Lightweight Aggregate Concrete with Regard to Bridge Structures—State of the Art

Abstract

1. Introduction

1.1. A Brief History of Lightweight Bridges

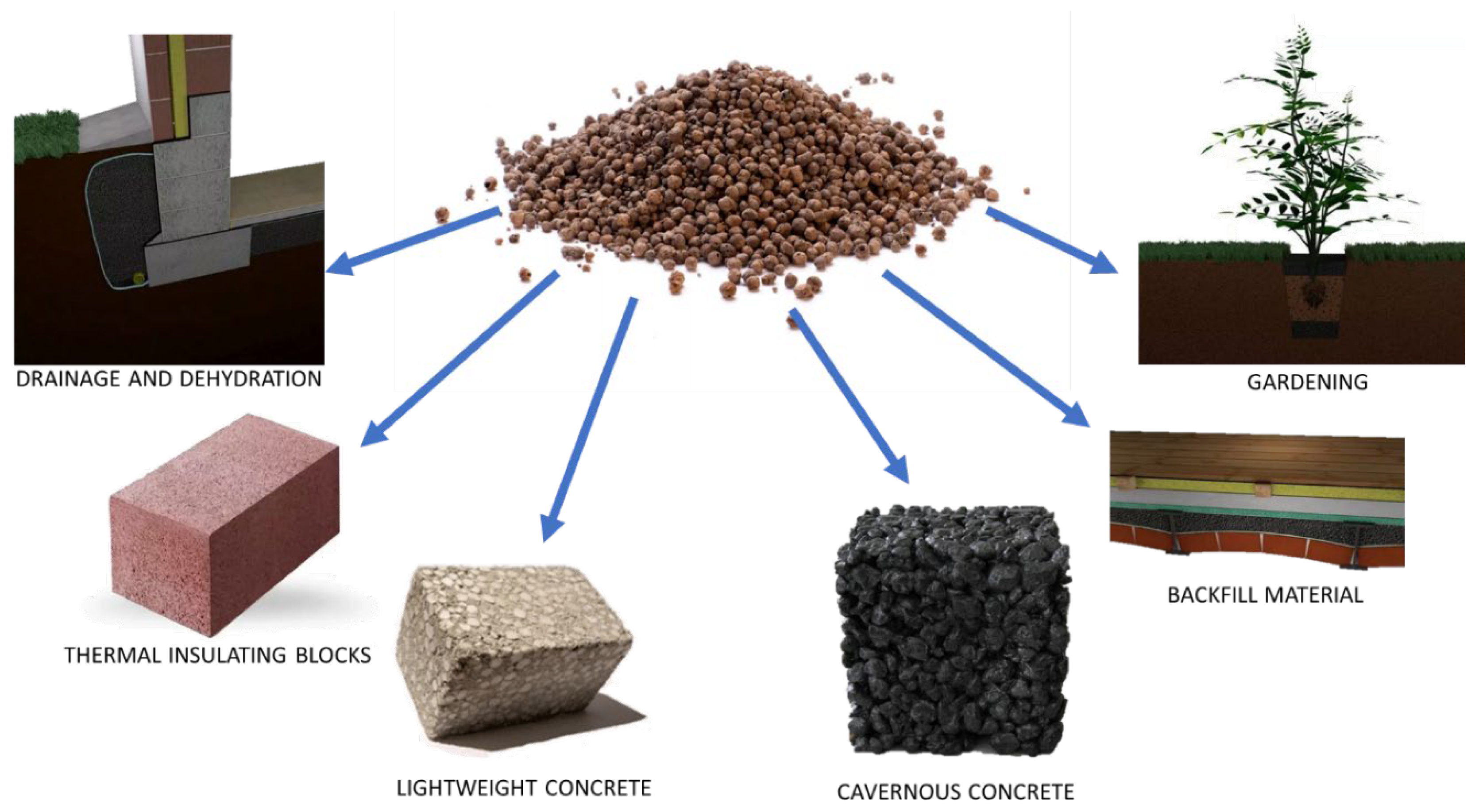

1.2. A Brief History of Lightweight Aggregates

2. The Aim and Scope of This Study

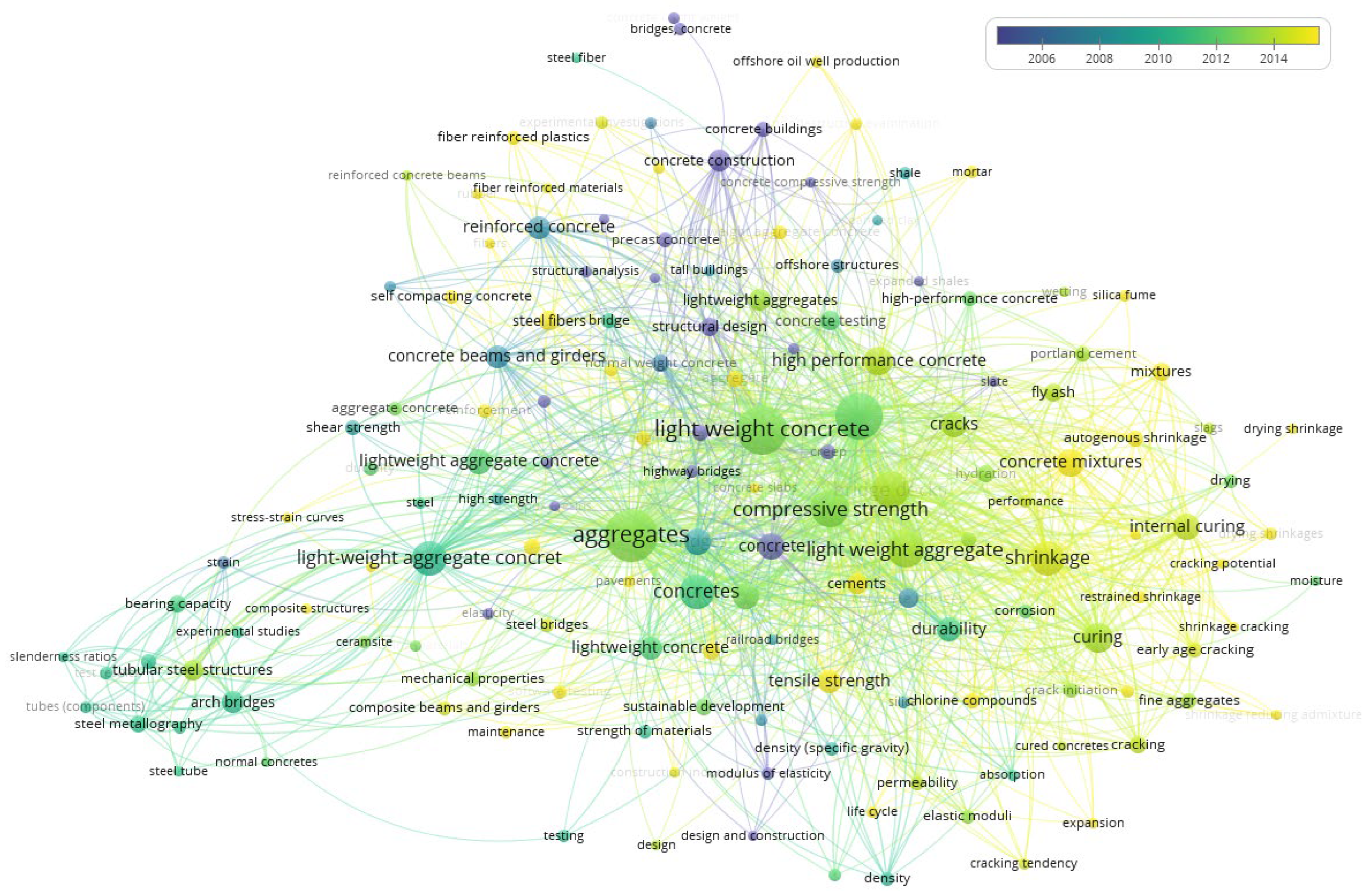

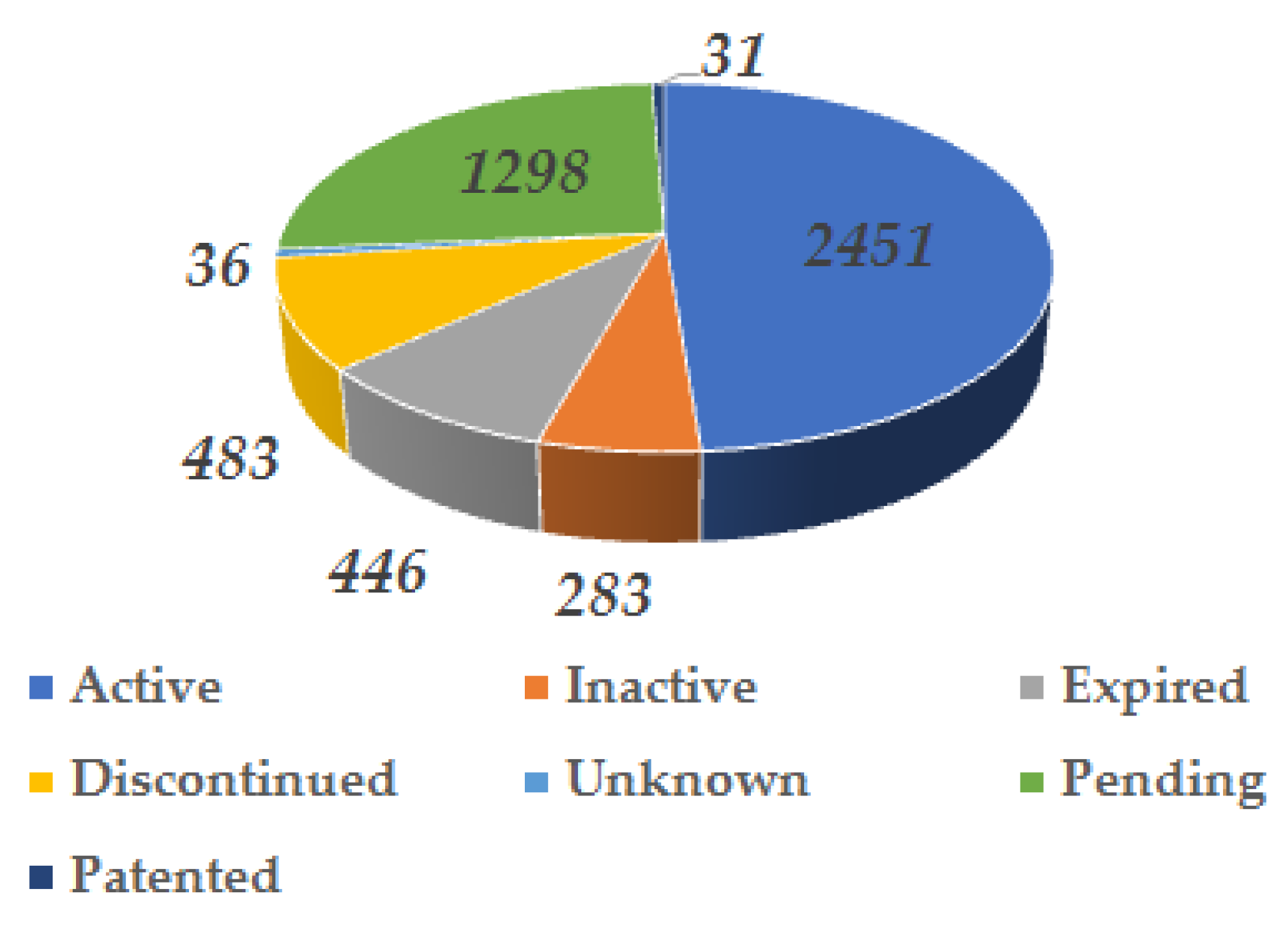

3. Lightweight Aggregate in Bridge Structures—Scientometric Analysis

4. Detailed Analysis of the Current State of Knowledge Regarding Concrete Structures That Use Lightweight Aggregates

4.1. Types of Lightweight Aggregates and Their Physical and Chemical Parameters

| Authors of the Papers | Name of Lightweight Aggregate | Bulk Aggregate Density [kg/m3] | Density [kg/m3] | Type of Cement | Compressive Strength [MPa] |

