Identification of Selected Physical and Mechanical Properties of Cement Composites Modified with Granite Powder Using Neural Networks

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

- -

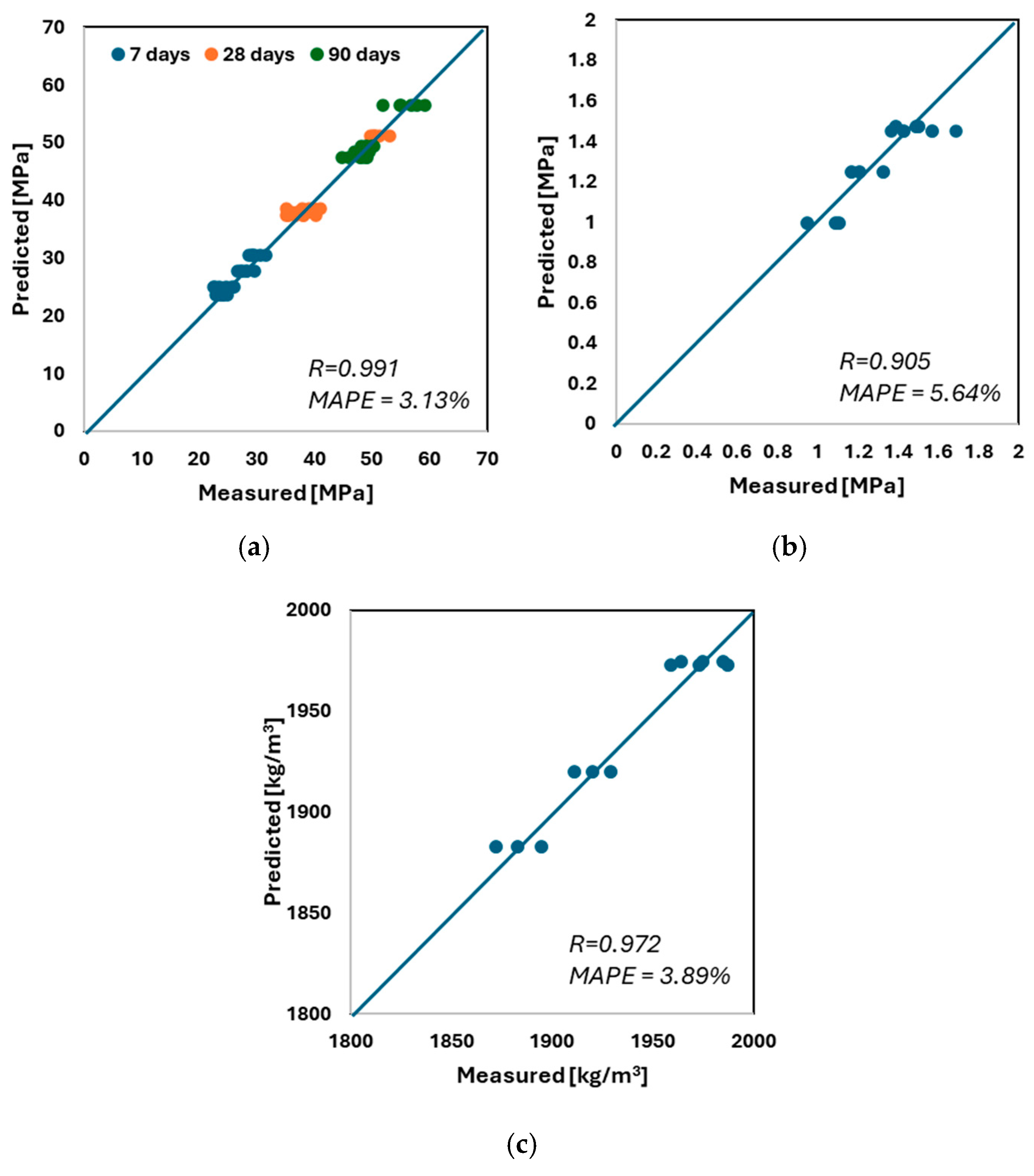

- The model achieved very high values of the linear regression coefficient (R > 0.9) for all predicted properties, along with very low mean absolute percentage errors (MAPE < 6%).

