Fretting Behavior of Biomimetic-Textured Silicone Rubber Under Varying Wetting Conditions

Highlights

- Fretting behavior of the textured silicone rubber is studied in wet environments.

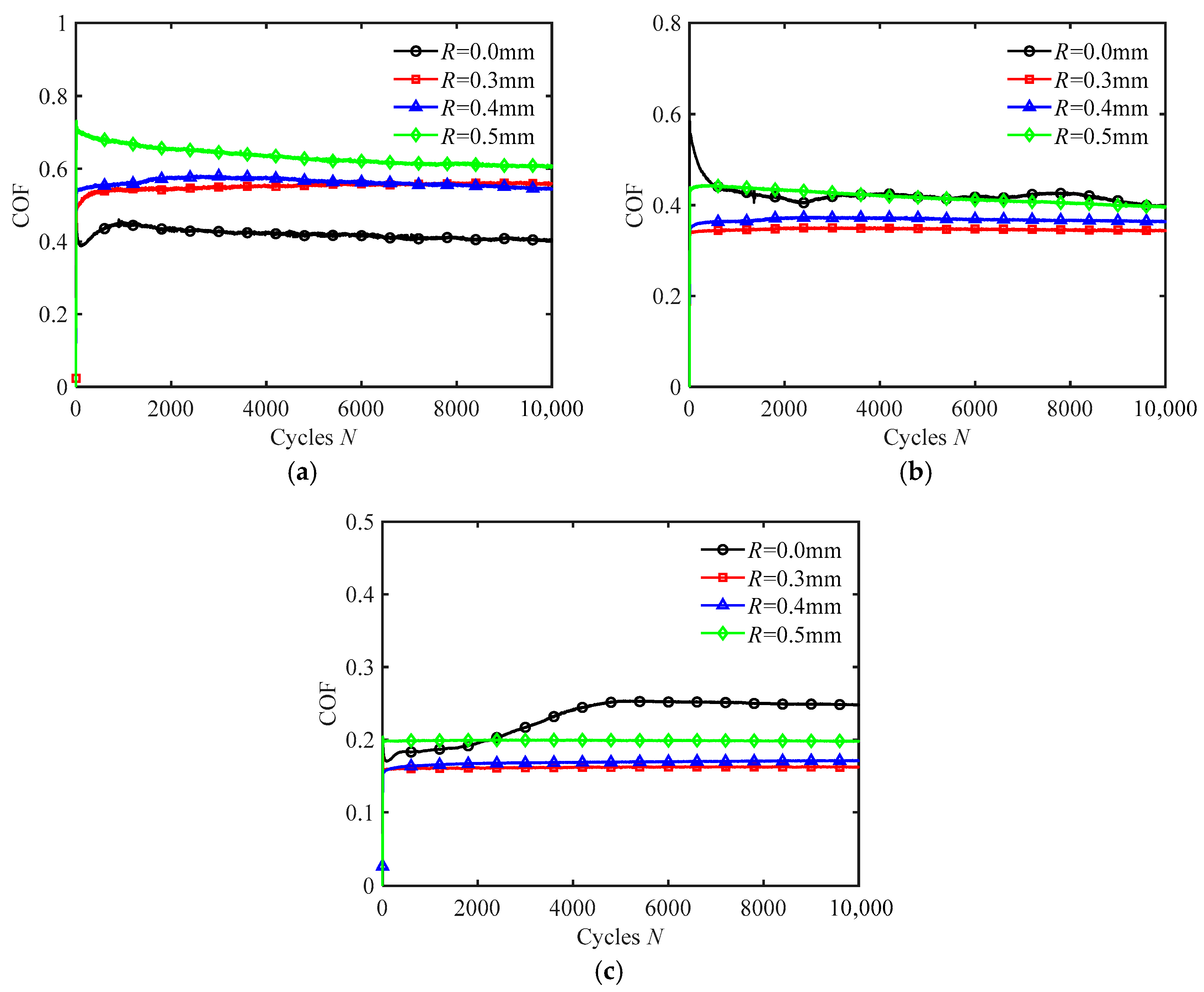

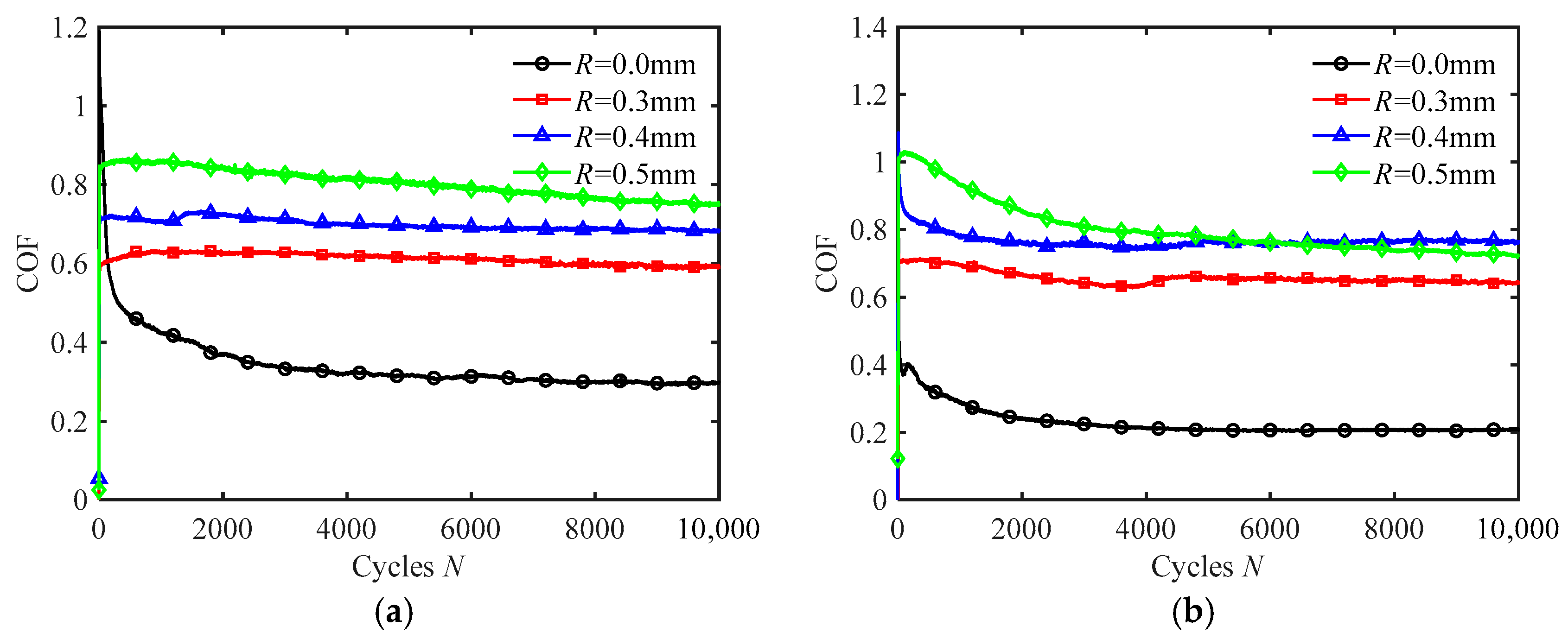

- The COF exhibits an upward trend with increasing texture dimensions.

- With increasing displacement amplitude, the COF of the smooth surface decreases gradually, while the COF of the textured surface increases.

