Challenges in Temperature Measurement in Hot Forging Processes: Impact of Measurement Method Selection on Accuracy and Errors in the Context of Tool Life and Forging Quality

Abstract

1. Introduction

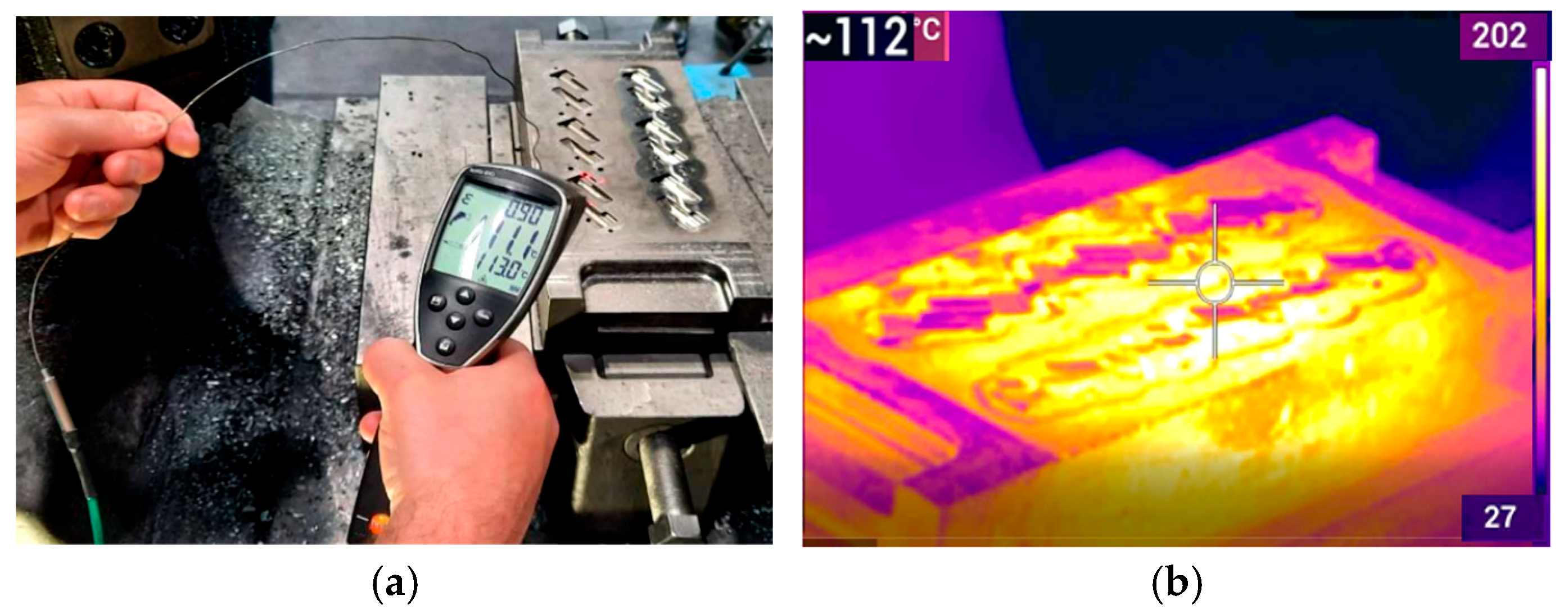

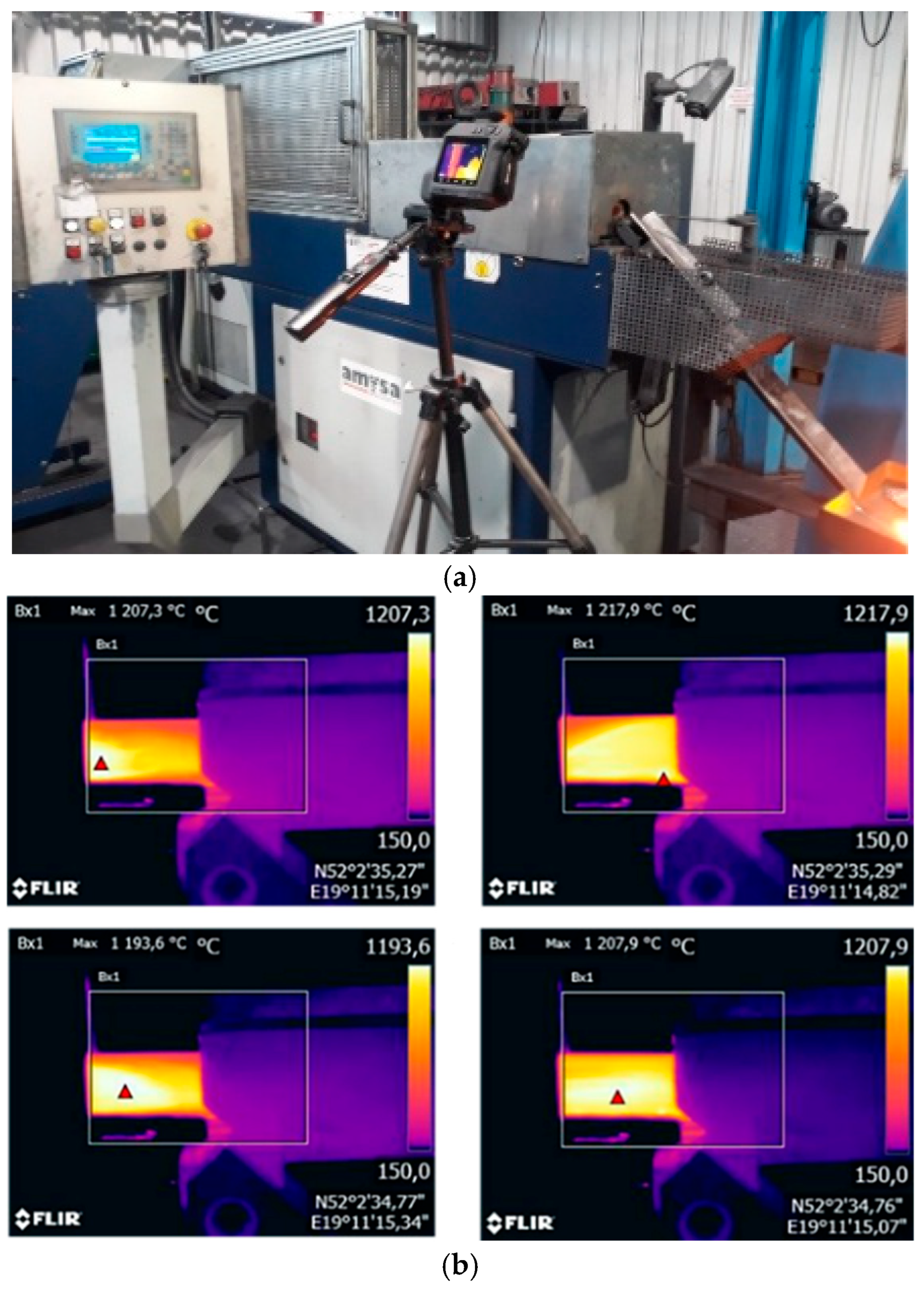

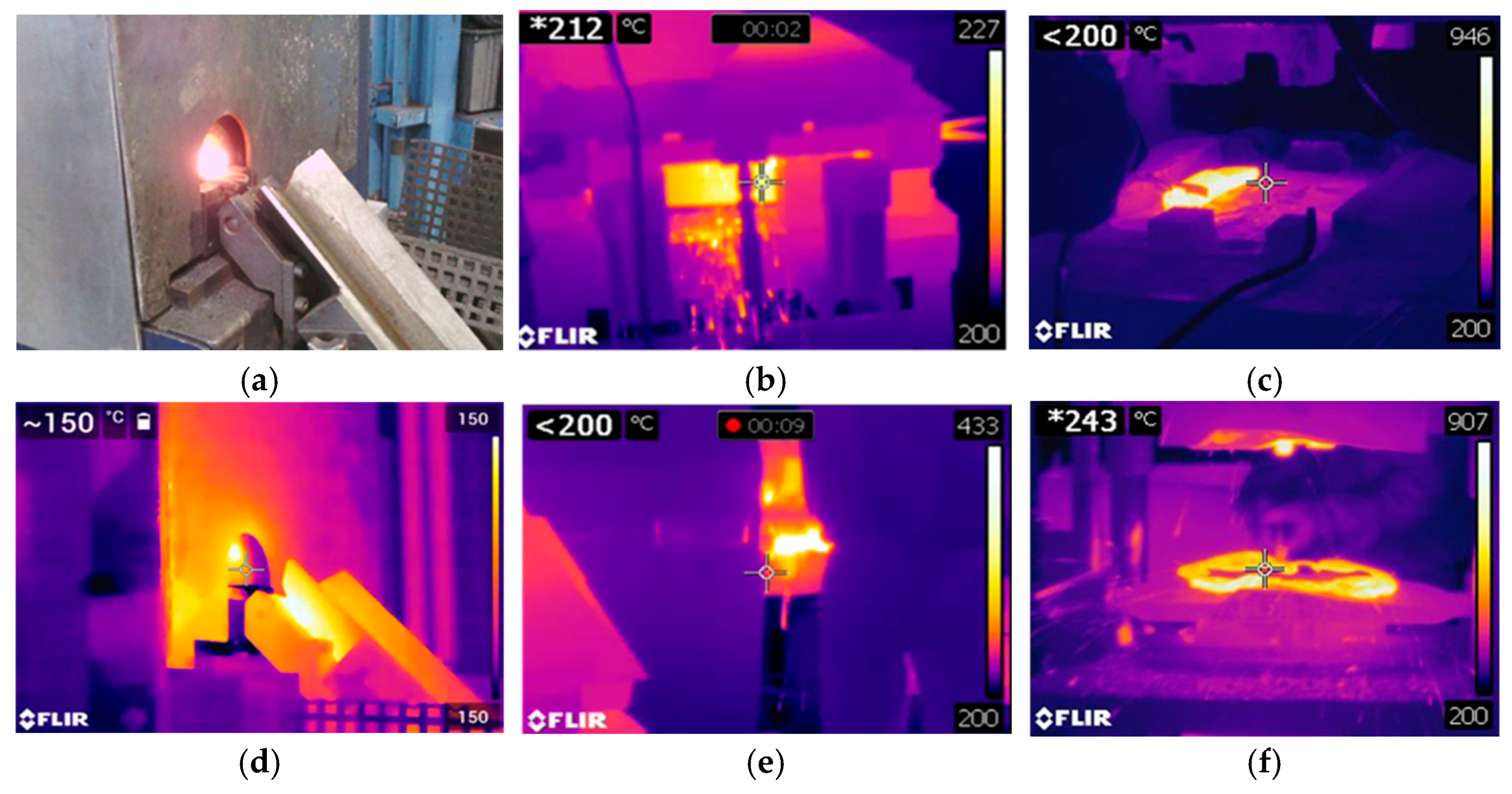

