Spherical Indentation Behavior of DD6 Single-Crystal Nickel-Based Superalloy via Crystal Plasticity Finite Element Simulation

Abstract

1. Introduction

2. Basic Theory of Crystal Plasticity

3. Experiments and Finite Element Modeling

3.1. Experiments

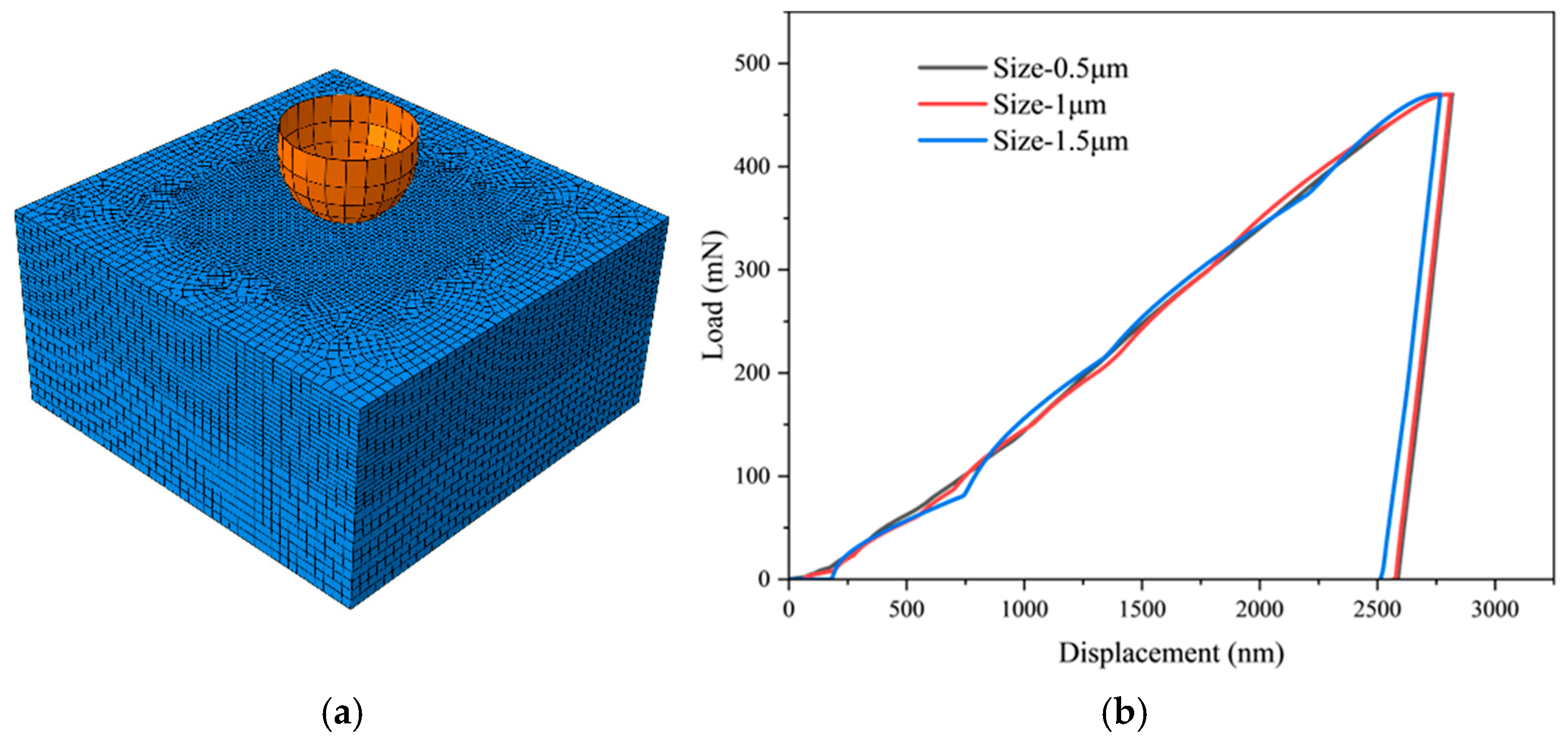

3.2. Finite Element Modeling

4. Results and Discussion

4.1. Experimental Results

4.2. Crystal Plasticity Parameters

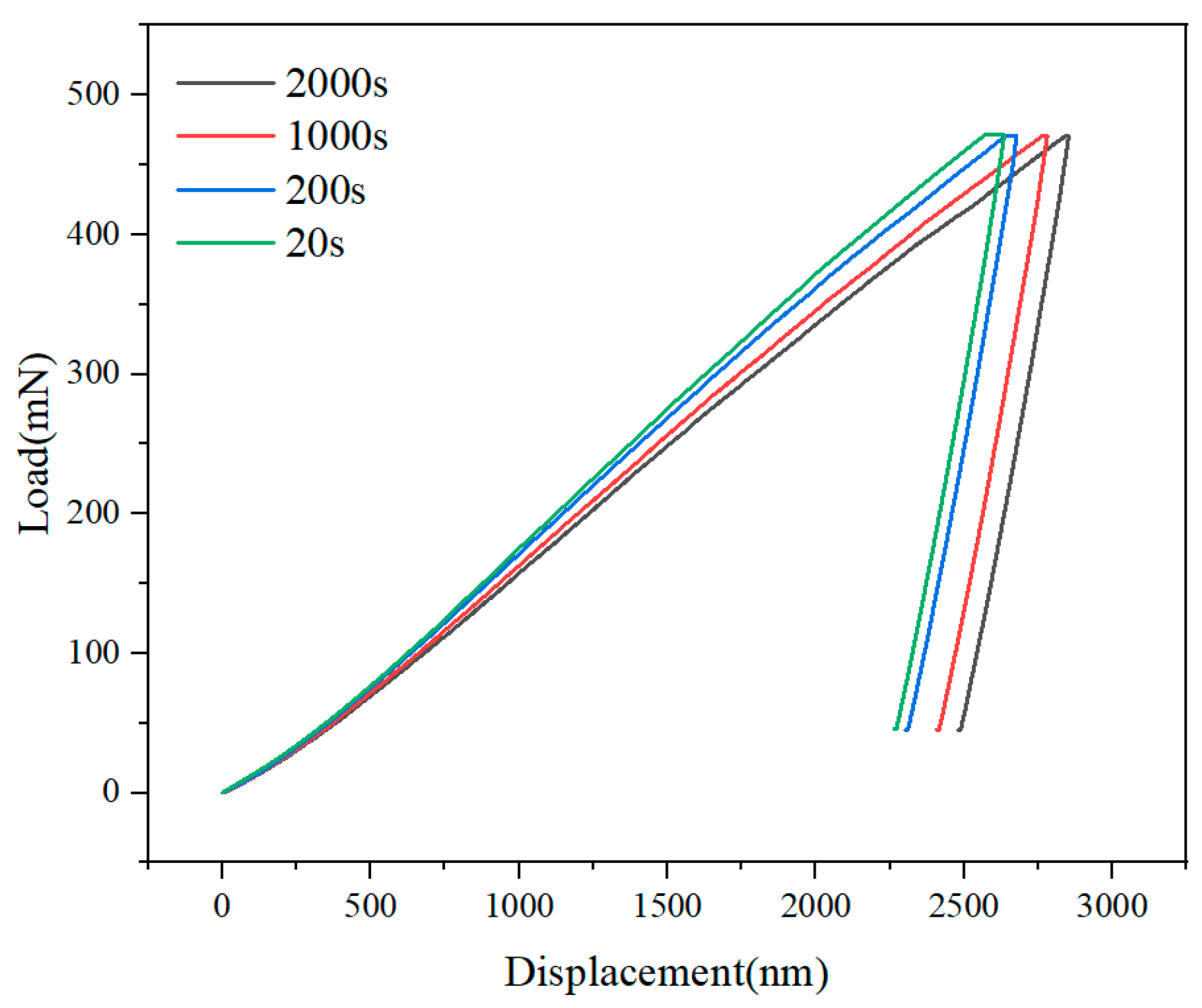

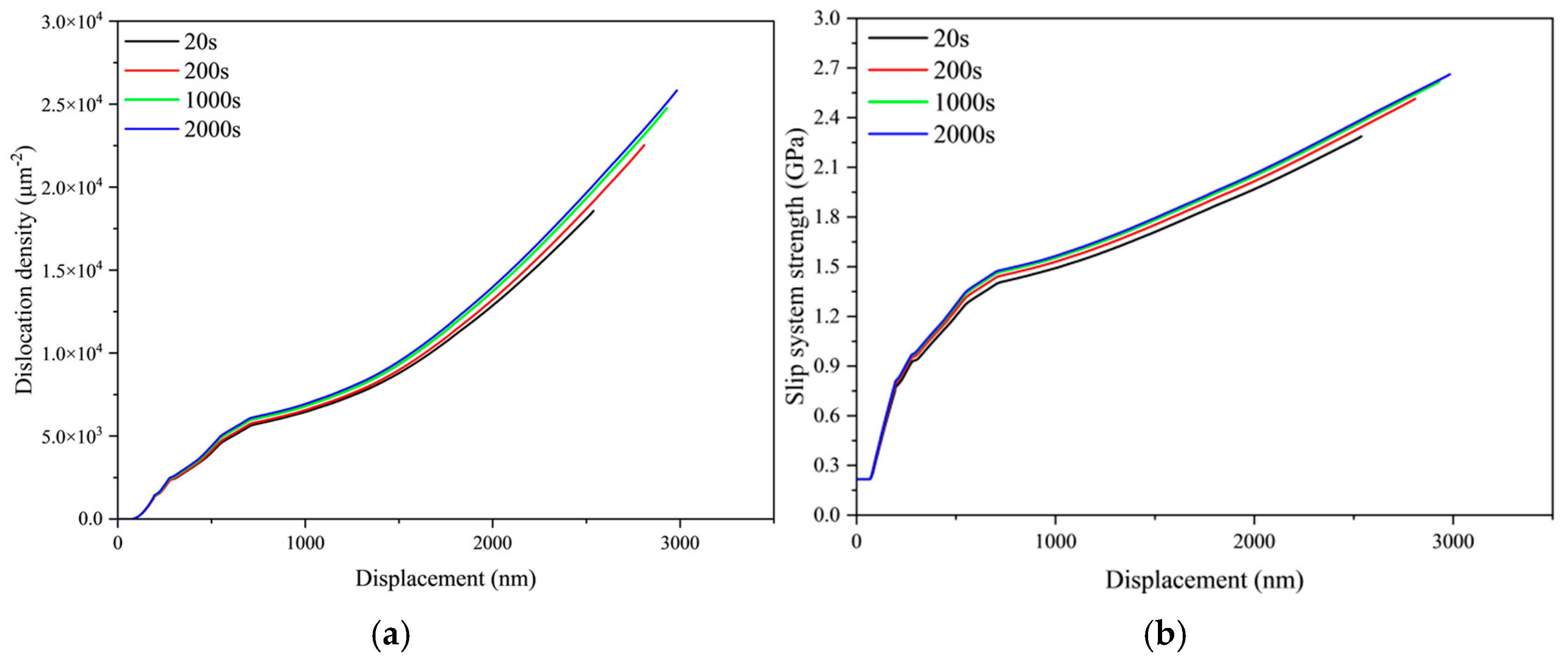

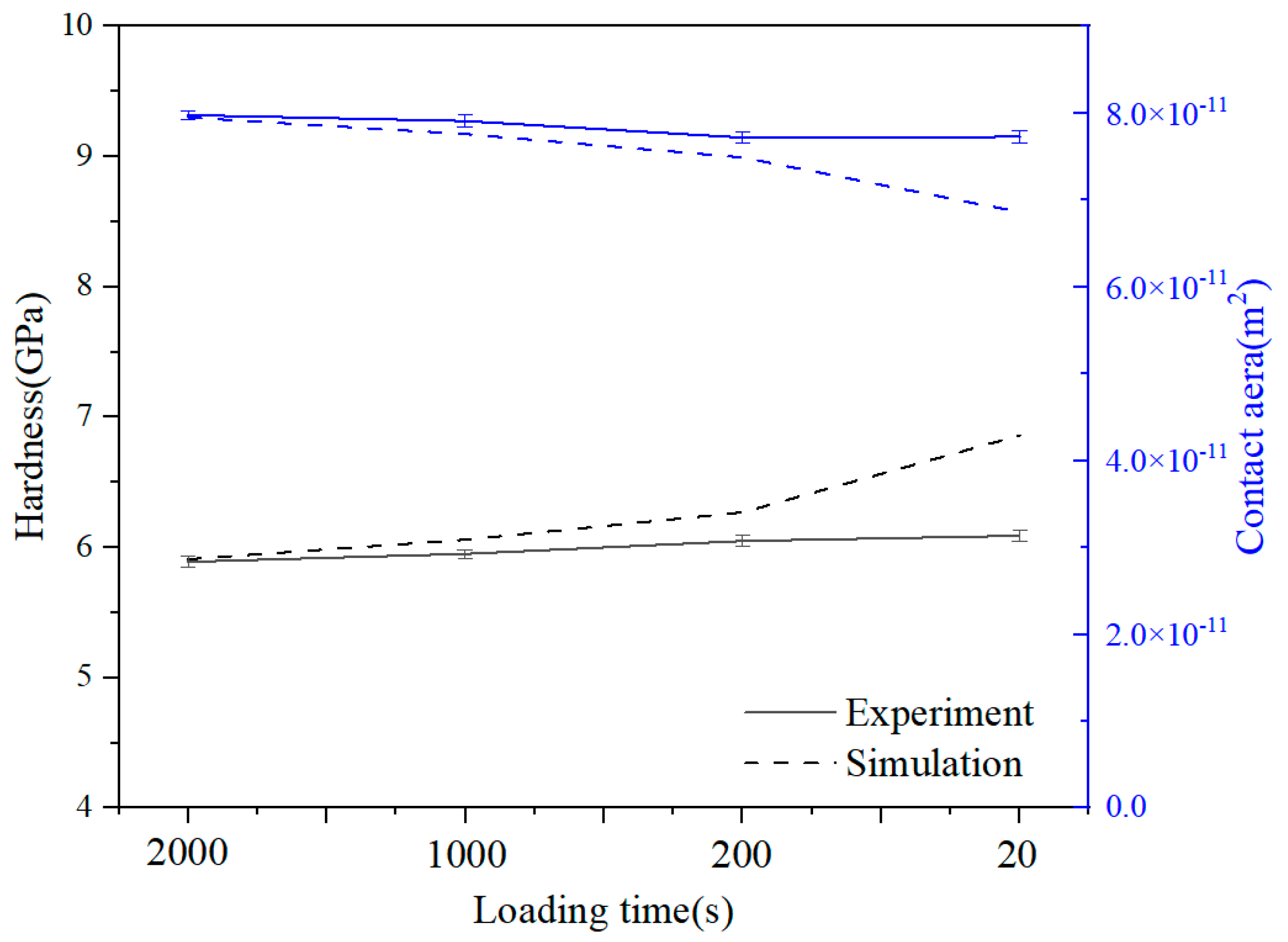

4.3. Mechanical Characterization Under Different Loading Rates

