Study on the Regulation of Early-Age Deformation Characteristics of High-Strength Coral Sand Grouting Materials

Abstract

1. Introduction

2. Materials and Methods

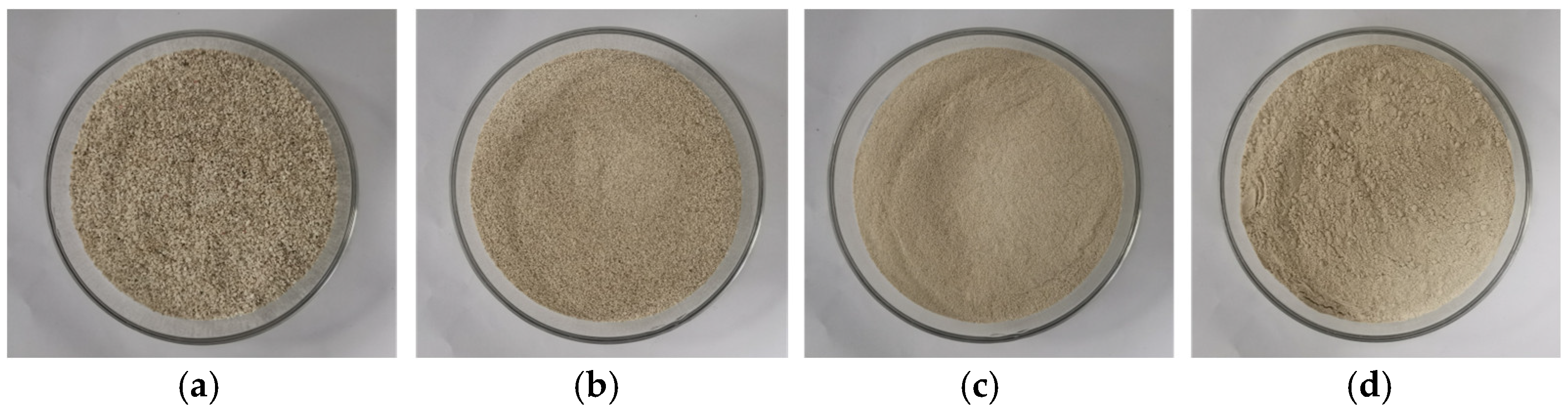

2.1. Raw Materials

2.2. Mix Proportion Design

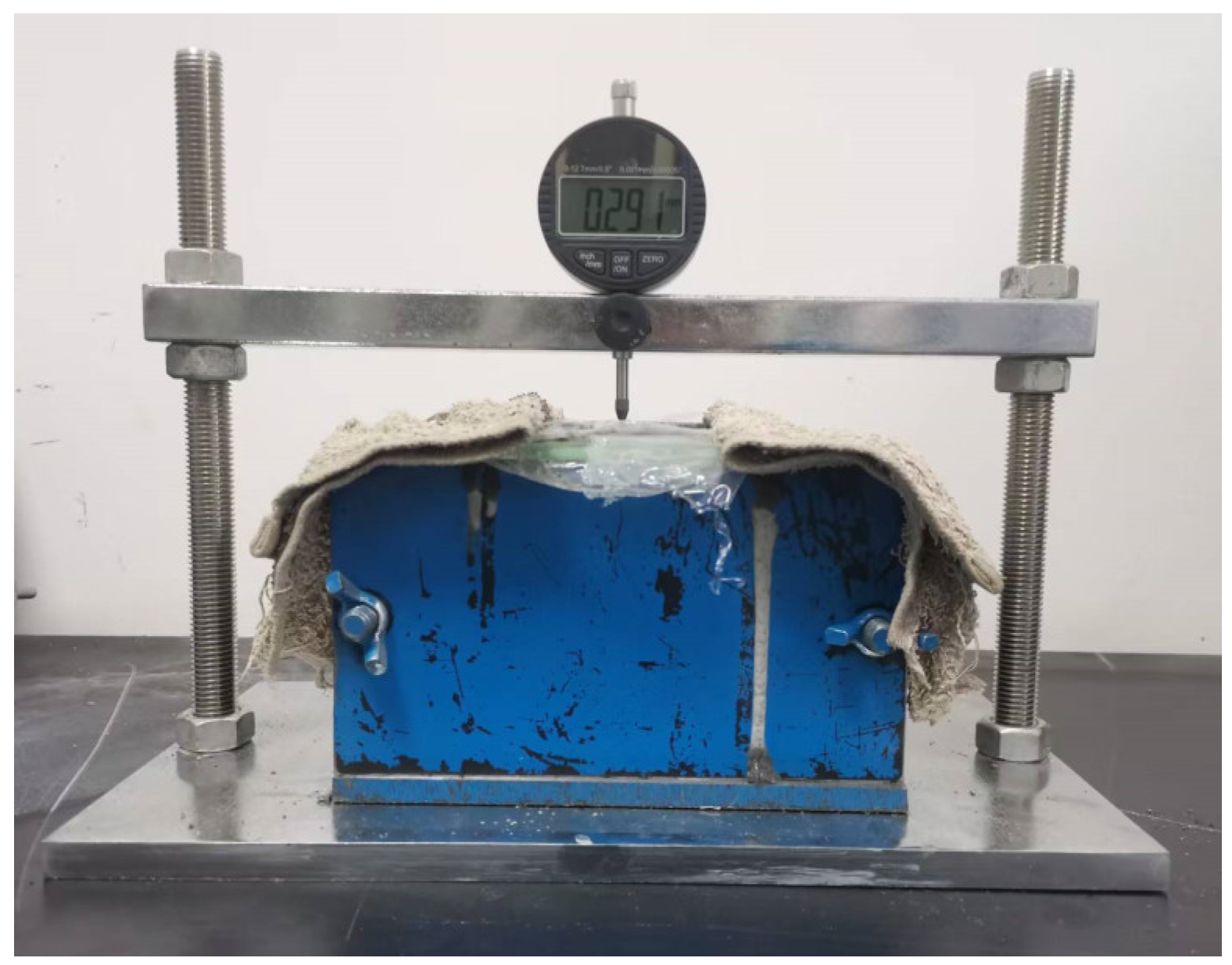

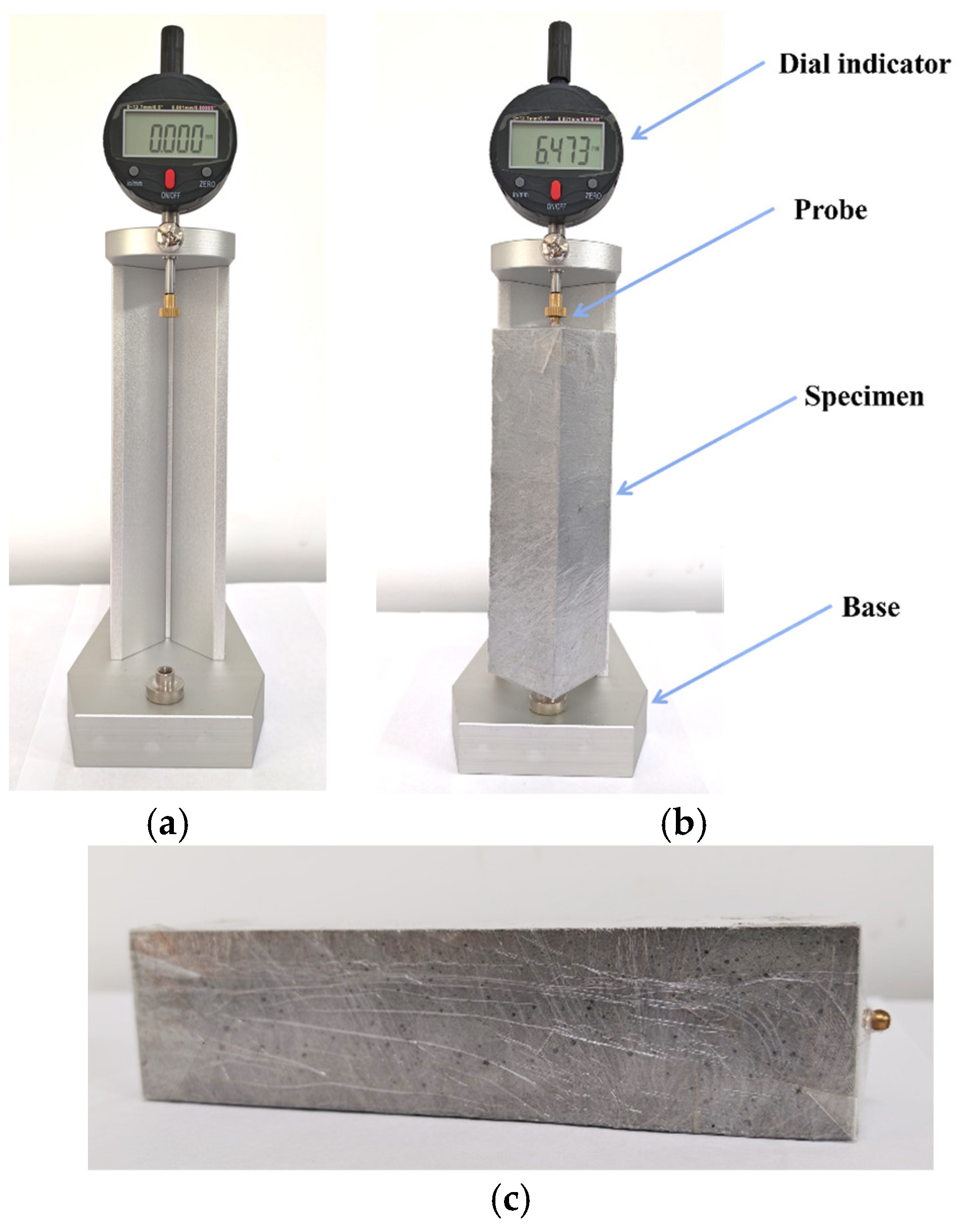

2.3. Experimental Methods

3. Results and Discussion

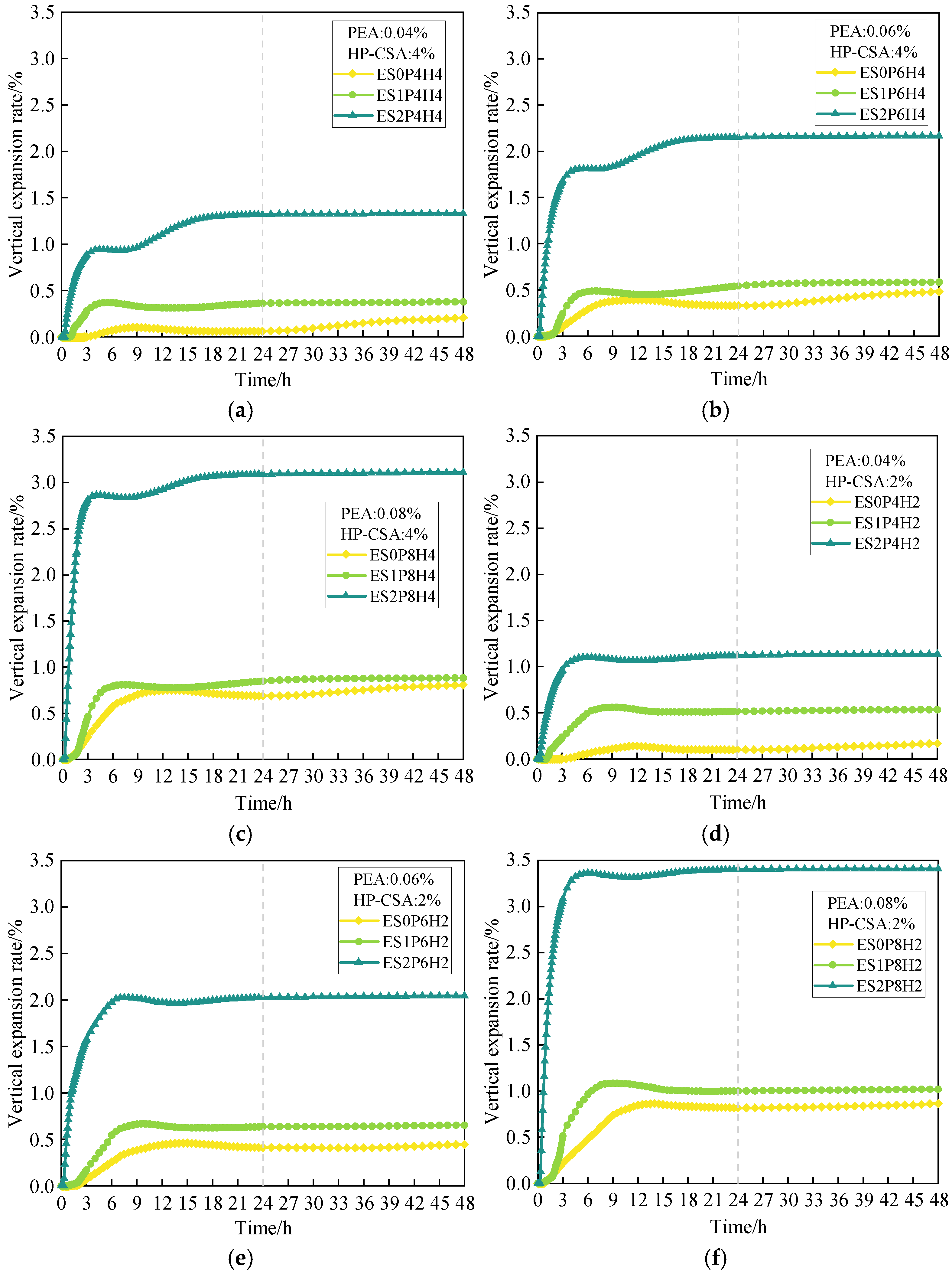

3.1. The Development of the Vertical Expansion Rate from 0 to 48 Hours

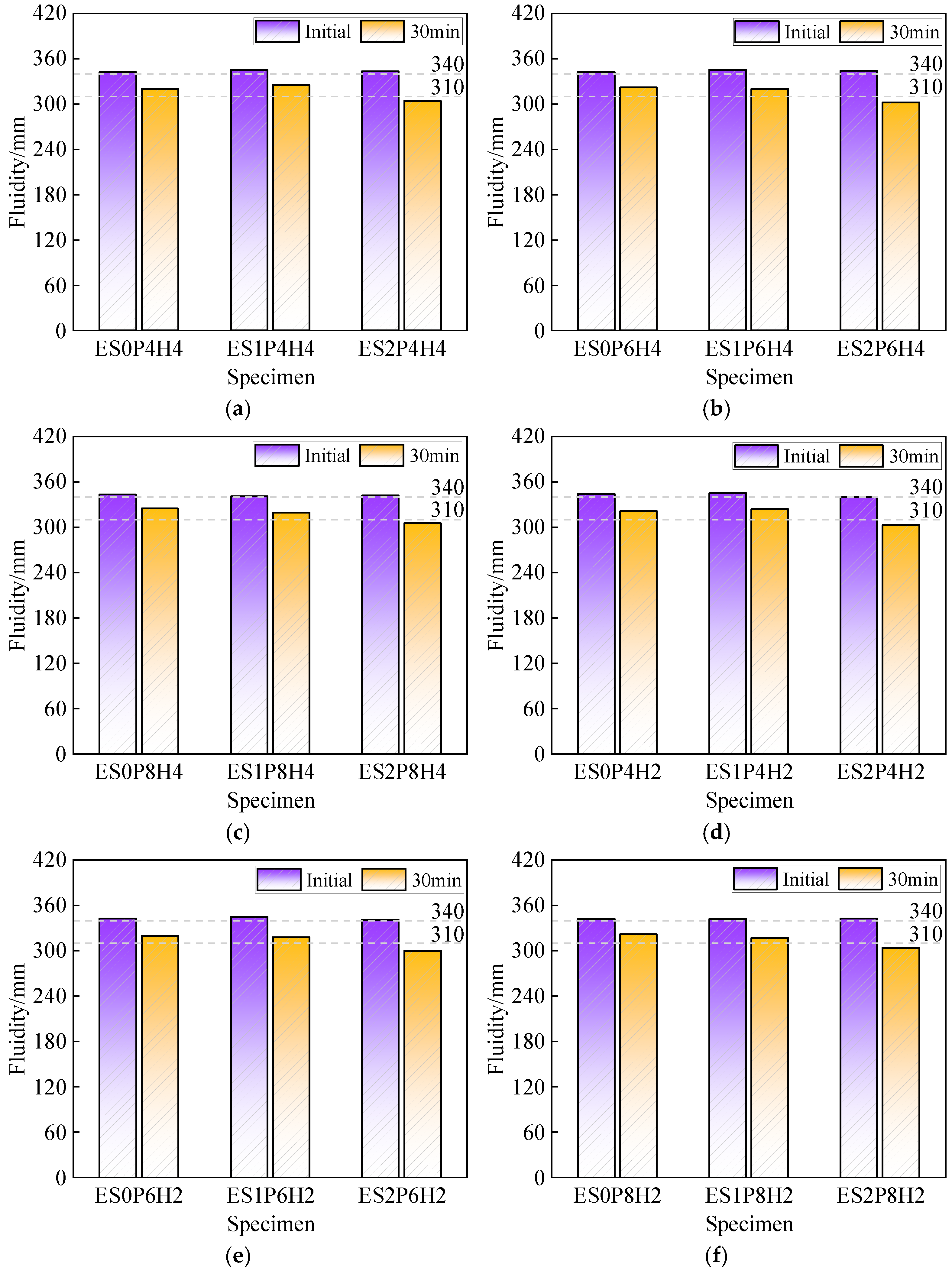

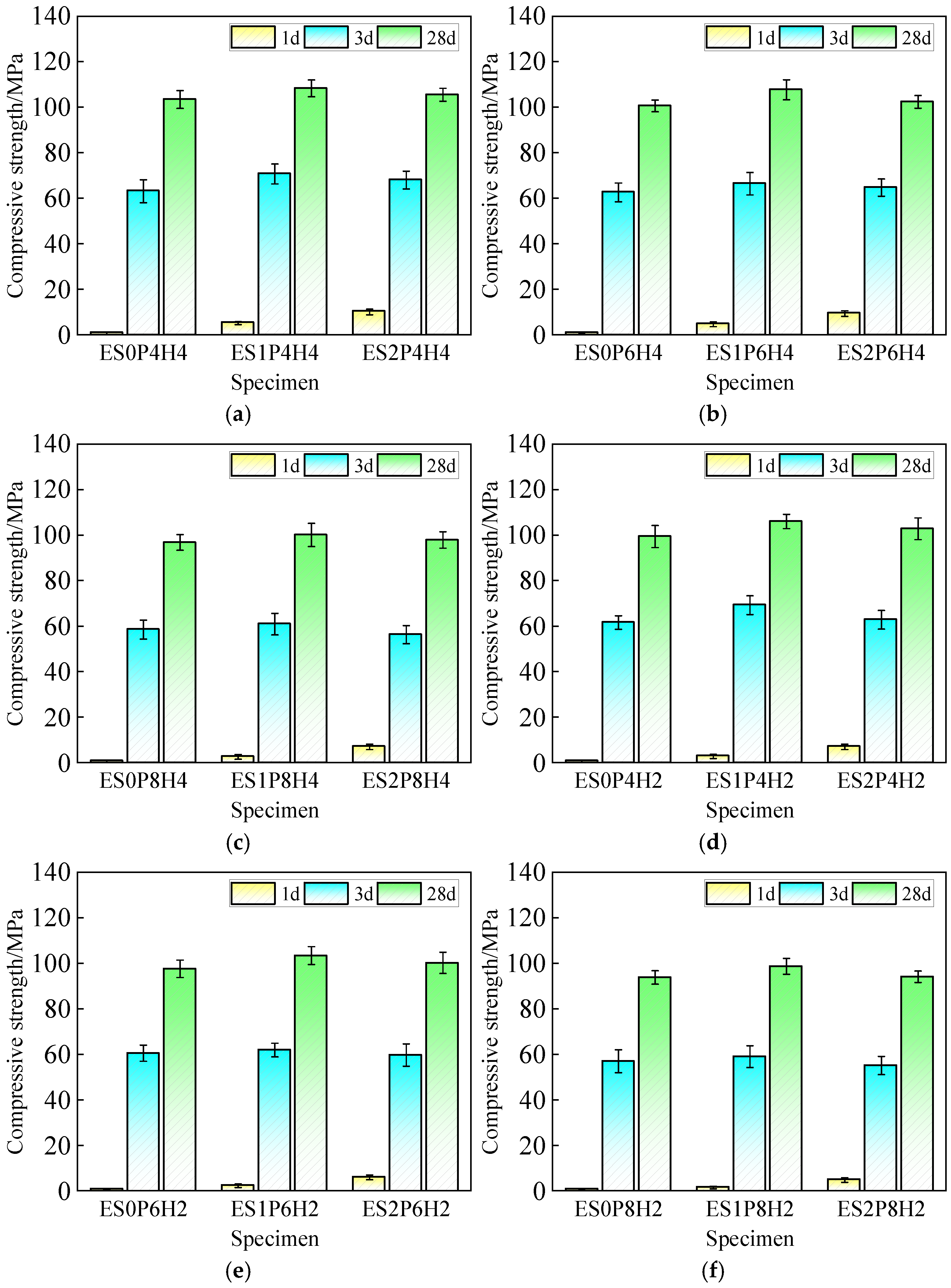

3.2. Fluidity and Mechanical Strength

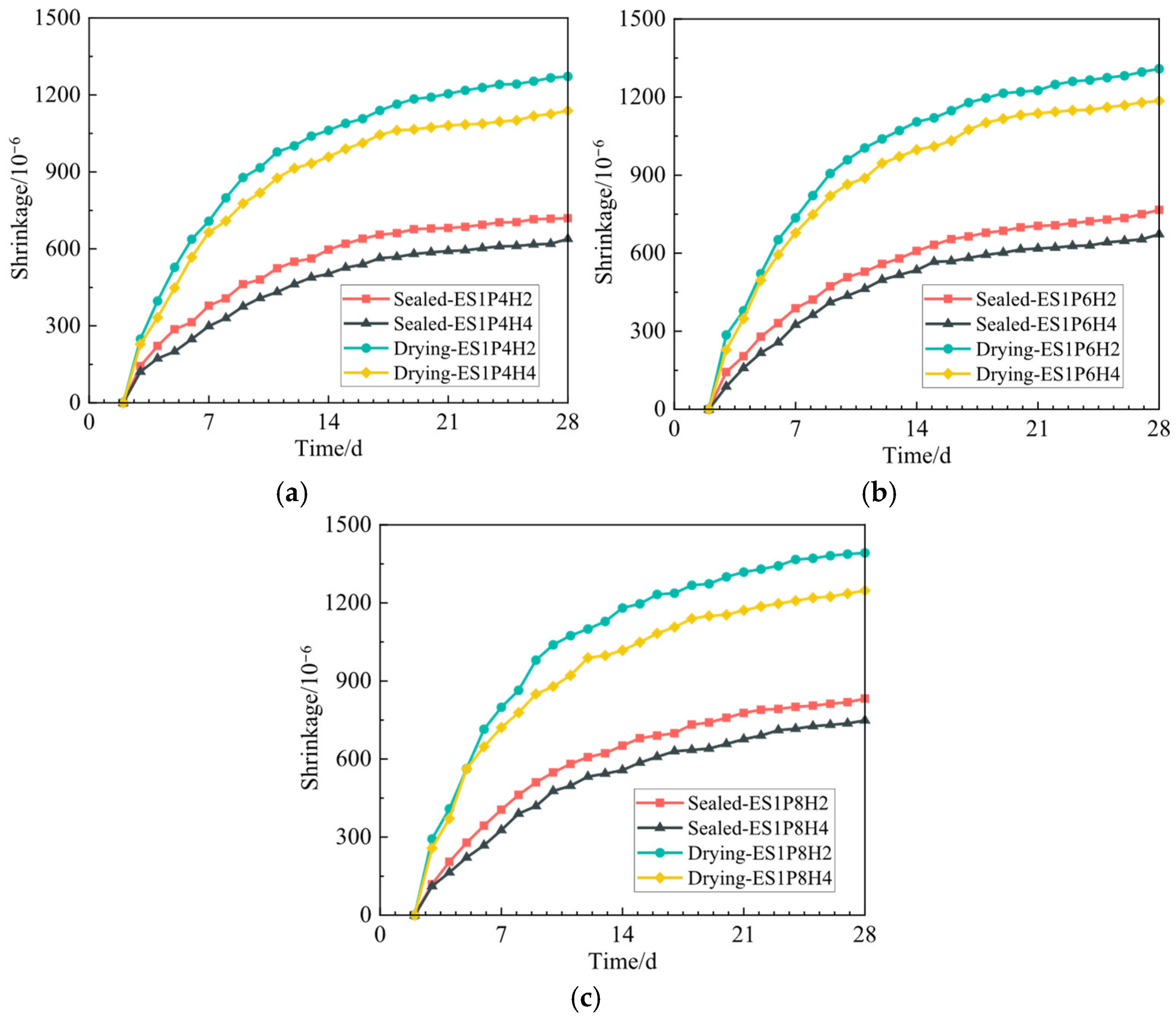

3.3. The Development of the Shrinkage Deformation from 2 to 28 Days

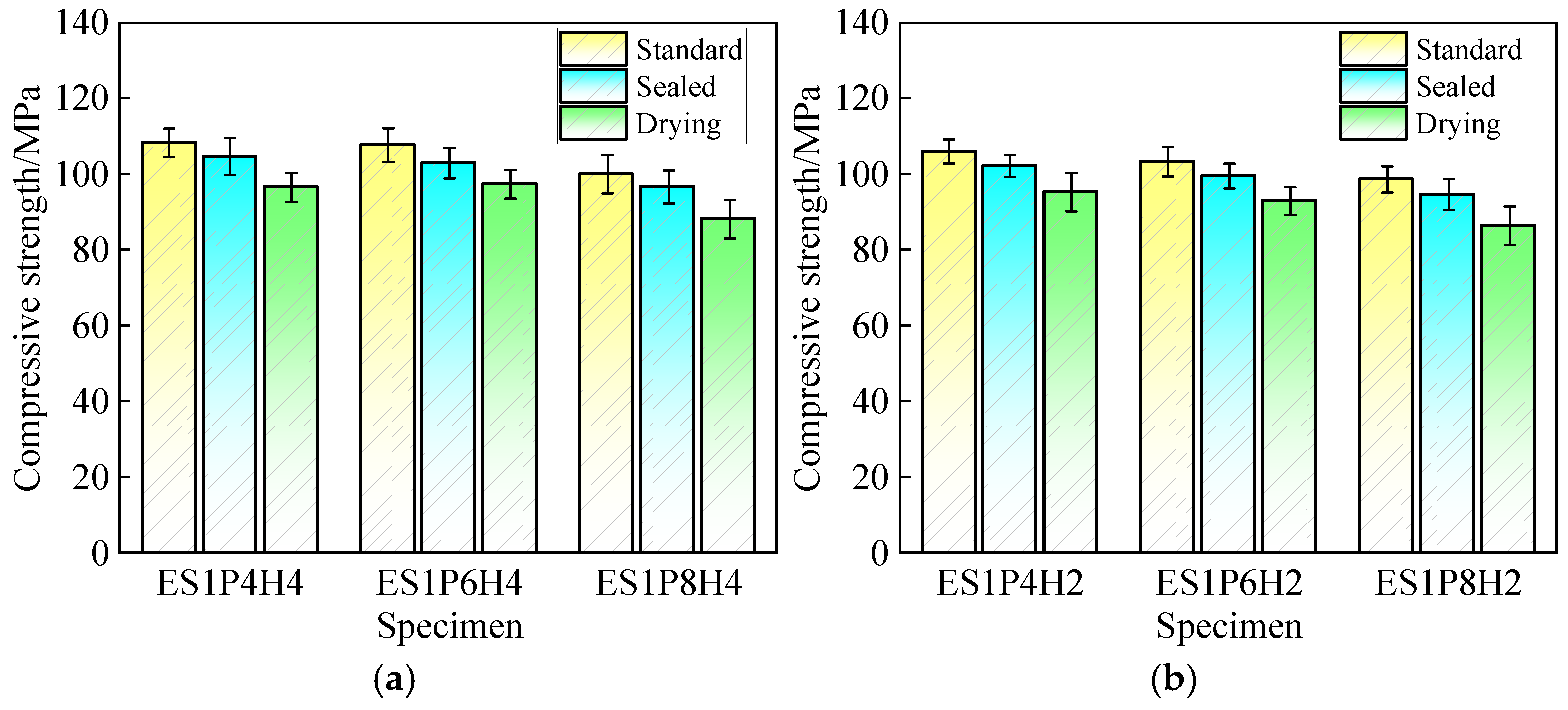

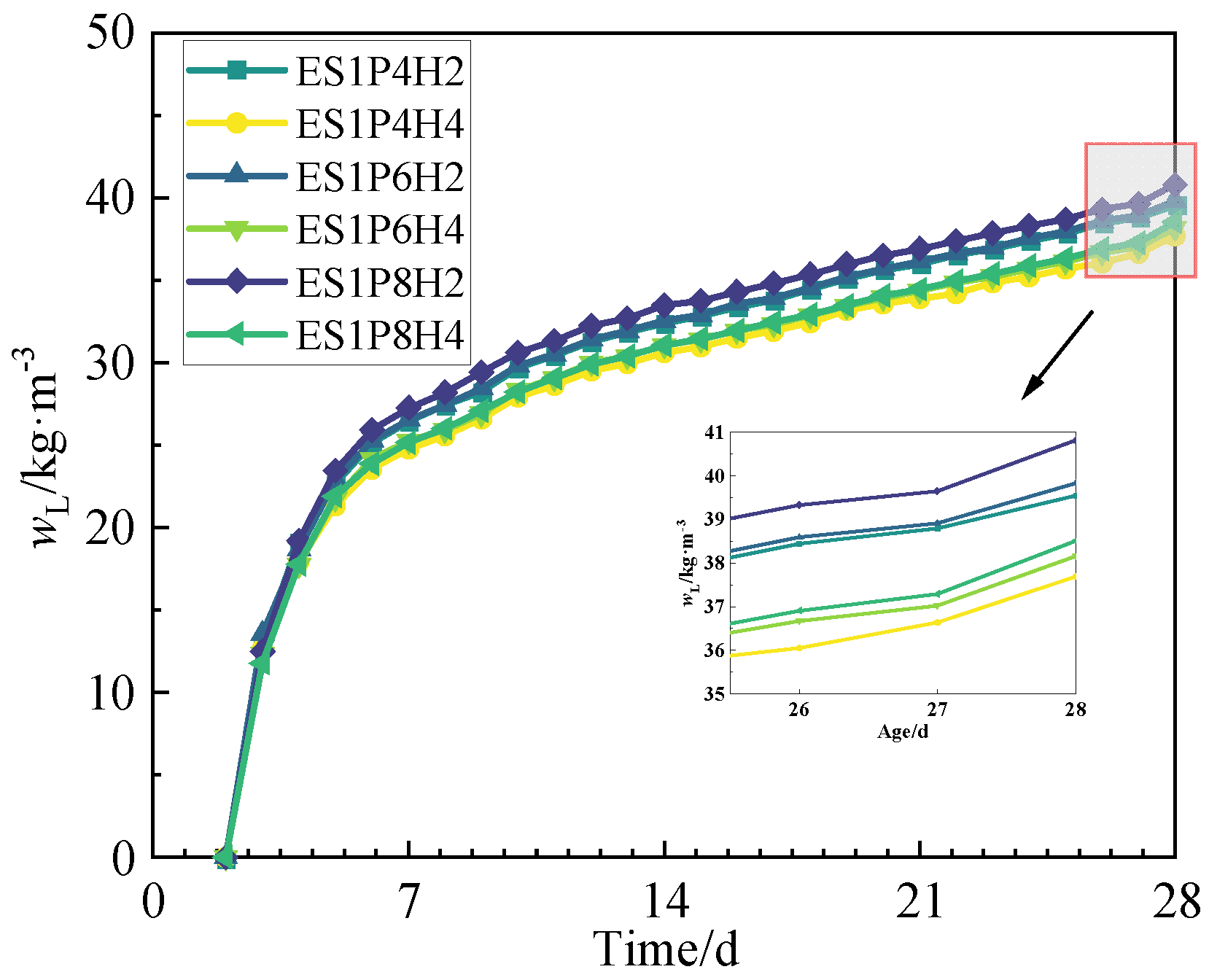

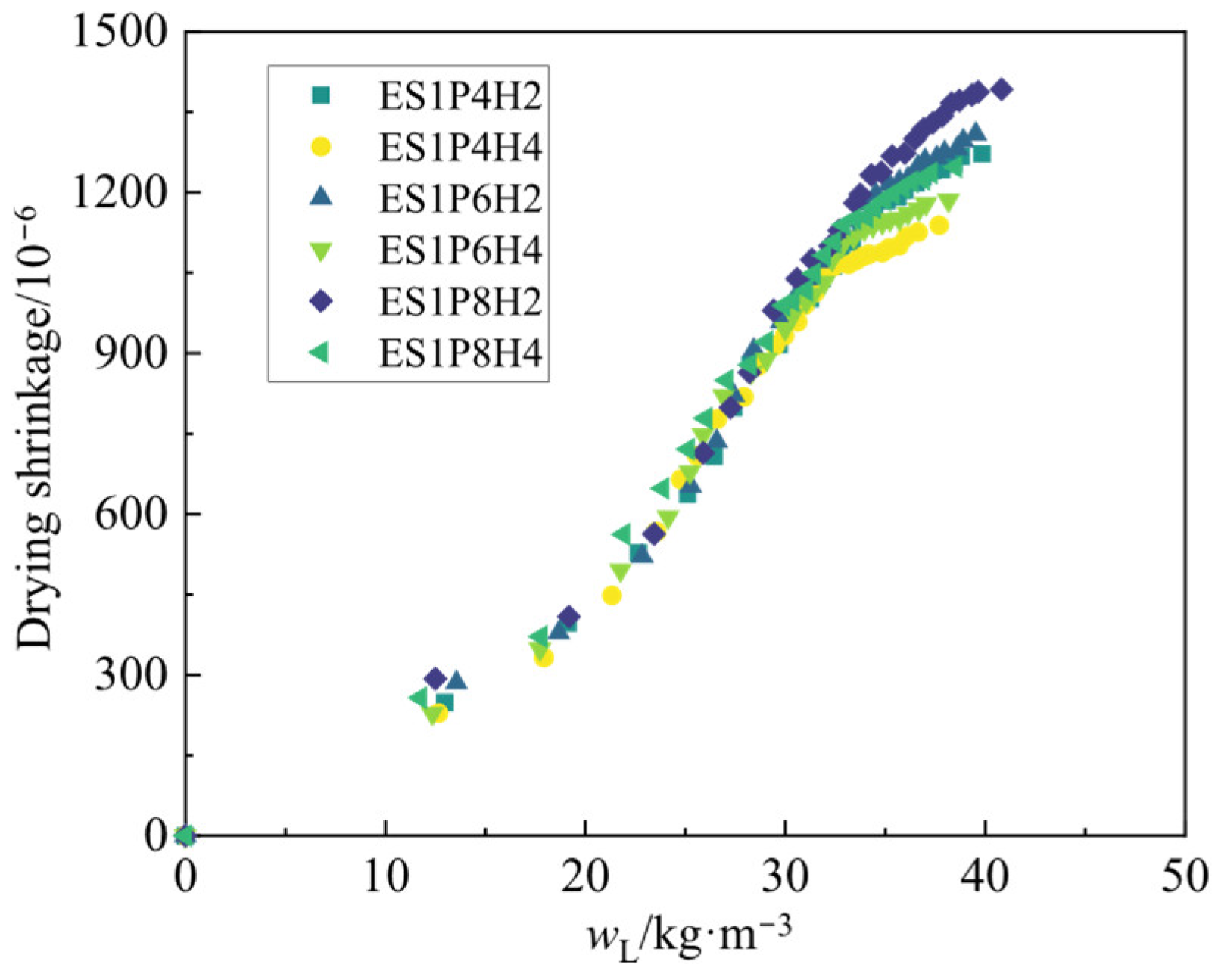

3.4. The Drying Shrinkage and Water Loss Rate

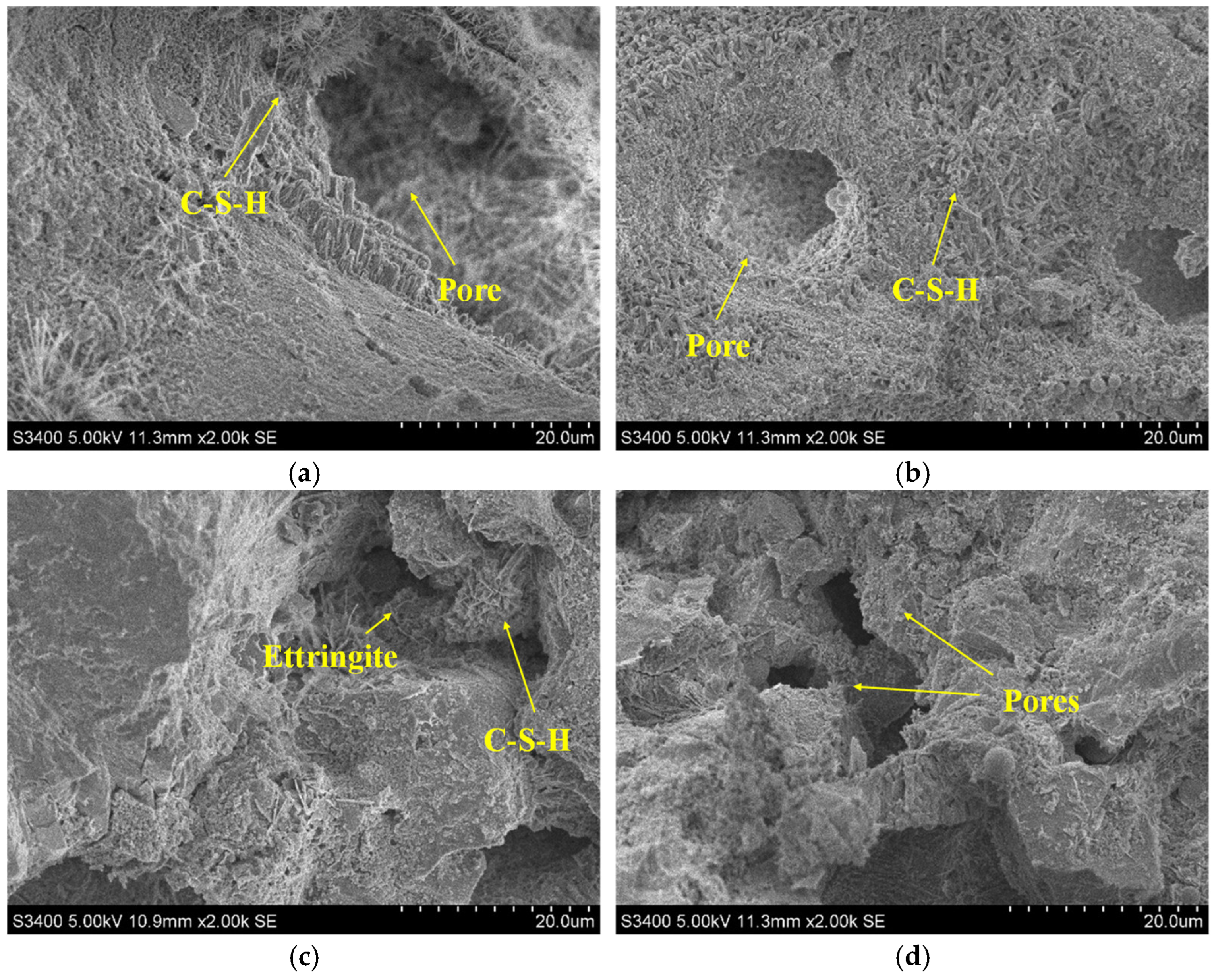

3.5. Microstructure

4. Conclusions

- The combined regulation of ES, PEA, and HP-CSA enables effective synchronization between the expansion performance window of PEA and the early-age strength development of the grout, thereby realizing precise control over the 48–hour vertical expansion curve of coral sand grouting