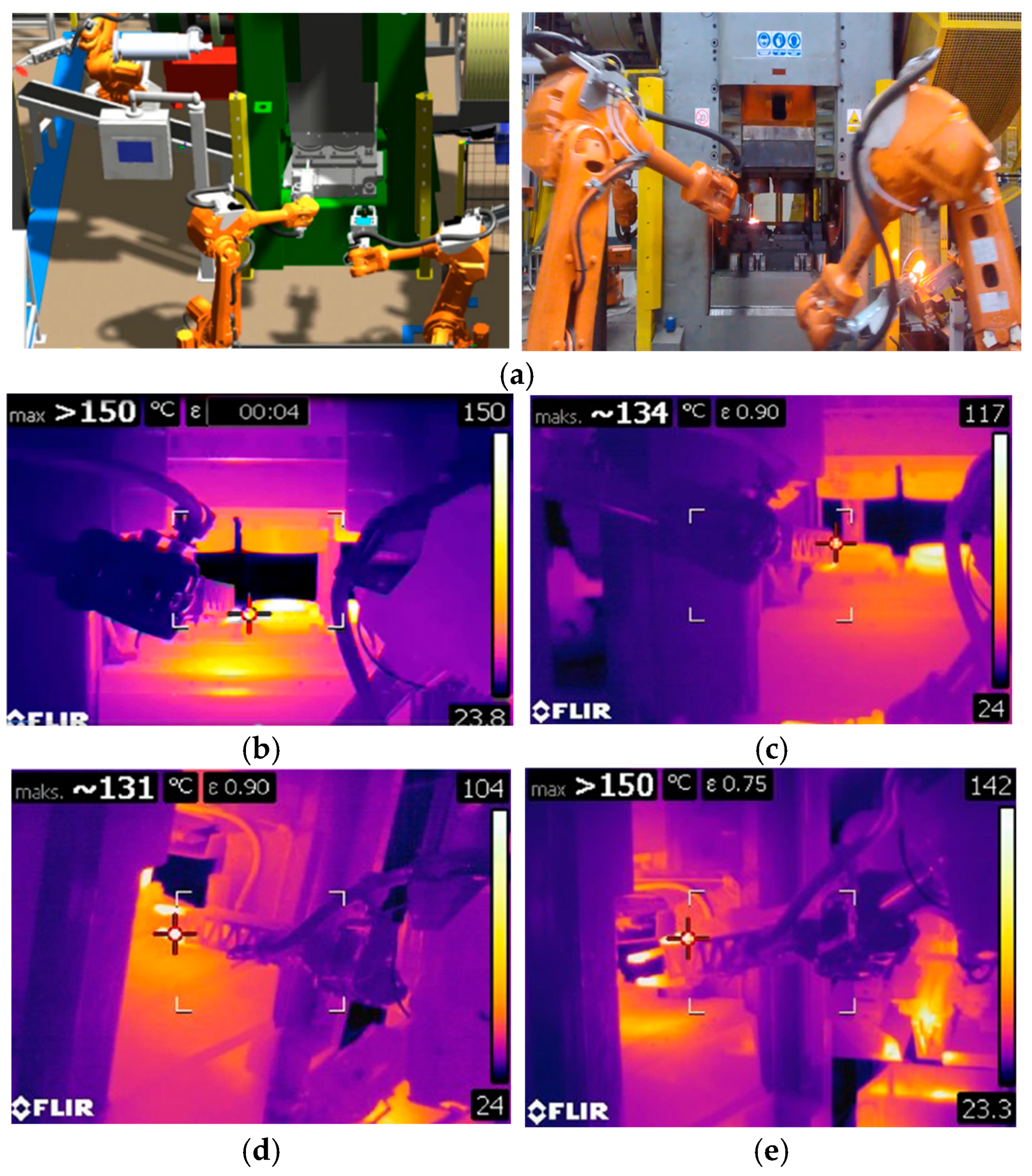

2. Materials and Methods

- Testo 830-T2 laser pyrometer with a K-type thermocouple (accuracy ±1.5 °C);

- MCR-type temperature recorder with K-type thermocouples (sampling rate 1 Hz);

- Flir T540 thermal imaging camera (spectral range 7.5–14 µm; accuracy ±2 °C).