Abstract

1. Introduction

2. Materials and Methods

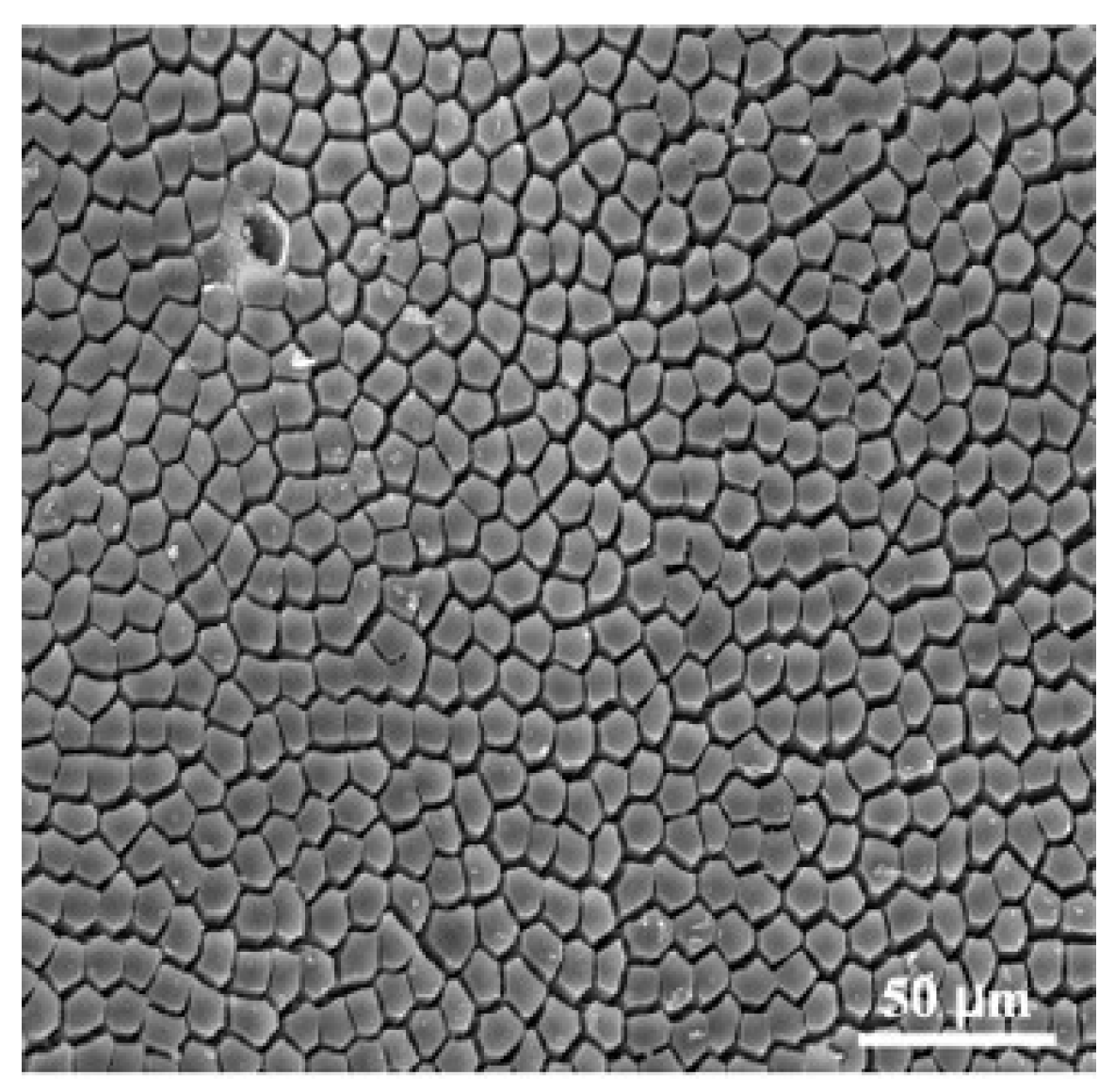

2.1. Materials of Experimental Samples and Preparation of Surface Texture

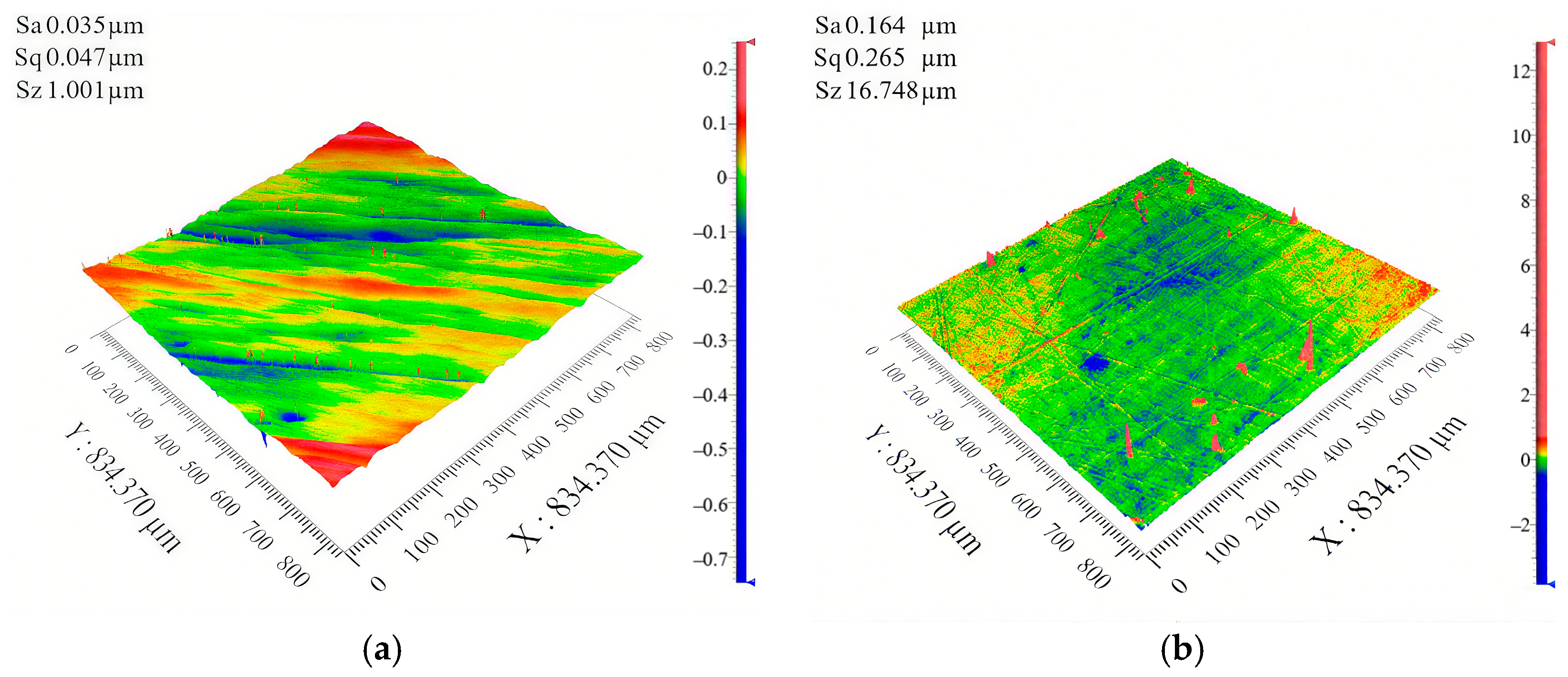

2.2. 3D Morphology Characterization

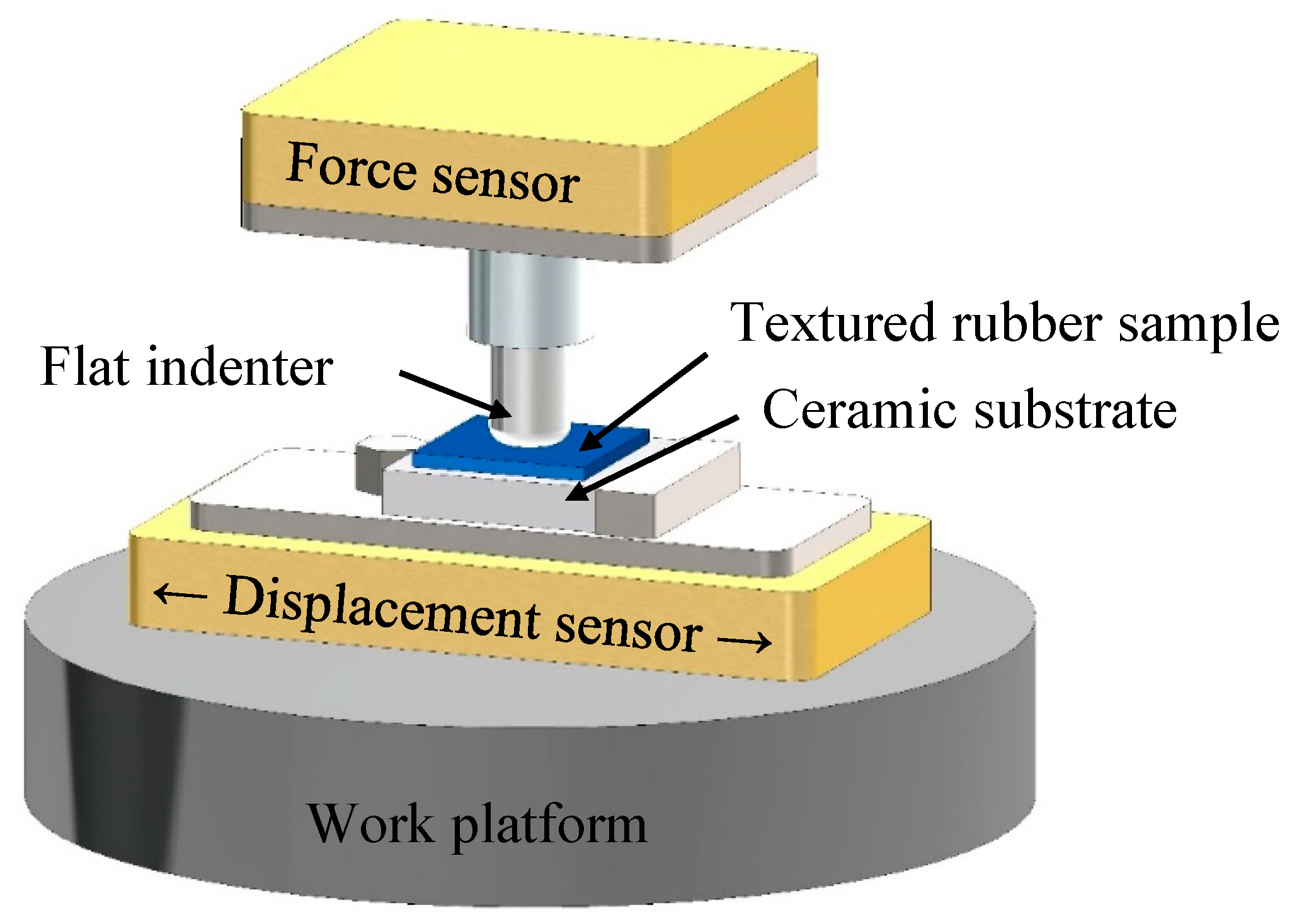

