Tribological Properties of Diamond/Diamond-like Carbon (DLC) Composite Coating in a Dry Environment

Abstract

1. Introduction

2. Experimental

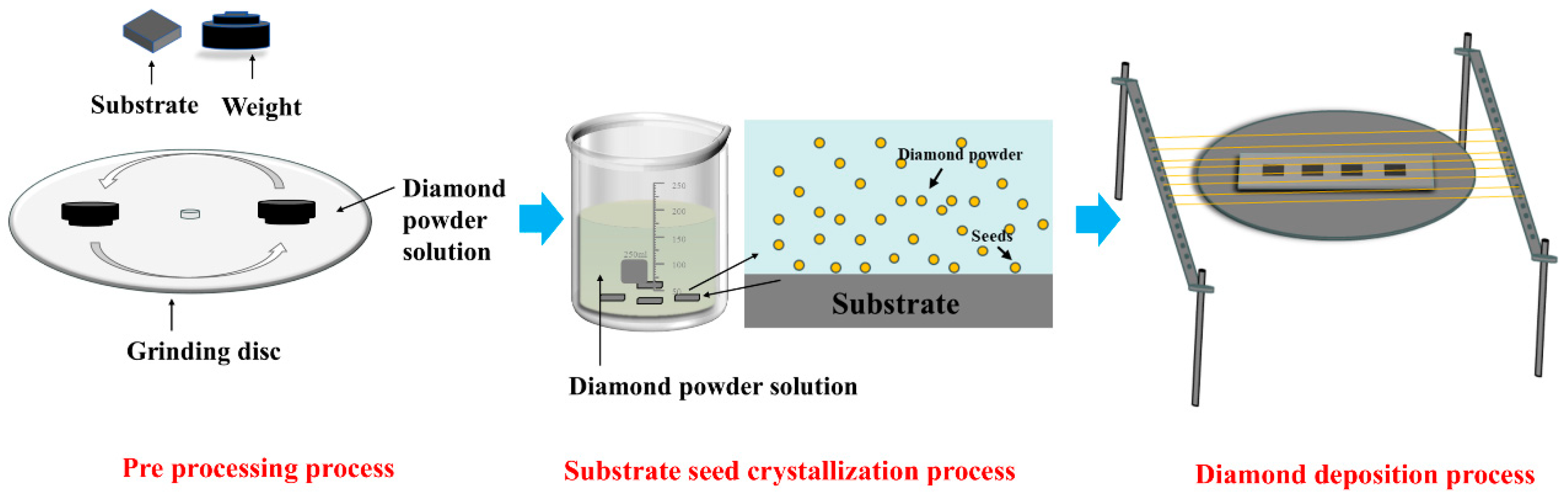

2.1. Preparation of Diamond Films

2.2. Preparation of Diamond/Diamond-like Carbon (DLC) Composite Coating

2.3. Friction and Wear Test

2.4. Characterization

3. Results and Discussion

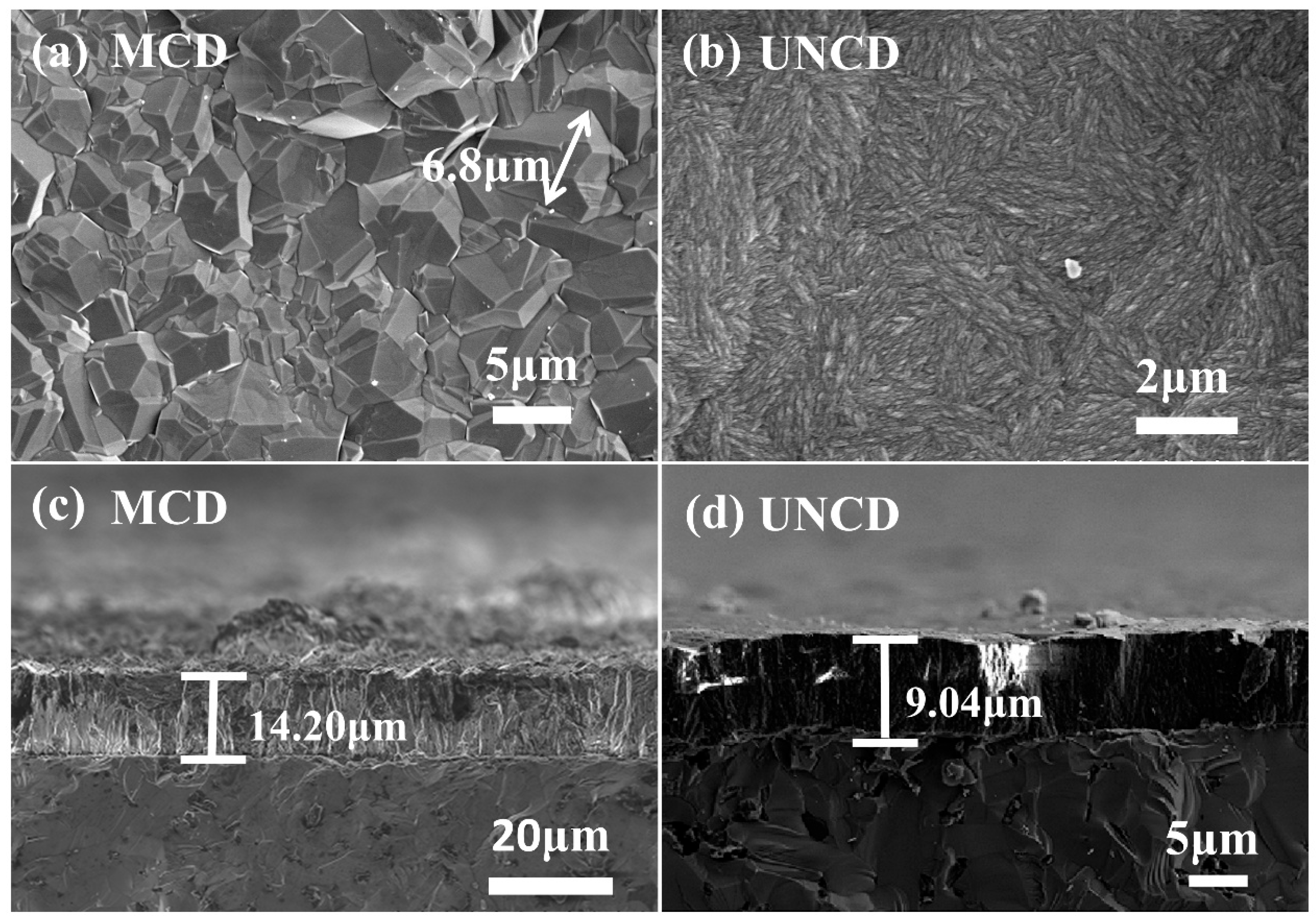

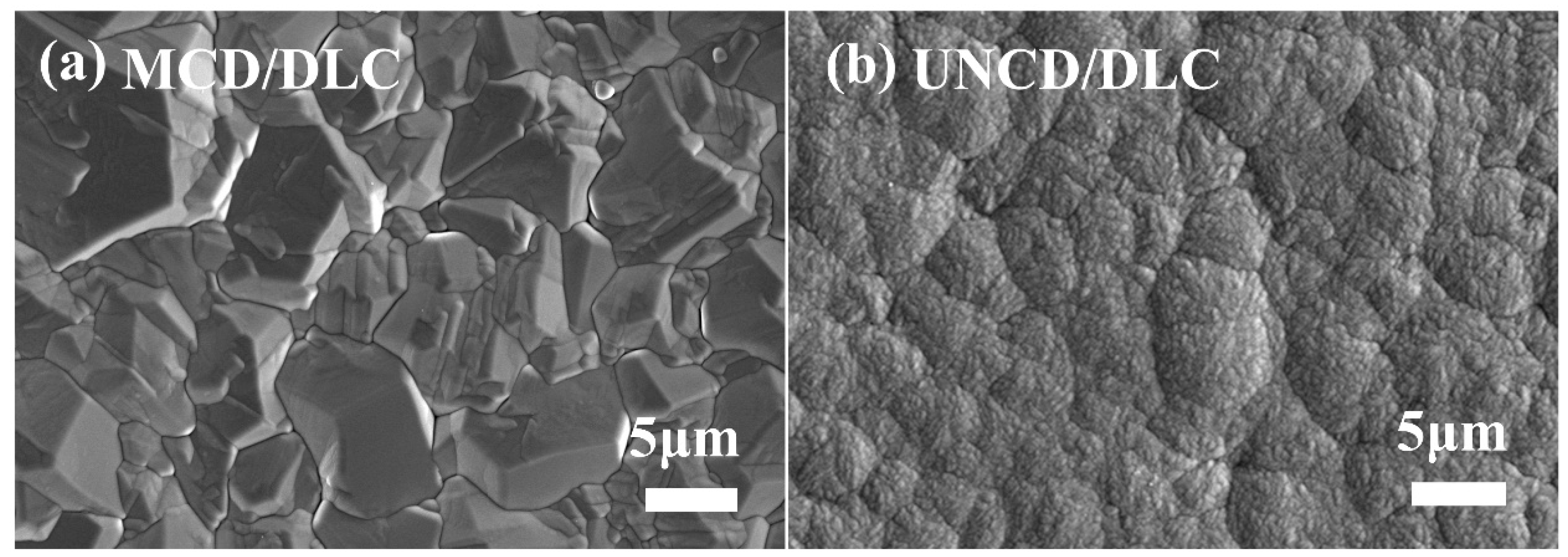

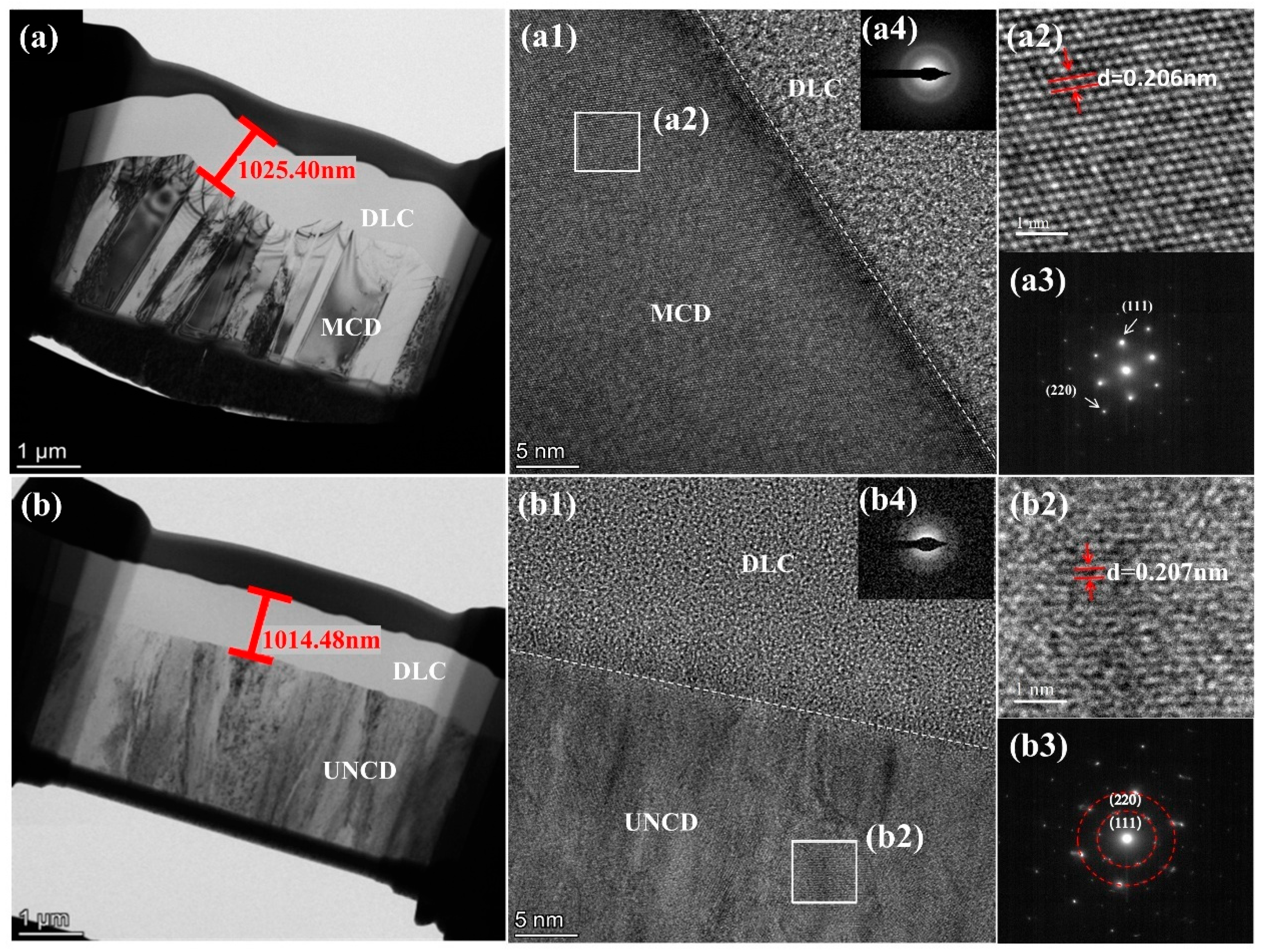

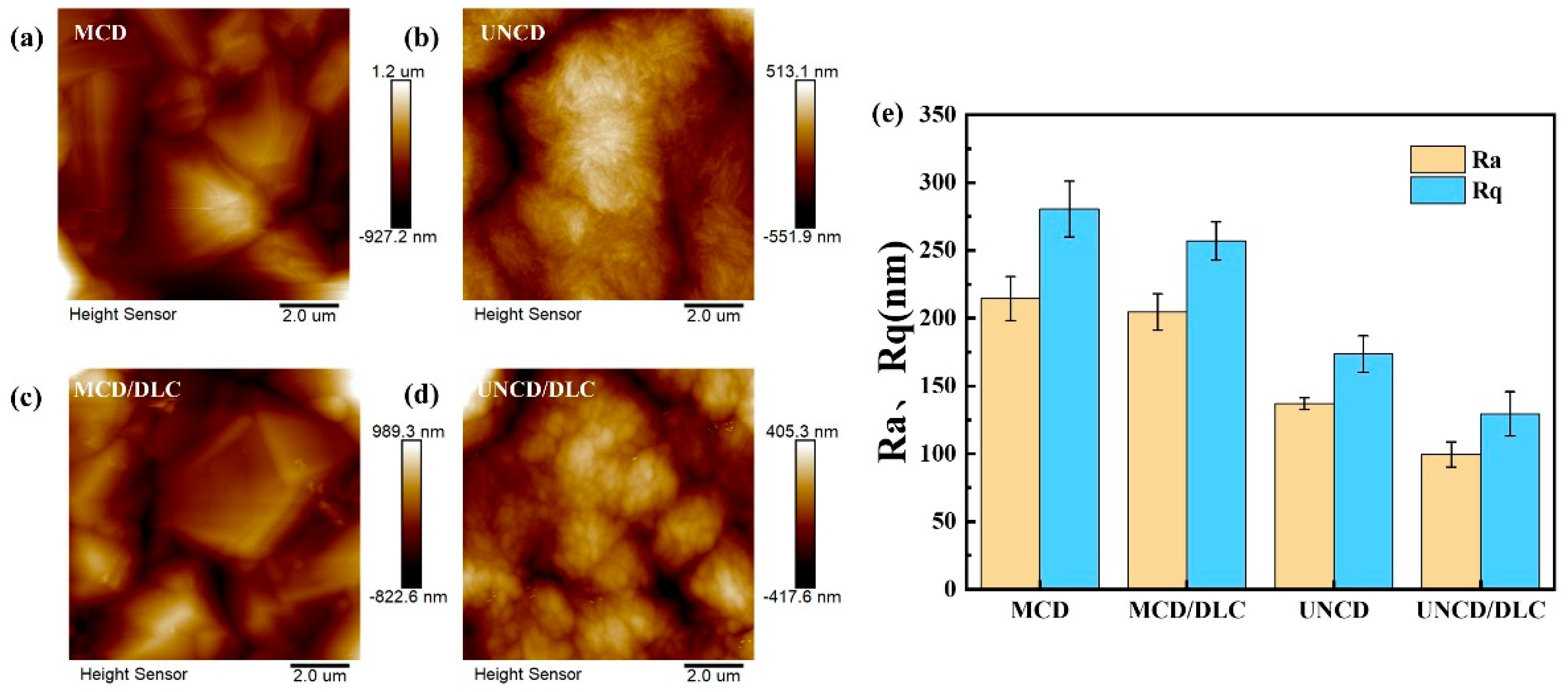

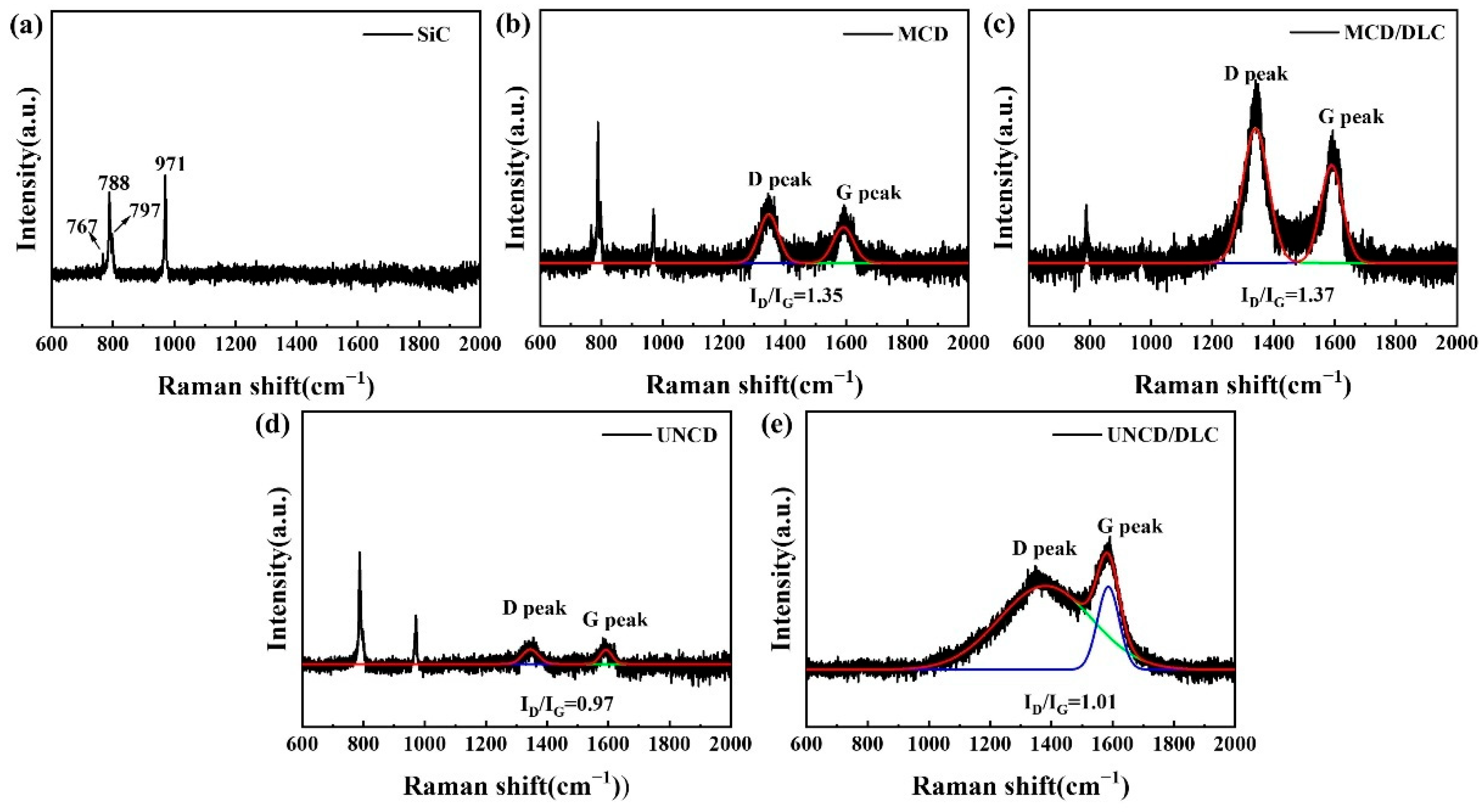

3.1. Surface Morphology and Structure Analysis of Single-Layer Diamond and Diamond/DLC Composite Coatings

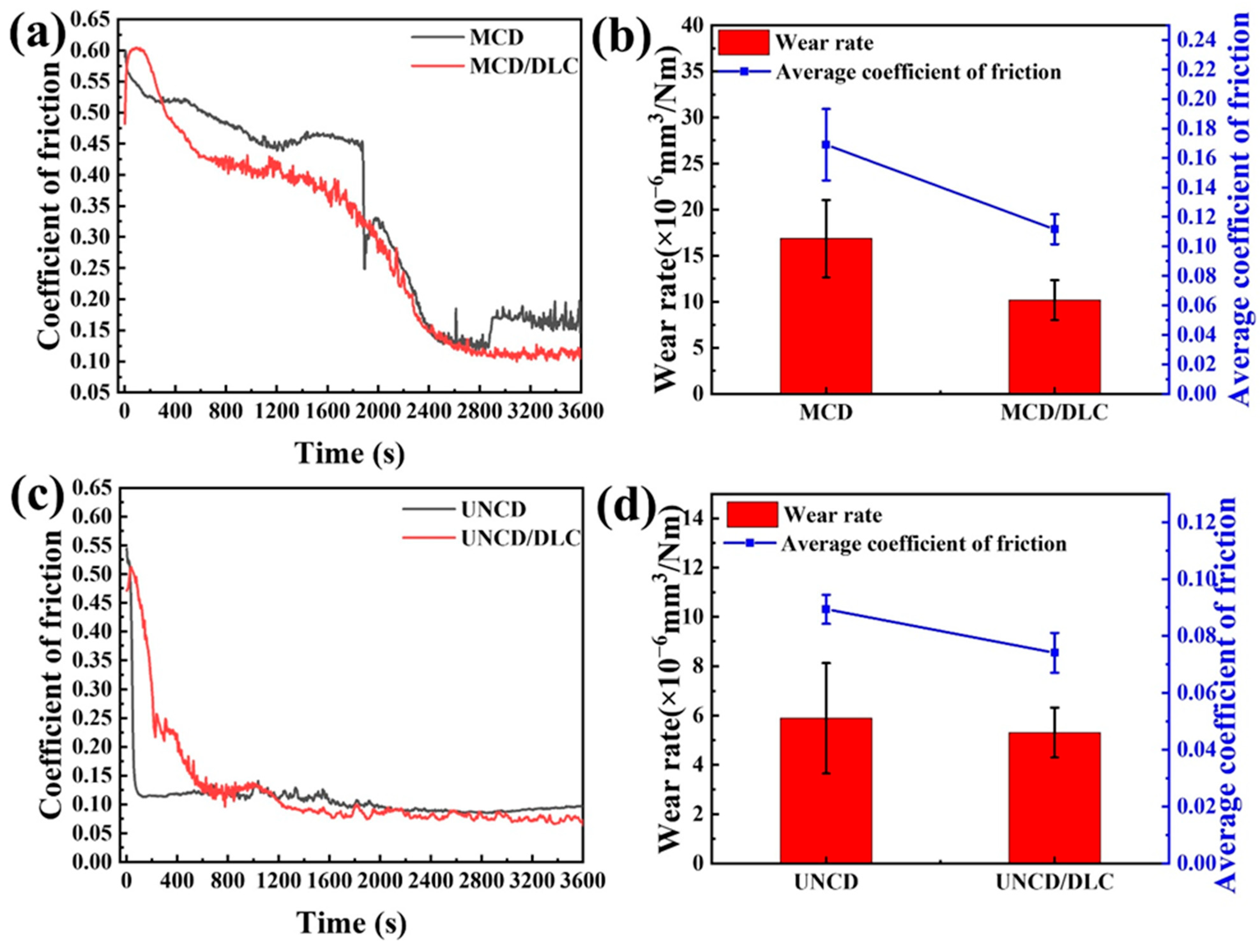

3.2. The Tribological Performance of the As-Prepared Coatings

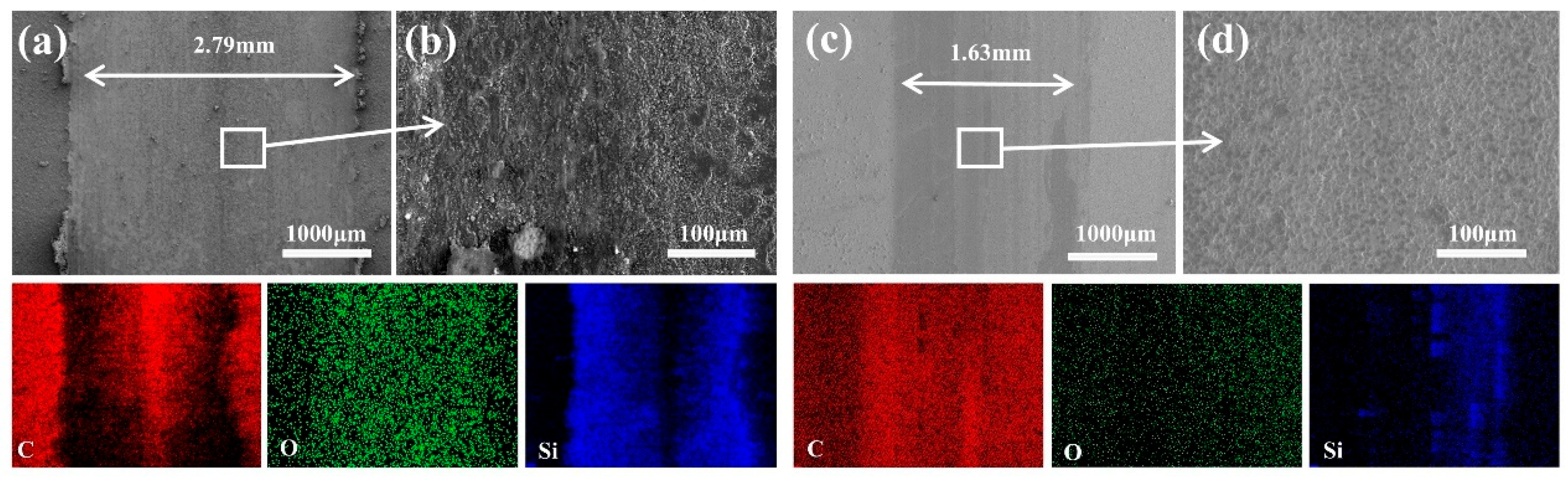

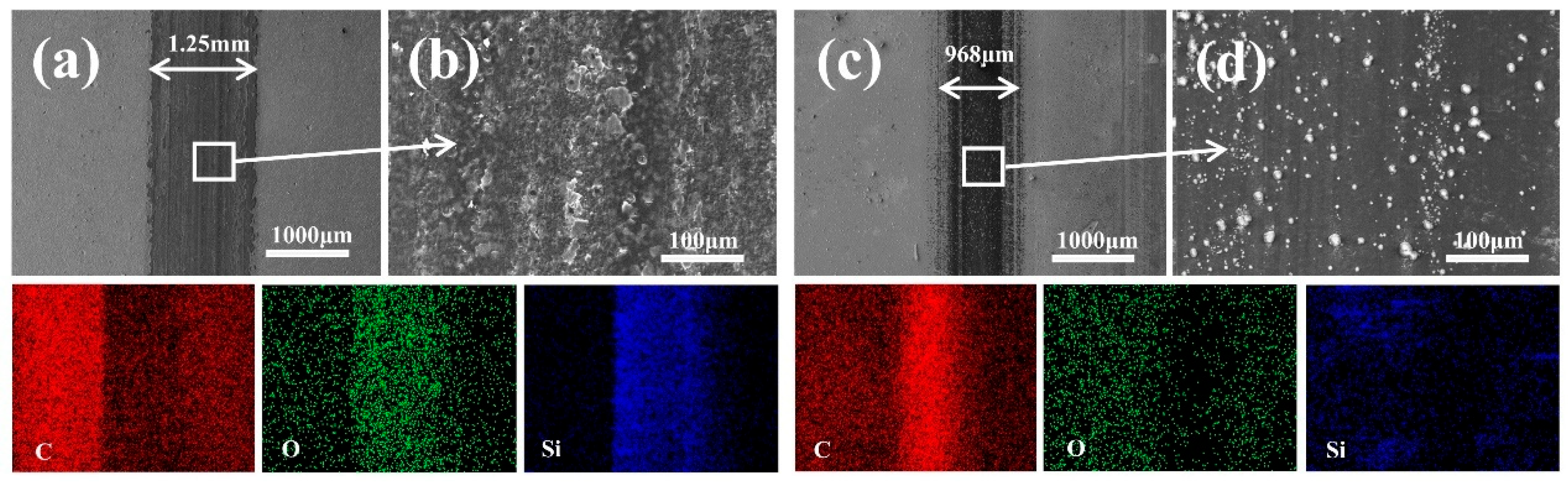

