Evaluation of Hazel-Derived Particleboard as a Substitute for Conventional Wood-Based Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials, Preparation of Panels, and Characterization of the Elaborated Panels

2.2. Statistical Analyses

3. Results and Discussion

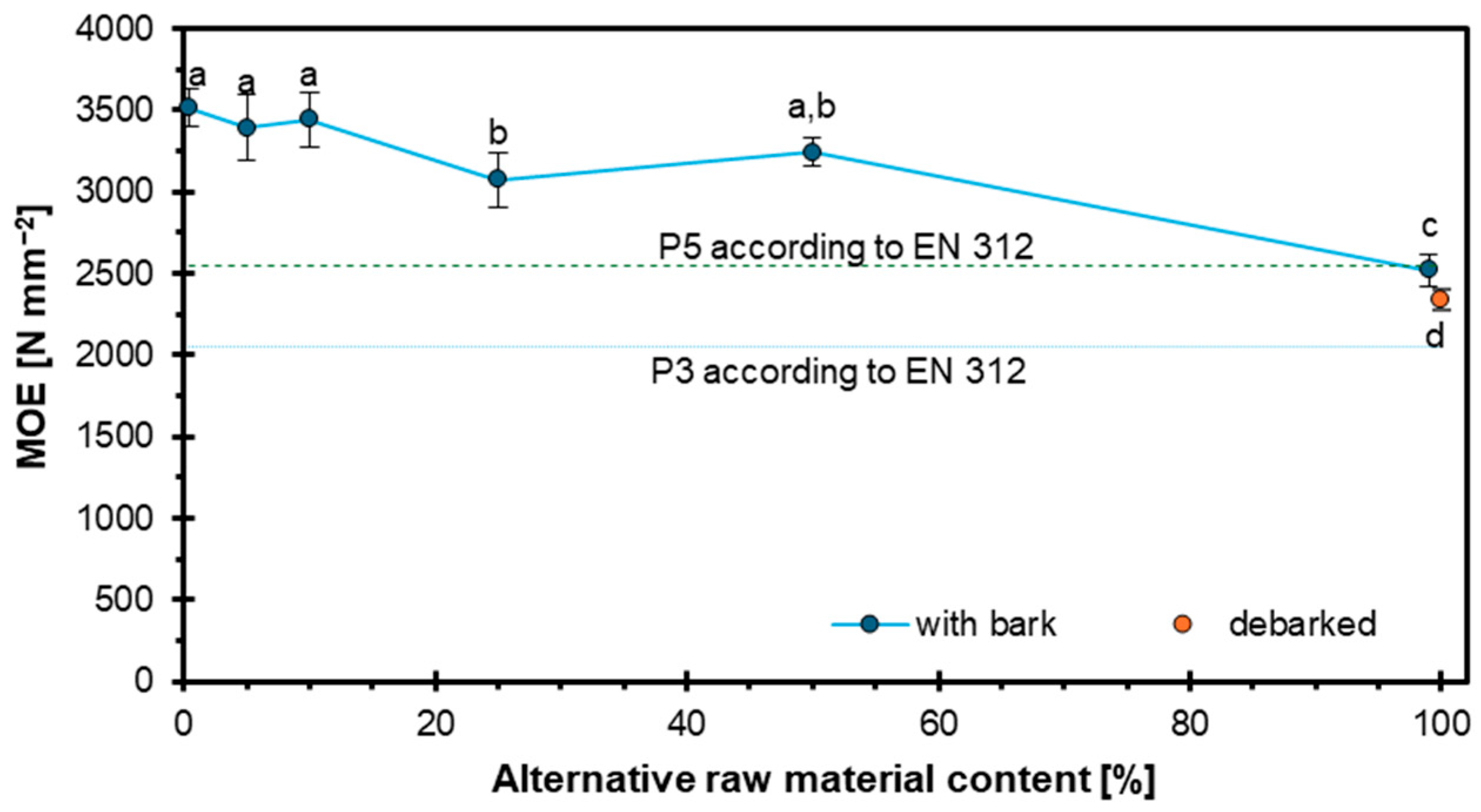

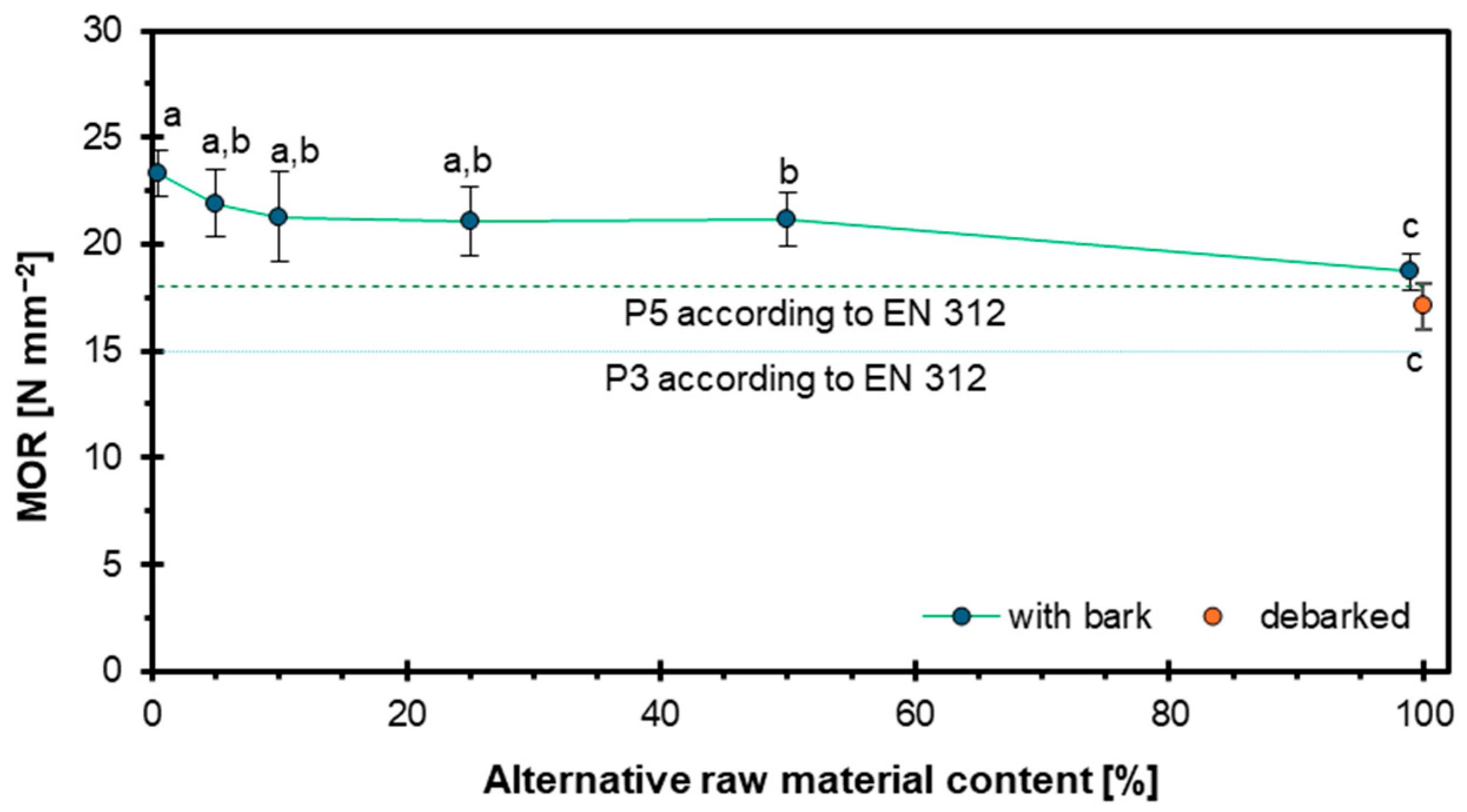

3.1. Determination of Modulus of Rupture and Modulus of Elasticity in Bending and of Bending Strength

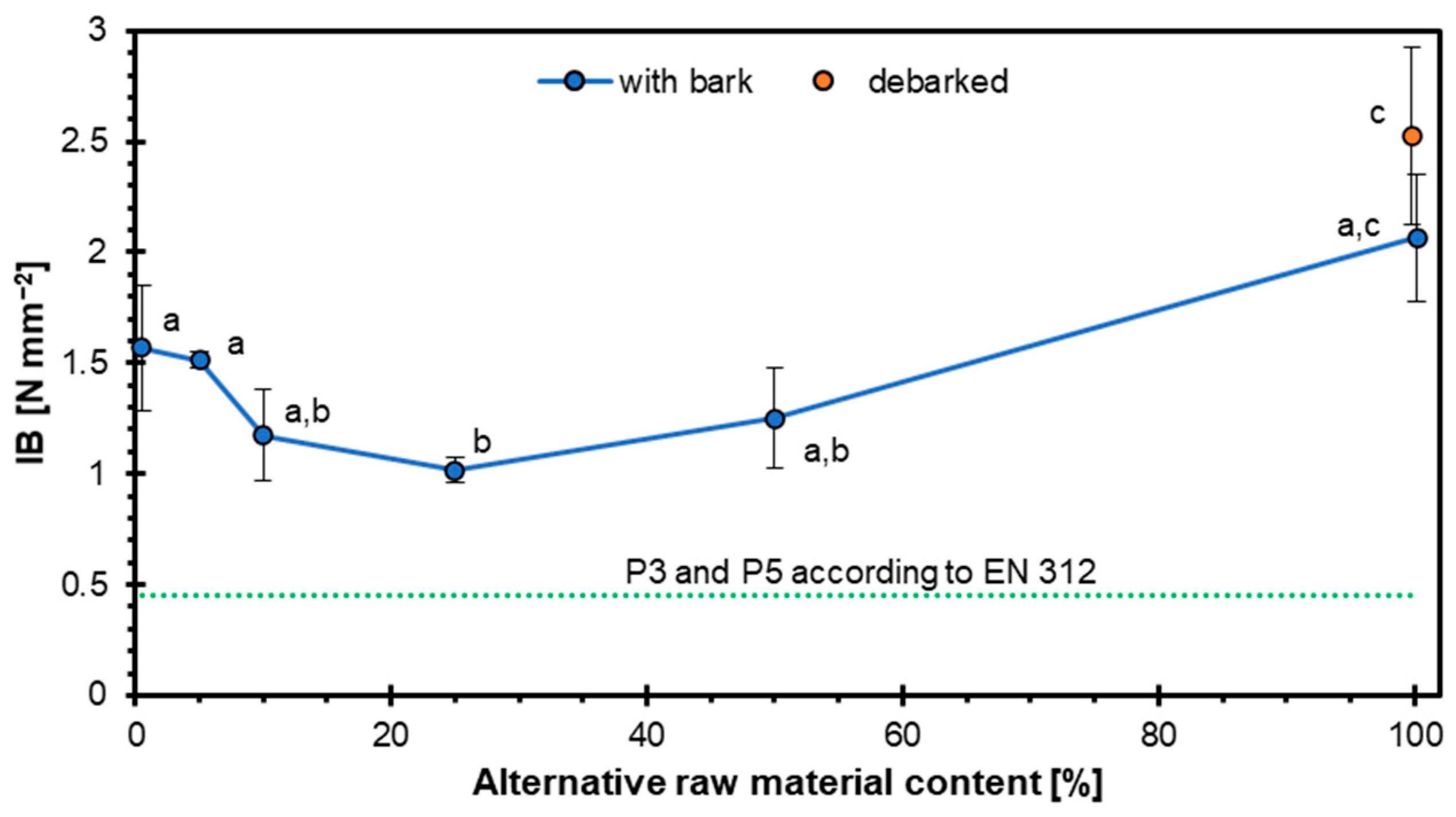

3.2. Internal Bond

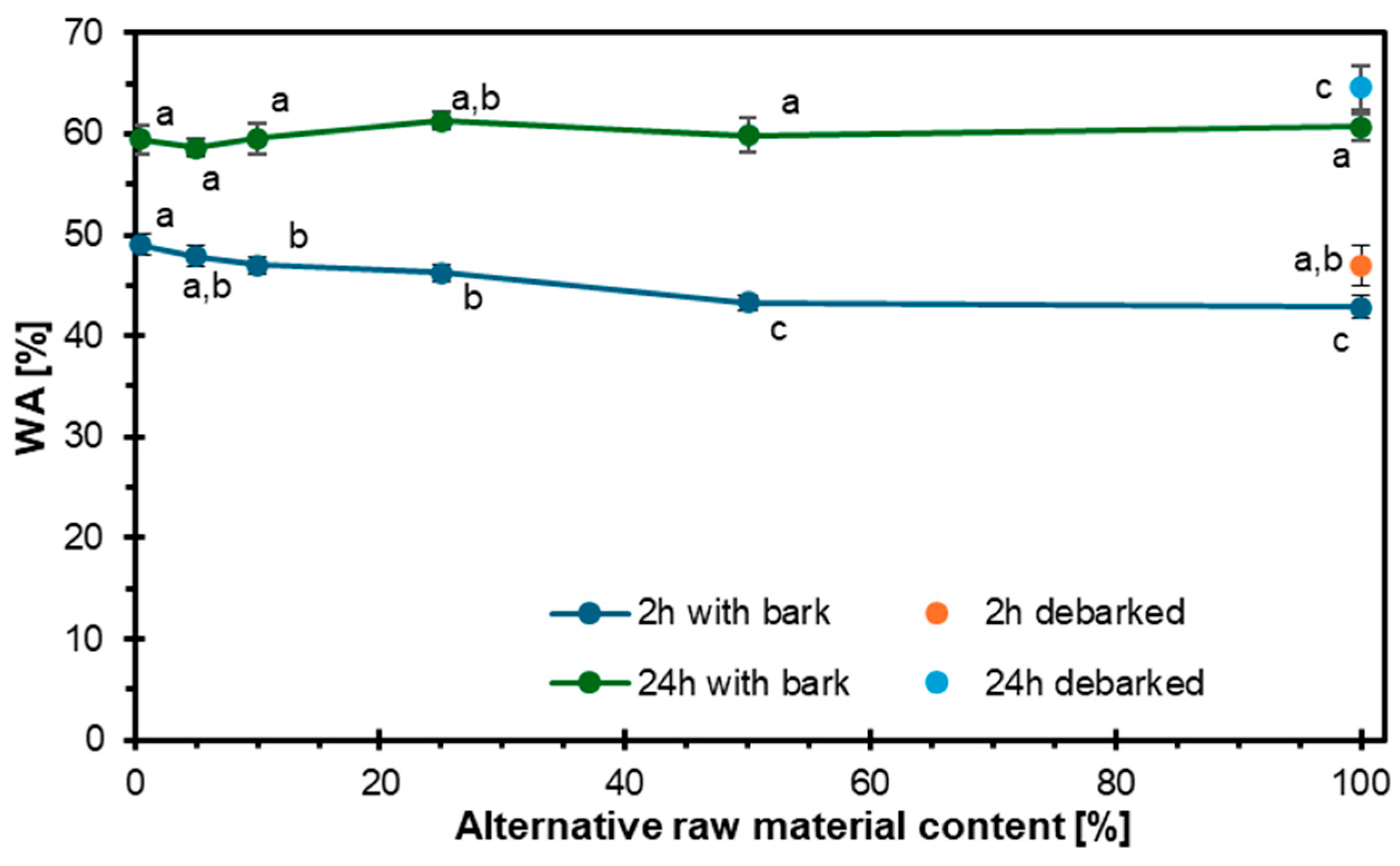

