Rapid-Optimized Process Parameters of 1080 Carbon Steel Additively Manufactured via Laser Powder Bed Fusion on High-Throughput Mechanical Property Testing

Abstract

1. Introduction

2. Materials and Experimental Methods

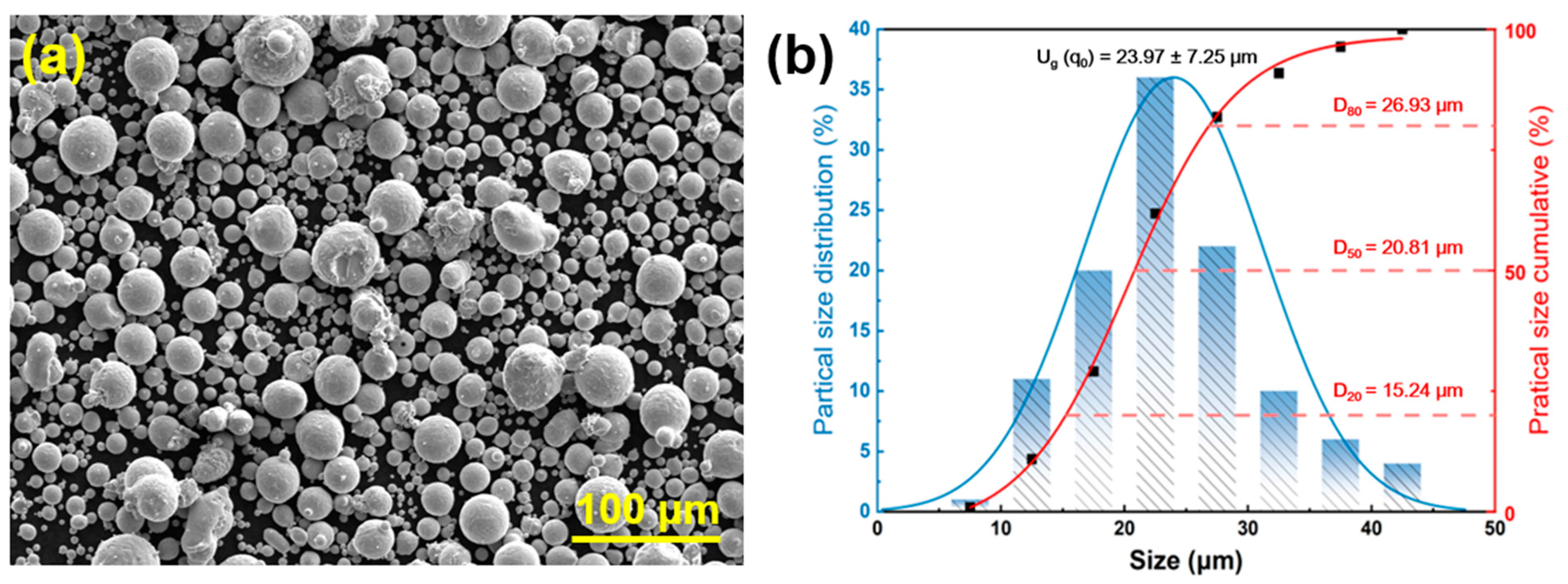

2.1. Raw Materials

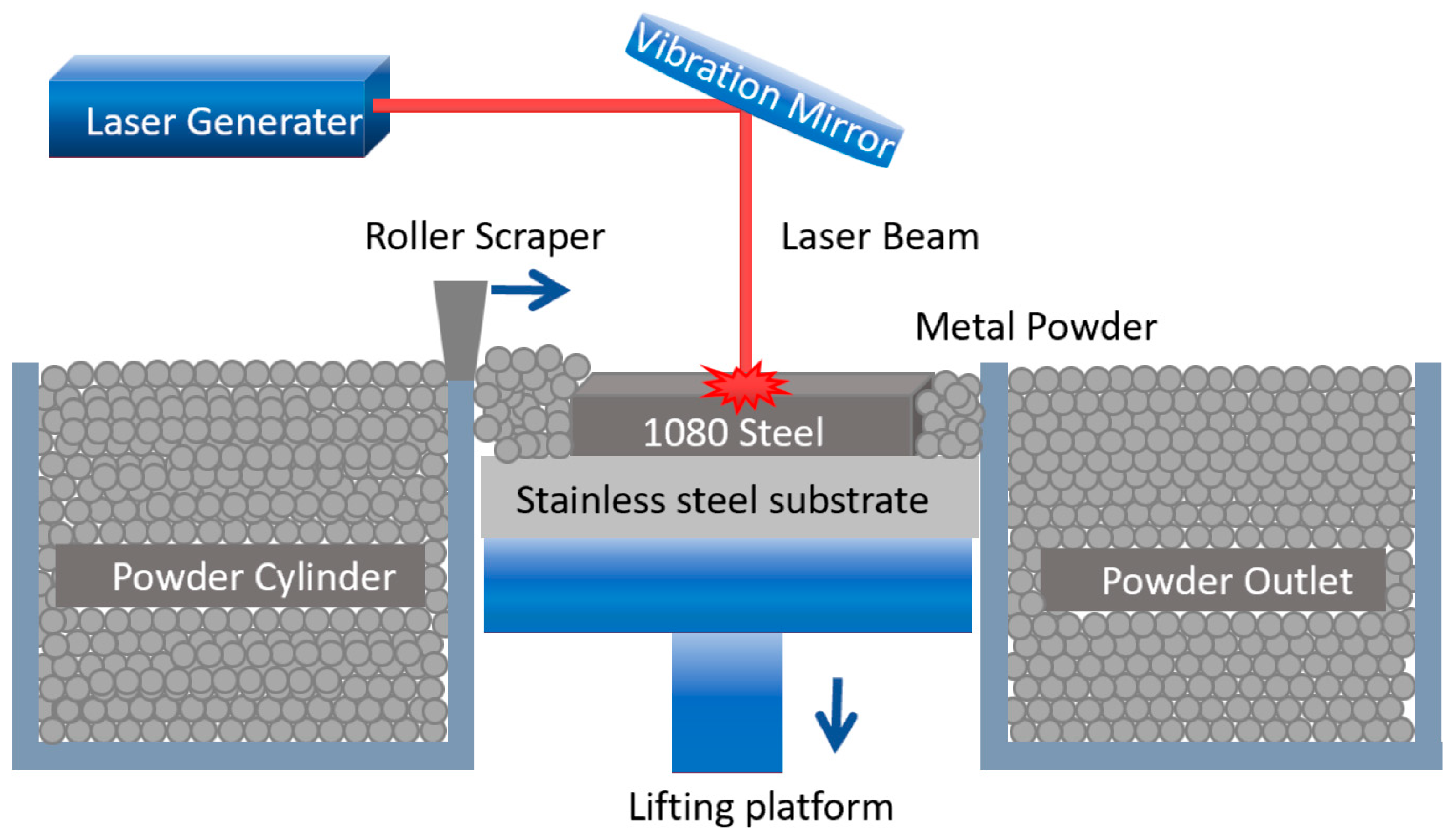

2.2. Experimental Methods

2.3. Material Characterization Techniques

3. Results

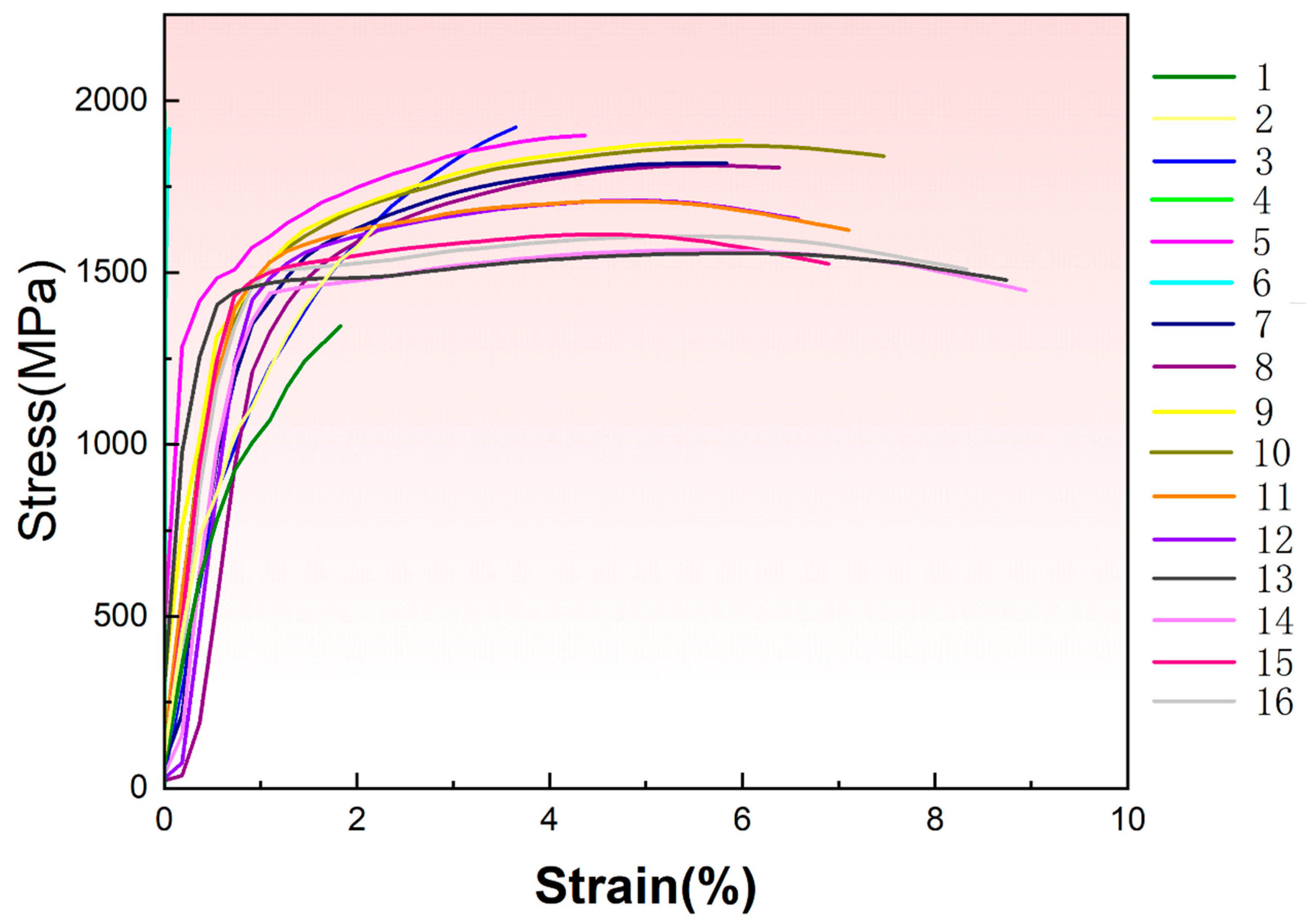

3.1. Mechanical Properties from High-Throughput Tensile Testing

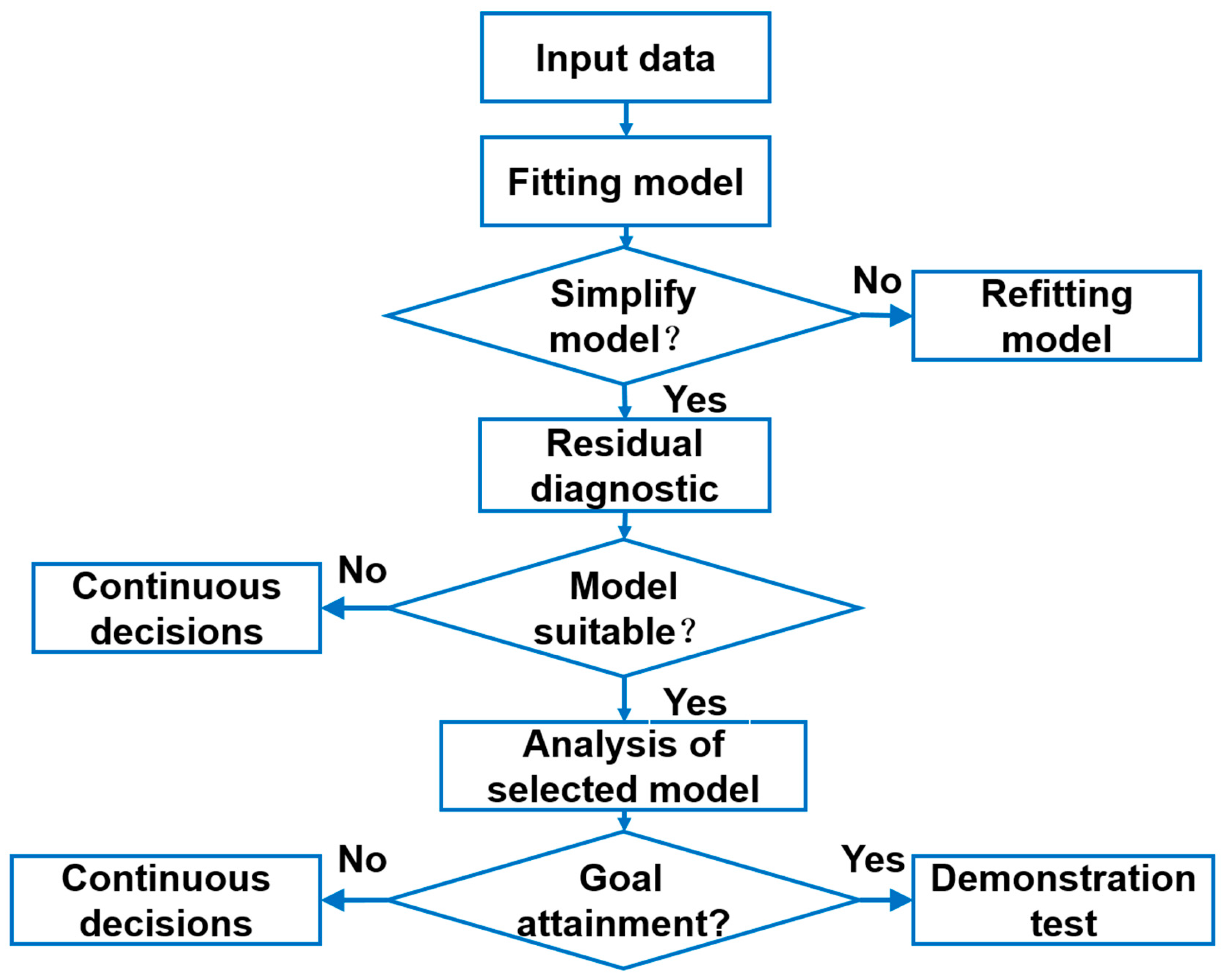

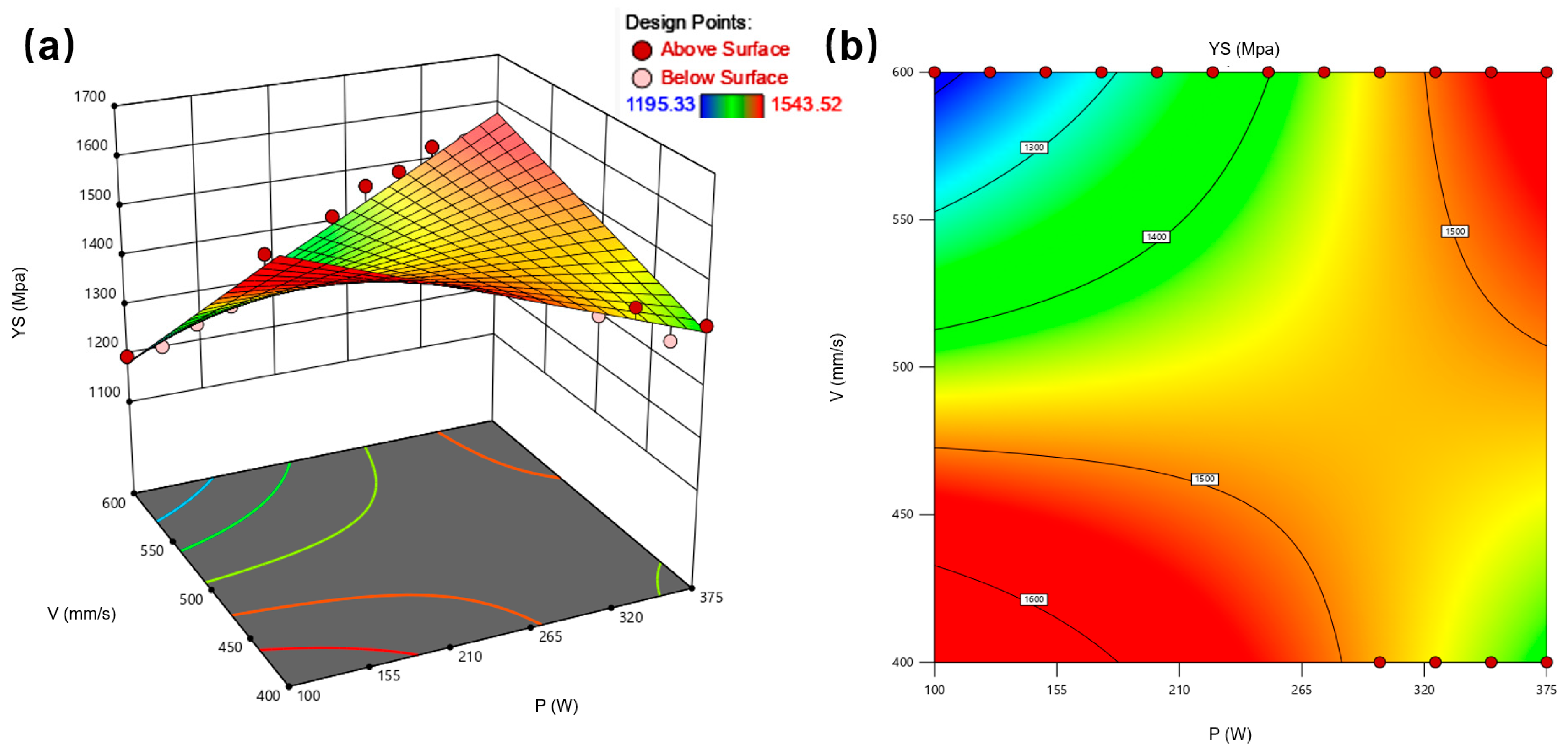

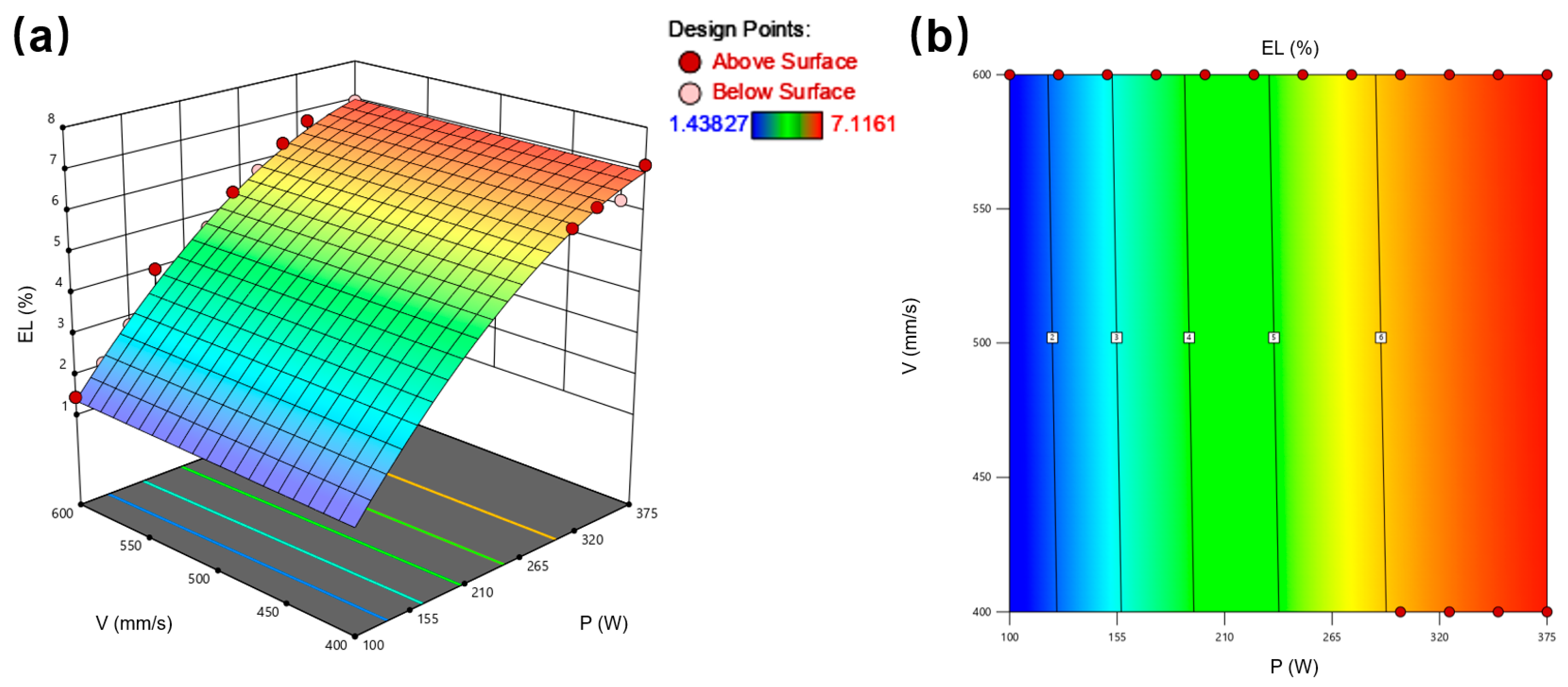

3.2. Process-Property Analytical Model