2.3. Fretting Test

3. Results and Discussion

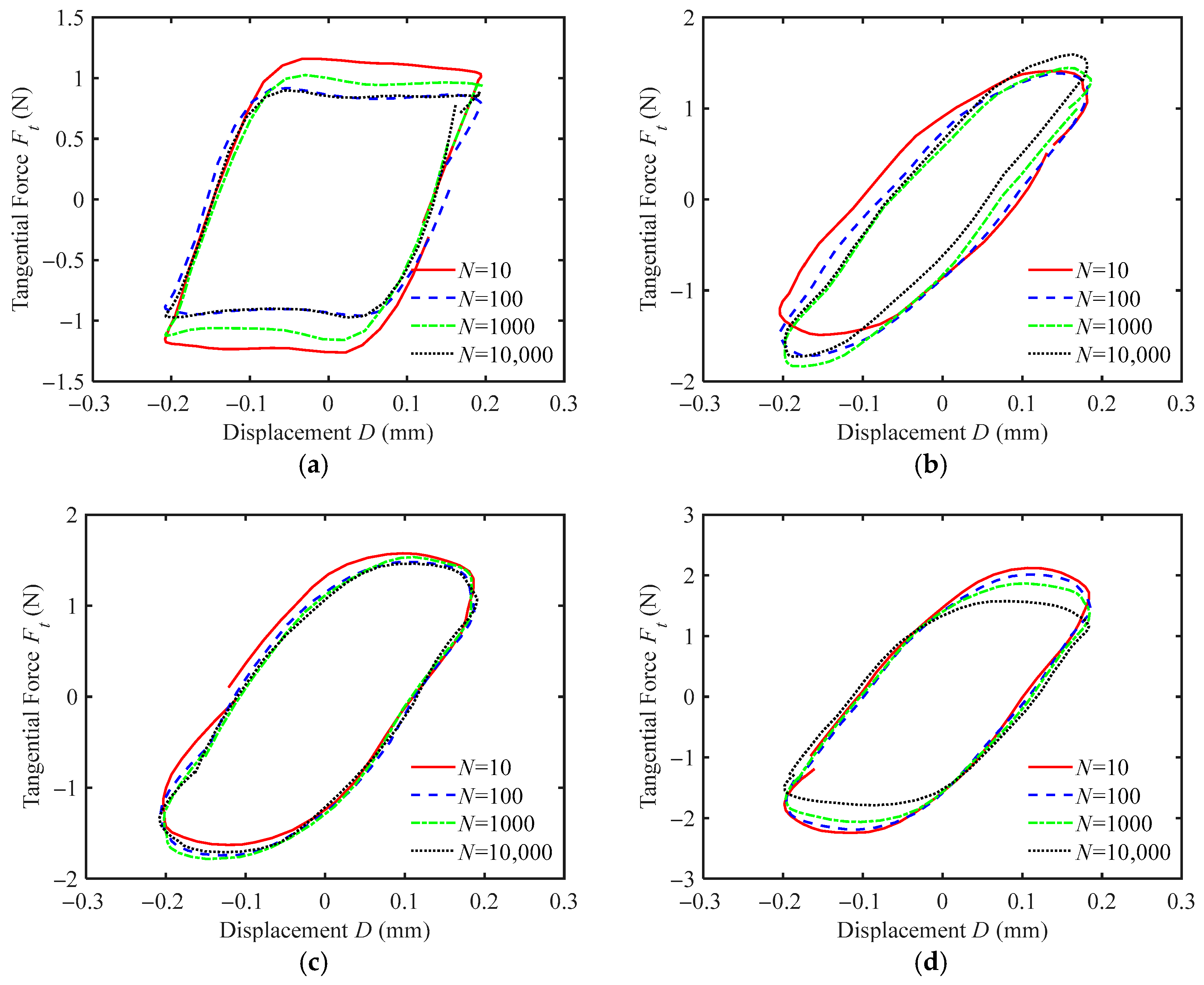

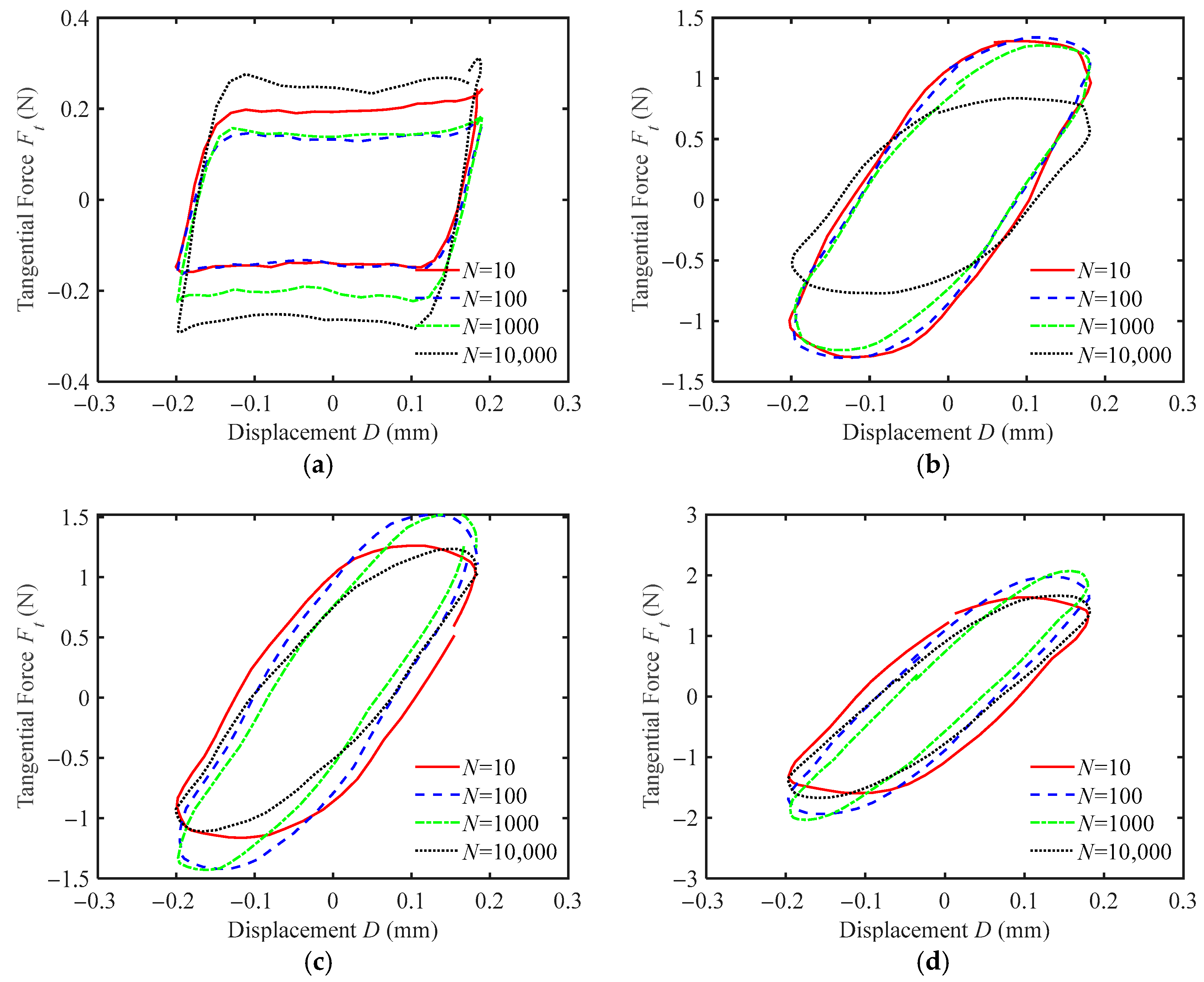

3.1. Ft-D Curves

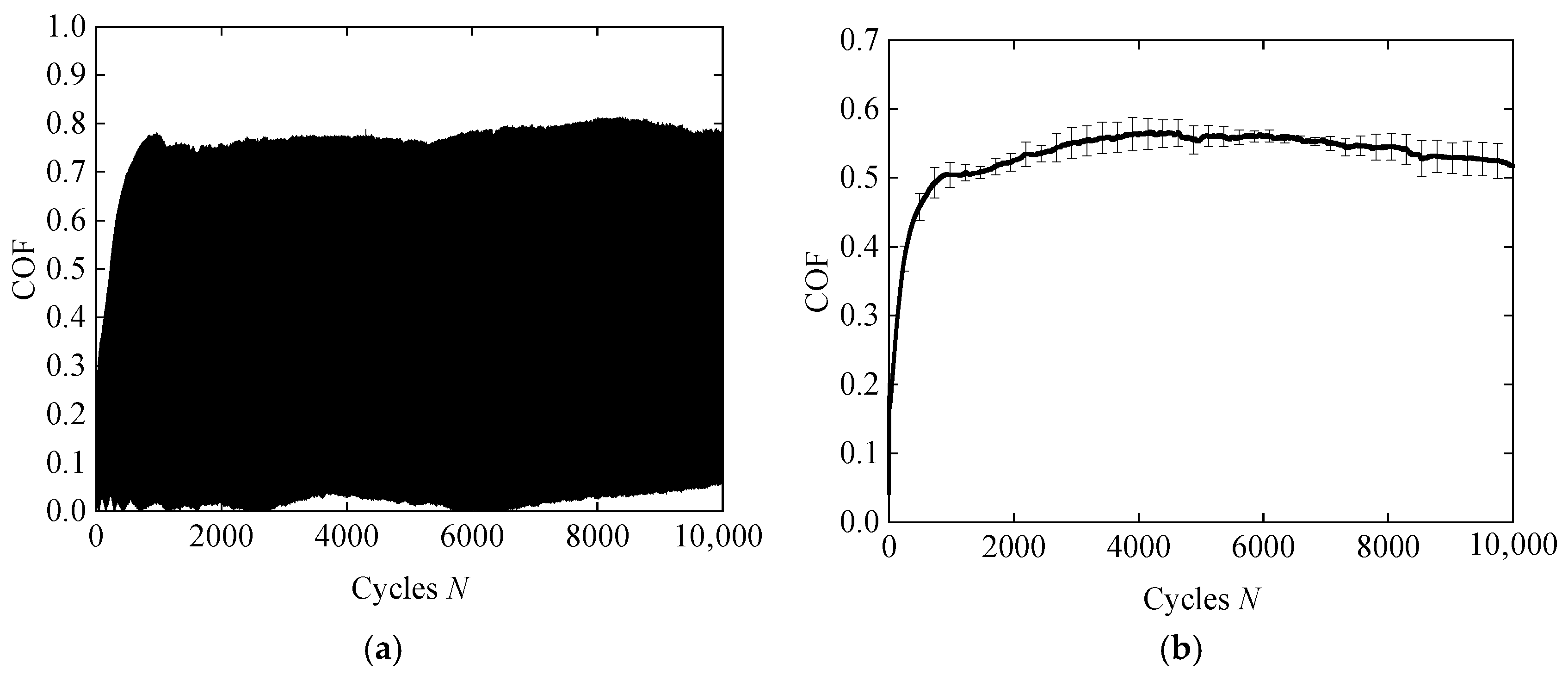

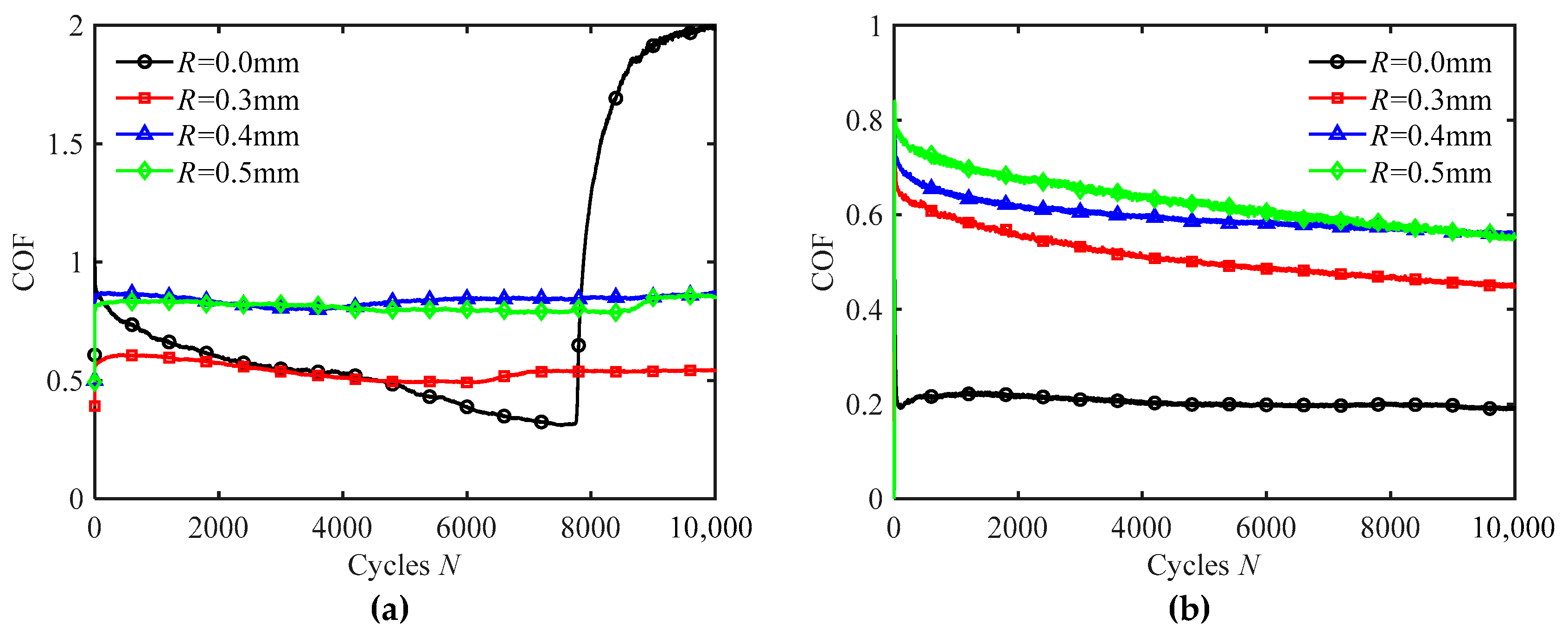

3.2. COF Curves

4. Conclusions

- (1)

- Texture size has little effect on the fretting regime for three different sizes: R = 0.3 mm, 0.4 mm, and 0.5 mm;

- (2)

- For a small normal force or high frequency, the COF of the textured surface is larger than that of the smooth surface. The COF exhibits an upward trend with increasing texture dimensions;

- (3)

- For a smooth or textured surface, the COF decreases as the normal force or frequency increases. With increasing displacement amplitude, the COF of the smooth surface decreases gradually, while the COF of the textured surface increases;

- (4)

- At low frequency and water wetting conditions, the COF of textured surfaces remains stable throughout the fretting process, while the COF of the smooth surface first decreases and then sharply increases, eventually exceeding the COF of the textured surfaces;

