Study on Compression Properties and Construction Applications of Loess Filling Materials for High Embankments Along G85 Expressway in Eastern Gansu Province

Abstract

1. Introduction

2. Test Scheme

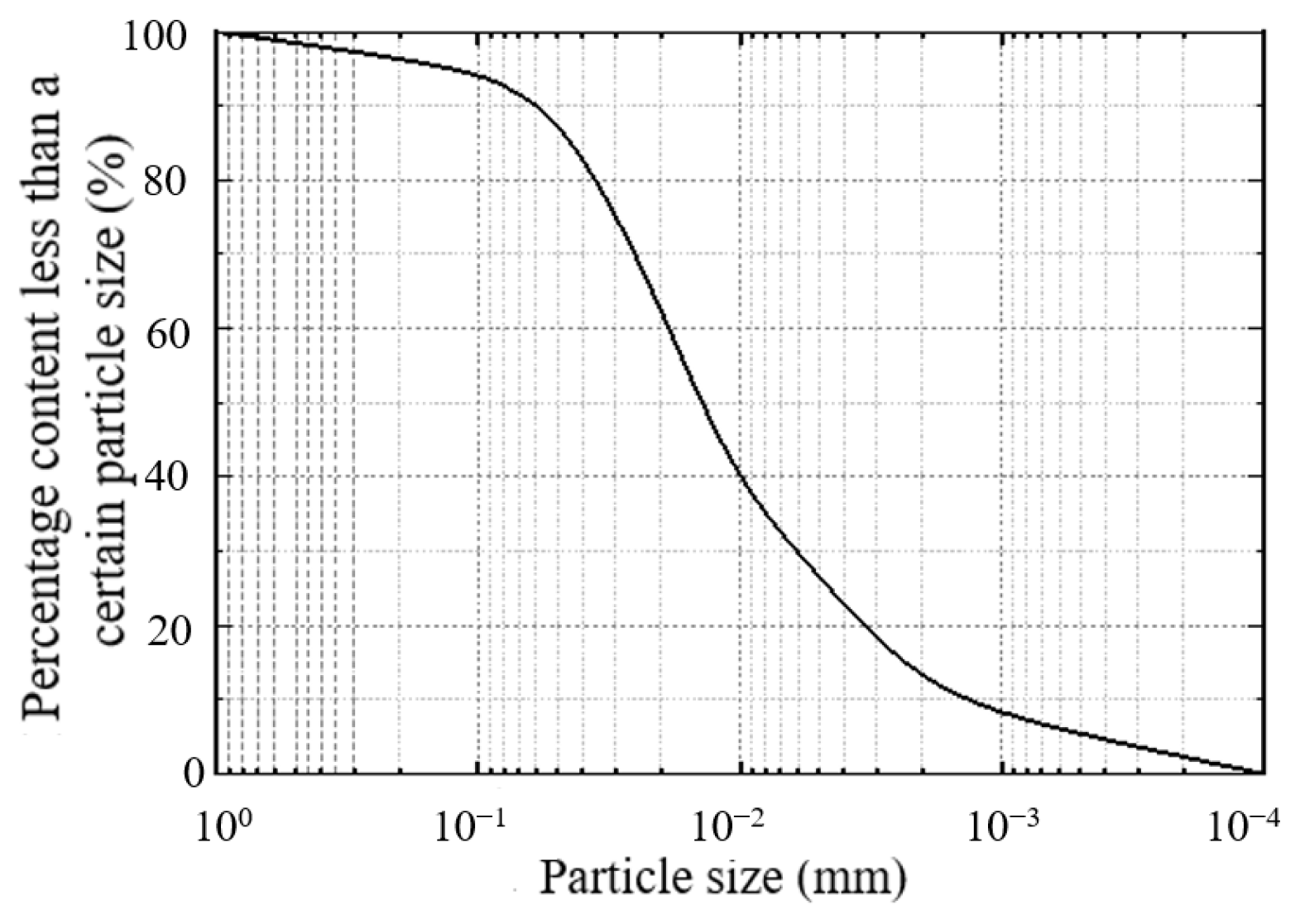

2.1. Site Conditions

