Cryogenic Tensile Strength of 1.6 GPa in a Precipitation-Hardened (NiCoCr)99.25C0.75 Medium-Entropy Alloy Fabricated via Laser Powder Bed Fusion

Abstract

1. Introduction

2. Experimental Methods

Material Preparation

3. Results and Discussion

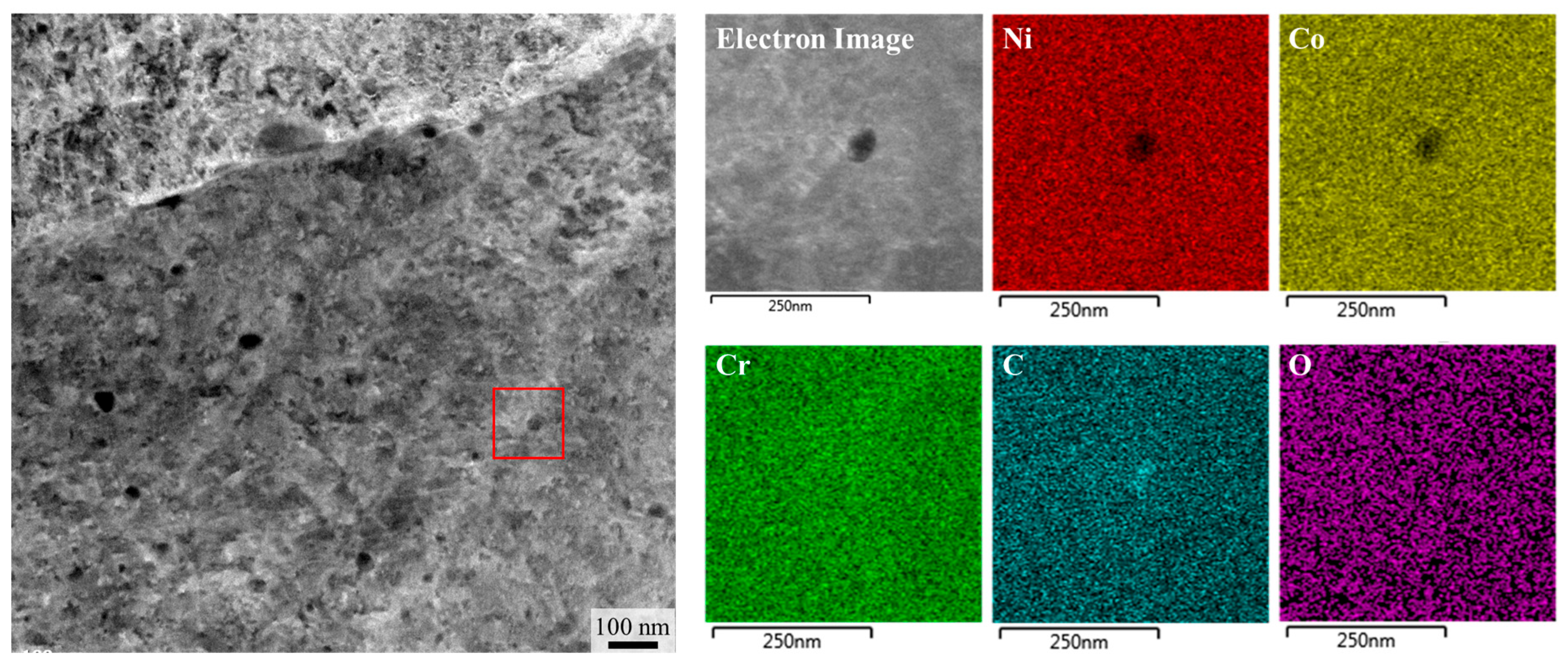

