High-Throughput Study on Nanoindentation Deformation of Al-Mg-Si Alloys

Abstract

1. Introduction

2. Experimental Procedure

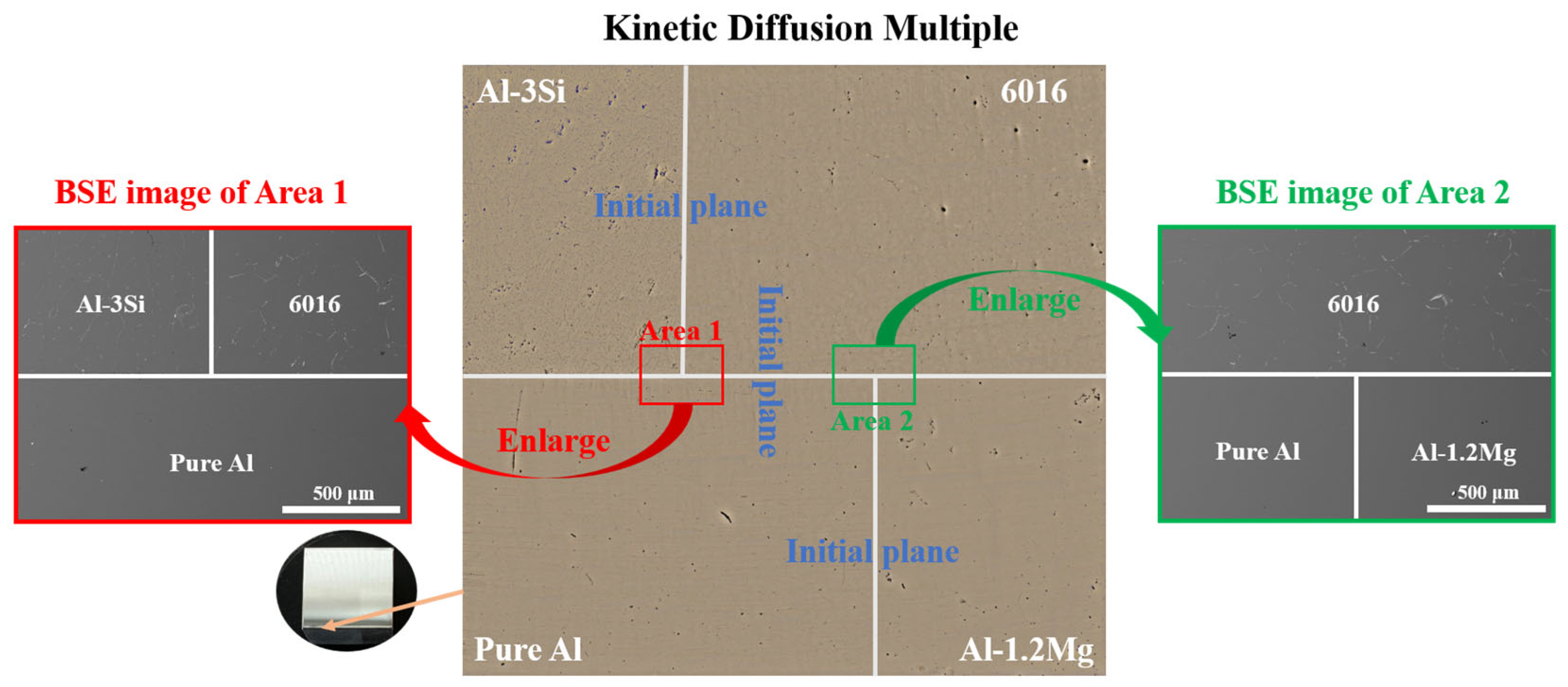

2.1. Fabrication of KDM

2.2. Composition Tests

2.3. Nanoindentation Tests

3. Equations Used in Nanoindentation Measurements

3.1. Hardness and Elastic Modulus Measurements

3.2. Nanoindentation Creep Measurement

4. Results

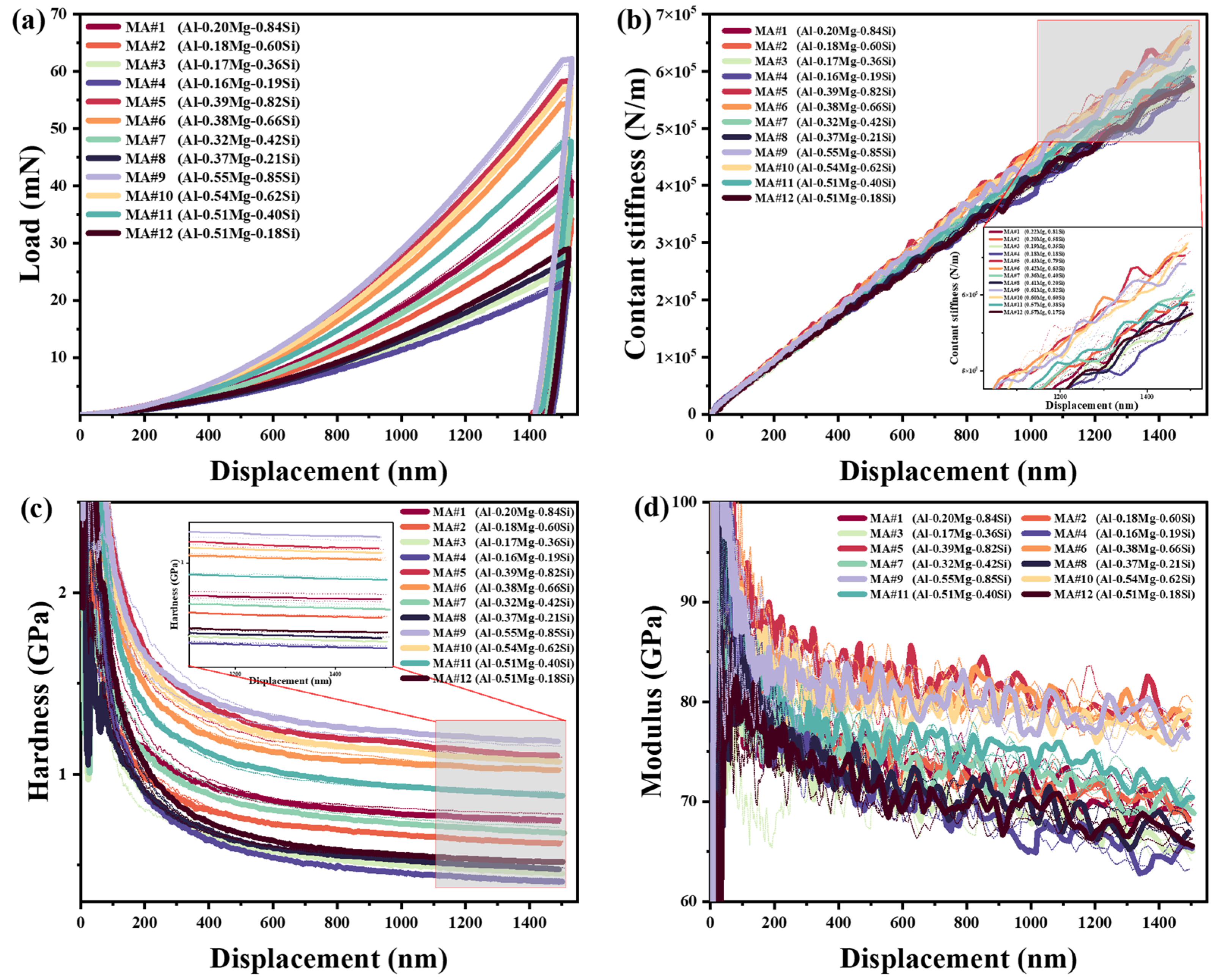

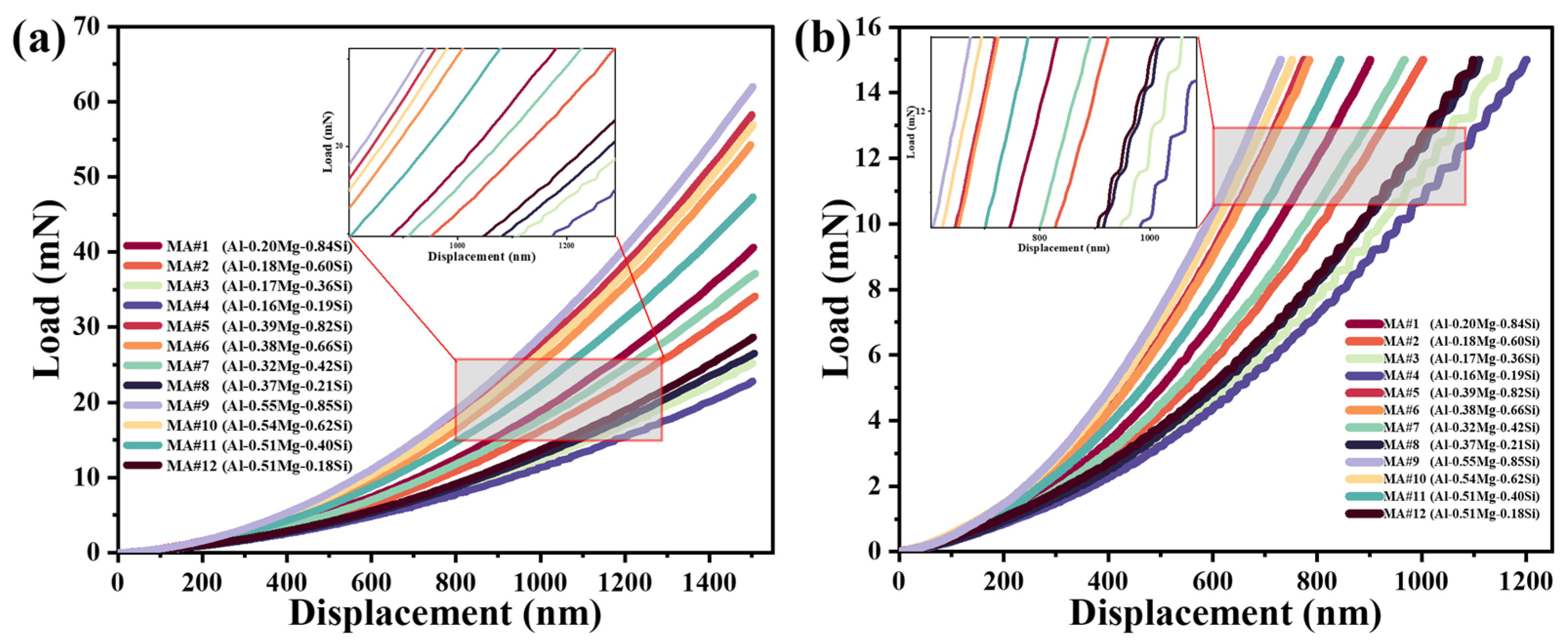

4.1. Constant Strain Rate Tests

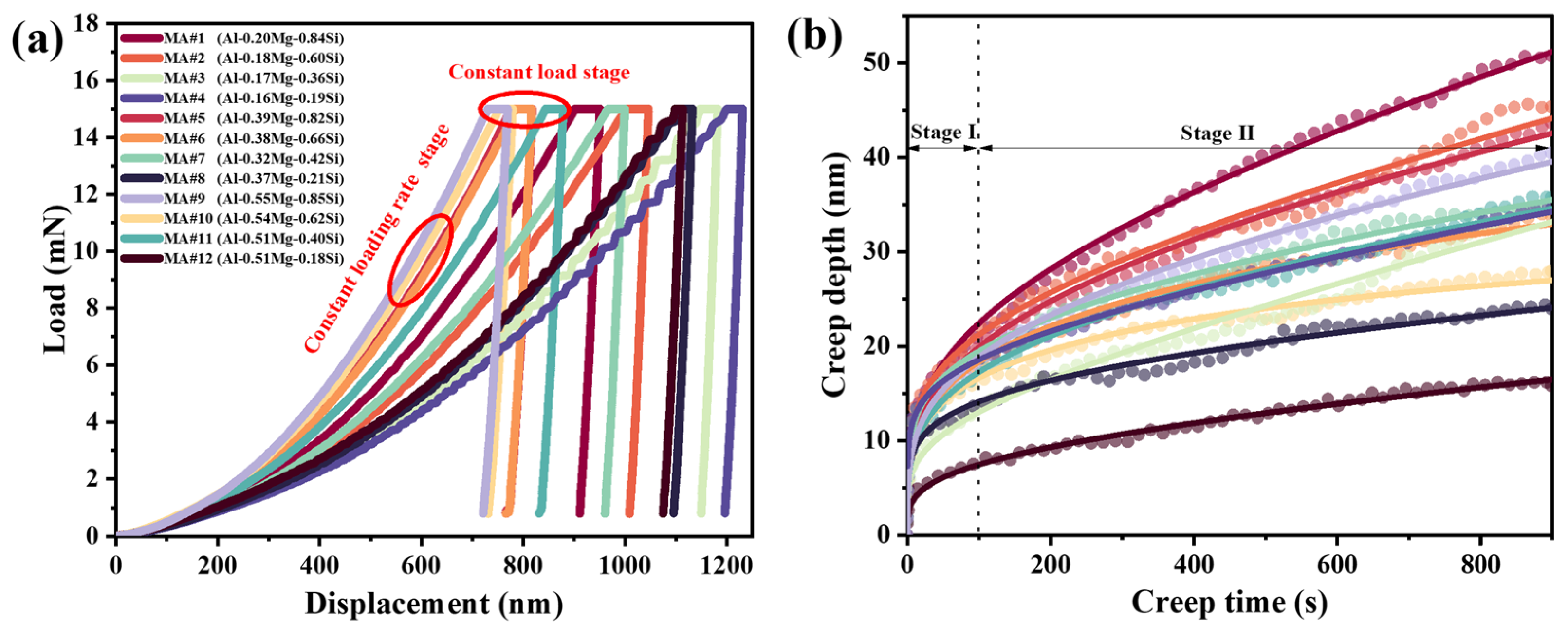

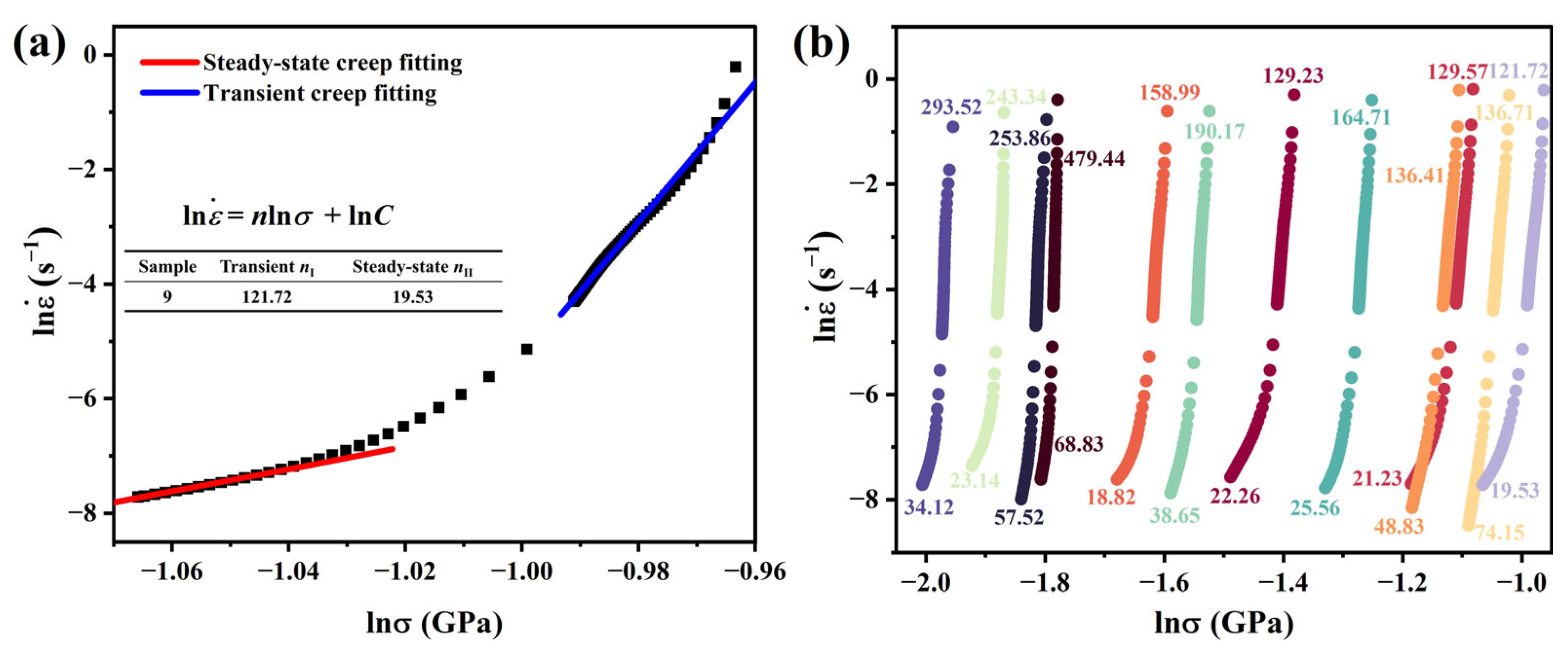

4.2. Nanoindentation Creep Tests

5. Discussion

5.1. Pop-In Effect During Loading