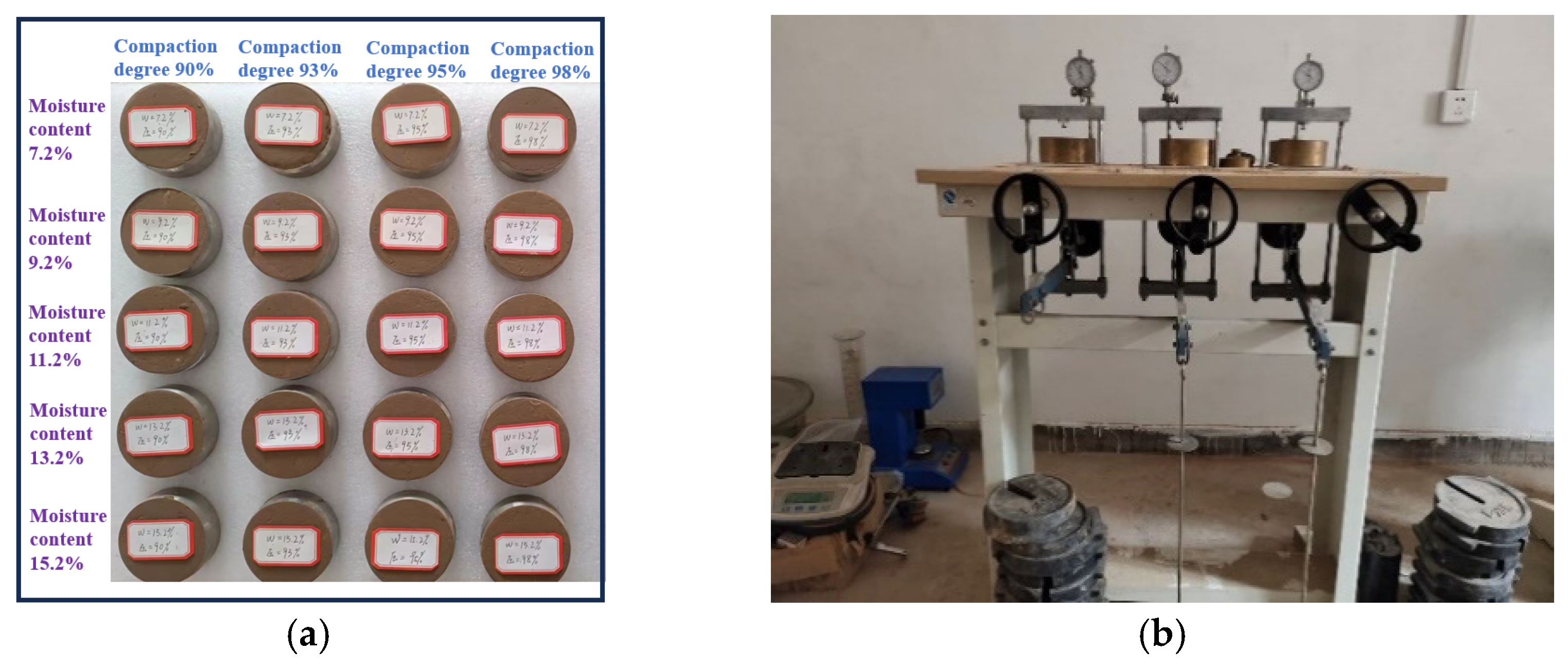

2.2. Remolded Soil Test

3. Results and Analysis

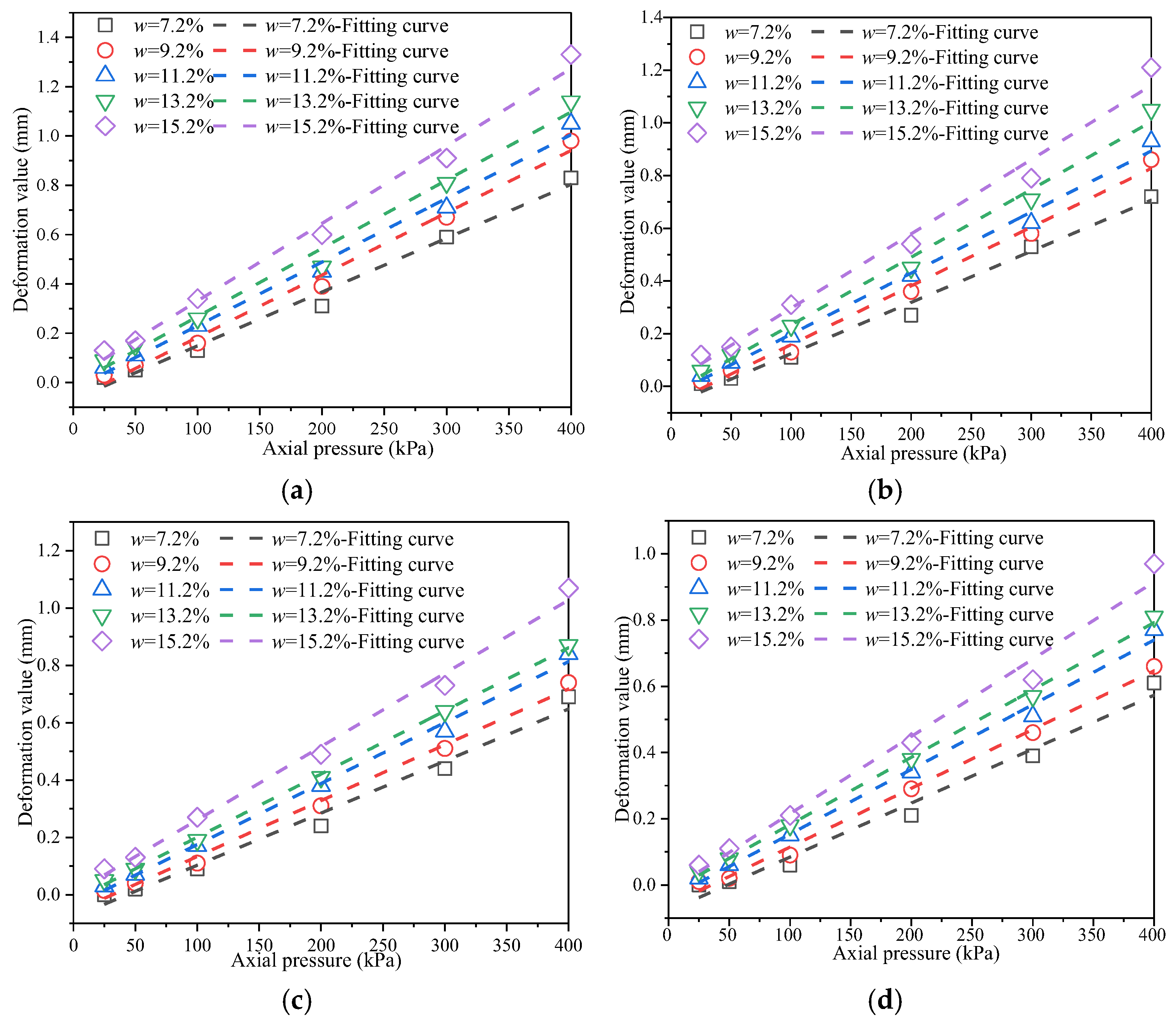

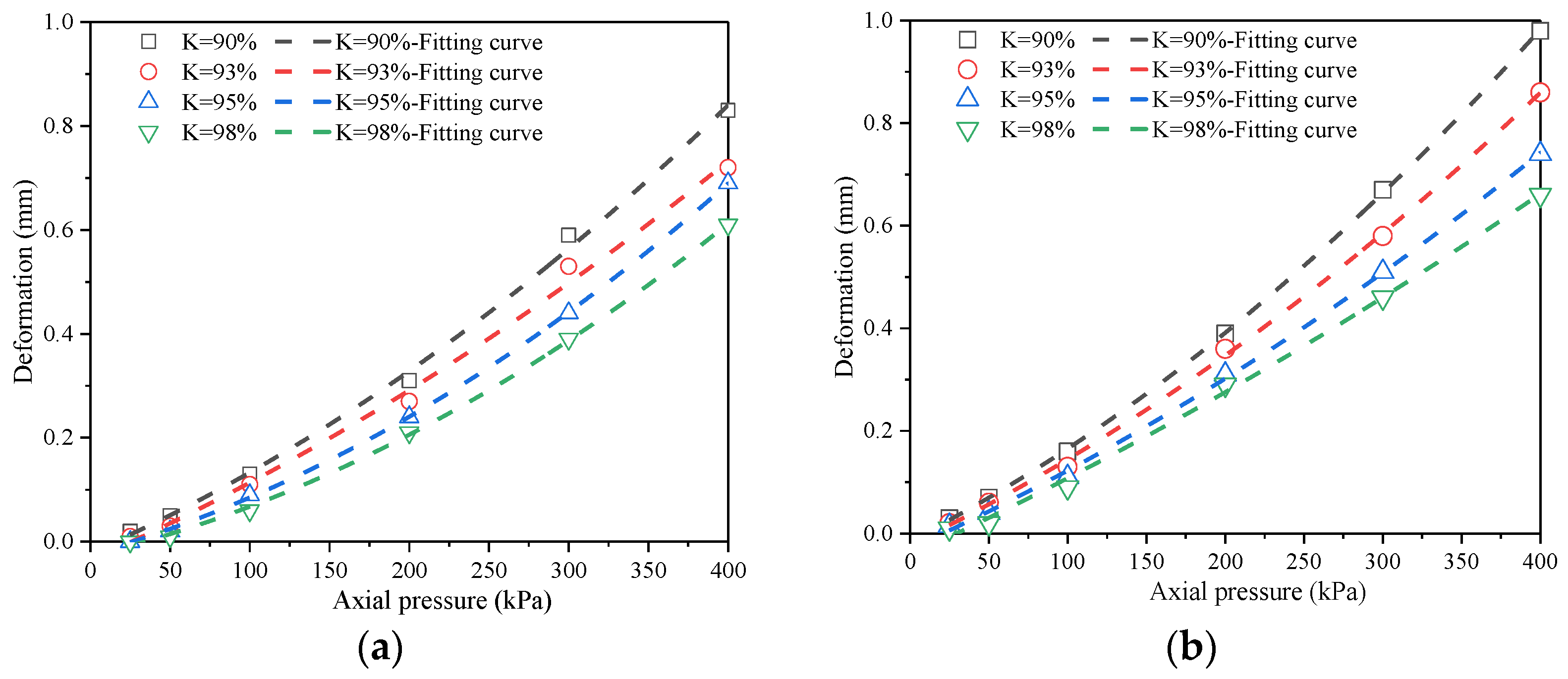

3.1. Analysis of Axial Compression and Deformation of Remolded Soil

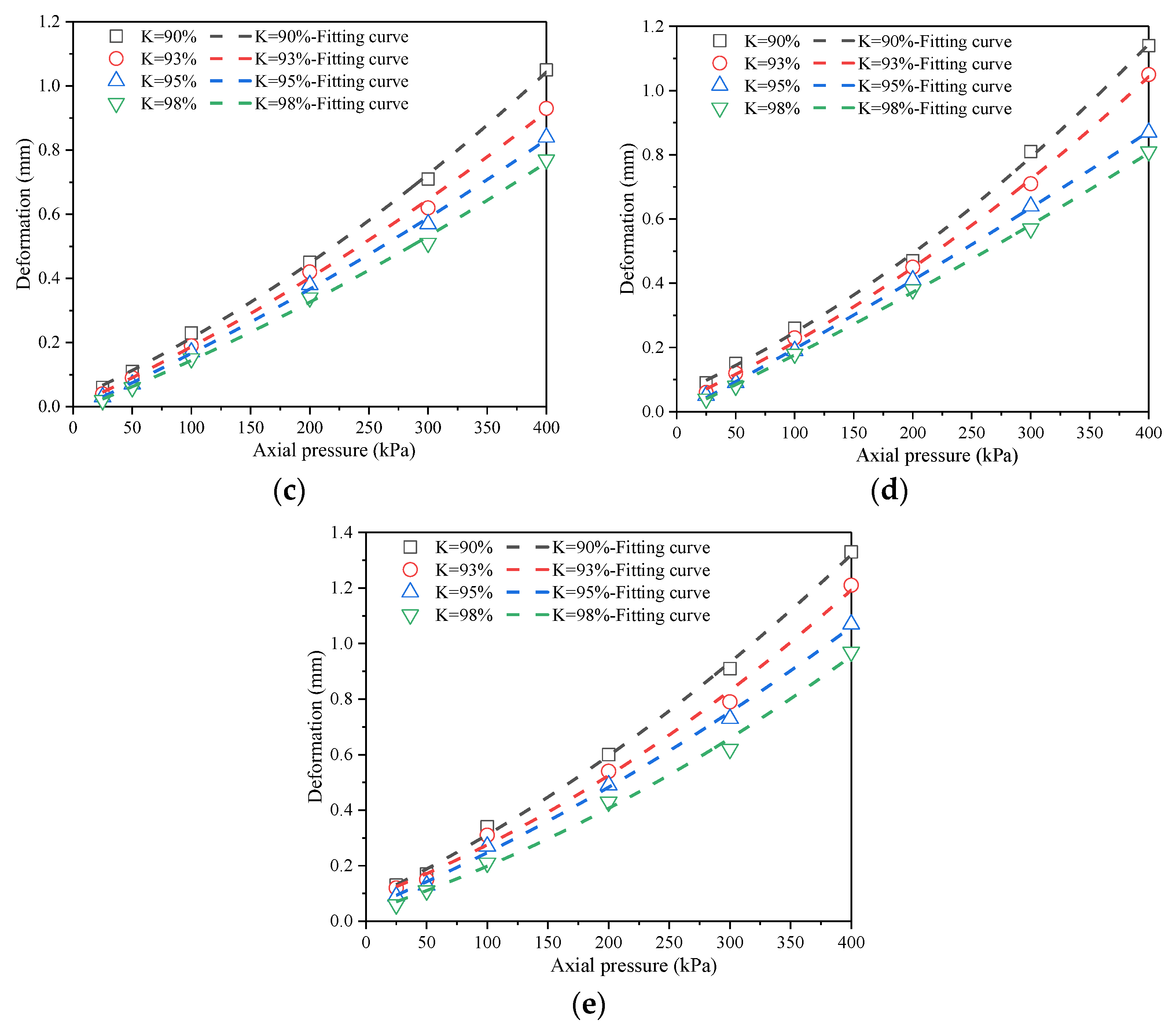

