Phase-Based Thermal Wave Analysis for Lateral Characterization of Subsurface Defects in Solid Materials via Modeling and Simulation

Abstract

1. Introduction

2. Theoretical Models and Methods

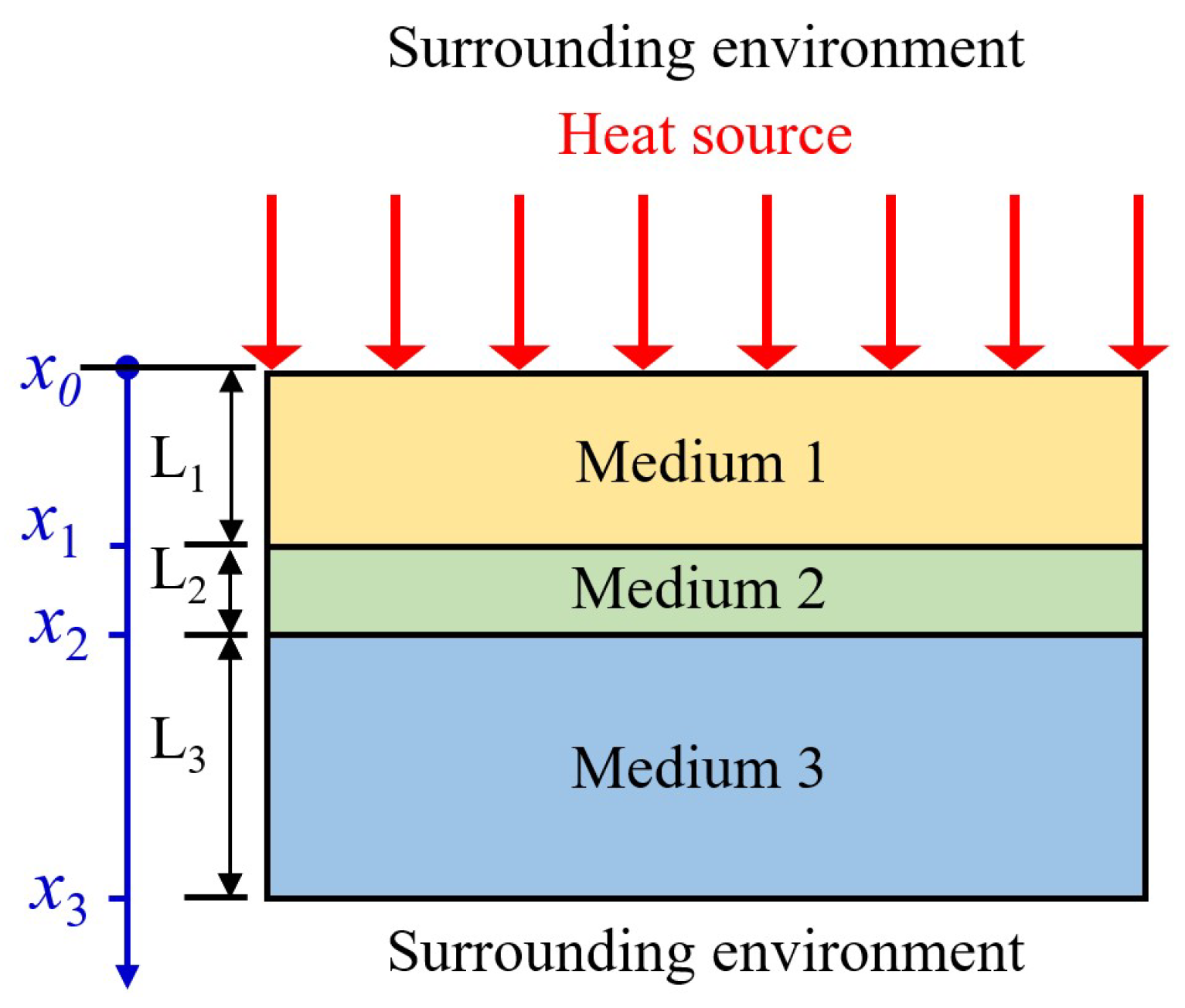

2.1. One-Dimensional Model of Three Layers for Thermal Response Analysis

- Boundary condition at the top surface:

- 2.

- Interface conditions between two media:

- 3.

- Boundary condition at the bottom surface:

- 4.