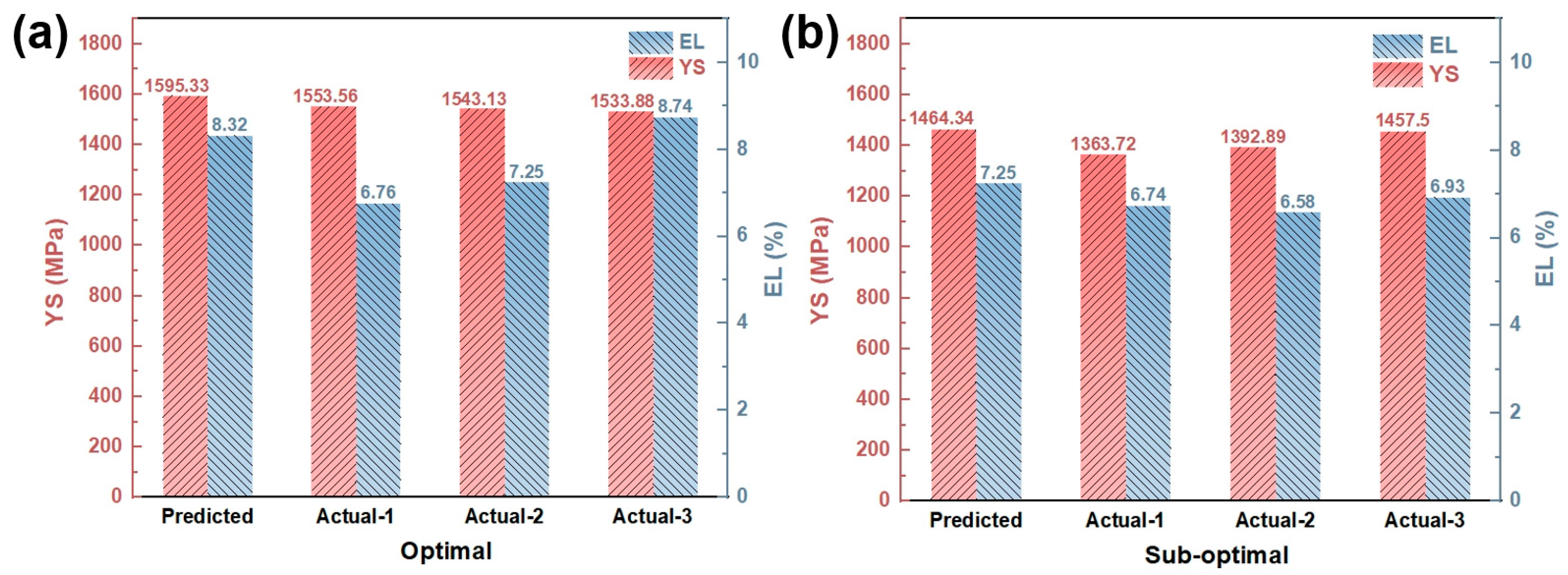

3.3. Process Optimization and Verification

4. Discussion

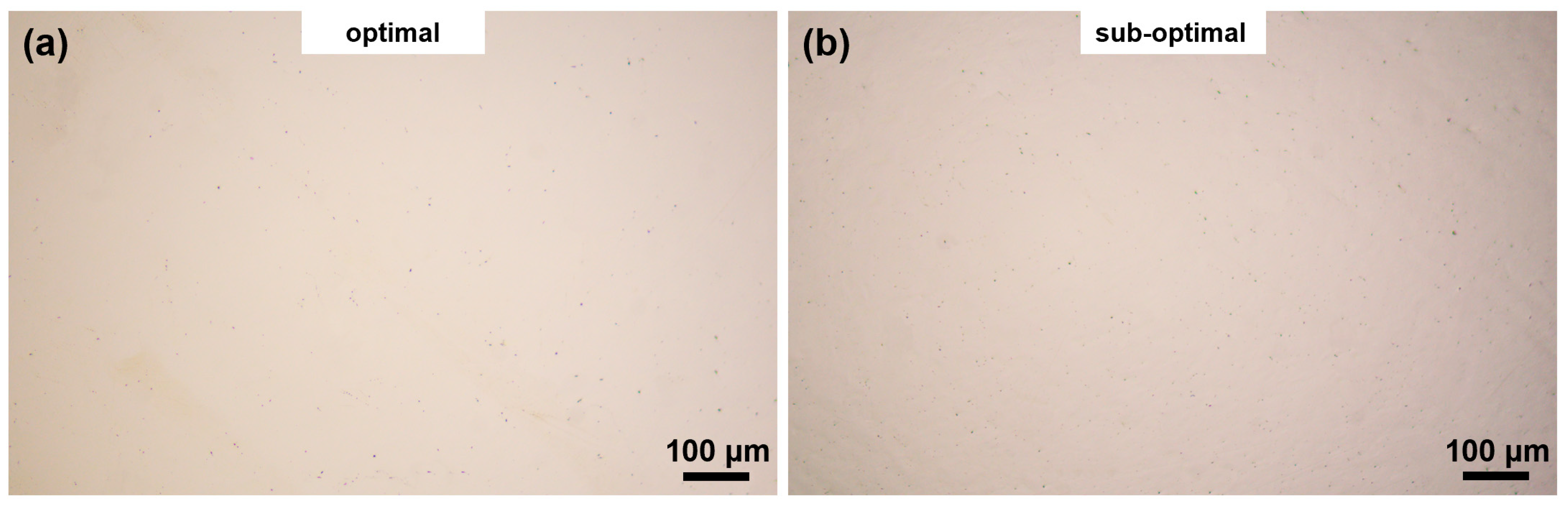

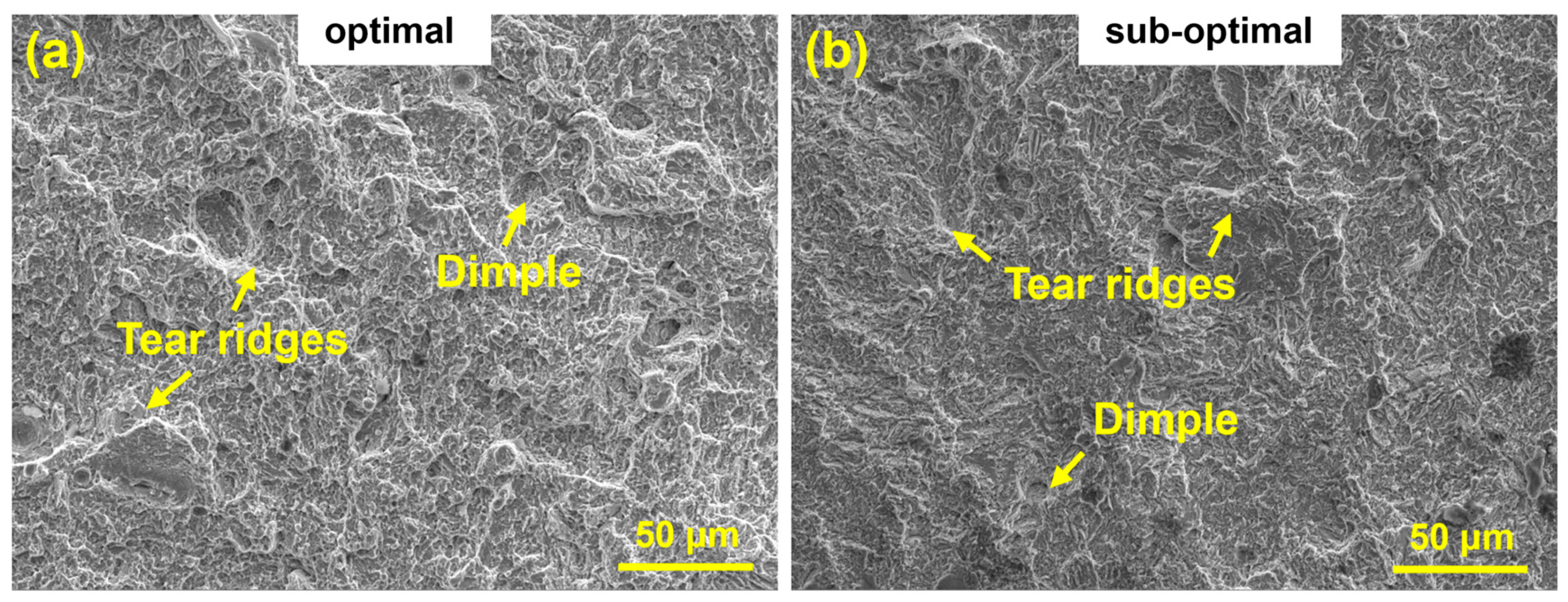

4.1. Optimal vs. Sub-Optimal Parameters: Process–Microstructure–Property Linkages

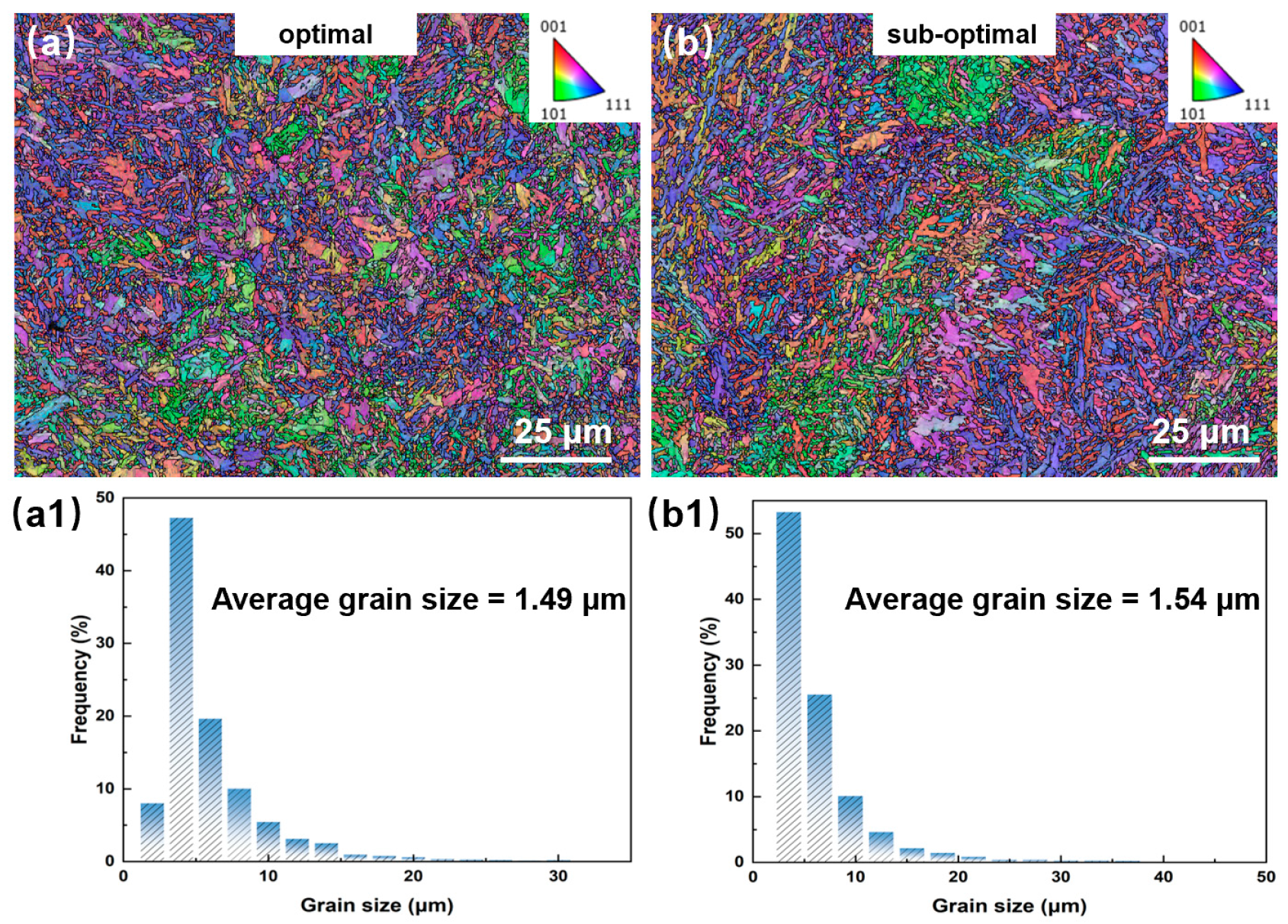

4.1.1. Grain Size and Morphology

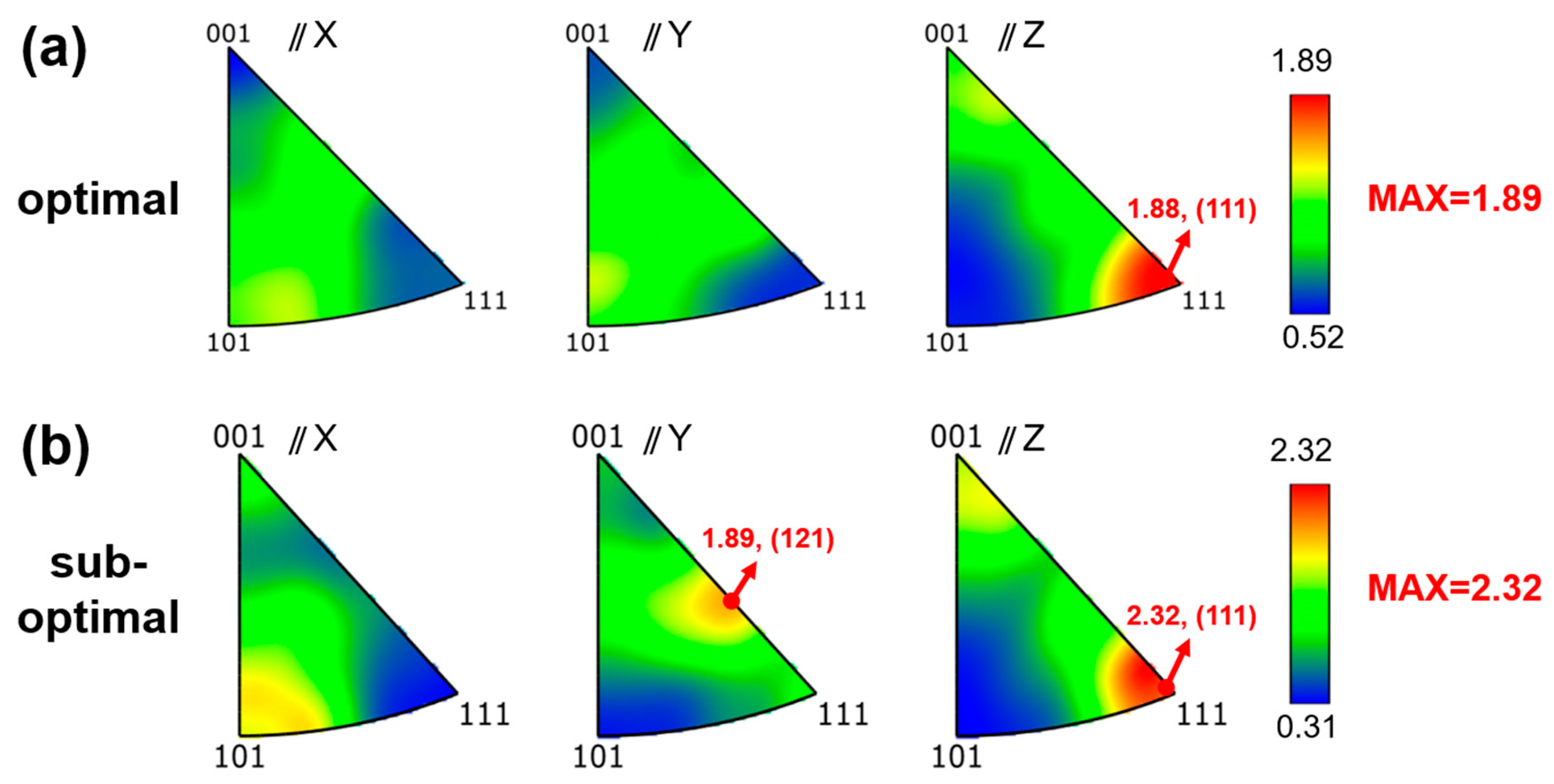

4.1.2. Crystallographic Texture

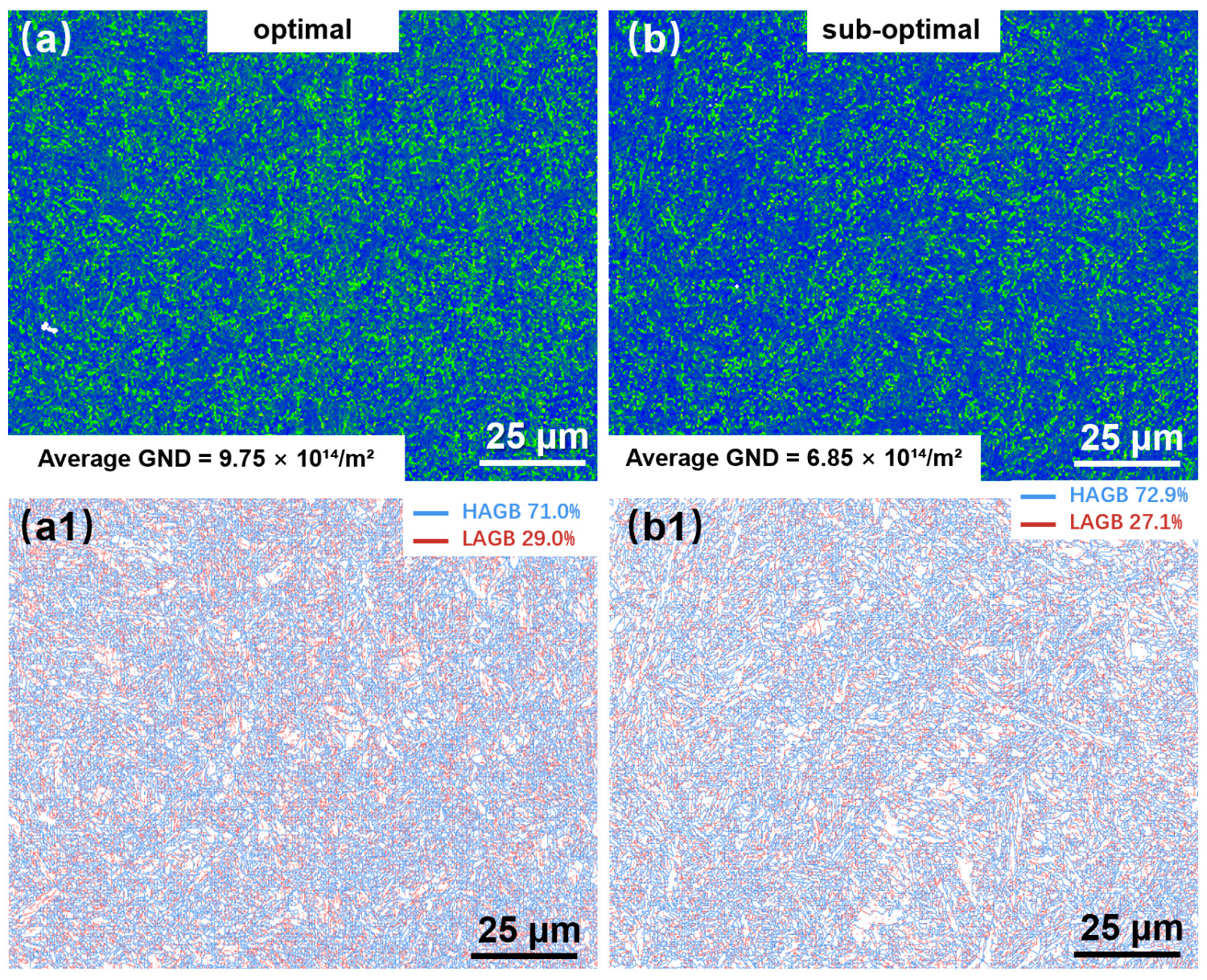

4.1.3. Geometric Dislocation Density

4.1.4. Process–Structure–Property Linkages of the Optimal and Sub-Optimal Specimens

4.2. Advantages of This High-Throughput Testing and Analytical Modeling Approach