3.2. Analysis of Axial Pressure and Pore Ratio of Reshaped Soil

3.3. Analysis of Compressibility of Remolded Soil

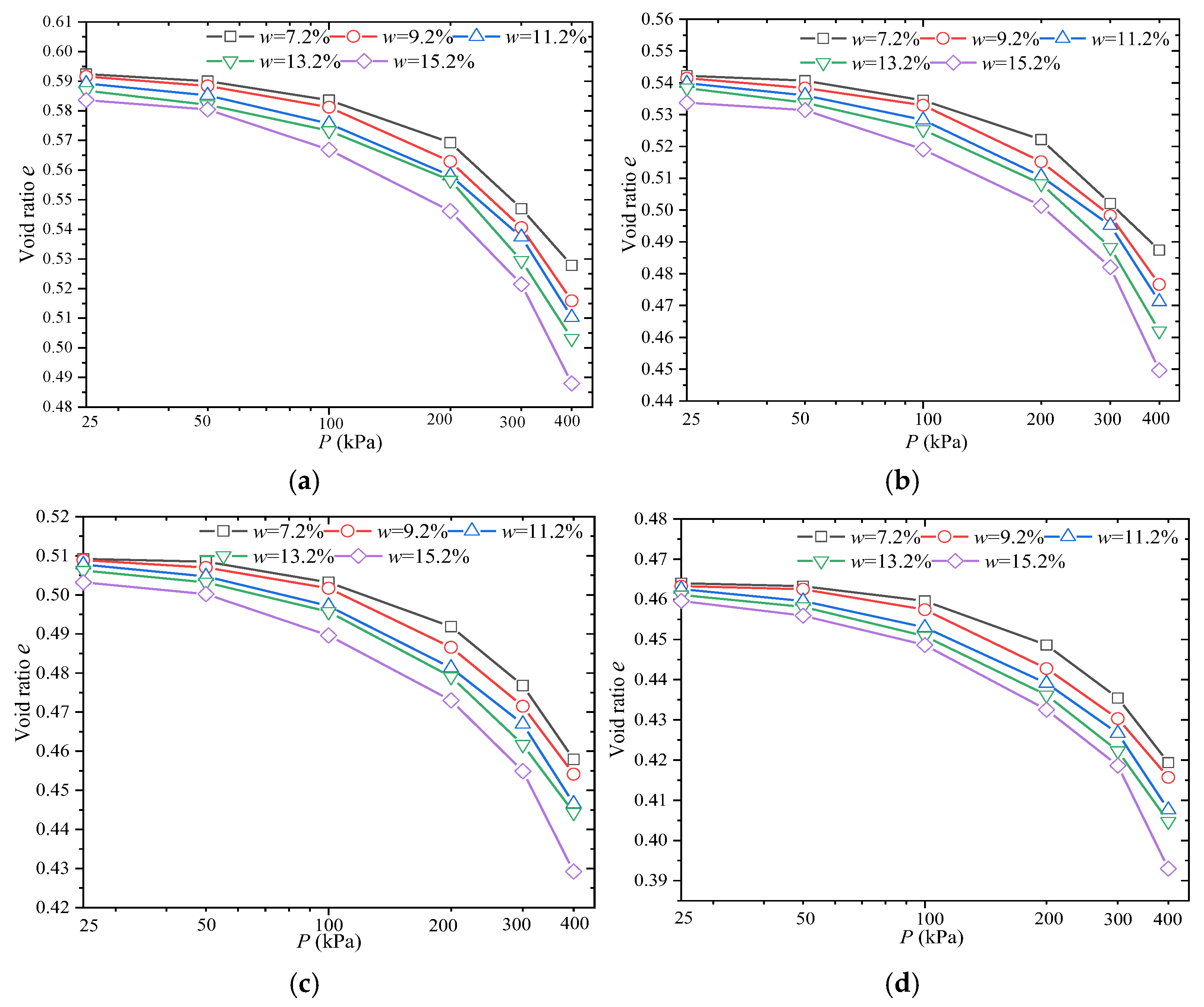

3.3.1. Compression Coefficient

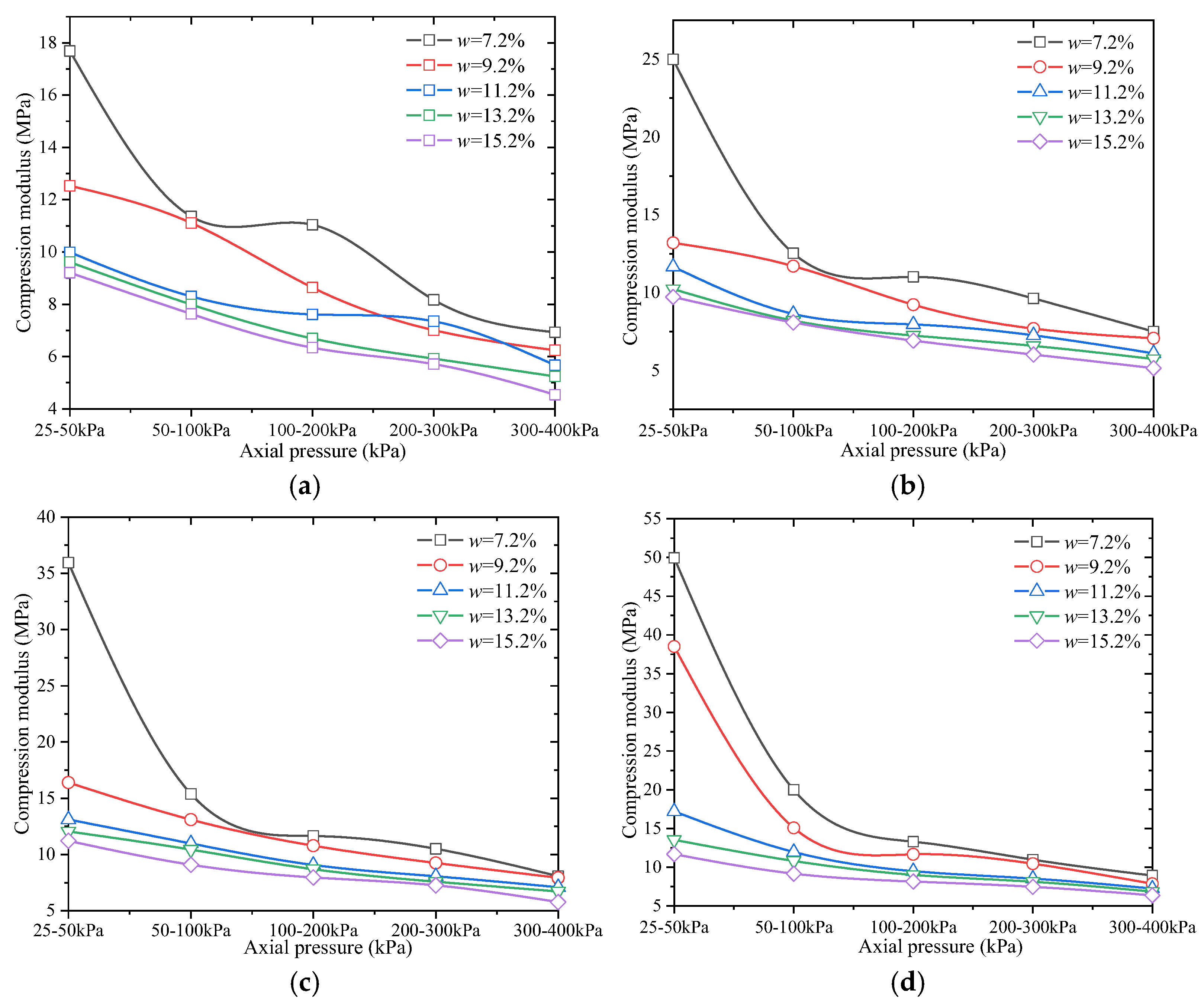

3.3.2. Compression Modulus

