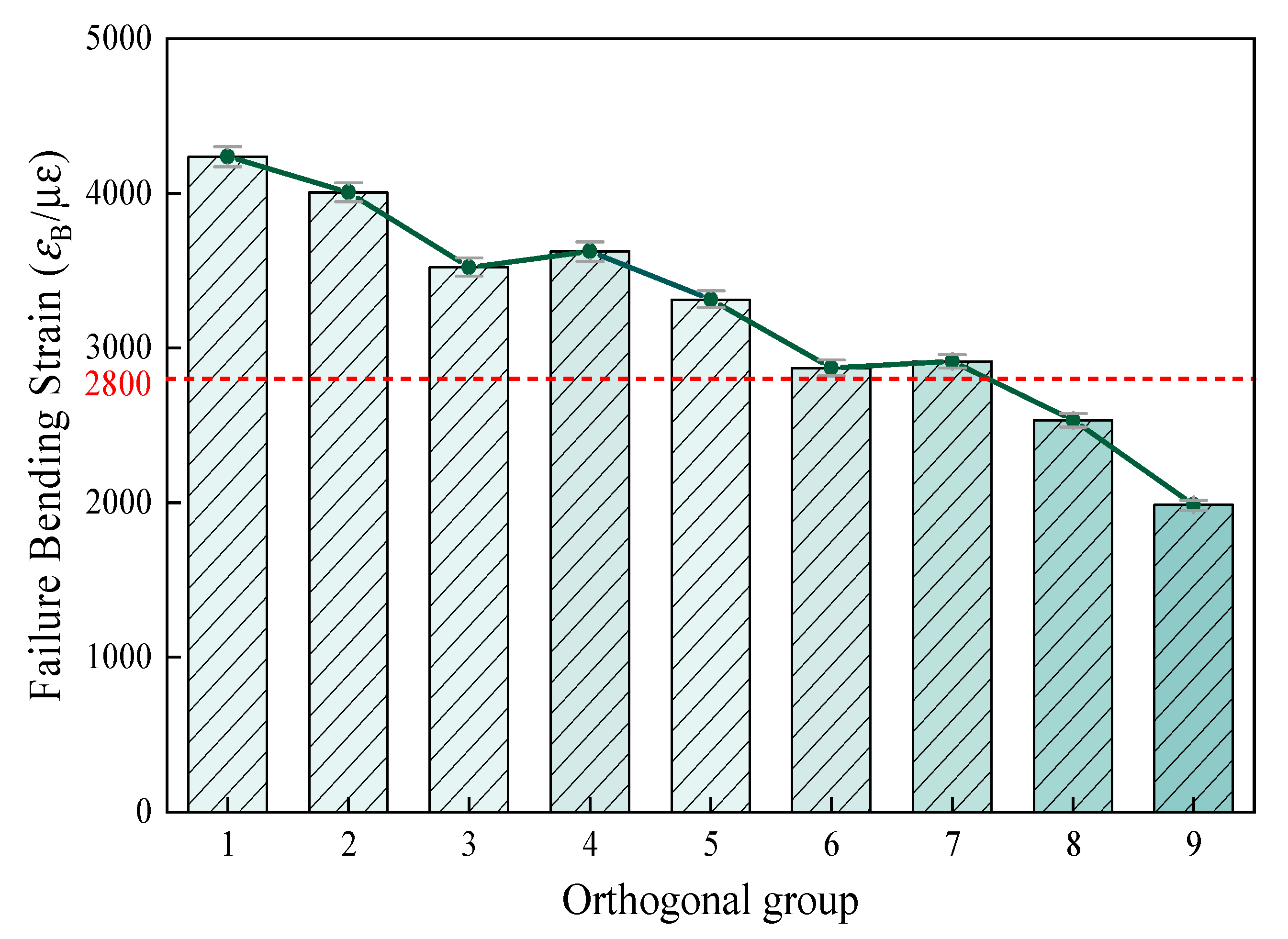

The analysis of the low-temperature cracking resistance is shown in

Figure 9.