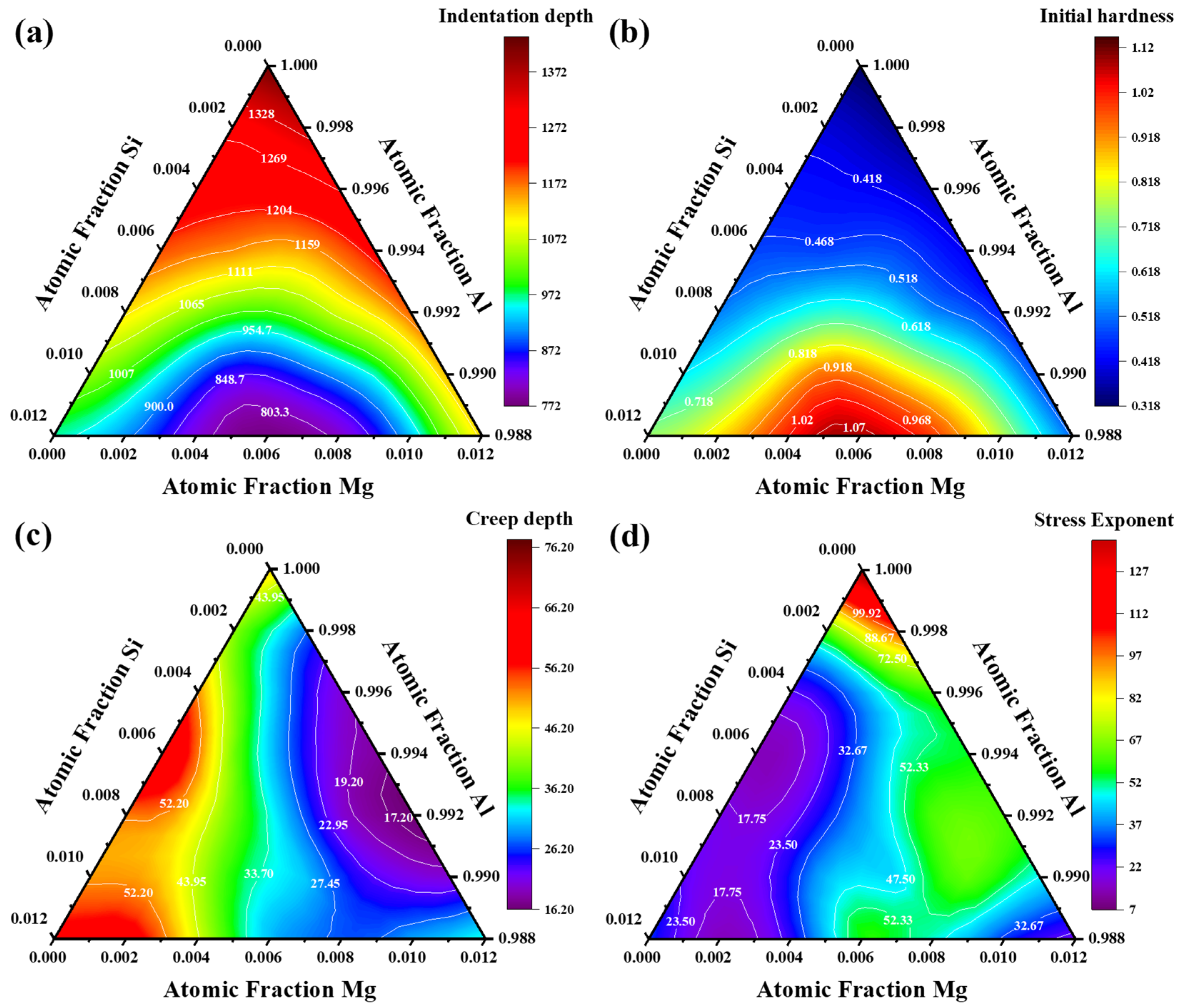

5.2. Indentation Size Effect on Hardness

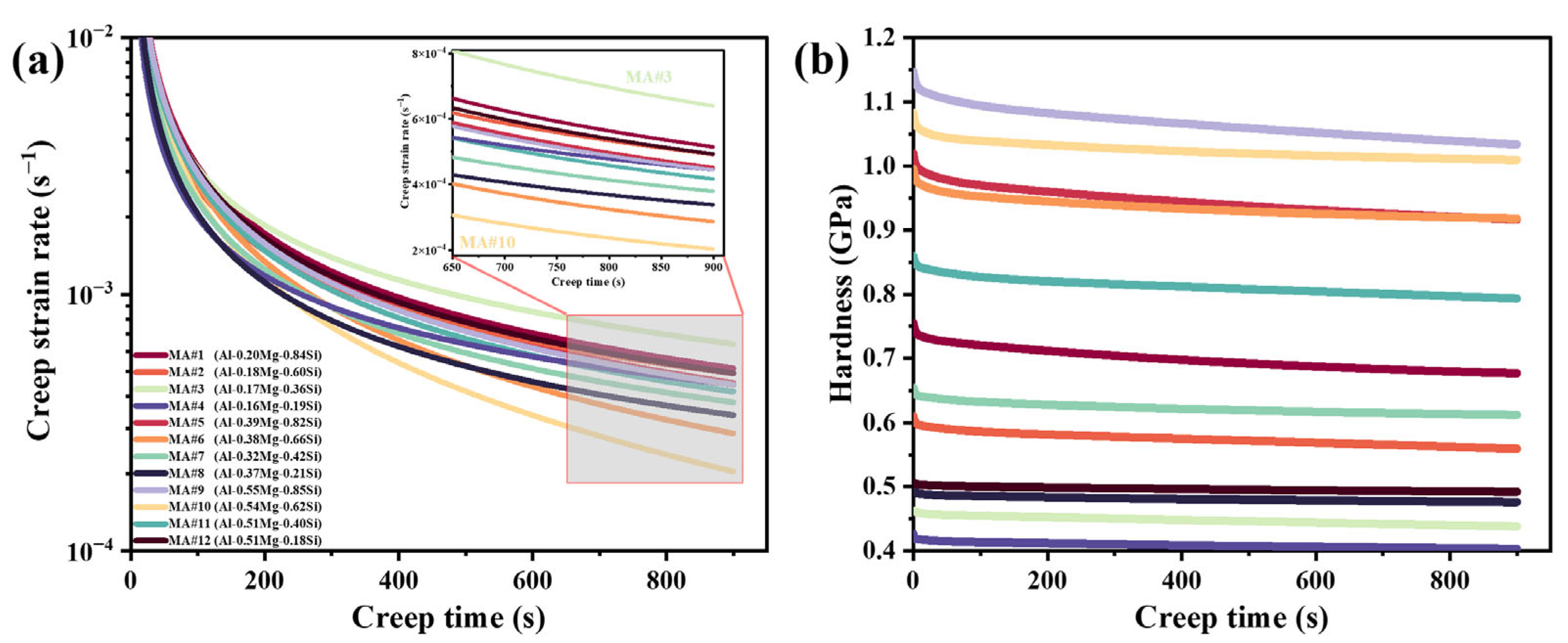

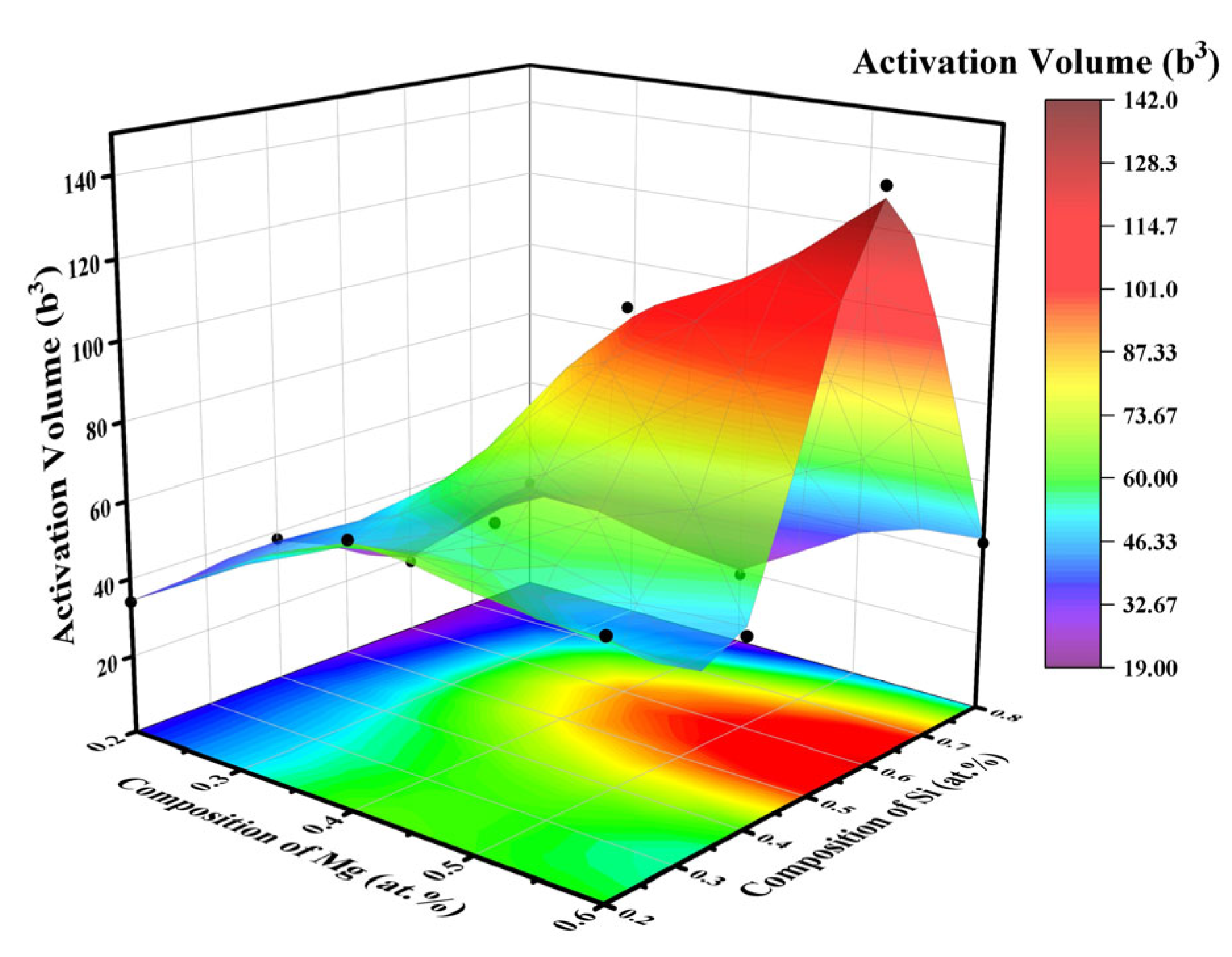

5.3. Indentation Creep Mechanisms

6. Conclusions

- Increased alloy content suppresses the occurrence and magnitude of pop-in events, indicating that higher alloying concentrations enhance obstacle density, thereby impeding dislocation motion. Although direct evidence of dislocation nucleation was not observed, the suppression of the pop-in effect can be reasonably attributed to hindered dislocation activity under higher solute concentrations. A critical Mg/Si atomic ratio threshold (~0.7–1.0) was identified, where precipitate hardening dominates over solute drag effects in suppressing pop-in.