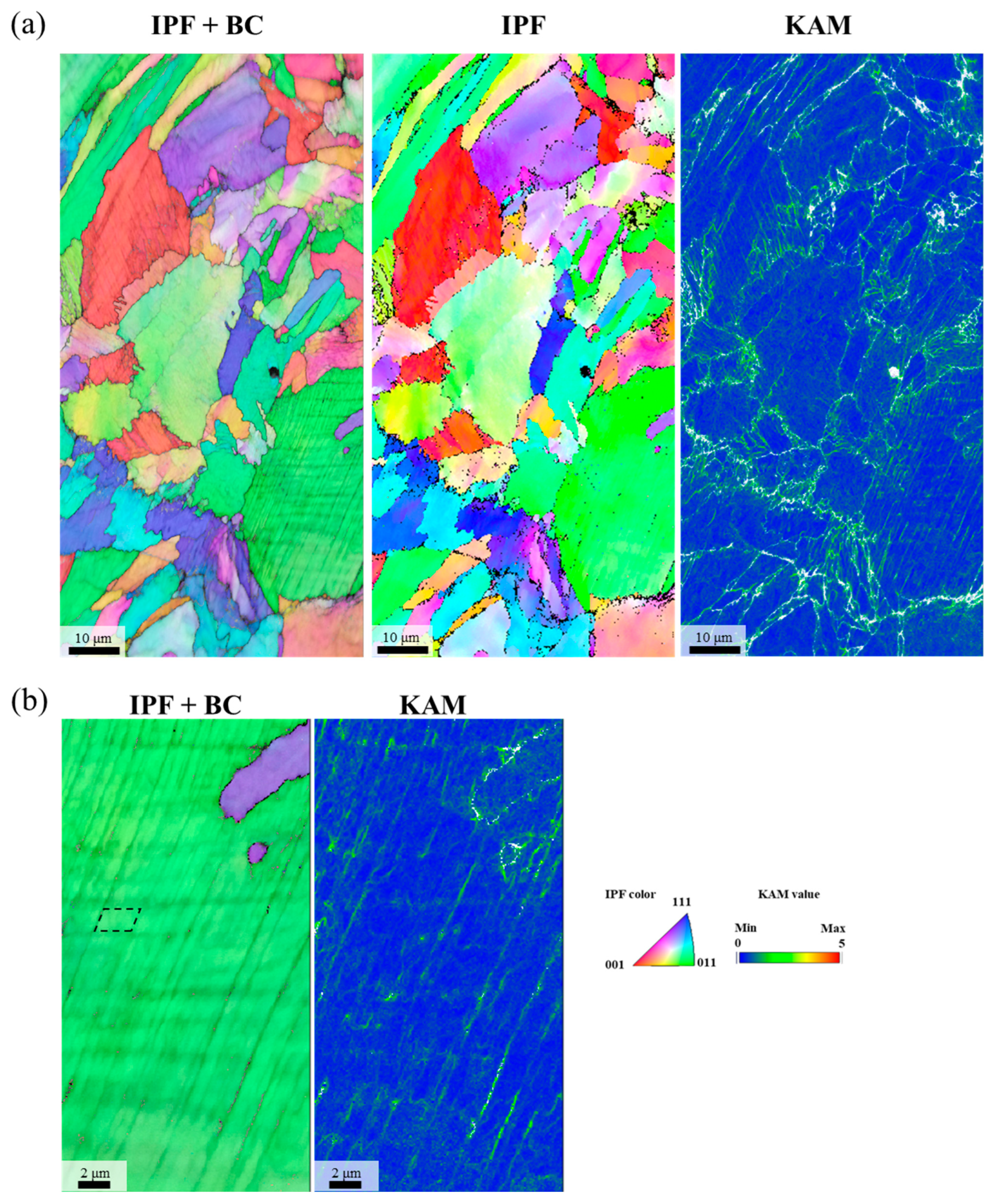

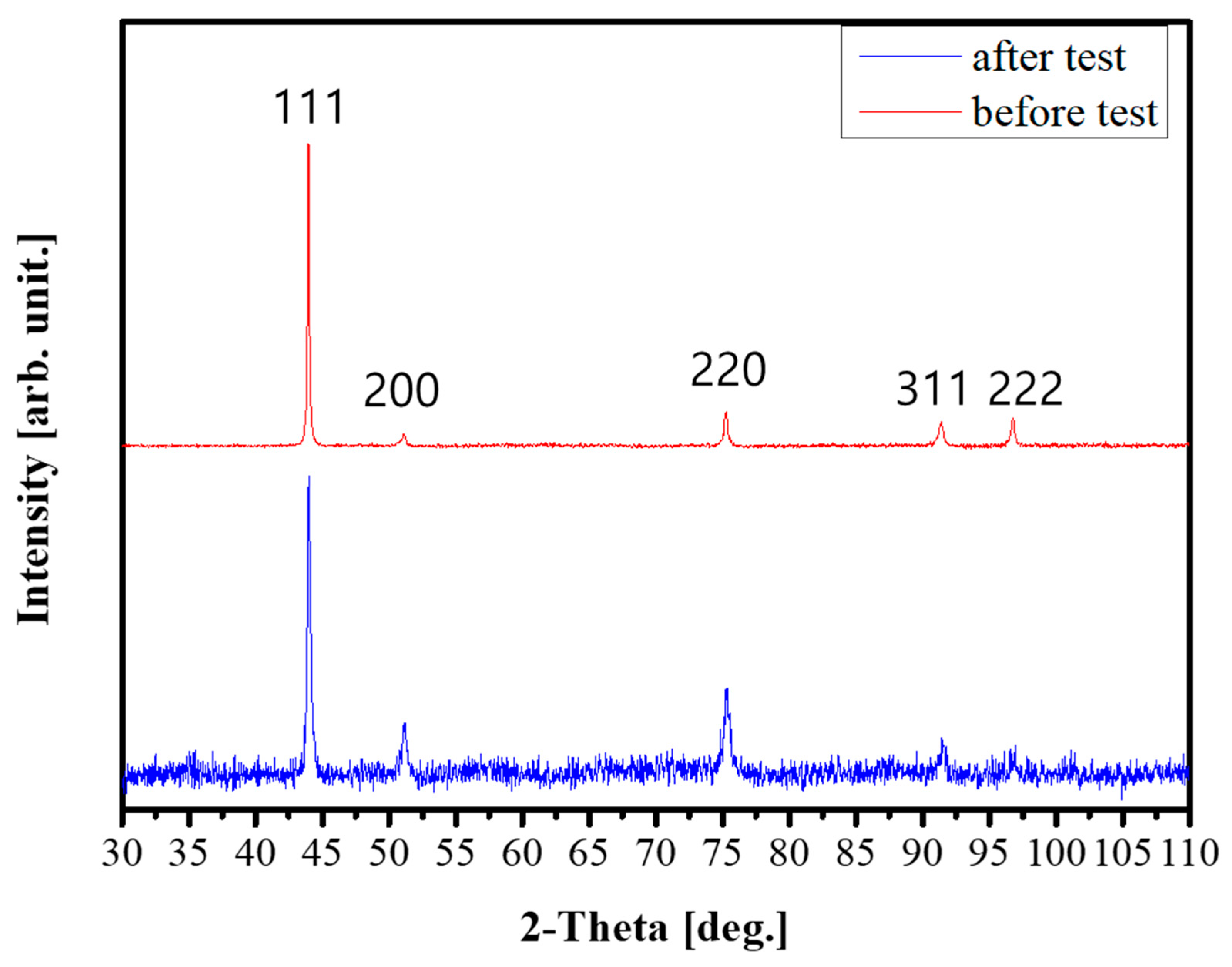

3.1. Microstructure Observation and Analysis Results

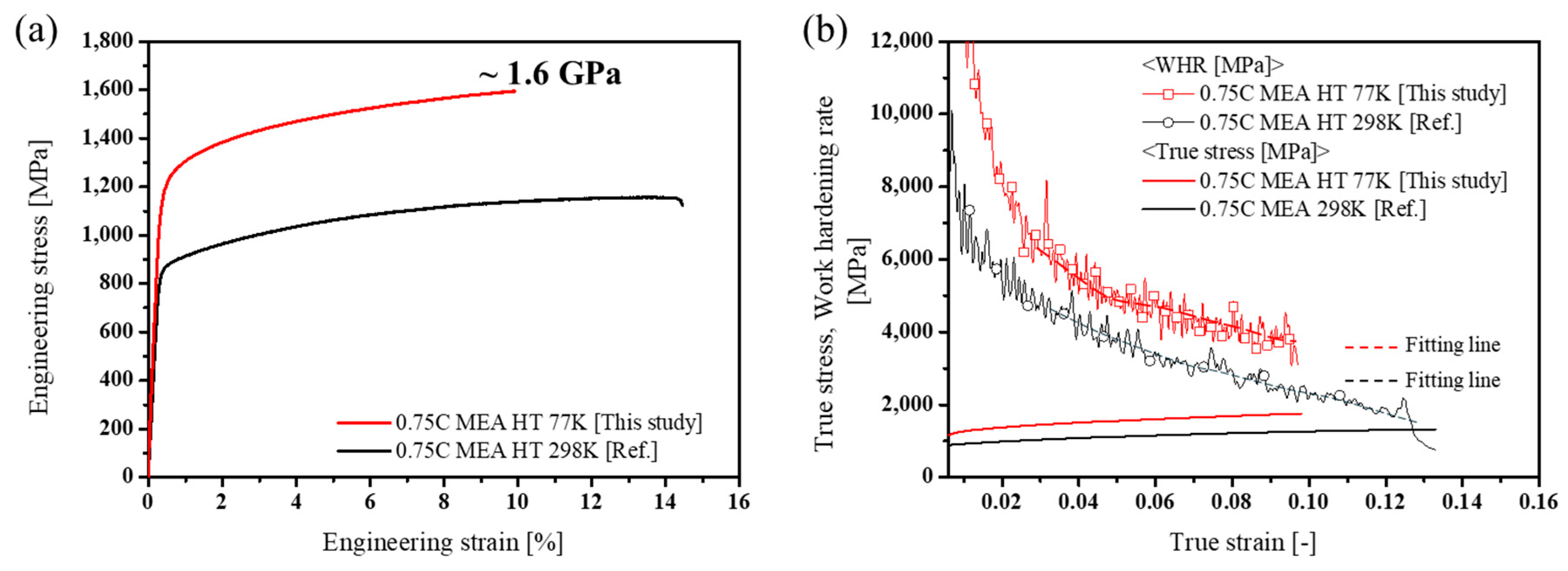

3.2. Cryogenic Tensile Mechanical Property

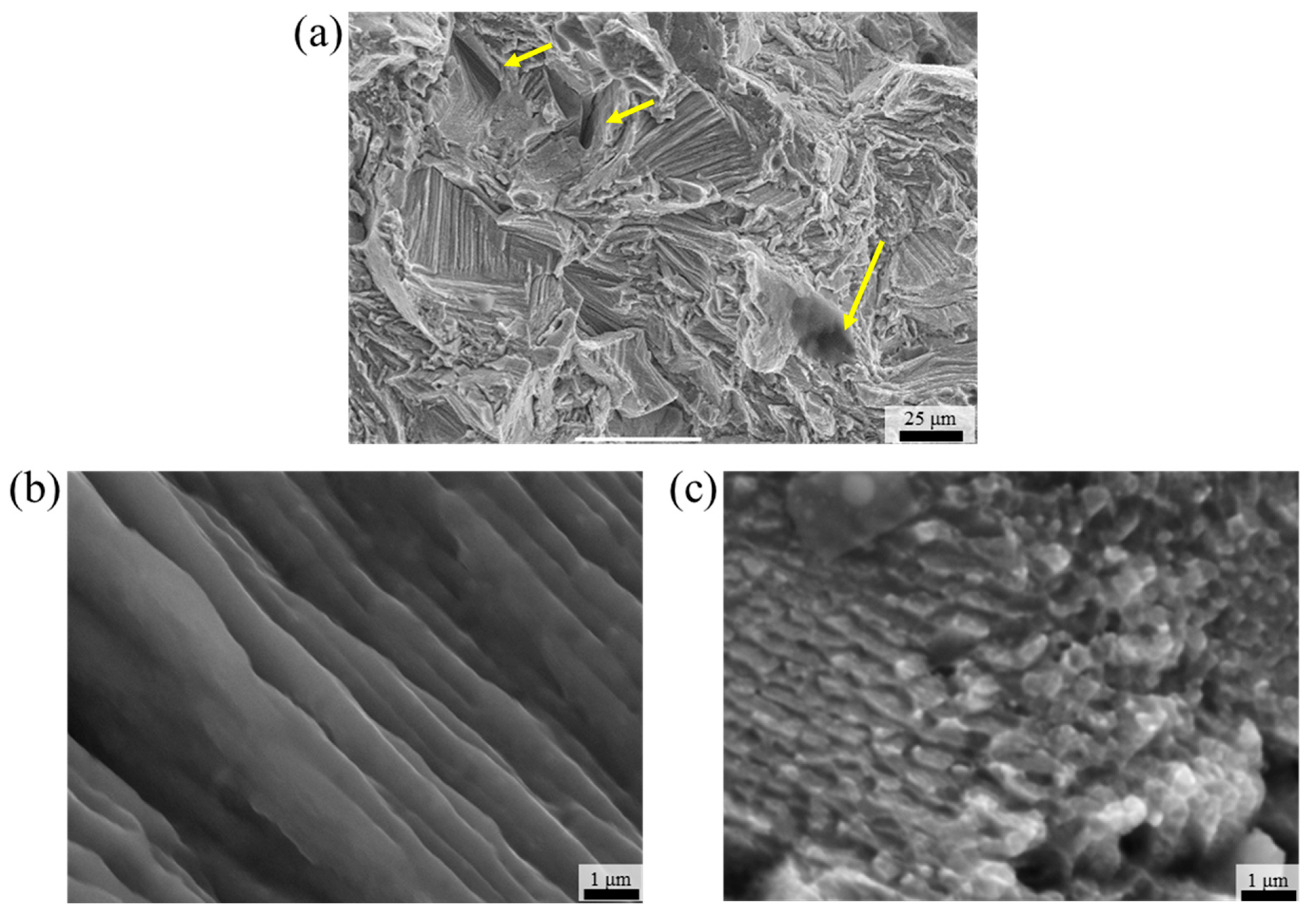

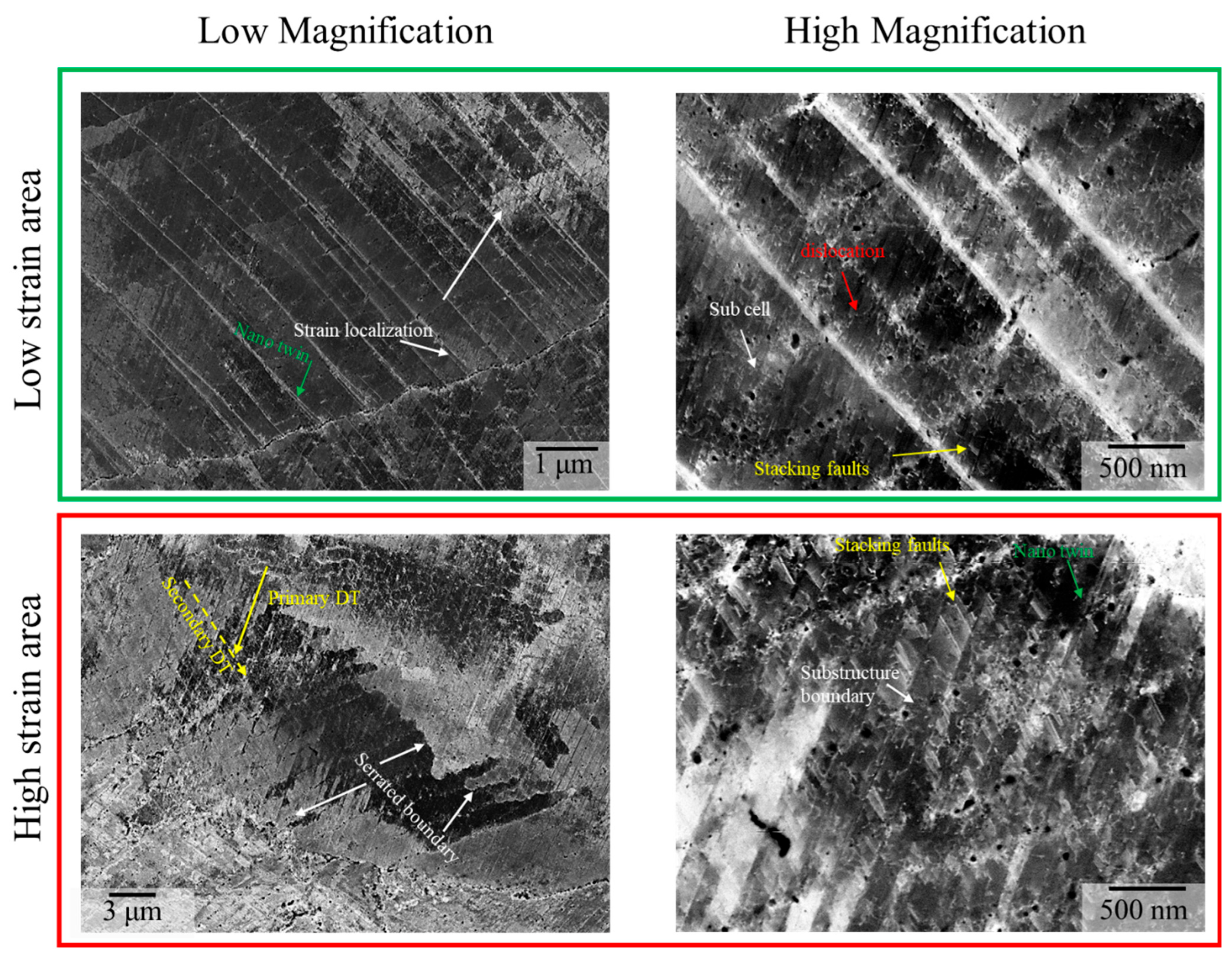

3.3. Fracture and Deformation Mechanisms

4. Conclusions

- The 0.75C MEA fabricated via LPBF exhibited a high relative density (>99.9%), columnar grain structure aligned along the building direction (BD), and refined substructures, all of which were retained after heat treatment. Post-heat treatment at 700 °C promoted the precipitation of Cr-rich carbides (Cr23C6) along grain and substructure boundaries. These precipitates contributed to microstructural stabilization by suppressing grain growth and dislocation motion via the Zener pinning effect. High dislocation densities were observed both before and after heat treatment, with the average dislocation density decreasing to approximately 6.2 × 1013 m−2 after heat treatment. Additionally, the fraction of stacking faults increased after heat treatment, likely due to a reduction in carbon solubility in the matrix, which decreased the stacking fault energy.