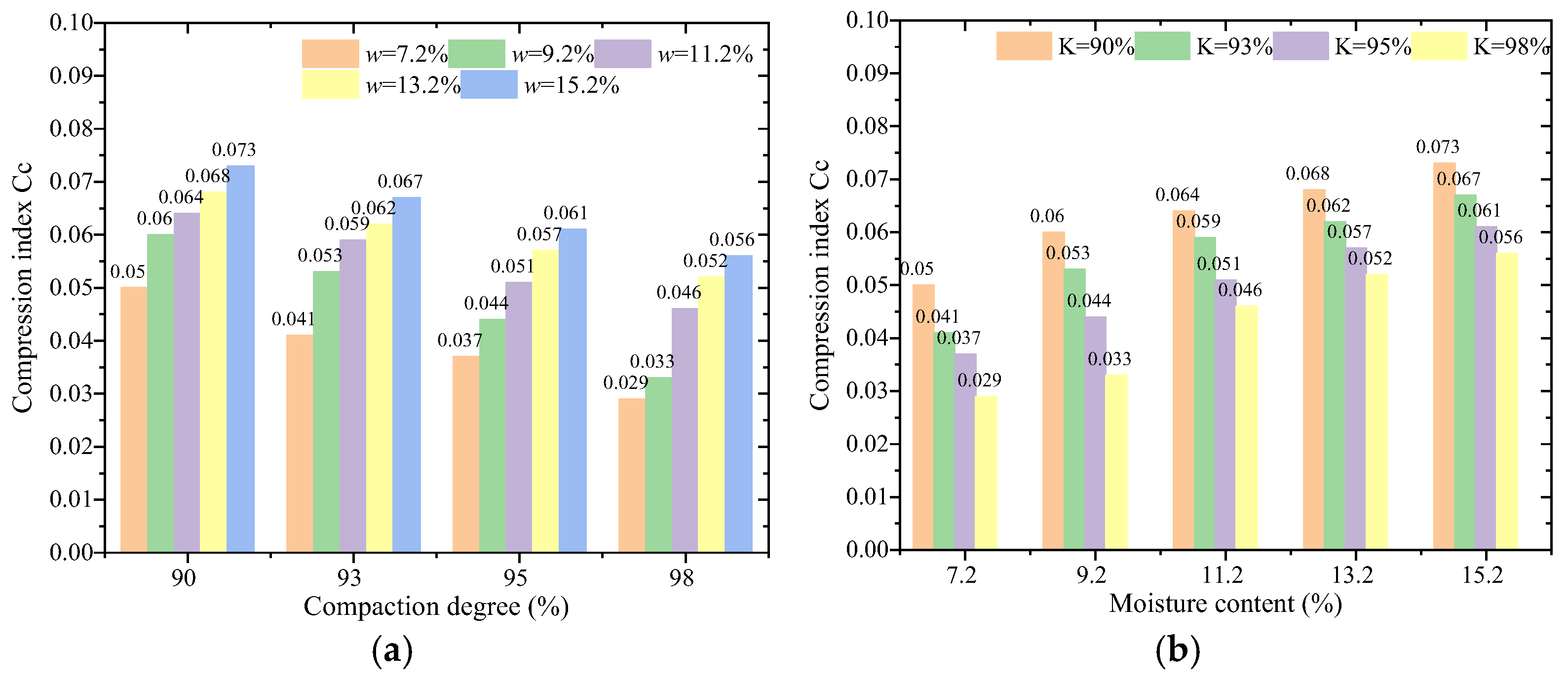

3.3.3. Compression Index

4. Engineering Examples

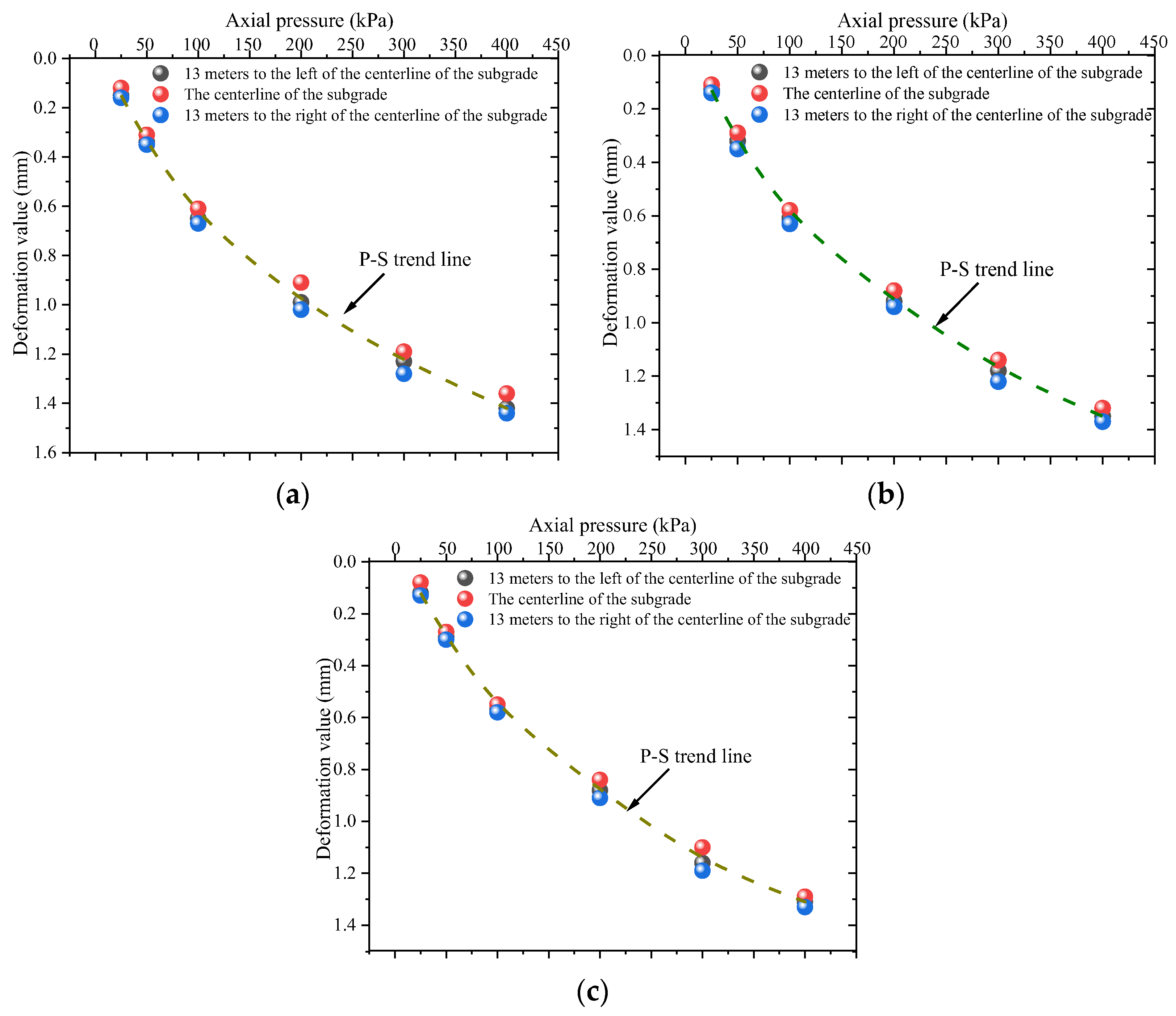

4.1. The Relationship Between Axial Pressure and Deformation of Compacted Loess in the Subgrade

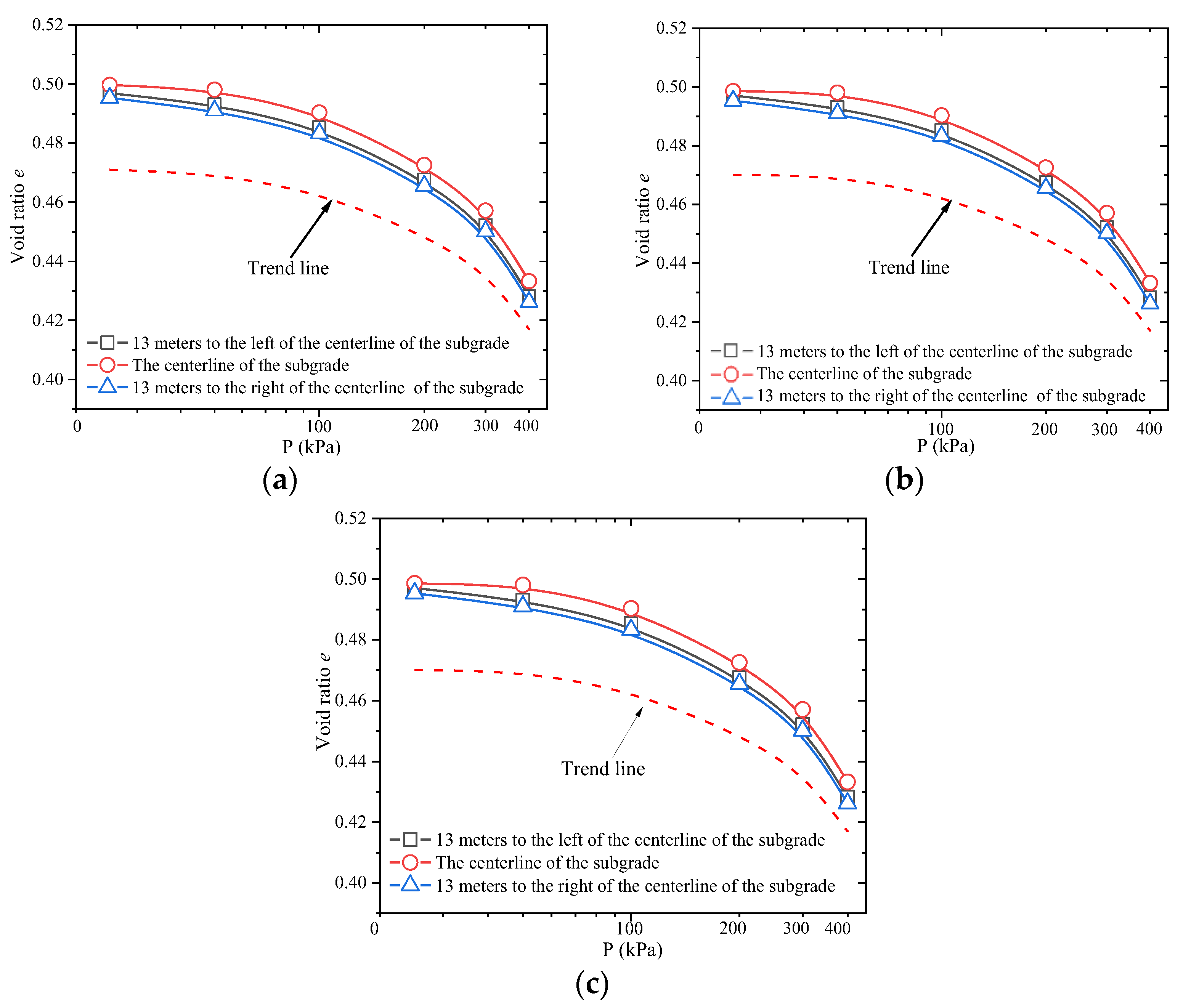