3.3. Water Absorption and Thickness Swelling

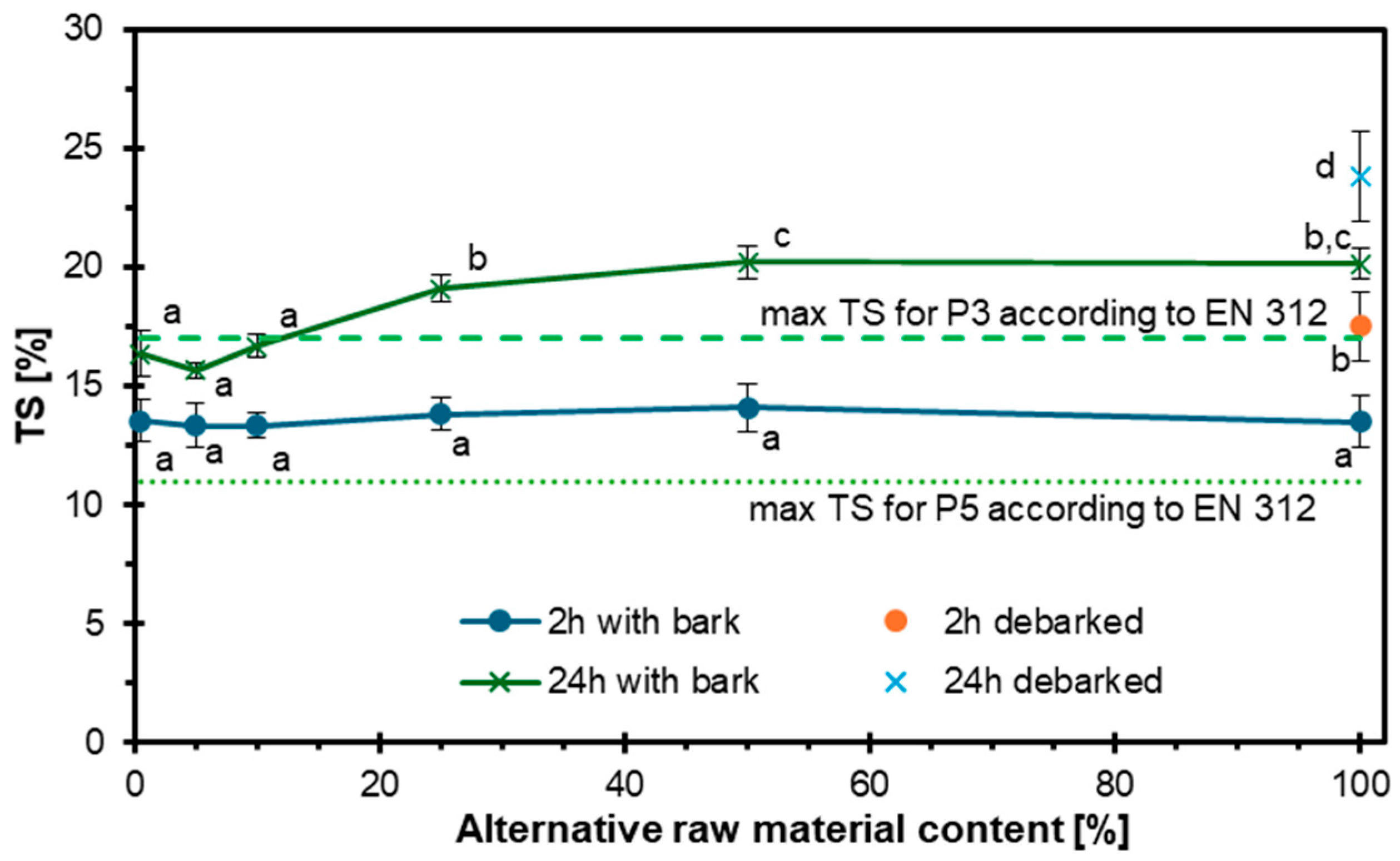

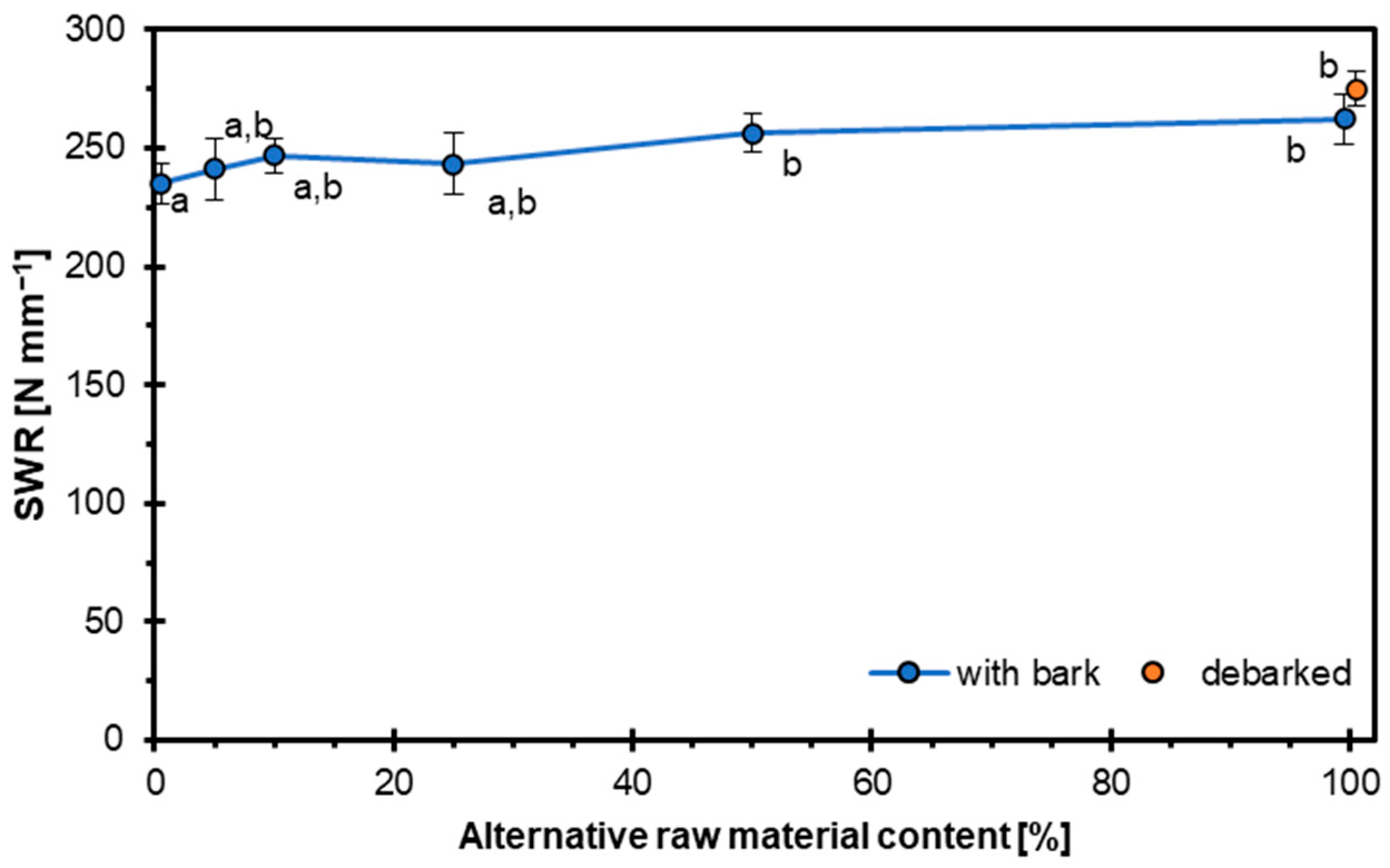

3.4. Screw Withdrawal Resistance

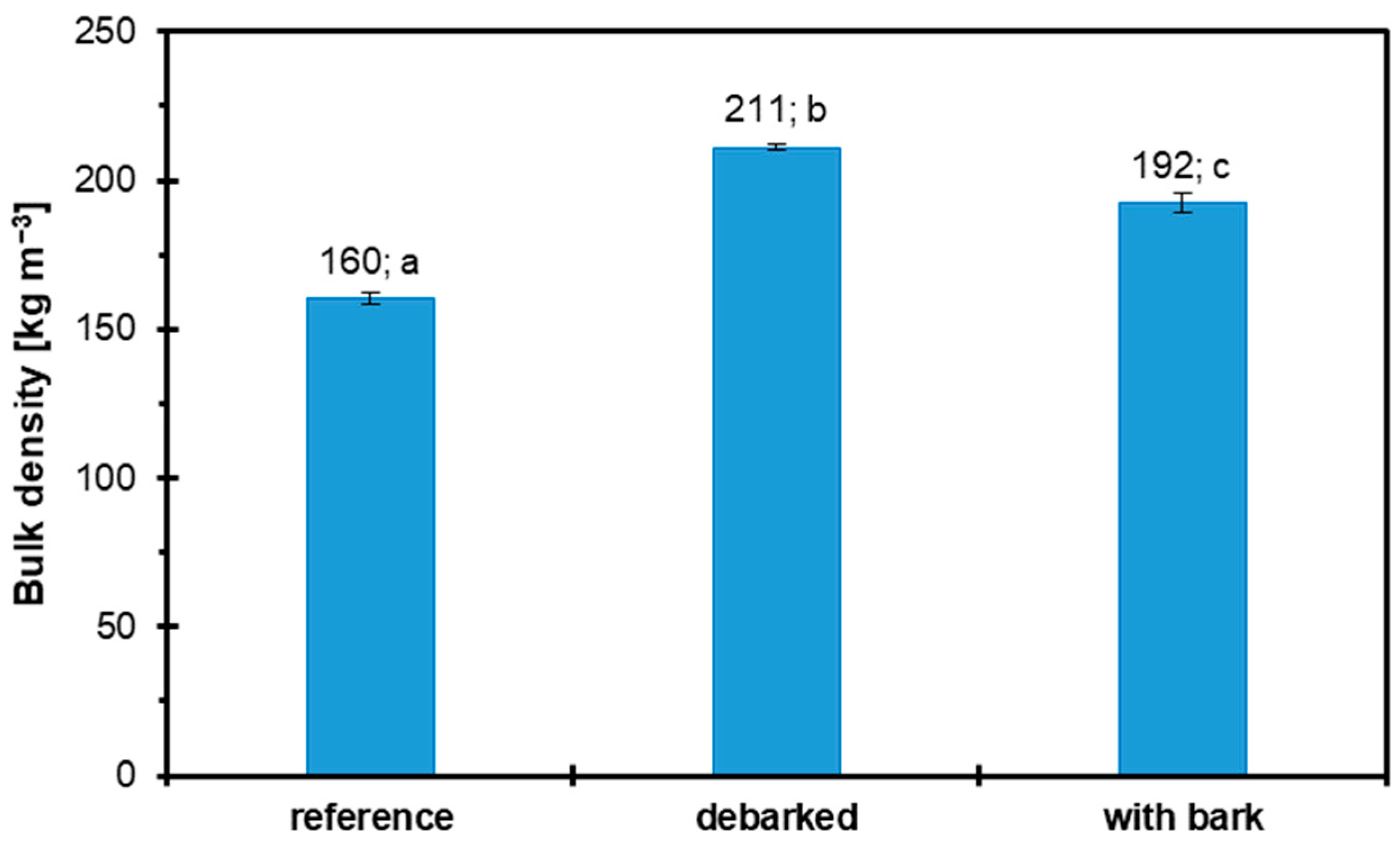

3.5. Bulk Density

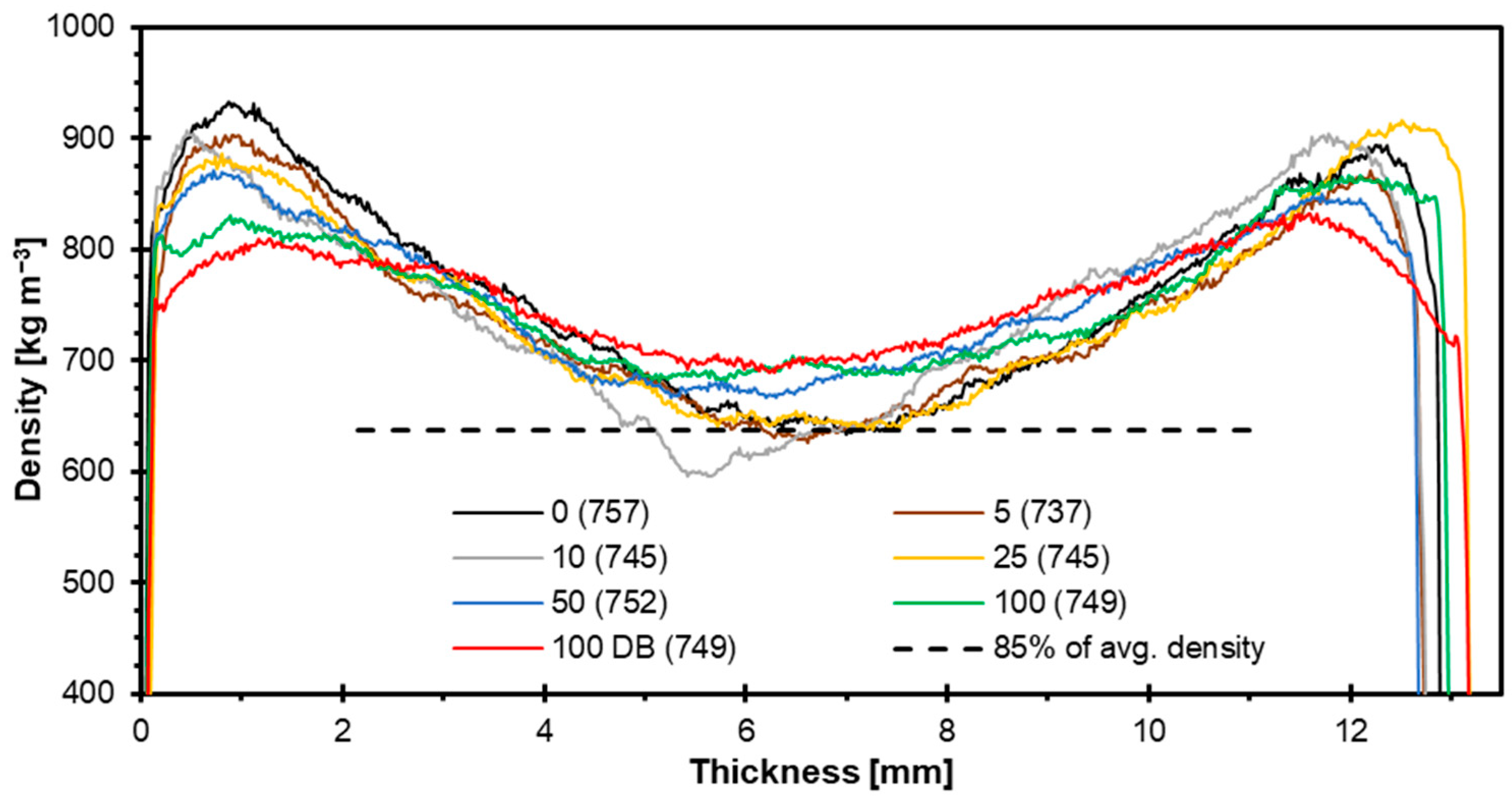

3.6. Density Profiles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Wood Production Is at Record Levels. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/768ba59e-c692-47c3-9a13-3c3c10993396/content/src/html/wood-production-record-levels.html#modal-l&gsc.tab=0 (accessed on 10 July 2025).