|---|---|---|---|---|---|

| Hess Pumice [60,61] | coarse pumice aggregate (Idaho, USA) | 689 | 1426 | N/A | 16.9 |

| fine pumice aggregate (Idaho, USA) | 785 | ||||

| Hossain [62] | coarse pumice aggregate (Papua Nowa Gwinea) | 680 | 1802–2520 | Portland CEM I + volcanic ash | 21–35 |

| Muralitharan [63] | coarse pumice aggregate (Turkey) | 870 | 1644–1656 | Portland CEM I 52.5 + volcanic ash | 18.66–19.11 |

| Karthika [64] | coarse pumice aggregate (Turkey) | 480 | N/A | Portland CEM I 42.5 | 12.2–6.86 |

| Hossain [68] | coarse pumice aggregate (Papua Nowa Gwinea) | 1870 | N/A | Portland CEM I, V + volcanic ash | 25–38 |

| Badogiannis [67] | coarse pumice aggregate | N/A | 1710–1840 | Portland CEM IV/B (P-W) 32.5R | 18.56 |

| Gündüz et al. [65] | coarse pumice aggregate (Turkey) | 815–935 | 1150–1271 | Portland CEM I 42.5 | 14.63–26.09 |

| fine pumice aggregate (Yali Island) | 895–925 | ||||

| Öz [66] | coarse pumice aggregate | 990 | 1206–1886 | Portland CEMI 42.5R | 13.69–7.04 |

| Authors of the Papers | Name of Lightweight Aggregate | Bulk Aggregate Density [kg/m3] | Density [kg/m3] | Type of Cement | Compressive Strength [MPa] |

|---|---|---|---|---|---|

| Richart et al. [70] | fine Haydite aggregate | 865 | 1490–1698 | Portland type I | 12.2–31.1 |

| coarse Haydite aggregate | 689 | ||||

| Iowa State Highway Commission [71] | coarse Haydite aggregate | 855–924 | N/A | Portland type I | 46.3–47.1 |

| Muralitharan [63] | coarse Idealite aggregate | 887 | 1644–1656 | Portland CEM I 52.5 + volcanic ash | 50.0–54.9 |

| Karthika [64] | coarse Materialite aggregate | 847 | N/A | Portland CEM I 42.5 | 44.5–46.1 |

| Wang et al. [72] | coarse Haydite aggregate | 693 | 1531 | Portland type I | 47.38–58.86 |

| Xia et al. [52] | coarse Haydite aggregate | 800 | 1856–1942 | Portland type I 42.5 | 21.82–34.91 |

| Authors of the Papers | Name of Lightweight Aggregate | Bulk Aggregate Density [kg/m3] | Density [kg/m3] | Type of Cement | Compressive Strength [MPa] |

|---|---|---|---|---|---|

| Wegian [78]. | fine/coarse Ceramsite aggregate | 510–1480 | 1360–2390 | Portland | 11.8–32.2 |

| Issa et al. [79] | coarse Ceramsite aggregate | 415 | 1760–1824 | Portland | 18.0–30.5 |

| Nemes et al. [89] | coarse Ceramsite aggregate | 1047–1380 | N/A | Portland CEM I 42.5 N/52.5 N | 43.5–78.0 |

| Yao et al. [90] | coarse Ceramsite aggregate | 415 | 1679–2167 | Portland CEM I 42.5 | 14.2–30.7 |

| Wei et al. [53] | coarse Ceramsite aggregate | 860 | 1724–1849 | Portland cement P. O 42.5 | 41.0–67.0 |

| Wu et al. [80] | coarse Ceramsite aggregate | 755–1019 | 1720–1940 | Portland cement P. O 42.5 | 47.0–86.0 |

| Zhao et al. [81] | coarse Ceramsite aggregate | 816–888 | 1695–1946 | Portland cement P.O. 52.5 | 47.2–64.8 |

| Pichór et al. [92] | coarse Ceramsite aggregate | 725–785 | 1500–1534 | Portland Cement CEM II 32.5 | 16.3–18.1 |

| Lo et al. [82] | coarse expanded clay aggregate | 405 | 1617–1851 | Portland Cement | 29.19–42.95 |

| Mohammed et al. [83] | coarse shale aggregate | 1784 | N/A | Portland type I | 25.7–44.8 |

| coarse clay aggregate (Arcosa) | 1590 | N/A | 32.1–47.7 |

| Authors of the Papers | Name of Lightweight Aggregate | Bulk Aggregate Density [kg/m3] | Density [kg/m3] | Type of Cement | Compressive Strength [MPa] |

|---|---|---|---|---|---|

| Lytag [99,100,101] | coarse Lytag aggregate | 750–850 | 1400–1800 | Portland CEM I | 22–50 |

| Zhang et al. [109] | Lytag 800 (Chiny) | N/A | N/A | Portland typ I 42.5 | 37.8–42.2 |

| Ahmad et al. [105] | coarse Lytag aggregate | 687 | 1879–1954 | Portland typ I | 36.6–37.7 |

| Yun Bai et al. [106] | coarse Lytag aggregate | 1520 | 1559–1977 | Portland typ I 42.5N | 20–40 |

| Punlert et al. [107] | coarse Lytag aggregate | 1660 | 1780–2210 | N/A | 40.94–42.34 |

| Domagała [108] | coarse Lytag aggregate | 720–730 | 1470–1920 | Portland cement CEM I 42.5 R | 25–83.5 |

| Zhang [104] | coarse Lytag aggregate | 794 | 1490–1940 | Portland typ I 42.5 | 28.9–50.2 |

| Domagała [51] | coarse Lytag aggregate | N/A | 1580–1710 | Portland cement CEM I 42.5 R | 39.0–47.5 |

4.2. Principles of Structural Design for Structural Lightweight Concrete

4.2.1. United States Design Guidelines

4.2.2. European Design Guidelines

4.2.3. China Design Guidelines

4.2.4. Summary of Design Guidelines

5. Lightweight Aggregate Concrete in Bridge Structures

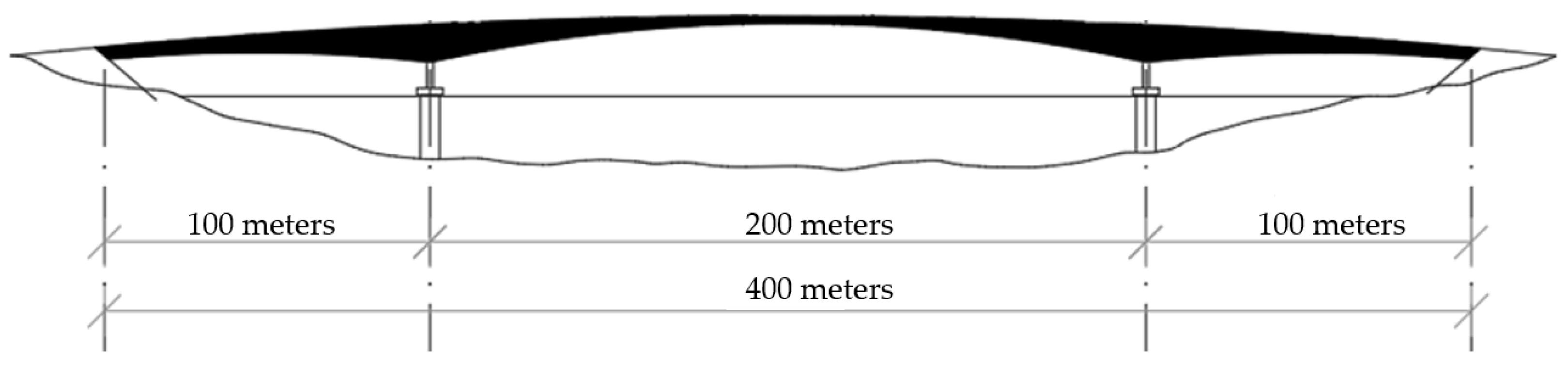

5.1. Bridge Structures in Japan

5.2. Bridge Structures in Norway

5.3. Bridge Structures in United States of America

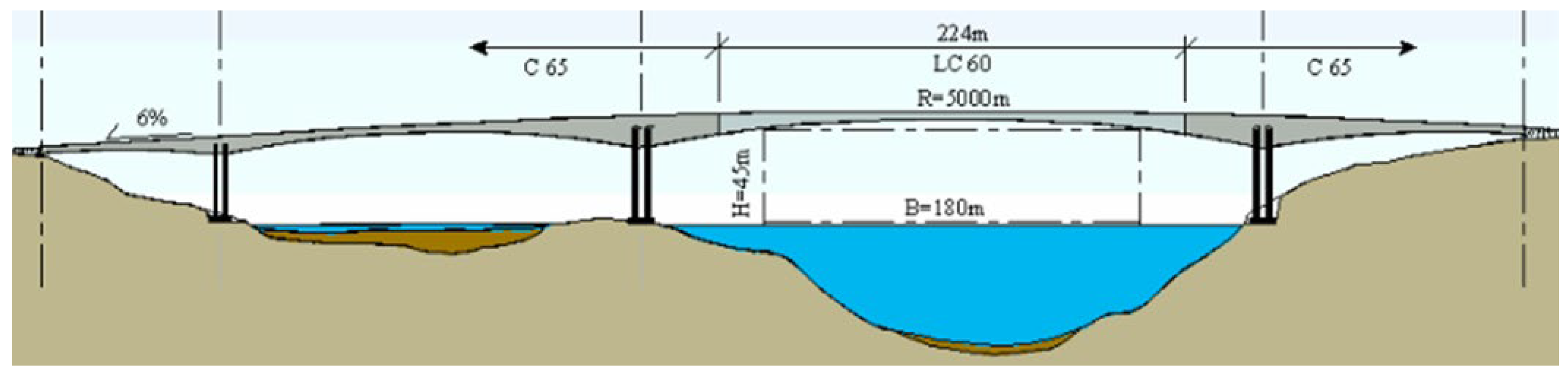

5.4. Bridge Structures in Europe

5.5. Use of Lightweight Aggregates for Tunnel Construction

6. Summary and Conclusions of the Literature Review

7. Future Research and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saleh, A.H. Mega Floating Concrete Bridge. Master’s Thesis, Master of Science, Concrete Structure Department, Delft University of Technology, Delft, The Nederland, 2010. [Google Scholar]

- Kouwenhoven, J.A. The Designing of the Eads Bridge. Technol. Cult. 1982, 23, 535–568. [Google Scholar] [CrossRef]

- Verantius, F. Machinae Novae Fausti Verantii Siceni: Cum Declaratione Latina, Italica, Hispanica, Gallica et Germanica; Heinz Moos Verlag: Munich, Germany, 1965; p. 1616. [Google Scholar]

- Biliszczuk, J. Mosty Podwieszone. In Projektowanie i Realizacja; Arkady: Warsaw, Poland, 2005. [Google Scholar]

- Finley, J. The Port Folio; Bradford & Inskeep: Philadelphia, PA, USA, 1810. [Google Scholar]

- Buonopane, S.G.; Billington, D.P. Theory and history of suspension bridge design from 1823 to 1940. J. Struct. Eng. 1993, 119, 954–977. [Google Scholar] [CrossRef]

- Pope, T. A Treatise on Bridge Architecture; Legare Street Press: Charleston, WV, USA, 1811. [Google Scholar]

- Navier, C.L. Rapport à Monsieur Becquey et Mémoire Sur Les PontsSuspendus; L’Impr. Royale: Paris, France, 1823. [Google Scholar]

- Dąbrowiecki, K. Dwustuletnia Historia Rozwoju Nowoczesnych Mostów Wiszących, Cz. 1. Wiek XIX. Nowocz. Bud. Inżynieryjne 2020, 2, 100–106. [Google Scholar]

- Dąbrowiecki, K. Dwustuletnia Historia Rozwoju Nowoczesnych Mostów Wiszących, Cz. 2. Wiek XX. Nowocz. Bud. Inżynieryjne 2020, 4, 90–99. [Google Scholar]

- Dąbrowiecki, K. Mosty Tacoma Narrows. Nowocz. Bud. Inżynieryjne 2010, 5, 66–70. [Google Scholar]

- Express Web Desk Danyang–Kunshan to Cangde Grand: These Are the World’s Longest Bridges; The Indian Express: Noida, India, 2018.

