Investigation on the Tensile Fracture Properties of Fully-Graded Concrete Considering Aggregate Morphological Characteristics via Peridynamics

Abstract

1. Introduction

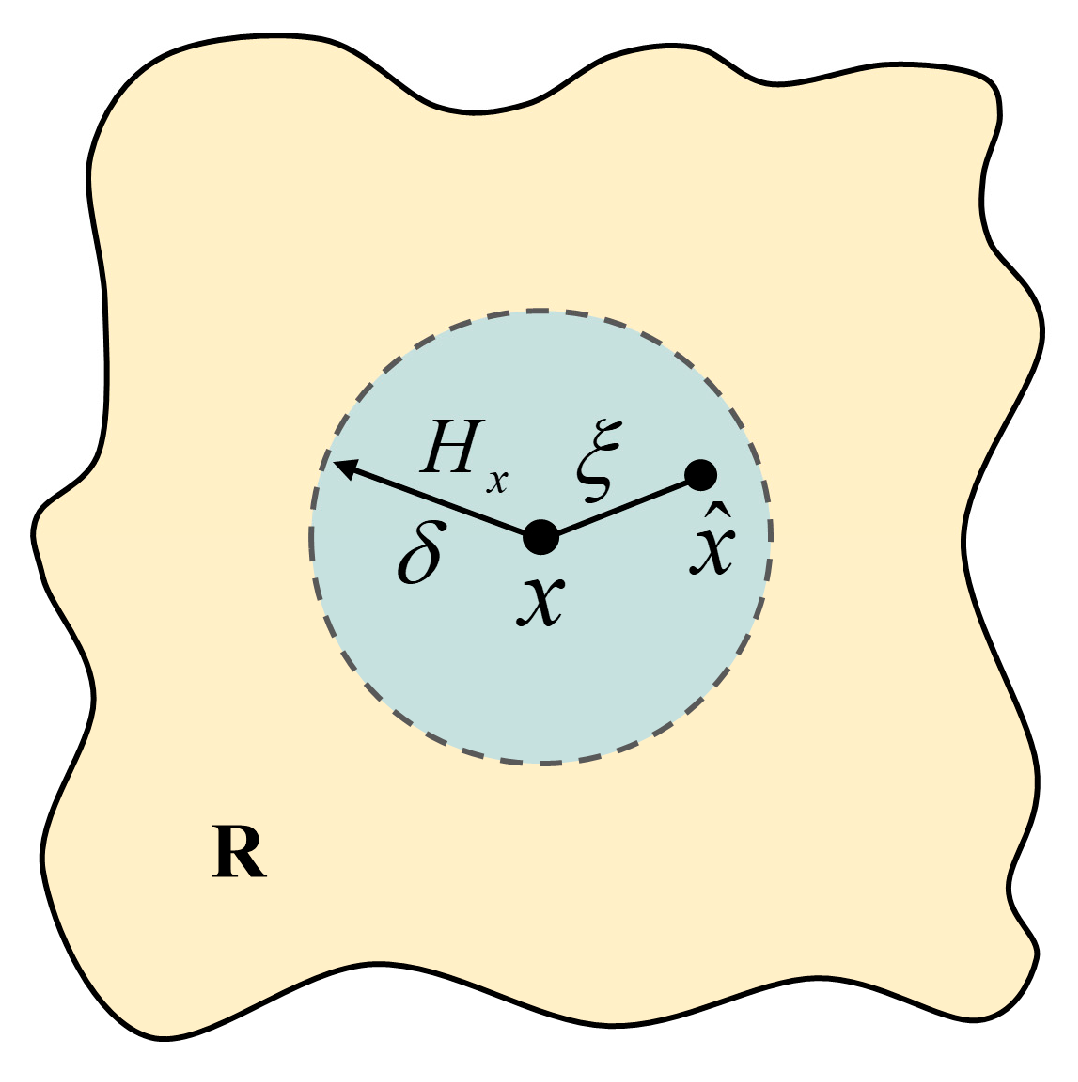

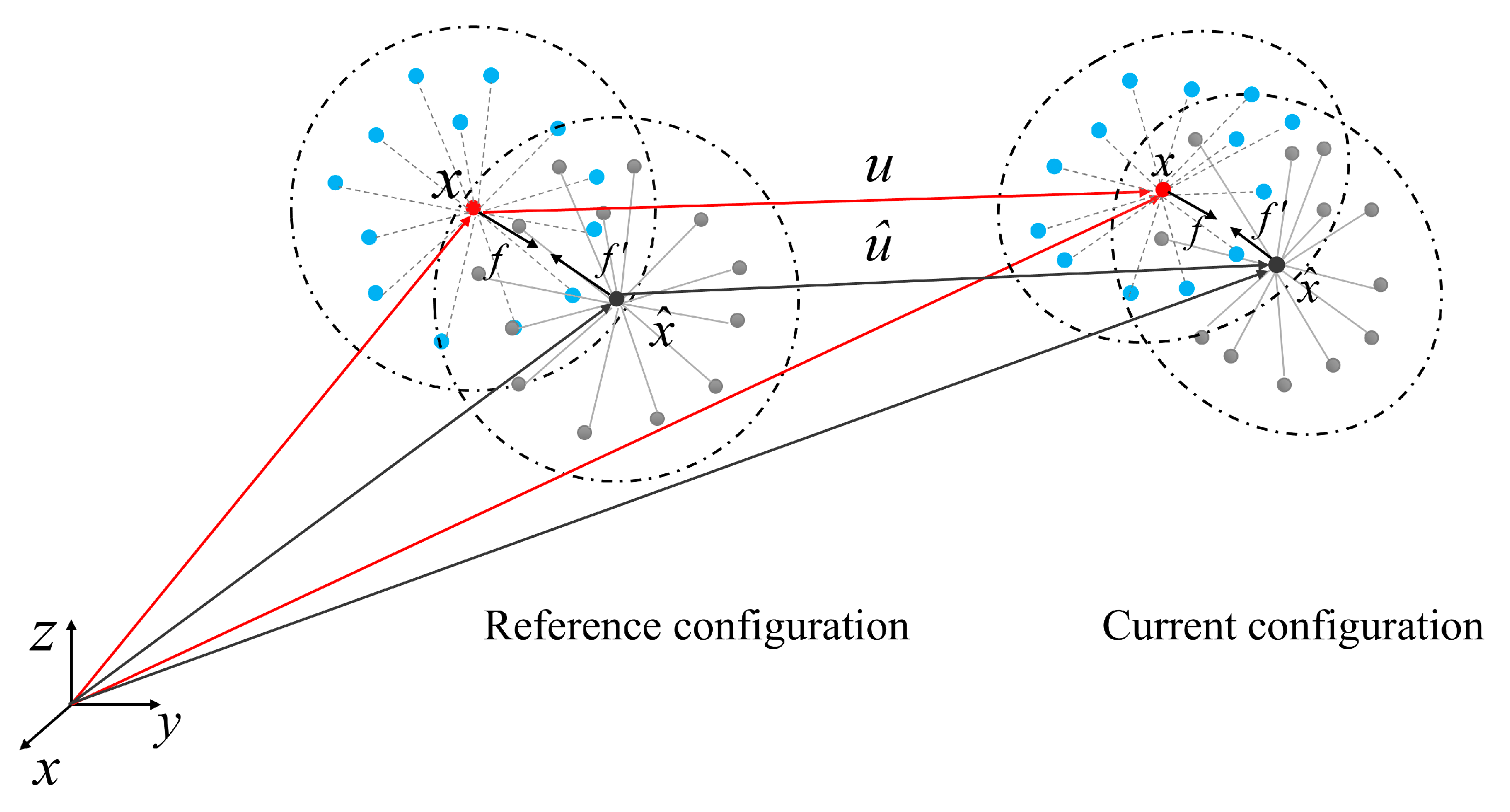

2. Theoretical Background of Peridynamics

2.1. Basic Theory

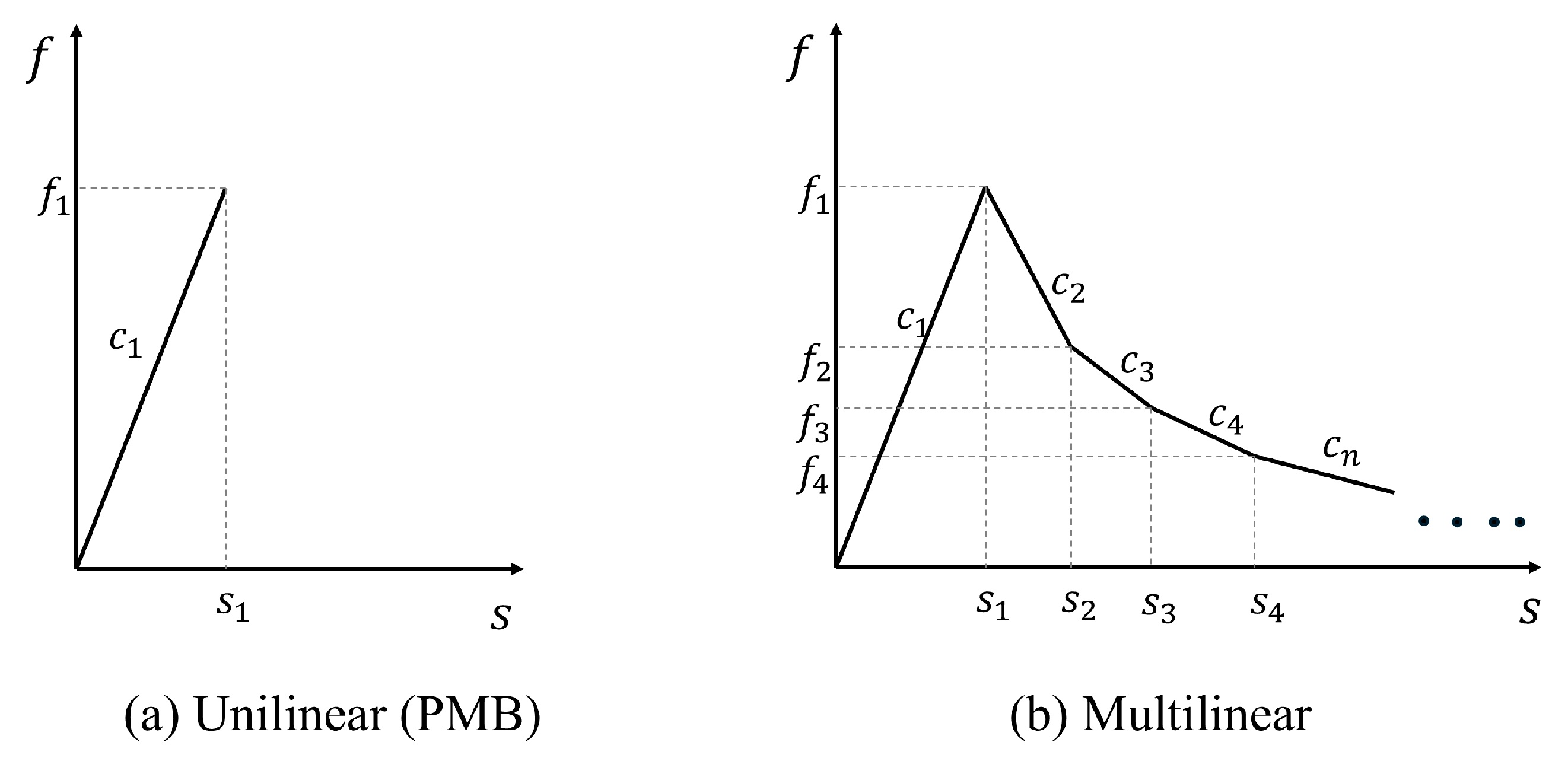

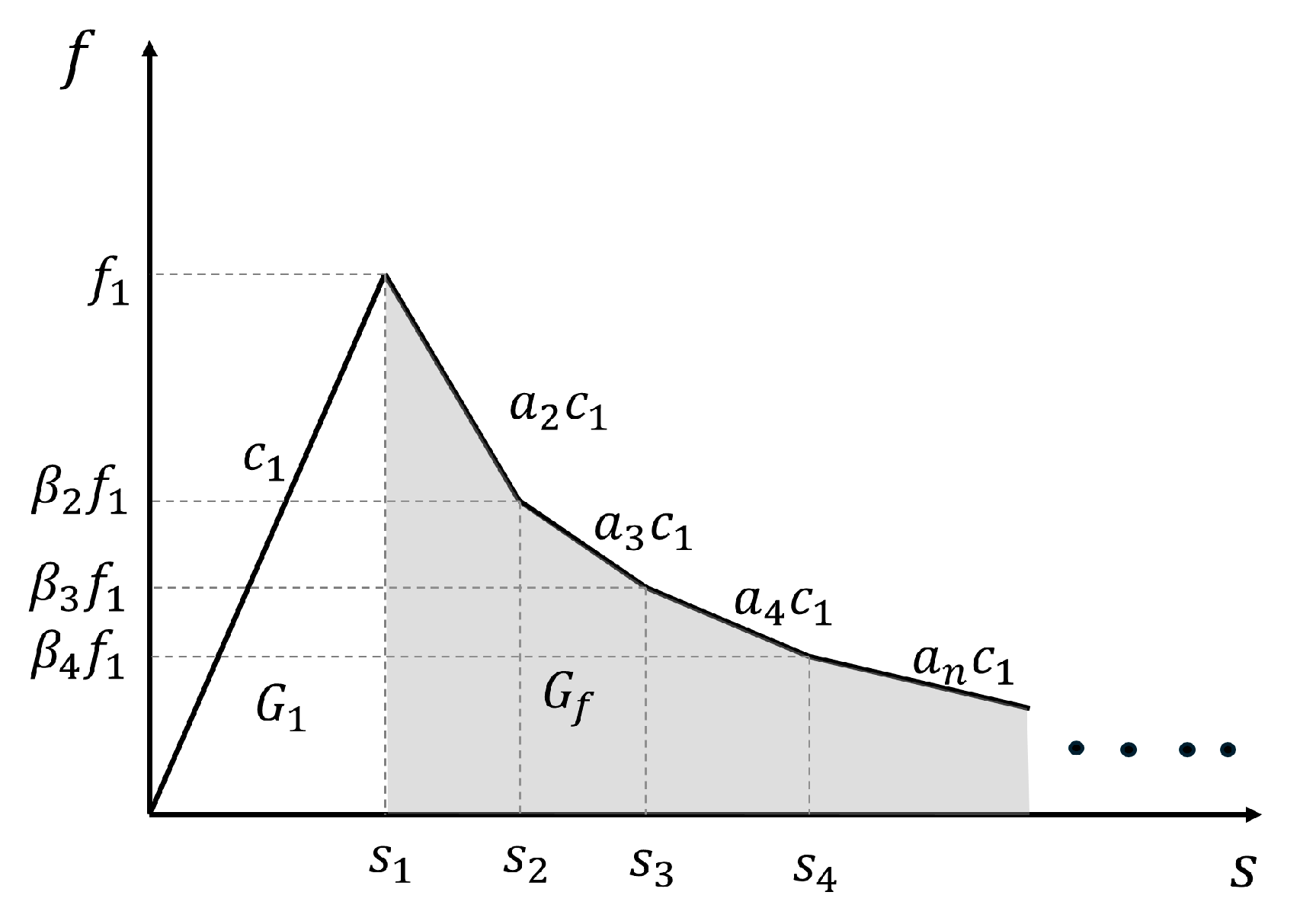

2.2. Multi-Segment Linear Constitutive Theory

3. Constructing a Fully Graded Concrete Model Considering Aggregate Morphology Characteristics

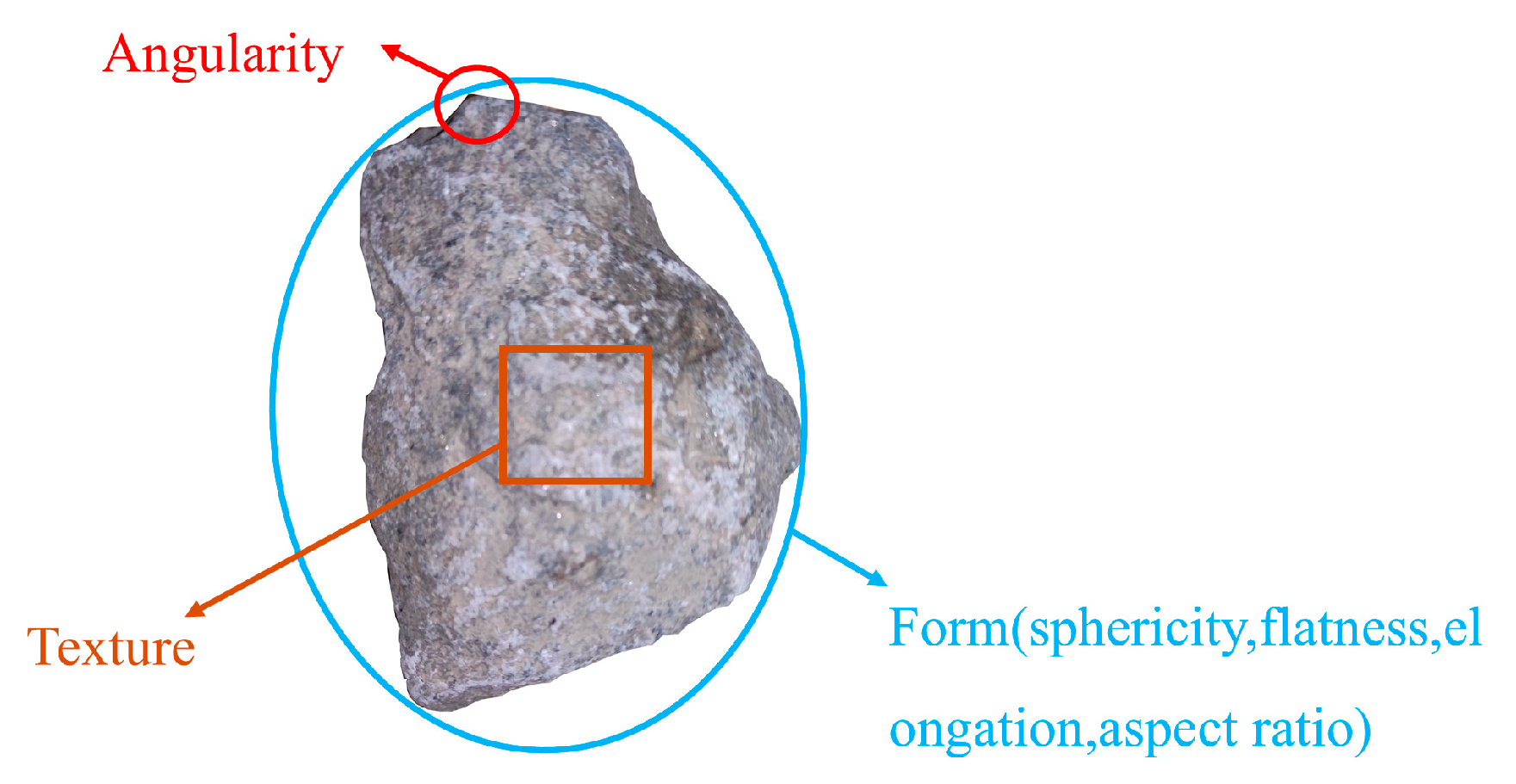

3.1. Parameters of Morphological Characteristics of Aggregates

3.2. Modeling Aggregates with Axial Ratio and Angularity Coefficient

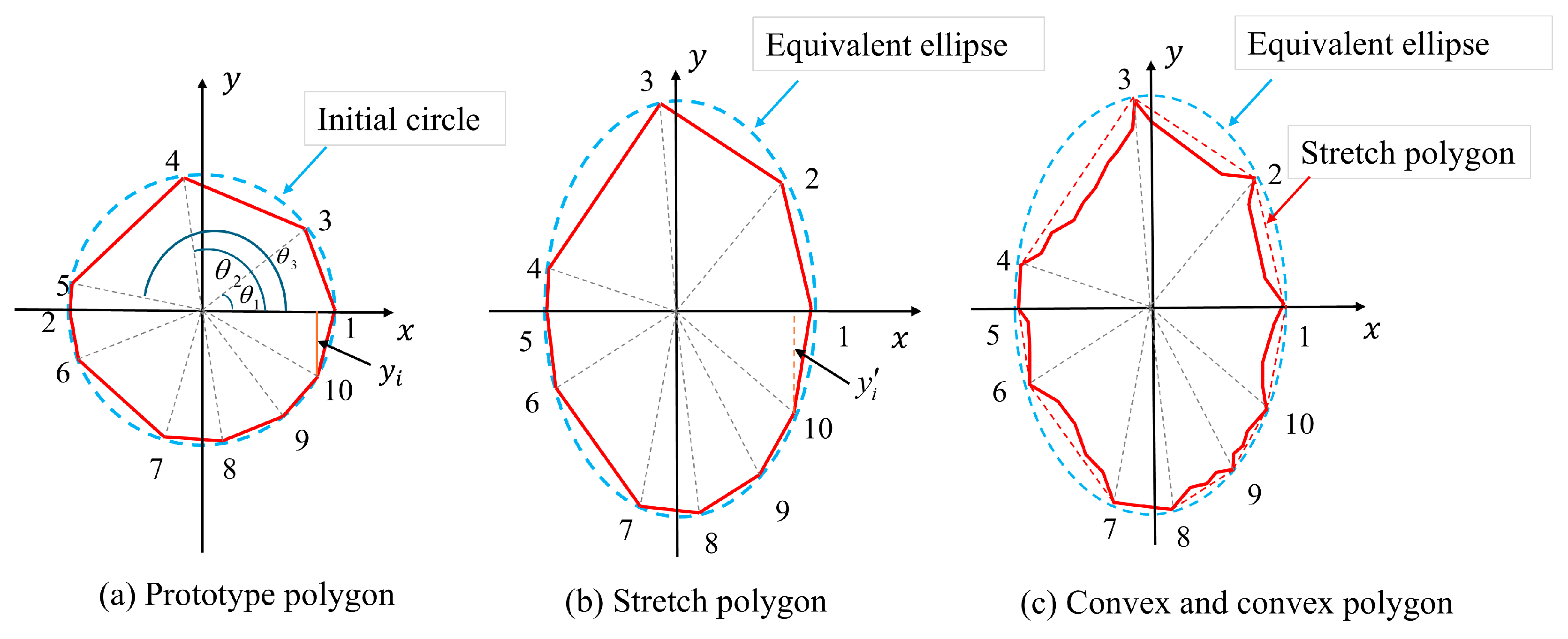

- Prototype polygon vertex count determination: Aggregate morphological parameters are correlated with variations in the number of polygonal variations in particle geometry [34]. The generation of prototype polygons is driven by specified morphological parameter inputs. As shown in Figure 6a, circular shapes centered at a fixed origin are generated based on the specified morphological parameters. The number of vertices in the prototype polygon varies depending on the interval of Ac, as shown in Equation (15).

- Determining the angle during aggregate generation: As shown in Figure 6a, when starting to construct a polygon, two vertices of the polygon are fixed at the center angle of 0 and , and the remaining vertices are randomized using Equation (16).where is a random number uniformly distributed between 0 and 1, and is any value not greater than 1. The generated must satisfy Equation (17).where is the angle value that has been determined to have been generated, is the minimum allowable angle interval, is the direct angle difference, is the difference value of the angle crossing, and is the difference value of the angle crossing .

- Determination of aggregate stretching values: Calculate the vertex coordinates of the prototype polygon using the characteristic angle and the radius of the circumscribed circle. The polygon is then stretched along the y-axis based on the reference axis length ratio. The coordinates of individual polygon vertices are further adjusted using Equation (18), as illustrated in