- -

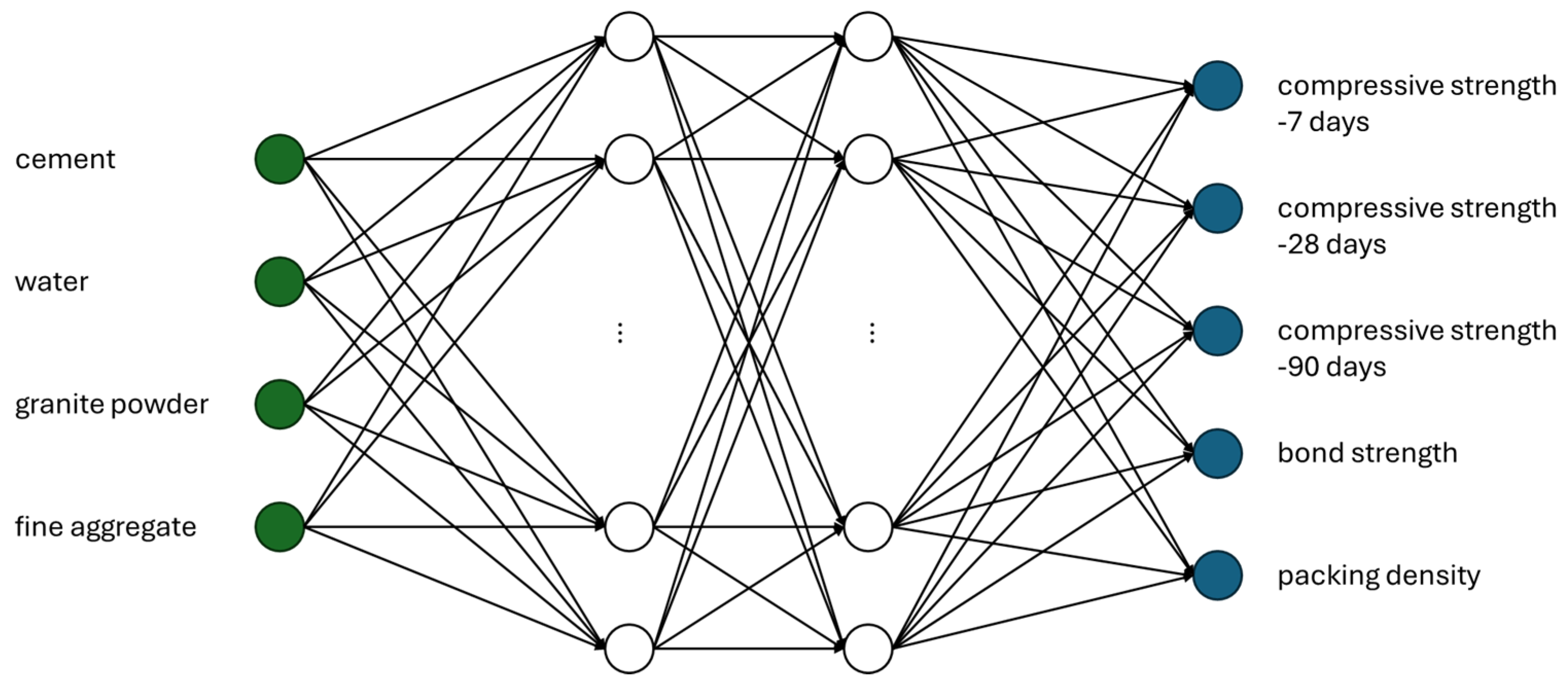

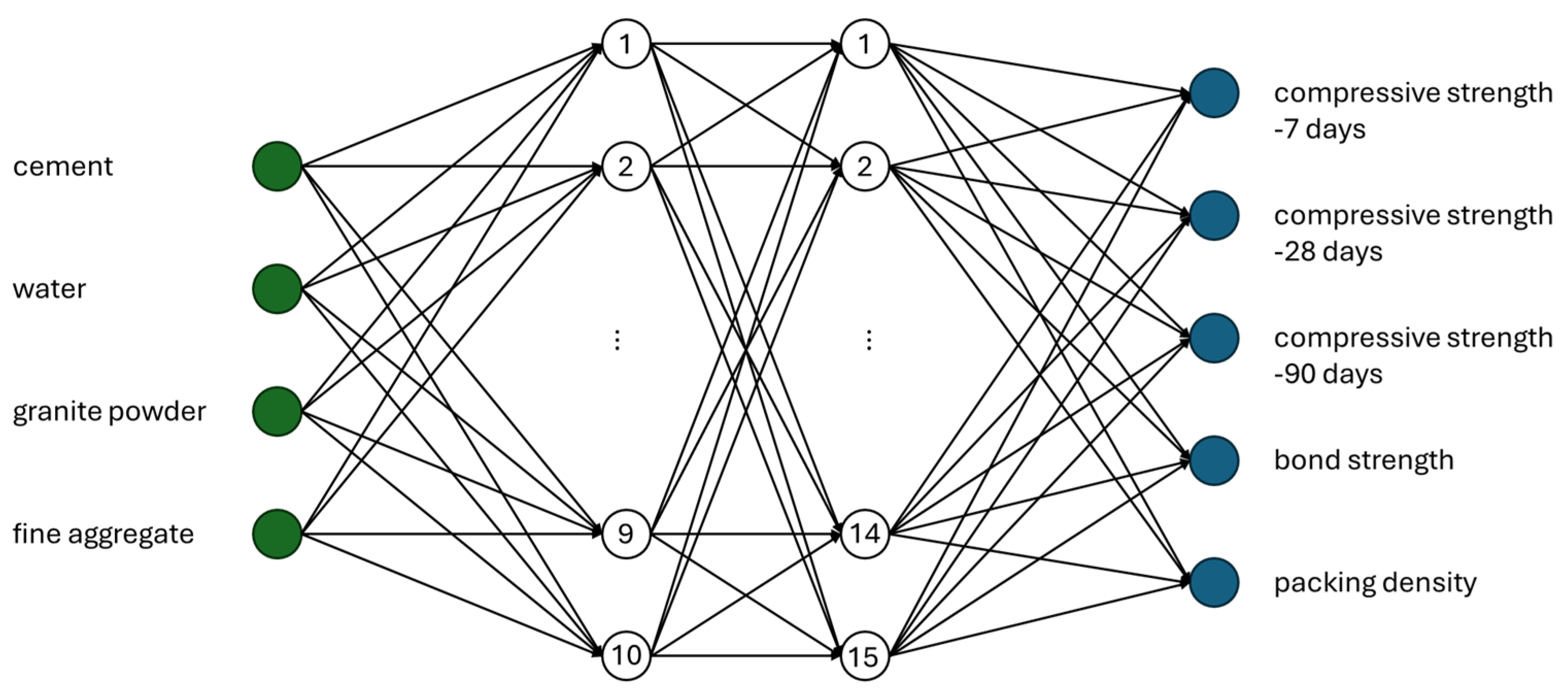

- The most accurate model was developed using a multilayer perceptron (MLP) neural network, with input parameters including granite powder content, cement content, sand content, and water content. The network architecture consists of two hidden layers with 10 neurons in the first layer and 15 neurons in the second. The output parameters include early compressive strength (7 days), 28-day compressive strength, late compressive strength (90 days), bonding strength, and packing density.

- -

- Utilizing granite powder, a waste product from rock cutting, offers a promising solution toward reaching Net Zero goals in the concrete industry. Since the granite powder used in this study is generated as a byproduct of the rock-cutting process, its associated CO2 emissions are attributed to that process. Therefore, incorporating it into concrete significantly reduces the overall carbon footprint of cement production.

Funding

Data Availability Statement

Conflicts of Interest

References

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2018, 10, 2213–2339. [Google Scholar] [CrossRef]

- Generowicz-Caba, N.; Kulczycka, J. LCA of Cement with Alternative Additives: Pathways to Sustainable Production. Materials 2025, 18, 3057. [Google Scholar] [CrossRef] [PubMed]

- Chajec, A.; Chowaniec, A.; Królicka, A.; Sadowski, Ł.; Żak, A.; Piechowka-Mielnik, M.; Šavija, B. Engineering of green cementitious composites modified with siliceous fly ash: Understanding the importance of curing conditions. Constr. Build. Mater. 2021, 313, 125209. [Google Scholar] [CrossRef]

