Experimental Study on Grouting Seepage Characteristics in Rough Single Microfissure Under Triaxial Stress States

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Ultrafine Cement

2.1.2. Sandstone-like Material

2.2. Preparation of Sandstone-like Specimens

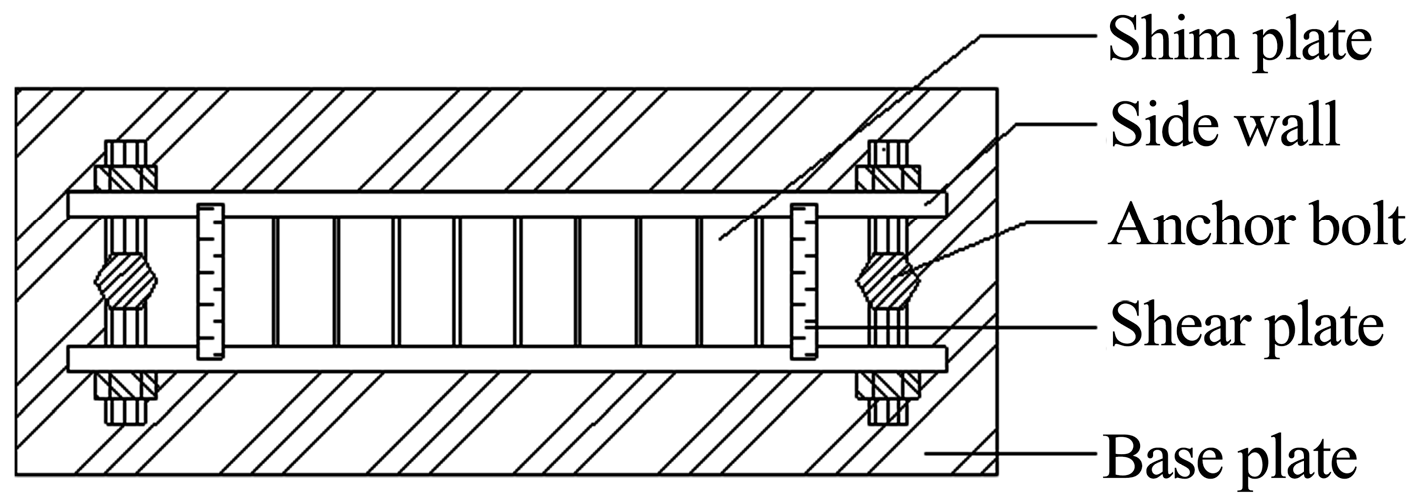

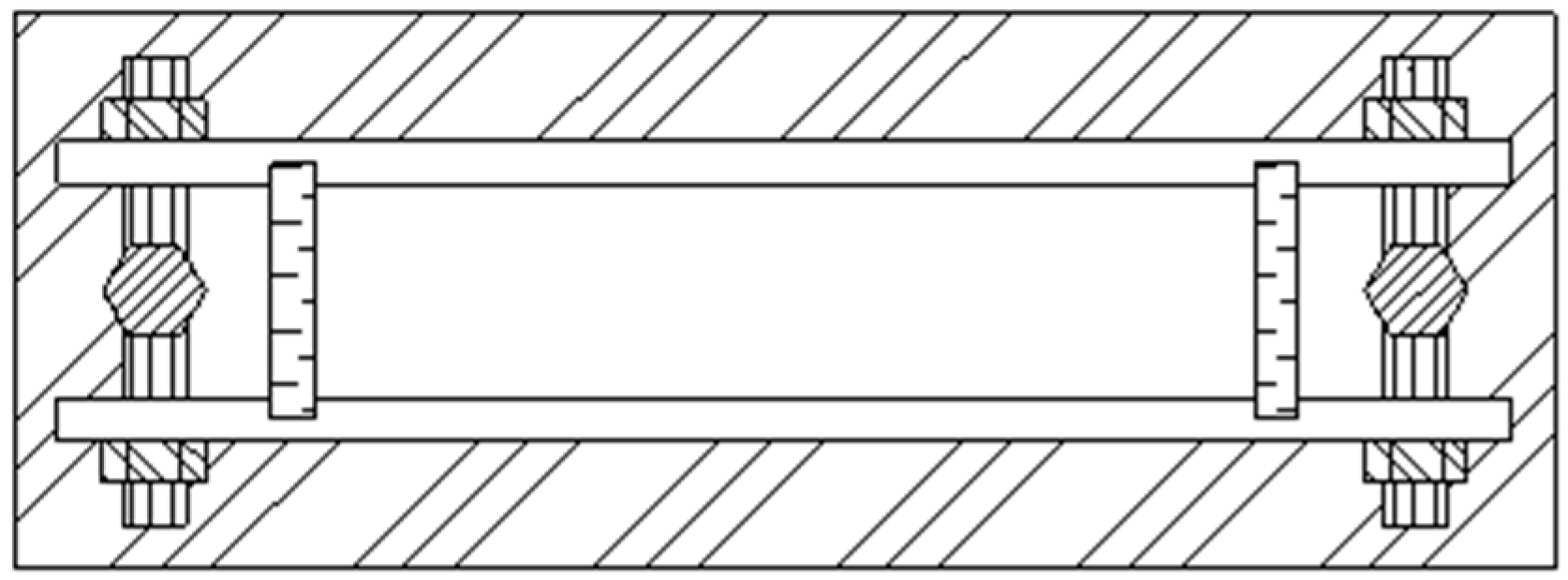

2.2.1. Mold Preparation

2.2.2. Fabrication Process of Sandstone-like Specimens

- (1)

- Preparation of cement mortar: the cement mortar required for the experiment was formulated according to specified mix proportions.

- (2)

- Mold preparation: the inner surfaces of Mold 1-1 and Mold 1-2 were uniformly coated with a layer of release agent.

- (3)

- Core specimen fabrication: the mortar was vibrated and compacted in the molds; the upper surfaces were finished, and the specimens were cured for 7 days to complete Specimens 1-1 and 1-2.

- (4)

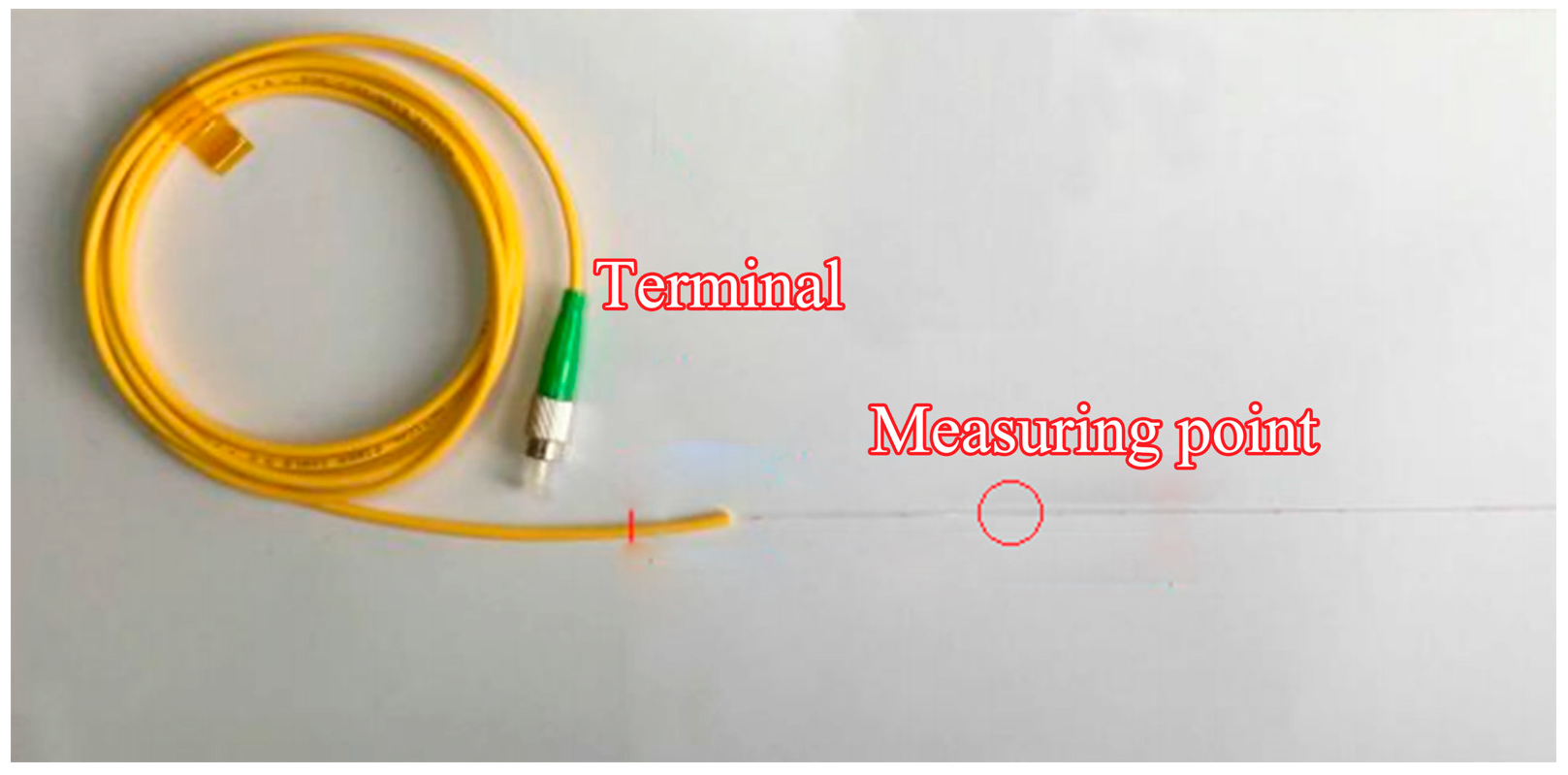

- Optical fiber integration: a groove was machined on the roughened surface of Specimen 1-1; an optical fiber segment with FBG sensing points was positioned within the groove and secured.

- (5)

- Specimen assembly: specimen 1-2 was placed onto the processed Specimen 1-1, ensuring precise contour matching to form the core specimen assembly.

- (6)

- Gap control and sealing: thin steel shims were inserted into the gaps at both ends of the core specimen; lateral gaps on the specimen surface were sealed.