- The temperature solution in each layer can be expressed as

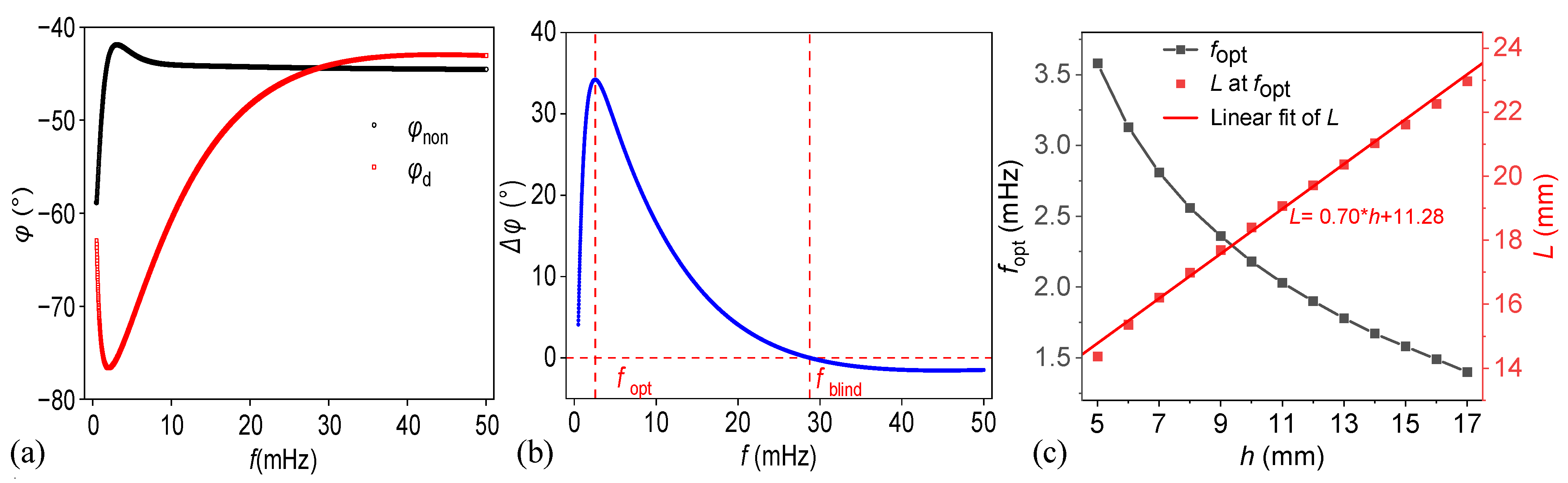

2.2. Phase-Difference-Based Defect Detection Method

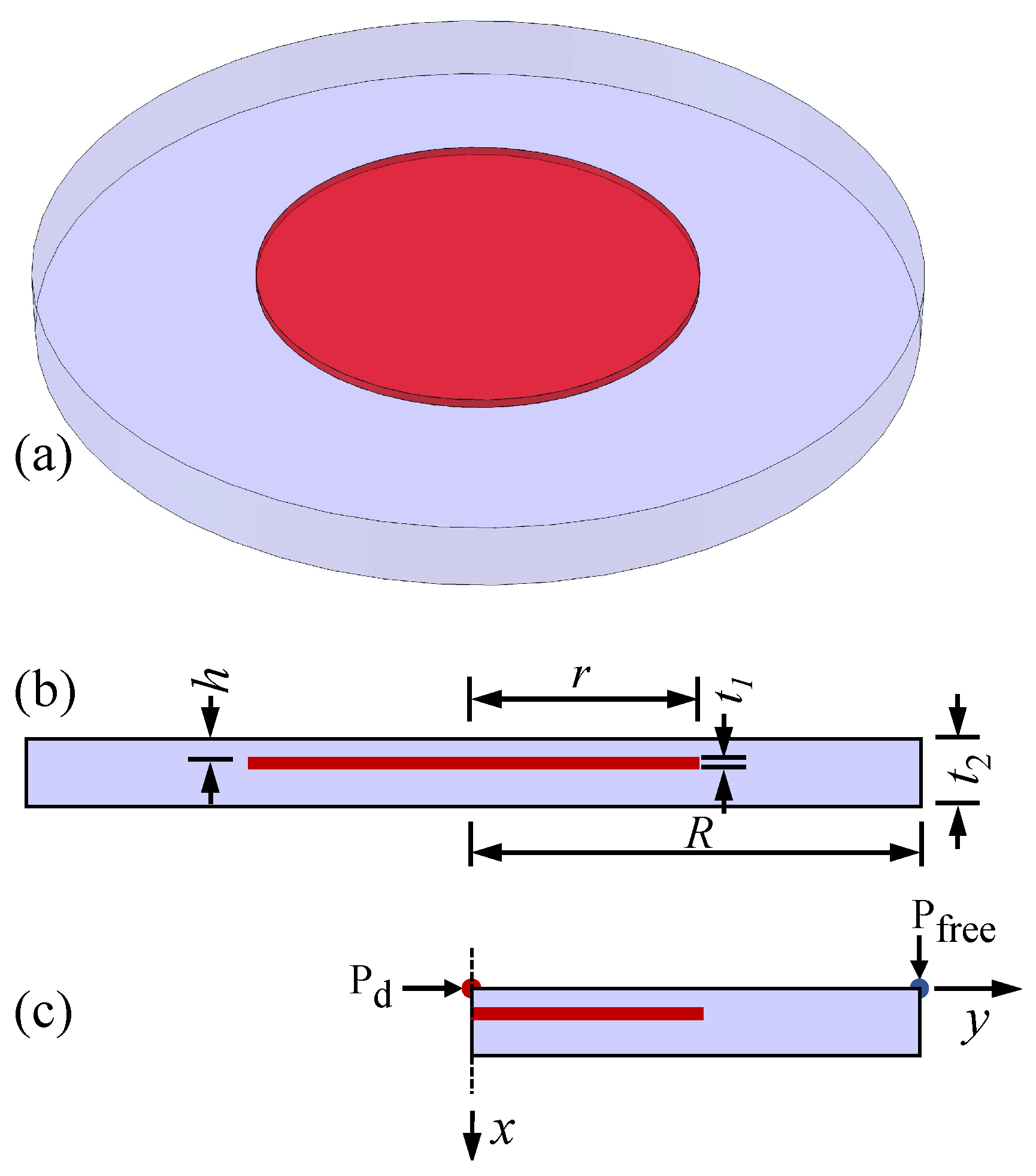

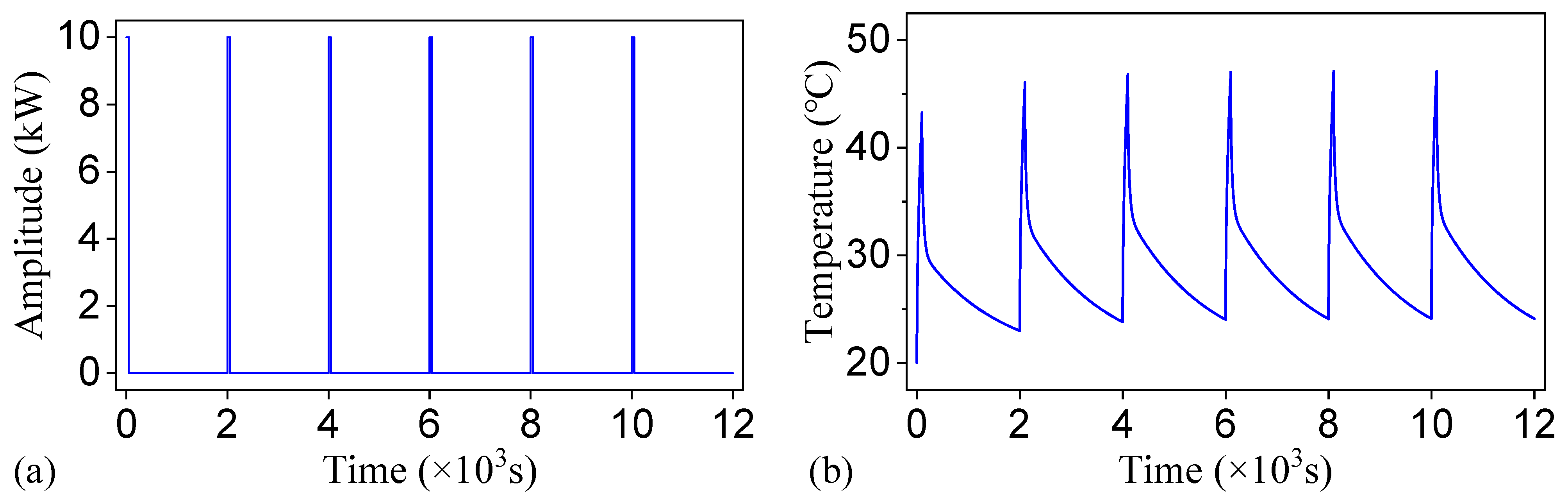

2.3. Finite Element Simulations for Thermal Response

3. Results and Discussion

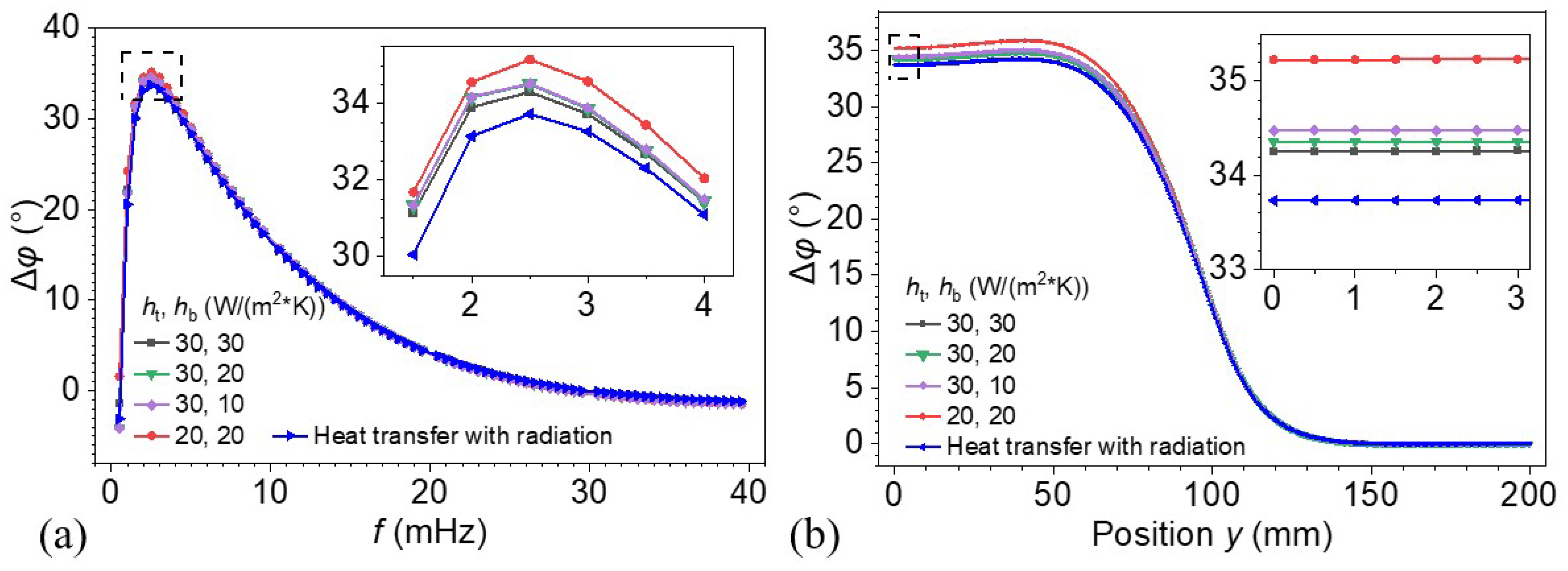

3.1. Effect of Convective and Radiative Boundary Conditions on Phase Response

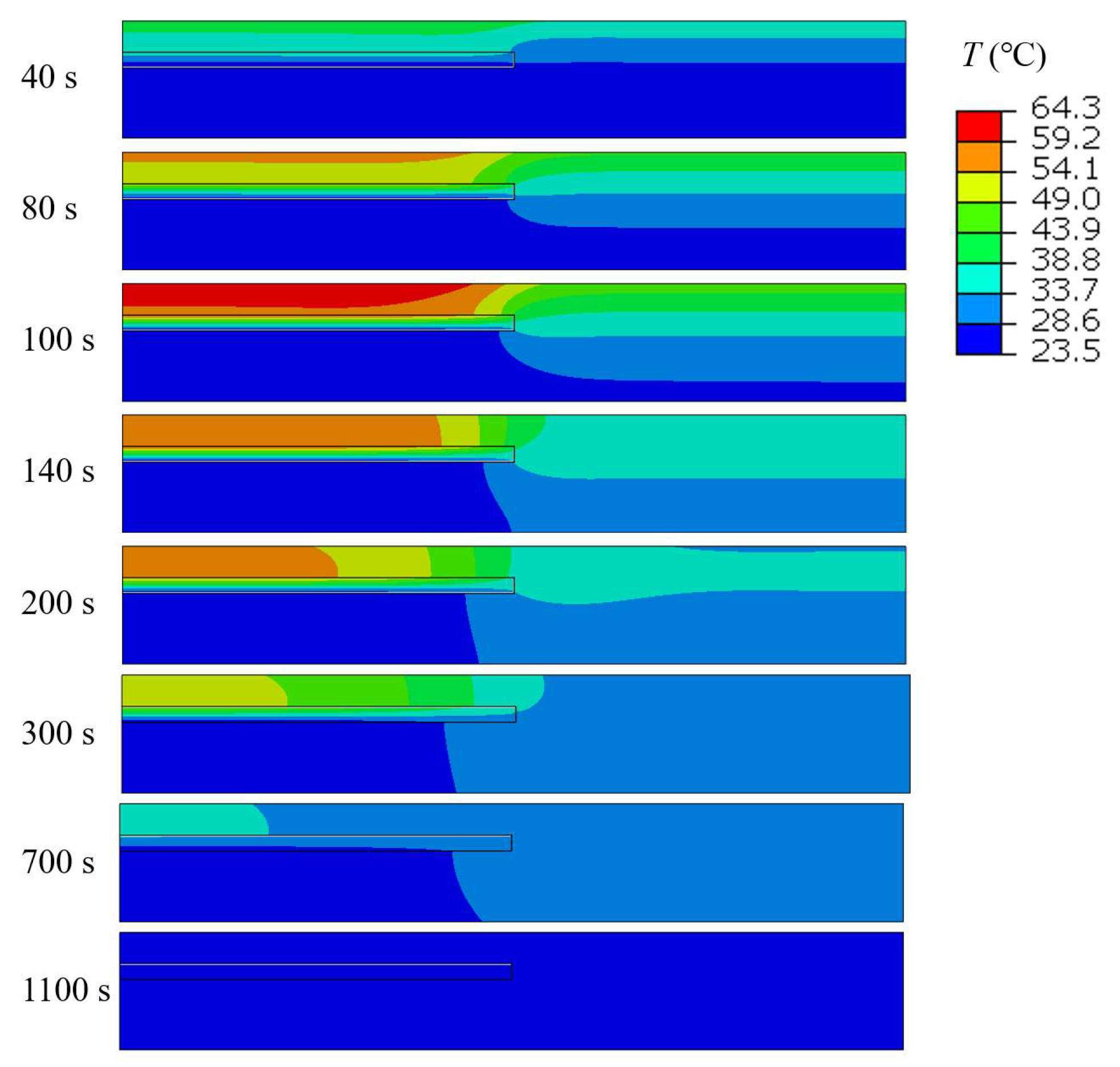

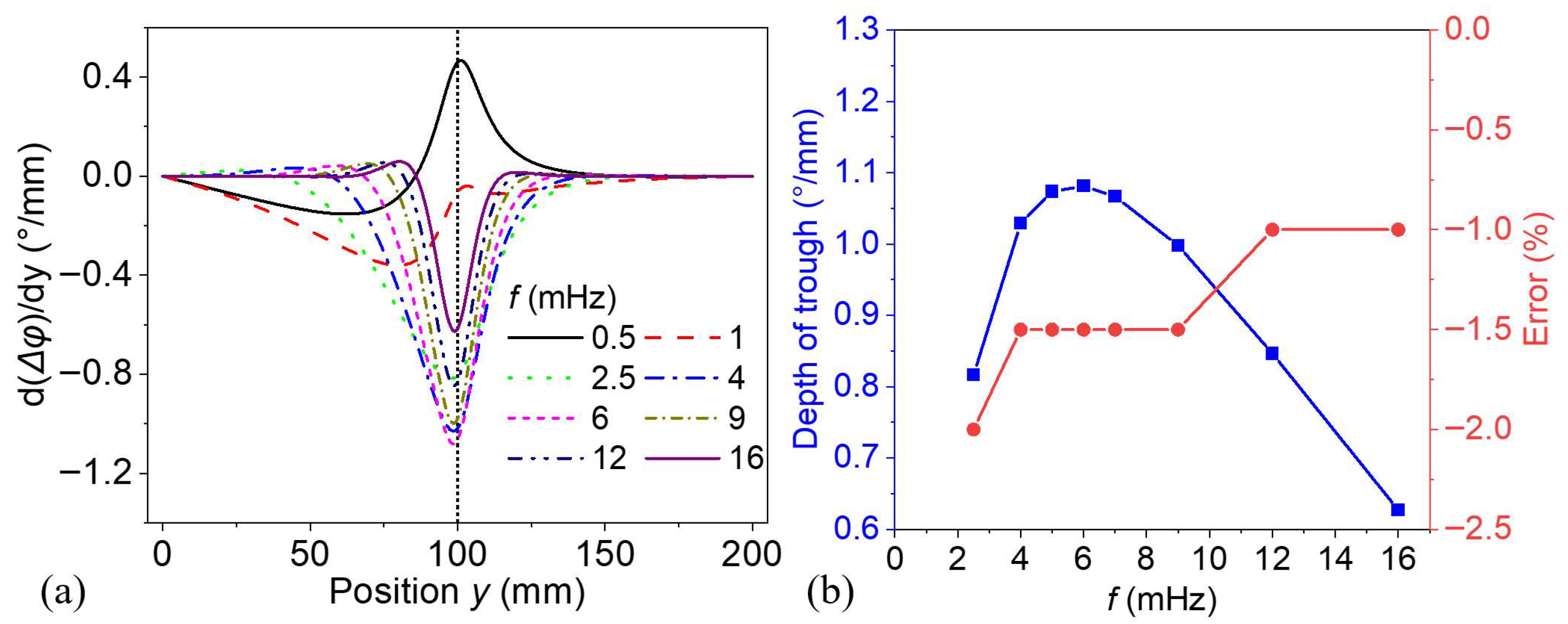

3.2. Lateral Heat Conduction Effect on the Defect Boundary Detection

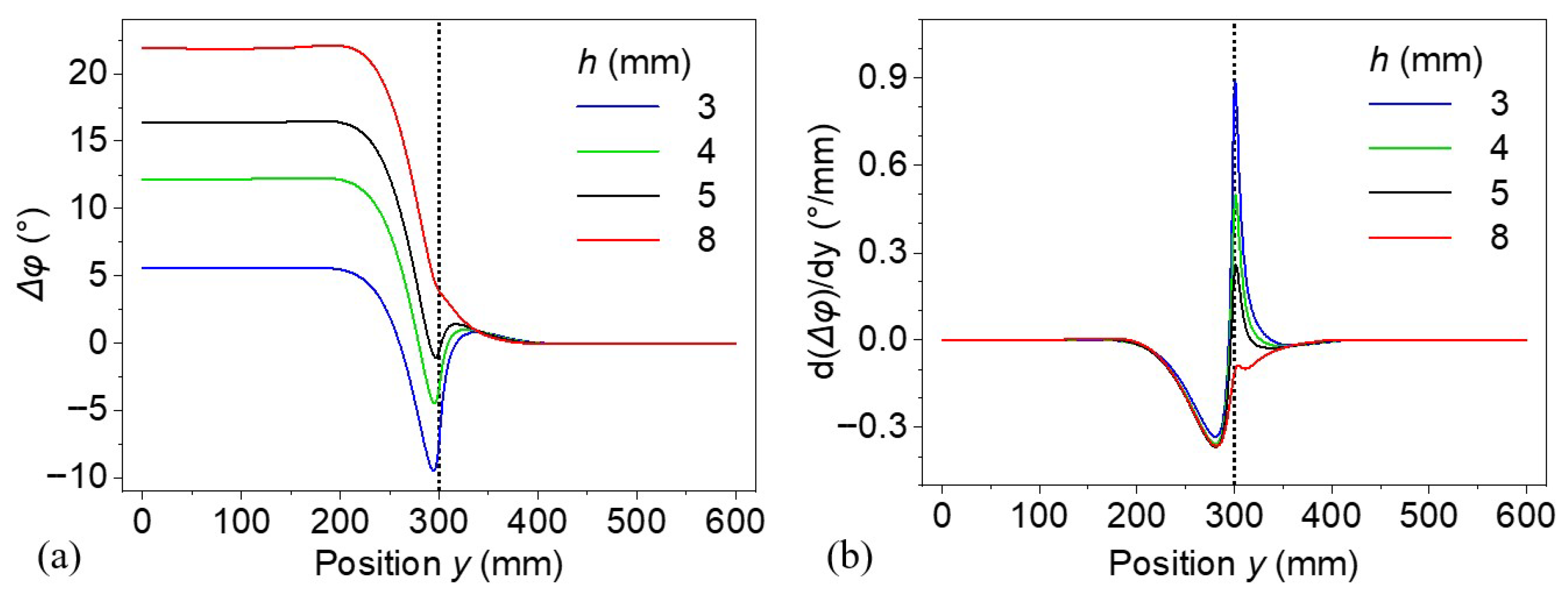

3.3. Defect Depth and Thickness Effect

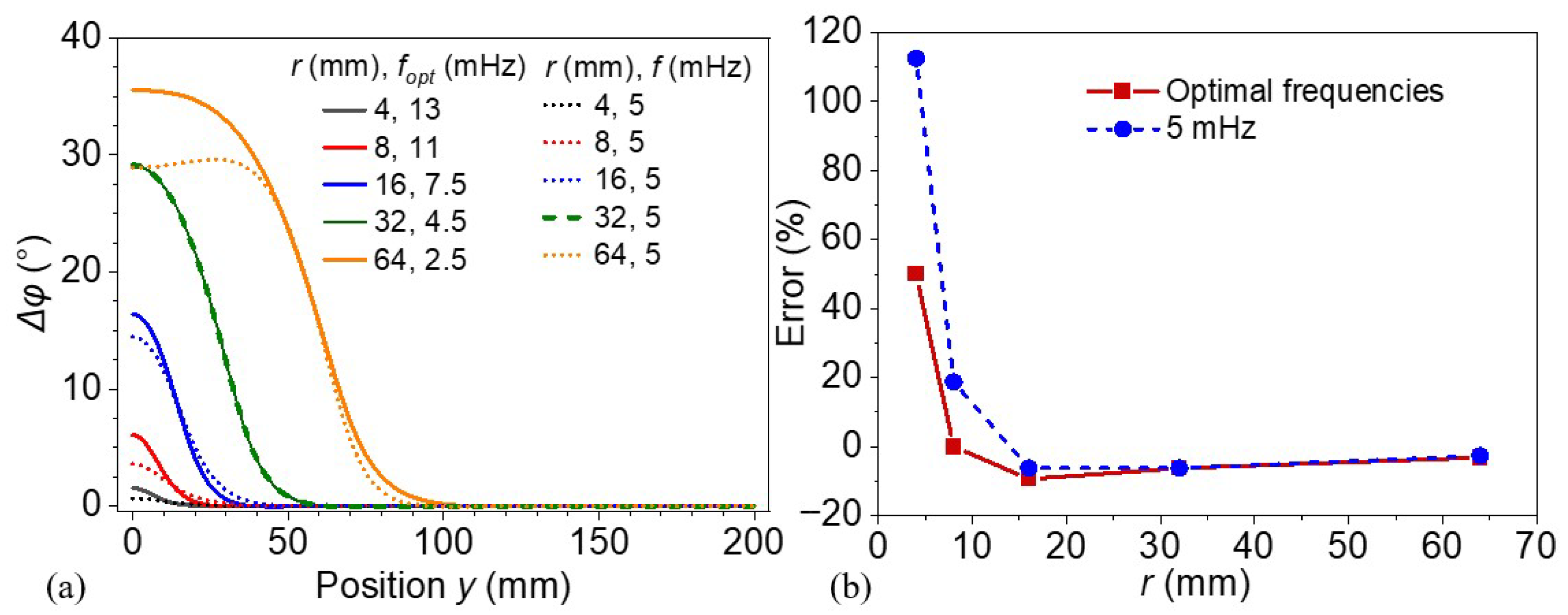

3.4. Impact of Lateral Defect Dimensions

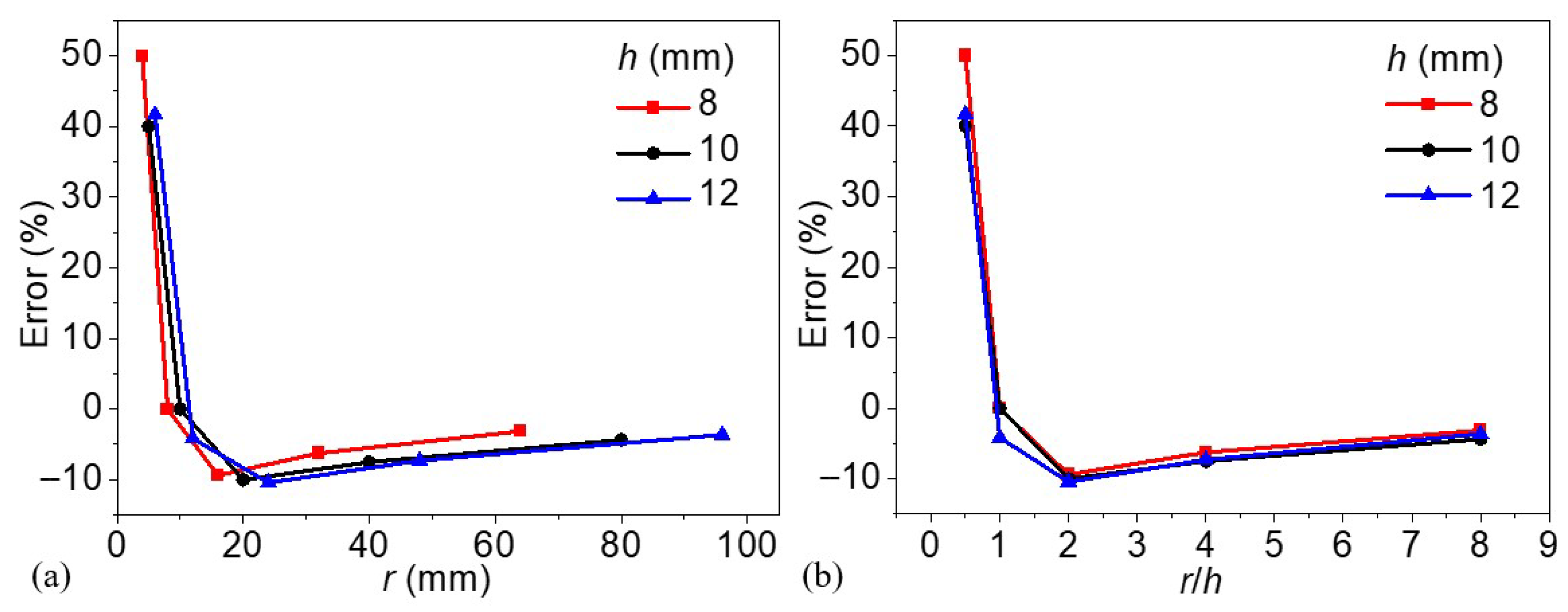

3.5. Effect of Radius-to-Depth Ratio

3.6. Limitations and Future Work

4. Conclusions