materials. Simply increasing the HP-CSA dosage accelerates the development of the vertical expansion curve, reduces the initial peak values, and shortens the time required to reach this peak. Within the scope of this study, the incorporation of appropriate dosages of calcium formate and HP-CSA can achieve secondary growth of vertical expansion rate in high-fluidity coral sand grouting materials during the ultra-early ages.

- From 2 to 28 days, coral sand grouting materials exhibit continuous shrinkage development with gradually decreasing shrinkage rate, progressively approaching an equilibrium state. Dry curing condition exerts a significant influence on the shrinkage deformation of the material. An excessive PEA dosage induces substantial shrinkage deformation in coral sand grouting materials. The combination of appropriate dosages of PEA and HP-CSA can effectively and synergistically regulate the deformation development of coral sand grouting materials during both 0–48 h and 2–28 d, thereby enabling a staged and controllable design of its deformation evolution.

- The drying shrinkage of coral sand grouting materials exhibits a positive correlation with the drying water loss rate, with all groups yielding R2 values exceeding 0.95, indicative of excellent fitting results. Different curing conditions induce significant variations in the 28-day compressive strength of coral sand grouting materials. Specimens subjected to standard curing achieved the highest strength, followed by those under sealed curing, whereas dry-cured specimens exhibited the lowest values.

- Based on the established mix proportions within this study, a high-strength coral sand grouting material is developed by incorporating ES, PEA, and HP-CSA at dosages of 1%, 0.06%, and 4%, respectively. The material meets the Class II fluidity requirements specified in the national standard, complies with the criteria for vertical expansion rate within 24 h, and exhibits shrinkage deformation within a reasonable range from 2 to 28 days, with its 28-day compressive strength reaching 107.8 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gong, W.; Yu, H.; Ma, H.; Zhu, H. Physical and mechanical properties and time-varying model of concrete structures under the simulated tidal environment of the South China Sea island and reef. Constr. Build. Mater. 2023, 366, 130180. [Google Scholar] [CrossRef]

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Wang, X.; Jiao, Y.; Wang, R.; Hu, M.; Meng, Q.; Tan, F. Engineering characteristics of the calcareous sand in Nansha Islands, South China Sea. Eng. Geol. 2011, 120, 40–47. [Google Scholar] [CrossRef]