The results of the ANOVA indicate that the total amount of filler and the proportion of cement and bentonite replacing the mineral powder had extremely significant effects on the low-temperature cracking resistance of CPAM. As can be seen from

Figure 9, with the increase in filler dosage, the failure bending strain decreased significantly. When the filler amount is the same, a higher the proportion of cement and bentonite replacement can be, and a lower failure bending strain of CPAM can be achieved. This change trend can clearly be observed from the test results of groups 1 to 9. Most groups met the requirement of failure bending strain. When the filler amount reached 6.3%, the failure bending strain of each group significantly decreased, which in group 9 was only 1984 Ꜫ

B/μꜪ, with the most significant decrease. Although the low-temperature failure bending strain of group 6 also decreased, it still met the requirement of ≥2800 Ꜫ

B/μꜪ specified in the standard.

4.4. Determination of the Optimal Ratio

Combining the test results of the single-factor ANOVA, groups 1, 2, and 3 exhibited poor early strength and high-temperature performance, even failing to meet the requirements. Groups 7, 8, and 9 had poor construction performance, which did not conform to the construction workability grade requirements. Therefore, groups 4, 5, and 6 were compared to determine the group with the optimal comprehensive performance, and the comparison results are shown in

Table 13.

From the comparison results in

Table 13, it can be concluded that the CPAM of group 6 has the best strength and water stability. In addition, the construction workability and high-temperature performance of groups 4, 5, and 6 are close. However, the low-temperature performance of group 6 is the worst, but it still meets the application requirements. Comprehensively considering the pavement performance of CPAM in different groups, group 6 performs well in all other aspects except for slightly poor low-temperature performance. Therefore, the CPAM group with the optimal comprehensive performance is group 6: the total amount of filler is 4.3%, the ratio of bentonite to cement is 0.2:1, and 50% of the mineral powder is replaced.