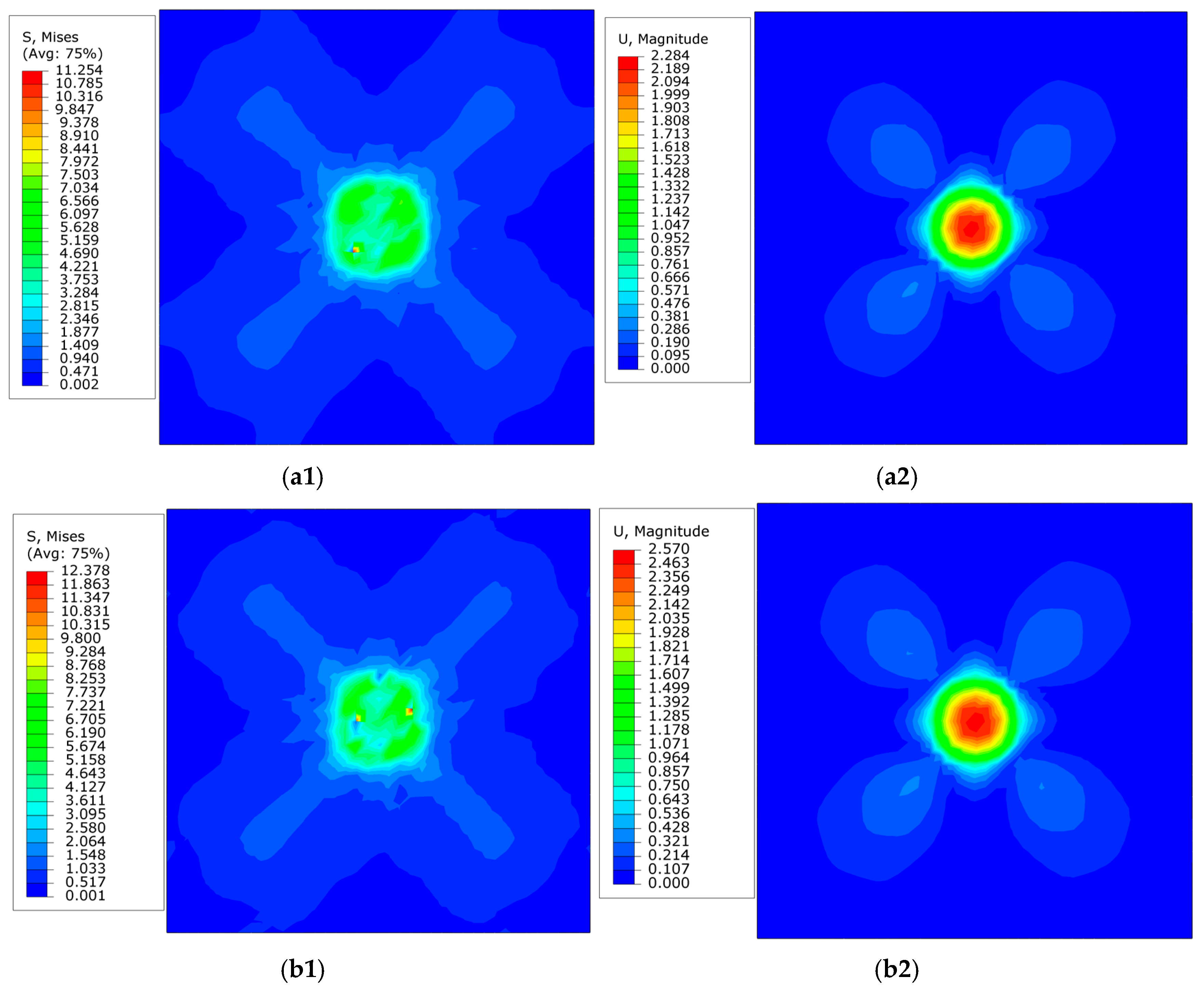

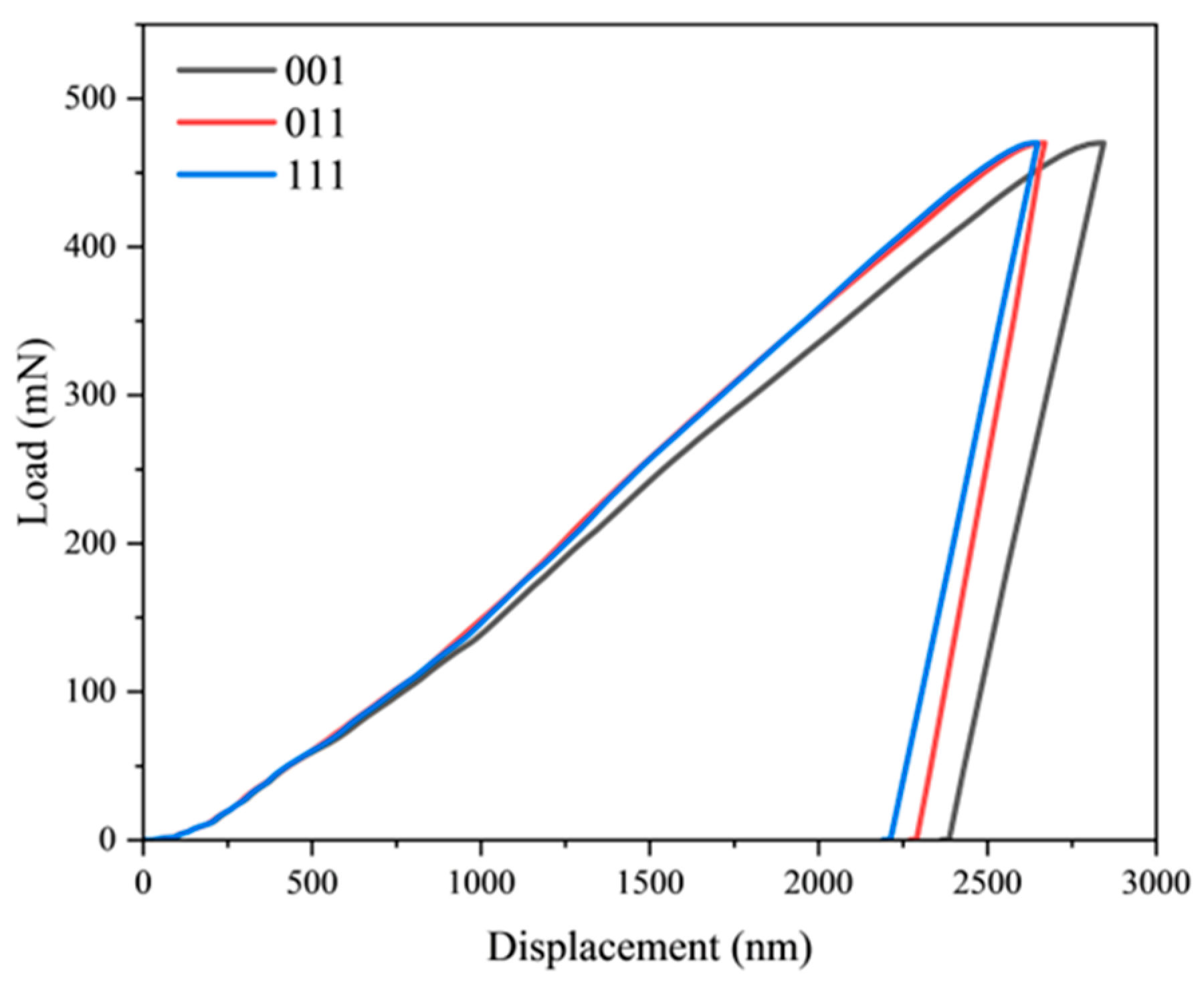

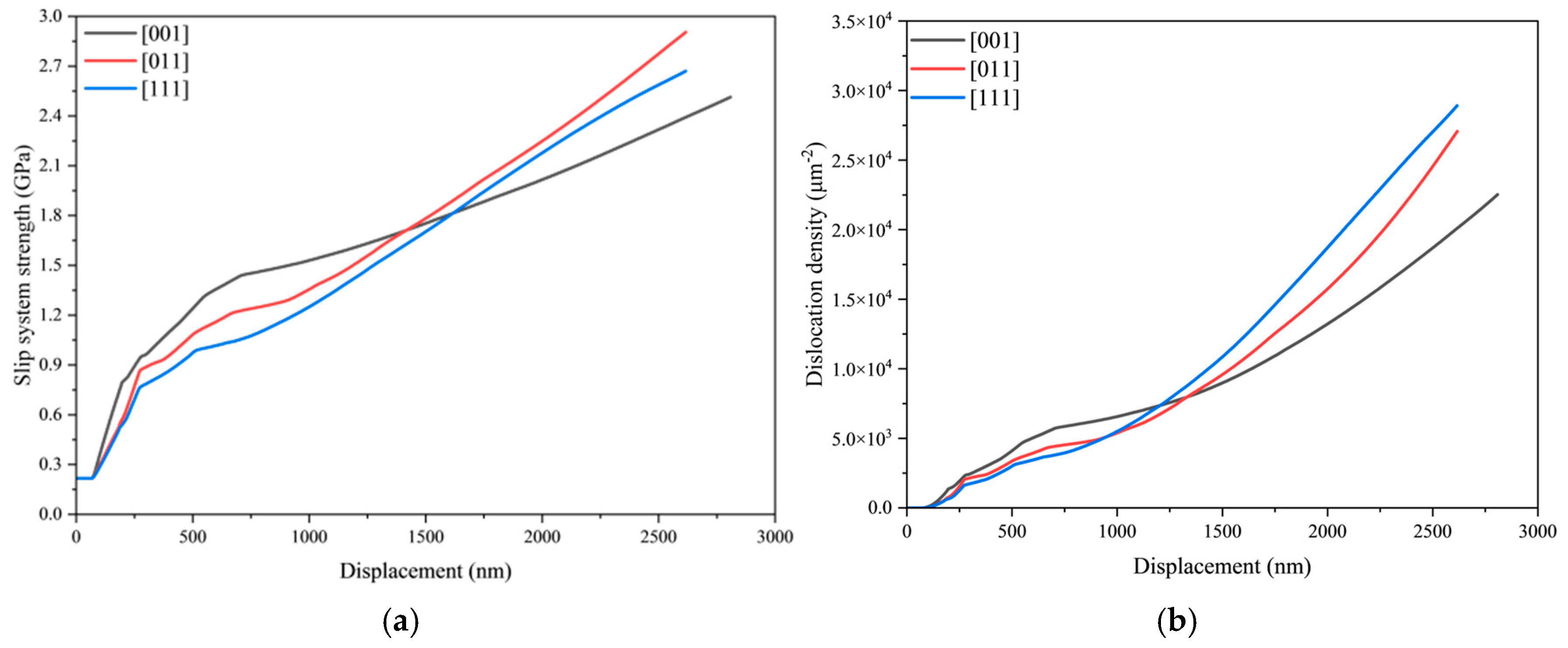

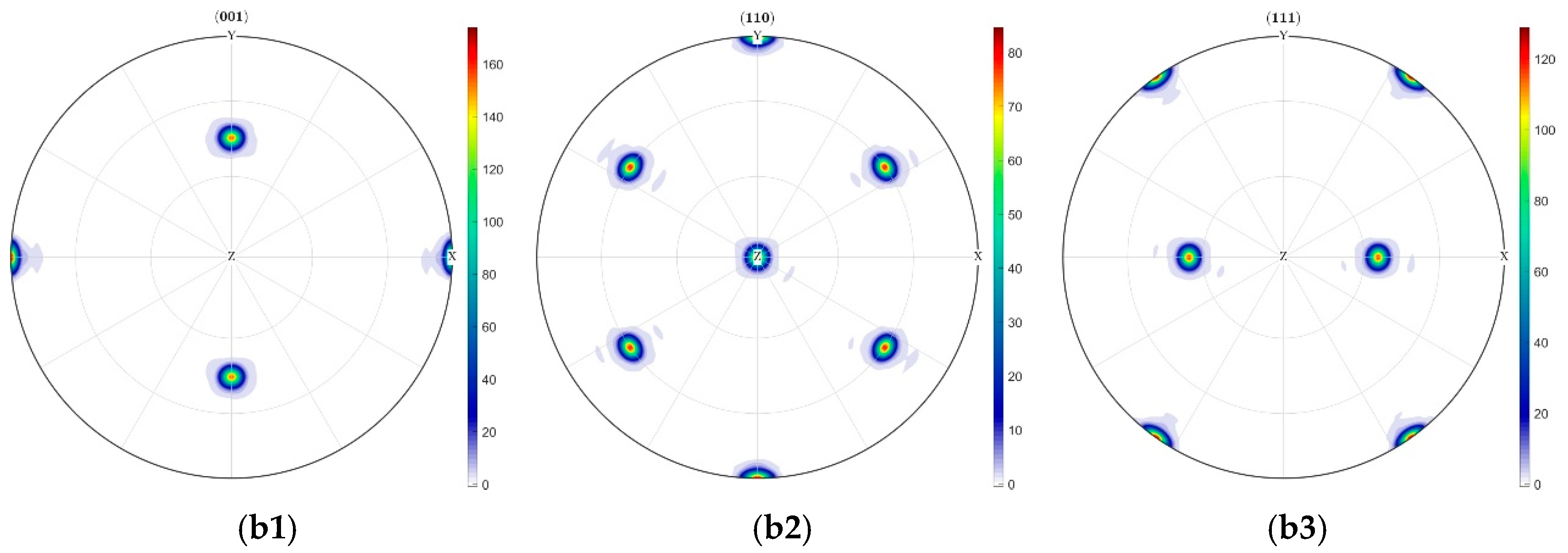

4.4. Mechanical Characterization Under Different Crystal Orientations

4.5. Hardness and Contact Area of DD6 Under Different Loading Rates and Crystal Orientations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gudivada, G.; Pandey, A.K. Recent Developments in Nickel-Based Superalloys for Gas Turbine Applications: Review. J. Alloys Compd. 2023, 963, 171128. [Google Scholar] [CrossRef]