- Wang, A.; Xu, Z.; Chu, Y.; Dai, J.; Xu, Q.; Liu, K.; Ding, Y.; Sun, D. Numerical characterization of the geometric shape of coral sand by particle shaping and study on the properties of graded composite coral fine aggregate. Compos. Part B Eng. 2025, 297, 112313. [Google Scholar] [CrossRef]

- Lyu, B.; Wang, A.; Zhang, Z.; Liu, K.; Xu, H.; Shi, L.; Sun, D. Coral aggregate concrete: Numerical description of physical, chemical and morphological properties of coral aggregate. Cement Concrete Comp. 2019, 100, 25–34. [Google Scholar] [CrossRef]

- Yi, J.; Wang, L.; Ma, L.; Zhang, Q.; Zhang, J.; Chi, J. Experimental study on basic mechanical properties of PVA fiber-reinforced coral cement-based composites. Materials 2023, 16, 2914. [Google Scholar] [CrossRef]

- Han, H.; Gao, G.; Li, Y.; Hou, D.; Han, Y. Effect of PVA fiber on the mechanical properties of seawater coral sand engineered cementitious composites. Materials 2024, 17, 1446. [Google Scholar] [CrossRef]

- Xue, X.; Li, W.; Hou, D.; Han, H.; Han, Y. Experimental study on uniaxial compression stress-strain relationship of hybrid fiber-reinforced coral sand ultra-high performance concrete. Materials 2025, 18, 2233. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.; Ma, H.; Tan, Y.; Mi, R.; Dou, X. Experimental investigation of whole stress-strain curves of coral concrete. Constr. Build. Mater. 2016, 122, 81–89. [Google Scholar] [CrossRef]

- Wang, C.; Sun, L.; Zhang, C.; Li, C.; Qiao, P.; Chen, X. Experimental study on the mechanical properties and uniaxial compressive constitutive relationship of sea sand coral concrete. J. Build. Eng. 2024, 87, 109062. [Google Scholar] [CrossRef]

- Zhou, L.; Guo, S.; Ma, W.; Xu, F.; Shi, C.; Yi, Y.; Zhu, D. Internal curing effect of saturated coral coarse aggregate in high-strength seawater sea sand concrete. Constr. Build. Mater. 2022, 331, 127280. [Google Scholar] [CrossRef]

- Cheng, S.; Shui, Z.; Sun, T.; Yu, R.; Zhang, G.; Ding, S. Effects of fly ash, blast furnace slag and metakaolin on mechanical properties and durability of coral sand concrete. Appl. Clay Sci. 2017, 141, 111–117. [Google Scholar] [CrossRef]

- Cheng, S.; Shui, Z.; Sun, T.; Yu, R.; Zhang, G. Durability and microstructure of coral sand concrete incorporating supplementary cementitious materials. Constr. Build. Mater. 2018, 171, 44–53. [Google Scholar] [CrossRef]