- United Nations Publication Forest Products in the UNECE Region Country Market Statements 2024. Available online: https://unece.org/sites/default/files/2025-04/ece-tim-sp-xx-publication-cms-v20250429-for-jwp-discussion.pdf (accessed on 10 July 2025).

- Neitzel, N.; Hosseinpourpia, R.; Walther, T.; Adamopoulos, S. Alternative Materials from Agro-Industry for Wood Panel Manufacturing—A Review. Materials 2022, 15, 4542. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from Agricultural Biomass and Recycled Wood Waste: A Review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Mirski, R.; Dukarska, D.; Derkowski, A.; Czarnecki, R.; Dziurka, D. By-Products of Sawmill Industry as Raw Materials for Manufacture of Chip-Sawdust Boards. J. Build. Eng. 2020, 32, 101460. [Google Scholar] [CrossRef]

- Trischler, J.; Sandberg, D.; Thörnqvist, T. Evaluating the Competition of Lignocellulose Raw Materials for Their Use in Particleboard Production, Thermal Energy Recovery, and Pulp- and Papermaking. BioResources 2014, 9, 6591–6613. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. Upcycling Different Particle Sizes and Contents of Pine Branches into Particleboard. Polymers 2022, 14, 4559. [Google Scholar] [CrossRef]

- Olarescu, A.M.; Lunguleasa, A. Cutting with Circular Saw of Traversal-Structured Panels Obtained from Spruce (Picea abies L.) Branches. Forests 2024, 15, 685. [Google Scholar] [CrossRef]

- Watkins, D.; Nuruddin, M.; Hosur, M.; Tcherbi-Narteh, A.; Jeelani, S. Extraction and Characterization of Lignin from Different Biomass Resources. J. Mater. Res. Technol. 2015, 4, 26–32. [Google Scholar] [CrossRef]