- Shi, X.; Guo, X.; Niu, L.; Kang, R.; Dong, Z. γ-Electrochemical Selective Dissolution Surface Modification Technique for K417G Nickel-Based Superalloy: Prediction Model of Modified Layer Thickness. Mater. Today Commun. 2025, 47, 113008. [Google Scholar] [CrossRef]

- Wang, S.; Sun, F.; Liu, X.; Chen, X.; Li, J.; He, L.; Zhao, Z. A Decomposition Method for Nickel-Based Superalloys by Sulfurization: Recycling Valuable Metals. J. Alloys Compd. 2025, 1025, 180359. [Google Scholar] [CrossRef]

- Tan, Q.; Liu, K.; Li, J.; Geng, S.; Sun, L.; Skuratov, V. A Review on Cracking Mechanism and Suppression Strategy of Nickel-Based Superalloys during Laser Cladding. J. Alloys Compd. 2024, 1001, 175164. [Google Scholar] [CrossRef]

- Xu, Z.; Wu, J.; Li, E.; Wang, Z.; Tang, J.; Tao, Y. Creep State Assessment of Nickel-Based Superalloy GH4169 Using Eddy Current-TMR Testing. NDT E Int. 2025, 156, 103458. [Google Scholar] [CrossRef]

- Madigana, C.S.; Vaddula, A.; Yerramsetti, S.D.; Buddaraju, K.M. Additive Manufacturing of Titanium and Nickel-Based Superalloys: A Review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Satish, G.J.; Gaitonde, V.N.; Kulkarni, V.N. Traditional and Non-Traditional Machining of Nickel-Based