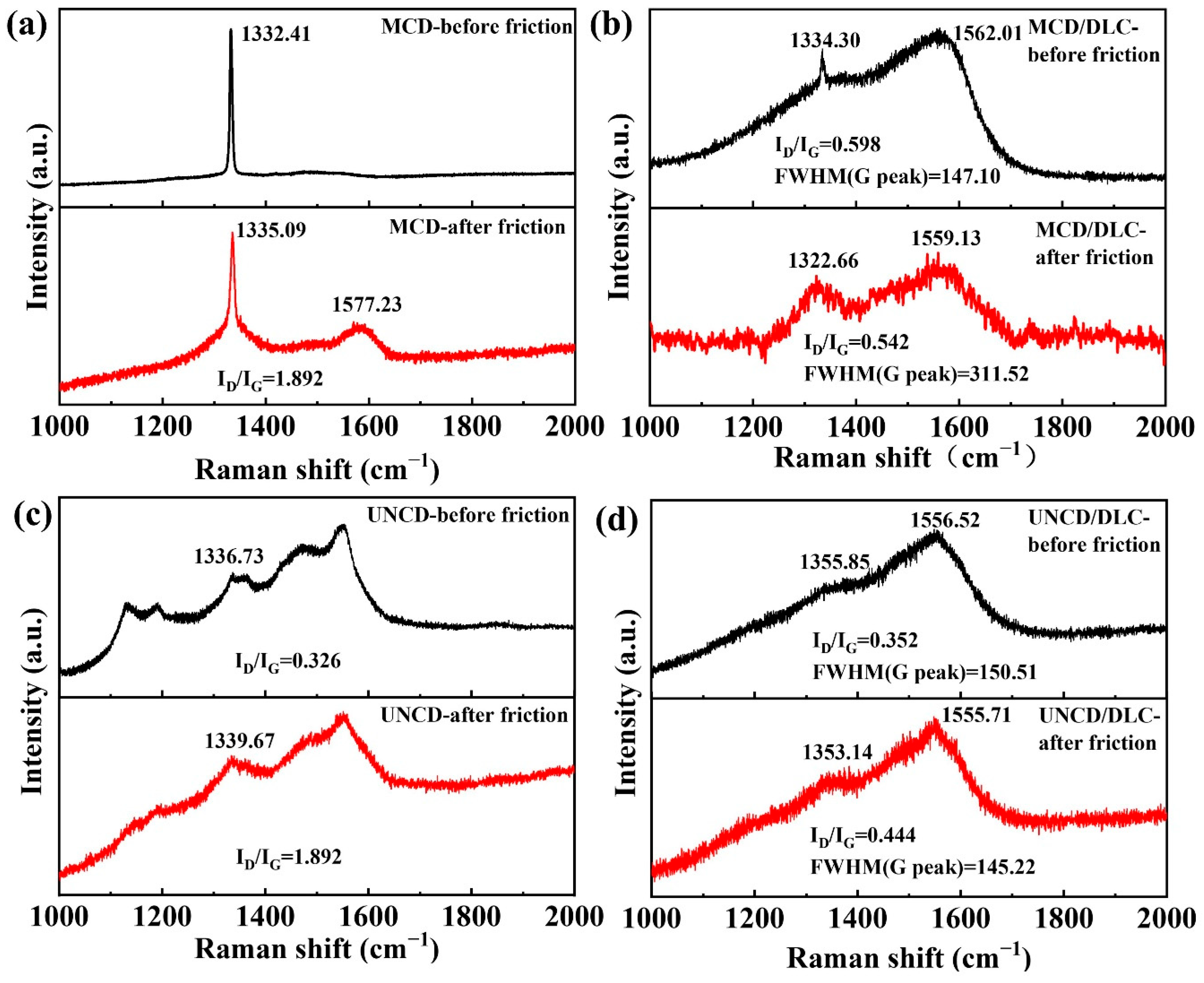

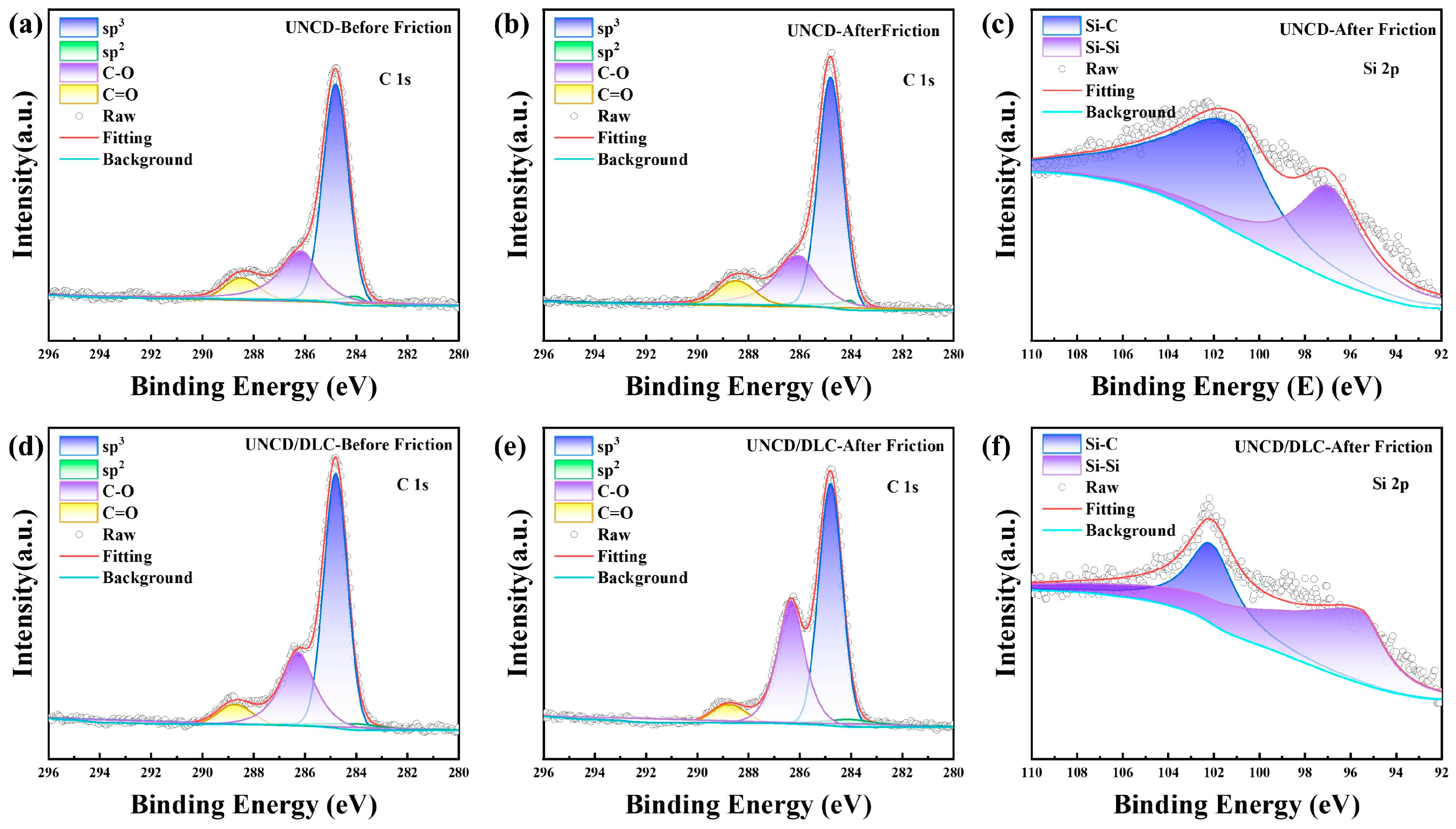

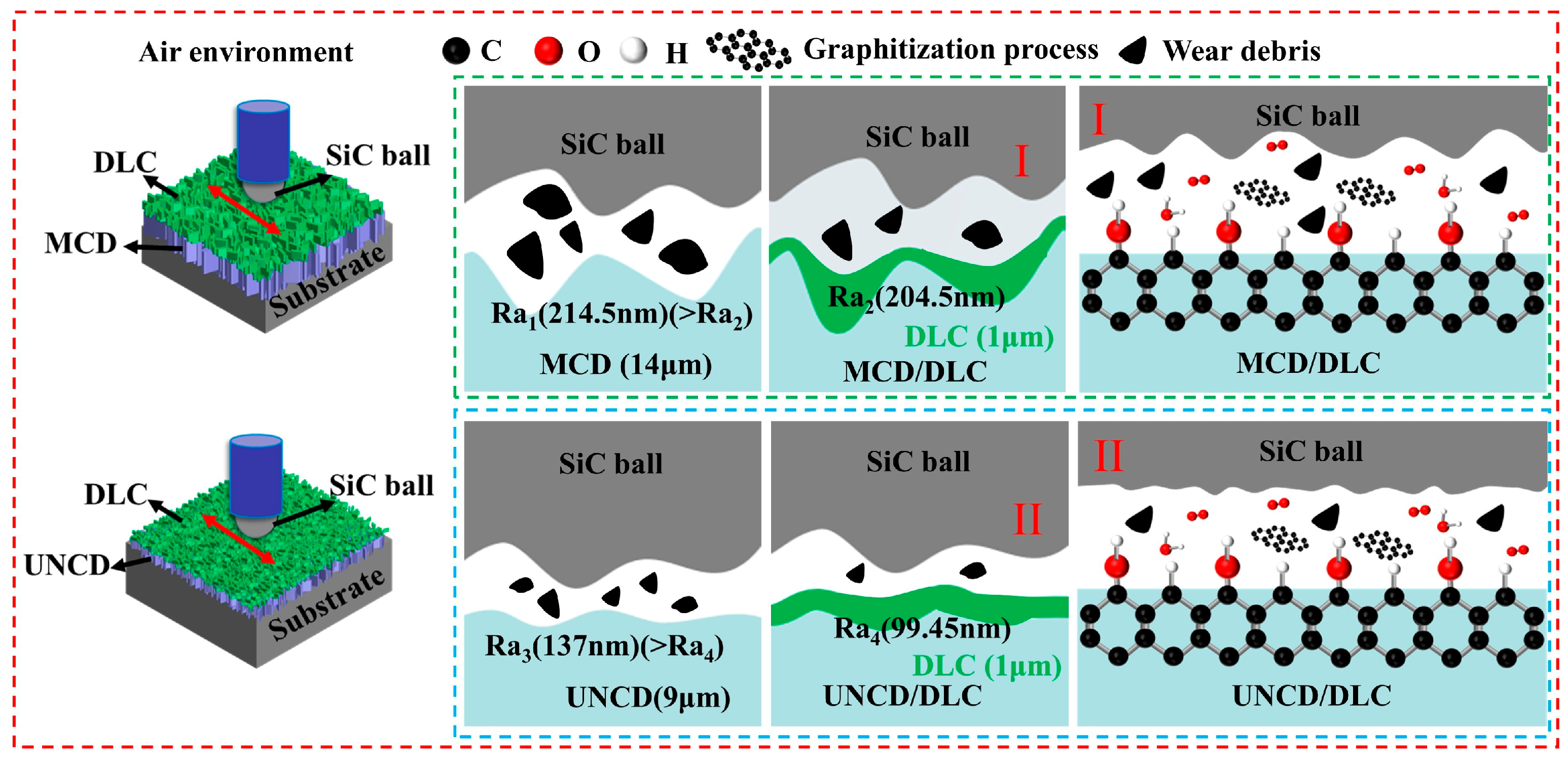

3.3. Friction Mechanism of Diamond Coatings with DLC Design in a Dry Environment

3.4. Discussion

4. Conclusions

- (1)

- DLC deposition effectively reduces the diamond coating surface roughness, with a reduction in magnitude being inversely proportional to the diamond grain size (27.4% Ra decrease for UNCD vs. 4.7% for MCD).

- (2)

- Diamond/DLC composites significantly enhance tribological performance: MCD/DLC: 33.73% lower friction coefficient and 39.55% reduced wear rate. UNCD/DLC: 16.85% lower friction coefficient and 9.69% reduced wear rate.

- (3)

- The introduction of a DLC coating can reduce wear using smooth interface morphology, and the sp2 phase transition caused by friction promotes the interface graphitization