Figure 6b.Here, denotes the vertical magnification factor, which is restricted to the range of [1.0, 3.5]. Based on the prescribed axis length ratio, an appropriate magnification factor within this interval is determined using the bisection algorithm. Next, the equivalent axis length ratio of the aggregate’s fitted ellipse is computed, as illustrated by the blue dotted line in Figure 6b. If the required axis length ratio is not achieved, the stretching process is repeated.

- Determining the aggregate indentation depth: During the indentation process, the initial indentation depth is uniformly distributed within the range , where denotes the side length of the polygon. The rules for identifying concave points on a polygon are defined as follows: let denote the length of the longest side, and the length of the current side. When , no concave points are placed on the side; when , four concave points are placed on the side and divided into five equal parts according to the current side length; when , eight concave points are placed on the side and divided into nine equal parts according to the current side length. The actual indentation depth of the aggregate polygon is obtained by multiplying the initial indentation depth by the indentation depth magnification factor. Figure 6c illustrates the comparison of the aggregate concavity before and after indentation. As the axis length ratio increases, the distance between the polygonal sides on either side of the aggregate’s long axis decreases. This results in an increased likelihood of edge intersections and excessively small internal angles, which in turn affect the efficiency and robustness of program execution. Therefore, the range of values for the concavity coefficient must be adjusted based on the vertical magnification factor. The minimum and maximum values of the concavity coefficient for each interval are presented in Table 1.

3.3. Establishment of a Concrete Micro-Scale Model

3.3.1. Concrete Fine-Scale Model Generation and Discretization