- (7)

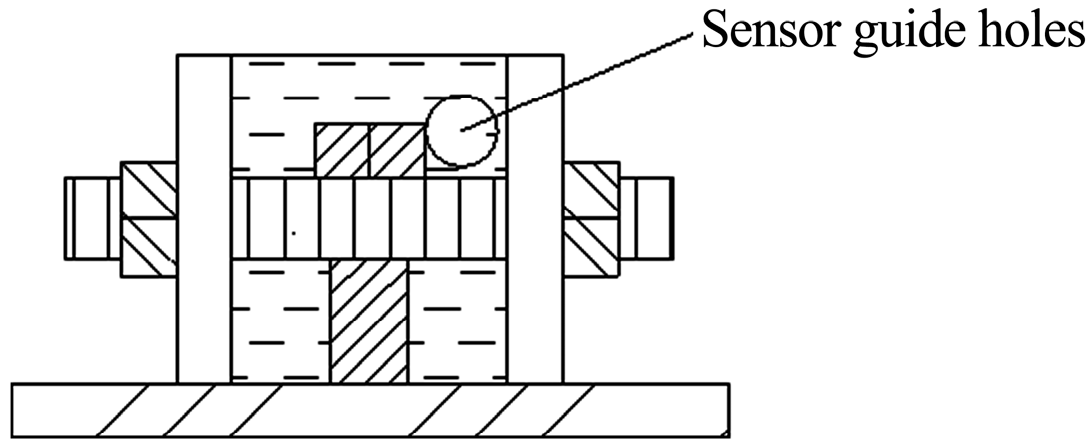

- Secondary mold setup: the core specimen assembly was placed into Mold 2. Exposed fiber-optic leads were guided out through designated ports.

- (8)

- Concrete encapsulation: concrete slurry was poured into Mold 2, followed by vibration, compaction, and surface finishing.

- (9)

- Demolding and shim removal: after 24 h of curing, Mold 2 was removed. The pre-inserted steel shims at both ends were extracted.

- (10)

- Final curing: curing continued for 28 days to complete the permeable test specimen with integrated monitoring capability.

- (1)

- Based on the composition and mix ratio of the sandstone-like material for microfissured specimens, precisely weigh sand, cement, iron concentrate powder, and water.

- (2)

- Thoroughly mix the measured cement, sand, and iron concentrate powder in a mixer.

- (3)

- After homogenizing the solid materials, add the pre-weighed water to the mixer and mix for 2 min. Subsequently, incorporate a water reducer and continue mixing for an additional 2 min.

- (4)

- Assemble the first mold set by replacing its spacer plates with a JRC = 10–12 pair. Coat the inner walls uniformly with mechanical lubricant. Fill the mold with the prepared concrete mixture, then vibrate the mold on a shaking table for 1 min. Repeat filling and vibration until the mixture aligns flush with the mold surface. Level the upper surface and seal it with plastic film, as shown in Figure 7. After casting Specimens 1-1 and 1-2, cure them at 20 °C ± 2 °C and 95% relative humidity for 24 h. Demold and continue curing for 7 days.

- (5)

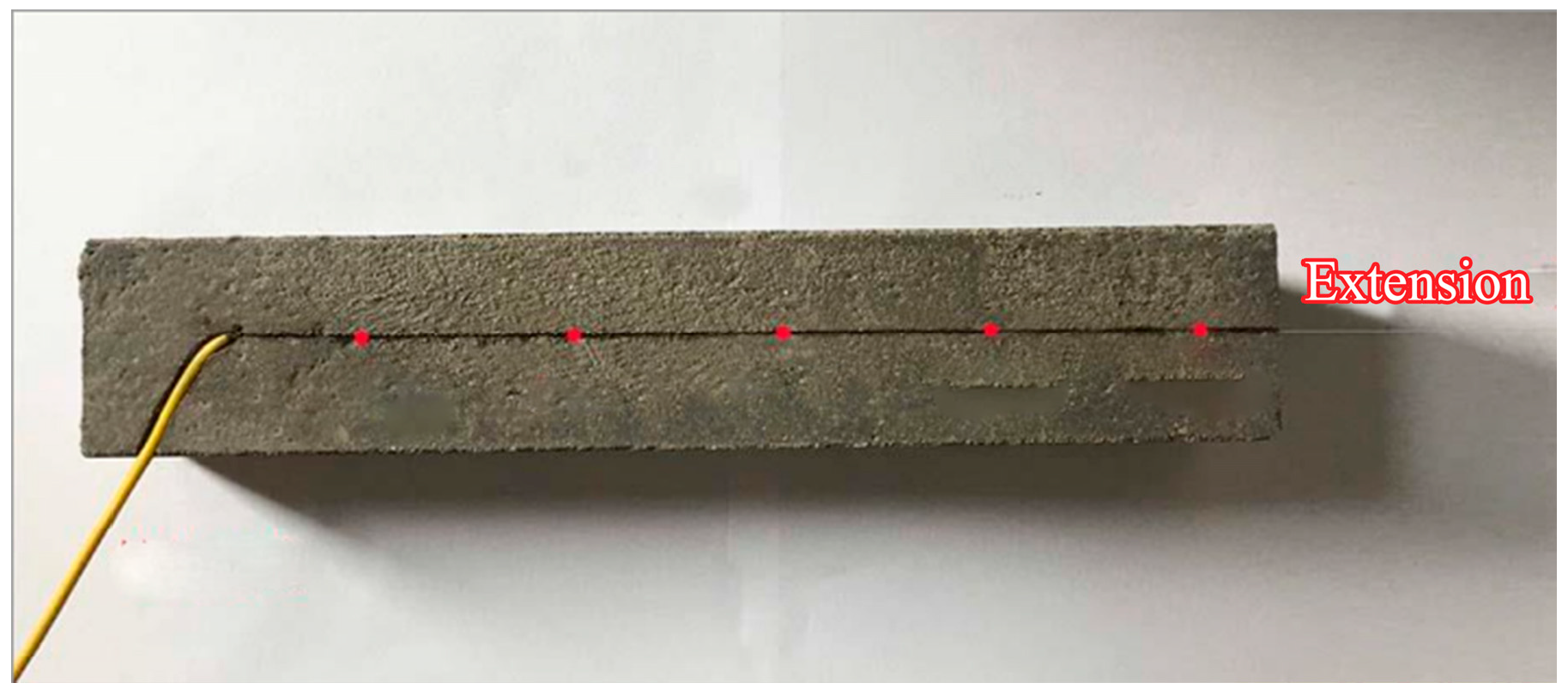

- Select Specimen 1-1 from Step (4). Machine a groove on its roughened surface to accommodate an FBG sensor. The groove width is 1–2 times the fiber diameter, and its depth equals the fiber diameter. Secure the FBG sensor in the groove using adhesive, as shown in Figure 8.

- (6)

- Position Specimen 1-2 onto the modified Specimen 1-1 from Step (5), ensuring full coupling of their roughness profiles to assemble the core specimen.

- (7)

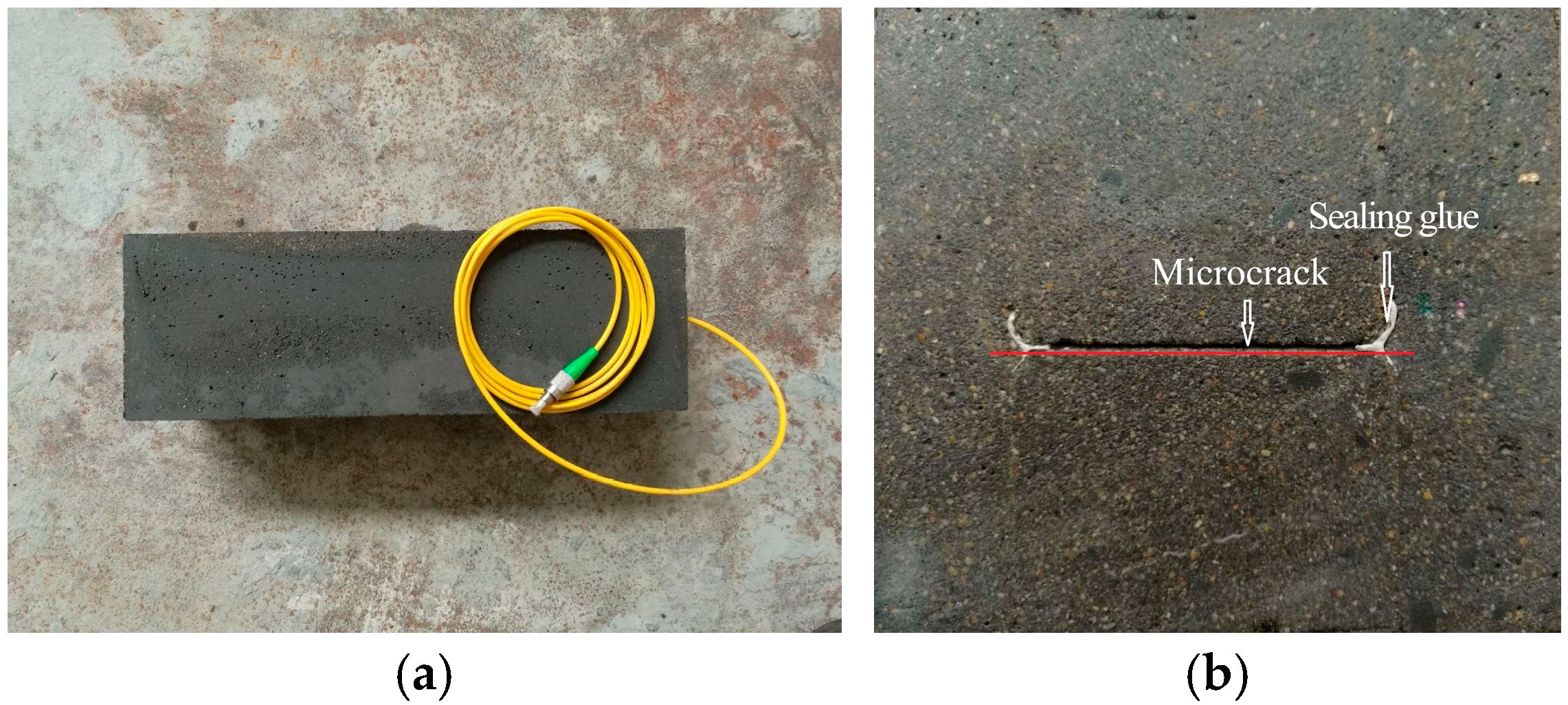

- Insert 200 μm-thick steel shims into gaps at both ends of the core specimen to create a uniform microfissure matching the shim thickness. Seal lateral gaps with waterproof adhesive to secure the specimens and prevent grout infiltration during subsequent casting. The shims penetrate 3–5 cm into the microfissure, with widths matching the specimen dimensions. The core specimen configuration is shown in Figure 10.