4.2.1. High Efficiency

4.2.2. Fine-Tuning Process Parameters to Achieve Customized Performance

5. Conclusions

- (1)

- This performance-oriented process optimization framework, built upon a high-throughput testing platform and advanced data analysis techniques, demonstrates exceptional efficiency. Within only 50 h, a comprehensive process–property database and predictive model were established, enabling the identification of processing parameters that yield the customized values of yield strength (YS) and elongation (EL).

- (2)

- Under the optimized process conditions, the LPBF-fabricated 1080 carbon steel exhibited a yield strength of 1543.52 MPa and an elongation of 7.58%. These values are in close agreement with the RSM-predicted results (1595.33 MPa and 8.32%), corresponding to relative errors of −3.25% and −8.89%, respectively, thereby validating the accuracy and reliability of the predictive model.

- (3)

- The superior mechanical performance at the optimal condition is primarily attributed to a relatively low volumetric energy density (VED), which results in refined grain structures (average grain size: 1.49 µm), an elevated geometrically necessary dislocation (GND) density (9.75 × 1014 m−2), and grain boundary-mediated dislocation strengthening. These underlying mechanisms were revealed through detailed microstructural characterization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dixit, M.K.; Kumar, P.P.; Banerjee, S. Impact of using high strength low alloy steel on reducing the embodied energy, carbon, and water impacts of building structures: A case study. Dev. Built Environ. 2025, 22, 100671. [Google Scholar] [CrossRef]

- Chen, M.-T.; Gong, Z.; Zhang, T.; Zuo, W.; Zhao, Y.; Zhao, O.; Zhang, G.; Wang, Z. Mechanical behavior of austenitic stainless steels produced by wire arc additive manufacturing. Thin-Walled Struct. 2024, 196, 111455. [Google Scholar] [CrossRef]

- Sirjani, F.K.; Shabani, A.; Raeissi, K.; Nahvi, S.M.; Molavian, A.M. Effect of heat treatment on microstructure and high-temperature oxidation behavior of flame-sprayed Ni-5 wt.% Al coating on low carbon steel. Results Surf. Interfaces 2025, 19, 100515. [Google Scholar] [CrossRef]

- Han, J.M.; Zhang, R.; Ajayi, O.O.; Barber, G.C.; Zou, Q.; Guessous, L.; Schall, D.; Alnabulsi, S. Scuffing behavior of gray iron and 1080 steel in reciprocating and rotational sliding. Wear 2010, 271, 1854–1861. [Google Scholar] [CrossRef]

- Kathleen, C.; Michael, E.; Cox, C.D.; Connor, S.; Jason, C. Optical image and Vickers hardness dataset for repair of 1080 steel using additive friction stir deposition of Aermet 100. Data Brief 2022, 41, 107862. [Google Scholar] [CrossRef]