- Cruz, F.; Valente, I.B.; Monteiro, F.; Maslov, D.; Miranda, T.; Pereira, E.B. Development and characterization of structural connections for modular artificial reefs. Ocean Eng. 2025, 320, 120311. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, L.; Cao, P.; Tan, Z.; Zhang, S.; Liu, S.; Wang, J. Development of a modified cement stabilized calcareous sand material with high strength and heavy metal ion adsorption for island pavement bases. Constr. Build. Mater. 2024, 448, 138204. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Li, M.; Huo, B.; Jin, L. Experimental study on performance optimization of grouting backfill material based on mechanically ground coal gangue utilizing urea and quicklime. Materials 2023, 16, 1097. [Google Scholar] [CrossRef]

- He, X.; Yang, J.; Niu, M.; Zhang, G.; Li, G. Study on expansion effect and hydration characteristics of ultra-high strength cement-based grouting materials based on humidity compensation. Case Stud. Constr. Mat. 2023, 18, e01941. [Google Scholar] [CrossRef]

- Han, Y.; Xie, Y.; Yue, Q.; Yang, F.; Ding, Z. Effect of Composite Expansive Agent on Early-Age Expansion Properties of Cementitious Grouting Material for Wind Power Project. J. Build. Mater. 2024, 27, 611–619. Available online: https://link.cnki.net/urlid/31.1764.TU.20231114.1550.002 (accessed on 20 June 2025). (In Chinese).