- Ninikas, K.; Mitani, A.; Koutsianitis, D.; Ntalos, G.; Taghiyari, H.R.; Papadopoulos, A.N. Thermal and Mechanical Properties of Green Insulation Composites Made from Cannabis and Bark Residues. J. Compos. Sci. 2021, 5, 132. [Google Scholar] [CrossRef]

- Neitzel, N.; Eder, M.; Hosseinpourpia, R.; Walther, T.; Adamopoulos, S. Chemical Composition, Particle Geometry, and Micro-Mechanical Strength of Barley Husks, Oat Husks, and Wheat Bran as Alternative Raw Materials for Particleboards. Mater. Today Commun. 2023, 36, 106602. [Google Scholar] [CrossRef]

- Kowaluk, G.; Szymanowski, K.; Kozłowski, P.; Kukuła, W.; Sala, C.; Robles, E.; Czarniak, P. Functional Assessment of Particleboards Made of Apple and Plum Orchard Pruning. Waste Biomass Valorization 2019, 11, 2877–2886. [Google Scholar] [CrossRef]

- Żabowski, B.; Kowaluk, G. Selected Properties of Particleboards Made of Different Cultivars of Apple Wood Particles. Ann. WULS For. Wood Technol. 2023, 123, 131–142. [Google Scholar] [CrossRef]

- Haris, N.I.N.; Osman Al Edrus, S.S.A.; Harun, N.H.; Harun, A.A.C.; Johar, N.; Wondi, M.H. Particleboard and Fiberboard Bonded with Green Binder; Springer: Gateway East, Singapore, 2025; Volume F391, pp. 111–124. [Google Scholar] [CrossRef]

- Tarigan, F.O.; Hakim, L.; Purwoko, A.; Sucipto, T.; Nasution, H.; Fatriasari, W.; Lubis, M.A.R.; Sutiawan, J.; Bakhsi, M.I.; Kim, N.H.; et al. Development and Characterization of Novel Hybrid Particleboard Made from Several Non-Wood Lignocellulosic Materials. Polymers 2025, 17, 451–461. [Google Scholar] [CrossRef]

- Janiszewska-Latterini, D.; Hochmańska-Kaniewska, P.; Kwaśniewska-Sip, P.; Czajka, M.; Pędzik, M. Effect of Wood Adhesive Modification with Liquefied Lignocellulosic Biomass and Nanocellulose on the Formaldehyde and Volatile Organic Compounds Emissions of Particleboards. Wood Mater. Sci. Eng. 2024, 19, 451–461. [Google Scholar] [CrossRef]

- Hartono, R.; Iswanto, A.H.; Herawati, E.; Suramana, R.E.; Sutiawan, J.; Amin, Y.; Sumardi, I. The Improvement of Sumatran Elephant (Elephas Maximus Sumatranus) Dung Particleboard Characteristics Using Bamboo Layering. Polymers 2022, 14, 3330. [Google Scholar] [CrossRef]

- Żabowski, B.; Wronka, A.; Kowaluk, G. Selected Physical and Mechanical Properties of Particleboards Manufactured from Plantation Willow and Poplar Wood. Materials 2024, 17, 4069. [Google Scholar] [CrossRef] [PubMed]

- Klímek, P.; Meinlschmidt, P.; Wimmer, R.; Plinke, B.; Schirp, A. Using Sunflower (Helianthus annuus L.), Topinambour (Helianthus tuberosus L.) and Cup-Plant (Silphium perfoliatum L.) Stalks as Alternative Raw Materials for Particleboards. Ind. Crops Prod. 2016, 92, 157–164. [Google Scholar] [CrossRef]

- Battistelle, R.A.G.; Fujino, D.M.; e Silva, A.L.C.; Bezerra, B.S.; de D. Valarelli, I. Physical and Mechanical Characterization of Sugarcane Bagasse Particleboards for Civil Construction. J. Sustain. Dev. Energy. Water Environ. Syst. 2016, 4, 408–417. [Google Scholar] [CrossRef]

- Mahmood, H.; Moniruzzaman, M.; Yusup, S.; Akil, H.M. Pretreatment of Oil Palm Biomass with Ionic Liquids: A New Approach for Fabrication of Green Composite Board. J. Clean. Prod. 2016, 126, 677–685. [Google Scholar] [CrossRef]

- Mahmood, H.; Moniruzzaman, M.; Yusup, S.; Akil, H.M. Comparison of Some Biocomposite Board Properties Fabricated from Lignocellulosic Biomass before and after Ionic Liquid Pretreatment. Chem. Eng. Trans. 2015, 45, 709–714. [Google Scholar] [CrossRef]

- Hristodorova, D.; Mihailov, V.; Savov, V. Influence of Density on the Withdrawal Staple Strength from Hemp Shive Panels. In Bulletin of the Transilvania University of Brasov. Series II: Forestry, Wood Industry, Agricultural Food Engineering; Transilvania University Press: Brașov, Romania, 2023; Volume 16, pp. 117–126. [Google Scholar] [CrossRef]

- Benthien, J.T.; Lüdtke, J.; Ohlmeyer, M. Effect of Increasing Core Layer Particle Thickness on Lightweight Particleboard Properties. Eur. J. Wood Wood Prod. 2019, 77, 1029–1043. [Google Scholar] [CrossRef]

- Kusumah, S.S.; Massijaya, S.Y.; Prasetyo, K.W.; Sutiawan, J.; Lubis, M.A.R.; Hermawan, D. Surface Modification of Eco-Friendly Particleboard Made from Sorghum Bagasse and Citric Acid Sucrose Adhesive. IOP Conf. Ser. Mater. Sci. Eng. 2020, 935, 012054. [Google Scholar] [CrossRef]

- World Population Review Hazelnut Production by Country. Available online: https://worldpopulationreview.com/country-rankings/hazelnut-production-by-country (accessed on 10 July 2025).