- The one-dimensional analytical model provides an initial estimate of the optimal excitation frequency that yields the maximum phase difference for a given defect depth, without accounting for lateral heat conduction. Three-dimensional finite element simulations further demonstrate that the optimal frequency increases as the lateral dimension of the defect decreases, beginning from a value that aligns with the analytical prediction when the lateral dimension is sufficiently large. In contrast, the maximum phase difference decreases with decreasing lateral defect size. The results indicate that lateral heat conduction has a significant impact on the selection of optimal excitation frequency and the accuracy of defect detection.

- The excitation frequency plays a pivotal role in determining defect visibility and boundary clarity in large-area thermal wave imaging. Lower frequencies are advantageous for detecting deeper defects due to longer thermal diffusion lengths, whereas higher frequencies enhance lateral resolution and boundary localization by restricting lateral heat diffusion. Frequencies below the optimal excitation frequency may result in increased detection error, while frequencies slightly above the optimal value offer a balance between phase contrast and lateral boundary resolution.

- Both the size and depth of a defect significantly influence the selection of the optimal excitation frequency and the accuracy of defect detection. In contrast, the phase difference is only marginally affected by defect thickness. Shallower defects tend to produce smaller phase differences, making them more difficult to detect. Detecting defects with small lateral dimensions presents a challenge due to reduced phase contrast and spatial resolution. Notably, the geometric ratio between the defect’s radius and depth emerges as a key parameter governing detection performance. The optimal excitation frequency increases as the radius-to-depth ratio decreases, with a ratio of approximately 2 identified as a potential threshold for the reliable detection of lateral defect boundaries. In this way, the study demonstrates that lock-in thermography has limited detection capability for defects with a relatively small radius-to-depth ratio.