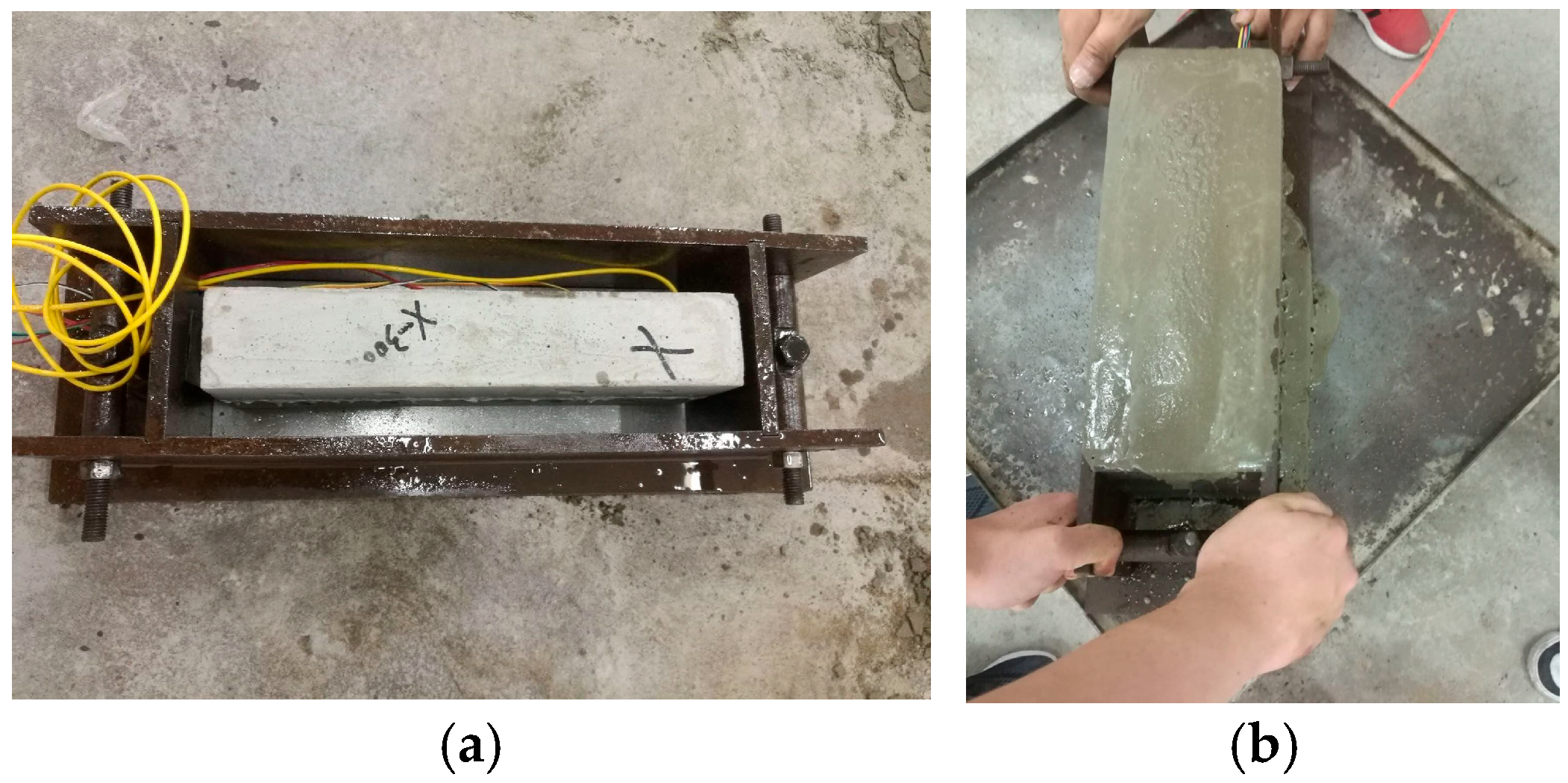

- (8)

- Prepare the second mold set by uniformly coating its inner walls with mechanical lubricant. Place the processed core specimen from Step (7) into the mold, routing exposed FBG sensor cables through the sensor lead-through holes on the insert plate, as shown in Figure 11.

- (9)

- Following steps (1) and (2), prepare fresh concrete grout. Fill the second mold with the mixture, vibrate on a shaking table for 30 s, and repeat filling/vibration cycles until the grout aligns flush with the mold surface. Level the top surface and cover it with plastic film.

- (10)

- After 24 h of curing at 20 °C ± 2 °C and 95% relative humidity, demold the specimen. Remove the steel shims and continue curing for an additional 28 h under identical conditions. This completes the fabrication of the sandstone-like grouting test block containing a 200 μm-aperture microfissure with JRC = 10–12, as shown in Figure 12a.