- Kasuga, A. Development of a New Bridge Construction Method Using Suspension Structures. Struct. Concr. 2011, 12, 65–75. [Google Scholar] [CrossRef]

- Ali, H.T.; Akrami, R.; Fotouhi, S.; Bodaghi, M.; Saeedifar, M.; Yusuf, M.; Fotouhi, M. Fiber Reinforced Polymer Composites in Bridge Industry. Structures 2021, 30, 774–785. [Google Scholar] [CrossRef]

- Qureshi, J. A Review of Fibre Reinforced Polymer Bridges. Fibers 2023, 11, 40. [Google Scholar] [CrossRef]

- Walsh, N.P. World’s Largest 3D-Printed Concrete Pedestrian Bridge Completed in China. Available online: https://www.archdaily.com/909534/worlds-largest-3d-printed-concrete-pedestrian-bridge-completed-in-china (accessed on 6 September 2023).

- EN 13055; Lightweight Aggregates. European Parliament: Warsaw, Poland, 2016.

- EN 206; Concrete-Requirements, Properties, Production and Compliance. Polish Committee for Standardization: Warsaw, Poland, 2018.

- EN 1992-1-1; Design of Concrete Structures—Part 1-1: General and Rules for Buildings. Polski Komitet Normalizacyjny: Warsaw, Poland, 2004.

- ASTM C330/C330M; Standard Specification for Lightweight Aggregates for Structural Concrete. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C331M; Standard Specification for Lightweight Aggregates for Concrete Masonry Units. ASTM International: West Conshohocken, PA, USA, 2023.

- Castrodale, R. Lightweight Concrete Bridge Design Primer; Federal Highway Administration: Washington, DC, USA, 2021. [Google Scholar]

- GB/T 17431.1; Lightweight Aggregates and Its Test Methods—Part 1: Lightweight Aggregates. China Environmental Science Press: Beijing, China, 2010.

- Thienel, K.C.; Haller, T.; Beuntner, N. Lightweight Concrete-from Basics to Innovations. Materials 2020, 13, 1–24. [Google Scholar] [CrossRef]

- Clarke, H. The Pantheon: Still the World’s Largest Unreinforced Concrete Dome. Available online: https://eandt.theiet.org/2022/03/15/pantheon-still-worlds-largest-unreinforced-concrete-dome (accessed on 16 February 2023).

- Bremner, T.W.; Ries, J.; Stephen, J. Hayde: Father of the Lightweight Concrete Industry. Concr. Int. 2009, 31, 35–38. [Google Scholar]

- Hayde, S.J. Process of Making Brick and Similar Articles. U.S. Patent No. 1,255,878, 12 February 1918. [Google Scholar]

- Havens, J.H. A Discussion on the Durability of Expanded Shale Aggregate for Exposed Concrete Structures (Bridges); Commonwealth of Kentucky Department of Highways: Lexington, KY, USA, 1960. [Google Scholar]

- Raithby, K.D.; Lydon, F.D. Lightweight Concrete in Highway Bridges. Int. J. Cem. Compos. Lightweight Concr. 1981, 2, 133–146. [Google Scholar] [CrossRef]

- Domagała, L. KonstrukcyjneLekkie Betony Kruszywowe; Cracow University of Technology: Cracow, Poland, 2014. [Google Scholar]

- Lightweight Aggregate Concrete Market Report: Trends, Forecast and Competitive Analysis to 2030; Research and Markets: Dublin, Ireland, 2024.

- Izolacja Stropów—LECA Polska. Available online: https://leca.pl/rozwiazania/izolacja-stropow (accessed on 21 March 2023).

- KLB-TRIOTHERM Und Nachhaltig Dämmen; Andernach. Available online: https://www.klb-klimaleichtblock.de/files/documents/Broschueren/2018_01/TRIOTHERM.pdf (accessed on 3 August 2025).

- Obieszczenie Ministra Inwestycji I Rozwoju z Dnia 8 Kwietnia 2019 r. w Sprawie Ogłoszenia Jednolitego Tekstu Rozporządzenia Ministra Infrastruktury w Sprawie Warunków Technicznych, Jakim Powinny Odpowiadać Budynkii Ich Usytuowanie; Ministerstwo Infrastruktury i Rozwoju: Warszawa, Poland, 2019.

- Izolacja w GruncieiDrenaże—LECA Polska. Available online: https://leca.pl/rozwiazania/izolacja-w-gruncie (accessed on 21 March 2023).

- Tutikian, B.F.; Nunes, M.F.O.; Leal, L.C.; Marquetto, L. Impact Sound Insulation of Lightweight Concrete Floor with EVA Waste. Build. Acoust. 2012, 19, 75–88. [Google Scholar] [CrossRef]

- Swamy, N.V.; Muthumani, K. Critical Review on Structural Light Weight Concrete. Int. J. Civ. Eng. Technol. 2017, 8, 252–263. [Google Scholar]

- STALITE Lightweight Aggregate—Production. Available online: https://www.stalite.com/production (accessed on 7 September 2023).

- Wall, J. Final Report of ASTM C330 Stalite ¾ Inch Coarse Lightweight Aggregate; Gold Hill: Okanagan, NC, USA, 2017. [Google Scholar]

- Utelite Corporation. Expanded Shale Safety Data Sheet Utelite; Nexreg: Leicestershire, UK, 2014. [Google Scholar]

- Northeast Solite Corporation-Products-Solite. Available online: https://northeastsolite.com/?page_id=831 (accessed on 7 September 2023).

- Arcosa Lightweight-Applications-Structural Lightweight Concrete. Available online: https://arcosalightweight.com/ (accessed on 7 September 2023).

- Laterlite-Products-Lightweight Aggregates. Available online: https://www.laterlite.com/products/lightweight-aggregates/ (accessed on 7 September 2023).

- Imerys-Minerals & More-Mulite. Available online: https://www.imerys.com/minerals/mullite (accessed on 20 June 2023).

- Łuczaj, K.; Urbańska, P. Certyd-Nowe, Lekkie, Wysokowytrzymałe Kruszywo Spiekane. Mater. Bud. 2015, 12, 42–45. [Google Scholar] [CrossRef]

- Chojnacka, E.; Mrozik, Ł. Kruszywo Lekkie Certyd Prefabrykacji. Mater. Bud. 2022, 8, 37–38. [Google Scholar]

- Nodullar-Light Clay Aggregate. Available online: https://archello.com/product/nodullar-light-clay-aggregates (accessed on 7 September 2023).

- Morante-Carballo, F.; Montalván-Burbano, N.; Carrión-Mero, P.; Espinoza-Santos, N. Cation Exchange of Natural Zeolites: Worldwide Research. Sustainability 2021, 13, 7751. [Google Scholar] [CrossRef]

- Malazdrewicz, S.; Ostrowski, K.A.; Sadowski, Ł. Large Panel System Technology in the Second Half of the Twentieth Century—Literature Review, Recycling Possibilities and Research Gaps. Buildings 2022, 12, 1822. [Google Scholar] [CrossRef]

- Elsevier, S. Scopus Your Brilliance, Connected; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Domagala, L. Modification of Properties of Structural Lightweight Concrete with Steel Fibres. J. Civ. Eng. Manag. 2011, 17, 36–44. [Google Scholar] [CrossRef]

- Xia, B.; Liu, Y.; Zhang, Q. Elastic Modulus Calculation of GRT Fiber—Rubberized Haydite Concrete. Adv. Mat. Res. 2012, 450–451, 423–427. [Google Scholar] [CrossRef]

- Wei, H.; Wu, T.; Yang, X. Properties of Lightweight Aggregate Concrete Reinforced with Carbon and/or Polypropylene Fibers. Materials 2020, 13, 640. [Google Scholar] [CrossRef] [PubMed]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Limited: Harlow, UK, 2011. [Google Scholar]

- Pumice: Origins, Uses, Technical Data. Available online: https://pumicestore.com/pumice-about.html#tds (accessed on 22 March 2023).

- IS-383; Specifications For Coarse and Fine Aggregates from Natural Sources For Concrete. Bureau of Indian Standards: New Delhi, India, 1970.

- IS 2386; Part 3 Methods of Test for Aggregates for Concrete Part 3 Specific Gravity, Density, Voids, Absorption and Bulking. Bureau of Indian Standards: New Delhi, India, 1963.

- IS 2386; Part 4 Methods of Test for Aggregates for Concrete Part 4 Mechanical Properties. Bureau of Indian Standards: New Delhi, India, 1963.

- Ries, J.P.; Akers, D.J.; Gruber, R.D.; Ramme, B.W.; Boyle, M.J.; Grygar, J.G.; Rowe, S.K.; Bremner, T.W.; Kluckowski, E.S.; Sheetz, S.R.; et al. Guide for Structural Lightweight-Aggregate Concrete; ACI Committee 213: Farmington Hills, MI, USA, 2014. [Google Scholar]

- HESS Pumice. Pumice-Aggregate Properties; HESS Pumice: Malad City, Idaho, 2025. [Google Scholar]

- HESS Pumice. Pumice Concrete-Mix Designs; HESS Pumice: Malad City, Idaho, 2025. [Google Scholar]

- Hossain, K.M.A. Lightweight Concrete Incorporating Volcanic Materials. Constr. Mater. 2012, 165, 111–120. [Google Scholar] [CrossRef]

- Muralitharan, R.S.; Ramasamy, V. Basic Properties of Pumice Aggregate. Int. J. Earth Sci. Eng. 2015, 8, 256–263. [Google Scholar]

- Karthika, R.B.; Vidyapriya, V.; Nandhini Sri, K.V.; Merlin Grace Beaula, K.; Harini, R.; Sriram, M. Experimental Study on Lightweight Concrete Using Pumice Aggregate. Mater. Today Proc. 2021, 43, 1606–1613. [Google Scholar] [CrossRef]

- Gündüz, L.; Uǧur, I. The Effects of Different Fine and Coarse Pumice Aggregate/Cement Ratios on the Structural Concrete Properties without Using Any Admixtures. Cem. Concr. Res. 2005, 35, 1859–1864. [Google Scholar] [CrossRef]

- Öz, H.Ö. Properties of Pervious Concretes Partially Incorporating Acidic Pumice as Coarse Aggregate. Constr. Build. Mater. 2018, 166, 601–609. [Google Scholar] [CrossRef]

- Badogiannis, E.G.; Christidis, I.; Tzanetatos, G.E. Evaluation of the Mechanical Behavior of Pumice Lightweight Concrete Reinforced with Steel and Polypropylene Fibers. Constr. Build. Mater. 2019, 196, 443–456. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Performance of Volcanic Ash and Pumice-Based Blended Cements in Sulphate and Sulphate-Chloride Environments. Adv. Cem. Res. 2006, 18, 71–82. [Google Scholar] [CrossRef]

- Design and Control of Haydite Concrete Mixtures; Hydraulic-Press Bick Company: Saint Louis, MO, USA, 1950.