3. Research and Results Discussion

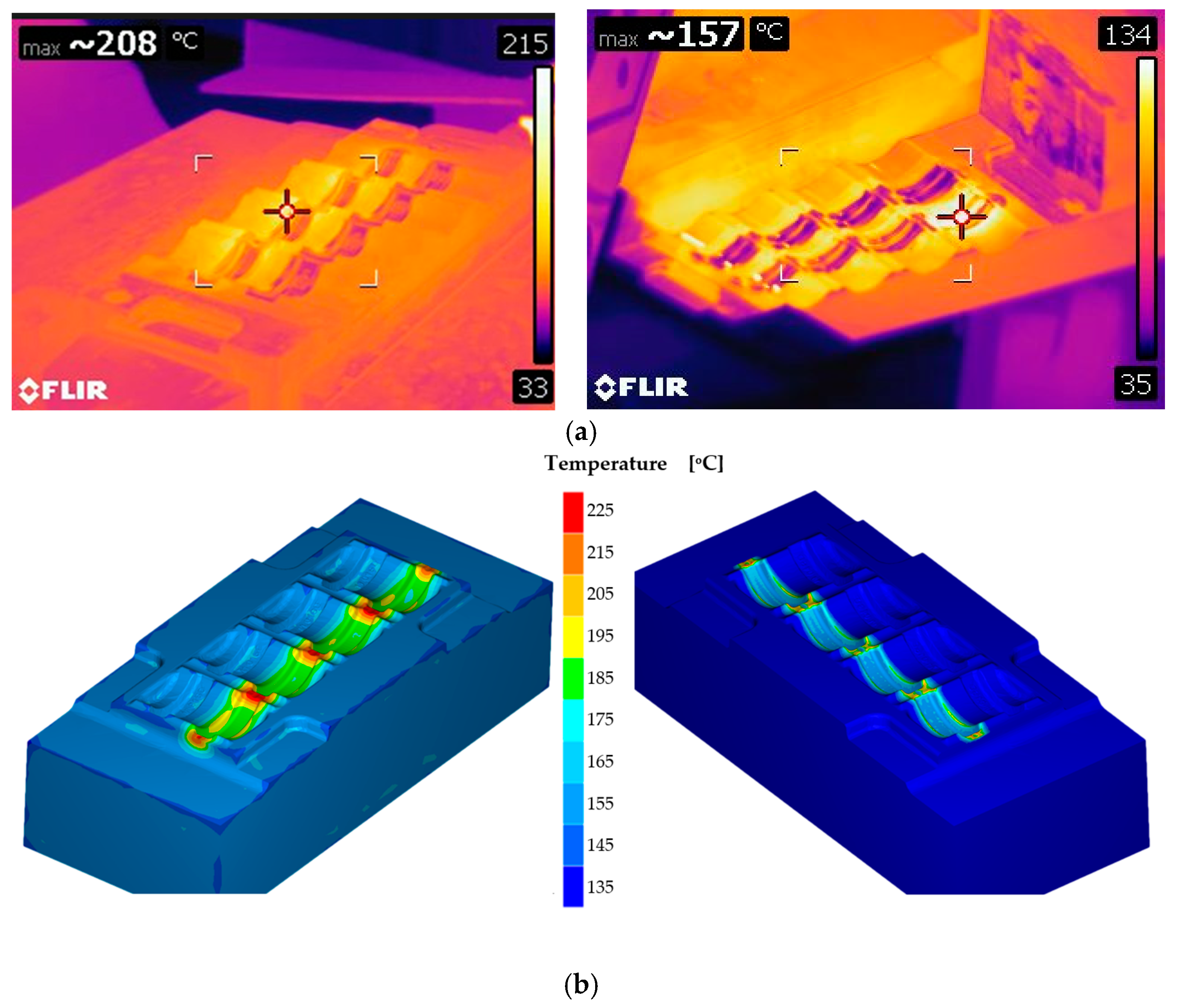

3.1. Thermal Imaging Tests for Analyzing Temperature Changes

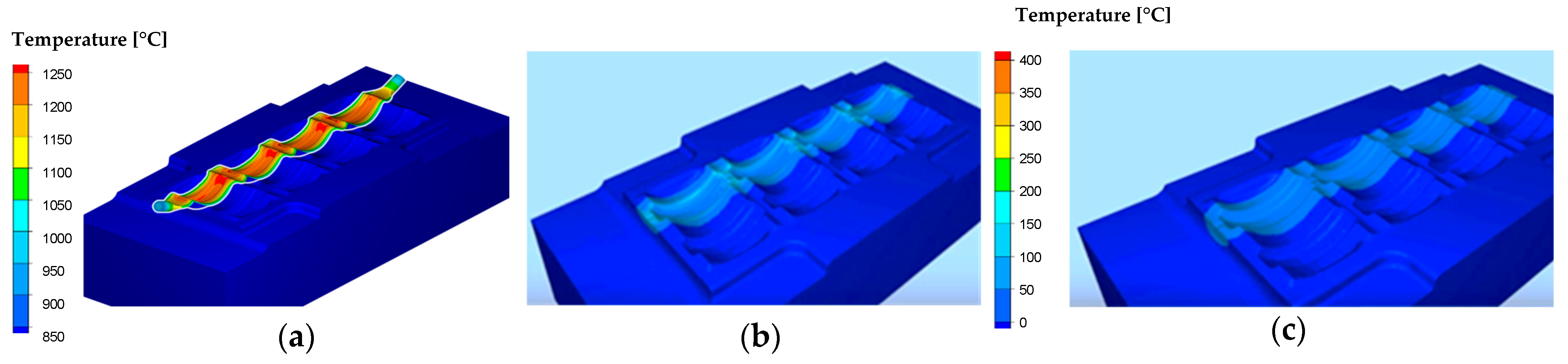

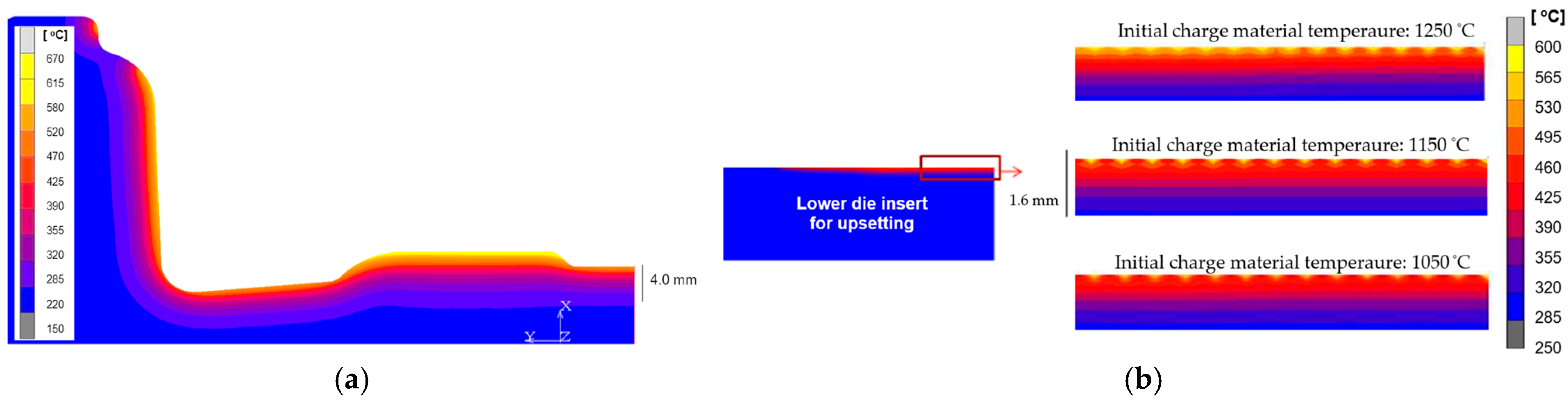

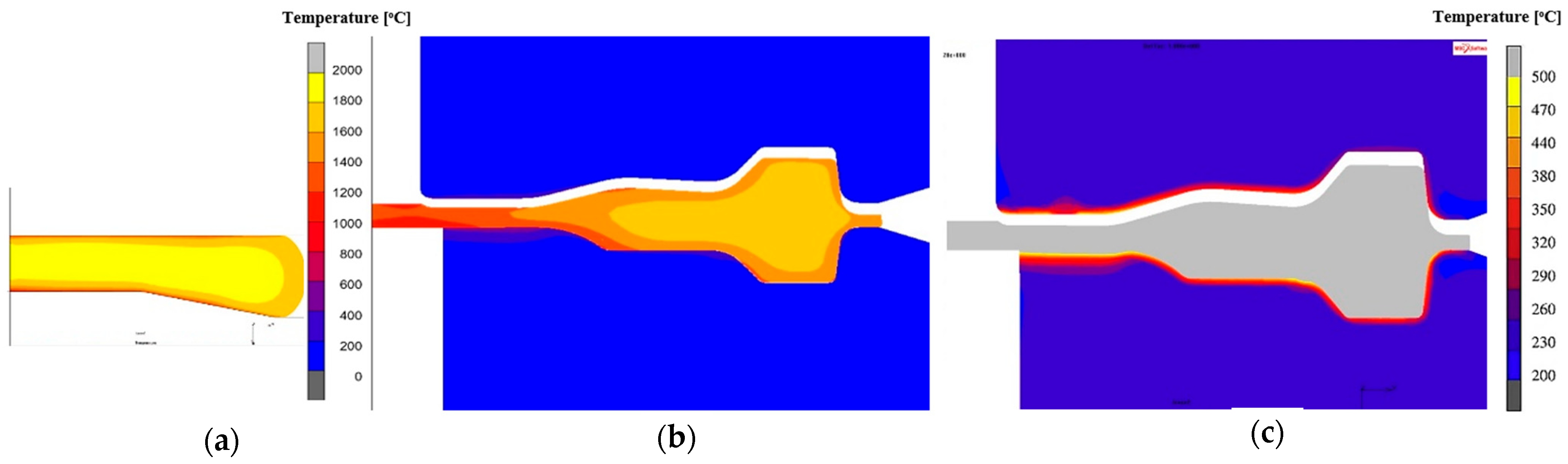

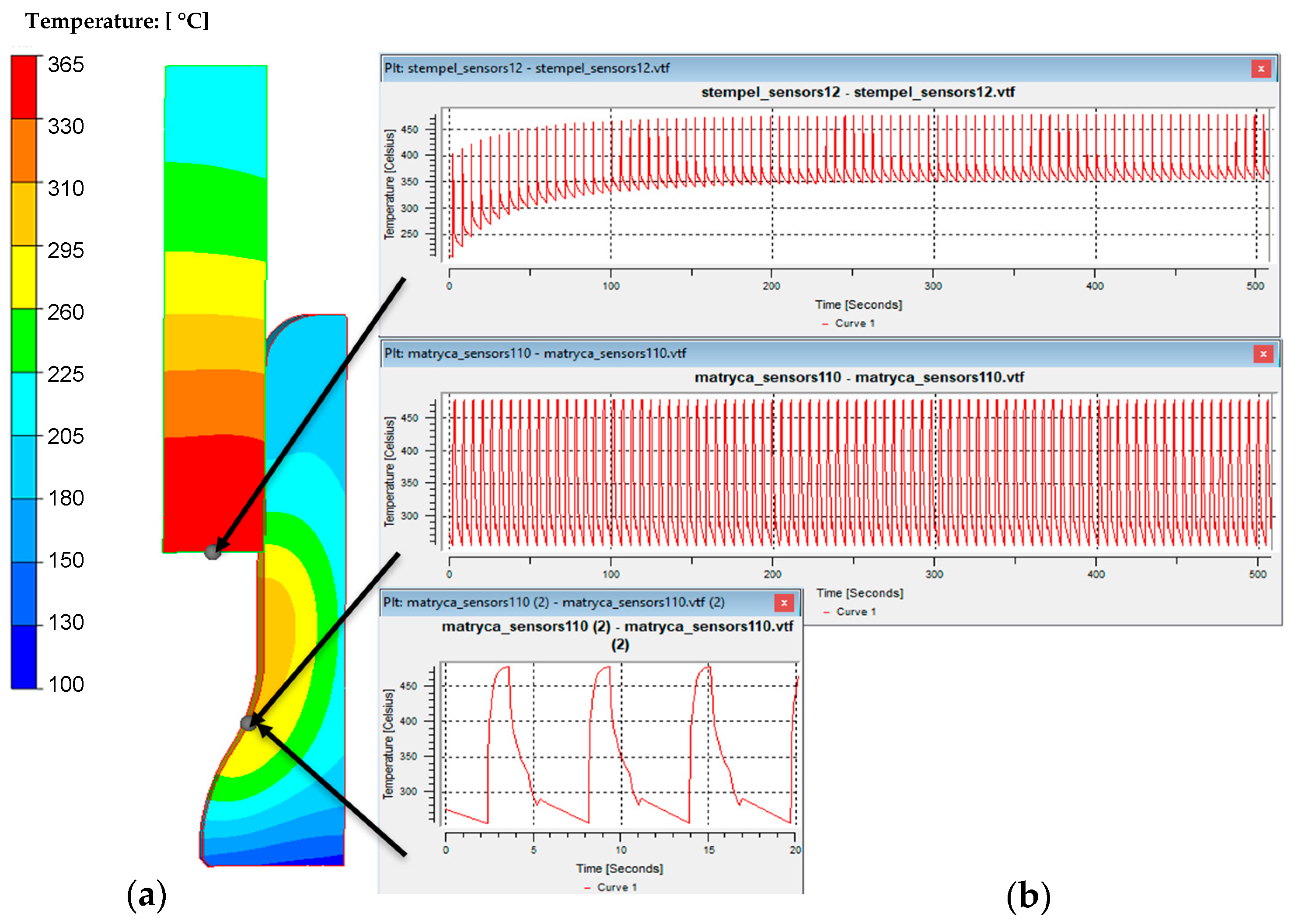

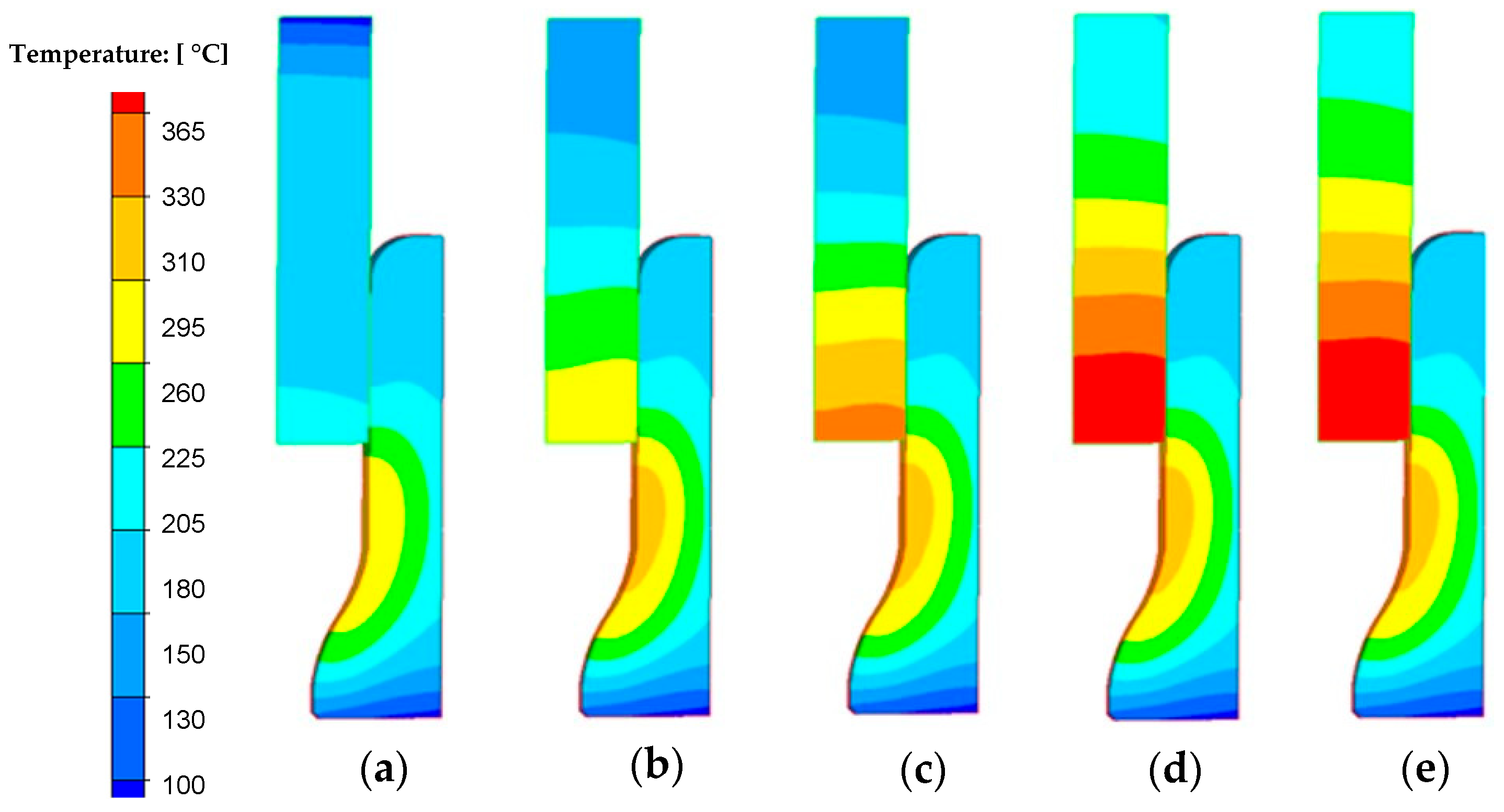

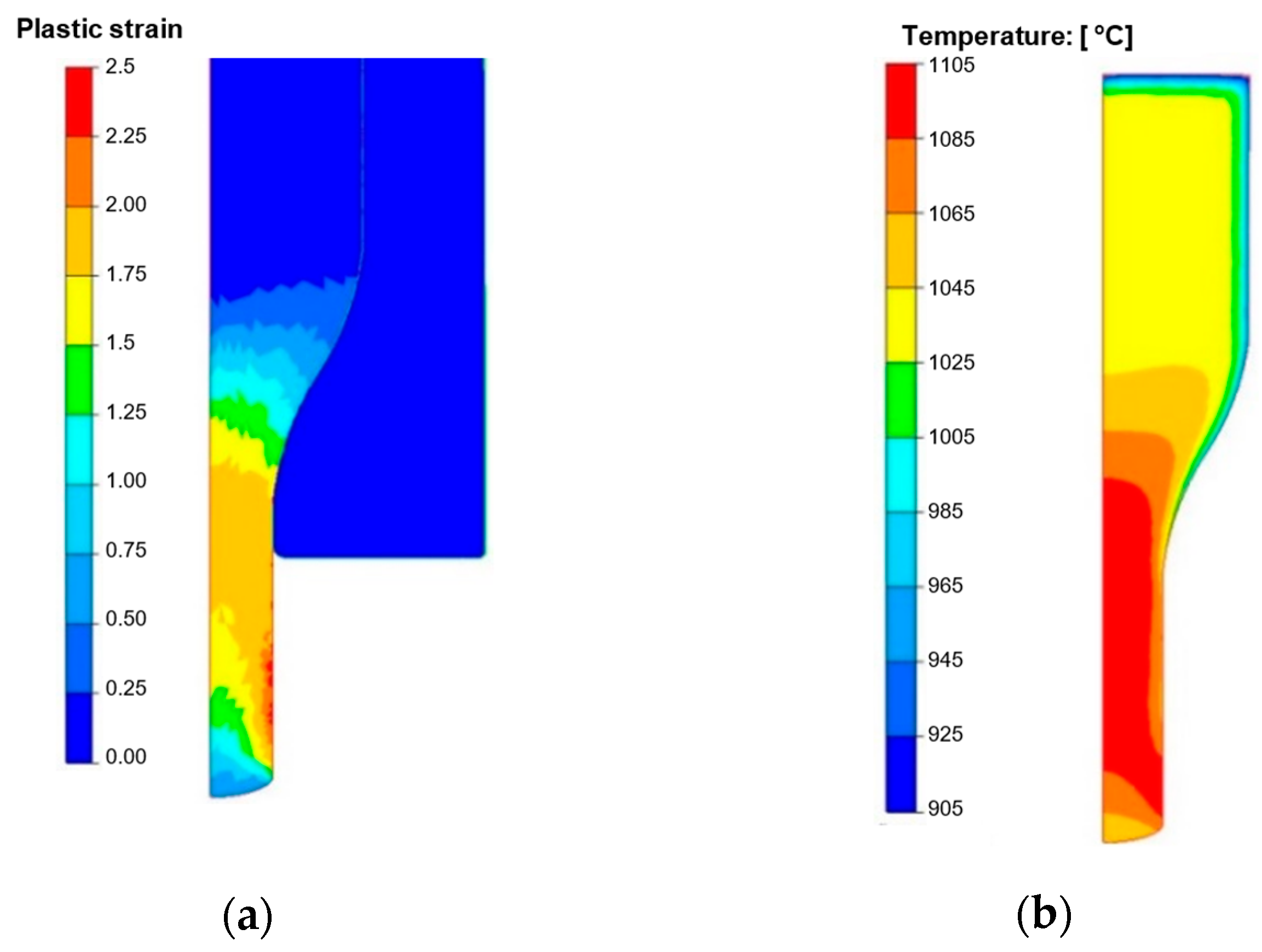

3.2. Numerical Modeling of Temperature Field Distributions

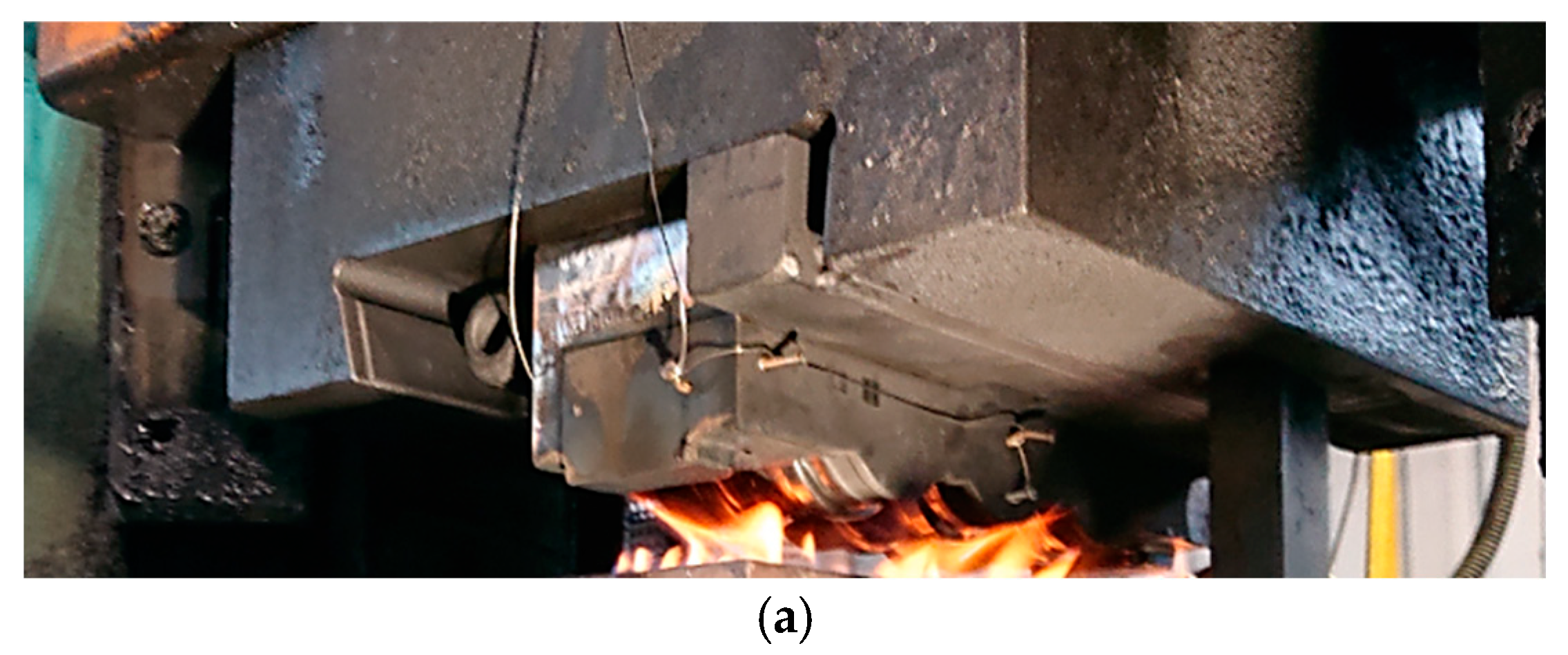