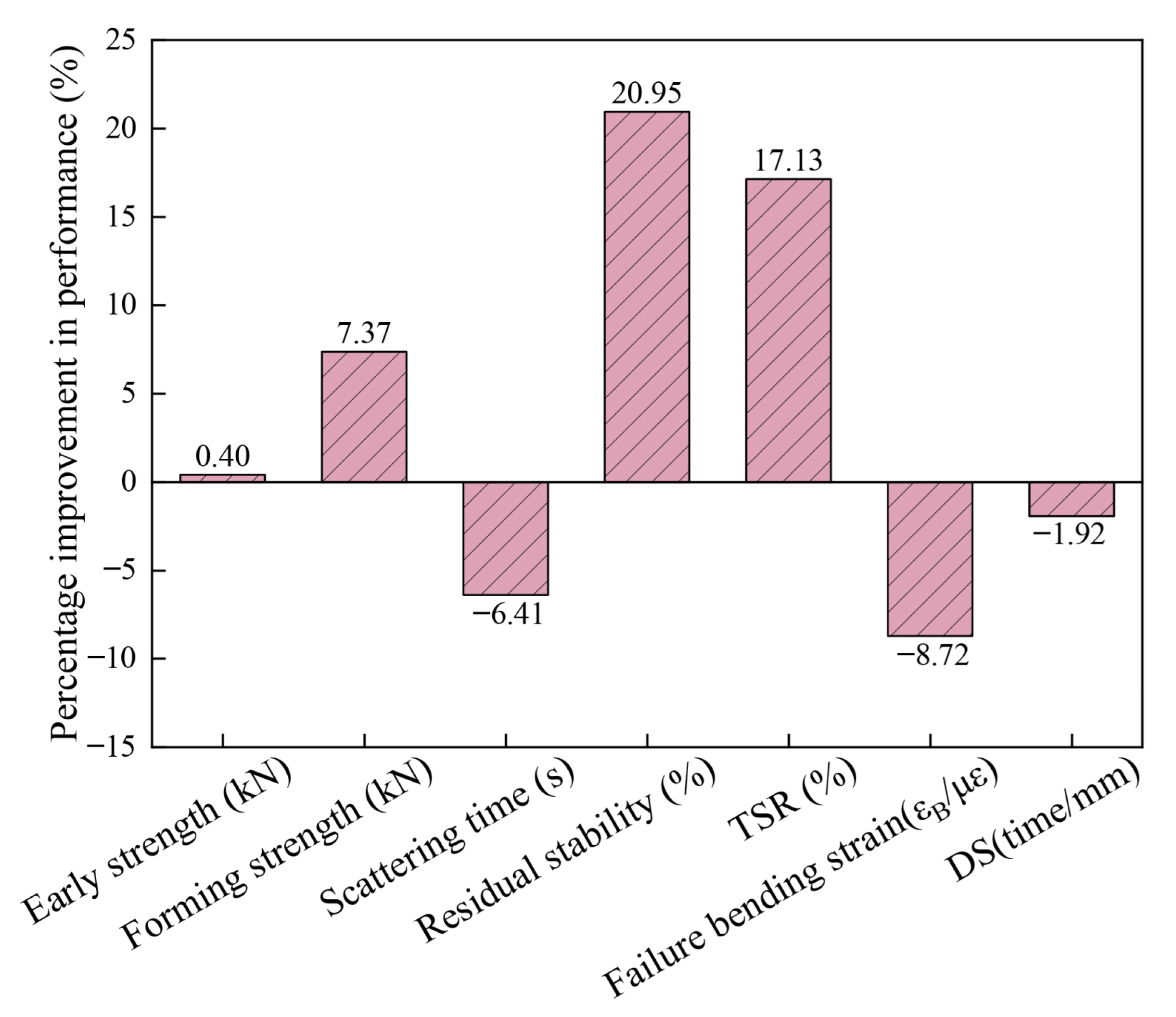

On this basis, the performance of the conventional group and group 6 were compared. The total amount of filler in the conventional group is 4.3%, and the filler is 100% lime powder.

Table 14 shows the performance comparison between group 6 and the conventional group. The percentages of improvement in each performance are shown in

Figure 10.

By contrast, when using the self-developed CPAM with a total filler amount of 4.3%, replacing 50% of the mineral powder with bentonite and cement, and with a ratio of bentonite to cement at 0.2:1, the strength and water stability of the CPAM can significantly improve, showing an increase of 20.95%, 17.15%, and 7.37% in residual stability, TSR, and molding strength. The improvement mechanism is that the hydration of cement and the pozzolanic reaction enhance the structural strength under water immersion conditions, while the water absorption expansion of bentonite effectively seals the fine pores. However, this combination only increased the early strength by 0.4%, mainly due to the softness of the initial asphalt slurry. The strength is mainly provided by the mineral material interlocking, and the improvement effect of the adhesive force of the slurry is not yet significant. On the other hand, although this modification had certain negative impacts on construction workability, low-temperature cracking resistance, and high-temperature performance, the variation ranges were small and all met the specification requirements; so, the negative impacts were within the controllable range.

Considering that the temperature performance of the CPAM in group 6 was not the best, in addition to recommending it as the group with relatively optimal comprehensive performance, we have supplementary suggestions on CPAM types more suitable for specific temperature conditions: group 3 has good water stability, low-temperature cracking resistance, and workability. Although its strength and high-temperature performance are slightly insufficient, it is more suitable for areas with low annual average temperature; Without considering workability, group 9 has excellent high-temperature performance, although its low-temperature cracking resistance is slightly insufficient, it is more suitable for areas with high annual average temperature. The recommended results are shown in

Table 15.

The research ultimately determined the key optimization parameters for the CPAM: when the total filler amount is 4.3%, the comprehensive performance is the best. An excessive or insufficient amount may affect the construction workability as well as the temperature performance. The ratio of bentonite and cement replacing the mineral powder is optimal at 50%, which can significantly improve the water stability, strength, and high-temperature performance. The ratio of bentonite to cement should be controlled at 0.2:1, as an excessive amount of bentonite will damage the low-temperature cracking resistance.