- To achieve equivalence with 3D planes, Walraven adapted Fuller’s gradation formula into a two-dimensional aggregate gradation formula, which is more suitable for developing a 2D concrete micro-model, as shown in Equation (19) [8].where represents the area fraction of aggregate particle size smaller than , is the specified particle size of coarse aggregate, is the percentage of coarse aggregate volume in the total concrete volume, and is the maximum particle size of aggregate.The aggregate particle sizes within a given gradation can be expressed as (where ). These sizes are determined using the initial circular area method. A random particle size is selected from the aggregate size set to compute the vertex coordinates of the corresponding polygonal aggregate. The polygons in this study are generated using the Tensile-Concave Synthesis Method. The area of each generated aggregate is calculated to verify whether it falls within the specified range. If this condition is not met, the generation process is repeated until the requirement is satisfied.

- After all aggregates are generated, they are sorted in descending order of size so that larger particles are placed first. When the number of aggregates is large, a comprehensive algorithm is employed to efficiently detect potential intersections. To reduce computational cost, the polygons are first enclosed within axis-aligned bounding boxes (AABB). If two aggregates are determined not to intersect, three possible situations may arise: intersection, separation, and overlap. The surrounding-number method [35] is subsequently used to determine whether a point lies inside the polygon, enabling the classification of the three aforementioned cases.

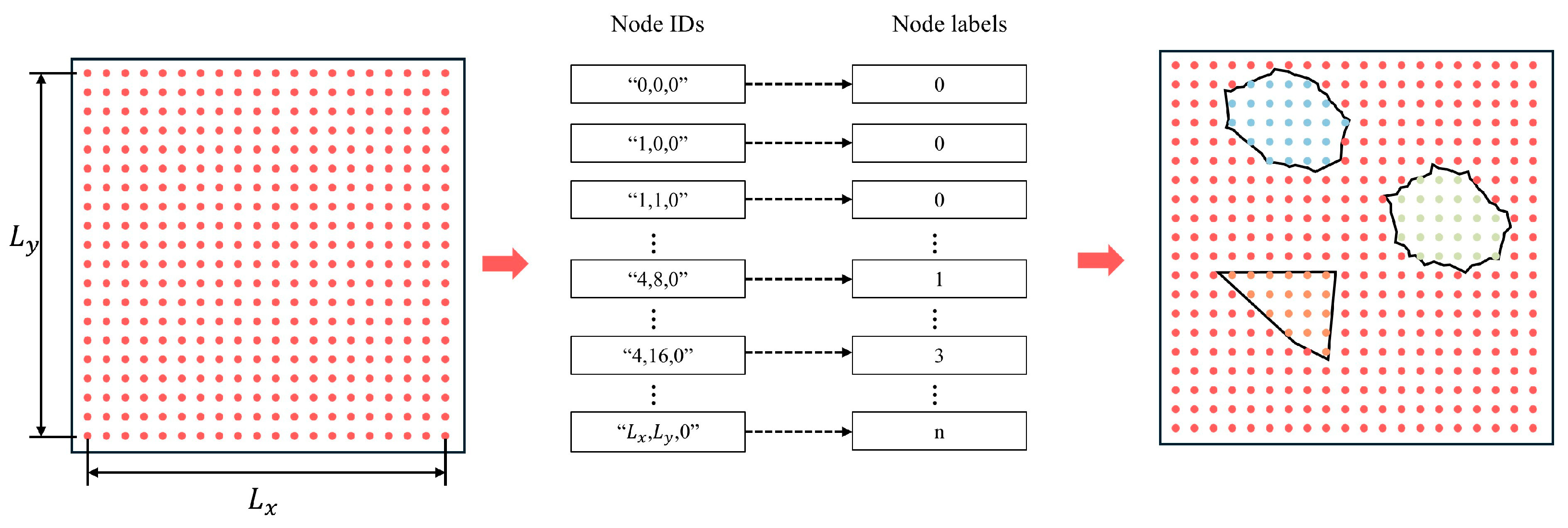

- Following aggregate placement within the designated domain, the node-tagging method is employed to assign material point attributes. This method involves calculating both the displacement and tag value of all material points within the domain. For example, as shown in Figure 8, nodes are uniformly distributed over a two-dimensional domain of size . Each node in the area is assigned a Node ID based on its coordinate value to prevent errors when assigning material properties. Node IDs are further categorized based on the material phase. All initial tags within an area are set to 0 (mortar area, red), and then different aggregates are marked as “1, 2, 3, 4, &, n”, where n is a positive integer (aggregate area, other colors), indicating that there are n aggregates in the model.