Superalloys: A Brief Review. Mater. Today Proc. 2021, 44, 1448–1454. [Google Scholar] [CrossRef]

- Gai, Y.; Zhang, R.; Yang, J.; Cui, C.; Qu, J. Effects of Heat Treatment on γ′ Precipitates and Tensile Properties of a Ni-Base Superalloy. Mater. Sci. Eng. A 2022, 842, 143079. [Google Scholar] [CrossRef]

- Ma, Z.; Gamage, R.P.; Zhang, C. Application of Nanoindentation Technology in Rocks: A Review. Geomech. Geophys. GeoEnergy GeoResour. 2020, 6, 60. [Google Scholar] [CrossRef]

- Bouchikhi, A.; Amar, M.; Arroug, L.; el Mahdi Safhi, A.; Haddaji, Y. Characterizing Nano-Indentation and Microstructural Properties of Mine Tailings-Based Geopolymers. Case Stud. Constr. Mater. 2024, 21, e03899. [Google Scholar] [CrossRef]

- Xu, W.; Tang, Z.; Xie, Y.; Long, G.; Luo, Z.; Kai, M.; Ma, G.; Zaland, S. Recent Advances and Insights in Nanoindentation Technique in the Characterization of Cement-Based Materials. J. Build. Eng. 2023, 80, 108022. [Google Scholar] [CrossRef]

- Guo, D.; Zhou, F.; Xu, B.; Wang, Y. Indentation Creep Characterization of Plasma-Sprayed Nanostructured La2(Zr0.75Ce0.25)2O7 Thermal Barrier Coatings. Ceram. Int. 2023, 49, 38382–38385. [Google Scholar] [CrossRef]