to accelerate the lubrication effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Wang, J.; Zhang, G.; Huo, Z.; Huang, Z.; Wu, L. A review of diamond synthesis, modification technology, and cutting tool application in ultra-precision machining. Mater. Des. 2023, 237, 112577. [Google Scholar] [CrossRef]

- Ding, M.; Liu, Y.; Lu, X.; Tang, W. Effect of laser ablation on microwave attenuation properties of diamond films. Materials 2019, 12, 3700. [Google Scholar] [CrossRef]

- Liu, D.; Zhao, J.; Lei, Y.; Wang, X.; Fu, W.; Song, X.; Long, W. Micropatterning of synthetic diamond by metal contact etching with Ti powder. Diam. Relat. Mater. 2022, 129, 109299. [Google Scholar] [CrossRef]

- Wang, H.; Song, X.; Wang, X.; Sun, F. Fabrication, tribological properties and cutting performances of high-quality multilayer graded MCD/NCD/UNCD coated PCB end mills. Diam. Relat. Mater. 2021, 118, 108505. [Google Scholar] [CrossRef]

- Song, X.; Lu, M.; Wang, H.; Wang, H.; Sun, F. Fracture mechanics of microcrystalline/nanocrystalline composited multilayer chemical vapor deposition self-standing diamond films. Ceram. Int. 2022, 48, 21868–21878. [Google Scholar] [CrossRef]

- Wang, H.; Yang, J.; Sun, F. Cutting performances of MCD, SMCD, NCD and MCD/NCD coated tools in high-speed milling of hot bending graphite molds. J. Mater. Process. Technol. 2020, 276, 116401. [Google Scholar] [CrossRef]

- Lee, T.; Kim, D.; Cho, S.; Kim, M. Advancements in Surface Coatings and Inspection Technologies for Extending the Service Life of Concrete Structures in Marine Environments: A Critical Review. Buildings 2025, 15, 304. [Google Scholar] [CrossRef]