4.2. Relationship Between Porosity Ratio of Compacted Loess and Load

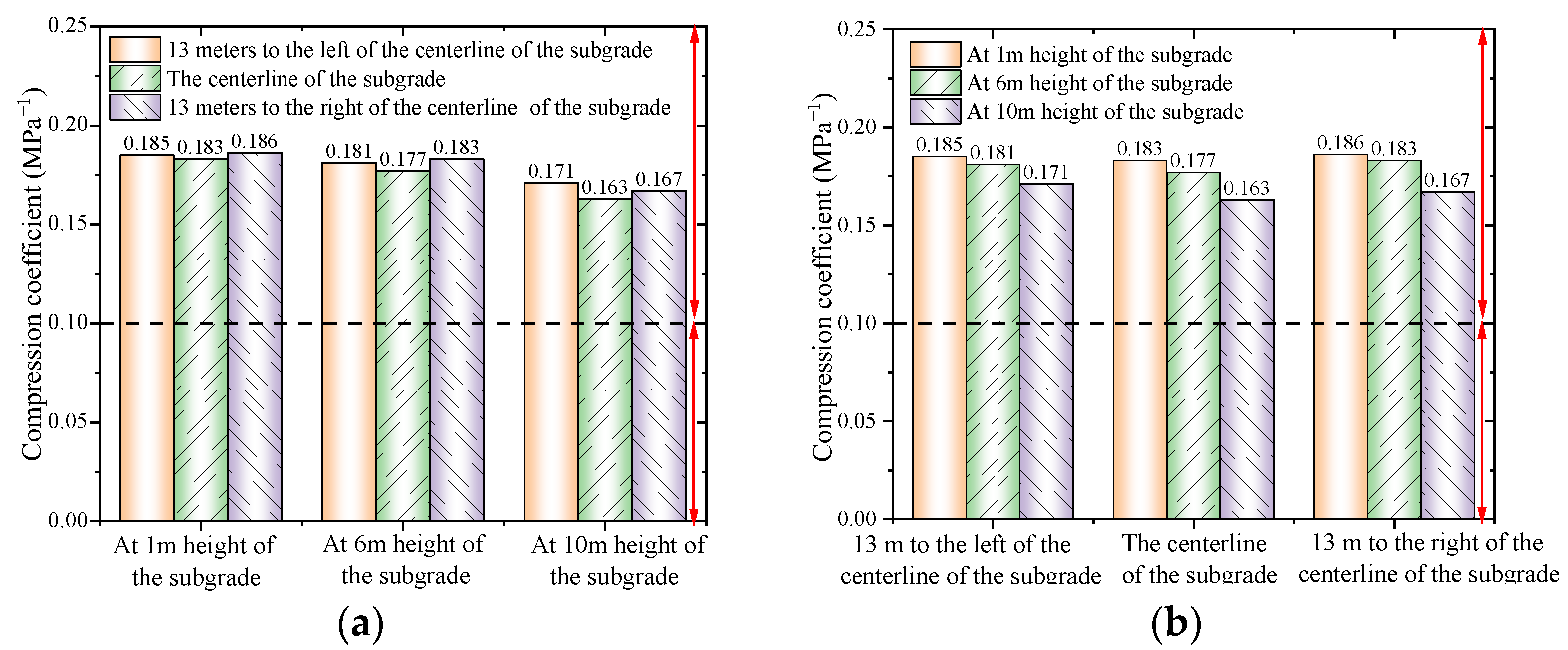

4.3. The Compression Coefficient of Compacted Loess in the Subgrade

5. Conclusions

- (1)

- Under the same compaction degree, the axial pressure of and variation in soil samples with different moisture contents form a linear function variation relationship; under the same moisture content, the axial pressure of and variation in soil samples with different compaction degrees form a quadratic function variation relationship.