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| NDT | Nondestructive testing |

| IRT | Infrared thermography |

| LIT | Lock-in thermography |

References

- Shaloo, M.; Schnall, M.; Klein, T.; Huber, N.; Reitinger, B. A Review of Non-Destructive Testing (NDT) Techniques for Defect Detection: Application to Fusion Welding and Future Wire Arc Additive Manufacturing Processes. Materials 2022, 15, 3697. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L. A generative adversarial network approach for removing motion blur in the automatic detection of pavement cracks. Comput.-Aided Civ. Infrastruct. Eng. 2024, 39, 3412–3434. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L. Detection of Pavement Cracks by Deep Learning Models of Transformer and UNet. IEEE Trans. Intell. Transp. Syst. 2024, 25, 15791–15808. [Google Scholar] [CrossRef]

- Holland, S.D.; Reusser, R.S. Material Evaluation by Infrared Thermography. Annu. Rev. Mater. Res. 2016, 46, 287–303. [Google Scholar] [CrossRef]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent Advances in Active Infrared Thermography for Non-Destructive Testing of Aerospace Components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef] [PubMed]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared Thermography for Temperature Measurement and Non-Destructive Testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef] [PubMed]

- Tran, Q.H.; Dang, Q.M.; Pham, X.T.; Truong, T.C.; Nguyen, T.X.; Huh, J. Passive infrared thermography technique for concrete structures health investigation: Case studies. Asian J. Civ. Eng. 2023, 24, 1323–1331. [Google Scholar] [CrossRef]

- Pozzer, S.; Omidi, Z.; El Refai, A.; López, F.; Ibarra-Castanedo, C.; Maldague, X. Passive infrared thermography for subsurface delamination detection in concrete infrastructure: Capabilities. Constr. Build. Mater. 2024, 419, 135542. [Google Scholar] [CrossRef]