- Richart, F.E.; Jensen, V.P. Tests of Plain and Reinforced Concrete Made with Haydite Aggregates. Univ. Ill. Eng. Exp. Station. Bull. 1931, 237, 1–81. [Google Scholar]

- Lightweight Aggregate Use in Structural Concrete; CRC Press: Boca Raton, FL, USA, 1969.

- Wang, L.; Song, Y. Mechanical Behavior and Failure Criterion of the Gangue-Based Haydite Concrete under Triaxial Loading. Mater. Struct. 2015, 48, 1419–1433. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, J.; He, Z.; Zhou, H. Production of High Performance Haydite from Sewage Sludge. Adv. Mat. Res. 2010, 113, 1097–1100. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, W. The Application of Sludge Shale Haydite in Building Materials. In Proceedings of the International Symposium on Water Resource and Environmental Protection, Xi’an, China, 20–22 May 2011; IEEE: Xi’an, China, 2011; pp. 1674–1677. [Google Scholar]

- Helland, S. Building Bridges and Marine Structures with Structural Lightweight Aggregate Concrete. Expanded Shale, Clay and Slate Institute: Salt Lake City, UT, USA, 1992. [Google Scholar]

- Roces, E.; Muñiz-Menéndez, M.; González-Galindo, J.; Estaire, J. Lightweight Expanded Clay Aggregate Properties Based on Laboratory Testing. Constr. Build. Mater. 2021, 313, 125486. [Google Scholar] [CrossRef]

- Franus, M. Właściwości Fizyczne I Mechaniczne Keramzytu Otrzymanego z Dodatkiem Glaukonitu. Budownictwoi Archit. 2012, 10, 5–14. [Google Scholar] [CrossRef]

- Wegian, F.M. Strength Properties of Lightweight Concrete Made with LECA Grading. Aust. J. Civ. Eng. 2012, 10, 11–22. [Google Scholar] [CrossRef]

- Issa, A.S.; Al-Asadi, A.K. Mechanical Properties of Lightweight Expanded Clay Aggregate (LECA) Concrete. Sci. Rev. Eng. Environ. Stud. 2022, 31, 161–175. [Google Scholar] [CrossRef]

- Wu, T.; Yang, X.; Wei, H.; Liu, X. Mechanical Properties and Microstructure of Lightweight Aggregate Concrete with and without Fibers. Constr. Build. Mater. 2019, 199, 526–539. [Google Scholar] [CrossRef]

- Zhao, S.; Li, C.; Zhao, M.; Zhang, X. Experimental Study on Autogenous and Drying Shrinkage of Steel Fiber Reinforced Lightweight-Aggregate Concrete. Adv. Mater. Sci. Eng. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.Z.; Li, Z.G. Influence of Aggregate Pre-Wetting and Fly Ash on Mechanical Properties of Lightweight Concrete. Waste Manag. 2004, 24, 333–338. [Google Scholar] [CrossRef]

- Mohammed, T.; Aguayo, F.; Nodehi, M.; Ozbakkaloglu, T. Engineering Properties of Structural Lightweight Concrete Containing Expanded Shale and Clay with High Volume Class F and Class C Fly Ash. Struct. Concr. 2023, 24, 4029–4046. [Google Scholar] [CrossRef]

- Bogas, J.A.; Real, S. A Review on the Carbonation and Chloride Penetration Resistance of Structural Lightweight Aggregate Concrete. Materials 2019, 12, 3456. [Google Scholar] [CrossRef]

- Horňáková, M.; Katzer, J.; Kobaka, J.; Konecny, P. Lightweight SFRC Benefitting from a Pre-Soaking and Internal Curing Process. Materials 2019, 12, 4152. [Google Scholar] [CrossRef] [PubMed]

- Horňáková, M.; Lehner, P. Relationship of Surface and Bulk Resistivity in the Case of Mechanically Damaged Fibre Reinforced Red Ceramic Waste Aggregate Concrete. Materials 2020, 13, 5501. [Google Scholar] [CrossRef] [PubMed]

- Lehner, P.; Horňáková, M. Effect of Amount of Fibre and Damage Level on Service Life of SFR Recycled Concrete in Aggressive Environment. Buildings 2021, 11, 489. [Google Scholar] [CrossRef]

- Horňáková, M.; Lehner, P. Analysis of Measured Parameters in Relation to the Amount of Fibre in Lightweight Red Ceramic Waste Aggregate Concrete. Mathematics 2022, 10, 229. [Google Scholar] [CrossRef]

- Nemes, R.; Abed, M.A.; Seyam, A.M.; Lublóy, É. Behavior of Structural Lightweight Concrete Produced with Expanded Clay Aggregate and after Exposure to High Temperatures. J. Therm. Anal. Calorim. 2022, 147, 8111–8118. [Google Scholar] [CrossRef]

- Yao, W.; Pang, J.; Liu, Y. Performance Degradation and Microscopic Analysis of Lightweight Aggregate Concrete after Exposure to High Temperature. Materials 2020, 13, 1566. [Google Scholar] [CrossRef]

- Zheng, W.; He, D.; Li, H.; Wang, F.; Yang, Y.; Zhang, J. The Preparation and Properties of a Shell Structure Ceramsite. Materials 2020, 13, 1009. [Google Scholar] [CrossRef] [PubMed]

- Pichór, W.; Latosińska, J. Możliwości Wykorzystania Keramzytu Modyfikowanego Komunalnym Osadem Ściekowym Do Wytwarzania Betonów Lekkich. In Proceedings of the Dni betonu, Tradycja i Nowoczesność, Cracow, Poland, 9 October 2006; pp. 1–8. [Google Scholar]

- Huang, L.; Yu, L.; Zhang, H.; Yang, Z. Composition and microstructure of 50-year lightweight aggregate concrete (LWAC) from Nanjing Yangtze River bridge (NYRB). Constr. Build. Mater. 2019, 216, 1–15. [Google Scholar] [CrossRef]

- Zhou, H.; Guo, G.; Wu, B. Nanjing Yangtze River Bridge Transit Capacity Based on Queuing Theory. Procedia Soc. Behav. Sci. 2013, 96, 2546–2552. [Google Scholar] [CrossRef]

- Aggregate Industries—Aggregates. Available online: https://www.aggregate.com/our-businesses/lytag/about-us (accessed on 17 October 2023).

- Fielding, M. Lytag Ligtweight Solutions—Aggregate Properties Summary Data Sheet; Holcim UK: London, UK, 2017. [Google Scholar]

- Lytag Lightweight Solutions Technical Manual—Section 1 Introduction to Lytag® Lightweight Aggregate; Laytag Ltd.: London, UK, 2017.

- Lytag Lightweight Solutions Technical Manual—Section 2 Introduction to Lytag® Lightweight Aggregate Concrete—LWAC; Laytag Ltd.: London, UK, 2016.

- Lytag Lightweight Solutions Technical Manual—Section 3 Mix Designs for Lytag Concrete; Laytag Ltd.: London, UK, 2017.

- Lytag Lightweight Solutions Technical Manual—Section 4 Design Guidance for Lytag LWAC Concrete; Laytag Ltd.: London, UK, 2017.

- Lytag lightweight solutions Technical Manual—Section 5 Manufacture of LWAC Using Lytag® LWA; Laytag Ltd.: London, UK, 2017.

- BS 5400-4; Steel, Concrete and Composite Bridges. Code of Practice for Design of Concrete Bridges; British Standards Institution: London, UK, 1990.

- Swamy, R.N.; Lambert, G.H. The Microstructure of Lytag Aggregate. Int. J. Cem. Compos. Lightweight Concr. 1981, 3, 273–282. [Google Scholar] [CrossRef]

- Zhang, L. Fundamental Mechanical Properties Of Lytag Concrete. In Proceedings of the 2nd International Conference on Multimedia Technology (ICMT2011), Hangzhou, China, 26 July 2011; IEEE: Hangzhou, China, 2011; pp. 3972–3974. [Google Scholar]

- Ahmad, S.; Sallam, Y.S.; Al-Hashmi, I.A.R. Optimising Dosage of Lytag Used as Coarse Aggregate in Lightweight Aggregate Concretes. J. S. Afr. Inst. Civ. Eng. 2013, 55, 80–84. [Google Scholar]

- Bai, Y.; Ratiyah, I.; Basheer, P.A.M. Properties of Lightweight Concrete Manufactured with Fly Ash, Furnace Bottom Ash, and Lytag. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004. [Google Scholar]

- Punlert, S.; Laoratanakul, P.; Kongdee, R.; Suntako, R. Effect of Lightweight Aggregates Prepared from Fly Ash on Lightweight Concrete Performances. J. Phys. Conf. Ser. 2017, 901, 012086. [Google Scholar] [CrossRef]

- Domagała, L. Durability of Structural Lightweight Concrete with Sintered Fly Ash Aggregate. Materials 2020, 13, 4565. [Google Scholar] [CrossRef] [PubMed]

- Zhang, A.; Zhang, L. The Frost Resistance of LYTAG Concrete. Adv. Mat. Res. 2014, 936, 1419–1422. [Google Scholar] [CrossRef]

- Wiater, A.; Piątek, B.; Siwowski, T. Research on Bridge Elements Made of Lightweight Concrete Reinforced with GFRP Rebars. In Proceedings of the Synergy of Culture and Civil Engineering–History and Challenges, Wrocław, Poland, 20–22 May 2021; IABSE: Wrocław, Poland, 2021; pp. 1–8. [Google Scholar]

- Ailian, Z. Application of Sintered Lytag Concrete in Bridge Reinforcement and Reconstruction Project in Cold Areas. BioTechnology 2014, 10, 15336–15340. [Google Scholar]

- Clarke, J.L. Structural Lightweight Aggregate Concrete; Blackie Academic & Professional: Glasgow, UK, 2005; Volume III. [Google Scholar]

- Pordesari, A.J.; Shafigh, P.; Ibrahim, Z.; Aslam, M. Engineering Properties of Coconut Shell Lightweight Concrete: A Comparative Study. Adv. Concr. Constr. 2021, 12, 303–316. [Google Scholar] [CrossRef]

- Nithya, S.; Gunasekaran, K.; Sankar, G. A Study on the Flexural Behaviour of Geopolymer Lightweight Eco-Friendly Concrete Using Coconut Shell as Coarse Aggregate. Adv. Civ. Eng. 2021, 2021, 5534019. [Google Scholar] [CrossRef]