- Khishtovani, G.; Kapanadze, N.; Matcharashvili, S.; Tsukhishvili, G. Hazelnut Production Sector in Georgia; PMC Research: Tbilisi, Georgia, 2023. [Google Scholar]

- Hicks, D. Biological Flora of Britain and Ireland: Corylus Avellana: No. 302. J. Ecol. 2022, 110, 3053–3089. [Google Scholar] [CrossRef]

- Wojciechowska, M.; Kowaluk, G. Challenges and Opportunities in Recycling Upholstery Textiles: Enhancing High-Density Fiberboards with Recycled Fibers. Fibers 2024, 12, 105. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. Supporting Circular Economy Principles by Recycling Window Frames into Particleboard. Materials 2024, 17, 4132. [Google Scholar] [CrossRef]

- Kowalczuk, A.; Kowaluk, G. Influence of Horse Chestnut (Aesculus hippocastanum L.) Seed Particlecontent on the Selected Particleboard Properties. Ann. WULS For. Wood Technol. 2024, 125, 79–89. [Google Scholar] [CrossRef]

- Pelc, O.; Kowaluk, G. Selected Physical and Mechanical Properties of Particleboards with Variable Shares of Nettle Urtica Dioica L. Lignocellulosic Particles. Ann. WULS For. Wood Technol. 2023, 123, 30–40. [Google Scholar] [CrossRef]

- EN 827; Adhesives—Determination of Conventional Solids Content and Constant Mass Solids Content. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319; Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 320; Particleboards and Fibreboards—Determination of Resistance to Axial Withdrawal of Screws. European Committee for Standardization: Brussels, Belgium, 2011.

- EN 317; Particleboards and Fiberboards—Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 312; Particleboards—Specifications. European Committee for Standardization: Brussels, Belgium, 2010.

- Tabarsa, T.; Ashori, A.; Gholamzadeh, M. Evaluation of Surface Roughness and Mechanical Properties of Particleboard Panels Made from Bagasse. Compos. Part B Eng. 2011, 42, 1330–1335. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Aritonang, W.; Azhar, I.; Supriyanto; Fatriasari, W. The Physical, Mechanical and Durability Properties of Sorghum Bagasse Particleboard by Layering Surface Treatment. J. Indian Acad. Wood Sci. 2017, 14, 1–8. [Google Scholar] [CrossRef]

- Lengyel, K.; Barbu, M.C.; Campean, M.; Badin, N.; Bogdan, B. Improving Properties of Particleboards with Reduced Density. BioResources 2018, 13, 1289–1302. [Google Scholar] [CrossRef]

- Nazerian, M.; Beyki, Z.; Gargarii, R.M.; Kool, F. The Effect of Some Technological Production Variables on Mechanical and Physica Properties of Particleboard Manufactured from Cotton (Gossypium hirsutum) Stalks. Maderas Cienc. Y Tecnol. 2016, 18, 167–178. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Effect of Press Cycle Time and Resin Content on Physical and Mechanical Properties of Particleboard Panels Made from the Underutilized Low-Quality Raw Materials. Ind. Crops Prod. 2008, 28, 225–230. [Google Scholar] [CrossRef]

- Slater, D.; Ennos, R. Interlocking Wood Grain Patterns Provide Improved Wood Strength Properties in Forks of Hazel (Corylus Avellana L.). Arboric. J. 2015, 37, 21–32. [Google Scholar] [CrossRef]

- Sun, H.; Li, W.; Zhang, X.; He, G.; Shi, J. The Effect of Knots in Tension Face on Bending Properties of Cunninghamia Lanceolate Juvenile Wood. J. For. Eng. 2024, 9, 34–39. [Google Scholar] [CrossRef]

- Thoemen, H.; Irle, M.; Sernek, M. Wood-Based Panels—An Introduction for Specialists; Brunel University Press: London, UK, 2010; ISBN 9781902316826. [Google Scholar]

- Sellers, T.J. Wood Adhesive Innovations and Applications in North America. For. Prod. J. 2001, 51, 12–22. [Google Scholar]

- Warmbier, K.; Wilczyński, A.; Danecki, L. Evaluation of Mechanical and Physical Properties of Particleboards with the Core Layer Made from Willow (Salix viminalis). BioResources 2014, 9, 894–905. [Google Scholar] [CrossRef]

- Zeidler, A. Variation of Wood Density in Turkish Hazel (Corylus colurna L.) Grown in the Czech Republic. J. For. Sci. 2012, 58, 145–151. [Google Scholar] [CrossRef]

- Cavus, V.; Sahin, S.; Esteves, B.; Ayata, U. Linear Behaviour of Thermal Conductivity As a Function of Density. BioResources 2019, 14, 6709–6715. [Google Scholar] [CrossRef]

- Sanches, F.L.; Hillig, É.; Iwakiri, S.; Napoli, L.M. Strength of Particleboard Produced with Mixed Wood Traditional and Nontraditional Forest Species. Cienc. Florest. 2016, 26, 559–569. [Google Scholar] [CrossRef]

- Zhang, B.; Yu, L.; Zhang, Q.; Li, D.; Tu, Y.; Xiao, G.; Wu, Z.; Zhang, Q.; Liang, J. Effects of Fire Retardants on Mechanical Properties and Water Resistance of Pinus Massoniana Particleboard. Wood Res. 2022, 67, 411–422. [Google Scholar] [CrossRef]

- Elhusain, L.W.E.; Standing, J.R. Pore and Density-Related Characteristics of a Lightweight Aggregate. Proc. Inst. Civ. Eng. Constr. Mater. 2025, 178, 1–14. [Google Scholar] [CrossRef]

- Dippenaar, M.A. Porosity Reviewed: Quantitative Multi-Disciplinary Understanding, Recent Advances and Applications in Vadose Zone Hydrology. Geotech. Geol. Eng. 2014, 32, 1–19. [Google Scholar] [CrossRef]

- Kwon, J.H.; Ayrilmis, N.; Han, T.H. Effect of Core Layer Composition on Water Resistance and Mechanical Properties of Hybrid Particleboard. Environ. Eng. Manag. J. 2018, 17, 2857–2864. [Google Scholar] [CrossRef]

- Ergun, M.E.; Özlüsoylu, İ.; İstek, A.; Can, A. Analysis and Impact of Activated Carbon Incorporation into Urea-Formaldehyde Adhesive on the Properties of Particleboard. Coatings 2023, 13, 1476. [Google Scholar] [CrossRef]

- Lerouge, T.; Pitois, O.; Grande, D.; Le Droumaguet, B.; Coussot, P. Synergistic Actions of Mixed Small and Large Pores for Capillary Absorption through Biporous Polymeric Materials. Soft Matter 2018, 14, 8137–8146. [Google Scholar] [CrossRef] [PubMed]

- Ridgway, C.J.; Gane, P.A.C.; El Abd, A.E.G.; Czachor, A. Water Absorption into Construction Materials: Comparison of Neutron Radiography Data with Network Absorption Models. Transp. Porous. Media 2006, 63, 503–525. [Google Scholar] [CrossRef]

- Leskinen, T.; Salas, C.; Kelley, S.S.; Argyropoulos, D.S. Wood Extractives Promote Cellulase Activity on Cellulosic Substrates. Biomacromolecules 2015, 16, 3226–3234. [Google Scholar] [CrossRef]