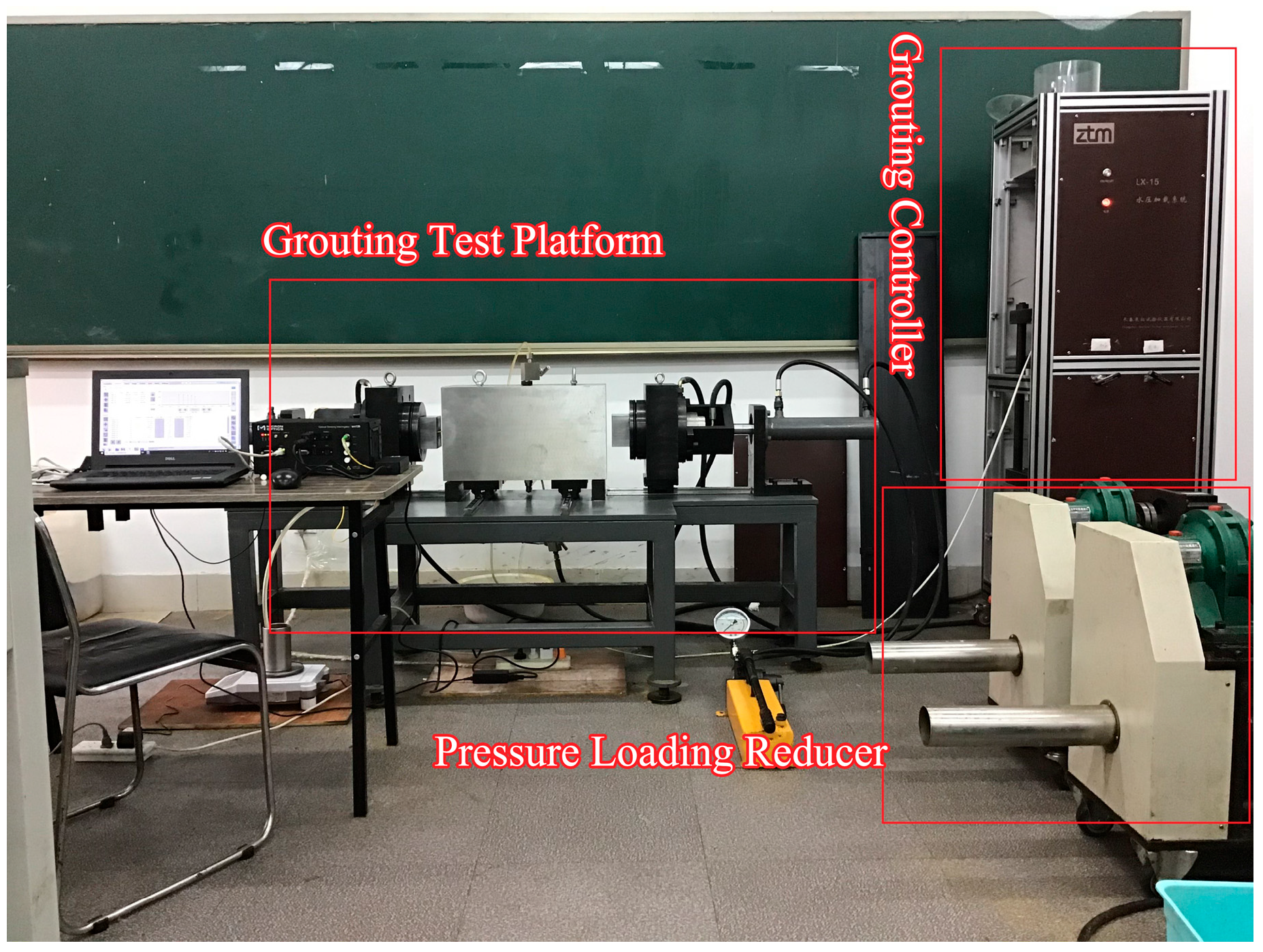

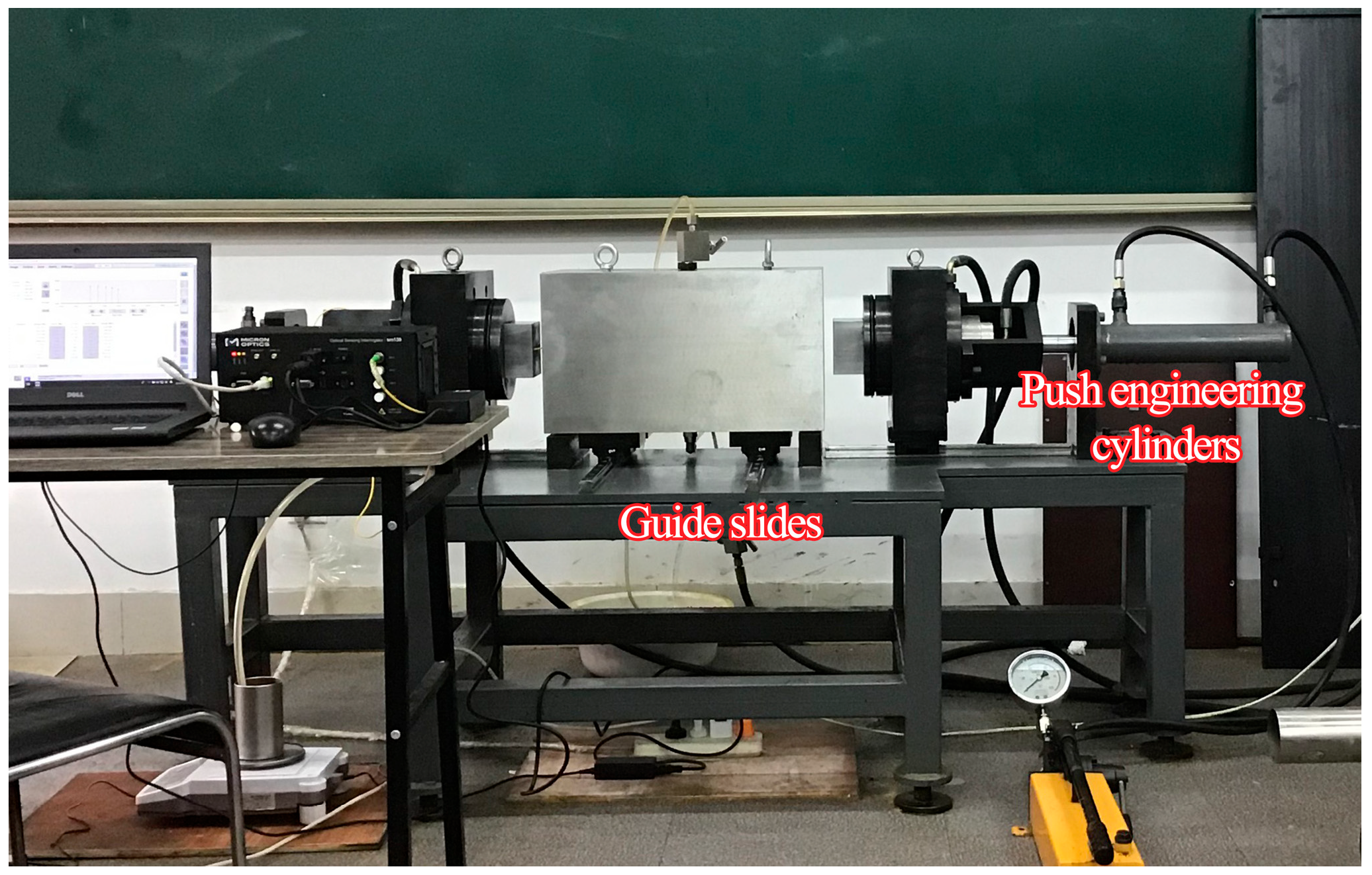

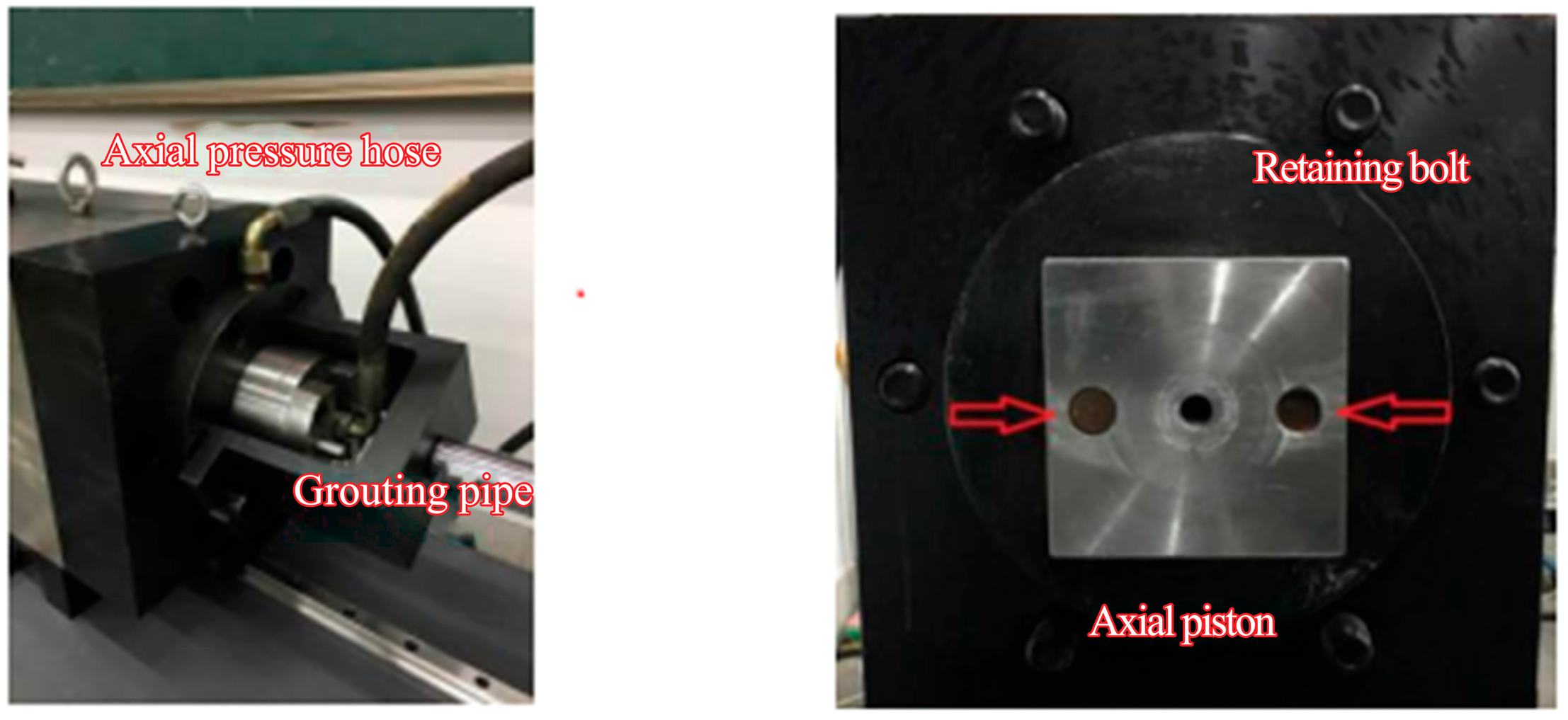

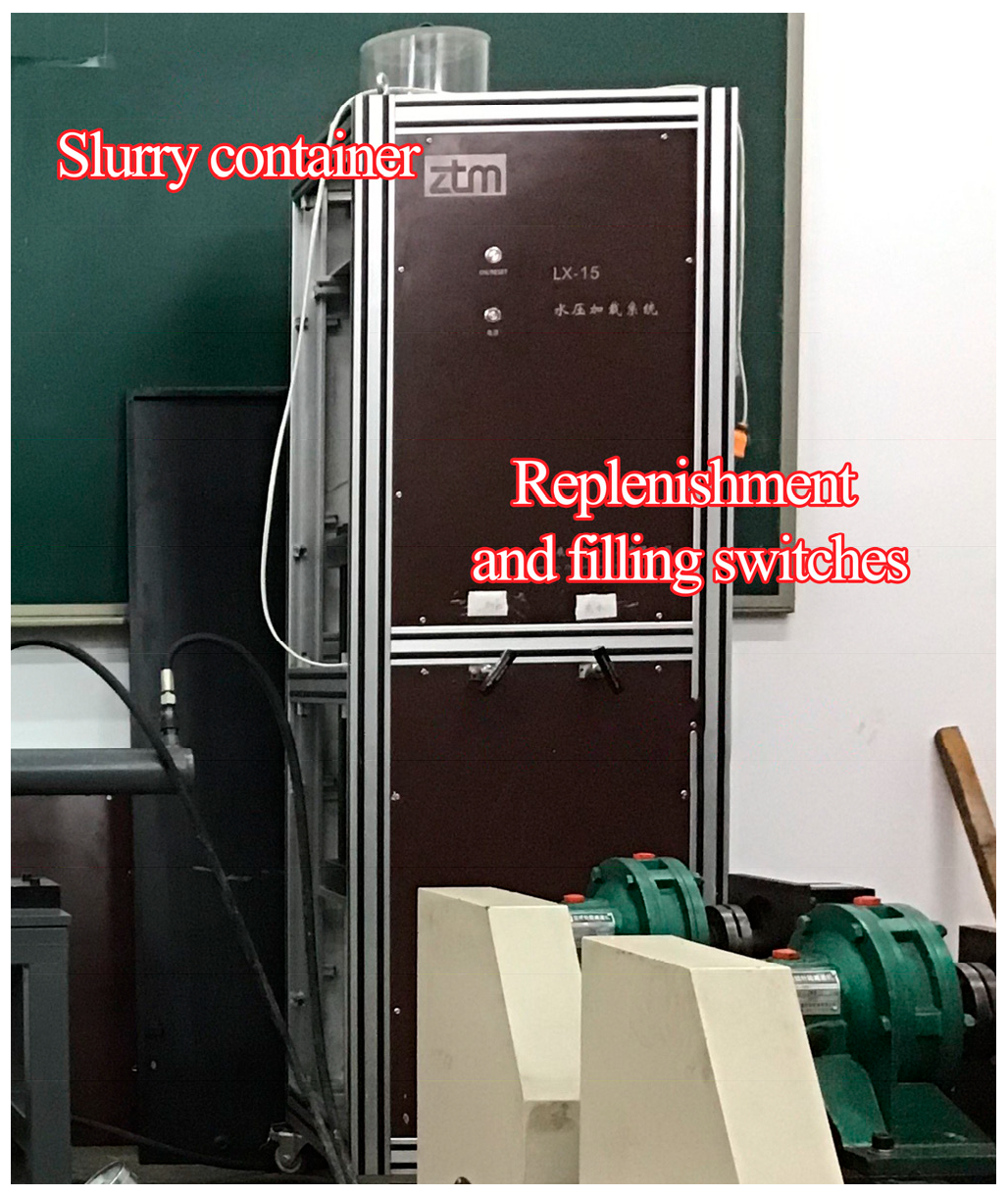

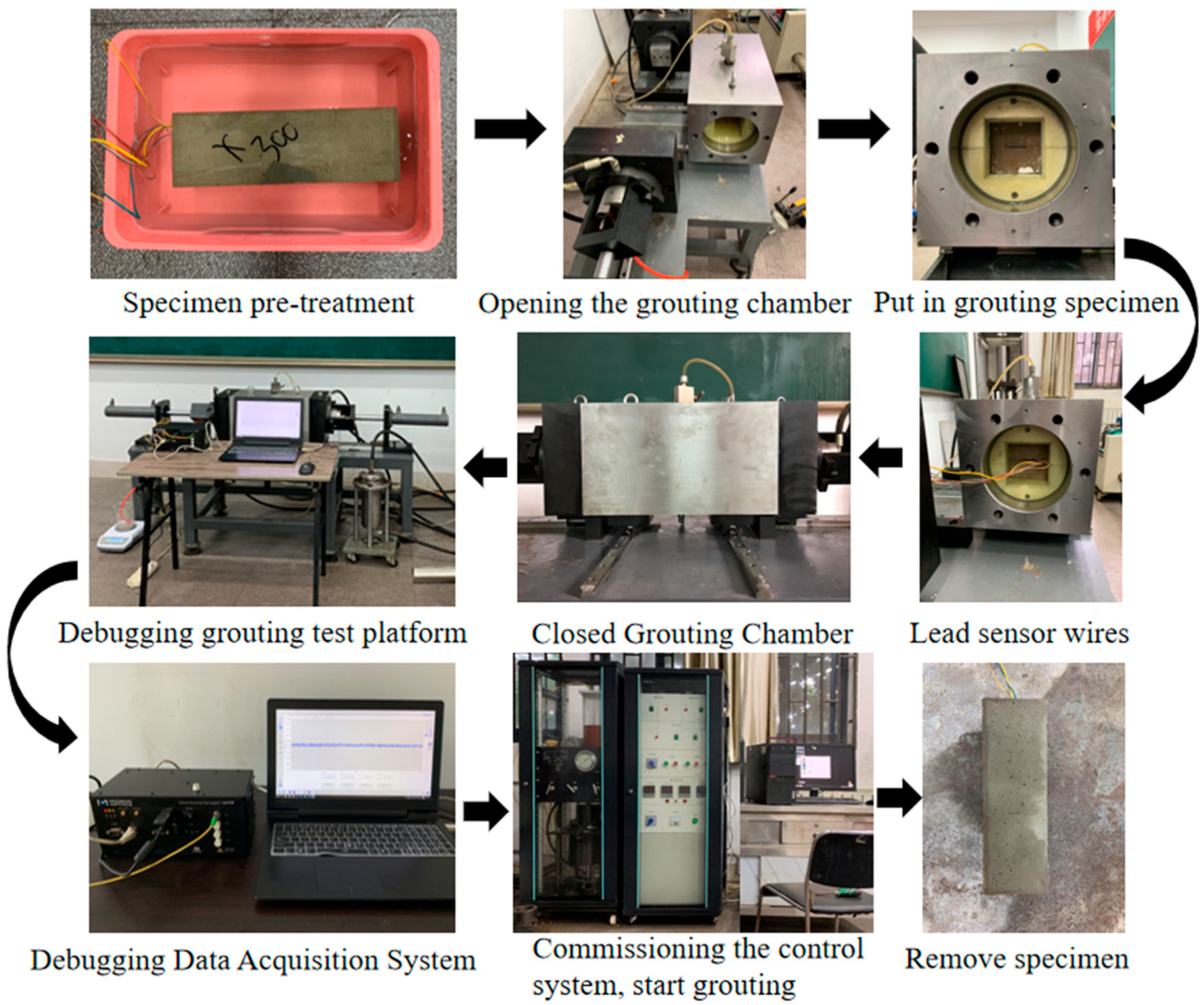

2.3. Grouting Test System

2.4. Test Loading Process

- (1)

- Apply a 0.5 MPa axial preload to ensure full contact between the axial pistons and specimen ends. Subsequently, incrementally increase confining and axial pressures in 0.5 MPa steps until reaching target confining stress levels.

- (2)

- Reset monitoring data on the FBG interrogator to eliminate strain effects induced by initial stress application.

- (3)

- Initiate grouting at 1.0 MPa pressure. Upon stabilization of grout flow, record strain values at all measurement nodes within the microfissure under this pressure condition, with data acquisition spanning a 60 s interval. Progressively elevate grouting pressure in 1.0 MPa increments until reaching the predefined limit. This protocol enables systematic investigation of sandstone microfissure grouting behavior under constant confining pressure with varying grouting pressures.