- Kim, S.; Hong, H.; Park, J.K.; Park, S.; Choi, S.; Kim, M. Effect of exposure conditions on the interfacial bond properties of SS400 plate coated with various epoxy resins. Coatings 2020, 10, 1159. [Google Scholar] [CrossRef]

- Kim, S.; Hong, H.; Han, T.H.; Park, S.; Choi, S.; Kim, M. Early-age tensile bond characteristics of epoxy coatings for underwater applications. Coatings 2019, 9, 757. [Google Scholar] [CrossRef]

- Won, B.; Kim, M.O.; Park, S.; Yi, J. Effects of water exposure on the interfacial bond between an epoxy resin coating and a concrete substrate. Materials 2019, 12, 3715. [Google Scholar] [CrossRef]

- Giaremis, S.; Righi, M.C. Tuning the adsorption of H2O, H2 and O2 molecules on diamond surfaces by B-doping. Surf. Interfaces 2024, 46, 104105. [Google Scholar] [CrossRef]

- Krishnan, A.; Kamaraj, M.; Nayak, P.K.; Ramaprabhu, S. Surface functionalized 2D MoO3-hBN heterostructure as friction modifiers in boundary lubrication regime. Surf. Interfaces 2024, 51, 104527. [Google Scholar] [CrossRef]

- Xiang, D.; Zhang, Z.; Chen, Y.; Hu, Y.; Lei, X. Study of tribological properties of textured boron-doped diamond film under water lubrication. Surf. Interfaces 2021, 23, 100983. [Google Scholar] [CrossRef]

- Wu, W.; Murashima, M.; Umehara, N.; Tokoroyama, T.; Zhang, R. Low friction of nitrogen-doped diamond-like carbon coating due to acidic liquid film and nitrogen-doped graphite oxide generated by dielectric barrier discharge in ambient air. Surf. Interfaces 2025, 56, 105591. [Google Scholar] [CrossRef]

- Xu, J.; Dai, J.; Ren, F.; Wang, Y.; Wang, P.; Xu, S.; Wu, S.; Lin, J.; Yang, Y.; Guo, D.; et al. Ultrahigh radiation resistance of nanocrystalline diamond films for solid lubrication in harsh radiative environments. Carbon 2021, 182, 525–536. [Google Scholar] [CrossRef]