- (2)

- With the increase in axial pressure, the pore ratio of each specimen gradually decreases. The pore ratio varies slightly within the load range of 25–100 kPa and significantly within the range of 100–400 kPa. The change in the pore ratio is negatively correlated with the compaction degree of the sample and positively correlated with the moisture content. Compression deformation is positively correlated with the compaction degree of the sample and negatively correlated with the moisture content.

- (3)

- Under an axial pressure of 100–200 kPa, the compression coefficient at a height of 10 m in the embankment ranges from 0.163 to 0.171 MPa−1; at 6 m, it ranges from 0.177 to 0.183 MPa−1; and at 1 m, it ranges from 0.183 to 0.186 MPa−1. These values indicate that the compacted loess across all embankment layers is characterized by low compressibility.

- (4)

- A comparison between the one-dimensional compression test results of remolded soil and those of compacted loess at various embankment levels confirms that the overall compaction meets the specified standards. However, the compaction quality near the side slopes of each layer is relatively lower, and additional dynamic compaction measures are recommended to improve uniformity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Guan, C.; Han, M.; Jia, J.; Liu, L.; Li, W. Estimation of settlement in loess-filled subgrade with consideration of lateral deformation. Arab. J. Sci. Eng. 2022, 47, 4713–4729. [Google Scholar] [CrossRef]

- Gu, C.; He, X.; Ge, M.; Liu, Y. Microstructure evolution of a compacted lateritic silt upon drying–wetting and loading. Can. Geotech. J. 2023, 60, 1599–1611. [Google Scholar] [CrossRef]

- Li, Z.; Ma, J.; Liu, X.; Liu, L.; Cai, G.; Peng, L.; Chen, B.; Liang, X.; Xiong, H. Exploring the temperature, humidity, and deformation characteristics of gravel replacement foundations in seasonally frozen zones: A model testing study. Bull. Eng. Geol. Environ. 2025, 84, 141. [Google Scholar] [CrossRef]

- Li, Z.; Lv, S.; Liu, L.; Guo, J.; Liu, T. Compressive Deformation Characteristics of Sintered Loess after Being Saturated with Water. Int. J. Geomech. 2024, 24, 04024177. [Google Scholar] [CrossRef]

- Jiang, Y.; Bai, C.; Zhang, Y.; Fan, J.; Yi, Y.; Deng, C. Compression Deformation and Collapsibility of Loess Subgrade Formed by Different Compaction Methods. J. Test. Eval. 2025, 53, 23–41. [Google Scholar] [CrossRef]

- Ge, M.; Pineda, J.; Sheng, D. Competing effects of wetting and volume change on G 0 in compacted loess. Géotechnique Lett. 2023, 13, 182–190. [Google Scholar] [CrossRef]

- He, J.; Li, T.; Rui, Y. Discrete Element Method Analyses of Bond Degradation Evolutions for Cemented Soils. Fractal Fract. 2024, 8, 119. [Google Scholar] [CrossRef]

- Liu, X.; Congress, S.S.C.; Cai, G.; Liu, L.; Liu, S.; Puppala, A.J.; Zhang, W. Development and validation of a method to predict the soil thermal conductivity u sing thermal piezocone penetration testing (T-CPTU). Can. Geotech. J. 2022, 59, 510–525. [Google Scholar] [CrossRef]

- Gu, F.; Xie, J.; Vuye, C.; Wu, Y.; Zhang, J. Synthesis of geopolymer using alkaline activation of building-related construction and demolition wastes. J. Clean. Prod. 2023, 420, 138335. [Google Scholar] [CrossRef]

- Li, Z.; Lv, S.; Zhao, J.; Zhu, J.; Shao, D.; Guan, C.; Liu, L. Experimental study on the effects of lateral constraints on the deformation and Mechanical properties of compacted Loess. Arab. J. Sci. Eng. 2025, 50, 1421–1437. [Google Scholar] [CrossRef]

- Garakani, A.A.; Haeri, S.M.; Khosravi, A.; Habibagahi, G. Hydro-mechanical behavior of undisturbed collapsible loessial soils under different stress state conditions. Eng. Geol. 2015, 195, 28–41. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Zhang, K.; Xiao, D.; Zhang, L. Effects of freeze-thaw on the water-heat process in a loess subgrade over a cut-fill transition zone by laboratory investigation. Cold Reg. Sci. Technol. 2019, 164, 102789. [Google Scholar] [CrossRef]

- Juang, C.H.; Dijkstra, T.; Wasowski, J.; Meng, X. Loess geohazards research in China: Advances and challenges for mega engineering projects. Eng. Geol. 2019, 251, 1–10. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, Z.; Guo, T.; Xu, T.; Zhu, L.; Xu, F.; Chen, C.; Liu, T. A measuring method for layered compactness of loess subgrade based on hydraulic compaction. Meas. Sci. Technol. 2021, 32, 055106. [Google Scholar] [CrossRef]

- Yue, J.; Zhang, H.; Zhang, Y.; Xu, S. Experimental investigation of influence of amide polymer on loess for subgrade. Sci. Rep. 2024, 14, 12229. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B.; Cetin, K.S. Freeze-thaw performance of phase change material (PCM) incorporated pavement subgrade soil. Constr. Build. Mater. 2019, 202, 449–464. [Google Scholar] [CrossRef]

- Bao, H.; Song, Z.; Lan, H.; Ma, Y.; Yan, C.; Liu, S. Analysis of the mechanical effects and influencing factors of cut-fill interface within loess subgrade. Eng. Fail. Anal. 2024, 163, 108488. [Google Scholar] [CrossRef]

- Jiang, M.J.; Li, T.; Hu, H.J.; Thornton, C. DEM analyses of one-dimensional compression and collapse behaviour of unsaturated structural loess. Comput. Geotech. 2014, 60, 47–60. [Google Scholar] [CrossRef]

- Qin, P.; Yan, Q.; Lu, Y.; Yang, C.; Song, Z.; Li, C. One-dimensional compressibility and creep characteristics of unsaturated compacted loess based on incremental loading and constant rate of strain methods. Sustainability 2023, 15, 13854. [Google Scholar] [CrossRef]

- Ge, M.; Pineda, J.A.; Sheng, D.; Burton, G.J.; Li, N. Microstructural effects on the wetting-induced collapse in compacted loess. Comput. Geotech. 2021, 138, 104359. [Google Scholar] [CrossRef]

- Guo, Y.; Ni, W.; Liu, H. Effects of dry density and water content on compressibility and shear strength of loess. Geomech. Eng. 2021, 24, 419–430. [Google Scholar]