- Chung, Y.; Lee, S.; Kim, W. Latest Advances in Common Signal Processing of Pulsed Thermography for Enhanced Detectability: A Review. Appl. Sci. 2021, 11, 12168. [Google Scholar] [CrossRef]

- Sun, J.G. Analysis of Pulsed Thermography Methods for Defect Depth Prediction. J. Heat Transf. 2005, 128, 329–338. [Google Scholar] [CrossRef]

- Lema, D.G.; Pedrayes, O.D.; Usamentiaga, R.; Garcia, D.F. Improved detection of subsurface defects through active thermography and ensembling techniques. Qual. Eng. 2023, 35, 669–685. [Google Scholar] [CrossRef]

- Elizalde, J.S.G.; Chiou, Y.S. Improving the detectability and confirmation of hidden surface corrosion on metal sheets using active infrared thermography. J. Build. Eng. 2023, 66, 105931. [Google Scholar] [CrossRef]

- Wang, F.; Liu, J.; Dong, B.; Liu, G.; Chen, M.; Wang, Y. Optimization of Thermal-Wave Radar Thermography by Transverse Heat Flow Suppression Technique for Accurate Defect Detection of CFRP Laminates. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Wei, Q.; Huang, J.; Zhu, J.; Zhuo, L.; Li, C. Experimental investigation on detection of coating debonds in thermal barrier coatings using vibrothermography with a piezoceramic actuator. NDT E Int. 2023, 137, 102859. [Google Scholar] [CrossRef]

- Tao, N.; Wang, L.; Wu, Z.; Wang, C.; Ma, Y.; Zhang, C.; Sun, J.G. Analysis of step-heating thermography methods for defect depth prediction. NDT E Int. 2023, 135, 102800. [Google Scholar] [CrossRef]

- Oswald-Tranta, B. Inductive thermography–review of a non-destructive inspection technique for surface crack detection. Quant. InfraRed Thermogr. J. 2025, 1–25. [Google Scholar] [CrossRef]

- Mohamed, D.; May, D.; Pareek, K.A.; Ras, M.A.; Wunderle, B. 2024 25th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Catania, Italy, 7–10 April 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–9. [Google Scholar]

- Sapieta, M.; Dekýš, V.; Kopas, P.; Jakubovičová, L.; Šavrnoch, Z. The Impact of Excitation Periods on the Outcome of Lock-In Thermography. Materials 2023, 16, 2763. [Google Scholar] [CrossRef] [PubMed]

- Sagarduy-Marcos, D.; Rodríguez-Aseguinolaza, J. Dimensionless numerical sensitivity analysis of narrow cracks by means of infrared lock-in thermography. Int. J. Therm. Sci. 2024, 200, 108935. [Google Scholar] [CrossRef]

- Pérez-Arbulu, J.; Ciria, J.C.; Mendioroz, A.; Celorrio, R.; Salazar, A. Characterization of semi-infinite inhomogeneous delaminations using lock-in thermography. NDT E Int. 2025, 155, 103417. [Google Scholar] [CrossRef]

- Sekhar Yadav, G.C.; Ghali, V.S.; Subhani, S.K. Time-Frequency Based Thermal Imaging: An Effective Tool for Quantitative Analysis. Russ. J. Nondestruct. Test. 2023, 59, 1165–1176. [Google Scholar] [CrossRef]

- Zhong, S.; Nsengiyumva, W. (Eds.) Infrared Thermography Testing and Evaluation of Fiber-Reinforced Composite Materials. In Nondestructive Testing and Evaluation of Fiber-Reinforced Composite Structures; Springer Nature: Singapore, 2022; pp. 197–271. [Google Scholar]

- Yang, R.; He, Y. Optically and non-optically excited thermography for composites: A review. Infrared Phys. Technol. 2016, 75, 26–50. [Google Scholar] [CrossRef]

- Delanthabettu, S.; Menaka, M.; Venkatraman, B.; Raj, B. Defect depth quantification using lock-in thermography. Quant. InfraRed Thermogr. J. 2015, 12, 37–52. [Google Scholar] [CrossRef]

- Rippa, M.; Vigorito, M.R.; Russo, M.R.; Mormile, P.; Trojsi, G. Active Thermography for Non-invasive Inspection of Wall Painting: Novel Approach Based on Thermal Recovery Maps. J. Nondestruct. Eval. 2023, 42, 63. [Google Scholar] [CrossRef]

- Das, P.; Arora, V.; Mulaveesala, R. Wavelet transform based post processing approach for pulse compression favourable frequency modulated thermal wave imaging for non-destructive testing and evaluation. Infrared Phys. Technol. 2025, 148, 105843. [Google Scholar] [CrossRef]

- Katırcıoğlu, F. Edge detection method based on heat conduction matrix for infrared images. Opt. Eng. 2020, 59, 093103. [Google Scholar] [CrossRef]

- Ranjit, S.; Kang, K.; Kim, W. Investigation of lock-in infrared thermography for evaluation of subsurface defects size and depth. Int. J. Precis. Eng. Manuf. 2015, 16, 2255–2264. [Google Scholar] [CrossRef]

- D’Accardi, E.; Palumbo, D.; Galietti, U. A comparison among different ways to investigate composite materials with lock-in thermography: The multi-frequency approach. Materials 2021, 14, 2525. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, g.; Li, W.; Dong, L.; Cai, D.; Wang, H.; Liu, H. Interface debonding defect detection of thermal barrier coatings with laser lock-in thermography based on edge sharpness optimization. Infrared Phys. Technol. 2025, 146, 105744. [Google Scholar] [CrossRef]

- Mulaveesala, R.; Tuli, S. Theory of frequency modulated thermal wave imaging for nondestructive subsurface defect detection. Appl. Phys. Lett. 2006, 89, 191913. [Google Scholar] [CrossRef]

- Subhani, S.K.; Suresh, B.; Ghali, V.S. Quantitative subsurface analysis using frequency modulated thermal wave imaging. Infrared Phys. Technol. 2018, 88, 41–47. [Google Scholar] [CrossRef]