4.5. Analysis of Asphalt Film Morphology and Mechanism

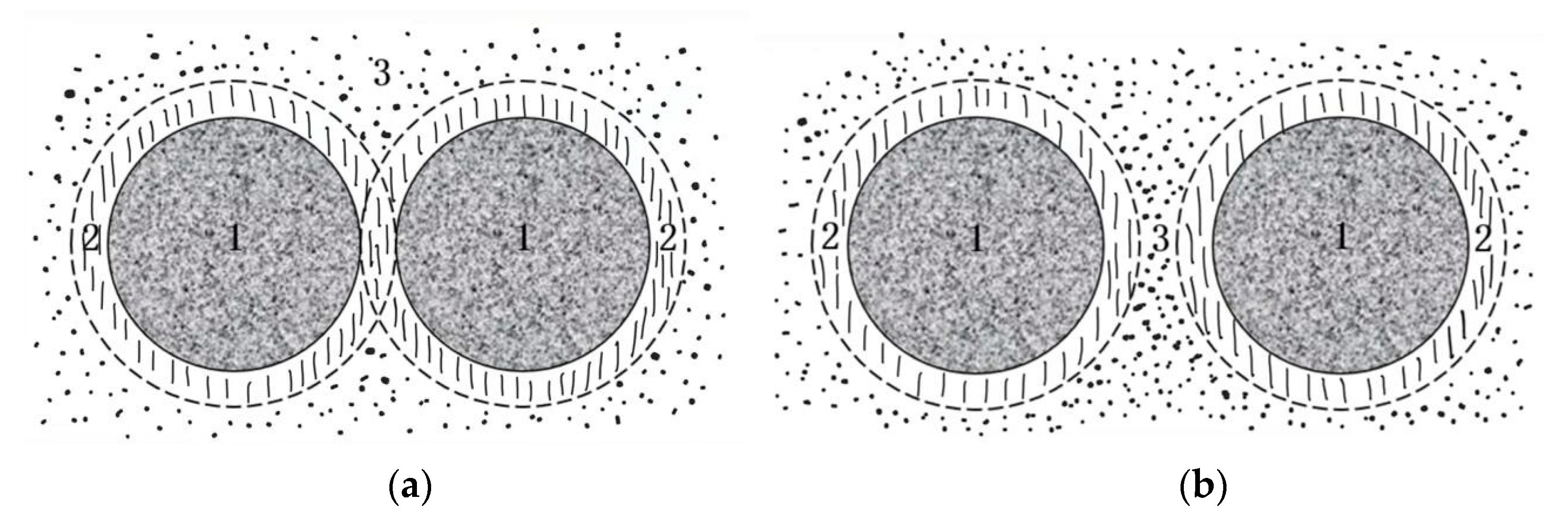

The filler, as the dispersed phase, not only affects the rheological and mechanical properties of the continuous phase asphalt binder but also significantly influences the road performance of asphalt mixtures, such as rutting, fatigue, water erosion, and low-temperature cracking [

21,

26]. The asphalt slurry formed by the filler and asphalt interacts with the mineral surface, and the adhesion of mixture comes from the cohesion of asphalt and the adhesion of asphalt slurry to the mineral. Asphalt molecules form a “structural asphalt” adsorption film on the surface of aggregates, while the asphalt that does not interact with the surface of the aggregates is “free asphalt”. As shown in

Figure 11, the structural asphalt adheres to each other, enhancing the cohesion of the mixture. However, when the asphalt amount is too large, the free asphalt is over-represented. The lubricating effect will cause the aggregate particles to slide, reducing the strength of the mixture. The specific surface area of the filler can reach 80% of the total aggregate surface area, significantly affecting the ratio of structural asphalt to free asphalt [

27,

28,

29], and the active fillers such as cement can further enhance the strength of the asphalt paste through hydration reactions. Therefore, optimizing the types and proportions of fillers can effectively improve the performance of CPAM.