- Gautam, A.; Tung, S. Advancing sustainability in concrete construction: Enhancing thermal resilience and structural strength with ground granulated blast furnace slag. Asian J. Civ. Eng. 2024, 25, 6119–6129. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Nasrollahi, M.; Bahmani, H.; Zajshoor, Z.; Sadeghi, M. Enhancing concrete strength and durability of normal and high-strength concrete: Exploring combined effects of optimized silica fume and slag. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 2309–2328. [Google Scholar] [CrossRef]

- Xu, K.; Yang, J.; He, H.; Wei, J.; Zhu, Y. Influences of Additives on the Rheological Properties of Cement Composites: A Review of Material Impacts. Materials 2025, 18, 1753. [Google Scholar] [CrossRef]

- Abbas, M.M.; Muntean, R. Marble Powder as a Sustainable Cement Replacement: A Review of Mechanical Properties. Sustainability 2025, 17, 736. [Google Scholar] [CrossRef]

- Drouna, K.; Boucetta, T.A.; Maherzi, W.; Ayat, A. Enhancing the Properties of Expanded Clay Aggregates through Cementitious Coatings Based on Waste Glass Powder and Granulated Slag: Impact on Lightweight Self-Compacting Concrete Performance. Constr. Build. Mater. 2025, 485, 141896. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, R.C.; Shrivastava, S. Long Term Studies on the Utilisation of Quartz Sandstone Wastes in Cement Concrete. J. Clean. Prod. 2017, 143, 634–642. [Google Scholar] [CrossRef]