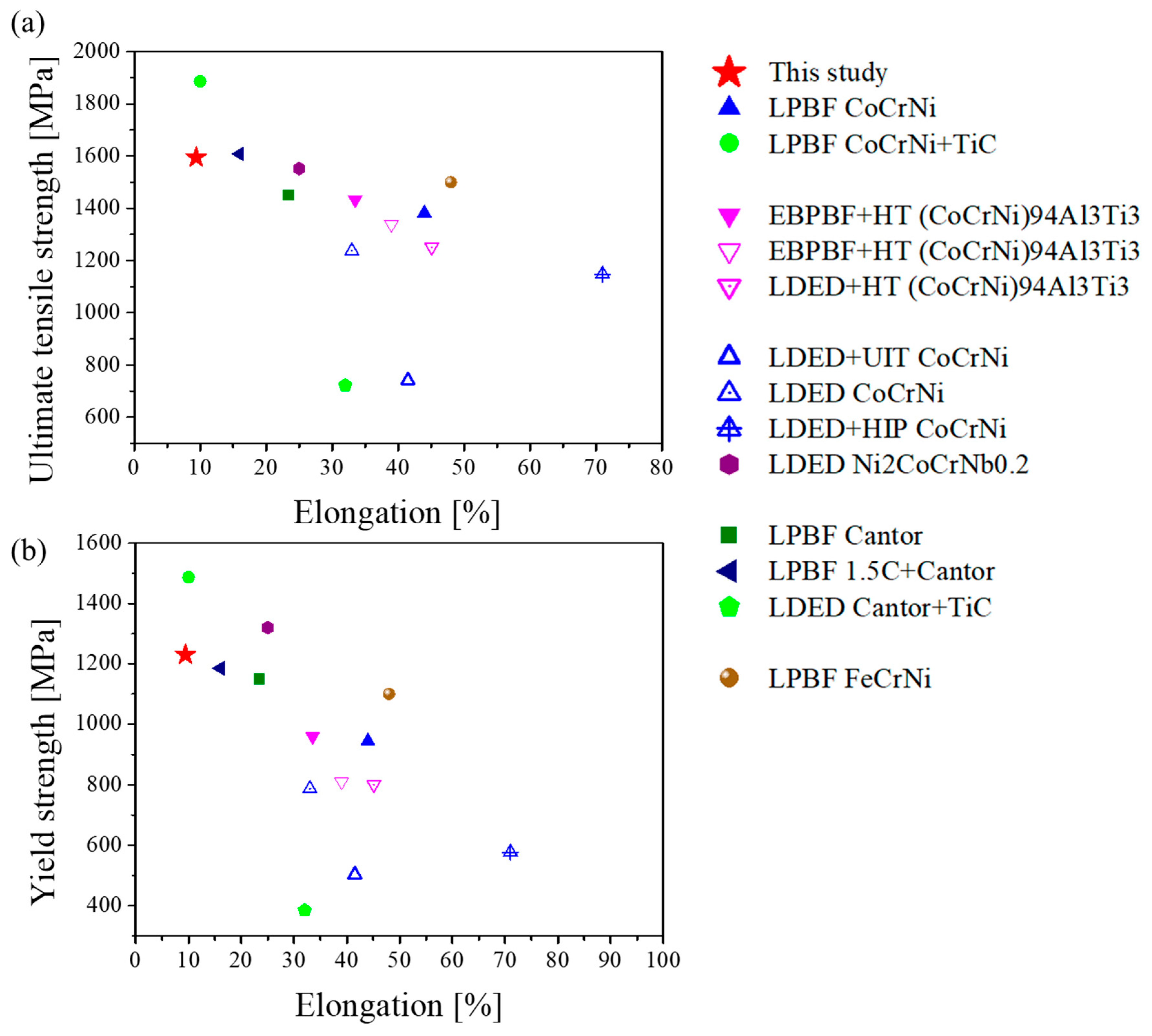

- Heat-treated 0.75C MEA exhibited excellent mechanical properties at cryogenic temperature (77 K), with a yield strength of 1.23 GPa, an ultimate tensile strength of 1.60 GPa, and an elongation of 9.4%. These values position it among the top two to three highest strength levels reported for AM-fabricated MEAs and HEAs to date. Notably, its ultimate tensile strength surpasses those of previously reported PBF-built precipitation-strengthened NiCoCr MEA. Compared to room temperature, the alloy demonstrated higher yield and tensile strengths at 77 K, accompanied by a reduction in elongation.