- Mishra, A.; Mondal, C.; Maity, J. Effect of Combined Cyclic Heat Treatment on AISI 1080 Steel: Part II-Mechanical Property Evaluation. Steel Res. Int. 2017, 88, 1600215. [Google Scholar] [CrossRef]

- Fujii, H.; Chung, Y.D.; Sun, Y.F. Friction stir welding of AISI 1080 steel using liquid CO2 for enhanced toughness and ductility. Sci. Technol. Weld. Join. 2013, 18, 500–506. [Google Scholar] [CrossRef]

- Mishra, S.; Mishra, A.; Show, B.K.; Maity, J. Simultaneous enhancement of ductility and strength in AISI 1080 steel through a typical cyclic heat treatment. Mater. Sci. Eng. A 2017, 688, 262–271. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. 2-Powder bed fusion processes: An overview. In Laser Additive Manufacturing. Elsevier: Amsterdam, The Netherlands, 2017; pp. 55–77. [Google Scholar] [CrossRef]

- Kirchheim, A.; Katrodiya, Y.; Zumofen, L.; Ehrig, F.; Wick, C. Dynamic conformal cooling improves injection molding. Int. J. Adv. Manuf. Technol. 2021, 114, 107–116. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Z.; Rao, D.; Yang, Y.; Zheng, L.; Wang, C.; Deng, P.; Niu, L.; Huang, Z. Synergistic enhancement of mechanical and tribological properties in WC-reinforced 316L stainless steel matrix composite fabricated by laser powder bed fusion. J. Mater. Res. Technol. 2025, 37, 617–628. [Google Scholar] [CrossRef]

- Sing, S.L.; Wiria, F.E.; Yeong, W.Y. Selective laser melting of lattice structures: A statistical approach to manufacturability and mechanical behavior. Robot. Comput. Integr. Manuf. 2018, 49, 170–180. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.-J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Shi, S.; Li, Z.; Yang, C.; Zeng, Z.; Cheng, X.; Gong, X. Multiscale simulation and experimental optimization of process parameters and post-treatment for laser powder bed fusion of high-strength Ni-based superalloy. J. Mater. Res. Technol. 2025, 37, 700–720. [Google Scholar] [CrossRef]

- Dai, K.; He, X.; Zhang, W.; Kong, D.; Guo, R.; Hu, M.; He, K.; Dong, C. Tailoring the microstructure and mechanical properties for Hastelloy X alloy by laser powder bed fusion via scanning strategy. Mater. Des. 2023, 235, 112386. [Google Scholar] [CrossRef]

- Enrique, P.D.; Minasyan, T.; Toyserkani, E. Laser powder bed fusion of difficult-to-print γ′ Ni-based superalloys: A review of processing approaches, properties, and remaining challenges. Addit. Manuf. 2025, 106, 104811. [Google Scholar] [CrossRef]

- Deep, A.; Beidokhti, M.M.; Piili, H. Preliminary manufacturability evaluation of complex geometrical parts based on layer thickness in the metal powder bed fusion process. In Progress in Additive Manufacturing; Springer: Cham, Switzerland, 2025; pp. 1–21. [Google Scholar]

- Azizi, N.; Jabari, E.; Hasanabadi, M.; Toyserkani, E. High-power laser powder bed fusion of Cu–Cr–Zr alloy: A comprehensive study on statistical process optimization, microstructure, and mechanical properties. J. Manuf. Process. 2025, 149, 931–954. [Google Scholar] [CrossRef]

- Fereiduni, E.; Ghasemi, A.; Sargent, N.; Balbaa, M.; Wang, L.; Elbestawi, M.; Sing, S.L.; Xiong, W. Synergy of laser powder bed fusion (LPBF) and heat treatment for CuNi2SiCr alloy enhancement. Mater. Des. 2025, 255, 114189. [Google Scholar] [CrossRef]

- Huang, R.; Shi, W.; Xu, K.; Wang, R.; Xie, H.; Wei, K. The influence of process parameters and building orientation on fracture toughness and fatigue crack growth behavior of laser powder bed fused tantalum. Int. J. Fatigue 2025, 199, 109086. [Google Scholar] [CrossRef]

- Lin, W.; Zhang, Z. Cracking Reduction and Texture Control in Laser Powder Bed Fusion Additive Manufactured Non-weldable Nickel Alloy. J. Mater. Eng. Perform. 2025, 1–14. [Google Scholar] [CrossRef]

- Ke, H.; Chris, K.; Adam, U.; Brooke, S. High throughput testing platform and application in wire arc additive manufactured superalloy: Anisotropy investigation and component qualification. Materialia 2021, 16, 101086. [Google Scholar] [CrossRef]

- Liu, J.; Shi, Y. Multi-objective Optimization in Selective Laser Melting of AlSi10Mg Alloy Based on Response Surface Methodology. J. Mater. Eng. Perform. 2024, 34, 3036–3046. [Google Scholar] [CrossRef]

- Zhou, Y.; Fang, Y.; Wang, J.; Xu, L.; Wang, D. Process Parameter Optimization on Selective Laser Melting of CuSn10 Powders Based on Response Surface Methodology. J. Phys. Conf. Ser. 2022, 2262, 012002. [Google Scholar] [CrossRef]

- Zhou, T.; Shi, G.; Wu, Q.; Wang, Z.; Che, J.; Wu, H. Optimization of Cutting Parameters for Cubic Boron Nitride Tool Wear in Hard Turning AISI M2. J. Mater. Eng. Perform. 2023, 33, 11298–11308. [Google Scholar] [CrossRef]

- Guo, C.; He, S.; Yue, H.; Li, Q.; Hao, G. Prediction modelling and process optimization for forming multi-layer cladding structures with laser directed energy deposition. Opt. Laser Technol. 2021, 134, 106607. [Google Scholar] [CrossRef]

- Zhou, T.; Wu, Q.; Wang, Z.; Zhao, G.; Li, S.; Guo, B.; Wu, H. Analysis of machined surface topography of AISI M2 in hard turning based on Box-Behnken Design. Proc. Inst. Mech. Eng. 2024, 238, 58–71. [Google Scholar] [CrossRef]

- Feng, Z.; Tan, H.; Fang, Y.; Lin, X.; Huang, W. Selective laser melting of TiB2/AlSi10Mg composite: Processability, microstructure and fracture behavior. J. Mater. Process. Tech. 2022, 299, 117386. [Google Scholar] [CrossRef]

- Alimohammadi, A.; Khorram, A.; Araee, A. Statistical modeling and optimization of clad geometry in laser cladding of Amdry 365 on Hastelloy X superalloy with response surface methodology. Vacuum 2024, 230, 113665. [Google Scholar] [CrossRef]

- Huang, G.; He, G.; Peng, X.; He, Y.; Chen, H.; Huang, K.; Liu, Y. Effect of processing parameters on the microstructure, mechanical properties and thermal expansion behavior of Invar 36 alloy manufactured by laser powder bed fusion. Mater. Sci. Eng. A 2024, 897, 146329. [Google Scholar] [CrossRef]

- Abele, E.; Stoffregen, H.A.; Kniepkamp, M.; Lang, S.; Hampe, M. Selective laser melting for manufacturing of thin-walled porous elements. J. Mater. Process. Tech. 2015, 215, 114–122. [Google Scholar] [CrossRef]

- Qinyao, S.; Dafan, D.; Lin, H.; Anping, D.; Cheng, Z.; Baode, S. Laser powder bed fusion of a non-equiatomic FeNiCoAl-based high-entropy alloy: Printability, microstructure, and mechanical properties. J. Alloys Compd. 2023, 938, 168562. [Google Scholar]