- Guo, K.; Dong, H.; Zhang, J.; Zhang, L.; Li, Z. Experimental Study of Alkali-Activated Cementitious Materials Using Thermally Activated Red Mud: Effect of the Si/Al Ratio on Fresh and Mechanical Properties. Buildings 2025, 15, 565. [Google Scholar] [CrossRef]

- Chajec, A. Granite Powder vs. Fly Ash for the Sustainable Production of Air-Cured Cementitious Mortars. Materials 2021, 14, 1208. [Google Scholar] [CrossRef]

- Ghodousian, O.; Ghodousian, A.; Shafaie, V.; Hajiloo, S.; Movahedi Rad, M. Study of Bonding between Façade Stones and Substrates with and without Anchorage Using Shear-Splitting Test—Case Study: Travertine, Granite, and Marble. Buildings 2023, 13, 1229. [Google Scholar] [CrossRef]

- Huts, A.; Konkol, J.; Marchuk, V. Granite Dust and Silica Fume as a Combined Filler of Reactive Powder Concrete. Materials 2024, 17, 6025. [Google Scholar] [CrossRef]

- Hou, W.; Zhang, Q.; Zhuang, Z.; Zhang, Y. Sustainable Reusing Marble Powder and Granite Powder in Cement-Based Materials: A Review. ACS Sustain. Chem. Eng. 2024, 12, 2484–2510. [Google Scholar] [CrossRef]

- Abed, J.M.; Al-Gburi, M.; Almssad, A. Evaluation of Physical and Mechanical Properties of Modified Cement-Lime Mortar Containing Recycled Granite Powder Waste as a Partial Fine Aggregate Replacement. Appl. Sci. 2024, 14, 10146. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, X.; Liu, X.; He, Z.; Cao, X.; Guan, B. Evaluation of Workability and Mechanical Properties in Cement Mortar after Compounding Igneous Rock Powder and Silica Fume. Buildings 2024, 14, 359. [Google Scholar] [CrossRef]

- Chajec, A.; Królicka, A.; Rainer, J.; Pachnicz, M.; Nieświec, M.; Kaczmarczyk, O.; Walendzik, I.; Kapeluszna, E. Beyond Filler Effects: The Role of Mechanical Activation in Transforming Quarry Waste into Functional Cementitious Components. Constr. Build. Mater. 2025, 490, 142637. [Google Scholar] [CrossRef]

- Czarnecki, S.; Chajec, A.; Malazdrewicz, S.; Sadowski, Ł. The prediction of abrasion resistance of mortars modified with granite powder and fly ash using artificial neural networks. Appl. Sci. 2023, 13, 4011. [Google Scholar] [CrossRef]

- Akter, S.T.; Hawas, A. Current Insight on Eco-Friendly Concrete: A Review. Buildings 2025, 15, 682. [Google Scholar] [CrossRef]

- Chabane, A.; Belebchouche, C.; Bensebti, S.-E.; Czarnecki, S.; Boukezzoula, A. Comparison of the accuracy of regulation models for self-compacting concrete creep evaluation. J. Build. Eng. 2022, 59, 105069. [Google Scholar] [CrossRef]

- Hematibahar, M.; Kharun, M.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Razveeva, I. Analysis of Models to Predict Mechanical Properties of High-Performance and Ultra-High-Performance Concrete Using Machine Learning. J. Compos. Sci. 2024, 8, 287. [Google Scholar] [CrossRef]

- Nigam, M.; Verma, M. Prediction of compressive strength of nano-silica concrete by using random forest algorithm. Asian J. Civ. Eng. 2024, 25, 5205–5213. [Google Scholar] [CrossRef]

- Li, Q.; Ren, G.; Wang, H.; Xu, Q.; Zhao, J.; Wang, H.; Ding, Y. Splitting tensile strength prediction of metakaolin concrete using machine learning techniques. Sci. Rep. 2023, 13, 20102. [Google Scholar] [CrossRef]

- Mahmoudian, A.; Bypour, M.; Kontoni, D.P.N. Tree-based machine learning models for predicting the bond strength in reinforced recycled aggregate concrete. Asian J. Civ. Eng. 2024, 25, 5899–5924. [Google Scholar] [CrossRef]

- Chajec, A.; Czarnecki, S.; Sadowski, Ł. Smart optimization of packing density for cleaner production of cementitious composites using mineral powders. Dev. Built Environ. 2024, 19, 100532. [Google Scholar] [CrossRef]