- Lim, S.; Tan, C.; Chen, K.; Lee, M.; Lee, W. Effect of different sand grading on strength properties of cement grout. Constr. Build. Mater. 2013, 38, 348–355. [Google Scholar] [CrossRef]

- Wang, Y.; Fu, C.; Kuang, H.; Qin, H.; Xu, T.; Meng, W. Experimental study on the mechanical properties of cement-based grouting materials after exposed to high temperatures. Case Stud. Constr. Mat. 2024, 20, e03068. [Google Scholar] [CrossRef]

- Li, L.; Chai, H.; Hu, Y.; He, R.; Wang, Z. Feasibility study on superabsorbent polymer (SAP) as internal curing agent for cement-based grouting material. Constr. Build. Mater. 2024, 411, 134286. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). State Administration for Market Regulation, National Standardization Administration: Beijing, China, 2021.

- Burnwal, R.K.; Singh, A. True-triaxial characterisation of the cement-based grout for application in underground space construction. Constr. Build. Mater. 2025, 487, 141887. [Google Scholar] [CrossRef]

- Gomes, S.D.; Ferrara, L.; Sánchez, L.; Moreno, M.S. A comprehensive review of cementitious grouts: Composition, properties, requirements and advanced performance. Constr. Build. Mater. 2023, 375, 130991. [Google Scholar] [CrossRef]

- Xie, Y.; Han, Y.; Peng, B.; Yang, F.; Han, H. Review on Preparation and Basic Properties of Cementitious Grouting Materials. Mater. Rep. 2024, 38, 171–181. Available online: https://kns.cnki.net/kcms2/article/abstract?v=mV2q5OJ_OLwKGUSrMxQM43O1mjU7q47nKCfH9sZnOiUnjqySiV57yVxXv_74EIjMs_Ls0PV5xBTOoXMC1FH-HKCCzNsA81Sy3SNsWwt-FpnZAPW9xz0KbeN1e9-vL7bxHORs7J42pItTlfg5iE0trrcO58VAGz1V8lPUQTFa5aDsmlK4dwcFGggLE0qUnhWOGB-1K6F7usA=&uniplatform=NZKPT&language=CHS (accessed on 20 June 2025). (In Chinese).

- GB/T50448-2015; Technical Code for Application of Cementitious Grout. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2015.

- Wang, Y.; Hu, Z.; Liu, J. Freeze-thaw resistance of concrete containing azodicarbonamide expansive agent. Constr. Build. Mater. 2023, 367, 130335. [Google Scholar] [CrossRef]

- Zheng, C.; Wang, T.; Zhou, Z.; Wang, S.; Ma, X. Influence of PEA on volume stability of cement-based grouting materials and its mechanism. Materials 2025, 18, 749. [Google Scholar] [CrossRef]

- Sun, Y.; Meng, X.; Fan, J.; Wang, S. Study on the mechanical properties and hydration synergy of MEA and UEA modified ultrafine cement grouting materials. Constr. Build. Mater. 2024, 423, 135898. [Google Scholar] [CrossRef]

- Oppong, F.; Yao, N.; Zhang, W.; Liu, Y.; Kolawole, O. Tentative application of expansive cementitious materials in grouting–a systematic review. Case Stud. Constr. Mat. 2023, 18, e02113. [Google Scholar] [CrossRef]

- Zhang, G.; Qiu, D.; Wang, S.; Wang, P. Effects of plastic expansive agent on the fluidity, mechanical strength, dimensional stability and hydration of high performance cementitious grouts. Constr. Build. Mater. 2020, 243, 118204. [Google Scholar] [CrossRef]

- Carballosa, P.; Calvo, J.G.; Revuelta, D.; Sánchez, J.J.; Gutiérrez, J.P. Influence of cement and expansive additive types in the performance of self-stressing and self-compacting concretes for structural elements. Constr. Build. Mater. 2015, 93, 223–229. [Google Scholar] [CrossRef]

- Hu, X.; Yang, B.; Peng, G.; Zhong, S.; Zhang, H. Investigation on hydration behavior and microscopic pore structure of early-age cement-based grouting material. J. Build. Eng. 2023, 80, 108050. [Google Scholar] [CrossRef]

- Chen, T.; Ren, B.; Wang, Z.; Meng, X.; Ning, Y.; Lyu, Y. Effect of early strength agent on the hydration of geopolymer mortar at low temperatures. Case Stud. Constr. Mat. 2022, 17, e01419. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Awed, A.M.; Xie, J.; Gu, F. Performance evaluation of high early strength micro-expansion geopolymer grout potentially used for sustainable road infrastructure. Transp. Geotech. 2024, 49, 101400. [Google Scholar] [CrossRef]

- Yang, Z.; Mao, J.; Li, B.; Li, S.; Qian, W.; Li, H.; Ren, J. Early strength development of mortar with addition of calcium formate and electric field curing in cold climates. Mag. Concrete Res. 2023, 76, 20–36. [Google Scholar] [CrossRef]

- Du, P.; Yang, J.; Chu, H.; Lu, X.; Cheng, X. Influence of additional components on mechanical and shrinkage properties of high performance cementitious grouting materials. Case Stud. Constr. Mat. 2024, 21, e03425. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Jiao, H.; Yang, Z.; Zheng, D.; Sun, J. Study on early hydration mechanism of double-liquid grouting material modified by composite early strength agent. Materials 2023, 16, 6475. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Hou, D.; Li, W.; Yue, Q.; Han, H. Study on Preparation and Early-Age Expansion Properties of High Strength Coral Sand Cementitious Grouting Material. J. Build. Mater. 2025, 1–12. Available online: https://link.cnki.net/urlid/31.1764.TU.20250430.1629.008 (accessed on 20 June 2025). (In Chinese).

- JGJ/T 70-2009; Standard for Test Method of Performance on Building Mortar. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- Han, Y.; Xie, Y.; Li, W.; Yue, Q.; Liu, Y.; Peng, B. Using SAP to control the deformation of shrinkage-compensating concretes at early age. Constr. Build. Mater. 2024, 416, 135139. [Google Scholar] [CrossRef]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Zhao, H.; Li, J.; Sun, G.; Jiang, J.; Xuan, W.; Chen, Y.; Tian, Q.; Liu, J. Effects of pre-soaked zeolite and CaO-based expansive agent on mechanical properties and autogenous deformation of early-age concrete. Constr. Build. Mater. 2020, 261, 120370. [Google Scholar] [CrossRef]

- Hua, T.; Cao, Z.; Zhang, S.; Guo, R. Relationship between expansion and strength of cement paste with CaO-based expansive agent. Materials 2024, 17, 6125. [Google Scholar] [CrossRef]

- Guo, X.; Liao, L.; Xie, K.; Xu, W.; Lu, L.; Huang, K. Early-Age mechanical and shrinkage performance of CaO-MgO expansive agent self-compacting concrete. J. Build. Eng. 2025, 111, 113165. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, G.; Ding, Q.; Yang, J.; Zhu, J.; Qi, D. Effect of expansive agent on lightweight micro-expansive ultra-high performance concrete: Properties, microstructure, and interfacial bonding in concrete-filled steel tube. Constr. Build. Mater. 2025, 462, 139996. [Google Scholar] [CrossRef]