- Nguyen, H.P.; Mueller, A.; Nguyen, V.T.; Nguyen, C.T. Development and Characterization of Lightweight Aggregate Recycled from Construction and Demolition Waste Mixed with Other Industrial By-Products. Constr. Build. Mater. 2021, 313, 1–10. [Google Scholar] [CrossRef]

- Abdulrasool, A.T.; Mohammed, S.S.; Kadhim, N.R.; Hussain, W.A.M. Sustainable Materials Used as Lightweight Aggregate: (An Overview). In Proceedings of the IOP Conference Series: Earth and Environmental Science 961, Bristol, UK, 10 January 2022; IOP Publishing Ltd.: Bristol, UK; Volume 961. [Google Scholar]

- Wongkvanklom, A.; Posi, P.; Khotsopha, B.; Ketmala, C.; Pluemsud, N.; Lertnimoolchai, S.; Chindaprasirt, P. Structural Lightweight Concrete Containing Recycled Lightweight Concrete Aggregate. KSCE J. Civ. Eng. 2018, 22, 3077–3084. [Google Scholar] [CrossRef]

- Li, A.; Zhou, G.; Zhang, X.; Meng, E. Compressive Mechanical Properties of a Novel Recycled Aggregate Concrete with Recycled Lightweight Aggregate. Adv. Mater. Sci. Eng. 2021, 2021, 2134082. [Google Scholar] [CrossRef]

- Kashyap, R.; Saxena, M.; Gautam, A.; Chauhan, S.; Mourya, A.; Verma, P. A Study on Recycled Lightweight Aggregate Concrete. J. Build. Pathol. Rehabil. 2022, 7, 28. [Google Scholar] [CrossRef]

- Streeter, D.A.; Wolfe, W.H.; Vaughn, R.E. Field Performance of Internally Cured Concrete Bridge Decks in New York State. Spec. Publ. 2012, 290, 1–16. [Google Scholar] [CrossRef]

- Sun, H.; Ye, L.; Ding, J. Shrinkage and Creep of High-Strength Lightweight Aggregate Concrete. J.-Tsinghua Univ. 2007, 47. [Google Scholar]

- Fiorio, B.; Beaucour, A.-L.; Ortola, S. Optimisation of the Mechanical Behaviour of Lightweight Aggregate Concrete by the Use of High Performances Cementitious Matrixes. In Proceedings of the Concrete Structures, Avignon, France, 16 April 2004; The Challenge of Creativity: Avignon, France, 2004. [Google Scholar]

- Sifan, M.; Nagaratnam, B.; Thamboo, J.; Poologanathan, K.; Corradi, M. Development and Prospectives of Lightweight High Strength Concrete Using Lightweight Aggregates. Constr. Build. Mater. 2023, 362, 1–19. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Wei, J.; Li, L.; Liu, J.; Wang, S.; Ding, Y. Mechanical Properties and Microstructure of Ultra-High Strength Concrete with Lightweight Aggregate. Case Stud. Constr. Mater. 2023, 18, e01745. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Li, L.; Paramasivam, P. Shrinkage of High-Strength Lightweight Aggregate Concrete Exposed to Dryenvironment. ACI Mater. J. 2005, 102, 86–92. [Google Scholar]

- Jackiewicz-Rek, W.; Konopska-Piechurska, M. Specyfikacje Betonu Projektowanego Do Obiektów Mostowych. Nowoczesne Budownictwo Inżynieryjne 2012, 5, 51–54. [Google Scholar]

- Graybeal, B.; Lwin, M.M. Lightweight Concrete in Highway Infrastructure. ASPIRE 2013, 3, 44–45. [Google Scholar]

- Thatcher, D.B.; Heffington, J.A.; Kolozs, R.T.; Sylva, G.S.; Breen, J.E.; Burns, N.H. Structural Lightweight Concrete Prestressed Girders and Panels; The University of Texas at Austin, Center for Transportation Research: Austin, TX, USA, 2001. [Google Scholar]

- 318-99/318R-99; Building Code Requirements for Structural Concrete & Commentary. American Concrete Institute: Farmington Hills: MI, USA, 1999.

- AASHTO LRFD. Bridge Construction Specifications, 1st ed.; AASHTO LRFD: Washington, DC, USA, 1998. [Google Scholar]

- AASHTO LRFD. Bridge Design Specifications, 8th ed.; AASHTO LRFD: Washington, DC, USA, 2017. [Google Scholar]

- Nair, H.; Ozyildirim, C.; Sprinkel, M.M. Use of Lightweight Concrete for Reducing Cracks in Bridge Decks; Virginia Transportation Research Council: Charlottesville, VA, USA, 2016. [Google Scholar]

- Rose, J.L.; Roberts-Wollmann, C.; Alhassan, M.; Fleck, B.E.; Napier, C.S.; Badie, S.S.; Fleck, K.; Oliva, M.G.; Bhide, S.B.; Girgis, A.F.; et al. State-of-the-Art Report on Full-Depth Precast Concrete Bridge Deck Panels; Precast/Prestressed Concrete Institute: Salt Lake City, UT, USA, 2011. [Google Scholar]

- Greene, G.G.; Graybeal, B.A. Lightweight Concrete: Mechanical Properties; Federal Highway Administration: Washington, DC, USA, 2013. [Google Scholar]

- Bajorek, G.; Kiernia-Hnat, M. Badania Typu Kruszyw Budowlanych a Ich Zamierzone Zastosowanie. Bud. Technol. Archit. 2013, 3, 54–56. [Google Scholar]

- PN-S-10040; Obiekty Mostowe—Konstrukcje Betonowe, Żelbetowei Sprężone—Wymaganiai Badania. Polish Committee for Standardization: Warsaw, Poland, 1999.

- Giergiczny, Z.; Świerczyński, W.; Heng, S. Trwałość Betonu W Konstrukcjach Mostowych. In Proceedings of the Wrocławskie Dni Mostowe, Dolnośląska Okręgowa Izba Inżynierów Budownictwa, Wroclaw, Poland, 21–23 November 2012. [Google Scholar]

- Jackiewicz-Rek, W. Betony Specjalne Do Obiektów Mostowych. Available online: https://www.izbudujemy.pl/artykuly/893/Betony-specjalne-do-obiektow-mostowych (accessed on 24 January 2023).

- Podolny, W.; Cox, W.R.; Hooks, J.M.; Miller, M.D.; Moreton, A.J.; Shahawy, M.A.; Edwards, D.; Madani, M.; Montgomery, R.K.; Pielstick, B.; et al. Performance of Concrete Segmental and Cable-Stayed Bridges in Europe; No. FHWA-PL-01-019; Federal Highway Administration U.S. Department of Transportation: Alexandria, Virginia, 2001. [Google Scholar]

- Tørset, J. Bridges in Norway. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2003. [Google Scholar]

- Lo, T.Y.; Cui, H.Z. Properties Of Lightweight Aggregate For Lightweight Concrete Production. Adv. Build. Technol. 2002, 1, 859–864. [Google Scholar] [CrossRef]

- Teychenne, D.C. Lightweight aggregates—their properties and uses in concrete in the UK. In Proceedings of the First International Congress on Lightweight Concrete, London, UK, 27–29 May 1968; pp. 23–37. [Google Scholar]

- GB 2839; National Standard for Production of Lightweight Expanded Clay Aggregate. National Standards of People’s Republic of China, China Standards Press: Beijing, China, 1981.

- GB/T 20473; Dry-Mixed Thermal Insulating Composition for Buildings. National Standards of People’s Republic of China, China Standards Press: Beijing, China, 2021.

- JTG D62; Design Code for Highway Bridges. National Standards of People’s Republic of China. China Standards Press: Beijing, China, 2020.

- TB/T 10002; Chinese Design Code for Railway Bridges. National Standards of People’s Republic of China, China Standards Press: Beijing, China, 2017.

- JTG/T D62-01; Design Code for Seismic Design of Bridges. National Standards of People’s Republic of China. China Standards Press: Beijing, China, 2008.

- Li, G.; Xiao, R. 63 Bridge Design Practice in China. In Bridge Engineering Handbook; Chen, W.-F., Duan, L., Eds.; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Rønvik, J. Raftsund Bridge Concrete Balanced Cantilever Bridge in Lofoten; AAS-Jakobsen: Oslo, Norway, 1998. [Google Scholar]

- Stolmasundet Bridge. Available online: https://www.exca.eu/projects/stolmasundet-bridge/ (accessed on 12 January 2023).

- Klein, J. George P. Coleman Bridge Replacement. Adv. Technol. Struct. Eng. 2012, 1–3. [Google Scholar] [CrossRef]

- Jakobsen, S.E.; Aas-Jakobsen, A. The Use of LWAC in the Pontoons of the Nordhordland Floating Bridge, Norway. In Proceedings of the International Symposium on Structural Lightweight Aggregate Concrete, Kristiansand, Norway, 18–22 June 2000; Helli Grafisk: Kristiansand, Norway, 2000; pp. 73–78. [Google Scholar]

- Gjerding-Smith, K. The Tower of the Grenland Bridge, Norway: Towers for Cable-Stayed Bridges. Struct. Eng. Int. 1998, 8, 280–282. [Google Scholar] [CrossRef]

- Gilley, R.D.; Mallela, J.; Mosher, J.; Ullman, G.L.; Littleton, P. South Carolina Demonstration Project: Rapid Removal and Replacement of the SC 703 Ben Sawyer Bridge Over the Intracoastal Waterway in Charleston County; Federal Highway Administration: Washington, DC, USA, 2011. [Google Scholar]

- Siwowski, T.; Kaleta, D.; Kulpa, M.; Poneta, P. Pierwszy Polski Most Kompozytowy—Koncepcja Technicznai Badania Wstępne. In Proceedings of the XXIV Seminarium “Współczesne Metody Budowy, Wzmacniania i Przebudowy Mostów”, Rosnówko, Poland, 3–4 June 2014. [Google Scholar]

- Kowalsky, M.J.; Priestley, N.M.J.; Seible, F. Dynamic Behavior of Lightweight Concrete Bridges. ACI Struct. J. 2000, 97, 602–618. [Google Scholar] [CrossRef]

- Siwowski, T.; Rajchel, M.; Kaleta, D. Charakterystyka Dynamiczna Mostu Drogowego Wykonanego Z Polimerowych Kompozytów Włóknistych FRP. J. Civ. Eng. Environ. Archit. 2017, XXXIV, 227–238. [Google Scholar] [CrossRef][Green Version]

- Maggenti, R.; Fereira, S. Shasta Viaduct Arch Bridge: Improved by Pumping a Lightweight Concrete Solution. Aspire Concr. Bridge Mag. 2019, 2019, 32–34. [Google Scholar]

- Otsuka, H.; Tsukahara, K.; Nakao, Y.; Sato, Y. Pumpability of High Strength Lightweight Concrete Using Artificial Lightweight Aggregate. Concr. J. 2003, 41, 36–43. [Google Scholar] [CrossRef]

- Kondo, T. Construction of Lightweight Concrete Railway Bridges. J. Soc. Mater. Sci. 1968, 18, 36–42. [Google Scholar] [CrossRef]

- Mochizuki, K.; Kondoh, S.; Saito, K. Construction of Four-Span Stress Ribbon Bridge with Roadway Slab Decks. In Proceedings of the FIP Symposium on Post-Tensioned Concrete Structures, London, UK, 25–27 September 1996; Federation Internationale de la Precontrainte: London, UK, 1996; pp. 161–168. [Google Scholar]

- Mutsuyoshi, H.; Nguyen, H.D.; Kasuga, A. Recent Technology of Prestressed Concrete Bridges in Japan. In Proceedings of the IABSE-JSCE Joint Conference on Advances in Bridge Engineering-II, Dhaka, Bangladesh, 8–10 August 2010. [Google Scholar]

- SHIOSAI BRIDGE IN JAPAN. Available online: https://www.youngcivilengineering.com/2017/01/shiosai-bridge-in-japan.html (accessed on 3 August 2025).