- Ji, X.; Xiao, G.; Lu, P.; Hao, X.; Fan, X. Characterization of Power-Law Constitutive Relationship of Nickel-Based Single Crystal Superalloys under Different Loading Rates by Nanoindentation with Different Types of Indenters. Int. J. Solids Struct. 2022, 259, 112025. [Google Scholar] [CrossRef]

- Wang, J.; Liang, J.; Wen, Z.; Yue, Z.; Peng, Y. Unveiling the Local Deformation Behavior of Typical Microstructures of Nickel-Based Single Crystals under Nanoindentation. Mech. Mater. 2022, 166, 104204. [Google Scholar] [CrossRef]

- Rezaee-Hajidehi, M.; Sadowski, P.; Stupkiewicz, S. Indentation-Induced Deformation Twinning in Magnesium: Phase-Field Modeling of Microstructure Evolution and Size Effects. J. Magnes. Alloys 2025, 13, 1721–1742. [Google Scholar] [CrossRef]

- Liu, D.; Ma, Z.; Zhao, H.; Ren, L.; Zhang, W. Nano-Indentation of Biomimetic Artificial Bone Material Based on Porous Ti6Al4V Substrate with Fe22Co22Ni22Ti22Al12 High Entropy Alloy Coating. Mater. Today Commun. 2021, 28, 102659. [Google Scholar] [CrossRef]

- Ali, M.E.S.; El-Houte, S.; Ibrahim, O.H.; Othman, K.I. Asymmetric Indentation: Problem and Solution. SN Appl. Sci. 2023, 5, 358. [Google Scholar] [CrossRef]

- Yang, P.Q.; Zhang, X.P.; Yao, Z.Q.; Shivpuri, R. Investigation on the Crystal Plasticity of α Phase Ti-6Al-4V Based on Nano-Indentation Simulation and Experiment. Mater. Charact. 2023, 203, 113074. [Google Scholar] [CrossRef]

- Mukherjee, R.; Misra, S. Nanomechanics of Minerals: Understandings and Developments through Instrumented Nanoindentation Techniques. Phys. Chem. Miner. 2023, 50, 10. [Google Scholar] [CrossRef]

- Shimanek, J.D.; Liu, Z.K.; Beese, A.M. Effects of Misorientation on Single Crystal Plasticity by Finite Element Methods. Comput. Mater. Sci. 2024, 237, 112879. [Google Scholar] [CrossRef]

- Wang, D.; Fan, Q.; Cheng, X.; Zhou, Y.; Shi, R.; Qian, Y.; Yang, L. Texture evolution and slip mode of a Ti-5.5 Mo-7.2 Al-4.5 Zr-2.6 Sn-2.1 Cr dual-phase alloy during cold rolling based on multiscale crystal plasticity finite element model. J. Mater. Sci. Technol. 2022, 111, 76–87. [Google Scholar] [CrossRef]

- Zhao, Q.; Wahab, M.A.; Ling, Y.; Liu, Z. Grain-Orientation Induced Stress Formation in AA2024 Monocrystal and Bicrystal Using Crystal Plasticity Finite Element Method. Mater. Des. 2021, 206, 109794. [Google Scholar] [CrossRef]

- Wu, J.; Zhao, H.; Wang, Y.; Lin, J.; Xiao, G.; Liu, E.; Shen, Q.; Yang, X. Micro Mechanical Property Investigations of Ni-Based High-Temperature Alloy GH4169 Based on Nanoindentation and CPFE Simulation. Int. J. Solids Struct. 2022, 258, 111999. [Google Scholar] [CrossRef]

- Han, Q.-N.; Rui, S.-S.; Qiu, W.; Su, Y.; Ma, X.; Su, Z.; Cui, H.; Shi, H. Effect of Crystal Orientation on the Indentation Behaviour of Ni-Based Single Crystal Superalloy. Mater. Sci. Eng. A 2020, 773, 773. [Google Scholar] [CrossRef]

- Zhou, X.; Zan, S.; Zeng, Y.; Guo, R.; Wang, G.; Wang, T.; Zhao, L.; Chen, M. Comprehensive Study of Plastic Deformation Mechanism of Polycrystalline Copper Using Crystal Plasticity Finite Element. J. Mater. Res. Technol. 2024, 30, 9221–9236. [Google Scholar] [CrossRef]

- Khan, R.; Pervez, T.; Alfozan, A.; Qamar, S.Z.; Mohsin, S. Numerical Modeling and Simulations of Twinning-Induced Plasticity Using Crystal Plasticity Finite Element Method. Crystals 2022, 12, 930. [Google Scholar] [CrossRef]

- Ni, W.; Cheng, Y.T.; Cheng, C.M. An Energy-Based Method for Analyzing Instrumented Spherical Indentation Experiments. J. Mater. Res. 2004, 19, 149–157. [Google Scholar] [CrossRef]

- Zhou, G.; Hu, Y.; Cao, Z.; Lee, M.G.; Li, D. A Physics-Constrained Neural Network for Crystal Plasticity Modelling of FCC Materials. Scr. Mater. 2024, 241, 115861. [Google Scholar] [CrossRef]

- Mao, Y.; Keshavarz, S.; Kilic, M.N.T.; Wang, K.; Li, Y.; Reid, A.C.; Liao, W.; Choudhary, A.; Agrawal, A. A Deep Learning-Based Crystal Plasticity Finite Element Model. Scr. Mater. 2025, 254, 116315. [Google Scholar] [CrossRef]