3. Experimental Results and Discussion

3.1. Ultrafine Cement Particle Size and Viscosity Analysis

3.1.1. Analysis of Ultrafine Cement Particle Size Test Results

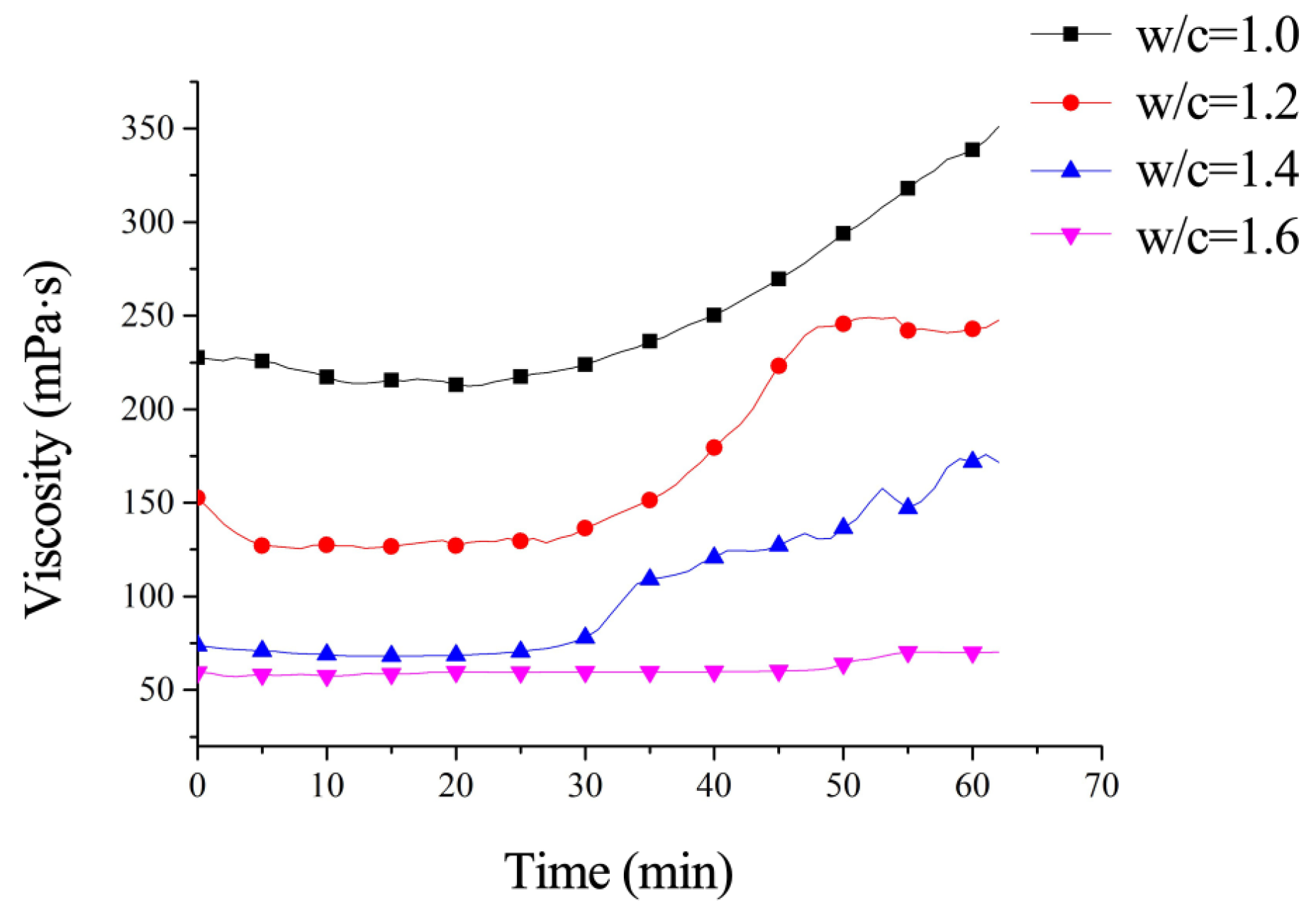

3.1.2. Viscosity Test Result Analysis

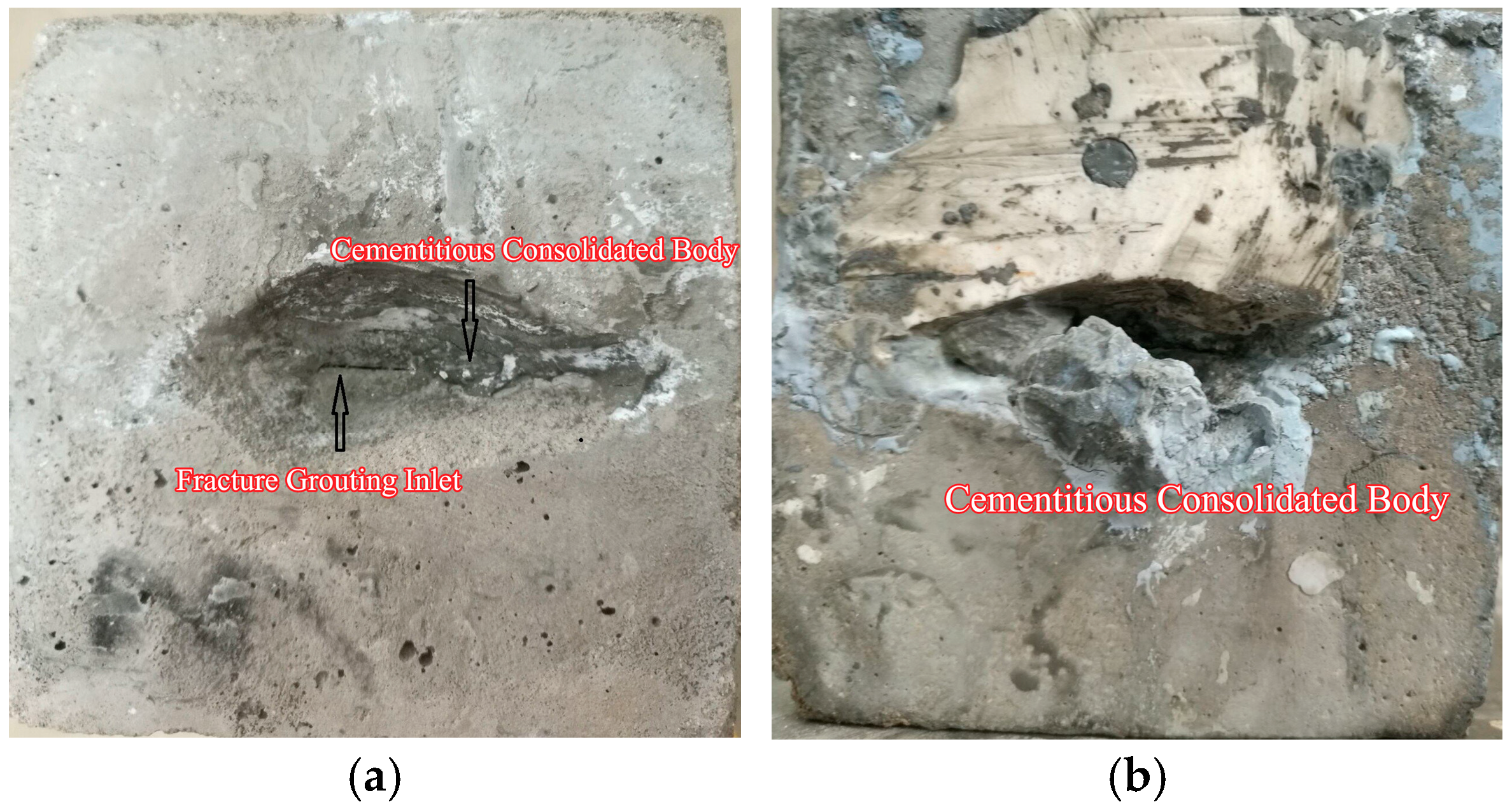

3.2. Injectability Analysis of Sandstone Microfissures

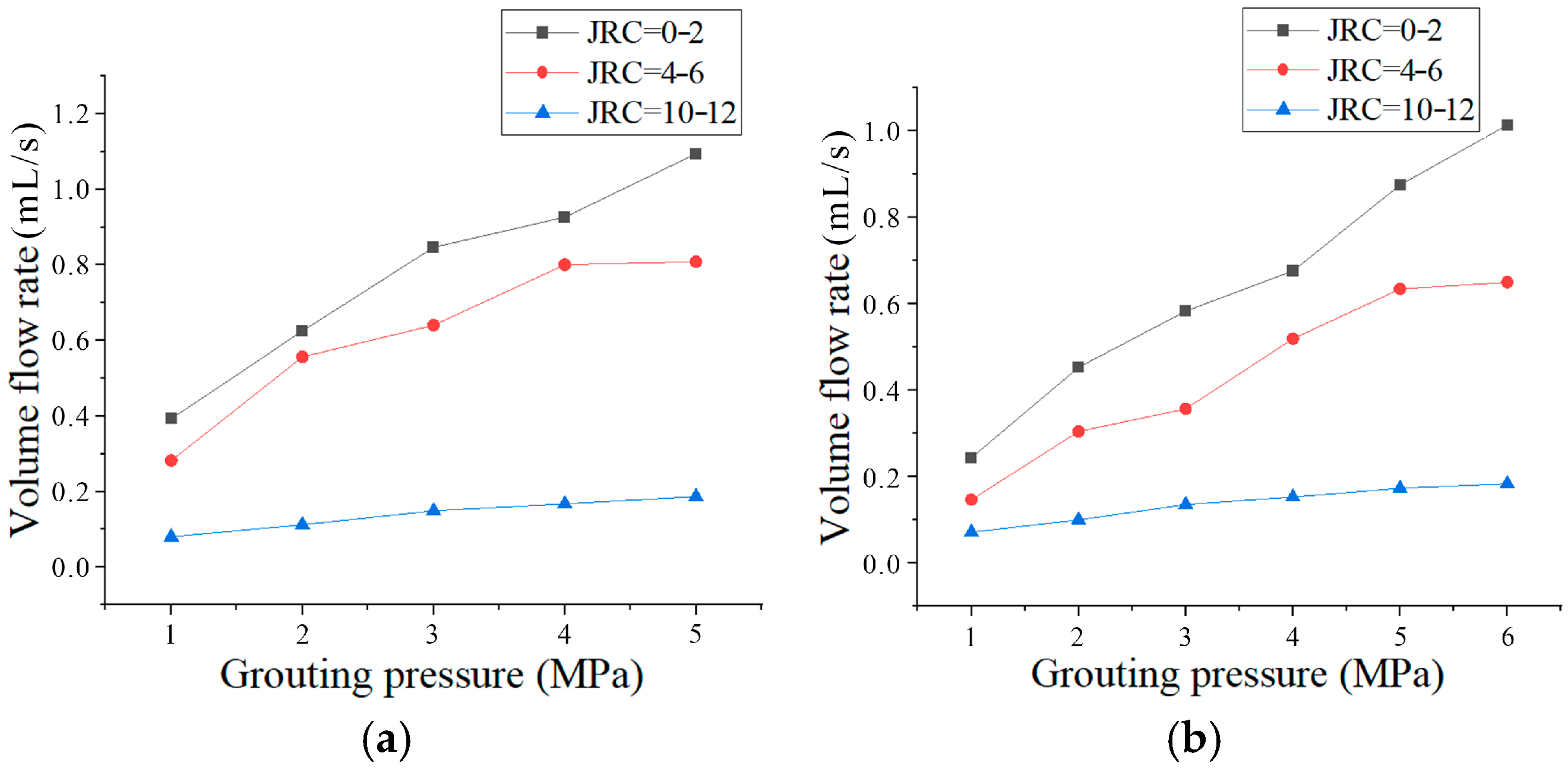

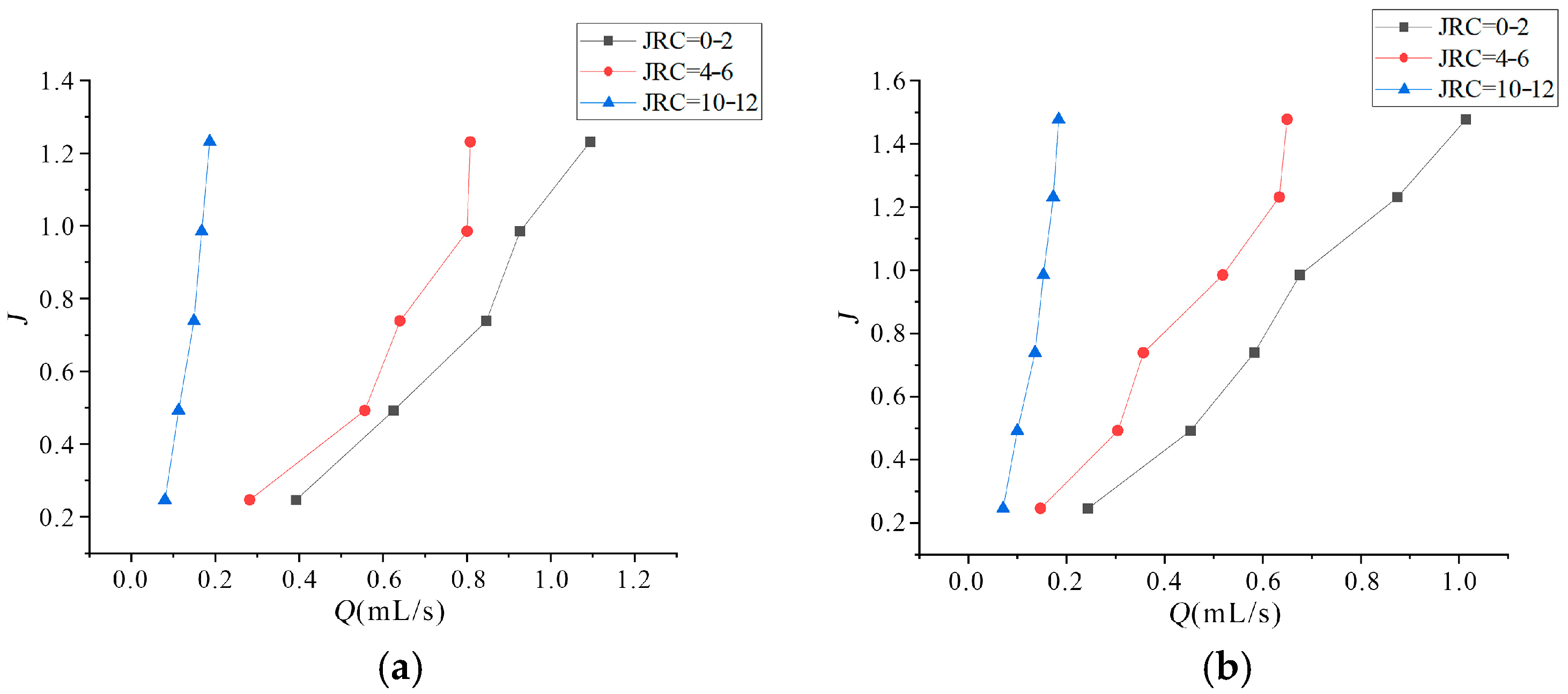

3.3. Seepage Dynamics Under Varied Roughness Conditions

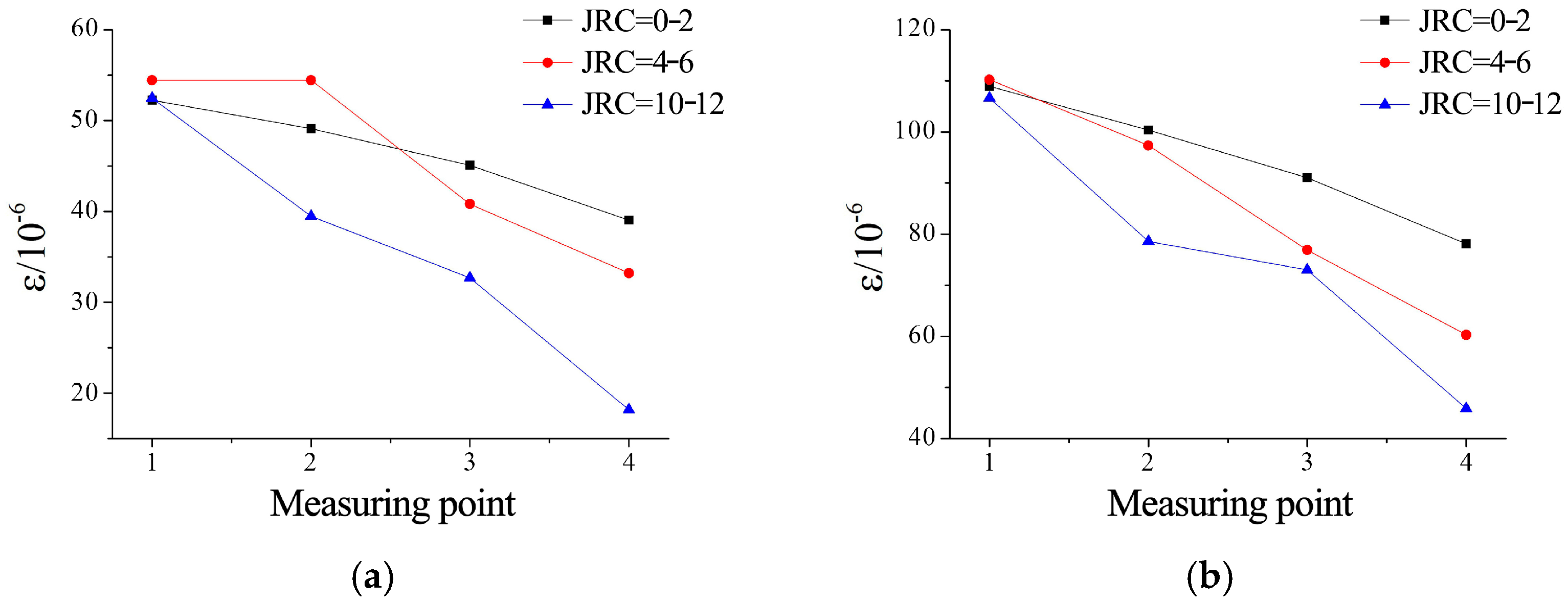

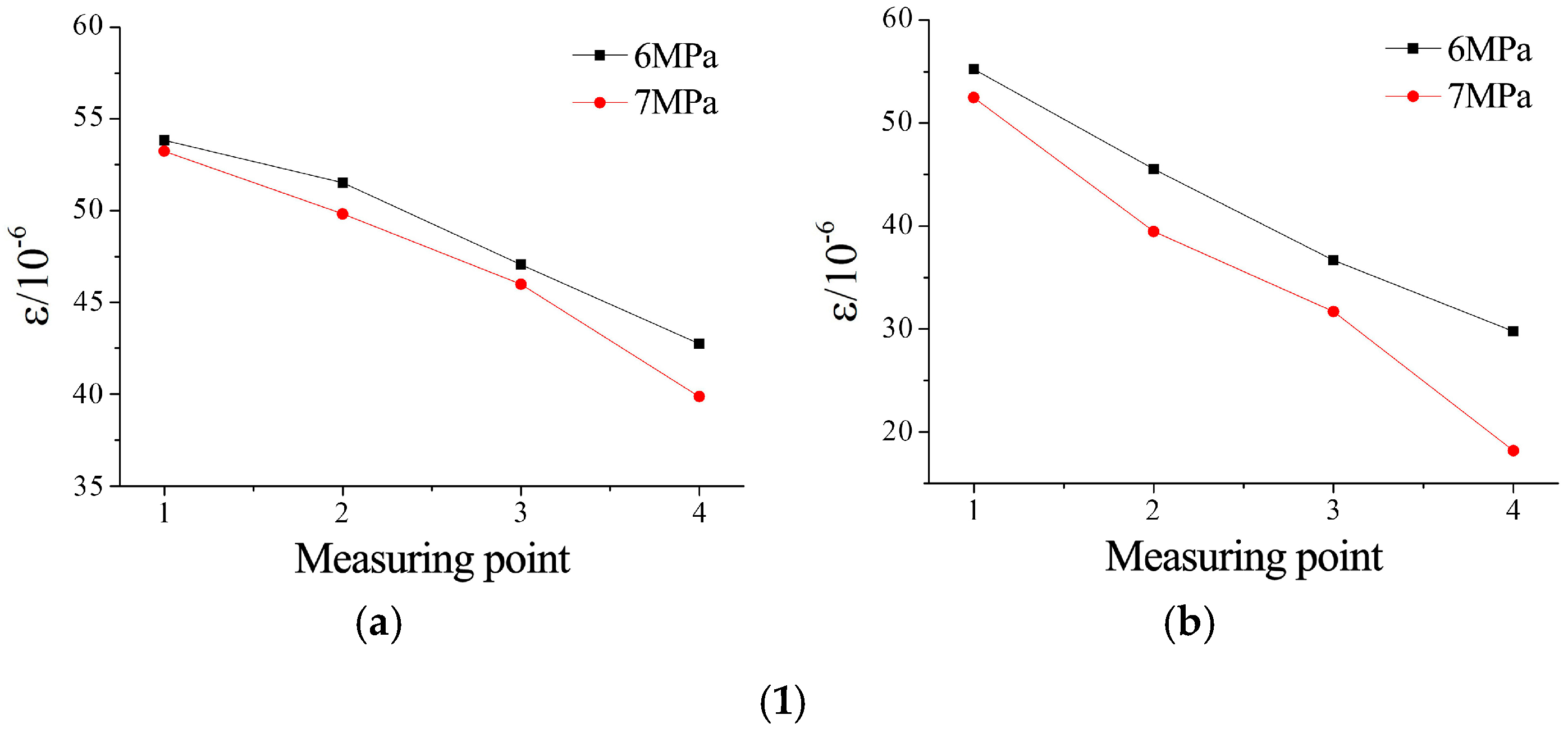

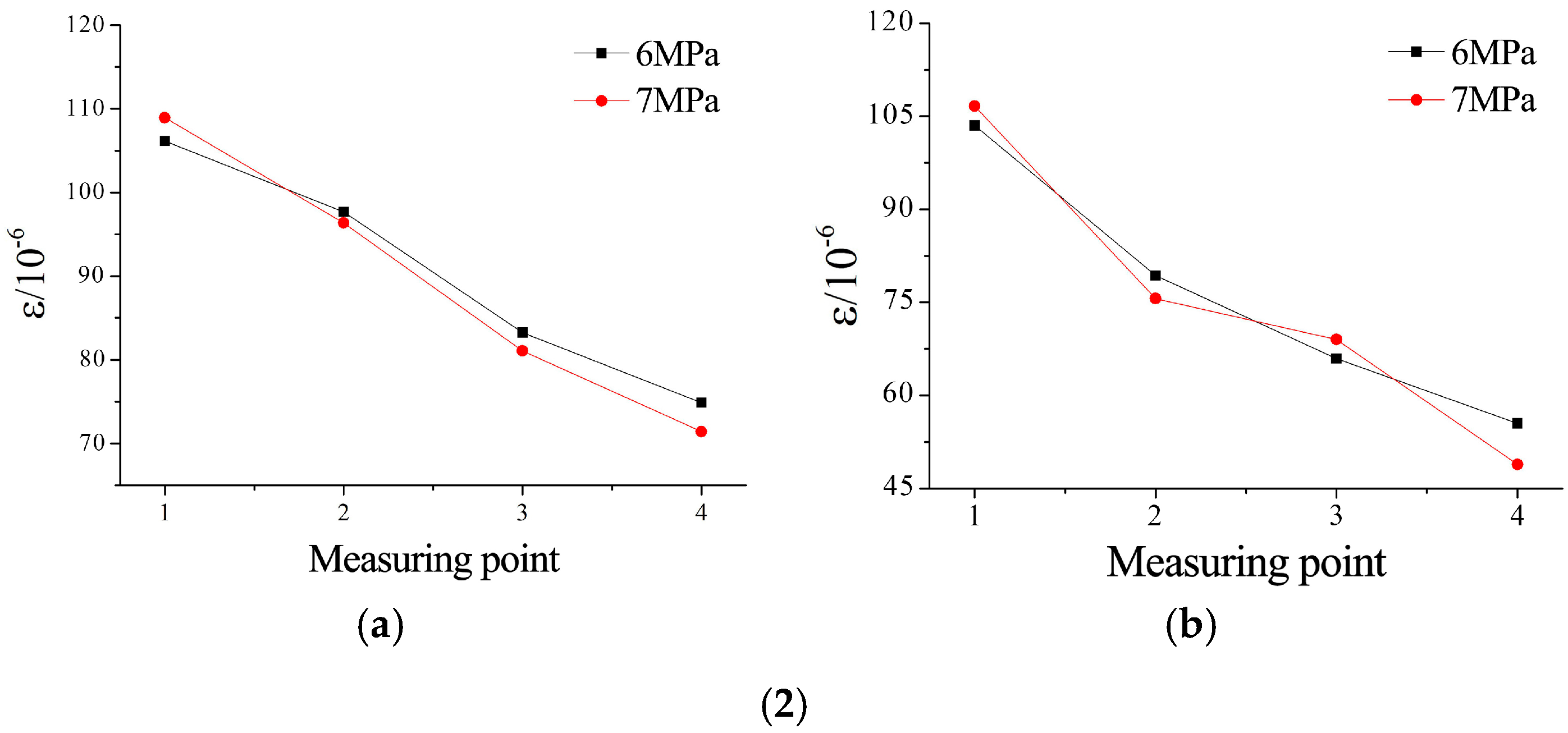

3.4. Deformation Characteristics of Microfissures with Varying Roughness

4. Conclusions

- (1)

- A novel method for preparing monitorable microfissure seepage specimens was proposed, enabling the fabrication of microfissured grouting specimens with preset apertures and roughness. By embedding FBG sensors within the specimens, real-time monitoring of microfissure surface deformation was achieved.

- (2)

- Experimental results indicate particle aggregation and deposition of ultrafine cement grout at microfissure inlets due to filtration effects, where larger aggregates are intercepted. Increasing surface roughness intensified deposition, reducing grouting simulation success rates. Cross-sectional analysis confirmed subsequent formation of dense cementitious bodies, achieving effective sealing.

- (3)

- Under identical confining and grouting pressures, ultrafine cement grout volume flow decreases with increasing roughness, while increasing grouting pressure elevates flow rates. This is attributed to pressure disrupting deposited particles and reopening flow channels. The rate of flow velocity increase diminishes with higher roughness.

- (4)

- For JRC = 10–12, increased grouting pressure exhibits limited influence on seepage behavior. This is attributed to enhanced flow resistance caused by rough microfissure surfaces, facilitating localized particle accumulation and blockage. Subsequent pressure increments prove insufficient to disperse deposits accumulated in regions with large resistance angles.

- (5)