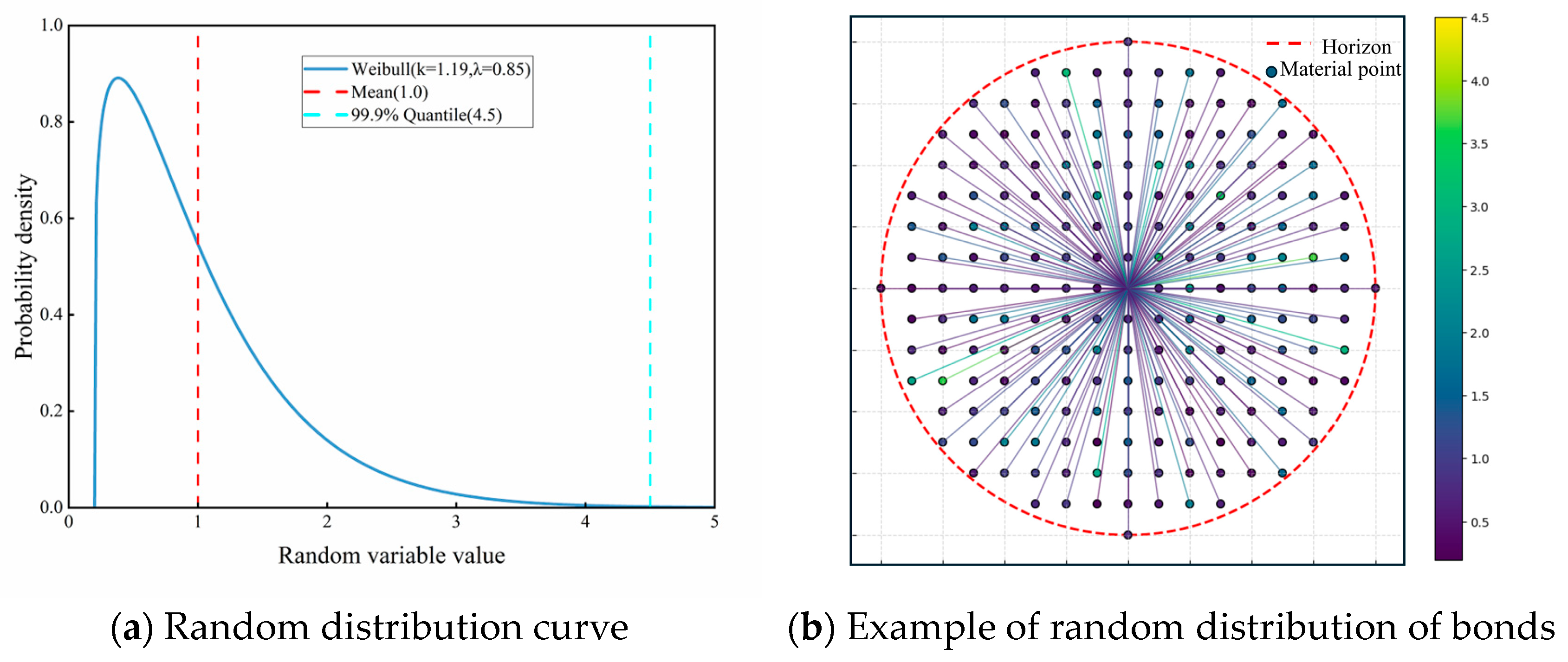

3.3.2. Methods for Establishing Internal Bonds in Concrete

3.3.3. Setting Random Defects Inside Concrete

4. Verification and Discussion of Results

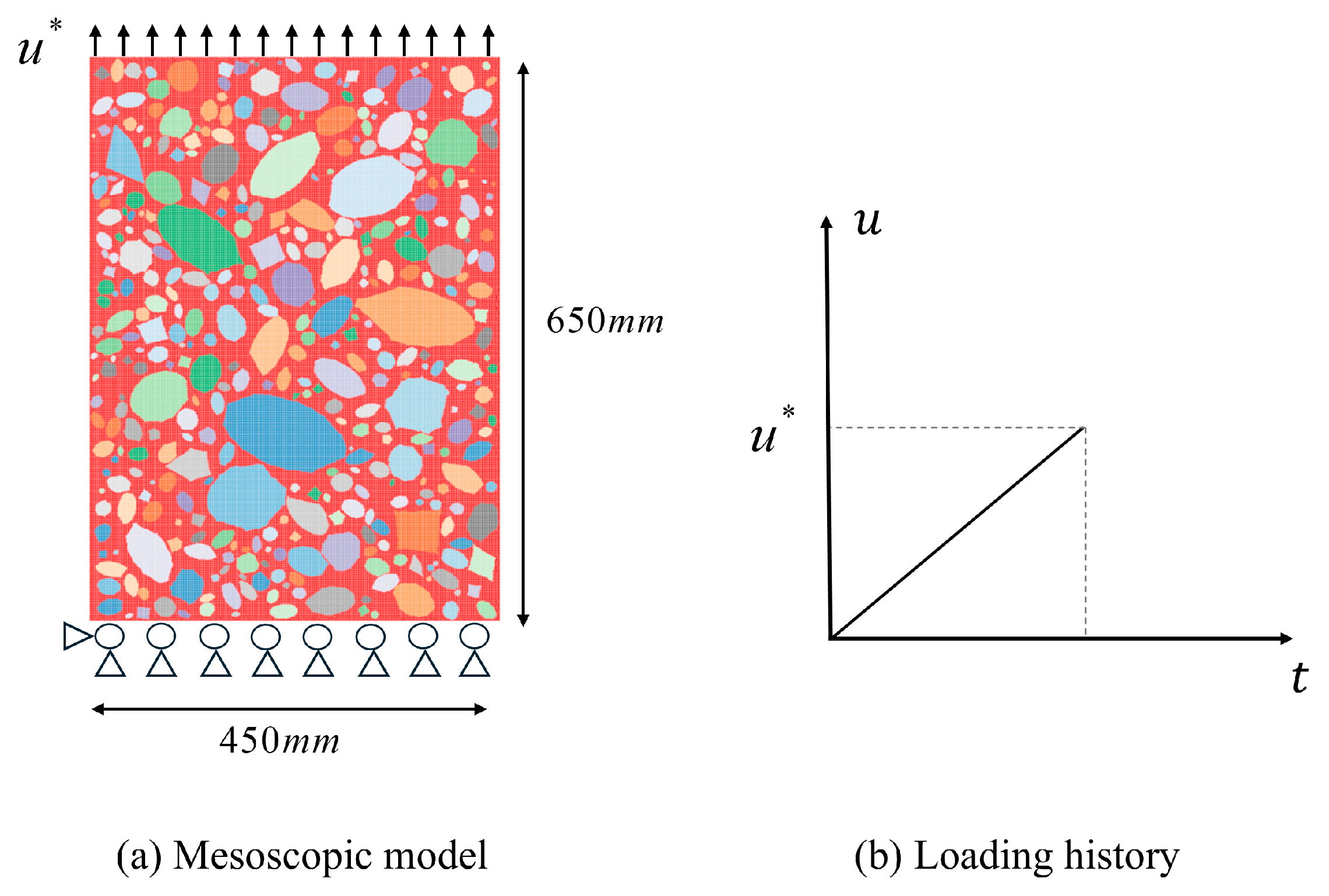

4.1. Setting Model and Material Parameters

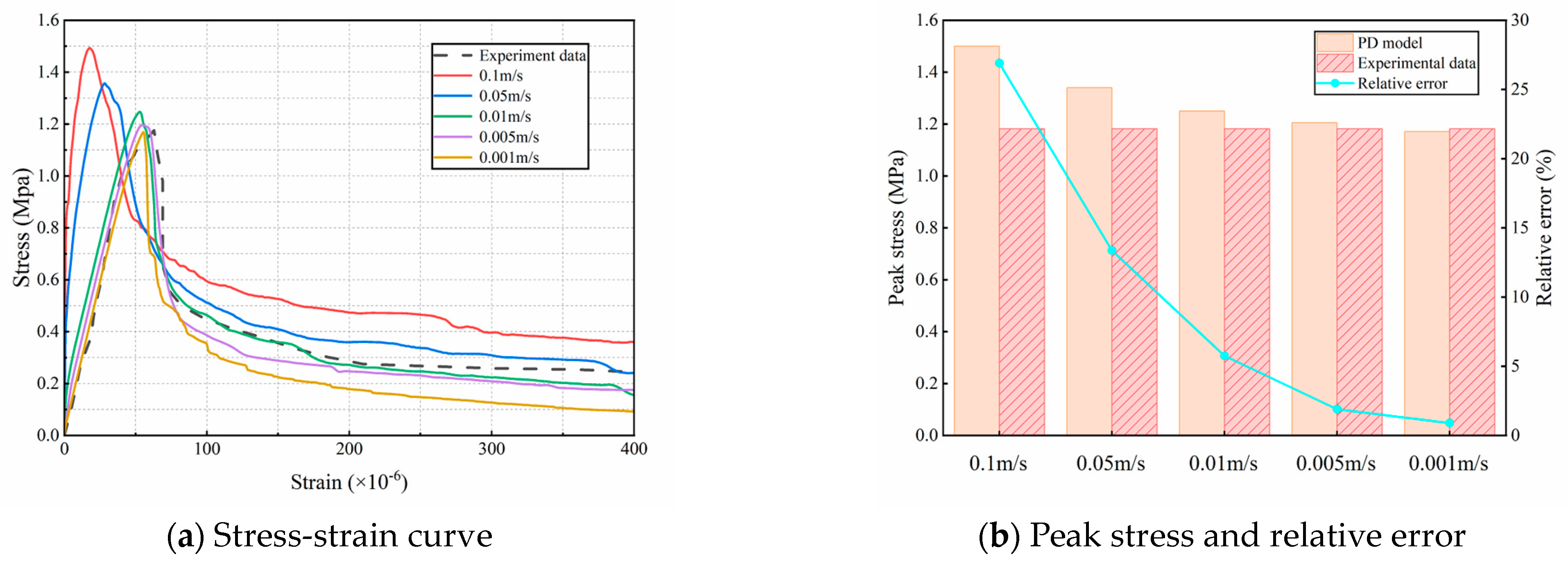

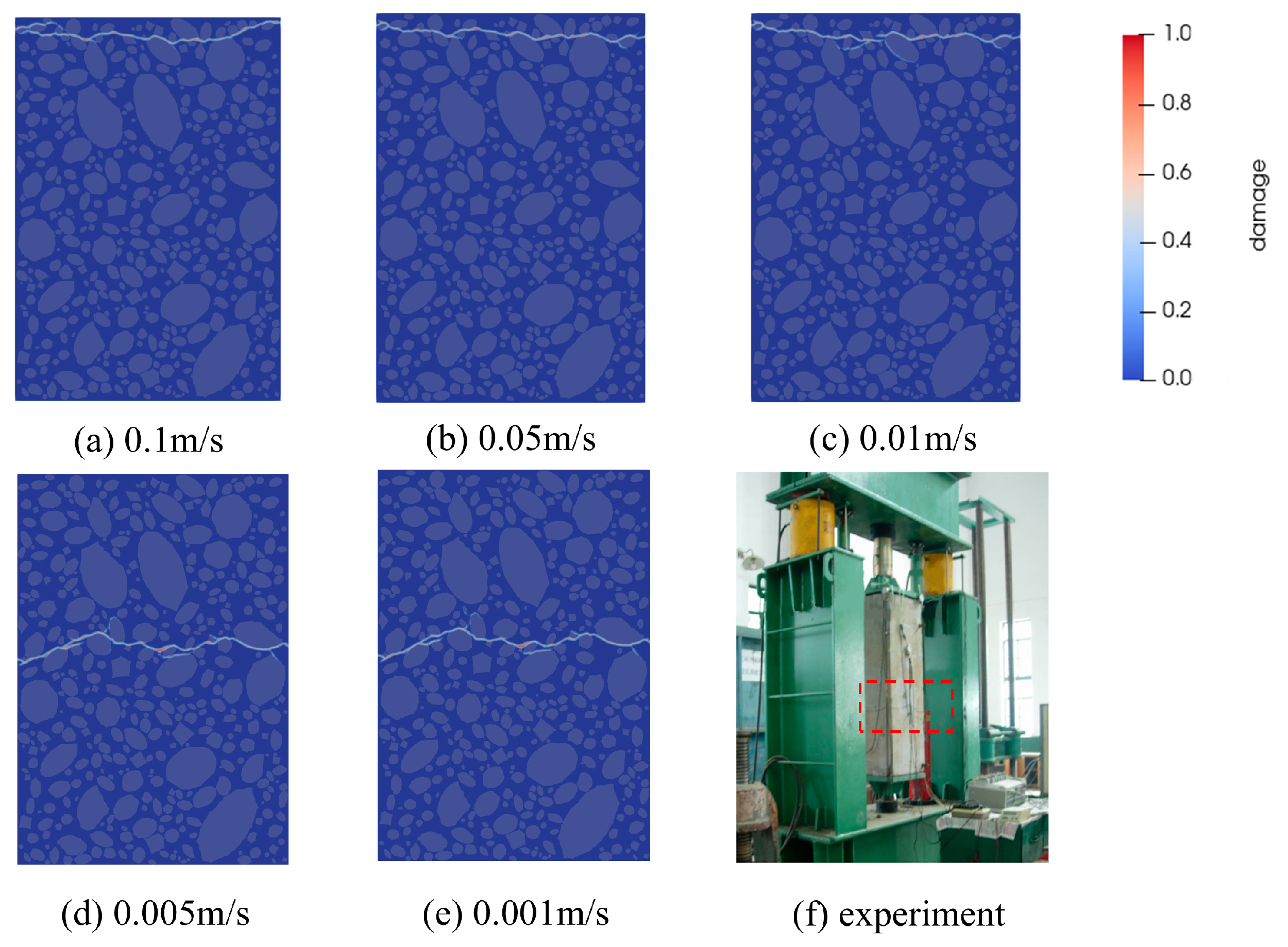

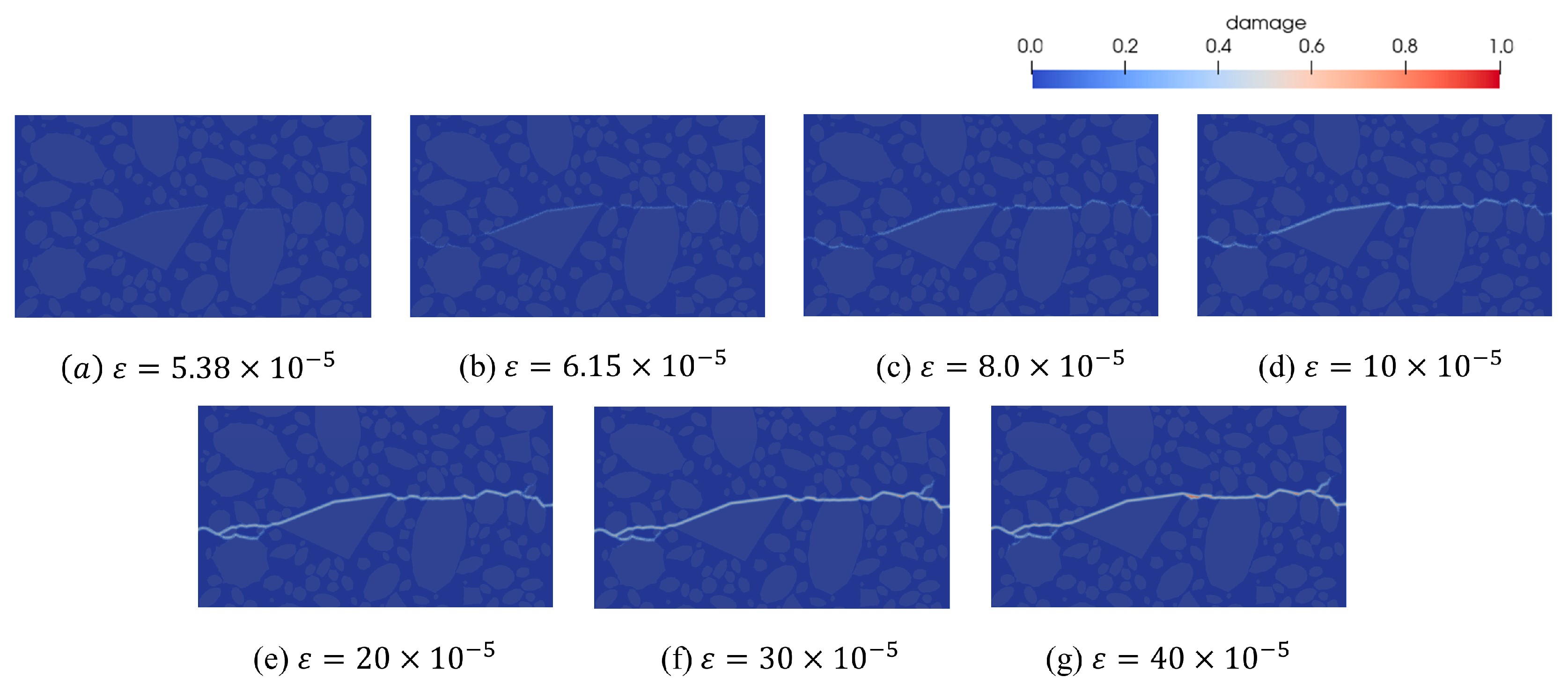

4.2. Impact of Loading Rate

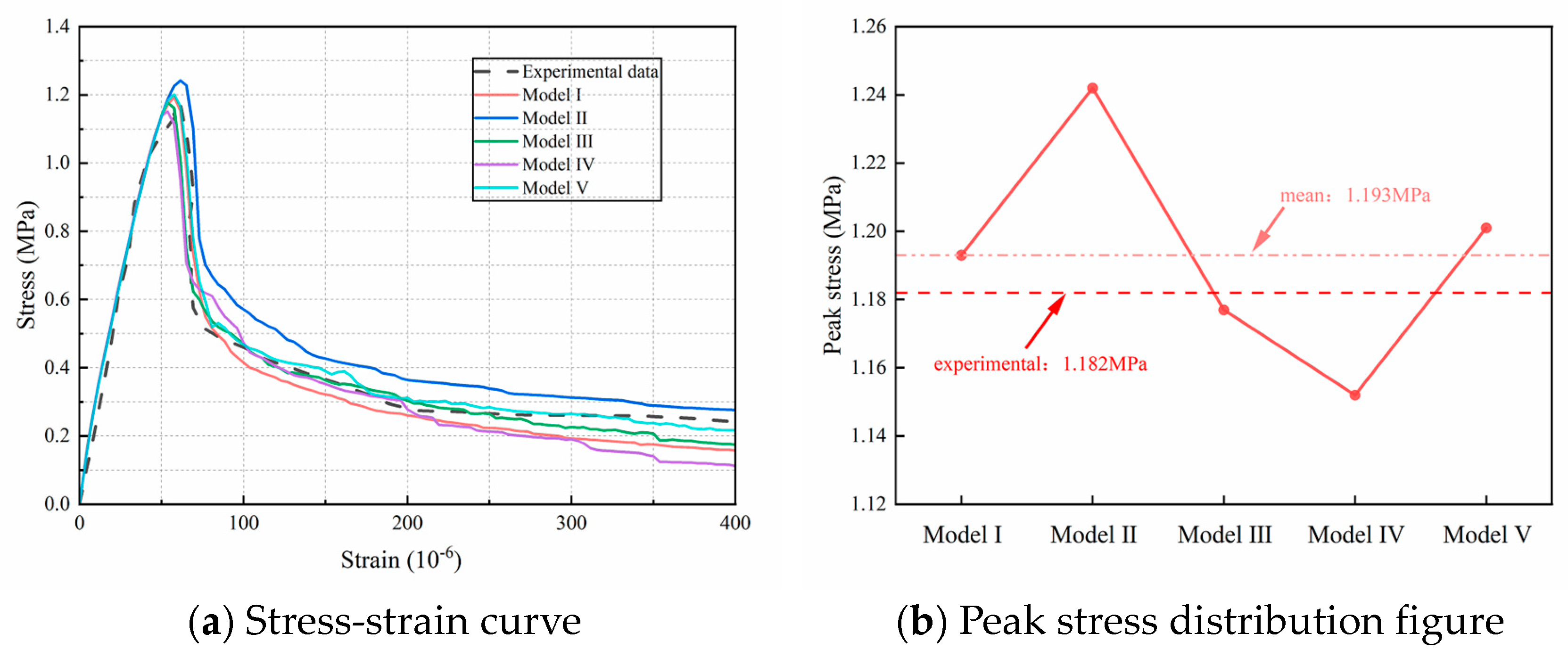

4.3. Effect of Aggregate Randomness on Uniaxial Tensile Properties

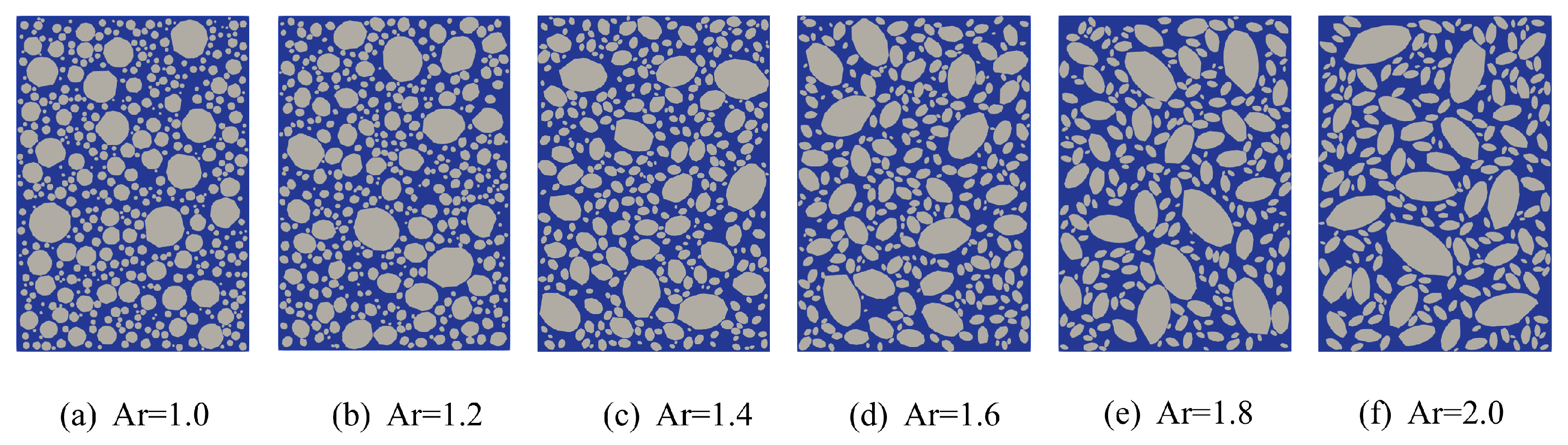

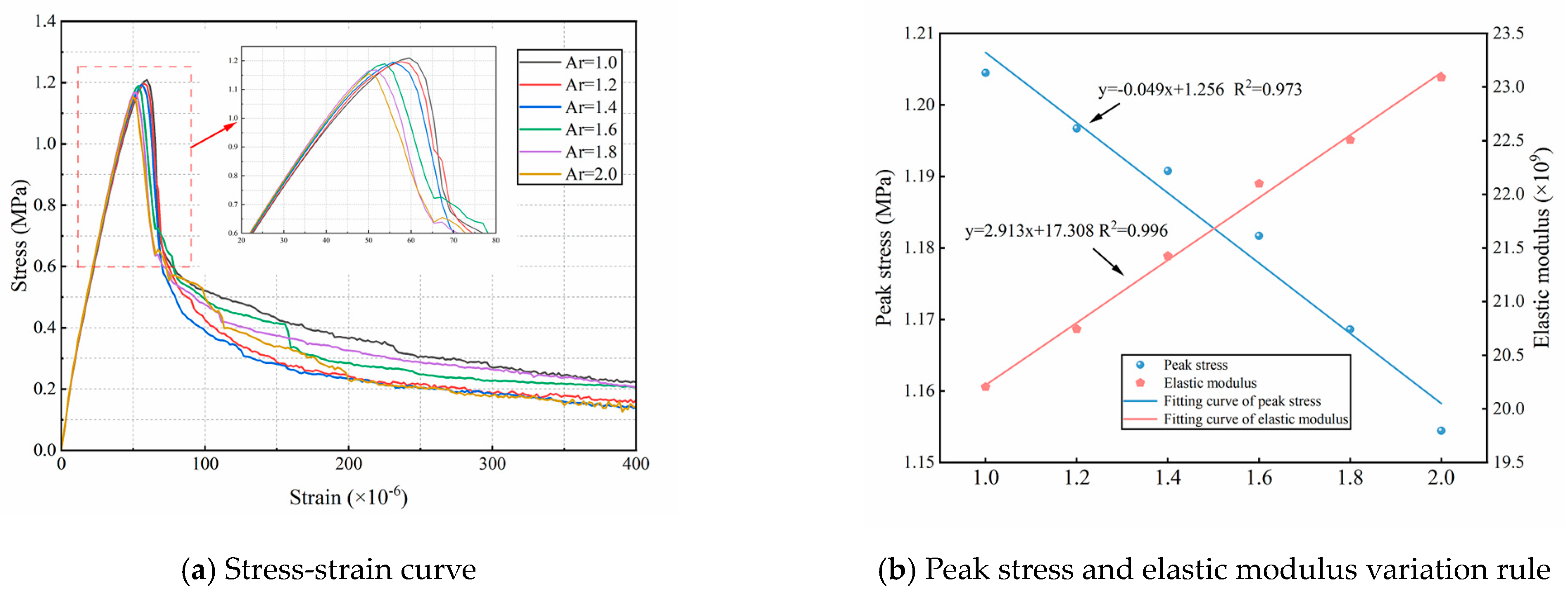

4.4. Effect of Aggregate Axial Ratio on Tensile Properties

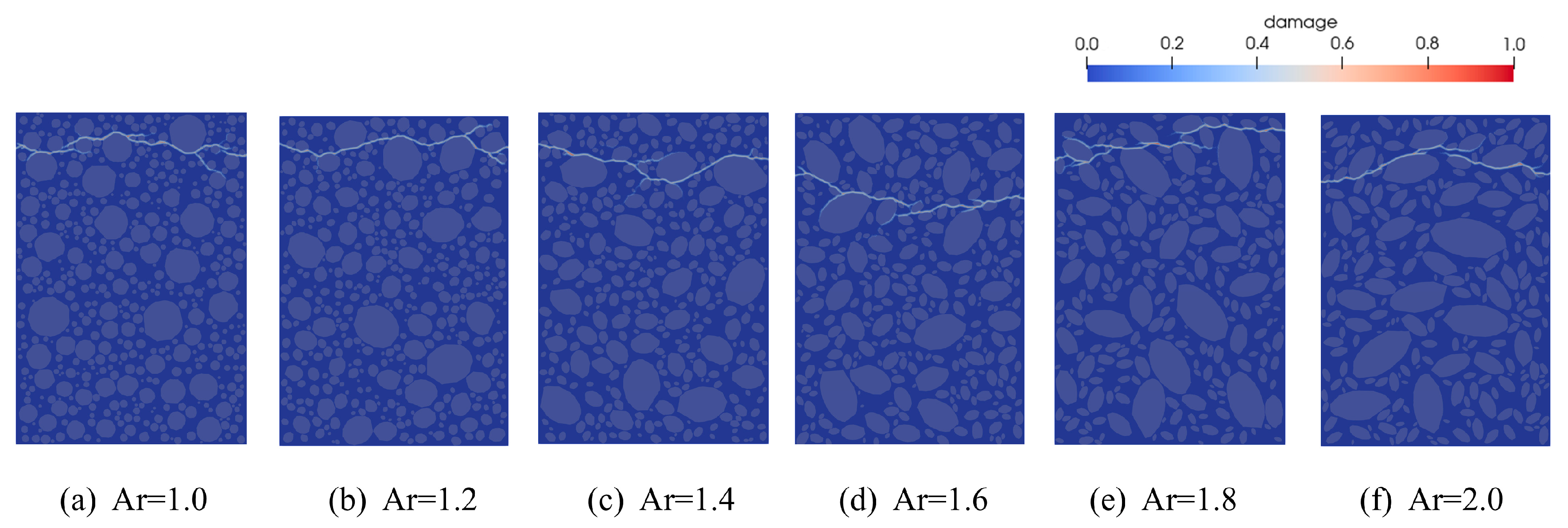

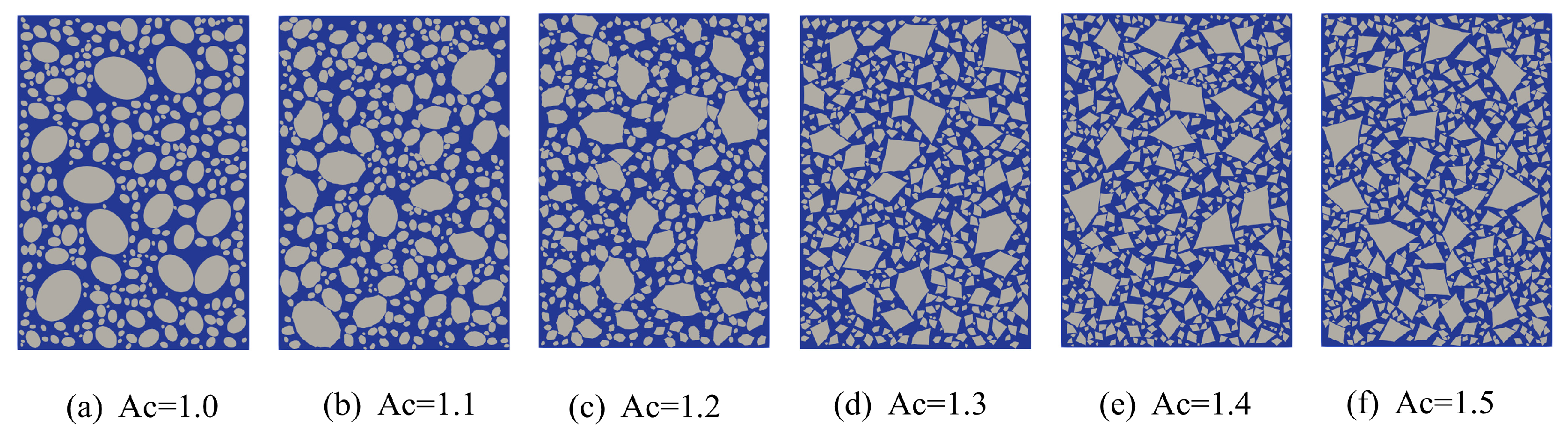

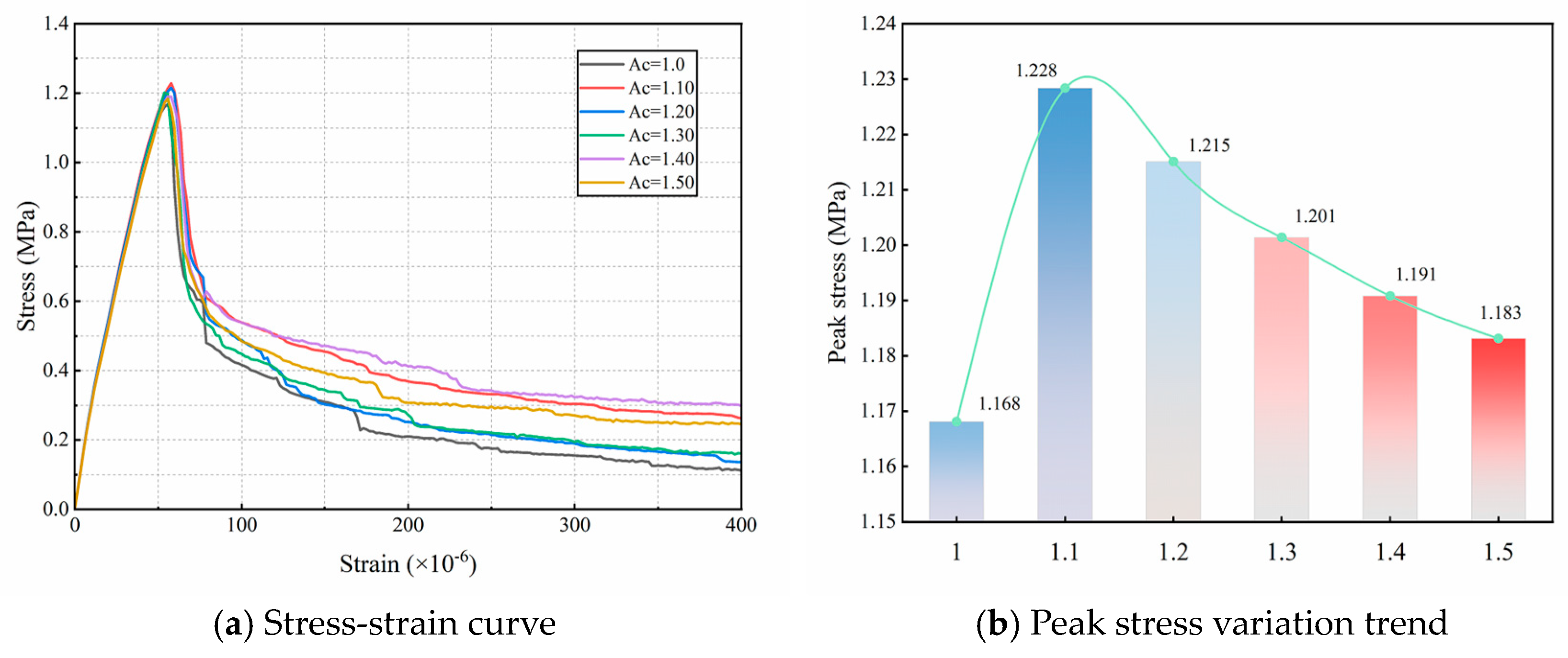

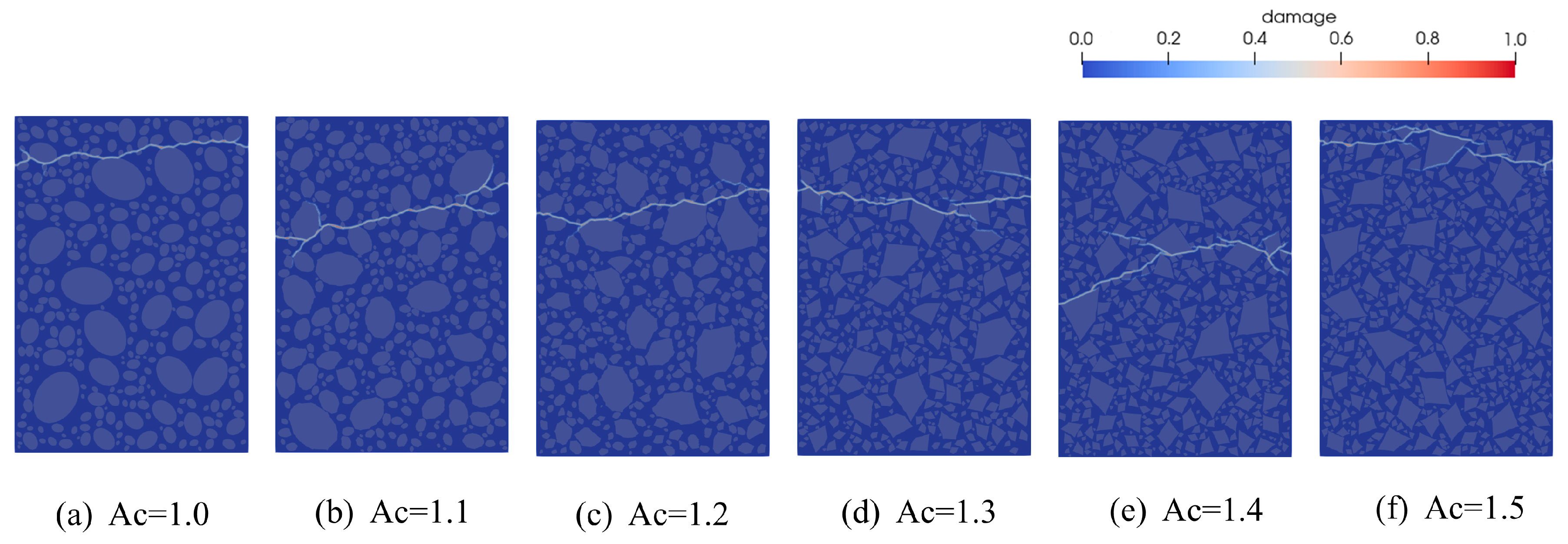

4.5. Effect of Aggregate Angularity Coefficient on Tensile Properties

5. Conclusions

- The proposed peridynamic model accurately simulates the complete stress–strain response of fully graded concrete under uniaxial tension, encompassing the elastic phase, crack initiation, propagation, and final failure. Moreover, phenomena such as crack initiation, coalescence, bridging, and branching are naturally captured without requiring predefined failure criteria or remeshing, offering a robust and reliable approach for simulating the entire tensile failure process of concrete.

- The peridynamic simulation results reveal pronounced strain rate-dependent behavior. As the loading rate decreases, concrete ductility decreases while tensile strength approaches a stable value. At higher loading rates, fracture tends to initiate near the loading point, whereas at lower rates, cracks propagate preferentially along pre-existing weak zones. A loading rate of is sufficient to satisfy quasi-static loading in simulation.