- Ramasubramanian, K.; Nikhil, C.; Rao, S.; Mandal, S.; Ganguly, R.; Rao, M.; Arunachalam, N. Tribological behavior of diamond coated reaction-bonded silicon carbide under dry and seawater environment. Surf. Coat. Technol. 2024, 476, 130204. [Google Scholar] [CrossRef]

- Miki, H.; Tsutsui, A.; Takeno, T.; Takagi, T. Friction properties of partially polished CVD diamond films at different sliding speeds. Diam. Relat. Mater. 2012, 24, 167–170. [Google Scholar] [CrossRef]

- Radhika, R.; Kumar, N.; Dash, S.; Tyagi, A.; Lin, I. Anomalous behavior of load-dependent friction on ultra-nanocrystalline diamond film. Adv. Eng. Mater. 2014, 16, 1098–1104. [Google Scholar] [CrossRef]

- Wu, F.; Liu, N.; Ma, Y.; Zhang, X.; Han, Y. Research on the influence of diamond coating microtexture on graphitization law and friction coefficient. Diam. Relat. Mater. 2022, 127, 109153. [Google Scholar] [CrossRef]

- Kumar, N.; Panda, K.; Dash, S.; Popov, C.; Reithmaier, J.; Panigrahi, B.; Tyagi, A.; Raj, B. Tribological properties of nanocrystalline diamond films deposited by hot filament chemical vapor deposition. AIP Adv. 2012, 2, 032164. [Google Scholar] [CrossRef]

- Rani, R.; Sankaran, K.J.; Panda, K.; Kumar, N.; Ganesan, K.; Chakravarty, S.; Lin, I. Tribofilm formation in ultrananocrystalline diamond film. Diam. Relat. Mater. 2017, 78, 12–23. [Google Scholar] [CrossRef]

- Erdemir, A.; Martin, J.M. Superior wear resistance of diamond and DLC coatings. Curr. Opin. Solid State Mater. Sci. 2018, 22, 243–254. [Google Scholar] [CrossRef]

- Konicek, A.R.; Grierson, D.S.; Gilbert, P.; Sawyer, W.; Sumant, A.; Carpick, R. Origin of ultralow friction and wear in ultrananocrystalline diamond. Phys. Rev. Lett. 2008, 100, 235502. [Google Scholar] [CrossRef]

- Kumar, N.; Ramadoss, R.; Kozakov, A.T.; Sankaran, K.; Dash, S.; Tyagi, A.; Tai, N.; Lin, I. Humidity-dependent friction mechanism in an ultrananocrystalline diamond film. J. Phys. D Appl. Phys. 2013, 46, 275501. [Google Scholar] [CrossRef]

- Ohtake, N.; Hiratsuka, M.; Kanda, K.; Akasaka, H.; Tsujioka, M.; Hirakuri, K.; Hirata, A.; Ohana, T.; Inaba, H.; Kano, M.; et al. Properties and classification of diamond-like carbon films. Materials 2021, 14, 315. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Ning, Z. High-temperature tribological properties of diamond-like carbon films: A review. Rev. Adv. Mater. Sci. 2021, 60, 276–292. [Google Scholar] [CrossRef]

- Zhang, R.; Shen, M.; He, Z. The unusual tribological behavior of diamond-like carbon films under high vacuum. Surf. Interface Anal. 2020, 52, 339–347. [Google Scholar] [CrossRef]

- Shi, B.; Wu, Y.; Liu, Y.; Wang, L.; Gao, J.; Hei, H.; Zheng, K.; Yu, S. A review on diamond-like carbon-based films for space tribology. Mater. Sci. Technol. 2022, 38, 1151–1167. [Google Scholar] [CrossRef]

- Wang, D.; Gong, Z.; Jiang, B.; Yu, G.; Liu, G.; Wang, N. Structure original of temperature depended superlow friction behavior of diamond-like carbon. Diam. Relat. Mater. 2020, 107, 107880. [Google Scholar] [CrossRef]

- Cui, Y.; Ma, J.; Wang, T.; Yan, B.; Qi, H.; Cai, Y.; Zhang, D.; Tian, Y.; Jaffery, S. Synergistic friction-reducing and anti-wear behaviors of DLC on NCD films via in situ synthesis by femtosecond laser ablation. Surf. Coat. Technol. 2021, 409, 126947. [Google Scholar] [CrossRef]

- Rani, R.; Panda, K.; Kumar, N.; Sankaran, K.; Pandian, R.; Ficek, M.; Bogdanowicz, R.; Haenen, K.; Lin, I. Triboenvironment dependent chemical modification of sliding interfaces in ultrananocrystalline diamond nanowall film: Correlation with friction and wear. J. Phys. Chem. C 2018, 122, 945–956. [Google Scholar] [CrossRef]

- Kuzmany, H.; Pfeiffer, R.; Salk, N.; Gunther, B. The mystery of the 1140 cm−1 Raman line in nanocrystalline diamond films. Carbon 2004, 42, 911–917. [Google Scholar] [CrossRef]

- Chen, C.; Tang, B.; Xu, H.; Pan, J.; Jiang, M.; Li, X.; Hu, X. Low-defect nanodiamonds and graphene nanoribbons enhanced electron field emission properties in ultrananocrystalline diamond films. ACS Appl. Electron. Mater. 2021, 3, 1648–1655. [Google Scholar] [CrossRef]

- Kunuku, S.; Chen, Y.C.; Chen, C.H.; Kandasami, A.; Chang, W.; Niu, H.; Leou, K.; Lin, I. Investigation of the spectral characteristics of silicon-vacancy centers in ultrananocrystalline diamond nanostructures and single crystalline diamond. J. Appl. Phys. 2020, 127, 035302. [Google Scholar] [CrossRef]

- Korepanov, V.I.; Hamaguchi, H.; Osawa, E.; Ermolenkov, V.; Lednev, I.; Etzold, B.; Levinson, O.; Zousman, B.; Epperla, C.; Chang, H. Carbon structure in nanodiamonds elucidated from Raman spectroscopy. Carbon 2017, 121, 322–329. [Google Scholar] [CrossRef]

- Ekimov, E.A.; Lyapin, S.G.; Grigoriev, Y.V.; Zibrov, I.P.; Kondrina, K.M. Size-controllable synthesis of ultrasmall diamonds from halogenated adamantanes at high static pressure. Carbon 2019, 150, 436–438. [Google Scholar] [CrossRef]

- Kudryavtsev, O.S.; Bagramov, R.H.; Pasternak, D.G.; Satanin, A.M.; Lebedev, O.I.; Filonenko, V.P.; Vlasov, I.I. Raman fingerprints of ultrasmall nanodiamonds produced from adamantane. Diam. Relat. Mater. 2023, 133, 109770. [Google Scholar] [CrossRef]

- Dolmatov, V.Y.; Lapchuk, N.M.; Lapchuk, T.M.; Nguyen, B.T.; Myllymaki, V.; Vehanen, A.; Yakovlev, R.Y. A study of defects and impurities in doped detonation nanodiamonds by EPR, Raman scattering, and XRD methods. J. Superhard Mater. 2016, 38, 219–229. [Google Scholar] [CrossRef]

- Takabayashi, S.; Ješko, R.; Shinohara, M.; Hayashi, H.; Sugimoto, R.; Ogawa, S.; Takakuwa, Y. Chemical structural analysis of diamond-like carbon films: II. Raman analysis. Surf. Sci. 2018, 668, 36–41. [Google Scholar] [CrossRef]

- Riley, P.R.; Joshi, P.; Narayan, J.; Narayan, R. Enhanced nucleation and large-scale growth of CVD diamond via surface-modification of silicon-incorporated diamond-like carbon thin films. Diam. Relat. Mater. 2021, 120, 108630. [Google Scholar] [CrossRef]