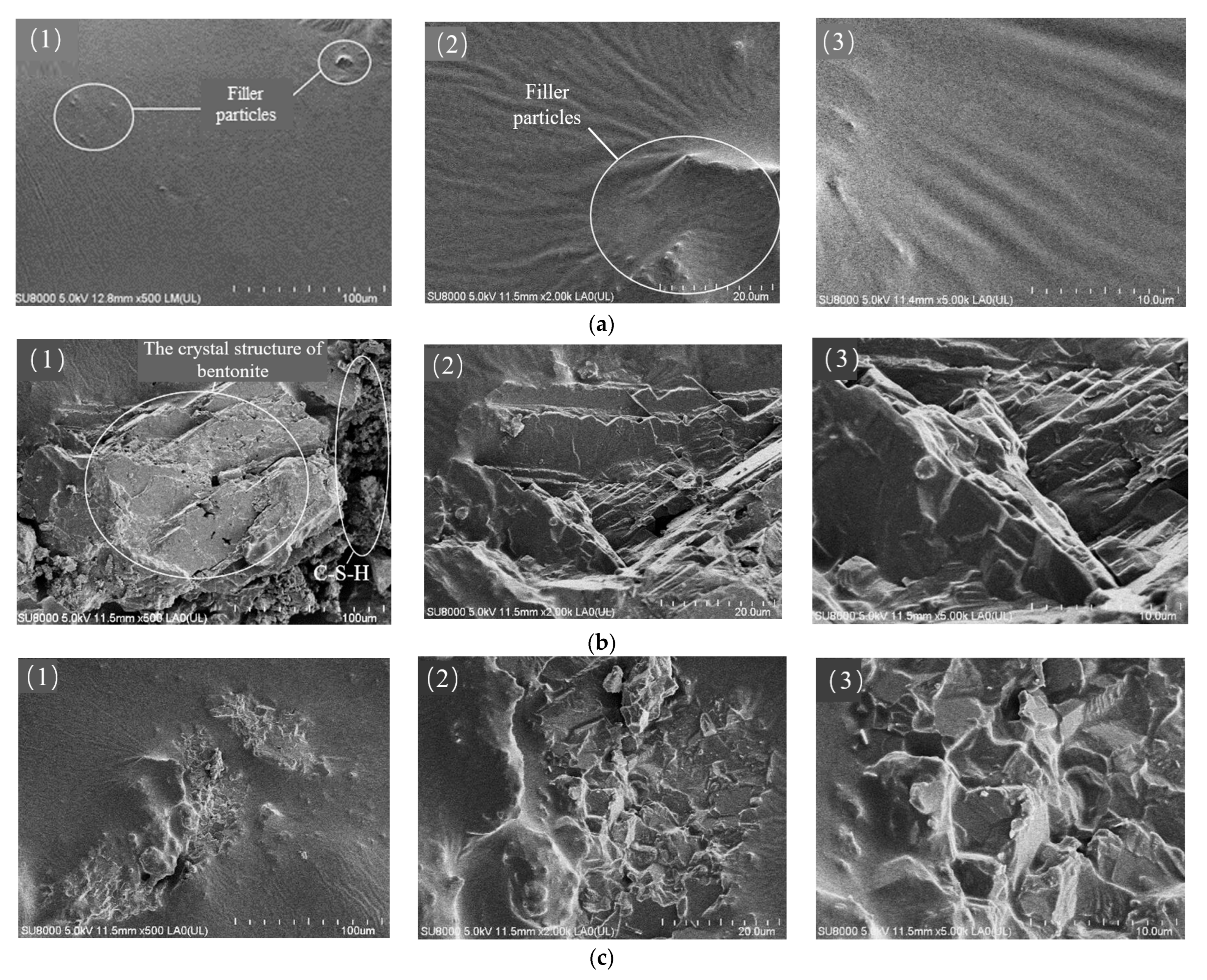

The surface microstructure of the CPAM before and after freeze–thaw was observed using SEM. The dispersion and mortar condition of cement and bentonite in the asphalt were analyzed. The results are shown in

Figure 12, where (1), (2), and (3) were magnified 500×, 2000×, and 5000×, respectively.

As can be seen from

Figure 12(a1), the surface of the mixture before the freeze–thaw cycle was smooth and flat, and the filler particles formed a uniform distribution of asphalt mortar structure. When magnified 2000 times, it can be observed that the filler particles buried inside the asphalt cause wrinkles at the edges of the protruding small particles from

Figure 12(a2).

Observing

Figure 12(b1), the mineral crystal structure of the main body was similar to the lamellar interlayer structure of bentonite, which was presumed to be the product of the expansion of bentonite after absorbing water, and the flocculant on the right side was presumed to be the product of the hydration of cement. From the volume size, it can be judged that the volume of bentonite after water absorption is much larger than that of the cement hydration product. From

Figure 12(b2,b3), it can be seen that the asphalt film on the surface of the CPAM after freeze–thaw had been damaged, the asphalt film had become rough, and some open pores appeared. The reason for this may be that water seeped into the damaged asphalt film and came into contact with cement and bentonite, the volume of bentonite expanded due to water absorption, and cement reacted with water to form hydration products. With localized magnification to 2000 times and 5000 times, the concave and convex structure can be seen more clearly, which is similar to the C-S-H gel structure observed by Belkowitz [

30]. The above conclusion proves that after adding bentonite and cement to the CAPM, the hydration products of the fillers can form a stable crosslinked gel structure between the aggregates, strengthen the adhesion between the mixtures, and reduce the voids, which in turn improves the road performance of the CAPM.