- (5)

- Under oil wetting conditions, the COF of the smooth surface remains relatively stable at low frequency, but the COF of textured surfaces first decreases and then stabilizes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| COF | coefficient of friction |

| PDMS | polydimethylsiloxane |

References

- Kim, D.W.; Baik, S.Y.; Min, H.H.; Chun, S.W.; Lee, H.J.; Kim, K.H.; Lee, J.Y.; Pang, C.H. Highly permeable skin patch with conductive hierarchical architectures inspired by amphibians and octopi for omnidirectionally enhanced wet adhesion. Adv. Funct. Mater. 2019, 29, 1807614. [Google Scholar] [CrossRef]

- Chen, Y.P.; Meng, J.X.; Gu, Z.; Wan, X.Z.; Jiang, L.; Wang, S.T. Bioinspired multiscale wet adhesive surfaces: Structures and controlled adhesion. Adv. Funct. Mater. 2020, 30, 1905287. [Google Scholar] [CrossRef]

- Zhang, L.W.; Chen, H.W.; Guo, Y.R.; Wang, Y.; Jiang, Y.G.; Zhang, D.Y.; Ma, L.R.; Luo, J.B.; Jiang, L. Micro-nano hierarchical structure enhanced strong wet friction surface inspired by tree frogs. Adv. Sci. 2020, 7, 2001125. [Google Scholar] [CrossRef]

- Ivanović, L.; Vencl, A.; Stojanović, B.; Marković, B. Biomimetics design for tribological applications. Tribol. Int. 2018, 40, 448–456. [Google Scholar] [CrossRef]

- Sun, J.Y.; Bhushan, B. Nanomanufacturing of bioinspired surfaces. Tribol. Int. 2019, 129, 67–74. [Google Scholar] [CrossRef]

- Bixler, G.D.; Bhushan, B. Fluid drag reduction with shark-skin riblet inspired microstructured surfaces. Adv. Funct. Mater. 2013, 23, 4507–4528. [Google Scholar] [CrossRef]

- Koch, K.; Bhushan, B.; Jung, Y.C.; Barthlott, W. Fabrication of artificial lotus leaves and significance of hierarchical structure for superhydrophobicity and low adhesion. Soft Matter 2009, 5, 1386–1393. [Google Scholar] [CrossRef]

- Ando, Y.; Sumiya, T. Friction properties of micro/nanogroove patterns in lubricating conditions. Tribol. Int. 2020, 151, 106428. [Google Scholar] [CrossRef]

- Federle, W.; Barnes, W.J.P.; Baumgartner, W.; Drechsler, P.; Smith, J.M. Wet but not slippery: Boundary friction in tree frog adhesive toe pads. J. R. Soc. Interface 2006, 3, 689–697. [Google Scholar] [CrossRef]

- Autumn, K.; Peattie, A.M. Mechanisms of adhesion in geckos. Integr. Comp. Biol. 2002, 42, 1081–1090. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Shi, L.P.; Wang, X.L. Physical mechanisms behind the wet adhesion: From amphibian toe-pad to biomimetics. Colloids Surf. B Biointerfaces 2021, 199, 111531. [Google Scholar] [CrossRef]

- Varenberg, M.; Gorb, S.N. Hexagonal surface micropattern for dry and wet friction. Adv. Mater. 2009, 21, 483–486. [Google Scholar] [CrossRef]

- Hossain, K.R.; Wu, J.Y.; Xu, X.; Cobra, K.; Jami, M.M.; Ahmed, M.B.; Wang, X.L. Tribological bioinspired interfaces for 3D printing. Tribol. Int. 2023, 188, 108904. [Google Scholar] [CrossRef]

- Li, J.F.; Zhou, F.; Wang, X.L. Modify the friction between steel ball and PDMS disk under water lubrication by surface texturing. Meccanica 2011, 46, 499–507. [Google Scholar] [CrossRef]

- Hao, T.Z.; Xiao, H.P.; Liu, S.H.; Liu, Y.B. Fingerprint-inspired surface texture for the enhanced tip pinch performance of a soft robotic hand in lubricated conditions. Friction 2022, 11, 1349–1358. [Google Scholar] [CrossRef]

- Hao, T.Z.; Xiao, H.P.; Liu, Y.B.; Pang, D.Z.; Liu, S.H. Gripping performance of soft grippers with fingerprint-like surface texture for objects with slippery surfaces. Tribol. Int. 2023, 189, 108992. [Google Scholar] [CrossRef]

- Xie, J.; Li, M.; Dai, Q.W.; Huang, W.; Wang, X.L. Key parameters of biomimetic patterned surface for wet adhesion. Int. J. Adhes. Adhes. 2018, 82, 72–78. [Google Scholar] [CrossRef]

- Drotlef, D.M.; Stepien, L.; Kappl, M.; Barnes, W.J.P.; Butt, H.J.; del Campo, A. Insights into the adhesive mechanisms of tree frogs using artificial mimics. Adv. Funct. Mater. 2013, 23, 1137–1146. [Google Scholar] [CrossRef]

- Li, M.; Huang, W.; Wang, X.L. Bioinspired, peg-studded hexagonal patterns for wetting and friction. Biointerphases 2015, 10, 031008. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.W.; Zhang, L.W.; Zhang, D.Y.; Zhang, P.F.; Han, Z.W. Bioinspired surface for surgical graspers based on the strong wet friction of tree frog toe pads. ACS Appl. Mater. Inter. 2015, 7, 13987–13995. [Google Scholar] [CrossRef]