- Dahal, M.; Oinam, Y.; Vashistha, P.; Oh, J.-E.; Pyo, S. Cementless ultra-high performance concrete (UHPC) using CaO-activated GGBFS and calcium formats as an accelerator. J. Build. Eng. 2023, 75, 107000. [Google Scholar] [CrossRef]

- Li, F.; Ran, X.; Li, Y.; Ou, W.; Li, P. Rapid hardening and high-fluidity ultra-high performance cement-based grout with calcium formate. Mater. Lett. 2025, 388, 138326. [Google Scholar] [CrossRef]

- Dong, J.; Wu, H.; Xie, S.; Shang, X.; Shi, Z.; Tu, Z.; Zhou, P.; Zhang, T. Impact of calcium formate and anhydrous sodium sulfate on the flowability, mechanical properties, and hydration characteristics of UHPC. J. Build. Eng. 2024, 96, 110534. [Google Scholar] [CrossRef]

- Zhou, S.; Shi, Z.; Li, J.; Xu, H. Influence of Early Strength Agents on the Mechanical Properties of Repair Materials for Ultra-High Performance Concrete. J. Build. Mater. 2024, 1–12. Available online: https://link.cnki.net/urlid/31.1764.TU.20240810.1105.012 (accessed on 29 July 2025). (In Chinese).

- Li, F.; Ma, Q. Hydration Action Mechanism of Additive in Spraying Shrinkage-Compensating Concrete in Mine Supporting. Coal Min. Technol. 2012, 17, 13–16. Available online: https://link.cnki.net/doi/10.13532/j.cnki.cn11-3677/td.2012.03.002 (accessed on 29 July 2025). (In Chinese).

- Zhang, J.; Hou, D.; Han, Y. Micromechanical modeling on autogenous and drying shrinkages of concrete. Constr. Build. Mater. 2012, 29, 230–240. [Google Scholar] [CrossRef]

- Liu, J.; Ju, B.; Xie, W.; Zhou, T.; Xiao, H.; Dong, S.; Yang, W. Evaluation of the effects of surface treatment methods on the properties of coral aggregate and concrete. Materials 2021, 14, 6784. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Yu, R.; Shui, Z.; Yi, S.; Li, X.; Ling, G.; He, Y. Influence of external water introduced by coral sand on autogenous shrinkage and microstructure development of ultra-high strength concrete (UHSC). Constr. Build. Mater. 2020, 252, 119111. [Google Scholar] [CrossRef]

- Xu, D.; Tang, J.; Hu, X.; Yu, C.; Han, F.; Sun, S.; Deng, W.; Liu, J. The influence of curing regimes on hydration, microstructure and compressive strength of ultra-high performance concrete: A review. J. Build. Mater. 2023, 76, 107401. [Google Scholar] [CrossRef]

- Xia, X.; Guo, J.; Qin, X.; Wang, K.; Zhang, P. Mitigating early age shrinkage in internally cured concrete under extreme dry conditions with MEA and SRA. J. Mater. Res. Technol. 2025, 36, 6451–6472. [Google Scholar] [CrossRef]

- Wang, X.; Wu, H.; Chen, R.; Wang, M.; Chen, R.; Weng, L.; Wang, D. Effects of seawater concentration on the drying shrinkage of seawater concrete. Constr. Build. Mater. 2024, 457, 139437. [Google Scholar] [CrossRef]

- Hou, D.; Ma, H.; Zhu, Y.; Li, Z. Calcium silicate hydrate from dry to saturated state: Structure, dynamics and mechanical properties. Acta Mater. 2014, 67, 81–94. [Google Scholar] [CrossRef]

| Test Performance | Standards | |

|---|---|---|

| Fluidity (mm) | Initial value | ≥340 |

| 30 min value | ≥310 | |

| Vertical expansion rate (%) | 3 h | 0.10–3.50 |

| The difference between 24 h and 3 h | 0.02–0.50 | |

| Component | CaO | CaSO4 | Ca4Al6O12SO4 | Ca(OH)2 | CaCO3 |

|---|---|---|---|---|---|

| Mass fraction (%) | 47 | 36 | 7 | 7 | 3 |

| Component | Cement | FFA | Coral Sand | Water | PS | DA | RPP |

|---|---|---|---|---|---|---|---|

| Proportion (kg/m3) | 715 | 306 | 1021 | 245 | 10 | 1.53 | 1.02 |

| Specimens | Cement (kg/m3) | HP-CSA (kg/m3) | PEA (kg/m3) | ES (kg/m3) |

|---|---|---|---|---|

| ES0P4H2 | 694.50 | 20.50 | 0.41 | 0 |

| ES1P4H2 | 694.50 | 20.50 | 0.41 | 10.21 |

| ES2P4H2 | 694.50 | 20.50 | 0.41 | 20.42 |

| ES0P6H2 | 694.50 | 20.50 | 0.61 | 0 |

| ES1P6H2 | 694.50 | 20.50 | 0.61 | 10.21 |

| ES2P6H2 | 694.50 | 20.50 | 0.61 | 20.42 |

| ES0P8H2 | 694.50 | 20.50 | 0.82 | 0 |

| ES1P8H2 | 694.50 | 20.50 | 0.82 | 10.21 |

| ES2P8H2 | 694.50 | 20.50 | 0.82 | 20.42 |

| ES0P4H4 | 674.00 | 41.00 | 0.41 | 0 |

| ES1P4H4 | 674.00 | 41.00 | 0.41 | 10.21 |

| ES2P4H4 | 674.00 | 41.00 | 0.41 | 20.42 |

| ES0P6H4 | 674.00 | 41.00 | 0.61 | 0 |

| ES1P6H4 | 674.00 | 41.00 | 0.61 | 10.21 |

| ES2P6H4 | 674.00 | 41.00 | 0.61 | 20.42 |

| ES0P8H4 | 674.00 | 41.00 | 0.82 | 0 |

| ES1P8H4 | 674.00 | 41.00 | 0.82 | 10.21 |

| ES2P8H4 | 674.00 | 41.00 | 0.82 | 20.42 |

| Specimens | Fitting Equations | R2 |

|---|---|---|

| ES1P4H2 | y = 37.86x − 193.14 | 0.9591 |

| ES1P6H2 | y = 38.82x − 199.67 | 0.9562 |

| ES1P8H2 | y = 40.13x − 200.09 | 0.9593 |

| ES1P4H4 | y = 36.17x − 177.19 | 0.9529 |

| ES1P6H4 | y = 37.14x − 181.73 | 0.9577 |

| ES1P8H4 | y = 37.74x − 162.40 | 0.9684 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, D.; Li, W.; Xue, X.; Liu, Z.; Han, H.; Han, Y. Study on the Regulation of Early-Age Deformation Characteristics of High-Strength Coral Sand Grouting Materials. Materials 2025, 18, 3740. https://doi.org/10.3390/ma18163740

Hou D, Li W, Xue X, Liu Z, Han H, Han Y. Study on the Regulation of Early-Age Deformation Characteristics of High-Strength Coral Sand Grouting Materials. Materials. 2025; 18(16):3740. https://doi.org/10.3390/ma18163740

Chicago/Turabian StyleHou, Dongxu, Wei Li, Xiao Xue, Zhi Liu, Hongwei Han, and Yudong Han. 2025. "Study on the Regulation of Early-Age Deformation Characteristics of High-Strength Coral Sand Grouting Materials" Materials 18, no. 16: 3740. https://doi.org/10.3390/ma18163740

APA StyleHou, D., Li, W., Xue, X., Liu, Z., Han, H., & Han, Y. (2025). Study on the Regulation of Early-Age Deformation Characteristics of High-Strength Coral Sand Grouting Materials. Materials, 18(16), 3740. https://doi.org/10.3390/ma18163740