- Ma, B.; Ma, X.; Wang, T.; Zhang, L. Enhancing defect detection in solid materials using low-duty cycle square wave lock-in thermography: A time-efficient and quantitative approach. Eng. Res. Express 2024, 6, 025422. [Google Scholar] [CrossRef]

- Li, G.; Zhang, S.; Zhou, M.; Li, Y.; Lin, L. A method to remove odd harmonic interferences in square wave reference digital lock-in amplifier. Rev. Sci. Instrum. 2013, 84, 025115. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.M.; Giorleo, L. Geometrical Limitations to Detection of Defects in Composites by Means of Infrared Thermography. J. Nondestruct. Eval. 2004, 23, 125–132. [Google Scholar] [CrossRef]

- Maldague, X.P. Introduction to NDT by active infrared thermography. Mater. Eval. 2002, 60, 1060–1073. [Google Scholar]

- Wallbrink, C.; Wade, S.A.; Jones, R. The effect of size on the quantitative estimation of defect depth in steel structures using lock-in thermography. J. Appl. Phys. 2007, 101, 104907. [Google Scholar] [CrossRef]

- Lahiri, B.B.; Bagavathiappan, S.; Reshmi, P.R.; Philip, J.; Jayakumar, T.; Raj, B. Quantification of defects in composites and rubber materials using active thermography. Infrared Phys. Technol. 2012, 55, 191–199. [Google Scholar] [CrossRef]

- Ta, Q.T.; Mac, V.H.; Huh, J.; Yim, H.J.; Lee, G. Automatic detection of subsurface defects in concrete structures using state-of-the-art deep learning-based object detectors on the infrared dataset. Eng. Struct. 2025, 329, 119829. [Google Scholar] [CrossRef]

- Deng, L.; Zuo, H.; Wang, W.; Xiang, C.; Chu, H. Internal Defect Detection of Structures Based on Infrared Thermography and Deep Learning. KSCE J. Civ. Eng. 2023, 27, 1136–1149. [Google Scholar] [CrossRef]

- Schmid, S.; Reinhardt, J.; Grosse, C.U. Spatial and temporal deep learning for defect detection with lock-in thermography. NDT E Int. 2024, 143, 103063. [Google Scholar] [CrossRef]

- Dong, Y.; Zhao, B.; Yang, J.; Cao, Y.; Cao, Y. Two-stage convolutional neural network for joint removal of sensor noise and background interference in lock-in thermography. NDT E Int. 2023, 137, 102816. [Google Scholar] [CrossRef]

- Wang, X.; Gao, M.; Wang, F.; Yang, F.; Yue, H.; Liu, J. Convolution Neural Network Fusion Lock-In Thermography: A Debonding Defect Intelligent Determination Approach for Aviation Honeycomb Sandwich Composites (HSCs). Metals 2023, 13, 881. [Google Scholar] [CrossRef]

- Salazar, A.; Sagarduy-Marcos, D.; Rodríguez-Aseguinolaza, J.; Mendioroz, A.; Ciria, J.C.; Celorrio, R. Resolution of multiple semi-infinite delaminations using lock-in infrared thermography. NDT E Int. 2024, 146, 103156. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Specific Heat Capacity (J/(kg·K)) | Thermal Conductivity (W/(m·K)) | Thermal Diffusivity (mm2/s) |

|---|---|---|---|---|

| Air | 1.161 | 1007 | 0.026 | 22.24 |

| Titanium | 4450 | 678 | 7 | 2.32 |

| Varied Parameter | Defect Depth h (mm) | Defect Thickness t1 (mm) | Defect Radius r (mm) |

|---|---|---|---|

| Excitation frequency f | 8 | 4 | 100 |

| Radius r | 8 | 4 | 4, 8, 12, 16, 20, 24, 32, 40, 48, 56, 64 |

| Radius-to-depth ratio r/h | 8 | 4 | 4, 8, 16, 32, 64 |

| 10 | 4 | 5, 10, 20, 40, 80 | |

| 12 | 4 | 6, 12, 24, 48 96 |

| Varied Parameter | Defect Depth h (mm) | Defect thickness t1 (mm) | Defect Radius r (mm) |

|---|---|---|---|

| Excitation frequency f | 8 | 4 | 300 |

| Depth h | 3 | 4 | 300 |

| 4 | 4 | 300 | |

| 5 | 4 | 300 | |

| 8 | 4 | 300 | |

| Thickness t1 | 3 | 4 | 300 |

| 3 | 6 | 300 | |

| 3 | 8 | 300 |

| r/h | fopt (mHz) | ||

|---|---|---|---|

| h = 8 mm | h = 10 mm | h = 12 mm | |

| 0.5 | 13.0 | 8.5 | 6.0 |

| 1 | 11.0 | 7.0 | 5.0 |

| 2 | 7.5 | 5.0 | 3.5 |

| 4 | 4.5 | 3.0 | 2.5 |

| 8 | 2.5 | 2.0 | 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, B.; Liu, C.; Sun, S.; Zhang, L. Phase-Based Thermal Wave Analysis for Lateral Characterization of Subsurface Defects in Solid Materials via Modeling and Simulation. Materials 2025, 18, 3753. https://doi.org/10.3390/ma18163753

Ma B, Liu C, Sun S, Zhang L. Phase-Based Thermal Wave Analysis for Lateral Characterization of Subsurface Defects in Solid Materials via Modeling and Simulation. Materials. 2025; 18(16):3753. https://doi.org/10.3390/ma18163753

Chicago/Turabian StyleMa, Botao, Chen Liu, Shupeng Sun, and Lin Zhang. 2025. "Phase-Based Thermal Wave Analysis for Lateral Characterization of Subsurface Defects in Solid Materials via Modeling and Simulation" Materials 18, no. 16: 3753. https://doi.org/10.3390/ma18163753

APA StyleMa, B., Liu, C., Sun, S., & Zhang, L. (2025). Phase-Based Thermal Wave Analysis for Lateral Characterization of Subsurface Defects in Solid Materials via Modeling and Simulation. Materials, 18(16), 3753. https://doi.org/10.3390/ma18163753