- Iturri, J.; Xue, L.J.; Kappl, M.; García-Fernández, L.; Barnes, W.J.P.; Butt, H.J.; del Campo, A. Torrent frog-inspired adhesives: Attachment to flooded surfaces. Adv. Funct. Mater. 2015, 25, 1499–1505. [Google Scholar] [CrossRef]

- Waterhouse, R.B. Fretting Corrosion; Pergamon Press: London, UK, 1972. [Google Scholar]

- Li, B.; Li, P.D.; Zhou, R.H.; Feng, X.Q.; Zhou, K. Contact mechanics in tribological and contact damage-related problems: A review. Tribol. Int. 2022, 171, 107534. [Google Scholar] [CrossRef]

- Okamoto, M.; Jibiki, T.; Ito, S.; Motoda, T. Role of cross-grooved type texturing in acceleration of initial running-in under lubricated fretting. Tribol. Int. 2016, 100, 126–131. [Google Scholar] [CrossRef]

- Cao, W.H.; Hu, T.C.; Fan, H.Z.; Ding, Q.; Hu, L.T. Fretting behaviour of textured Ti-6Al-4V alloy under oil lubrication. Int. J. Surf. Sci. Eng. 2021, 15, 165–184. [Google Scholar] [CrossRef]

- Wang, J.F.; Xue, W.H.; Gao, S.Y.; Li, S.; Duan, D.L. Effect of groove surface texture on the fretting wear of Ti-6Al-4V alloy. Wear 2021, 486, 204079. [Google Scholar] [CrossRef]

- Su, J.; Zhang, T.F.; Ke, L.L. Fretting wear behavior of silicone rubber under quartz sand abrasives. Wear 2025, 564, 205721. [Google Scholar] [CrossRef]

- Liu, R.T.; Su, J.; Zhang, T.F.; Ke, L.L. Fretting Wear behaviors of silicone rubber under dry friction and different lubrication conditions. Materials 2024, 17, 2598. [Google Scholar] [CrossRef]

- Shit, S.C.; Shah, P. A review on silicone rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Murarash, B.; Itovich, Y.; Varenberg, M. Tuning elastomer friction by hexagonal surface patterning. Soft Matter 2011, 7, 5553. [Google Scholar] [CrossRef]

- Cai, C.; Chen, Z.; Chen, Y.J.; Li, H.; Yang, Z.; Liu, H.Z. Mechanisms and applications of bioinspired underwater/wet adhesives. J. Polym. Sci. 2021, 59, 2911–2945. [Google Scholar] [CrossRef]

- Thirunavukkarasu, N.; Peng, S.Q.; Gunasekaran, H.B.; Yang, Z.; Wu, L.X.; Weng, Z.X. Responsive friction modulation of 3D printed elastomeric bioinspired structures. Tribol. Int. 2022, 175, 107823. [Google Scholar] [CrossRef]

- Zhong, Y.H.; Zheng, L.; Gao, Y.H.; Liu, Z.N. Numerical simulation and experimental investigation of tribological performance on bionic hexagonal textured surface. Tribol. Int. 2019, 129, 151–161. [Google Scholar] [CrossRef]

- Steinier, J.; Termonia, Y.; Deltour, J. Smoothing and differentiation of data by simplified least square procedure. Anal. Chem. 1972, 44, 1906–1909. [Google Scholar] [CrossRef] [PubMed]

- ASTM G204-21; Standard Test Method for Damage to Contacting Solid Surfaces under Fretting Conditions. ASTM International: West Conshohocken, PA, USA, 2021.

- Baek, D.K.; Khonsari, M.M. Friction and wear of a rubber coating in fretting. Wear 2005, 258, 898–905. [Google Scholar] [CrossRef]

- Shu, Y.J.; Ke, L.L.; Su, J.; Shen, F. Experimental studies on fretting wear behavior of pvdf piezoelectric thin films. Materials 2021, 14, 734. [Google Scholar] [CrossRef]

- Darko, C. The link between swelling ratios and physical properties of EPDM rubber compound having different oil amounts. J. Polym. Res. 2022, 29, 325. [Google Scholar] [CrossRef]

- Valentín, J.L.; Carretero-González, J.; Mora-Barrantes, I.; Chassé, W.; Saalwächter, K. Uncertainties in the determination of cross-link density by equilibrium swelling experiments in natural rubber. Macromolecules 2008, 41, 4717–4729. [Google Scholar] [CrossRef]

- Chu, H.Z.; Liu, D.; Cui, Z.W.; Wang, K.; Qiu, G.X.; Liu, G.Y. Effect of crosslink density on solubility parameters of styrene butadiene rubber and the application in pre-screening of new potential additives. Polym. Test. 2020, 81, 106253. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Su, J.; Ke, L.; Bai, S.; Yu, G. Fretting Behavior of Biomimetic-Textured Silicone Rubber Under Varying Wetting Conditions. Materials 2025, 18, 3861. https://doi.org/10.3390/ma18163861

Zhang T, Su J, Ke L, Bai S, Yu G. Fretting Behavior of Biomimetic-Textured Silicone Rubber Under Varying Wetting Conditions. Materials. 2025; 18(16):3861. https://doi.org/10.3390/ma18163861

Chicago/Turabian StyleZhang, Tengfei, Jie Su, Liaoliang Ke, Sichun Bai, and Guojun Yu. 2025. "Fretting Behavior of Biomimetic-Textured Silicone Rubber Under Varying Wetting Conditions" Materials 18, no. 16: 3861. https://doi.org/10.3390/ma18163861

APA StyleZhang, T., Su, J., Ke, L., Bai, S., & Yu, G. (2025). Fretting Behavior of Biomimetic-Textured Silicone Rubber Under Varying Wetting Conditions. Materials, 18(16), 3861. https://doi.org/10.3390/ma18163861