- Marchese, G.; Parizia, S.; Rashidi, M.; Saboori, A.; Manfredi, D.; Ugues, D.; Lombardi, M.; Hryha, E.; Biamino, S. The role of texturing and microstructure evolution on the tensile behavior of heat-treated Inconel 625 produced via laser powder bed fusion. Mater. Sci. Eng. A 2020, 769, 138500. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | S | P | Fe |

|---|---|---|---|---|---|---|

| Wt% | 0.75 | 0.19 | 0.79 | 0.01 | 0.01 | Bal. |

| No. | P (W) | V (mm/s) | h (μm) | VED (J/mm3) |

|---|---|---|---|---|

| 1 | 100 | 600 | 120 | 46.3 |

| 2 | 125 | 600 | 120 | 57.9 |

| 3 | 150 | 600 | 120 | 69.4 |

| 4 | 175 | 600 | 120 | 81.0 |

| 5 | 200 | 600 | 120 | 92.6 |

| 6 | 225 | 600 | 120 | 104.2 |

| 7 | 250 | 600 | 120 | 115.7 |

| 8 | 275 | 600 | 120 | 127.3 |

| 9 | 300 | 600 | 120 | 138.9 |

| 10 | 325 | 600 | 120 | 150.5 |

| 11 | 350 | 600 | 120 | 162.0 |

| 12 | 375 | 600 | 120 | 173.6 |

| 13 | 350 | 400 | 120 | 243.1 |

| 14 | 375 | 400 | 120 | 260.4 |

| 15 | 300 | 400 | 120 | 208.3 |

| 16 | 325 | 400 | 120 | 225.7 |

| No. | P (W) | V (mm/s) | h (μm) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| 1 | 100 | 600 | 120 | 1195.3 ± 5.8 | 1.4 ± 0.1 |

| 2 | 125 | 600 | 120 | 1203.0 ± 6.6 | 2.1 ± 0.2 |

| 3 | 150 | 600 | 120 | 1237.2 ± 13.1 | 2.8 ± 0.5 |

| 4 | 175 | 600 | 120 | 1262.4 ± 17.1 | 4.0 ± 0.4 |

| 5 | 200 | 600 | 120 | 1359.5 ± 16.7 | 3.9 ± 0.6 |

| 6 | 225 | 600 | 120 | 1333.6 ± 13.0 | 4.7 ± 0.1 |

| 7 | 250 | 600 | 120 | 1415.1 ± 20.2 | 5.4 ± 0.4 |

| 8 | 275 | 600 | 120 | 1467.9 ± 18.7 | 5.8 ± 0.5 |

| 9 | 300 | 600 | 120 | 1487.2 ± 15.6 | 6.3 ± 0.2 |

| 10 | 325 | 600 | 120 | 1528.4 ± 12.6 | 6.7 ± 0.5 |

| 11 | 350 | 600 | 120 | 1530.6 ± 10.9 | 6.6 ± 0.4 |

| 12 | 375 | 600 | 120 | 1543.5 ± 8.0 | 7.0 ± 0.1 |

| 13 | 350 | 400 | 120 | 1404.7 ± 19.2 | 6.5 ± 1.4 |

| 14 | 375 | 400 | 120 | 1420.1 ± 12.9 | 7.1 ± 0.5 |

| 15 | 300 | 400 | 120 | 1477.8 ± 7.1 | 6.2 ± 0.8 |

| 16 | 325 | 400 | 120 | 1480.5 ± 15.8 | 6.5 ± 0.8 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Significant |

|---|---|---|---|---|---|---|

| Model | 203,124.9099 | 3 | 67,708.3033 | 96.6238 | <0.0001 | Significant |

| P | 616.6186 | 1 | 616.6186 | 0.8780 | 0.3667 | |

| V | 7703.0096 | 1 | 7703.0097 | 10.9926 | 0.0061 | |

| PV | 18,012.3838 | 1 | 18,012.3838 | 25.7047 | 0.0002 | |

| Residual | 8408.9021 | 12 | 700.74183 | |||

| Cor Total | 211,533.8119 | 15 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Significant |

|---|---|---|---|---|---|---|

| Model | 49.31 | 4 | 12.33 | 262.50 | <0.0001 | Significant |

| P | 4.21 | 1 | 4.21 | 89.70 | <0.0001 | |

| V | 0.0026 | 1 | 0.0026 | 0.0556 | 0.8179 | |

| P × V | 0.0003 | 1 | 0.0003 | 0.0072 | 0.9340 | |

| P2 | 1.24 | 1 | 1.24 | 26.43 | 0.0003 | |

| V2 | 0.0000 | 0 | ||||

| Residual | 0.5166 | 11 | 0.0470 | |||

| Cor Total | 49.83 | 15 |

| Std. Dev. | Mean | C.V.% | R2 | Adjusted R2 | Predicted R2 | Adeq Precision | |

|---|---|---|---|---|---|---|---|

| YS | 26.47 | 1396.68 | 1.90 | 0.9602 | 0.9503 | 0.9312 | 30.0679 |

| EL | 0.2167 | 5.19 | 4.17 | 0.9896 | 0.9859 | 0.9769 | 46.6148 |

| YS (MPa) | EL (%) | ||

|---|---|---|---|

| Optimal | Predicted | 1595.33 | 8.32 |

| Actual-1 | 1553.56 | 6.76 | |

| Actual-2 | 1543.13 | 7.25 | |

| Actual-3 | 1533.88 | 8.74 | |

| Actual Mean | 1543.52 | 7.58 | |

| Actual STD | 8.04 | 0.84 | |

| Actual C. V | 0.52% | 11.1% | |

| Deviation rate | −3.25% | −8.89% | |

| YS (MPa) | EL (%) | ||

| Sub-optimal | Predicted | 1464.34 | 7.25 |

| Actual-1 | 1363.72 | 6.74 | |

| Actual-2 | 1392.89 | 6.58 | |

| Actual-3 | 1457.5 | 6.93 | |

| Actual Mean | 1404.70 | 6.75 | |

| Actual STD | 39.19 | 0.14 | |

| Actual C. V | 2.79% | 2.12% | |

| Deviation rate | −4.07% | −6.90% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, J.; Jiang, M.; Huang, G.; Wu, X.; Huang, K. Rapid-Optimized Process Parameters of 1080 Carbon Steel Additively Manufactured via Laser Powder Bed Fusion on High-Throughput Mechanical Property Testing. Materials 2025, 18, 3705. https://doi.org/10.3390/ma18153705

Feng J, Jiang M, Huang G, Wu X, Huang K. Rapid-Optimized Process Parameters of 1080 Carbon Steel Additively Manufactured via Laser Powder Bed Fusion on High-Throughput Mechanical Property Testing. Materials. 2025; 18(15):3705. https://doi.org/10.3390/ma18153705

Chicago/Turabian StyleFeng, Jianyu, Meiling Jiang, Guoliang Huang, Xudong Wu, and Ke Huang. 2025. "Rapid-Optimized Process Parameters of 1080 Carbon Steel Additively Manufactured via Laser Powder Bed Fusion on High-Throughput Mechanical Property Testing" Materials 18, no. 15: 3705. https://doi.org/10.3390/ma18153705

APA StyleFeng, J., Jiang, M., Huang, G., Wu, X., & Huang, K. (2025). Rapid-Optimized Process Parameters of 1080 Carbon Steel Additively Manufactured via Laser Powder Bed Fusion on High-Throughput Mechanical Property Testing. Materials, 18(15), 3705. https://doi.org/10.3390/ma18153705