- The numerical model of fully graded concrete based on randomly generated aggregate morphology exhibits noticeable variability in its results. This variability stems from the irregular shapes and spatial distributions of aggregates, which strongly affect internal force transmission mechanisms. Therefore, to minimize the impact of aggregate randomness, at least five realizations should be employed in both numerical simulations and physical experiments.

- As the axial length-to-radius ratio (Ar) of aggregates increases, the slope of the elastic segment of the tensile stress–strain curve increases, whereas the peak stress decreases. An increased Ar modifies the spatial distribution of the ITZ, leading to a concentration of interface bonds, which adversely affects the fracture behavior of the specimen. Therefore, moderately reducing the aggregate Ar may facilitate a more favorable and uniform stress distribution in fully graded concrete.

- As the angularity coefficient (Ac) of the aggregates increased, the ultimate tensile strength of fully graded concrete specimens initially increased, peaking at Ac = 1.10, before gradually decreasing. Crack propagation progressively transitioned from a single isolated crack to a dominant crack accompanied by multiple branches, with the crack path becoming increasingly tortuous. Overall, increasing Ac can enhance the tensile strength of fully graded concrete to a certain extent; however, excessive angularity does not necessarily result in further improvement. Therefore, selecting an appropriate angularity coefficient is essential for optimizing the tensile performance of fully graded concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, C.; Qiu, Q.; Wang, X.; Zhang, S.; Wang, G.; Wei, P. Concrete aggregate-gradation effect and strength-criterion modification for fully graded hydraulic concrete. Materials 2024, 17, 3816. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhao, L.; Wang, H.; Tu, J. Experimental study on damage law of fully graded concrete under tension compression cyclic load. In Proceedings of the 2021 7th International Conference on Hydraulic and Civil Engineering & Smart Water Conservancy and Intelligent Disaster Reduction Forum (ICHCE & SWIDR), Nanjing, China, 6–8 November 2021; pp. 693–698. [Google Scholar]

- Song, Y.-P.; Wang, H.-L.; Wang, B.-T. Simulation of the behaviour of fully-graded concrete at a mesoscopic level based on a rigid body spring discrete element model. Comput. Methods Exp. Mater. Characterisation II 2013, 51, 10. [Google Scholar] [CrossRef]

- Guan, J.; Song, Z.; Zhang, M.; Yao, X.; Li, L.; Hu, S. Concrete fracture considering aggregate grading. Theor. Appl. Fract. Mech. 2020, 112, 102833. [Google Scholar] [CrossRef]

- Huang, Z.; Cao, J.; Gong, F.; Nie, D.; Li, W.; Lin, P.; Zhang, H. Multi-scale thermo-poro-mechanical simulation of the frost resistance of low-heat and moderate-heat hydraulic concrete considering the aging microstructure. Constr. Build. Mater. 2024, 453, 139062. [Google Scholar] [CrossRef]

- Guo, J.; Lin, W.; Qin, X.; Xu, Y.; Dong, K. Mesoscopic study on fracture behavior of fully graded concrete under uniaxial tension by using the phase-field method. Eng. Fract. Mech. 2022, 272, 108678. [Google Scholar] [CrossRef]