- Panich, A.M.; Shames, A.I.; Mogilyansky, D.; Goren, S.D.; Dolmatov, V.Y. Detonation nanodiamonds fabricated from tetryl: Synthesis, NMR, EPR and XRD study. Diam. Relat. Mater. 2020, 108, 107918. [Google Scholar] [CrossRef]

- Pandey, M.; D’cunha, R.; Tyagi, A.K. Defects in CVD diamond: Raman and XRD studies. J. Alloys Compd. 2002, 333, 260–265. [Google Scholar] [CrossRef]

- Liu, Z.; Zhuang, Z.; Chen, X.; Lin, Q.; Shen, B.; Chen, S. Corrosion resistance of diamond films with different grain sizes. Diam. Relat. Mater. 2024, 146, 111162. [Google Scholar] [CrossRef]

- Hao, J.; Zhang, Y.; Zhu, X.; Li, N.; Dai, J.; Wang, X.; Kim, M.J.; Zhang, H. Synergetic effect of diamond particle size on thermal expansion of Cu-B/diamond composite. Ceram. Int. 2024, 50, 53015–53024. [Google Scholar] [CrossRef]

- Mohammadinia, E.; Elahi, S.M.; Shahidi, S. Structural and optical properties of Ni-embedded hydrogenated diamond-like carbon (Ni-DLC) prepared by co-deposition of RF-sputtering and RF-PECVD method. Mater. Sci. Semicond. Process. 2018, 74, 7–12. [Google Scholar] [CrossRef]

- Bouabibsa, I.; Lamri, S.; Sanchette, F. Structure, mechanical and tribological properties of Me-doped diamond-like carbon (DLC) (Me = Al, Ti, or Nb) hydrogenated amorphous carbon coatings. Coatings 2018, 8, 370. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Sun, F. Tribological behavior and cutting performance of monolayer, bilayer and multilayer diamond coated milling tools in machining of zirconia ceramics. Surf. Coat. Technol. 2018, 353, 49–57. [Google Scholar] [CrossRef]

- Liang, H.; Yang, X.; Yue, C.; Zhao, G.; Zhang, J.; Wang, Y. A comparative friction and wear study of diamond and diamond-like carbon films against Cu. Tribol. Int. 2024, 193, 109344. [Google Scholar] [CrossRef]

- Radhika, R.; Kumar, N.; Dash, S.; Ravindran, T.R.; Arivuolia, D.; Tyagi, A.K. Friction mechanism in diamond-like carbon film sliding against various counterbodies. Mater. Technol. 2014, 29, 366–371. [Google Scholar] [CrossRef]

- Chowdhury, S.; Laugier, M.T.; Henry, J. XRD stress analysis of CVD diamond coatings on SiC substrates. Int. J. Refract. Met. Hard Mater. 2007, 25, 39–45. [Google Scholar] [CrossRef]

- Nandihalli, N. Microwave-driven synthesis and modification of nanocarbons and hybrids in liquid and solid phases. J. Energy Storage 2025, 111, 115315. [Google Scholar] [CrossRef]

- Sarno, M.; Senatore, A.; Scarpa, D.; Cirillo, C. “Green” synthesis of nanocarbons for reduced friction and wear. Lubricants 2020, 8, 13. [Google Scholar] [CrossRef]

- Zhang, H.; Song, H.; Pang, M.; Yang, G.; Ji, F.; Jiang, N.; Nishimura, K. Tribological performance of microcrystalline diamond (MCD) and nanocrystalline diamond (NCD) coating in dry and seawater environment. Crystals 2022, 12, 1345. [Google Scholar] [CrossRef]

- Wolfrum, A.K.; Quitzke, C.; Matthey, B.; Herrmann, M.; Michaelis, A. Wear behavior of diamond-silicon nitride composites sintered with FAST/SPS. Wear 2018, 396, 172–181. [Google Scholar] [CrossRef]

- Hagarová, M.; Baranová, G.; Heželová, M.; Truchly, M.; Vojtko, M.; Petrus, O.; Csik, D. High-Temperature Mechanical and Tribological Performance of W-DLC Coating with Cr interlayer on X40CrMoV5-1 Hot Work Tool Steel. Coatings 2024, 14, 971. [Google Scholar] [CrossRef]

- Xiang, D.; Su, Z.; Li, Y.; Zhang, Z. The effect of laser texture on adhesion and tribological properties of boron-doped diamond film on WC-Co cemented carbide. Diam. Relat. Mater. 2022, 130, 109469. [Google Scholar] [CrossRef]

| Parameter | MCD | UNCD |

|---|---|---|

| CH4/H2 (Gas flow ratio)/% | 3 | 3 |

| N2/H2 (Gas flow ratio)/% | 0 | 5 |

| Power/kW | 4.4 | 3.6 |

| Barometric pressure/kPa | 2.3 | 2.0 |

| Height of wire from base/mm | 8 | 10 |

| Deposition time/h | 12 | 24 |

| Sample | Percentage of Individual Peaks/% (Before Friction) | Percentage of Individual Peaks/% (After Friction) | ||||

|---|---|---|---|---|---|---|

| sp2 | sp3 | C-Ox | sp2 | sp3 | C-Ox | |

| MCD | 8.64 | 62.98 | 28.37 | 8.27 | 62.96 | 28.77 |

| MCD/DLC | 26.42 | 50.01 | 23.58 | 30.69 | 52.27 | 17.05 |

| UNCD | 2.92 | 62.55 | 34.53 | 2.84 | 61.65 | 35.51 |

| UNCD/DLC | 4.30 | 61.29 | 34.41 | 5.23 | 54.33 | 40.45 |

| Sample | Percentage of Individual Peaks/% (Before Friction) | Percentage of Individual Peaks/% (After Friction) | |||

|---|---|---|---|---|---|

| Si-C | Si-Si | Si-Ox | Si-C | Si-Si | |

| MCD | 70.28 | 29.72 | 41.80 | 40.23 | 17.97 |

| MCD/DLC | 31.85 | 68.15 | 36.50 | 25.48 | 38.02 |

| UNCD | 42.48 | 57.52 | ~ | 61.93 | 38.07 |

| UNCD/DLC | 59.81 | 40.19 | ~ | 34.39 | 65.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Ou, Z.; Mu, Y.; Chen, X.; Yang, S.; Guo, P.; Jiang, N.; Nishimura, K.; Mao, X.; Song, H.; et al. Tribological Properties of Diamond/Diamond-like Carbon (DLC) Composite Coating in a Dry Environment. Materials 2025, 18, 3879. https://doi.org/10.3390/ma18163879

Yang C, Ou Z, Mu Y, Chen X, Yang S, Guo P, Jiang N, Nishimura K, Mao X, Song H, et al. Tribological Properties of Diamond/Diamond-like Carbon (DLC) Composite Coating in a Dry Environment. Materials. 2025; 18(16):3879. https://doi.org/10.3390/ma18163879

Chicago/Turabian StyleYang, Chengye, Zhengxiong Ou, Yuanyuan Mu, Xingqiao Chen, Shihao Yang, Peng Guo, Nan Jiang, Kazuhito Nishimura, Xinbiao Mao, Hui Song, and et al. 2025. "Tribological Properties of Diamond/Diamond-like Carbon (DLC) Composite Coating in a Dry Environment" Materials 18, no. 16: 3879. https://doi.org/10.3390/ma18163879

APA StyleYang, C., Ou, Z., Mu, Y., Chen, X., Yang, S., Guo, P., Jiang, N., Nishimura, K., Mao, X., Song, H., & Li, H. (2025). Tribological Properties of Diamond/Diamond-like Carbon (DLC) Composite Coating in a Dry Environment. Materials, 18(16), 3879. https://doi.org/10.3390/ma18163879