- Under constant grouting pressure, the relative strain variation between measurement points increases with roughness. Complex strain responses at secondary measurement points (e.g., points 2 and 3) under varying pressures suggest that heightened roughness amplifies the fluctuation range of normal resistance angles during grout flow.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FBG | Fiber Bragg grating |

| JRC | Joint roughness coefficient |

References

- Zhao, Y.M.; Feng, X.T.; Jiang, Q.; Han, Y.; Zhou, Y.Y.; Guo, H.G.; Kou, Y.Y.; Shi, Y.E. Large deformation control of deep roadways in fractured hard rock based on cracking—Restraint method. Rock Mech. Rock Eng. 2021, 54, 1–22. [Google Scholar] [CrossRef]

- Zhang, C.X.; Li, D.Y.; Ma, J.Y.; Zhu, Q.Q.; Luo, P.K.; Chen, Y.D.; Han, M.G. Dynamic shear fracture behaviour of granite under axial static preforce by 3D high-speed digital image correlation. Rock Mech. Rock Eng. 2023, 56, 7905–7922. [Google Scholar] [CrossRef]

- Ma, J.Y.; Li, D.Y.; Du, S.H.; Han, Z.Y.; Luo, P.K.; Zhao, J.J. Comparison of subcritical crack growth and dynamic fracture propagation in rocks under double-torsion tests. Int. J. Rock Mech. Min. Sci. 2023, 170, 7905–7922. [Google Scholar] [CrossRef]

- Luo, P.K.; Li, D.Y.; Ru, W.K.; Gong, H.; Wang, M.M. Hard rock fragmentation by dynamic conical pick indentation under confining pressure. Int. J. Rock Mech. Min. Sci. 2024, 183, 105932. [Google Scholar] [CrossRef]

- Yang, S.Q.; Chen, M.; Jing, H.W.; Chen, K.F.; Meng, B. A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng. Geol. 2017, 217, 89–101. [Google Scholar] [CrossRef]

- Haimson, B.; Chang, C. A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of Westerly granite. Int. J. Rock Mech. Min. Sci. 2000, 37, 285–296. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, W.R.; Wang, Y.T.; He, M.C.; Xue, H.J.; Wei, H.Y. Evolution and control mechanism of rockburst in rock anchored by new energy-absorbing material. Rock Mech. Rock Eng. 2023, 56, 4569–4582. [Google Scholar] [CrossRef]

- Wu, J.Y.; Jing, H.W.; Yin, Q.; Yu, L.Y.; Meng, B.; Li, S.C. Strength prediction model considering material, ultrasonic and stress of cemented waste rock backfill for recycling gangue. J. Clean. Prod. 2020, 276, 123189. [Google Scholar] [CrossRef]