- Sachdev, D.; Gupta, S.; Bhullar, N.K.; Verma, G. Recent Progress on the Correlation Between Hydrophobicity and the Water Absorption of Different Materials. J. Inorg. Organomet. Polym. Mater. 2025, 1–26. [Google Scholar] [CrossRef]

- Frankó, B.; Carlqvist, K.; Galbe, M.; Lidén, G.; Wallberg, O. Removal of Water-Soluble Extractives Improves the Enzymatic Digestibility of Steam-Pretreated Softwood Barks. Appl. Biochem. Biotechnol. 2018, 184, 599–615. [Google Scholar] [CrossRef]

- Kebbi-Benkeder, Z.; Colin, F.; Dumarçay, S.; Gérardin, P. Quantification and Characterization of Knotwood Extractives of 12 European Softwood and Hardwood Species. Ann. For. Sci. 2015, 72, 277–284. [Google Scholar] [CrossRef]

- Jin, Z.; Li, B.; Yin, J.; Chen, Q.; Fu, Y.; Lü, B. Research Progress for the Evaluation of Wood Pore Connectivity. Linye Kexue/Scientia Silvae Sin. 2022, 58, 177–186. [Google Scholar] [CrossRef]

- Carrasco, L.O.; Bucci, S.J.; Scholz, F.G.; Loto, D.; Gasparri, I.; Goldstein, G.; Campanello, P.I. Biophysical Properties of Inner Bark and Sapwood in Tree Species from Forests with Contrasting Precipitation in Subtropical South America. Front. For. Glob. Change 2022, 5, 1–13. [Google Scholar] [CrossRef]

- Taj, M.A.; Kazemi Najafi, S.; Ebrahimi, G. Withdrawal and Lateral Resistance of Wood Screw in Beech, Hornbeam and Poplar. Eur. J. Wood Wood Prod. 2009, 67, 135–140. [Google Scholar] [CrossRef]

- Aytekin, A. Determination of Screw and Nail Withdrawal Resistance of Some Important Wood Species. Int. J. Mol. Sci. 2008, 9, 626–637. [Google Scholar] [CrossRef]

- Lin, H.T.; Tsai, M.T.; Wonodihardjo, A.S. Withdrawal Resistance and Failure Mode of Semi-Circular Wooden Composite with Different Fasteners. Key Eng. Mater. 2018, 765, 295–299. [Google Scholar] [CrossRef]

- Lee, H.W.; Jang, S.S.; Kang, C.W. Evaluation of Withdrawal Resistance of Screw-Type Fasteners Depending on Lead-Hole Size, Grain Direction, Screw Size, Screw Type and Species. J. Korean Wood Sci. Technol. 2021, 49, 181–190. [Google Scholar] [CrossRef]

- Ringhofer, A.; Brandner, R.; Schickhofer, G. Withdrawal Resistance of Self-Tapping Screws in Unidirectional and Orthogonal Layered Timber Products. Mater. Struct. Constr. 2015, 48, 1435–1447. [Google Scholar] [CrossRef]

- Hamid Mirdad, M.A.; Niederwestberg, J.; Jucutan, A.; Chui, Y.H. Prediction of Withdrawal Stiffness of Self-Tapping Screws. In Proceedings of the 13th World Conference on Timber Engineering, Oslo, Norway, 19–22 June 2023; Volume 2, pp. 1117–1122. [Google Scholar] [CrossRef]

- Mirdad, M.A.H.; Jucutan, A.; Khan, R.; Niederwestberg, J.; Chui, Y.H. Embedment and Withdrawal Stiffness Predictions of Self-Tapping Screws in Timber. Constr. Build. Mater. 2022, 345, 128394. [Google Scholar] [CrossRef]

- Firmansyah, B.Y.; Nugroho, W.O.; Tjahjanto, H.H. Experimental and Numerical Study on the Withdrawal Behaviour of Lag Screws on Wood Side-Grain. E3S Web Conf. 2023, 429, 05008. [Google Scholar] [CrossRef]

- Farajollah Pour, M.; Hatefnia, H.; Dorieh, A.; Valizadeh Kiamahalleh, M.; Mohammadnia Afrouzi, Y. Research on Medium Density Fiberboard (MDF) Behavior against Screw Axial Withdrawal: Impact of Density and Operational Variables. Structures 2022, 39, 194–206. [Google Scholar] [CrossRef]

- Sydor, M.; Potok, Z.; Pędzik, M.; Hitka, M.; Rogoziński, T. The Influence of Feed Rate during Pilot Hole Drilling on Screw Withdrawal Resistance in Particleboard. Eur. J. Wood Wood Prod. 2024, 82, 5–13. [Google Scholar] [CrossRef]

- Mutiar, S.; Kasim, A.; Emriadi; Asben, A. Bark Characteristics of Acacia Auriculiformis A. Cunn. Ex Benth. and Acacia Mangium Willd. From Industrial Plantation Forest. J. Penelit. Kehutan. Wallacea 2020, 9, 43–49. [Google Scholar] [CrossRef]

- Pelc, O.; Wronka, A. Potential Utilization of Nettle (Urtica dioica L.) Shives as a Raw Material for Particleboards. Ann. WULS For. Wood Technol. 2025, 42, 31–42. [Google Scholar] [CrossRef]

| Panel Name/Variant | Reference/Alternative Raw Material Content [% w/w] | Density [kg m−3] | Thickness [mm] | Resination [%] |

|---|---|---|---|---|

| 0%/reference | 100/0 | 700 | 13 | 15 |

| 5% | 95/5 | |||

| 10% | 90/10 | |||

| 25% | 75/25 | |||

| 50% | 50/50 | |||

| 100% | 0/100 | |||

| 100 DB 1 | 0/100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wronka, M.; Wojnicz, D.; Wronka, A.; Kowaluk, G. Evaluation of Hazel-Derived Particleboard as a Substitute for Conventional Wood-Based Composites. Materials 2025, 18, 3773. https://doi.org/10.3390/ma18163773

Wronka M, Wojnicz D, Wronka A, Kowaluk G. Evaluation of Hazel-Derived Particleboard as a Substitute for Conventional Wood-Based Composites. Materials. 2025; 18(16):3773. https://doi.org/10.3390/ma18163773

Chicago/Turabian StyleWronka, Marta, Damian Wojnicz, Anita Wronka, and Grzegorz Kowaluk. 2025. "Evaluation of Hazel-Derived Particleboard as a Substitute for Conventional Wood-Based Composites" Materials 18, no. 16: 3773. https://doi.org/10.3390/ma18163773

APA StyleWronka, M., Wojnicz, D., Wronka, A., & Kowaluk, G. (2025). Evaluation of Hazel-Derived Particleboard as a Substitute for Conventional Wood-Based Composites. Materials, 18(16), 3773. https://doi.org/10.3390/ma18163773