- Post-deformation microstructural analysis revealed that extensive deformation twinning (DT) occurred under cryogenic conditions, which was attributed to the reduced stacking fault energy (SFE). DTs intersected with high-angle grain boundaries and substructure boundaries, leading to dislocation locking and the activation of a dynamic Hall–Petch effect, resulting in a high work hardening rate (WHR). While dislocation restriction by substructures and stacking faults was the dominant strengthening mechanism at room temperature, at 77 K, the combined interaction among DTs, SFs, and precipitates acted as a synergistic strengthening mechanism, contributing significantly to both uniform deformation and high strength retention. Furthermore, WHR vs. true strain analysis showed that the WHR remained consistently higher—by approximately 1 GPa—across the entire strain range at cryogenic temperature. These findings suggest that multiple temperature-sensitive strengthening mechanisms were sequentially activated in this alloy, enabling the simultaneous retention of high strength and superior work hardening capability under cryogenic conditions.

- In this study, a NiCoCr MEA alloy with excellent cryogenic tensile strength was successfully developed by employing the LPBF process in combination with carbide strengthening. For future work, it will be necessary to evaluate the material’s potential as a next-generation structural alloy operable over a wide temperature range by conducting additional tests such as fatigue, creep, and fracture toughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pickering, E.J.; Jones, N.G. High-entropy alloys: A critical assessment of their founding principles and future prospects. Int. Mater. Rev. 2016, 61, 183–202. [Google Scholar] [CrossRef]

- Li, C.; Ferry, M.; Kruzic, J.J.; Li, X. Review: Multi-principal element alloys by additive manufacturing. J. Mater. Sci. 2022, 57, 9903–9935. [Google Scholar] [CrossRef]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Miracle, D.B. High-entropy alloys: A current evaluation of founding ideas and core effects and exploring “nonlinear alloys”. JOM 2017, 69, 2130–2136. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. High-entropy alloy: Challenges and prospects. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Holcomb, G.R.; Tylczak, J.; Carney, C. Oxidation of CoCrFeMnNi high entropy alloys. JOM 2015, 67, 2326–2339. [Google Scholar] [CrossRef]

- Oliveros, D.; Fraczkiewicz, A.; Dlouhy, A.; Zhang, C.; Song, H.; Sandefld, S.; Legros, M. Orientation-related twinning and dislocation glide in a Cantor high entropy alloy at room and cryogenic temperature studied by in situ TEM straining. Mater. Chem. Phys. 2021, 272, 124955. [Google Scholar] [CrossRef]

- Han, Z.; Ren, W.; Yang, J.; Tian, A.; Du, Y.; Liu, G.; Wei, R.; Zhang, G.; Chen, Y. The corrosion behavior of ultra-fine grained CoNiFeCrMn high-entropy alloys. J. Alloys Compd. 2020, 816, 152583. [Google Scholar] [CrossRef]

- Podolskiy, A.V.; Shapovalov, Y.O.; Tabachnikova, E.D.; Tortika, A.S.; Tikhonovsky, M.A.; Joni, B.; Ódor, E.; Ungar, T.; Maier, S.; Rentenberger, C.; et al. Anomalous evolution of strength and microstructure of high-entropy alloy CoCrFeNiMn after high-pressure torsion at 300 and 77 K. Adv. Eng. Mater. 2020, 22, 1900752. [Google Scholar] [CrossRef]

- Lee, J.; Park, H.; Kim, M.; Kim, H.-J.; Suh, J.-Y.; Kang, N. Role of hydrogen and temperature in hydrogen embrittlement of equimolar CoCrFeMnNi high-entropy alloy. Met. Mater. Int. 2021, 27, 166–174. [Google Scholar] [CrossRef]

- Yoshida, S.; Ikeuchi, T.; Bhattacharjee, T.; Bai, Y.; Shibata, A.; Tsuji, N. Effect of elemental combination on friction stress and Hall-Petch relationship in face-centered cubic high/medium entropy alloys. Acta Mater. 2019, 171, 201–215. [Google Scholar] [CrossRef]

- Filho, F.D.C.G.; Ritchie, R.O.; Meyers, M.A.; Monteiro, S.N. Cantor-derived medium-entropy alloys: Bridging the gap between traditional metallic and high-entropy alloys. J. Mater. Res. Technol. 2022, 17, 1868–1895. [Google Scholar] [CrossRef]

- Adomako, N.K.; Km, J.H.; Hyun, Y.T. High-temperature oxidation behaviour of low-entropy alloy to medium- and high-entropy alloys. J. Therm. Anal. Calorim. 2018, 133, 13–26. [Google Scholar] [CrossRef]

- Wang, D.P.; Shen, J.W.; Chen, Z.; Chen, F.G.; Guo, P.Y. Relationship of corrosion behavior between single-phase equiatomic CoCrNi, CoCrNiFe, CoCrNiFeMn alloys and their constituents in NaCl solution. Acta Metall. Sin. Engl. Lett. 2021, 34, 1574–1584. [Google Scholar] [CrossRef]