- At larger indentation depths, the ISE is primarily governed by the density of GNDs, while the density of SSDs has minimal influence on hardness variations. Based on the Nix-Gao analysis, the corrected hardness H0 increases with Si content, suggesting that Si atoms contribute more significantly to strengthening than Mg atoms. Notably, under a constant total alloying level, an atomic Mg-to-Si ratio of approximately 1 yields the highest H0, indicating a potential synergistic effect at this composition.

- The stress exponent and activation volume suggest that dislocation motion dominates the steady-state creep stage. During the transient creep stage, high strain rates significantly increase contact stress, leading to an elevated dislocation nucleation rate and a high density of GNDs. Consequently, the nI value is much larger than nII.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Trink, B.; Weißensteiner, I.; Uggowitzer, P.J.; Strobel, K.; Hofer-Roblyek, A.; Pogatscher, S. Processing and microstructure–property relations of Al-Mg-Si-Fe crossover alloys. Acta Mater. 2023, 257, 119160. [Google Scholar] [CrossRef]

- Zhu, S.; Shih, H.-C.; Cui, X.; Yu, C.-Y.; Ringer, S.P. Design of solute clustering during thermomechanical processing of AA6016 Al–Mg–Si alloy. Acta Mater. 2021, 203, 116455. [Google Scholar] [CrossRef]

- Dong, Q.; Zhang, Y.; Wang, J.; Huang, L.; Nagaumi, H. Enhanced strength-conductivity trade-off in Al-Mg-Si alloys with optimized Mg/Si ratio. J. Alloys Compd. 2024, 970, 172682. [Google Scholar] [CrossRef]

- Zhong, H.; Rometsch, P.A.; Estrin, Y. The influence of Si and Mg content on the microstructure, tensile ductility, and stretch formability of 6xxx alloys. Metall. Mater. Trans. A 2013, 44, 3970–3983. [Google Scholar] [CrossRef]

- Jin, D.; Li, H.; Yang, C.; Han, Y.; Zhu, Z.; Miao, Y.; Xu, C.; Chen, B. The Effects of Mg and Si Contents on the Microstructure and Solidification Behavior of Dilute Al-Mg-Si-Fe Alloys. JOM 2023, 75, 4845–4857. [Google Scholar] [CrossRef]