- Xing, Y.; Gao, D.; Jin, S.; Zhang, A.; Guo, M. Study on mechanical behaviors of unsaturated loess in terms of moistening level. KSCE J. Civ. Eng. 2019, 23, 1055–1063. [Google Scholar] [CrossRef]

- Cheng, X.; Cai, X.; Zha, W.; Zhou, Y.; Gong, L. Engineering characteristics test on pile–net composite foundation in loess areas. Proc. Inst. Civ. Eng.-Geotech. Eng. 2022, 175, 3–14. [Google Scholar] [CrossRef]

- Li, S.; Lai, Y.; Zhang, M.; Jin, L. Seismic analysis of embankment of Qinghai–Tibet railway. Cold Reg. Sci. Technol. 2009, 55, 151–159. [Google Scholar] [CrossRef]

- Guo, Y.; Pei, W.; Zhang, M.; Liu, D.; Bai, R.; Zhou, Y.; Li, G. Numerical study on cooling performance of the L-shaped crushed-rock embankment in permafrost regions. Cold Reg. Sci. Technol. 2025, 230, 104380. [Google Scholar] [CrossRef]

- Ganguly, S.; Margel, S. Fabrication and applications of magnetic polymer composites for soft robotics. Micromachines 2023, 14, 2173. [Google Scholar] [CrossRef]

- Pan, J.; Zhao, P.; Wang, N.; Huang, F.; Dou, S. Research progress in stable interfacial constructions between composite polymer electrolytes and electrodes. Energy Environ. Sci. 2022, 15, 2753–2775. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Y.; Li, L.; Zhao, G.; Xu, S. Adhesive performance and impermeability mechanism of loess embankment using caster oil based polyurethane reinforce. Constr. Build. Mater. 2023, 364, 130006. [Google Scholar] [CrossRef]

- Hu, C.M.; Wang, X.Y.; Mei, Y.; Yuan, Y.L.; Zhang, S.S. Compaction techniques and construction parameters of loess as filling material. Geomech. Eng. 2018, 15, 1143–1151. [Google Scholar]

- Khan, M.O.; Marcinek, T.; Iwan, A.K. Impact of climate change on root zone soil moisture in two Polish cities. Sylwan 2024, 168, 717–735. [Google Scholar]

- Li, H.; Chen, Z.; Zhu, L.; Tang, L.; Liu, G.; Qu, L.; Zhou, Z. Dynamic properties of Malan loess based on triaxial shear tests. Geol. J. 2024, 59, 2487–2495. [Google Scholar] [CrossRef]

- Luo, L.; Wang, X.; Xue, C.; Wang, D.; Lian, B. Laboratory experiments and numerical simulation study of composite-material-modified loess improving high-speed railway subgrade. Polymers 2022, 14, 3215. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Wu, M.; Wu, X.; Zhang, F.; Zhang, J.; Qiao, H.; Zhang, Y.; Zhang, Y. Study on the performance of collapsible loess subgrade improved by steel slag. J. Build. Eng. 2024, 84, 108642. [Google Scholar] [CrossRef]

- Lenoir, T.; Dubreucq, T.; Lambert, T.; Killinger, D. Safety factor calculation of a road structure with cement-modified loess as subgrade. Transp. Geotech. 2021, 30, 100604. [Google Scholar] [CrossRef]

- Liu, L.; Li, Z.; Guo, J.; Lv, S.; Liu, X.; Cai, G.; Fan, G. Compression characteristics and microscopic mechanism of high-temperature sintered loess. Constr. Build. Mater. 2025, 490, 142456. [Google Scholar] [CrossRef]

- Liu, L.; Liu, T.; Liu, X.; Li, Z.; Cai, G. Key influencing factors and prediction model for the tensile strength of compacted clayey loess. Bull. Eng. Geol. Environ. 2025, 84, 404. [Google Scholar] [CrossRef]

| Soil Sample | Density ρ (g/cm3) | Dry Density ρd (g/cm3) | Moisture Content ω (%) | Plastic Limit ωp (%) | Liquid Limit ωL (%) | Optimum Moisture Content ωop (%) | Maximum Dry Density ρdmax (g/cm3) |

|---|---|---|---|---|---|---|---|

| Loess | 1.78 | 1.63 | 9.5 | 9 | 25 | 11.2 | 1.882 |

| Moisture Content (%) | Compaction Degree (%) | Sample Size | Compaction Method | Number of Samples | Axial Pressure (kPa) |

|---|---|---|---|---|---|

| 7.2 | 90 | 60 cm3 ring knife sample | Standard proctor compaction | 2 | 25-50-100-200-300-400 |

| 93 | 2 | ||||

| 95 | 2 | ||||

| 98 | 2 | ||||

| 9.2 | 90 | 60 cm3 ring knife sample | Standard proctor | 2 | 25-50-100-200-300-400 |

| 93 | 2 | ||||

| 95 | 2 | ||||

| 98 | 2 | ||||

| 11.2 | 90 | 60 cm3 ring knife sample | Standard proctor | 2 | 25-50-100-200-300-400 |

| 93 | 2 | ||||

| 95 | 2 | ||||

| 98 | 2 | ||||

| 13.2 | 90 | 60 cm3 ring knife sample | Standard proctor | 2 | 25-50-100-200-300-400 |

| 93 | 2 | ||||

| 95 | 2 | ||||

| 98 | 2 | ||||

| 15.2 | 90 | 60 cm3 ring knife sample | Standard proctor | 2 | 25-50-100-200-300-400 |

| 93 | 2 | ||||

| 95 | 2 | ||||

| 98 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Chen, Y.; Yi, X.; Zhao, J.; Liu, L.; Wang, H.; Han, M. Study on Compression Properties and Construction Applications of Loess Filling Materials for High Embankments Along G85 Expressway in Eastern Gansu Province. Materials 2025, 18, 3811. https://doi.org/10.3390/ma18163811

Sun W, Chen Y, Yi X, Zhao J, Liu L, Wang H, Han M. Study on Compression Properties and Construction Applications of Loess Filling Materials for High Embankments Along G85 Expressway in Eastern Gansu Province. Materials. 2025; 18(16):3811. https://doi.org/10.3390/ma18163811

Chicago/Turabian StyleSun, Wei, Yongle Chen, Xiaoli Yi, Jinpeng Zhao, Lulu Liu, Hongli Wang, and Meng Han. 2025. "Study on Compression Properties and Construction Applications of Loess Filling Materials for High Embankments Along G85 Expressway in Eastern Gansu Province" Materials 18, no. 16: 3811. https://doi.org/10.3390/ma18163811

APA StyleSun, W., Chen, Y., Yi, X., Zhao, J., Liu, L., Wang, H., & Han, M. (2025). Study on Compression Properties and Construction Applications of Loess Filling Materials for High Embankments Along G85 Expressway in Eastern Gansu Province. Materials, 18(16), 3811. https://doi.org/10.3390/ma18163811