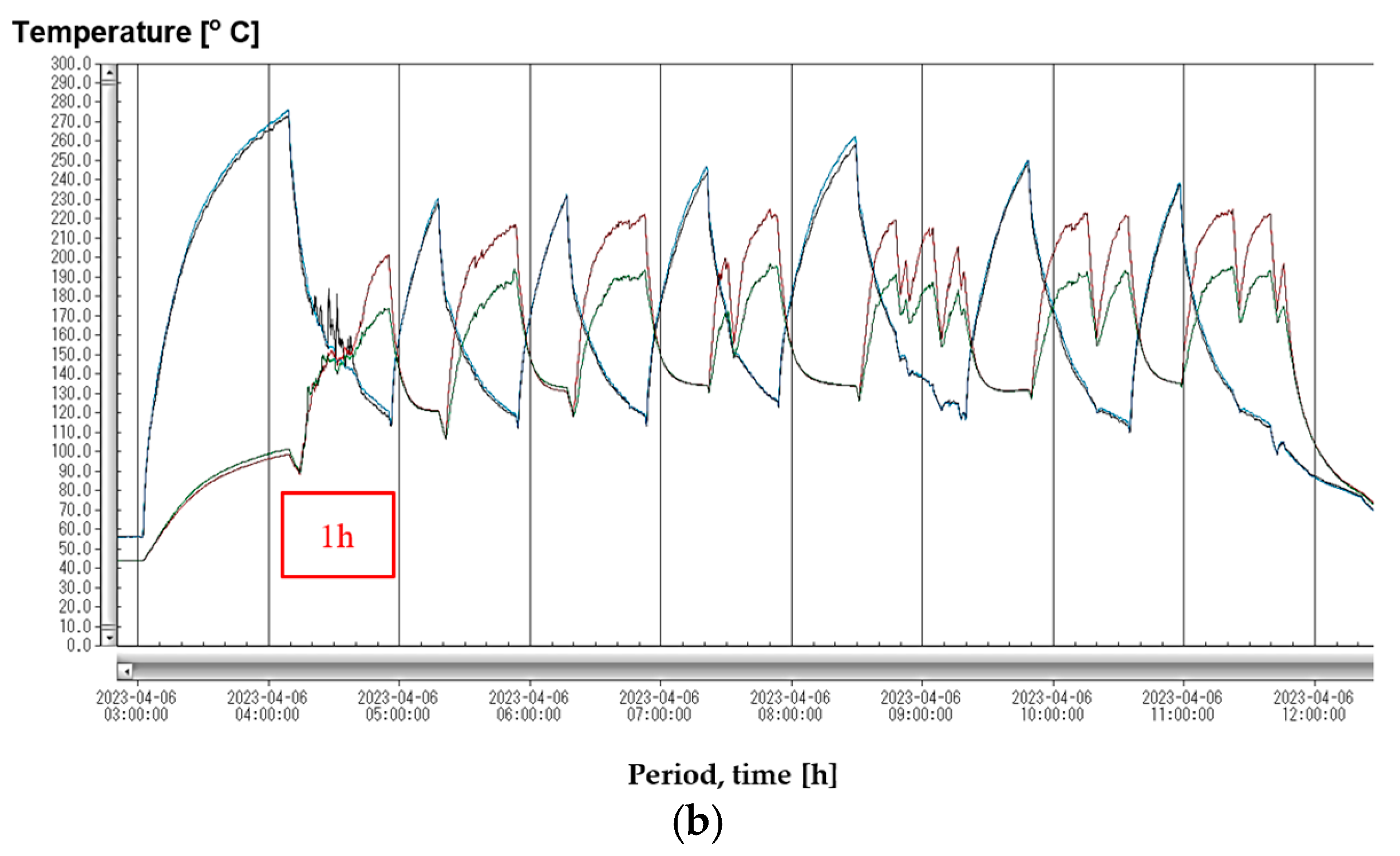

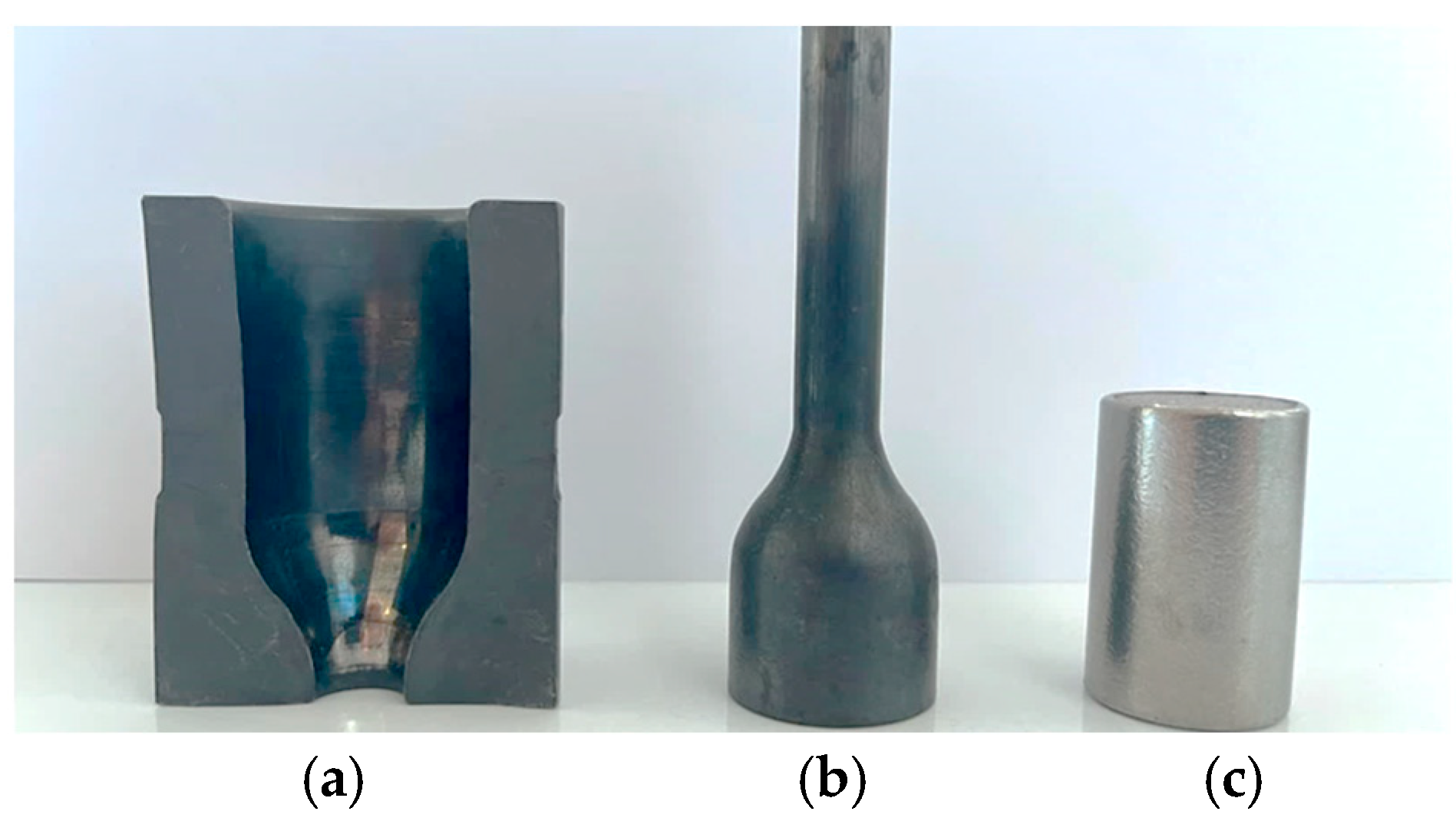

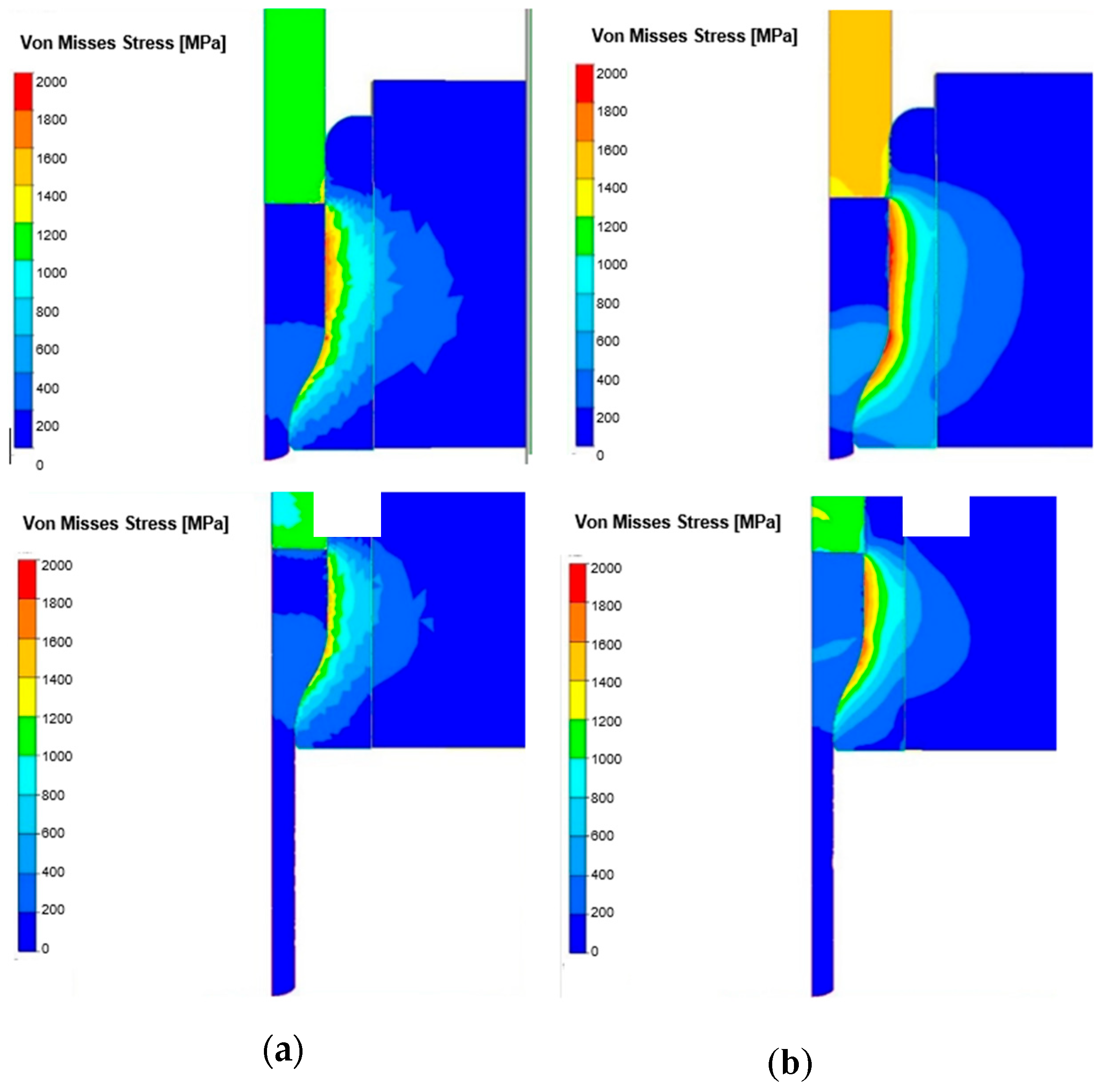

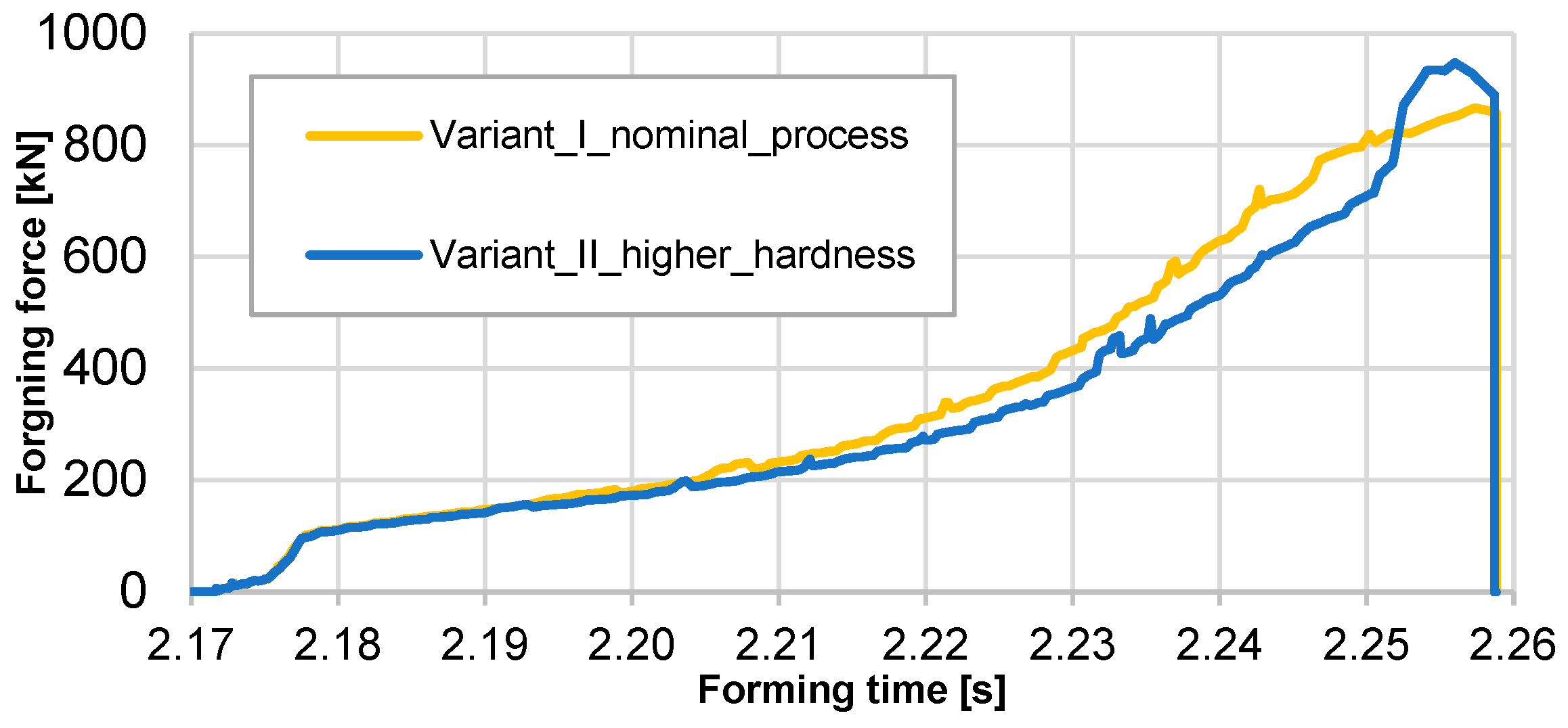

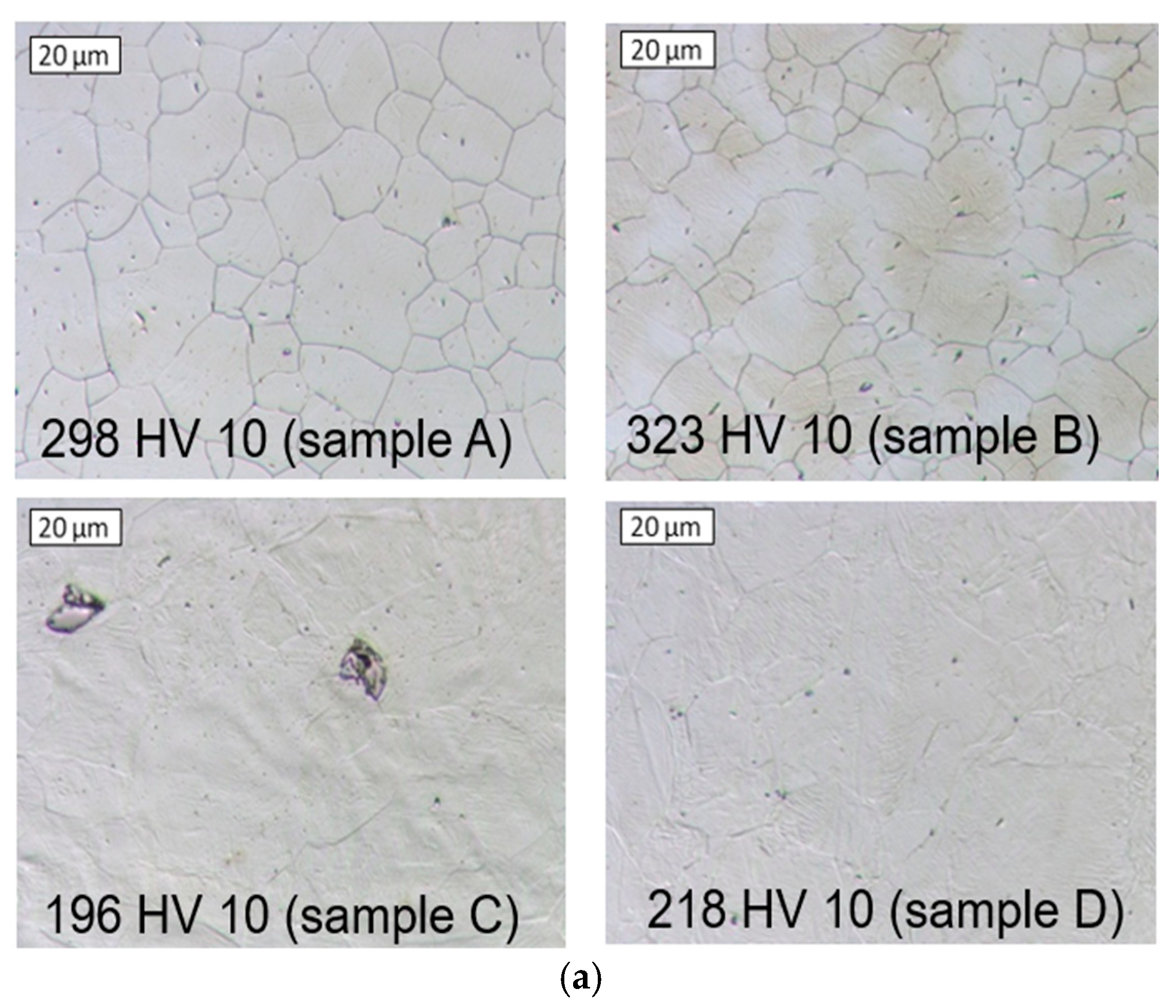

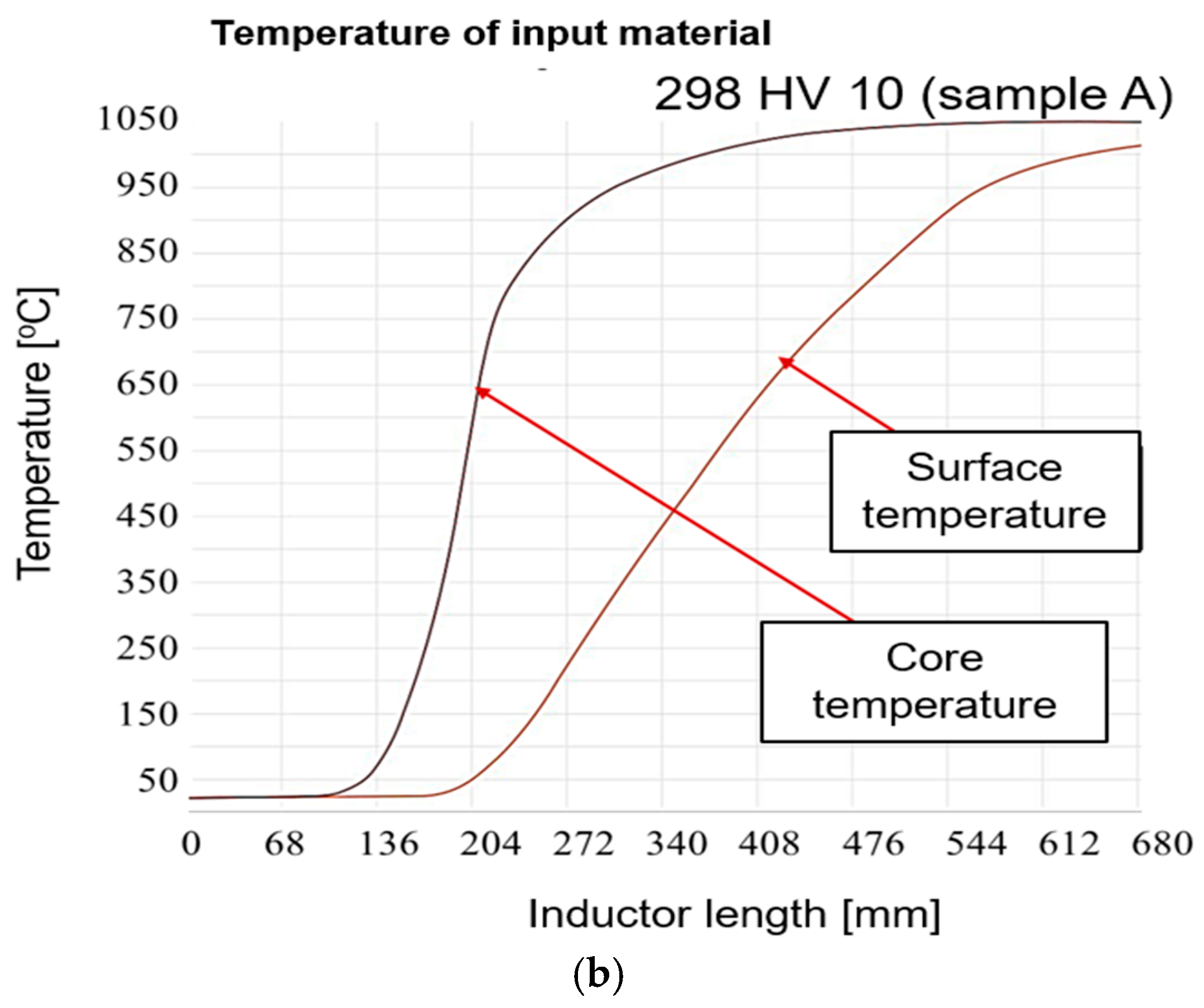

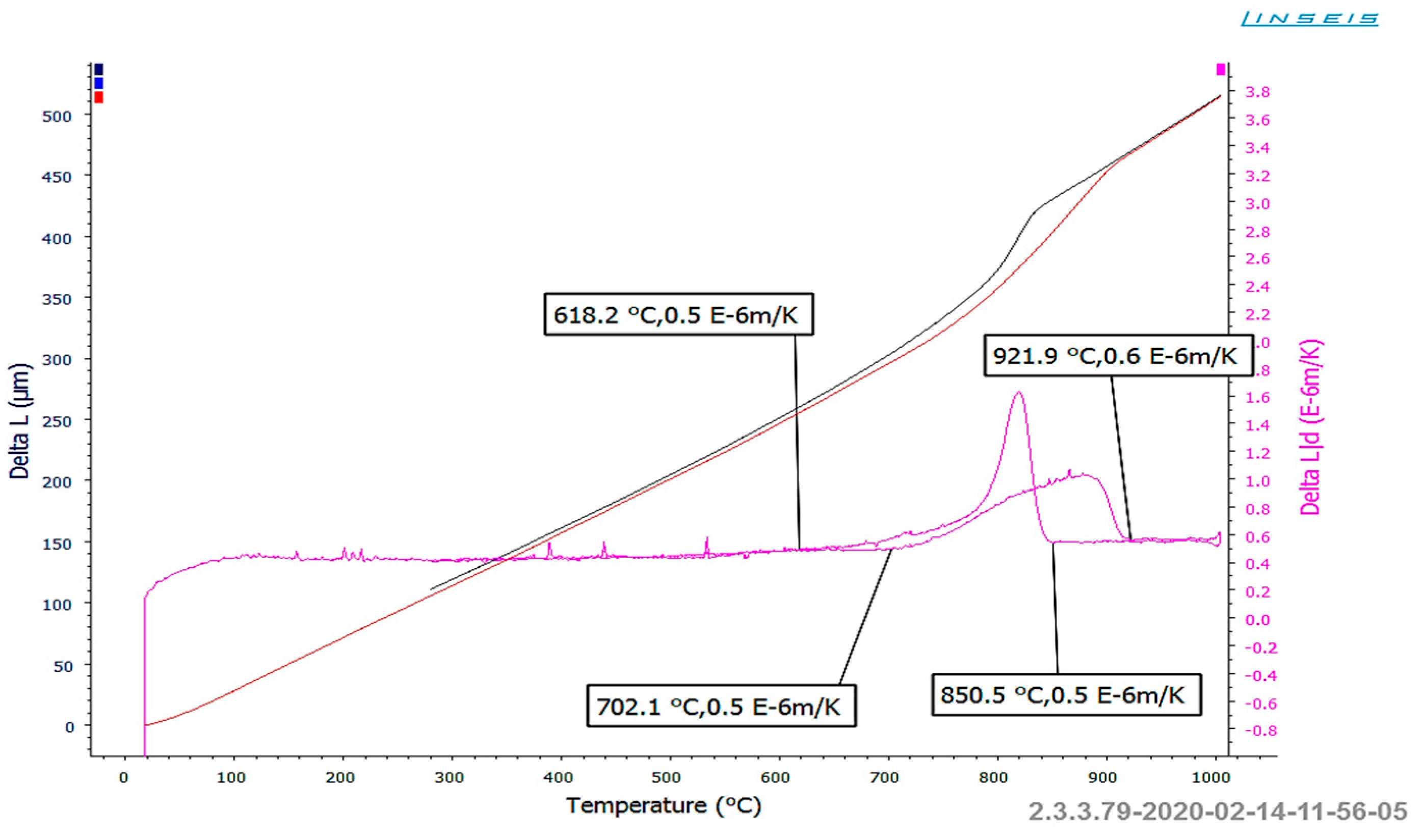

3.3. Application of Different Methods of Temperature Measurements to Solve Problem of Premature Wear of Dies Used in the Production of Engine Valve Forgings

4. Summary and Conclusions