- Jagadesh, P.; Oyebisi, S.; Hareesh Muthu, A.; Sarulatha, A.; Supikshaa, K.; Vhishva laxmy, V.P. Microscopic Analyses and Performance Characteristics of Granite Powder Blended Cement. Constr. Build. Mater. 2024, 426, 136006. [Google Scholar] [CrossRef]

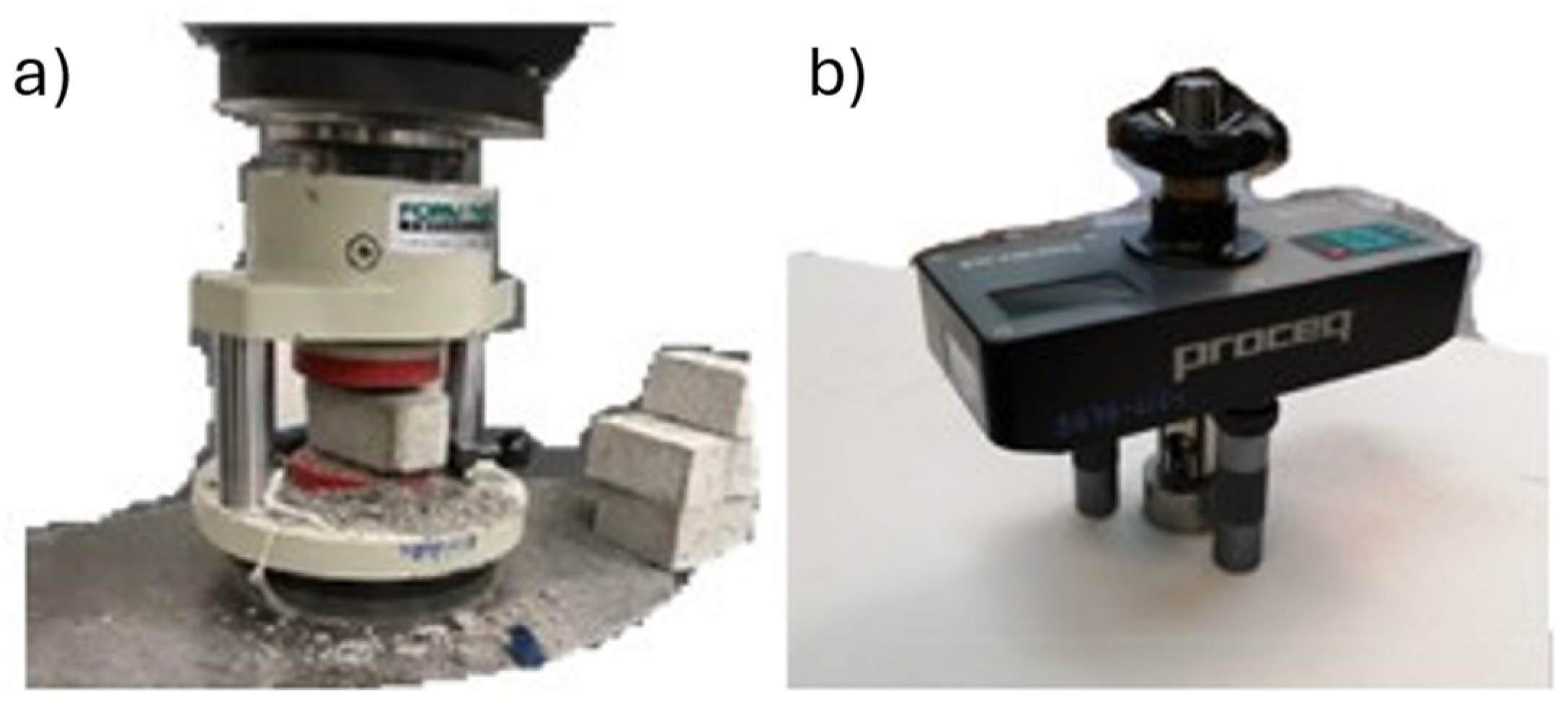

- EN 12390–3:2019–07; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- ASTM D4541-17; Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Raman, S.; Nateriya, R. Synthesizing Sustainable Construction Paradigms: A Comprehensive Review and Bibliometric Analysis of Granite Waste Powder Utilization and Moisture Correction in Concrete. Rev. Adv. Mater. Sci. 2024, 63, 20240084. [Google Scholar] [CrossRef]

- Jahed Armaghani, D.; Skentou, A.D.; Izadpanah, M.; Karoglou, M.; Khandelwal, M.; Konstantakatos, G.; Mamou, A.; Tsoukalas, M.Z.; Zengin, B.; Asteris, P.G. Deep neural networks for the estimation of granite materials’ compressive strength using non-destructive indices. In Applications of Artificial Intelligence in Mining and Geotechnical Engineering; Elsevier: Amsterdam, The Netherlands, 2024; pp. 45–74. [Google Scholar] [CrossRef]