- Niwa, J.; Okamoto, T.; Maehori, S. Application of Super Lightweight Aggregates to Concrete Structures. Concr. J. 2000, 38, 3–9. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, T.; Ishikawa, Y.; Tochigi, T.; Sasajima, M. High Performance Lightweight Concrete. Concr. J. 1999, 37, 12–18. [Google Scholar] [CrossRef]

- Suntharavadivel, T.G.; Aravinthan, T. Overview of External Post-Tensioning in Bridges. In Proceedings of the 2005 Southern Region Engineering Conference: Managing Resources for a Sustainable Future (SREC 2005), Toowoomba, Australia, 15 October 2005; ACQUIRe, Central Queensland University: Toowoomba, Australia, 2005; pp. 1–10. [Google Scholar]

- Akiyama, H. Fundamentally Structural Characteristics of Integral Bridges. Ph.D. Thesis, Kanazawa University, Kanazawa, Japan, 2008. [Google Scholar]

- Hosaka, T.; Umehara, T.; Nakamura, S.; Nishiumi, K. Design and Experiments on a New Railway Bridge System Using Concrete Filled Steel Pipes. In Proceedings of the Composite Construction—Conventional and Innovative, Innsbruck, Austria, 16–18 September 1997; International Association for Bridge and Structural Engineering: Innsbruck, Austria, 1997; pp. 367–372. [Google Scholar]

- Fergestad, S.; Jordet, E.A.; Nielsen, K.H.; Walstad, T. Long Span Bridges. An Evaluation of the Economical and Technical Potential of High Strength Concrete in Long Span Concrete Bridge Construction. In Nordisk Betong; Nordiska Betongfoerbundet: Stockholm, Sweden, 1988; pp. 31–33. [Google Scholar]

- Fergestad, S.; Jordet, E.A.; Nielsen, K.H. Norddalsfjord Bridge—Present Design and Evaluation of Future Possibilities Using High Strength Normal Weight and LWA-Concrete. In Proceedings of the International Symposium on Strait Crossings, Trondheim, Norway, 10–13 June 1986. [Google Scholar]

- Aas-Jakobsen, A. Norddalsfjord Bridge. Available online: https://www.aaj.no/wp-content/uploads/2017/09/Norddalsfjord_referanse_eng.pdf (accessed on 3 August 2025).

- Tuffner, J. Declaration of Performance No. 09 Lightweight Aggregate Liapor 8 4/8 2015. Available online: https://www.liapor.com/medien_en/lia_downloads/datei/130_dop09_liapor_8_48.pdf (accessed on 3 August 2025).

- Fergestad, S.; Naess, K. Instrumentation and Monitoring of Norddalsfjord Bridge, Norway. IABSE Rep. 1987, 56, 165–173. [Google Scholar] [CrossRef]

- Takács, P.F. Deformations in Concrete Cantilever Bridges: Observations and Theoretical Modelling. Ph.D. Thesis, The Norwegian University of Science and Technology, Trondheim, Norway, 2002. [Google Scholar]

- Helland, S. Lightweight Aggregate Concrete in Norwegian Bridges. In Proceedings of the International Symposium on Structural LWAC, Kristiansand, Norway, 20–24 June 2000. [Google Scholar]

- Rosseland, S.; Thorsen, T.A. The Stolma Bridge—World Record of Free Cantilevering. In Proceedings of the Second International Symposium on Structural Lightweight Aggregate Concrete, Kristiansand, Norway, 18–22 June 2000; Helli Grafisk: Kristiansand, Norway, 2000; pp. 406–415. [Google Scholar]

- Dąbrowiecki, K. Dwustuletnia Historia Rozwoju Nowoczesnych Mostów Wiszących, Cz. 3. Wiek XXI. Nowocz. Bud. Inżynieryjne 2020, 5, 100–109. [Google Scholar]

- Ingebrigisen, T. Stolma Bridge, Norway. Struct. Eng. Int. 1999, 2, 100–102. [Google Scholar] [CrossRef]

- Radomski, W. Betony Niekonwencjonalne w Mostownictwie. In Proceedings of the Dni Betonu, Wisła, Poland, 13–15 October 2014. [Google Scholar]

- Melby, K.; Jordet, E.A.; Hansvold, C. Long-Span Bridges in Norway Constructed in High-Strength LWA Concrete. Eng. Struct. 1996, 18, 845–849. [Google Scholar] [CrossRef]

- Fidjestol, P. High Performance Lightweight Concrete Bridges—Norwegian Background And Experience. In Proceedings of the International Symposium on High Performance Concrete, Floride, FL, USA, 26–29 October 2003. [Google Scholar]

- Holm, T.A.; Bremner, T. State-of-the-Art Report on High-Strength, High-Durability Structural Low-Density Concrete for Applications in Severe Marine Environments; US Army Corps of Engineers: Washington, DC, USA, 2000. [Google Scholar]

- Harmon, K. Rugsundet Bridge, Norway; Expanded Shale, Clay and Slate Institute: Salt Lake City, UT, USA, 2002. [Google Scholar]

- Fergestad, S.; Rambjør, S. Raftsundet Bridge in Lofoten, Norway. A Cantilevered Bridge with a Lightweight Concrete Main Span of 298m. Available online: https://www.scribd.com/document/599509696/Raftsundet-Bridge-in-Lofoten-Norway-a-Cantilevered-Bridge-With-a-Lightweight-Concrete-Main-Span-of-298m (accessed on 3 August 2025).

- Castrodale, R.W.; Harmon, K. Lightweight Concrete for Long-Span Bridges. In Safety and Reliability of Bridge Structures; Mahmoud, K., Ed.; CRC Press: London, UK, 2009. [Google Scholar]

- Kvåle, K.A.; Øiseth, O.; Rønnquist, A.; Sigbjörnsson, R. Modal Analysis of a Floating Bridgewithout Side-Mooring. In Proceedings of the Conference Proceedings of the Society for Experimental Mechanics Series, Orlando, FL, USA, 2–5 February 2015; Springer: New York, NY, USA, 2015; Volume 2, pp. 127–136. [Google Scholar]

- Wiig, M. Lightweight Aggregates (LWA) in High-Strength Concrete Application in Long Span Bridge Construction. FIB note 1992/4. 1992. [Google Scholar]

- Raithby, K.D. A Review of the International Use of Lightweight Concrete in Highway Bridges; Federal Highway Administration (FHWA): London, UK, 1981. [Google Scholar]

- Mousa, A.; Mahgoub, M.; Hussein, M. Lightweight Concrete in America: Presence and Challenges. Sustain. Prod. Consum. 2018, 15, 131–144. [Google Scholar] [CrossRef]

- Vaysburd, A.M. Durability of Lightweight Concrete Bridge in Severe Environments. Concr. Int. 1996, 18, 33–38. [Google Scholar]

- Thompson, K.W.L. Use of Light Weight Concrete in California’s Bridges. In Proceedings of the 2008 Concrete Bridge Conference, St. Louis, MO, USA, 4–7 May 2008. [Google Scholar]

- Woodruff, G.B. Light Weight Concrete Pavement On The San Francisco Oakland Bridge. ACI J. Proc. 1938, 34, 225–240. [Google Scholar] [CrossRef] [PubMed]

- Middlebrook, R.F.; Mladjov, R.V. The San Francisco—Oakland Bay Bridge. Available online: https://www.structuremag.org/article/san-francisco-oakland-bay-bridge-second-crossing (accessed on 24 January 2023).

- Murugesh, G.; Cormier, K. When Lighter Is Better. ASPIRE 2007, 1, 20–24. [Google Scholar]

- Kodkani, S.S.; Szympruch, C.H.; Healy, R.J.; Pines, W.N.; Hoffmann, J.W. Lightweight Superstructure Replacement of the Bridge Carrying Baltimore Harbor Tunnel Throughway over Patapsco River Flats. In Proceedings of the International Bridge Conference, National Harbor, MD, USA, 10–12 June 2019; Engineers’ Society of Western Pennsylvania: Pittsburgh, PA, USA, 2019; pp. 19–35. [Google Scholar]

- Shasta Arch Bridge Project: Using Arcosa Lightweight Aggregate for High-Performance Concrete Solutions. Available online: https://arcosalightweight.com/case-studies/structural-lightweight-concrete/shasta-bridge (accessed on 5 January 2023).

- Ozyildirim, C.H.; Zickler, A.M.; Napier, C.S.; Castrodale, R.W. Lightweight Concrete Bridges In Virginia. In Proceedings of the National Bridge Conference, National Harbor, MD, USA, 5–8 June 2017. [Google Scholar]

- Lutz, J.G.; Scalia, D.J. Deck Widening and Replacement of Woodrow Wilson Memorial Bridge. PCI J. 1984, 29, 74–93. [Google Scholar] [CrossRef]

- Castrodale, R.W. Lightweight Concrete for Accelerated Bridge Construction. In Proceedings of the ABC Center at Florida International University (FIU), Miami, FL, USA 14 July 2011. [Google Scholar]

- Kassner, B.L.; Brown, M.C.; Schokker, A.J. Material Investigation of the Full-Depth, Precast Concrete Deck Panels of the Old Woodrow Wilson Bridge; Virginia Transportation Research Council (VTRC): Charlottesville, VA, USA, 2007. [Google Scholar]

- Abrahams, M.J. The Use of Lightweight Concrete for the George, P. Coleman Bridge Reconstruction—Yorktown, Virginia. In Proceedings of the International Symposium on Lightweight Concrete Bridges, Biarritz, France, 18–20 September 1996; Caltrans & Pacific Custom Materials: Sacramento, CA, USA, 1996. [Google Scholar]

- Prize Bridge Award: Movable Span Coleman Bridge. Mod. Steel Constr. 1998, 38, 60–65.

- Castrodale, R.W.; Robinson, G.M. Performance of Lightweight Concrete Bridge Decks. In Proceedings of the Concrete Bridge Conference, St. Louis, MO, USA, 4–7 May 2008; National Concrete Bridge Council (NCBC): St. Louis, MO, USA, 2008. [Google Scholar]

- Fisher, S.J.; Suarez, J.M.; Kerley, M. VDOT I-95 Accelerated Bridge Construction Project. In Proceedings of the National Accelerated Bridge Construction Conference, Miami, FL, USA, 3–5 December 2014; Florida International University: Miami, FL, USA, 2014; pp. 76–84. [Google Scholar]

- Barriers, M. I-95 ACCELERATED BRIDGE CONSTRUCTION RICHMOND, VA. Available online: https://www.lindsay.com/uploads/files/resources/397-i_95_va.pdf (accessed on 3 August 2025).