The Main Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dieter, G.E.; Kuhn, H.A.; Semiatin, S.L. (Eds.) Handbook of Workability and Process Design; ASM International: Materials Park, OH, USA, 2003; ISBN 978-0-87170-778-9. [Google Scholar]

- Liu, Y.; Wu, Y.; Wang, J.; Liu, S. Defect Analysis and Design Optimization on the Hot Forging of Automotive Balance Shaft Based on 3D and 2D Simulations. Int. J. Adv. Manuf. Technol. 2018, 94, 2739–2749. [Google Scholar] [CrossRef]

- Hawryluk, M.; Gronostajski, Z.; Jabłoński, P.; Suliga, M. An integrated vision control system for the evaluation of the shape-dimensional accuracy and quality of valve forgings used in motor truck engines. Measurement 2023, 210, 112541. [Google Scholar] [CrossRef]

- Hawryluk, M.; Rychlik, M. An implementation of robotization for the chosen hot die forging process. Arch. Civ. Mech. Eng. 2022, 22, 119. [Google Scholar] [CrossRef]

- Xu, Z.; Xiao, J.; Chen, S. A novel high-dynamic actuator based in-situ micro-forging process for wire arc additive manufacturing of aluminum alloy. J. Mater. Process. Technol. 2024, 324, 118259. [Google Scholar] [CrossRef]

- Krušič, V.; Arentoft, M.; Rodič, T. A combined approach to determine workpiece-tool-press deflections and tool loads in multistage cold-forging. J. Mater. Process. Technol. 2011, 211, 35–42. [Google Scholar] [CrossRef]

- Shen, L.; Zhou, J.; Zhang, S. Microstructure and mechanical properties of hot forging die manufactured by bimetal-layer surfacing technology. J. Mater. Process. Technol. 2017, 239, 147–159. [Google Scholar] [CrossRef]