- Czarnecki, S.; Hadzima-Nyarko, M.; Chajec, A.; Sadowski, Ł. Design of a machine learning model for the precise manufacturing of green cementitious composites modified with waste granite powder. Sci. Rep. 2022, 12, 13242. [Google Scholar] [CrossRef]

- Fathy, I.N.; Dahish, H.A.; Alkharisi, M.K.; Mahmoud, A.A.; Fouad, H.E.E. Predicting the Compressive Strength of Concrete Incorporating Waste Powders Exposed to Elevated Temperatures Utilizing Machine Learning. Sci. Rep. 2025, 15, 25275. [Google Scholar] [CrossRef]

- Endzhievskaya, I.G.; Endzhievskiy, A.S.; Galkin, M.A.; Molokeev, M.S. Machine Learning Methods in Assessing the Effect of Mixture Composition on the Physical and Mechanical Characteristics of Road Concrete. J. Build. Eng. 2023, 76, 107248. [Google Scholar] [CrossRef]

- Moj, M.; Czarnecki, S. Comparative Analysis of Selected Machine Learning Techniques for Predicting the Pull-Off Strength of the Surface Layer of Eco-Friendly Concrete. Adv. Eng. Softw. 2024, 195, 103710. [Google Scholar] [CrossRef]

- Rojo-López, G.; González-Fonteboa, B.; Pérez-Ordóñez, J.L.; Martínez-Abella, F. Parametric Analysis in Sustainable Self-Compacting Mortars Using Genetic Programming. Constr. Build. Mater. 2023, 404, 133189. [Google Scholar] [CrossRef]

- Dafico, L.C.M.; Barreira, E.; Almeida, R.M.S.F.; Vicente, R. Machine Learning Models Applied to Moisture Assessment in Building Materials. Constr. Build. Mater. 2023, 405, 133330. [Google Scholar] [CrossRef]