- Zheng, Z.; Xie, C.; Chen, J.; Huang, Z. A Crystal Plasticity Model of Low Cycle Fatigue Damage Considering Dislocation Density, Stress Triaxiality and Lode Parameter. Int. J. Fatigue 2023, 175, 107823. [Google Scholar] [CrossRef]

- Srivastava, A.; Needleman, A. Non-Schmid Continuum Slip Crystal Plasticity with Implications for Dissipation Rate. J. Mech. Phys. Solids 2025, 194, 105928. [Google Scholar] [CrossRef]

- Paudel, Y.; Giri, D.; Priddy, M.W.; Barrett, C.D.; Inal, K.; Tschopp, M.A.; Rhee, H.; El Kadiri, H. A Review on Capturing Twin Nucleation in Crystal Plasticity for Hexagonal Metals. Metals 2021, 11, 1373. [Google Scholar] [CrossRef]

- Han, X.; Li, S.; Sun, C.; Lu, S. Modelling Micropit Formation in Rolling Contact Fatigue of Bearings with a Crystal Plasticity Damage Theory Coupled with Cohesive Finite Elements. Eng. Fract. Mech. 2024, 297, 109873. [Google Scholar] [CrossRef]

- Pandre, S.; Pandre, S.; Mhatre, V.; Kotkunde, N.; Singh, S.K. Strain Hardening Behavior of DP 590 Steel Using Dislocation Density Based Kock-Mecking Model. Mater. Today Proc. 2021, 46, 9323–9327. [Google Scholar] [CrossRef]

- Liu, E.; You, M.; Zhao, H.; Wu, J.; Yang, X.; Xiao, G.; Lin, J. Research on the Heterogeneous Deformation Behavior of Nickel Base Alloy Based on CPFEM. Cryst. Res. Technol. 2024, 59, 2400170. [Google Scholar] [CrossRef]

| wt.% (Cr) | wt.% (Co) | wt.% (W) | wt.% (Mo) | wt.% (Al) |

| 0.8~4.8 | 8.5~9.5 | 7.0~9.0 | 1.5~0.5 | 5.2~6.2 |

| wt.% (Nb) | wt.% (Ta) | wt.% (Re) | wt.% (Hf) | wt.% (Ni) |

| 0~1.2 | 6.0~8.5 | 1.6~0.4 | 0.05~0.1 | Residuals |

| Loading Time (s) | H (GPa) | Ac (m2) |

|---|---|---|

| 2000 | 5.89 ± 0.042 | 7.98 × 10−11 ± 5 × 10−13 |

| 1000 | 5.95 ± 0.031 | 7.91 × 10−11 ± 7 × 10−13 |

| 200 | 6.05 ± 0.041 | 7.72 × 10−11 ± 6 × 10−13 |

| 20 | 6.09 ± 0.045 | 7.73 × 10−11 ± 7 × 10−13 |

| Symbol | Description | Valve | Unit |

|---|---|---|---|

| Elastic constant | 200 | MPa | |

| Elastic constant | 138 | MPa | |

| Elastic constant | 46 | MPa | |

| n | Rate sensitivity coefficient | 25 | - |

| Reference strain rate on α slip system | 0.0005 | s−1 | |

| Initial dislocation density | 5000 | mm−2 | |

| Critical shear stress | 215 | MPa | |

| Burgers vector magnitude | 2.53 × 10−7 | mm | |

| Shear modulus | 106.21 | MPa | |

| Multiplication coefficient of dislocation | 305,000 | mm−1 | |

| Annihilation coefficient of dislocation | 2 | - |

| Loading Time (s) | H (GPa) | Ac (m2) |

|---|---|---|

| 2000 | 5.91 | 7.95 × 10−11 |

| 1000 | 6.06 | 7.76 × 10−11 |

| 200 | 6.27 | 7.49 × 10−11 |

| 20 | 6.86 | 6.86 × 10−11 |

| 200-(011) | 6.07 | 7.11 × 10−11 |

| 200-(111) | 6.57 | 7.15 × 10−11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, X.; Zhang, P.; Xing, H.; You, M.; Liu, E.; Xing, X.; Xiao, G.; Tian, Y. Spherical Indentation Behavior of DD6 Single-Crystal Nickel-Based Superalloy via Crystal Plasticity Finite Element Simulation. Materials 2025, 18, 3662. https://doi.org/10.3390/ma18153662

Hao X, Zhang P, Xing H, You M, Liu E, Xing X, Xiao G, Tian Y. Spherical Indentation Behavior of DD6 Single-Crystal Nickel-Based Superalloy via Crystal Plasticity Finite Element Simulation. Materials. 2025; 18(15):3662. https://doi.org/10.3390/ma18153662

Chicago/Turabian StyleHao, Xin, Peng Zhang, Hao Xing, Mengchun You, Erqiang Liu, Xuegang Xing, Gesheng Xiao, and Yongxi Tian. 2025. "Spherical Indentation Behavior of DD6 Single-Crystal Nickel-Based Superalloy via Crystal Plasticity Finite Element Simulation" Materials 18, no. 15: 3662. https://doi.org/10.3390/ma18153662

APA StyleHao, X., Zhang, P., Xing, H., You, M., Liu, E., Xing, X., Xiao, G., & Tian, Y. (2025). Spherical Indentation Behavior of DD6 Single-Crystal Nickel-Based Superalloy via Crystal Plasticity Finite Element Simulation. Materials, 18(15), 3662. https://doi.org/10.3390/ma18153662