- Dong, W.; Zhao, A.; Lin, Q.; Wang, Z. A new tube forging process for manufacturing hollow parts with inner flange at an arbitrary location. J. Mater. Process. Technol. 2024, 328, 118421. [Google Scholar] [CrossRef]

- Maillard, S.; Cadith, J.; Bouteille, P.; Legros, G.; Bodnar, J.L.; Detalle, V. Non-destructive Testing of Forged Metallic Materials by Active Infrared Thermography. Int. J. Thermophys. 2012, 33, 1982–1988. [Google Scholar] [CrossRef]

- Jolgaf, M.; Hamouda, A.M.S.; Sulaiman, S.; Ahmad, M.M.H.M. Development of a CAD/CAM system for the closed-die forging process. J. Mater. Process. Technol. 2003, 138, 436–442. [Google Scholar] [CrossRef]

- Srinivasan, N.; Ramakrishnan, N.; Venugopal Rao, A.; Swamy, N. CAE for forging of titanium alloy aero-engine disc and integration with CAD–CAM for fabrication of the dies. J. Mater. Process. Technol. 2002, 124, 353–359. [Google Scholar] [CrossRef]

- Li, S.Y.; Cheng, S.Y. Design Optimization for Cold Forging by an Integrated Methodology of CAD/FEM/ANN. Adv. Mater. Res. 2010, 97–101, 3281–3284. [Google Scholar] [CrossRef]

- Jakubek, B.; Grochalski, K.; Sokol, H. Thermovision measurements of rolling bearings. Measurement 2022, 189, 110512. [Google Scholar] [CrossRef]

- Suliga, M.; Wartacz, R.; Michalczyk, J. High speed multi-stage drawing process of hot-dip galvanised steel wires. Int. J. Adv. Manuf. Technol. 2022, 120, 7639–7655. [Google Scholar] [CrossRef]

- Li, T.; Long, H.; Shi, T.; Yang, J.; Duan, J. Cutting temperature measurement using a novel near-infrared two-color pyrometer under dry and wet cutting of Ti-6Al-4V alloy. J. Mater. Process. Technol. 2022, 309, 117751. [Google Scholar] [CrossRef]

- Bouissa, Y.; Bohlooli, N.; Shahriari, D.; Champliaud, H.; Morin, J.B.; Jahazi, M. FEM modeling and experimental validation of quench-induced distortions of large size steel forgings. J. Manuf. Process. 2020, 58, 592–605. [Google Scholar] [CrossRef]

- Hawryluk, M.; Widomski, P.; Kaszuba, M.; Polak, S. Methods of temperature determination and measurement verification in applications related to hot die forging processes. High Temp. High Press. 2020, 49, 223–239. [Google Scholar] [CrossRef]

- Plogmeyer, M.; Kruse, J.; Stonis, M.; Paetsch, N.; Behrens, B.-A. Temperature measurement with thin film sensors during warm forging of steel. Microsyst. Technol. 2021, 27, 3841–3850. [Google Scholar] [CrossRef]

- Suliga, M.; Muskalski, Z. The influence of single draft on TRIP effect and mechanical properties of 0,09C-1,57Mn-0,9Si steel wires. Arch. Metall. Mater. 2009, 54, 677–684. [Google Scholar]

- Sharma, S.; Sharma, M.; Gupta, V.; Singh, J. A Systematic Review of Factors Affecting the Process Parameters and Various Measurement Techniques in Forging Processes. Steel Res. Int. 2022, 94, 2200529. [Google Scholar] [CrossRef]

- Malinowski, Z. Analysis of temperature fields in the tools during forging of axially symmetrical parts. Arch. Metall. Mater. 2001, 46, 93–118. [Google Scholar]

- Hawryluk, M.; Dolny, A.; Mroziński, S. Low cycle fatigue studies of WCLV steel (1.2344) used for forging tools to work at higher temperatures. Arch. Civ. Mech. Eng. 2018, 18, 465–478. [Google Scholar] [CrossRef]

- Hawryluk, M.; Rychlik, M.; Więcław, M.; Jabłoński, P. Analysis of the industrial process of producing a hub forging used in motorcar power transmission systems-A case study. J. Manuf. Mater. Process. 2021, 5, 32. [Google Scholar] [CrossRef]

- Zhang, Y.-C.; Wei, B.; Fu, X.-B. An unsteady temperature field measurement method for large hot cylindrical shell forging based on infrared spectrum. Measurement 2014, 58, 12–20. [Google Scholar] [CrossRef]

- Zhou, H.C.; Han, S.D.; Sheng, F.; Zheng, C.G. Numerical simulation on a visualization monitoring method of three-dimensional temperature distribution in furnace. Power Eng. 2003, 23, 2154–2159. [Google Scholar]

- Hawryluk, M.; Dudkiewicz, Ł.; Szymańska, T.; Polak, S.; Ziemba, J.; Gronostajski, Z. Application of numerical simulations for a multi-variant analysis of the construction of tools assigned for hot precision forging of small size forgings in multiple systems. Mater. Metal. 2024, 69, 1215–1229. [Google Scholar] [CrossRef]

- Lei, W.G.; Mao, X.N.; Lu, Y.F. Numerical simulation of temperature field and thermal stress field in quenching process of TC21 titanium alloy forging. Rare Met. Mater. Eng. 2011, 40, 1721–1726. [Google Scholar]

- DIN EN 10084; Steels for Quenching and Tempering Suitable for Carburizing and Direct Hardening; Technical Delivery Conditions and Testing Methods. Beuth Verlag: Berlin, Germany, 1999.

- Hawryluk, M.; Dworzak, Ł.; Kaszuba, M.; Jabłoński, P. Research and Measurements of Gripper Heating Temperature During Forging Transfer in Industrial Forging Process; Internal raport SPR No. 209; Faculty of Mechanical Engineering, Wrocław University of Science and Technology: Wrocław, Poland, 2018. (In Polish) [Google Scholar]

- Hawryluk, M. Methods of Analysis and Increasing the Durability of Forging Tools Used in Hot Die Forging Processes: Monograph; Library of Problems of Machine Design and Operation; Scientific Publishing House of the Institute of Exploitation Technology-PIB: Radom, Poland, 2016; p. 218. [Google Scholar]

- Hawryluk, M.; Lachowicz, M.; Janik, M.; Gronostajski, Z.; Stachowicz, M. Effect of the heating temperature of a nickel-chromium Steel charge material on the stability of the forging process and the durability of the die. Arch. Metall. Mater. 2023, 68, 711–722. [Google Scholar] [CrossRef]

| Element | C [%] | Si [%] | Mn [%] | Cr [%] | Mo [%] | V [%] | P [%] | S [%] | Ni [%] |

|---|---|---|---|---|---|---|---|---|---|

| 16MnCrS5 (1.7131) | 0.14–0.19 | ≤0.40 | 1.00–1.30 | 0.80–1.10 | - | 0.10–0.25 | ≤0.025 | ≤0.035 | – |

| NCF3015 (1.4016/1.4057) | ≤0.08 | ≤0.50 | ≤0.50 | 13.5–15.5 | 0.40–1.00 | - | ≤0.015 | ≤0.010 | 30.0–33.5 |

| 1.2343 (H11) | 0.33–0.42 | 0.80–1.20 | 0.25–0.50 | 4.80–5.50 | 1.10–1.50 | 0.25–0.50 | ≤0.03 | ≤0.03 | |

| 1.2344 (H13) | 0.37–0.43 | 0.90–1.20 | 0.30–0.50 | 4.80–5.50 | 1.20–1.50 | 0.90–1.10 | ≤0.03 | ≤0.03 | |

| 1.2365 (WLV/H10) | 0.28–0.35 | 0.10–0.40 | 0.15–0.45 | 2.70–3.20 | 2.50–3.00 | 0.40–0.70 | |||

| Unimax | 0.50 | 0.20 | 0.50 | 5.00 | 2.30 | 0.50 | |||

| W360 | 0.50 | 0.25 | 0.50 | 4.50 | 3.00 | 0.60 |

| Temperature Set on the Induction Heater [°C] | Temperature from Thermovision Camera [°C] | Temperature of Pyrometer on Induction Heater [°C] |

|---|---|---|

| 1250 | 1209 | 1257 |

| 1213 | 1266 | |

| 1197 | 1259 | |

| 1199 | 1313 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hawryluk, M.; Dudkiewicz, Ł.; Krawczyk, J.; Janik, M.; Lachowicz, M.; Skwarski, M. Challenges in Temperature Measurement in Hot Forging Processes: Impact of Measurement Method Selection on Accuracy and Errors in the Context of Tool Life and Forging Quality. Materials 2025, 18, 3850. https://doi.org/10.3390/ma18163850

Hawryluk M, Dudkiewicz Ł, Krawczyk J, Janik M, Lachowicz M, Skwarski M. Challenges in Temperature Measurement in Hot Forging Processes: Impact of Measurement Method Selection on Accuracy and Errors in the Context of Tool Life and Forging Quality. Materials. 2025; 18(16):3850. https://doi.org/10.3390/ma18163850

Chicago/Turabian StyleHawryluk, Marek, Łukasz Dudkiewicz, Jakub Krawczyk, Marta Janik, Marzena Lachowicz, and Mateusz Skwarski. 2025. "Challenges in Temperature Measurement in Hot Forging Processes: Impact of Measurement Method Selection on Accuracy and Errors in the Context of Tool Life and Forging Quality" Materials 18, no. 16: 3850. https://doi.org/10.3390/ma18163850

APA StyleHawryluk, M., Dudkiewicz, Ł., Krawczyk, J., Janik, M., Lachowicz, M., & Skwarski, M. (2025). Challenges in Temperature Measurement in Hot Forging Processes: Impact of Measurement Method Selection on Accuracy and Errors in the Context of Tool Life and Forging Quality. Materials, 18(16), 3850. https://doi.org/10.3390/ma18163850