- Kamta, P.N.; Mejias, A.; Roudet, F.; Louis, G.; Touzin, M.; Chicot, D. Indentation creep analysis of T22 and T91 chromium based steels. Mater. Sci. Eng. A 2016, 652, 315–324. [Google Scholar] [CrossRef]

- Mao, S.; Wang, C.; Li, N.; Wang, J.; Chen, Y.; Xu, G.; Guo, Y.; Cui, Y. Kinetic diffusion multiple: A high-throughput approach to screening the composition-microstructure-micromechanical properties relationships. Calphad 2018, 61, 219–226. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhu, S.; Wang, J.; Xu, G.; Chen, F.; Cui, Y. Mapping of microstructure features and micromechanical properties of Ti-xAl-yFe (x = 0–6, y = 4–10 wt.%) alloys via diffusion couple method. J. Mater. Res. Technol. 2022, 18, 3526–3540. [Google Scholar] [CrossRef]

- Wang, C.; Li, N.; Cui, Y.; Pérez-Prado, M. Effect of solutes on the rate sensitivity in Ti-xAl-yMo-zV and Ti-xAl-yMo-zCr β-Ti alloys. Scr. Mater. 2018, 149, 129–133. [Google Scholar] [CrossRef]

- Wilson, P.; Field, R.; Kaufman, M. The use of diffusion multiples to examine the compositional dependence of phase stability and hardness of the Co-Cr-Fe-Mn-Ni high entropy alloy system. Intermetallics 2016, 75, 15–24. [Google Scholar] [CrossRef]

- Gebhardt, T.; Music, D.; Takahashi, T.; Schneider, J.M. Combinatorial thin film materials science: From alloy discovery and optimization to alloy design. Thin Solid Film. 2012, 520, 5491–5499. [Google Scholar] [CrossRef]

- Babaei-Dehkordi, A.; Soltanieh, M.; Mirjalili, M.; Asherloo, M.; Mostafaei, A. Understanding Interfacial Reactions in Ti–Ni Diffusion Couple. Materials 2023, 16, 2267. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, Q.; Zhou, S.; Cui, C.; Meng, X.; Li, Z. High-Throughput Method Accelerating Design of Copper Alloys. J. Alloys Compd. 2025, 1036, 182117. [Google Scholar] [CrossRef]

- Li, N.; Wang, C.; Monclús, M.; Yang, L.; Molina-Aldareguia, J. Solid solution and precipitation strengthening effects in basal slip, extension twinning and pyramidal slip in Mg-Zn alloys. Acta Mater. 2021, 221, 117374. [Google Scholar] [CrossRef]

- Bond, T.; Badmos, A.; Ahmed, R.; Obayemi, J.; Salifu, A.; Rahbar, N.; Soboyejo, W. Indentation size effects in aluminum and titanium alloys. Mater. Sci. Eng. A 2022, 839, 142542. [Google Scholar] [CrossRef]

- Koch, S.; Abad, M.D.; Renhart, S.; Antrekowitsch, H.; Hosemann, P. A high temperature nanoindentation study of Al–Cu wrought alloy. Mater. Sci. Eng. A 2015, 644, 218–224. [Google Scholar] [CrossRef]

- Haghshenas, M.; Khalili, A.; Ranganathan, N. On room-temperature nanoindentation response of an Al–Li–Cu alloy. Mater. Sci. Eng. A 2016, 676, 20–27. [Google Scholar] [CrossRef]

- Wang, J.; Xu, G.; Zeng, X.; Llorca, J.; Cui, Y. Exploring the correlation between solvent diffusion and creep resistance of Mg-Ga HCP alloys from high throughput liquid-solid diffusion couple. Mater. Des. 2021, 197, 109243. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Yan, C.; Wang, R.; Wang, Y.; Wang, X.; Lin, Z.; Bai, G.; Zhang, Y. Size effects in indentation measurements of Zr–1Nb–0.05 Cu alloy. Mater. Sci. Eng. A 2015, 628, 50–55. [Google Scholar] [CrossRef]

- Zhu, S.; Wu, Y.; Hong, S.; Cheng, J.; Wei, Z.; Zhang, B. Room temperature nanoindentation creep behavior of CoNiCrMo-based high entropy amorphous alloy coatings prepared by HVAF. Intermetallics 2023, 163, 108076. [Google Scholar] [CrossRef]

- Barnoush, A. Correlation between dislocation density and nanomechanical response during nanoindentation. Acta Mater. 2012, 60, 1268–1277. [Google Scholar] [CrossRef]

- Wu, L.; Yao, T.; Wang, Y.; Zhang, J.; Xiao, F.; Liao, B. Understanding the mechanical properties of vanadium carbides: Nano-indentation measurement and first-principles calculations. J. Alloys Compd. 2013, 548, 60–64. [Google Scholar] [CrossRef]

- Ma, Y.; Peng, G.; Wen, D.; Zhang, T. Nanoindentation creep behavior in a CoCrFeCuNi high-entropy alloy film with two different structure states. Mater. Sci. Eng. A 2015, 621, 111–117. [Google Scholar] [CrossRef]

- Sadeghilaridjani, M.; Mukherjee, S. High-temperature nano-indentation creep behavior of multi-principal element alloys under static and dynamic loads. Metals 2020, 10, 250. [Google Scholar] [CrossRef]

- Yamada, H.; Kami, T.; Ogasawara, N. Effects of Testing Temperature on the Serration Behavior of an Al–Zn–Mg–Cu Alloy with Natural and Artificial Aging in Sharp Indentation. Metals 2020, 10, 597. [Google Scholar] [CrossRef]

- McCormigk, P. A model for the Portevin-Le Chatelier effect in substitutional alloys. Acta Metall. 1972, 20, 351–354. [Google Scholar] [CrossRef]

- Rowe, R.A.; Tajyar, A.; Munther, M.; Johanns, K.E.; Allison, P.G.; Momeni, K.; Davami, K. Nanoscale serration characteristics of additively manufactured superalloys. J. Alloys Compd. 2021, 854, 156723. [Google Scholar] [CrossRef]