- Qin, X.; Gu, C.; Shao, C.; Fu, X.; Vallejo, L.; Chen, Y. Numerical analysis of fracturing behavior in fully-graded concrete with oversized aggregates from mesoscopic perspective. Constr. Build. Mater. 2020, 253, 119184. [Google Scholar] [CrossRef]

- Ma, H.; Xu, W.; Li, Y. Random aggregate model for mesoscopic structures and mechanical analysis of fully-graded concrete. Comput. Struct. 2016, 177, 103–113. [Google Scholar] [CrossRef]

- Zou, X.; D’Antino, T.; Sneed, L.H. Investigation of the bond behavior of the fiber reinforced composite-concrete interface using the finite difference method (FDM). Compos. Struct. 2021, 278, 114643. [Google Scholar] [CrossRef]

- Jiang, S.; Lin, A.; Ooi, E.T.; Gao, J.; Sun, L.; Du, C. Dynamic fracture modeling of concrete composites based on nonlocal multiscale damage model and scaled boundary finite element methods. Eng. Anal. Bound. Elem. 2024, 167, 105909. [Google Scholar] [CrossRef]

- Yazdi, S.R.S.; Amiri, T. An efficient automatic adaptive algorithm for cohesive crack propagation modeling of concrete structures using matrix-free unstructured galerkin finite volume method. Comput. Math. Appl. 2021, 97, 237–250. [Google Scholar] [CrossRef]

- Unger, J.F.; Eckardt, S.; Könke, C. Modelling of cohesive crack growth in concrete structures with the extended finite element method. Comput. Methods Appl. Mech. Eng. 2007, 196, 4087–4100. [Google Scholar] [CrossRef]

- Qin, X.; Wang, X.; Guo, J.; Xu, B.; Lin, W.; Wang, K.; Chen, X. Parameter investigation and efficiency evaluation of unified phase-field theory in mesoscale fracture analysis of fully-graded concrete under uniaxial tension. Eng. Fract. Mech. 2025, 314, 110696. [Google Scholar] [CrossRef]

- Silling, S.A. Reformulation of elasticity theory for discontinuities and long-range forces. J. Mech. Phys. Solids 2000, 48, 175–209. [Google Scholar] [CrossRef]