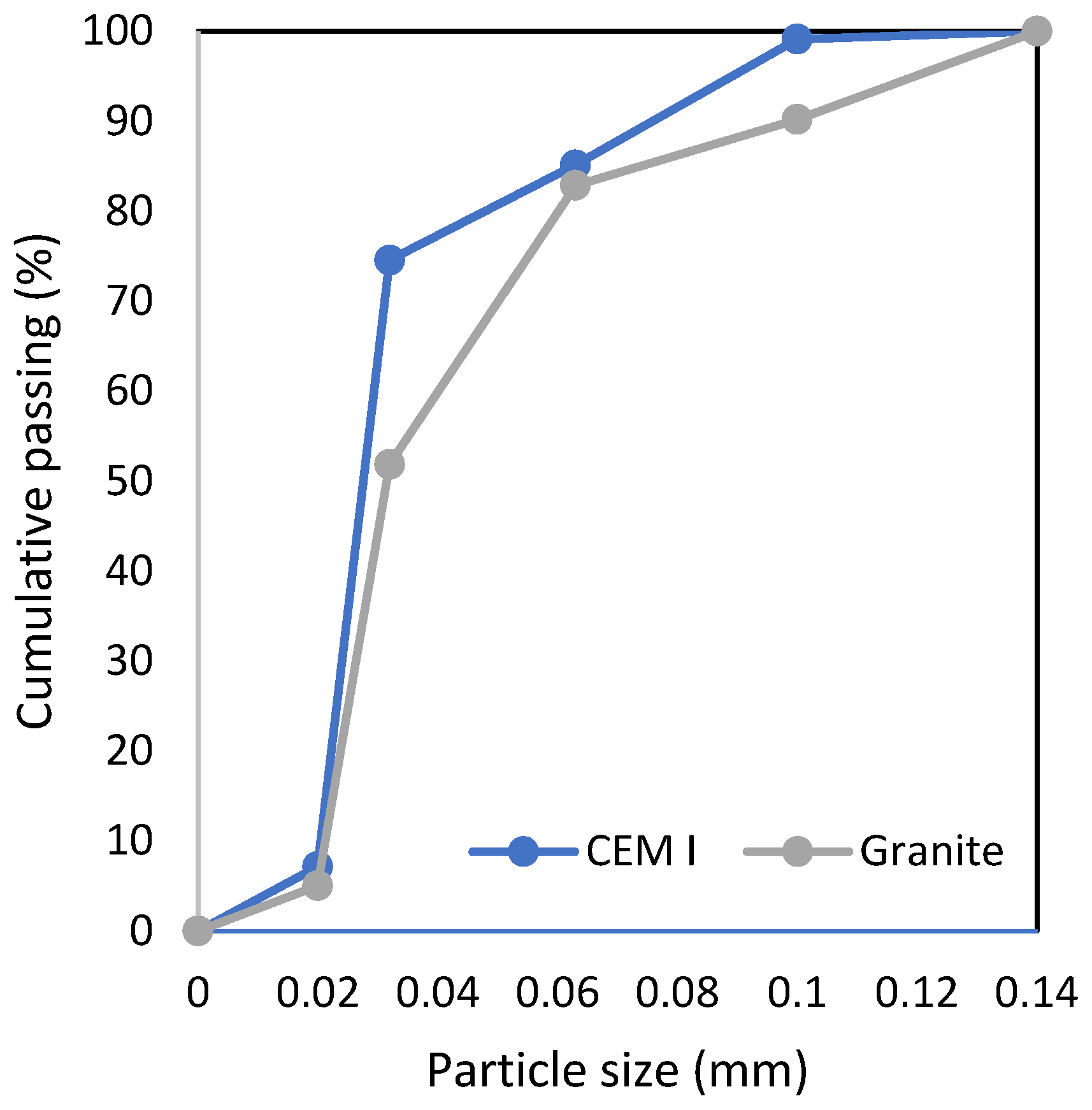

| Material | CaO | SiO2 | Al2O3 | K2O | SO3 | MgO | FeO | NaO | Fe2O3 |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 56.62 | 16.03 | 6.1 | 7.32 | 6.62 | 2.61 | 2.26 | 2.44 | |