- Barnoush, A.; Bies, C.; Vehoff, H. In situ electrochemical nanoindentation of FeAl (100) single crystal: Hydrogen effect on dislocation nucleation. J. Mater. Res. 2009, 24, 1105–1113. [Google Scholar] [CrossRef]

- Chen, C.-L.; Richter, A.; Thomson, R. Mechanical properties of intermetallic phases in multi-component Al–Si alloys using nanoindentation. Intermetallics 2009, 17, 634–641. [Google Scholar] [CrossRef]

- Schuh, C.A. Nanoindentation studies of materials. Mater. Today 2006, 9, 32–40. [Google Scholar] [CrossRef]

- Hale, C.; Rollings, W.; Weaver, M. Activation energy calculations for discontinuous yielding in Inconel 718SPF. Mater. Sci. Eng. A 2001, 300, 153–164. [Google Scholar] [CrossRef]

- Ziaja, W.; Motyka, M.; Poręba, M. Plasticity of nickel-based superalloy 625 at elevated temperature. Adv. Manuf. Sci. Technol. 2017, 41, 41–49. [Google Scholar]

- Somekawa, H.; Schuh, C.A. Effect of solid solution elements on nanoindentation hardness, rate dependence, and incipient plasticity in fine grained magnesium alloys. Acta Mater. 2011, 59, 7554–7563. [Google Scholar] [CrossRef]

- Huang, H.; Jiang, M.; Yan, J. New evidences for understanding the serrated flow and shear band behavior in nanoindentation of metallic glasses. J. Alloys Compd. 2021, 857, 157587. [Google Scholar] [CrossRef]

- Guo, Q.; Hou, H.; Pan, Y.; Pei, X.; Song, Z.; Liaw, P.K.; Zhao, Y. Hardening-softening of Al0. 3CoCrFeNi high-entropy alloy under nanoindentation. Mater. Des. 2023, 231, 112050. [Google Scholar] [CrossRef]

- Dhale, K.; Banerjee, N.; Outeiro, J.; Singh, R.K. Investigation of the softening behavior in severely deformed micromachined sub-surface of Zr-based bulk metallic glass via nanoindentation. J. Non-Cryst. Solids. 2022, 576, 121280. [Google Scholar] [CrossRef]

- Li, C.; Zhu, F.; Ding, J.; Yin, J.; Wang, Z.; Zhao, Y.; Kou, S. Investigation on Creep Behavior of Zr-based Bulk Metallic Glass by Nanoindentation. Rare Metal Mat. Eng. 2020, 49, 3353–3360. [Google Scholar]

- Yabuuchi, K.; Kuribayashi, Y.; Nogami, S.; Kasada, R.; Hasegawa, A. Evaluation of irradiation hardening of proton irradiated stainless steels by nanoindentation. J. Nucl. Mater. 2014, 446, 142–147. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Liang, Z.; Pharr, G. Decoupling indentation size and strain rate effects during nanoindentation: A case study in tungsten. J. Mech. Phys. Solids 2022, 165, 104935. [Google Scholar] [CrossRef]

- Hu, J.; Sun, W.; Jiang, Z.; Zhang, W.; Lu, J.; Huo, W.; Zhang, Y.; Zhang, P. Indentation size effect on hardness in the body-centered cubic coarse-grained and nanocrystalline tantalum. Mater. Sci. Eng. A 2017, 686, 19–25. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, W.; Peng, G.; Zhang, T.; Zhang, Y. Nanoindentation deformation of refine-grained AZ31 magnesium alloy: Indentation size effect, pop-in effect and creep behavior. Mater. Sci. Eng. A 2018, 725, 522–529. [Google Scholar] [CrossRef]

- Durst, K.; Backes, B.; Franke, O.; Göken, M. Indentation size effect in metallic materials: Modeling strength from pop-in to macroscopic hardness using geometrically necessary dislocations. Acta Mater. 2006, 54, 2547–2555. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Zhang, Z.-n.; Li, Y.-l.; Wu, W.-p. Effects of loading rate and peak load on nanoindentation creep behavior of DD407Ni-base single crystal superalloy. Trans. Nonferrous Met. Soc. China 2022, 32, 206–216. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Ritchie, R.O.; Meyers, M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 2019, 102, 296–345. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, W.; Ma, Y.; Huang, Y.; Tang, Y.; Cheng, F.; Yu, Q. Indentation size effect and micromechanics characterization of intermetallic compounds in the Au–Sn system. Mater. Sci. Eng. A 2014, 610, 161–170. [Google Scholar] [CrossRef]

- Xing, X.; Wang, Y.; Xiao, G.; Yu, S.; Ma, Y.; Shu, X.; Wu, Y. Rate-dependent indentation size effect on hardness and creep behavior of a titanium metallization film on alumina substrate. J. Mater. Res. Technol. 2021, 15, 4662–4671. [Google Scholar] [CrossRef]

- Fan, Q.; Gan, K.; Yan, D.; Li, Z. Nanoindentation creep behavior of diverse microstructures in a pre-strained interstitial high-entropy alloy by high-throughput mapping. Mater. Sci. Eng. A 2022, 856, 143988. [Google Scholar] [CrossRef]

- Wang, H.; Dhiman, A.; Ostergaard, H.E.; Zhang, Y.; Siegmund, T.; Kruzic, J.J.; Tomar, V. Nanoindentation based properties of Inconel 718 at elevated temperatures: A comparison of conventional versus additively manufactured samples. Int. J. Plast. 2019, 120, 380–394. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, X.; Rong, X.; Zhang, X.; Zhao, D.; He, C.; Zhao, N. Macro-and meso-mechanic investigations on the mechanical properties of heterostructured Al matrix composites featuring intragranular reinforcement. Mater. Res. Lett. 2024, 12, 408–416. [Google Scholar] [CrossRef]

- Niu, X.; Dong, G.; Li, X.; Geng, X.; Zhou, J. Effect of indentation depth and strain rate on mechanical properties of Sn0.3Ag0.7Cu. Microelectron. Reliab. 2022, 128, 114429. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, C.; Bei, H.; He, X.; Hu, W. Room temperature nanoindentation creep of nanocrystalline Cu and Cu alloys. Mater. Lett. 2012, 70, 26–29. [Google Scholar] [CrossRef]