- Li, W.; Guo, L. Meso-fracture simulation of cracking process in concrete incorporating three-phase characteristics by peridynamic method. Constr. Build. Mater. 2018, 161, 665–675. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, M.; Chu, X. Hydro-thermo-mechanical coupled peridynamic modeling of freeze–thaw fracture of concrete. Acta Mech. 2024, 235, 7475–7496. [Google Scholar] [CrossRef]

- Gu, X.; Zhang, Q. A modified conjugated bond-based peridynamic analysis for impact failure of concrete gravity dam. Meccanica 2020, 55, 547–566. [Google Scholar] [CrossRef]

- Chen, Z.; Niazi, S.; Bobaru, F. A peridynamic model for brittle damage and fracture in porous materials. Int. J. Rock Mech. Min. Sci. 2019, 122, 104059. [Google Scholar] [CrossRef]

- Wu, P.; Yang, F.; Chen, Z.; Bobaru, F. Stochastically homogenized peridynamic model for dynamic fracture analysis of concrete. Eng. Fract. Mech. 2021, 253, 107863. [Google Scholar] [CrossRef]

- Pan, Y.; Wu, P.; Fan, S.; Peng, X.; Chen, Z. Peridynamic simulation of fatigue crack growth in porous materials. Eng. Fract. Mech. 2024, 300, 109984. [Google Scholar] [CrossRef]

- Dong, Y.; Su, C.; Qiao, P. An improved mesoscale damage model for quasi-brittle fracture analysis of concrete with ordinary state-based peridynamics. Theor. Appl. Fract. Mech. 2021, 112, 102829. [Google Scholar] [CrossRef]

- Chen, W.; Gu, X.; Zhang, Q.; Xia, X. A refined thermo-mechanical fully coupled peridynamics with application to concrete cracking. Eng. Fract. Mech. 2021, 242, 107463. [Google Scholar] [CrossRef]

- Cheng, Z.; Ren, X.; Zhang, J.; Zhang, X. Peridynamics thermomechanical coupling simulation of damage in engineered cementitious composite-concrete bonding specimens under high temperature. Eng. Fract. Mech. 2024, 306, 110211. [Google Scholar] [CrossRef]

- Wu, L.; Huang, D.; Wang, H.; Ma, Q.; Cai, X.; Guo, J. A comparison study on numerical analysis for concrete dynamic failure using intermediately homogenized peridynamic model and meso-scale peridynamic model. Int. J. Impact Eng. 2023, 179, 104657. [Google Scholar] [CrossRef]

- Shi, C.; Shi, Q.; Tong, Q.; Li, S. Peridynamics modeling and simulation of meso-scale fracture in recycled coarse aggregate (RCA) concretes. Theor. Appl. Fract. Mech. 2021, 114, 102949. [Google Scholar] [CrossRef]

- Zheng, Z.; Wei, X.; Tian, C. Mesoscale models and uniaxial tensile numerical simulations of concrete considering material heterogeneity and spatial correlation. Constr. Build. Mater. 2021, 312, 125428. [Google Scholar] [CrossRef]

- Zhou, S.; Wu, C.; Li, J.; Shi, Y.; Luo, M.; Guo, K. Study on the influence of fractal dimension and size effect of coarse aggregate on the frost resistance of hydraulic concrete. Constr. Build. Mater. 2024, 431, 136526. [Google Scholar] [CrossRef]

- Petersson, P.E. Crack Growth and Development of Fracture Zones in Plain Concrete and Similar Materials; Report TVBM-1006; IAEA: Vienna, Austria, 1981. [Google Scholar]

- Wu, F. Experimental Investigation of the Complete Uniaxial Tensile Stress–Strain Behavior of Concrete. Master’s Thesis, Hunan University, Changsha, China, 2006. [Google Scholar]

- Nemegeer, D.E.; Tatnall, P.C. Measuring toughness characteristics of sfrc—A critical view of astm c1018. In Proceedings of the American Concrete Institute Spring Conference, Milwaukee, WI, USA, 4–9 June 1995. [Google Scholar]

- Zhang, D.; Huang, X.; Zhao, Y. Investigation of the shape, size, angularity and surface texture properties of coarse aggregates. Constr. Build. Mater. 2012, 34, 330–336. [Google Scholar] [CrossRef]

- Kuo, C.-Y.; Freeman, R.B. Imaging indices for quantification of shape, angularity, and surface texture of aggregates. Transp. Res. Rec. 2000, 1721, 57–65. [Google Scholar] [CrossRef]

- Gu, X.; Tran, Y.; Hong, L. Quantification of coarse aggregate shape in concrete. Front. Struct. Civ. Eng. 2014, 8, 308–321. [Google Scholar] [CrossRef]

- Hong, L.; Gu, X. Influences of surface roughness and shape of coarse aggregates on mechanical properties of concrete. Constr. Build. Mater. 2014, 65, 338–349. [Google Scholar] [CrossRef]

- Hormann, K.; Agathos, A. The point in polygon problem for arbitrary polygons. Comput. Geom. 2001, 20, 131–144. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L. Mesoscale simulation on thermal cracking in concrete by using a coupled thermal–mechanical lattice Boltzmann-Peridynamic model. Eng. Fract. Mech. 2025, 320, 111101. [Google Scholar] [CrossRef]

- Silling, S.A.; Demmie, P.N.; Warren, T.L. Peridynamic simulation of high-rate material failure. In Proceedings of the 2007 Applied Mechanics and Materials Conference, Austin, TX, USA, 3–7 June 2007. [Google Scholar]

- Du, C.; Chen, X.; Yang, Y.; Chen, Y.; Jiang, S. Experimental study on the complete tensile stress-deformation curve of fully graded concrete. Exp. Tech. 2018, 42, 491–497. [Google Scholar] [CrossRef]

- Deng, P.; Xu, K.; Guo, S. Effects of coarse aggregate morphology on concrete mechanical properties. J. Build. Eng. 2023, 63, 105408. [Google Scholar] [CrossRef]

- Wu, P.; Zhao, J.; Chen, Z.; Bobaru, F. Validation of a stochastically homogenized peridynamic model for quasi-static fracture in concrete. Eng. Fract. Mech. 2020, 237, 107293. [Google Scholar] [CrossRef]

- Hou, K.; Hua, W.; Xiao, Y.; Wang, X.; Yang, T. Insights into the failure mechanisms of cement-treated recycled aggregate materials (CRAMs) under uniaxial compression via peridynamics. Constr. Build. Mater. 2024, 451, 138726. [Google Scholar] [CrossRef]

- Huang, X.; Kong, X.; Chen, Z.; Fang, Q. Peridynamics modelling of dynamic tensile failure in concrete. Int. J. Impact Eng. 2021, 155, 103918. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Hu, X.; Yang, C.; Li, C.L.; Zhu, H.D.; Jiao, J. Dynamic axial tension test on the fully-graded concrete. J. Hydraul. Eng. 2014, 45, 720–727. [Google Scholar] [CrossRef]

- Xu, L.; Jiang, L.; Shen, L.; Dong, Y.; Ren, Q. 3D mesostructure generation of fully-graded concrete based on hierarchical point cloud and aggregate coarsening. Constr. Build. Mater. 2022, 350, 128790. [Google Scholar] [CrossRef]

- Ichino, H.; Kuwahara, N.; Beppu, M.; Williamson, E.B.; Himi, A. Effects of the shape, size, and surface roughness of glass coarse aggregate on the mechanical properties of two-stage concrete. Constr. Build. Mater. 2024, 411, 134296. [Google Scholar] [CrossRef]

- Yamei, H.; Lihua, W.; Xirong, C. Testing and correction of coarse aggregate particle shape based on DIP technology. J. Yangtze River Sci. Res. Inst. 2018, 35, 5. [Google Scholar] [CrossRef]

| Ac Range Interval | Minimum Concavity Magnification Factor | Maximum Concavity Magnification Factor |

|---|---|---|

| 0.0 | ||

| 0.0 | ||

| 0.0 | ||

| 0.0 |

| Parameters | Label | Value |

|---|---|---|

| Size of material point | 1 | |

| Horizon | ||

| Time step | ||

| Final displacement |

| Class | Density | Young’s Modulus | Poisson Ratio | ||

|---|---|---|---|---|---|

| Aggregate | 2700 | 50 | 0.33 | - | - |

| Mortar | 2000 | 15 | 0.33 | 0.70 | 50.9 |

| ITZ | - | 10 | 0.33 | 0.22 | 16 |

| Class | Experiment | Model I | Model II | Model III | Model IV | Model V | Mean |

|---|---|---|---|---|---|---|---|

| Peak stress (MPa) | 1.182 | 1.195 | 1.242 | 1.177 | 1.152 | 1.201 | 1.193 |

| Relative error | - | 1.10% | 5.08% | −0.42% | −2.54% | 1.61% | 0.93% |

| Ar | 1.0 | 1.20 | 1.40 | 1.60 | 1.80 | 2.0 |

|---|---|---|---|---|---|---|

| Peak stress (MPa) | 1.204 | 1.198 | 1.191 | 1.182 | 1.169 | 1.154 |

| Elastic modulus (×109) | 20.208 | 20.743 | 21.424 | 22.099 | 22.507 | 23.089 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Li, H.; Deng, W.; Wu, K.; Yao, T.; Zhou, Z.; Wu, Y. Investigation on the Tensile Fracture Properties of Fully-Graded Concrete Considering Aggregate Morphological Characteristics via Peridynamics. Materials 2025, 18, 3750. https://doi.org/10.3390/ma18163750

Chen J, Li H, Deng W, Wu K, Yao T, Zhou Z, Wu Y. Investigation on the Tensile Fracture Properties of Fully-Graded Concrete Considering Aggregate Morphological Characteristics via Peridynamics. Materials. 2025; 18(16):3750. https://doi.org/10.3390/ma18163750

Chicago/Turabian StyleChen, Jie, Houmin Li, Weichao Deng, Keyang Wu, Tianhao Yao, Zhengpeng Zhou, and Yunlong Wu. 2025. "Investigation on the Tensile Fracture Properties of Fully-Graded Concrete Considering Aggregate Morphological Characteristics via Peridynamics" Materials 18, no. 16: 3750. https://doi.org/10.3390/ma18163750

APA StyleChen, J., Li, H., Deng, W., Wu, K., Yao, T., Zhou, Z., & Wu, Y. (2025). Investigation on the Tensile Fracture Properties of Fully-Graded Concrete Considering Aggregate Morphological Characteristics via Peridynamics. Materials, 18(16), 3750. https://doi.org/10.3390/ma18163750