| Granite | 8.3 | 53.63 | 19.9 | 3.29 | 5.54 | 3.46 | 3.46 | 2.42 |

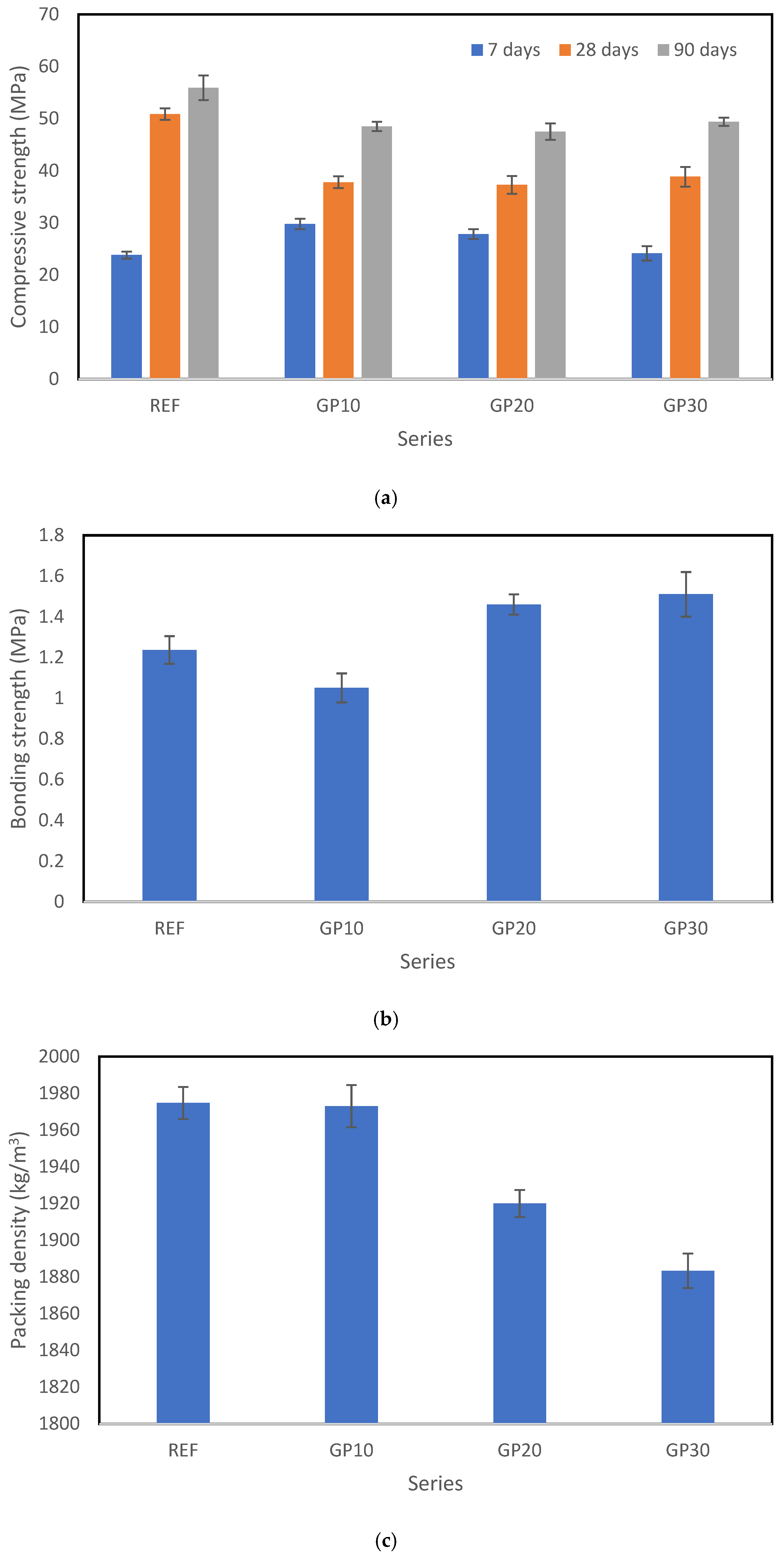

| Series [-] | Cement [kg/m3] | Water [kg/m3] | Granite Powder [kg/m3] | Fine Aggregate [kg/m3] |

|---|---|---|---|---|

| Ref | 512.0 | 266 | 0.0 | 1536.0 |

| GP10 | 460.8 | 266 | 51.2 | 1536.0 |

| GP20 | 409.6 | 266 | 102.4 | 1536.0 |

| GP30 | 358.4 | 266 | 153.6 | 1536.0 |

| Compressive Strength 7 Days [MPa] | Compressive Strength 28 Days [MPa] | Compressive Strength 90 Days [MPa] | Bonding Strength [MPa] | Packing Density [kg/m3] | |

|---|---|---|---|---|---|

| Mean | 26.38 | 41.19 | 50.33 | 1.31 | 1937.76 |

| Min | 22.58 | 35.14 | 44.86 | 0.95 | 1872.00 |

| Max | 31.55 | 53.10 | 59.10 | 1.69 | 1987.00 |

| Std. | 2.72 | 5.80 | 3.64 | 0.20 | 39.48 |

| CV | 10.30 | 14.09 | 7.24 | 15.20 | 2.04 |

| Author | Predicted Properties | Model | Granite Usage | R, MAPE |

|---|---|---|---|---|

| Armaghani et al. [30] | Unconfined uniaxial compressive strength | ANN-LM 3-10-1 | stone | R = 0.992, MAPE = 5.08% |

| Czarnecki et al. [31] | Compressive strength | RF | Cement substitutes max 30% | R = 0.989, MAPE = 3.30% |

| Fathy et al. [32] | Compressive strength | XGB | Cement substitutes max 9% | R = 0.999, MAPE = 0.5% |

| Chajec et al. [25] | Packing density | MLP 4-6-1 | Cement substitutes max 30% | R = 0.956, MAPE = 0.582% |

| Endzhievskaya et al. [33] | Density | DT and RF | Microsilica substitute, Natural aggregate | MAE = 5.13—compression MAE = 33.37—density MAE = 0.36—bending |

| Moj et al. [34] | Bonding strength | RF | Cement substitutes max 30% | R2 = 0.944, MAPE = 3.23% |

| Rojo-López et al. [35] | Flow, Tfunnel | Genetic programming | Cement substitute up to 25% | R2 = 0.944—flow, R2 = 0.978—tfunnel |

| Czarnecki et al. [18] | Abrasion | NN and RF | Cement substitutes max 30% | R2 = 0.939, MAPE = 10.61% |

| Dafico et al. [36] | Moisture | NN | stone | R2 = 0.999, MAPE = 2.70% |

| This work | Compressive strength, bonding strength, packing density, | MLP 4-10-15-5 | R = 0.991, MAPE = 3.13%,—compression R = 0.905, MAPE = 5.64%—bonding, R = 0.972, MAPE = 3.89%—packing density |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czarnecki, S. Identification of Selected Physical and Mechanical Properties of Cement Composites Modified with Granite Powder Using Neural Networks. Materials 2025, 18, 3838. https://doi.org/10.3390/ma18163838

Czarnecki S. Identification of Selected Physical and Mechanical Properties of Cement Composites Modified with Granite Powder Using Neural Networks. Materials. 2025; 18(16):3838. https://doi.org/10.3390/ma18163838

Chicago/Turabian StyleCzarnecki, Slawomir. 2025. "Identification of Selected Physical and Mechanical Properties of Cement Composites Modified with Granite Powder Using Neural Networks" Materials 18, no. 16: 3838. https://doi.org/10.3390/ma18163838

APA StyleCzarnecki, S. (2025). Identification of Selected Physical and Mechanical Properties of Cement Composites Modified with Granite Powder Using Neural Networks. Materials, 18(16), 3838. https://doi.org/10.3390/ma18163838