- Yang, X.-S.; Zhai, H.-R.; Ruan, H.-H.; Shi, S.-Q.; Zhang, T.-Y. Multi-temperature indentation creep tests on nanotwinned copper. Int. J. Plast. 2018, 104, 68–79. [Google Scholar] [CrossRef]

- Ma, P.; Zhang, Z.; Liu, X.; Shi, X.; Prashanth, K.; Jia, Y. Microstructure and Nanoindentation Creep Behavior of Binary Al-Cu Alloy Synthesized at High Pressure. JOM 2023, 75, 176–183. [Google Scholar] [CrossRef]

- Xiao, Y.; Kozak, R.; Haché, M.J.; Steurer, W.; Spolenak, R.; Wheeler, J.M.; Zou, Y. Micro-compression studies of face-centered cubic and body-centered cubic high-entropy alloys: Size-dependent strength, strain rate sensitivity, and activation volumes. Mater. Sci. Eng. A 2020, 790, 139429. [Google Scholar] [CrossRef]

- Ahn, B.; Mitra, R.; Lavernia, E.J.; Nutt, S.R. Effect of grain size on strain rate sensitivity of cryomilled Al–Mg alloy. J. Mater. Sci. 2010, 45, 4790–4795. [Google Scholar] [CrossRef]

| MA | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mg (wt.%) | 0.20 | 0.18 | 0.17 | 0.16 | 0.39 | 0.38 | 0.32 | 0.37 | 0.55 | 0.54 | 0.51 | 0.51 |

| Si (wt.%) | 0.84 | 0.60 | 0.36 | 0.19 | 0.82 | 0.66 | 0.42 | 0.21 | 0.85 | 0.62 | 0.40 | 0.18 |

| Mg (at.%) | 0.22 | 0.20 | 0.19 | 0.18 | 0.43 | 0.42 | 0.36 | 0.41 | 0.61 | 0.60 | 0.57 | 0.57 |

| Si (at.%) | 0.81 | 0.58 | 0.35 | 0.18 | 0.79 | 0.63 | 0.40 | 0.20 | 0.82 | 0.60 | 0.38 | 0.17 |

| MA | Mg (wt.%) | Si (wt.%) | Mg + Si | Load (mN) |

|---|---|---|---|---|

| 4 | 0.16 | 0.19 | 0.35 | 23.29 ± 0.41 |

| 3 | 0.17 | 0.36 | 0.53 | 26.06 ± 0.74 |

| 8 | 0.37 | 0.21 | 0.58 | 26.68 ± 0.31 |

| 12 | 0.51 | 0.18 | 0.69 | 28.50 ± 0.18 |

| 7 | 0.32 | 0.42 | 0.74 | 37.81 ± 0.76 |

| 2 | 0.18 | 0.6 | 0.78 | 34.41 ± 0.28 |

| 11 | 0.51 | 0.4 | 0.91 | 47.73 ± 0.52 |

| 1 | 0.2 | 0.84 | 1.04 | 41.01 ± 1.31 |

| 6 | 0.38 | 0.66 | 1.04 | 54.62 ± 0.58 |

| 10 | 0.54 | 0.62 | 1.16 | 57.20 ± 0.45 |

| 5 | 0.39 | 0.82 | 1.21 | 58.23 ± 0.05 |

| 9 | 0.55 | 0.85 | 1.4 | 61.61 ± 0.49 |

| MA Sample | H0 (GPa) | HIni (GPa) | nI | nII | V* (b3) |

|---|---|---|---|---|---|

| 1 | 0.674 ± 0.032 | 0.751 ± 0.021 | 129.23 ± 3.21 | 22.26 ± 2.26 | 30 |

| 2 | 0.546 ± 0.002 | 0.608 ± 0.002 | 158.99 ± 2.23 | 18.82 ± 2.11 | 19 |

| 3 | 0.375 ± 0.018 | 0.462 ± 0.013 | 243.34 ± 4.19 | 23.14 ± 3.19 | 38 |

| 4 | 0.304 ± 0.016 | 0.424 ± 0.009 | 293.52 ± 3.92 | 34.12 ± 3.23 | 34 |

| 5 | 0.958 ± 0.009 | 1.016 ± 0.006 | 129.57 ± 2.57 | 21.23 ± 2.14 | 19 |

| 6 | 0.939 ± 0.015 | 0.993 ± 0.011 | 136.41 ± 1.92 | 48.83 ± 2.07 | 102 |

| 7 | 0.608 ± 0.015 | 0.654 ± 0.009 | 190.17 ± 2.17 | 38.65 ± 1.98 | 58 |

| 8 | 0.385 ± 0.016 | 0.495 ± 0.011 | 253.86 ± 2.55 | 57.52 ± 2.14 | 66 |

| 9 | 1.077 ± 0.011 | 1.147 ± 0.007 | 121.72 ± 3.01 | 19.53 ± 1.86 | 44 |

| 10 | 0.979 ± 0.012 | 1.081 ± 0.006 | 136.71 ± 2.81 | 74.15 ± 2.41 | 142 |

| 11 | 0.787 ± 0.035 | 0.858 ± 0.018 | 164.71 ± 2.13 | 25.56 ± 2.03 | 47 |

| 12 | 0.431 ± 0.014 | 0.504 ± 0.007 | 479.44 ± 3.34 | 68.83 ± 2.58 | 61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, T.; Xu, G.; Chen, F.; Zhu, S.; Cui, Y. High-Throughput Study on Nanoindentation Deformation of Al-Mg-Si Alloys. Materials 2025, 18, 3663. https://doi.org/10.3390/ma18153663

Shen T, Xu G, Chen F, Zhu S, Cui Y. High-Throughput Study on Nanoindentation Deformation of Al-Mg-Si Alloys. Materials. 2025; 18(15):3663. https://doi.org/10.3390/ma18153663

Chicago/Turabian StyleShen, Tong, Guanglong Xu, Fuwen Chen, Shuaishuai Zhu, and Yuwen Cui. 2025. "High-Throughput Study on Nanoindentation Deformation of Al-Mg-Si Alloys" Materials 18, no. 15: 3663. https://doi.org/10.3390/ma18153663

APA StyleShen, T., Xu, G., Chen, F., Zhu, S., & Cui, Y. (2025). High-Throughput Study on Nanoindentation Deformation of Al-Mg-Si Alloys. Materials, 18(15), 3663. https://doi.org/10.3390/ma18153663