- Shane, J.; Strong, K.; Gransberg, D.D.; Ahn, J.; Allan, N.; Brisk, D.; Hunt, J.; Puerto, C.L.; Owens, J.; Scheepbouwer, E.; et al. Project Management Strategies for Complex Projects Case Study; Transportation Research Board: Washington, DC, USA, 2014. [Google Scholar]

- Nasser, G.D. Lord Delaware Bridge Replacement—Precast Concrete Replaces Steel in West Point, Va. PCI J. 2008, 53, 44–52. [Google Scholar] [CrossRef]

- Ozyildirim, C.; Davis, R.T. Bulb-T Beams with Self-Consolidating Concrete on Route 33 in Virginia. Transp. Res. Rec. 2007, 2020, 76–82. [Google Scholar] [CrossRef]

- Ozyildirim, C.H. Bulb-T Beams with Self Consolidating Concrete on the Route 33 Bridge Over the Pamunkey River in Virginia; Virginia Transportation Research Council (VTRC): Charlottesville, VA, USA, 2008. [Google Scholar]

- Ozyildirim, C. Evaluation of Lightweight High Performance Concrete in Bulb-T Beams and Decks in Two Bridges on Route 33 in Virginia Virginia; Virginia Transportation Research Council (VTRC): Charlottesville, VA, USA, 2009. [Google Scholar]

- Ozyildirim, C.H. Lightweight HPC on Route 106 Bridge in Virginia. HPC Bridge Views 2004, 3, 1–38. [Google Scholar]

- Waldron, C.J.; Thomas, C.E.; Adil, N.J.; Gomez, J.P. Demonstration of Use of High-Performance Lightweight Concrete in Bridge Superstructure in Virginia. J. Perform. Constr. Facil. 2005, 19, 146–154. [Google Scholar] [CrossRef]

- Nassar, A.J. Investigation of Transfer Length, Development Length, Flexural Strength and Prestress Loss Trend in Fully Bonded High Strength Lightweight Prestressed Girders. Master of Science in Civil Engineering; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 2002. [Google Scholar]

- HB-17 Standard Specification for Highway Bridges; American Association of State Highway Officials: Washington, DC, USA, 1996.

- Ozyildirim, C.; Gomez, J.P. First Bridge Structure with Lightweight High-Performance Concrete Beams and Deck in Virginia; Virginia Transportation Research Council (VTRC): Charlottesville, VA, USA, 2005. [Google Scholar]

- Paeglītis, A.; Zvejnieks, V.; Šahmenko, G. Light Weight Concrete Application in Latvian Bridges. In Proceedings of the Fib Symposium 2004, Avignon, France, 26–28 April 2004; pp. 198–199. [Google Scholar]

- Paeglītis, A.; Sahmenko, G. Light Weight Concrete Application in Bridges. In Proceedings of the International Conference on Concrete for Transportation Infrastructure, Dundee, UK, 5–7 July 2005; pp. 151–158. [Google Scholar]

- Paeglītis, A.; Sahmenko, G. Bridges with Lightweight Aggregate Concrete Structures. Balt. J. Road Bridge Eng. 2006, 1, 55–61. [Google Scholar]

- Paeglītis, A.; Lieckalniņš, A.; Jurka, I. Rehabilitation of a Historical Bridge over the Abava River in Latvia. In Proceedings of the Development in Short and Medium Span Bridge Engineering, Calgary, AB, Canada, 13 July 1998; pp. 1201–1209. [Google Scholar]

- Paeglītis, A. Extension of Lifetime of Multispan Concrete Arch Bridge. In Proceedings of the IABSE Symposium, Melbourne 2002: Towards a Better Built Environment—Innovation, Sustainability, Information Technology, International Association for Bridge and Structural Engineering (IABSE). Zurich, Switzerland, 11–13 September 2002; pp. 129–136. [Google Scholar]

- Lukoševiius, M. Serviceability Analysis of Reinforced Lightweight Concrete Elements. Master’s Thesis, Vilniaus Gediminas Technical University, Vilnius, Lithuania, 2018. [Google Scholar]

- Paeglītis, A. Two New Bridges over Highway near Riga. In Proceedings of the IABSE Symposium, Shanghai 2004: Metropolitan Habitats and Infrastructure, International Association for Bridge and Structural Engineering (IABSE), Zurich, Switzerland, 21–23 September 2004; pp. 76–77. [Google Scholar]

- Vion, P.; Poineau, D. L’expertise et La Réparation Du Pont En Maçonnerie Sur Le Loup à Villeneuve-Loubet. In Proceedings of the ARCH’01: Troisième Conference Internationale Sur Les Pontsen Arc, Paris, France, 3 September 2001; Presses de l’Ecolenationale des Ponts et Chaussées: Paris, France, 2001; pp. 261–268. [Google Scholar]

- Vion, P.; Poineau, D. Assessment, Repair and Widening of the Villeneuve-Loubet Bridge, France. Struct. Eng. Int. 2008, 4, 343–345. [Google Scholar] [CrossRef]

- Cathelain, B.; Falempin, M.; Edon, G.; Poineau, D.; Arnaud, G.; Jacquet, P.; Placidi, M.; Regallet, D. Le pont de Beaumont-sur-Oise (Val-d’Oise). Travaux. 1988, 636, 81–87. [Google Scholar]

- Barras, P.; de Matteis, D.; Derais, J.-F.; Duviard, M.; Guillot, D.; Lacombe, J.-M.; Lacoste, G.; Lecointre, D.; Ojeda, V.; Paillusseau, P.; et al. Prestressed Concrete Bridges Built Using the Cantilever Method: Design Guide; SETRA: Bagneux, France, 2003. [Google Scholar]

- Grube, H.; Knop, D. Widening of the Rhine River Bridge at Cologne-Deutz. Application of Pre-Stressed Lightweight Aggregate Concrete. Int. J. Lightweight Concr. 1980, 2, 71–79. [Google Scholar] [CrossRef]

- Lange, C.; Riutort, T.; Lebris, J.; Holand, I.; Hammer, T.A.; Fluge, F. Lightweight Concrete for a Cable-Stayed Bridge—The “Iroise” Bridge in Brest. In Proceedings of the Structural Lightweight Aggregate Concrete, Sandefjord, Norway, 16–18 September 2015; Norwegian Concrete Association: Sandefjord, Norway, 1995; pp. 287–298. [Google Scholar]

- Combault, J. Fixed Links and Long Span Bridges The New Challenges of Structural Engineering. Available online: http://abece.com.br/web/download/pdf/simposio/JCombault%20-%20Presentation%20-%20Part%203.pdf (accessed on 3 August 2025).

- Cusson, D. Chapter 9—Benefits and Case Studies Using Internal Curing of Concrete. In State-of-the-Art Report on Internal Curing of Concrete, RILEM TC-196; National Research Council Canada: Ottawa, ON, Canada, 2007; pp. 127–136. [Google Scholar]

- El Zareef, M.A.M. Conceptual and Structural Design of Buildings Made of Lightweight And Infra-Lightweight Concrete. Technol. Univ. Diss. 2010, 2010, 1–119. [Google Scholar] [CrossRef]

- Biondini, F.; Bontempi, F.; Frangopol, D.M.; Malerba, P.G. Reliability of Material and Geometrically Non-Linear Reinforced and Prestressed Concrete Structures. Comput. Struct. 2004, 82, 1021–1031. [Google Scholar] [CrossRef]

- Manhoudt, J.H.J. Koningspleijbridge, FIB Notes 1987/1. 1987; 5–6.

- Głomb, J.; Jendrzejek, S. Kształtowanie Ciągłych Konstrukcji Mostowych z Betonów o Różnych Cechach. Archiwum Inżynierii Lądowej 1983, XXIX, 233–241. [Google Scholar]

- Konopska-Piechurska, M.; Walkowiak, R.; Weretelnik, J. Zastosowanie Technologii Betonu Lekkiego Przy Realizacji Budowy Mostu Drogowego w Toruniu. Budownictwo. Technol. Archit. 2014, 1, 38–40. [Google Scholar]

- Salamak, M.; Markocki, B. Przebudowa i Wzmocnienie Estakady nad Rynkiem w Chorzowie. In Proceedings of the XXIV Seminarium Współczesne Metody Budowy Wzmacniania I Przebudowy Mostów, Poznań, Poland, 3–4 June 2014. [Google Scholar]

- Rybka, J.; Stana, M.; Markocki, B.; Kanawka, S.; Oleszek, R. Projekt Przebudowy Estakady nad Rynkiem w Chorzowie. In Proceedings of the XXIII Seminarium “Współczesne Metody Budowy Wzmacniania i Przebudowy Mostów, Poznań, Poland, 1 June 2013. [Google Scholar]

- Siwowski, T. Pierwsze Polskie Obiekty Mostowe Kompozytów FRP. Drogownictwo 2017, 11, 352–358. [Google Scholar]

- Siwowski, T. Przykłady Zastosowań Betonów Niekonwencjonalnych w Polskim Mostownictwie. Geoinżynieria Drog. 2005, 4, 40–46. [Google Scholar]

- Siwowski, T. Wspóczesne Mosty Podkarpacia. Drogownictwo 2016, 3, 75–82. [Google Scholar]

- Siwowski, T.; Kaleta, D.; Kulpa, M.; Własak, L. Projekt i Badania Pierwszego Polskiego Mostu z Kompozytów FRP. In Proceedings of the VII Ogólnopolska Konferencja Mostowców—Konstrukcjai Wyposażenie Mostów, Wisła, Poland, 28-29 May 2015. [Google Scholar]

- Siwowski, T.; Kulpa, M.; Rajchel, M. The Polish Experience in FRP Composite Bridge Construction. In Proceedings of the IABSE Symposium “Synergy of Culture and Civil Engineering—History and Challenges”, Ghent, Belgium, 14–16 April 2021; pp. 1–8. [Google Scholar]

- Dammyr, Ø.; Nilsen, B.; Thuro, K.; Grøndal, J. Possible Concepts for Waterproofing of Norwegian TBM Railway Tunnels. Rock. Mech. Rock. Eng. 2014, 47, 985–1002. [Google Scholar] [CrossRef]

- Choi, H.; Ma, S. An Optimal Lightweight Foamed Mortar Mix Suitable for Tunnel Drainage Carried out Using the Composite Lining Method. Tunn. Undergr. Space Technol. 2015, 47, 93–105. [Google Scholar] [CrossRef]

- He, K.; Guo, R.; Ma, Q.; Yan, F.; Lin, Z. The Study on Tunnel Fire Resistance Layer of Lightweight Aggregate Concrete Based on Finite Element Thermal Analysis. In Proceedings of the International Conference on Advances in Mechanical Engineering and Industrial Informatics, Kunming, China, 25–26 February 2015; pp. 1689–1694. [Google Scholar]

- Junek, V.; Kolísko, J.; Kroc, M.; Bradáčová, I. Developing Fire Resistant Construction for Tunnel Construction Using Lightweight Aggregate Concrete. Adv. Mat. Res. 2015, 1106, 172–176. [Google Scholar] [CrossRef]

- Rahman, F.U. Design and Construction of Submerged Floating Tunnel. The Constructor Buliding Ideas. Available online: https://theconstructor.org/transportation/design-construction-submerged-floating-tunnel/563263/#goog_rewarded (accessed on 3 August 2025).