- Salimian, M.H.; Baghbanan, A.; Hashemolhosseini, H.; Dehghanipoodeh, M.; Norouzi, S. Effect of grouting on shear behavior of rock joint. Int. J. Rock Mech. Min. Sci. 2017, 98, 159–166. [Google Scholar] [CrossRef]

- Zhang, J.P.; Liu, L.M.; Li, Q.H.; Peng, W.; Zhang, F.T.; Cao, J.Z.; Wang, H. Development of cement-based self-stress composite grouting material for reinforcing rock mass and engineering application. Constr. Build. Mater. 2019, 201, 314–327. [Google Scholar] [CrossRef]

- Pantazopoulos, I.A.; Markou, I.N.; Christodoulou, D.N.; Droudakis, A.I.; Atmatzidis, D.K.; Antiohos, S.K.; Chaniotakis, E. Development of microfine cement grouts by pulverizing ordinary cements. Cem. Concr. Compos. 2012, 34, 593–603. [Google Scholar] [CrossRef]

- Pantazopoulos, I.A.; Atmatzidis, D.K. Dynamic properties of microfine cement grouted sands. Soil Dyn. Earthq. Eng. 2012, 42, 17–31. [Google Scholar] [CrossRef]

- Mirza, J.; Mirza, M.S.; Roy, V.; Saleh, K. Properties of microfine cement grouts at 4 °C, 10 °C and 20 °C. Constr. Build. Mater. 2013, 47, 1145–1153. [Google Scholar] [CrossRef]

- Song, W.L.; Zhu, Z.D.; Pu, S.Y.; Wan, Y.; Huo, W.W.; Song, S.G.; Zhang, J.; Yao, K.; Hu, L.L. Efficient use of steel slag in alkali-activated fly ash-steel slag-ground granulated blast furnace slag ternary blends. Constr. Build. Mater. 2020, 259, 119814. [Google Scholar] [CrossRef]

- Guan, L.L.; Chen, Y.G.; Ye, W.M.; Wu, D.B.; Deng, Y.F. Foamed concrete utilizing excavated soil and fly ash for urban underground space backfilling: Physical properties, mechanical properties, and microstructure. Tunn. Undergr. Space Technol. 2023, 134, 104995. [Google Scholar] [CrossRef]

- Guo, Y.C.; Huang, Y.L.; Li, J.M.; Ouyang, S.Y.; Fan, B.T.; Liu, Y.H.; Hou, G.F. Preparation of the geopolymer grouting material by coal-based solid wastes for the aquiclude key strata and its application. Constr. Build. Mater. 2023, 408, 133539. [Google Scholar] [CrossRef]

- Kaufmann, J.; Winnefeld, F.; Hesselbarth, D. Effect of the addition of ultrafine cement and short fiber reinforcement on shrinkage, rheological and mechanical properties of Portland cement pastes. Cem. Concr. Compos. 2004, 26, 541–549. [Google Scholar] [CrossRef]

- Guo, W.J.; Du, G.X.; Xue, Q.; Liao, J.H. Effect of naphthalene based superplasticizers on performance of ultrafine white cement. Adv. Mater. Res. 2011, 1270, 182–187. [Google Scholar] [CrossRef]

- Ding, W.Q.; Duan, C.; Zhang, Q.Z. Experimental and Numerical Study on a Grouting Diffusion Model of a Single Rough Fracture in Rock Mass. Appl. Sci. 2020, 10, 7041. [Google Scholar] [CrossRef]

- Du, X.M.; Fang, H.Y.; Wang, S.Y.; Xue, B.H.; Wang, F.M. Experimental and practical investigation of the sealing efficiency of cement grouting in tortuous fractures with flowing water. Tunn. Undergr. Space Technol. 2021, 108, 103693. [Google Scholar] [CrossRef]

- Song, H.R.; Lu, Y.L.; Dong, H.; Wang, J.Y. Experimental study on the effect of mixing parameters on the rheological behaviour and micro-flocculation structure of ultrafine Portland cement slurry. Constr. Build. Mater. 2024, 449, 138526. [Google Scholar] [CrossRef]

- Liu, D.W.; Huang, L.L.; Li, J.L.; Shen, Q.S. Formulation and performance of nano-composite clay-cement based grouting materials in water-bearing sandy soil. Case Stud. Constr. Mater. 2024, 21, e03891. [Google Scholar] [CrossRef]

- Lei, G.; Yang, Z.; Zhang, Z.L.; Shen, Z.Z.; Liu, Y. Effects of fracture roughness and infiltration solution on the seepage characteristics of a single fracture in concrete. J. Build. Eng. 2024, 97, 110806. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, Z.J.; Weng, L.; Wu, L.J.; Zhou, Y.; Liu, Q.S. Grouting diffusion characteristics in rough sandstone fracture with flowing water: Insights from NMR experimental investigation. Tunn. Undergr. Space Technol. 2025, 157, 106372. [Google Scholar] [CrossRef]

- Xu, Y.; Ye, X.Y.; Du, X.Q. Microscopic Mechanism of Particle Clogging in Porous Media During Managed Aquifer Recharge: From X-Ray Computed Tomography (CT) Imaging to Numerical Modelling. Hydrol. Process. 2024, 38, e70002. [Google Scholar] [CrossRef]

- Niu, S.Y.; Zou, Z.K.; Shu, L.C.; Yu, L.; Li, Y.L.; Li, Y.X. Physical experiment and pore-scale investigation of the clogging of polydisperse particles in saturated porous media during artificial groundwater recharge. J. Hydrol. 2024, 639, 131569. [Google Scholar] [CrossRef]

- Liu, X.W.; Jia, C.; Liu, B.; Liu, Q.S.; Weng, D.; Chen, H.X. Mechanical characteristics and damage model for rock-like specimen with two parallel grout-filled cracks. Theor. Appl. Fract. Mech. 2024, 133, 104565. [Google Scholar] [CrossRef]

- Zhang, J.L.; Zhou, X.H.; Liu, X.R.; Kong, Y.; Xu, B.; Suliman, L. Deformation characteristics and seepage mechanism of fractured rock mass under triaxial compression process. Soils Found. 2025, 65, 101630. [Google Scholar] [CrossRef]

- Song, W.J. Study on Roughness Characteristics of Deep Mine Microfractured Rock Mass and Its Seepage Mechanism. Ph.D. Thesis, Shandong University of Science and Technology, Qingdao, China, 2018. [Google Scholar]

- Qiao, W.G.; Li, D.Y.; Wang, C.G.; Zhang, X.T.; Kong, D.S.; Lin, D.G.; Wu, Y.K.; Shao, W.; Zhang, Y.Q.; Han, S.F. Research on Bolt-Grouting Support and Water Sealing Technology for Strongly Weathered Rock Mass in Underground Engineering of Qingdao City; Technical Achievement Report; Shandong University of Science and Technology: Qingdao, China, 2008. [Google Scholar]

- Zhang, S.; Qiao, W.G.; Wu, Y.; Jiang, F.; Liu, H. Grouting seepage characteristics in microfracture under triaxial stress conditions: Device design and experimental study. Case Stud. Constr. Mater. 2024, 21, e03751. [Google Scholar] [CrossRef]

- Qian, J.Z.; Wang, M.; Zhang, Y.; Yan, X.S.; Zhao, W.D. Experimental study of the transition from non-Darcian to Darcy behavior for flow through a single fracture. J. Hydrodyn. 2015, 27, 679–688. [Google Scholar] [CrossRef]

- Chen, Y.F.; Zhou, J.Q.; Hu, S.H.; Hu, R.; Zhou, C.B. Evaluation of Forchheimer equation coefficients for non-Darcy flow in deformable rough-walled fractures. J. Hydrol. 2015, 529, 993–1006. [Google Scholar] [CrossRef]

- Yin, Q.; Liu, R.C.; Jing, H.W.; Su, H.J.; Yu, L.Y.; He, L.X. Experimental study of nonlinear flow behaviors through fractured rock samples after high-temperature exposure. Rock Mech. Rock Eng. 2019, 52, 2963–2983. [Google Scholar] [CrossRef]

- Sun, X.K. Study on the Diffusion Mechanisms of Grouting Within Fractured Rock Mass Under Deep Ground. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2019. [Google Scholar]

- Jiang, S.Y. Properties and Grout Diffusion Law of Graphene Cement-Based Anti-Dispersive Grouting Water Plugging Composites. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2022. [Google Scholar]

- Ren, B. Study on Seepage Characteristics and Application of Surface Ground Re-Grouting Slurry of Fractured Rock Bodies in Fault Broken Zones. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2023. [Google Scholar]

| Setting Time | Compressive Strength/MPa | Flexural Strength/MPa | |||

|---|---|---|---|---|---|

| Initial Setting Time/min | Final Setting Time/min | 3d | 28d | 3d | 28d |

| ≥30 | ≤600 | 23 | 52.5 | 4 | 7 |

| Density/kg·m−3 | Compressive Strength/MPa | Flexural Strength/MPa | Setting Time | |

|---|---|---|---|---|

| Initial Setting Time/mm | Final Setting Time/mm | |||

| 3000 | 47.5 | 8.7 | 115 | 310 |

| Confining Pressure (MPa) | Microfissure Opening (μm) | Axial Pressure (MPa) | JRC | a | b | R2 |

|---|---|---|---|---|---|---|

| 6 | 200 | 6 | 0–2 | 0.309 | 0.751 | 0.99 |

| 4–6 | 0.240 | 1.399 | 0.95 | |||

| 10–12 | 0.546 | 31.723 | 0.99 | |||

| 7 | 7 | 0–2 | 0.997 | 0.476 | 0.99 | |

| 4–6 | 1.492 | 0.948 | 0.97 | |||

| 10–12 | 0.515 | 39.257 | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Zhang, S.; Wang, M.; Qin, J.; Fan, W.; Wu, Y. Experimental Study on Grouting Seepage Characteristics in Rough Single Microfissure Under Triaxial Stress States. Materials 2025, 18, 3746. https://doi.org/10.3390/ma18163746

Yang M, Zhang S, Wang M, Qin J, Fan W, Wu Y. Experimental Study on Grouting Seepage Characteristics in Rough Single Microfissure Under Triaxial Stress States. Materials. 2025; 18(16):3746. https://doi.org/10.3390/ma18163746

Chicago/Turabian StyleYang, Minghao, Shuai Zhang, Mingbin Wang, Junling Qin, Wenhan Fan, and Yue Wu. 2025. "Experimental Study on Grouting Seepage Characteristics in Rough Single Microfissure Under Triaxial Stress States" Materials 18, no. 16: 3746. https://doi.org/10.3390/ma18163746

APA StyleYang, M., Zhang, S., Wang, M., Qin, J., Fan, W., & Wu, Y. (2025). Experimental Study on Grouting Seepage Characteristics in Rough Single Microfissure Under Triaxial Stress States. Materials, 18(16), 3746. https://doi.org/10.3390/ma18163746