- Popov, D.; Pervaiz, F.; Alqadi, M.; Raza, N.; Lim, S.-S. Feasibility Study of Submerged Floating Crossing; TU Delft Repository: Delft, The Netherlands, 2018. [Google Scholar]

- Qinxi, L.; Shuping, J.; Xiang, C. Experiment on Pressure Characteristics of Submerged Floating Tunnel with Different section Types Under Wave Condition. Pol. Marit. Res. 2018, 25, 54–60. [Google Scholar] [CrossRef]

- Mumbrú, V.C. Submerged Floating Tunnels: A Review and Study of Their Use for Strait Crossing. Engineering’s Thesis, Departament d’Enginyeria Civil i Ambiental, Barcelona, Spain, 2019. [Google Scholar]

- Bjerkås, M. Mooring Concept for Long Floating Bridges Ice Loads on Bridges. In Proceedings of the Strait Crossings, Bergen, Norway, 16–19 June 2013. [Google Scholar]

| Selected Keywords | Number of Phrases | ||

|---|---|---|---|

| (Scopus) | (LENS) | (WorldCat) | |

| Step 1 | |||

| concrete | 588,385 | 979,020 | 1,317,812 |

| bridge | 540,728 | 1,070,255 | 1,010,362 |

| aggregate | 456,831 | 873,820 | 598,455 |

| lightweight | 176,382 | 194,123 | 356,571 |

| Step 2 | |||

| concrete + bridge | 51,815 | 61,906 | 14,442 |

| concrete + aggregate | 55,453 | 69,796 | 22,776 |

| concrete + lightweight | 13,183 | 15,862 | 8751 |

| lightweight + aggregate | 9067 | 11,355 | 5515 |

| bridge + aggregate | 5002 | 10,488 | 555 |

| bridge + lightweight | 3244 | 3587 | 778 |

| Step 3 | |||

| concrete + aggregate + lightweight | 6361 | 7449 | 2427 |

| concrete + bridge + aggregate | 1658 | 1999 | 195 |

| concrete + bridge + lightweight | 1040 | 1047 | 204 |

| bridge + aggregate + lightweight | 314 | 379 | 63 |

| Step 4 | |||

| concrete + bridge + aggregate + lightweight | 265 | 294 | 0 |

| Component | Proportion 6 ksi (41.37 MPa) | Proportion 8 ksi (55.16 MPa) |

|---|---|---|

| Cement CEM III | 504 Ib (228.61 kg) | 671 Ib (304.36 kg) |

| Fly ash class C | 168 Ib (76.20 kg) | 316 Ib (143.34 kg) |

| Lightweight aggregate expanded clay | 1264 Ib (573.34 kg) | 1123 Ib (509.38 kg) |

| Sand | 1149 Ib (521.18 kg) | 1029 Ib (466.75 kg) |

| Water | 222 Ib (100 kg) | 247 Ib (112.04 kg) |

| Compression strength after 1 day | 4000 psi (27.57 MPa) | 5500 psi (37.92 MPa) |

| Compression strength after 28 day | 7200 psi (49.64 MPa) (laboratory) 7800 psi (53.78 MPa) (in field) | 8600 psi (59.29 MPa) (laboratory) 7500 psi (51.71 MPa) (in field) |

| Density | 118 pcf (1890 kg/m3) | 122 pcf (1954 kg/m3) |

| Density Class | D1.0 | D1.2 | D1.4 | D1.6 | D1.8 | D2.0 |

|---|---|---|---|---|---|---|

| Density range [kg/m3] | ≥800 ≤1000 | ≥1000 ≤1200 | ≥1200 ≤1400 | ≥1400 ≤1600 | ≥1600 ≤1800 | ≥1800 ≤2000 |

| Requirements for Concrete in Bridge Structure Construction | Applicable Conditions |

|---|---|

| Cement Class: | CEM I |

| Compressive strength class [MPa] | From C20/25 (from C30/37 for newly designed structures) |

| Exposure class: | XA, XC, XF, XS, XD |

| Consistency class | S2–S4 |

| Water | V1–V3 |

| Maximum aggregate grain size class (Dmax): | Dmax = 16 mm |

| Aggregate absorption: | Max 4%: |

| Frost resistance | F150 |

| Lp. | Name | Year of Completion | Type of Lightweight Aggregate | Bridge Components | Density [kg/m3] | Cube Strength [MPa] |

|---|---|---|---|---|---|---|

| 1 | Raftsundet | 1998 | Stalite + Natural sand | Full | 1950 | 60 |

| 2 | Sandhornøya | 1989 | Liapor + Natural sand | Deck + Beams | 1950 | 55 |

| 3 | Støvset | 1993 | Liapor + Natural sand | Full | 1924 | 55 |

| 4 | Stolma | 1998 | LECA + Natural sand | Full | 1950 | 60 |

| 5 | Norddalsfjord | 1987 | Liapor + Natural sand | Full | N/A | 45/35 |

| 6 | Nordhordaland | 1994 | LECA + Natural sand | Deck | 1900 | 55 |

| Liapor + Natural sand | Pontoons | |||||

| 7 | Rugsung | 2000 | Stalite + Natural sand | Full | 1950 | 60 |

| 8 | Boknasundet | 1990 | Liapor + Natural sand | Deck + Beams | 1950 | 60 |

| 9 | Bergsoysundet | 1992 | Liapor + Natural sand | Pontoons | 1900 | 53.6 |

| 10 | Grenland | 1996 | Liapor + Natural sand | Deck + Beams | N/A | 55 |

| 11 | Eidsvoll | 1992 | Liapor + Natural sand | Superstructure | 1880 | 55 |

| 12 | Sunday | 2003 | Stalite + Natural sand | Full | 1970 | 60 |

| No. | Name | Country | Year of Completion | Type of Lightweight Aggregate | Bridge Components | Density [kg/m3] |

|---|---|---|---|---|---|---|

| 1 | Coronado Bridge, CA | USA | 1969 | Expanded shale + Natural sand | Full | 1842 |

| 2 | Antioch Bridge, CA | USA | 1978 | Baypor F-43 + Natural sand | Full | 1842 |

| 3 | Arthur Ravenel Jr. Bridge (Cooper River Bridge),SC | USA | 1992 | Solite/Stalite + Natural Sand | Full | 1842 |

| 4 | Brooklyn Bridge, NY | USA | 1999 | Solite + Natural sand | Deck | 1890 |

| 5 | Neuse River Bridge, NC | USA | 1999 | Stalite + Natural sand | Full | 1842 |

| 6 | I-95 Bridge over James River, Va | USA | 2002 | Solite + Natural sand | Deck + Superstructure | 1842 |

| 7 | I-95 Bridges North of Downtown, Va | USA | 2014 | Solite + Natural sand | Deck | 1842 |

| 8 | Benicia-Martinez Bridge, CA | USA | 2007 | Stalite + Natural sand | Full | 2002 |

| 9 | Skagit River Bridge, WA | USA | 2013 | Stalite + Natural sand | Emergency repair | 2130/1954 |

| 10 | San Francisco-Oakland Bay Bridge | USA | 1961 | Ceramsite + Natural sand | Deck | 1522 |

| 11 | I-895 Bridge over the Patapsco River Flats—Baltimore, MD | USA | 2019 | Stalite + Natural sand | Deck + Superstructure | 1602 |

| 12 | Shasta Arch Bridge on Southbound I-5—Shasta County, CA | USA | 2018 | Ceramsite + Natural sand | Box grider | 1922 |

| 13 | Route 198 (Dutton Road) Bridge over Harper Creek—Gloucester County, VA | USA | 2016 | Stalite + Natural sand | Grider + Deck | 1842 |

| 14 | Woodrow Wilson Bridge over the Potomac River—Washington, D.C. | USA | 1983 | Stalite + Natural sand | Remove Deck | 1842 |

| 15 | Coleman Bridge over the York River—Yorktown, VA | USA | 1983 | Stalite + Natural sand | Deck | 1842 |

| 16 | Beach Bridge—Norht Haven, ME | USA | 2013 | Stalite + Natural sand | Griders | 1922 |

| 17 | Route 33 Bridges over the Mattaponi and Pamunkey Rivers—West Point, VA | USA | 2006/2007 | Stalite + Natural sand | Grider/Deck | 2002/1922 |

| 18 | Silver Creek Overpass Bridge Utah | USA | 1968 | Expanded shale + Natural sand | Deck | 1762 |

| 19 | Heart of America Bridge, Missouri | USA | 1985 | Buildex + Kaw river sand | Deck | 1762 |

| 20 | Ohio Turnpike Twin Bridges, Ohio | USA | 1984 | Haydite + Natural sand | Deck | 1858 |

| 21 | Sebastian Inlet Bridge, Florida | USA | 1964 | Solite + Natural sand | Full | 1842 |

| 22 | William Preston Lane Jr. Bridge, Maryland (East boud) | USA | 1952 | Solite + Natural sand | Full | 1650 |

| 23 | William Preston Lane Jr. Bridge, Maryland (East boud) | USA | 1988 | Solite + Natural sand | Remove Deck | 1682 |

| 24 | Sebastian Inlet Bridge, Florida | USA | 1964 | Solite + Natural sand | Full | 1842 |

| 25 | Wabash River Bridge, Indiana | USA | 1994 | Expanded shale | Griders | 2002 |

| 26 | Pulaski Skyway, NJ | USA | 2018 | N/A | Deck | 1922 |

| 27 | Ben Sawyer Bridge—Sullivan’s Island, SC | USA | 2010 | N/A | Deck | 1842 |

| 28 | Massaponax Church Road (Route 608) Bridge over Interstate 95—Spotsylvania County, VA | USA | 2009 | N/A | Deck | 1922 |

| 29 | Marc Basnight Bridge over the Oregon Inlet—Outer Banks, NC | USA | 2019 | N/A | Deck | 1922 |

| 30 | Francis Scott Key Bridge—Baltimore, MD | USA | 1977 | N/A | Deck | 1794 |

| 31 | Route 22 Bridge over the Kentucky River—Gratz, KY | USA | 2010 | N/A | Griders | 2002 |

| 32 | I-85 Ramp over State Route 34—Newnan, GA | USA | 2010 | N/A | Griders | 1922 |

| 33 | Boulevard (Route 161) Bridge across the James River—Richmond, VA | USA | 1959 | N/A | Deck | 1762 |

| 34 | Walt Whitman Bridge Philadelphia, PA | USA | 2007 | Solite + Natural sand | Remove Deck | N/A |

| 35 | William Preston Lane Jr. Bridge, Maryland (West bound) | USA | 1975 | Norlite + Natural sand | FULL | N/A |

| 36 | Parrotts Ferry Bridge, CA | USA | 1979 | N/A | Full | N/A |

| 37 | Sam White Bridge, UT | USA | 2011 | N/A | Full | N/A |

| 38 | Thaddeus Kosciusko Bridge (I-87), NY | USA | 2013 | N/A | Deck | N/A |

| 39 | I-40 Bridge over the French Broad River, TN | USA | 2015 | N/A | Full | N/A |

| 40 | US 15/29 Bridge over Broad Run near Gainesville, VA | USA | 2007 | N/A | Deck | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piechaczek, M.; Ostrowski, K.A.; Furtak, K. Lightweight Aggregate Concrete with Regard to Bridge Structures—State of the Art. Materials 2025, 18, 3874. https://doi.org/10.3390/ma18163874

Piechaczek M, Ostrowski KA, Furtak K. Lightweight Aggregate Concrete with Regard to Bridge Structures—State of the Art. Materials. 2025; 18(16):3874. https://doi.org/10.3390/ma18163874

Chicago/Turabian StylePiechaczek, Marcin, Krzysztof Adam Ostrowski, and Kazimierz Furtak. 2025. "Lightweight Aggregate Concrete with Regard to Bridge Structures—State of the Art" Materials 18, no. 16: 3874. https://doi.org/10.3390/ma18163874

APA StylePiechaczek, M., Ostrowski, K. A., & Furtak, K. (2025). Lightweight Aggregate Concrete with Regard to Bridge Structures—State of the Art. Materials, 18(16), 3874. https://doi.org/10.3390/ma18163874