- Stephan-Scherb, C.; Schulz, W.; Schneider, M.; Karafiludis, S.; Lapanche, G. High-temperature oxidation in dry and humid atmospheres of the equiatomic CrMnFeCoNi and CrCoNi high- and medium-entropy alloys. Oxid. Met. 2021, 95, 105–133. [Google Scholar] [CrossRef]

- Moravcik, I.; Peighambardoust, N.S.; Motallebzadeh, A.; Moravcikova-Gouvea, L.; Liu, C.; Prabhakar, J.M.; Dlouhy, I.; Li, Z. Interstitial nitrogen enhances corrosion resistance of an equiatomic CoCrNi medium-entropy alloy in sulfuric acid solution. Mater. Charact. 2021, 172, 110869. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.S.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2016, 7, 10602. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Reinhart, C.; Hunfeld, J.; Eggeler, G.; George, E.P. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 2017, 128, 292–303. [Google Scholar] [CrossRef]

- Agustianingrum, M.P.; Lee, U.; Park, N. High-temperature oxidation behaviour of CoCrNi medium-entropy alloy. Corros. Sci. 2020, 173, 108755. [Google Scholar] [CrossRef]

- Zhu, M.; He, F.; Yuan, Y.; Guo, S.; Wei, G. A comparative study on the corrosion behavior of CoCrNi medium-entropy alloy and 316L stainless steel in simulated marine environment. Intermetallics 2021, 139, 107370. [Google Scholar] [CrossRef]

- Saha, J.; Bhattacharjee, P.P. Influences of thermomechanical processing by severe cold and warm rolling on the microstructure, texture, and mechanical properties of an equiatomic CoCrNi medium-entropy alloy. J. Mater. Eng. Perform. 2021, 30, 8956–8971. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Bae, J.W.; Asghari-Rad, P.; Park, J.M.; Kim, J.G.; Kim, H.S. Effect of annealing on microstructure and tensile behavior of CoCrNi medium entropy alloy processed by high-pressure torsion. Entropy 2018, 20, 849. [Google Scholar] [CrossRef]

- Zhou, K.; Cui, D.; Chai, Z.; Zhang, Y.; Zhu, C.; Wang, Z.; Li, J.; Wang, J. In-situ tailoring microstructures to promote strength-ductility synergy in laser powder bed fusion of NiCoCr medium-entropy alloy. Addit. Manuf. 2023, 66, 103443. [Google Scholar] [CrossRef]

- Li, C.; Jain, M.; Liu, Q.; Cao, Z.; Ferry, M.; Kruzic, J.J.; Gludovatz, B.; Li, X. Multi-scale microstructure manipulation of an additively manufactured CoCrNi medium entropy alloy for superior mechanical properties and tunable mechanical anisotropy. Addit. Manuf. 2024, 84, 104104. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Yang, S.; Lee, K.-A. Superior temperature-dependent mechanical properties and deformation behavior of equiatomic CoCrFeMnNi high-entropy alloy additively manufactured by selective laser melting. Sci. Rep. 2020, 10, 8045. [Google Scholar] [CrossRef]

- Jamil, I.R.; Mustaquim, A.M.; Islam, M.; Thakur, M.S.H.; Hasan, M.N. Effect of powder bed fusion process parameters on microstructural and mechanical properties of FeCrNi MEA: An atomistic study. Met. Mater. Int. 2023, 29, 659–673. [Google Scholar] [CrossRef]

- Jarlöv, A.; Zhu, Z.; Ji, W.; Gao, S.; Hu, Z.; Vivegananthan, P.; Tian, Y.; Kripalani, D.R.; Fan, H.; Seet, H.L.; et al. Recent progress in high-entropy alloys for laser powder bed fusion: Design, processing, microstructure, and performance. Mater. Sci. Eng. R 2024, 161, 100834. [Google Scholar] [CrossRef]

- Kwon, H.; Kim, E.S.; Heo, Y.-U.; Choe, J.; Kim, R.E.; Ahn, S.Y.; Oh, S.-H.; Park, J.M.; Lee, B.-J.; Kim, H.S. Restructuring the cell network of non-equiatomic CoCrFeNiMoC medium-entropy alloy fabricated by laser powder bed fusion. J. Mater. Sci. Technol. 2025, 214, 143–152. [Google Scholar] [CrossRef]

- Pan, C.; Zhu, D.; Luo, H.; Kosiba, K.; Qu, S.; Yang, C.; Li, X. Fabrication of high-performance CoCrNi medium-entropy alloy by laser powder bed fusion: The effect of grain boundary segregation. Compos. Part B Eng. 2023, 253, 110540. [Google Scholar] [CrossRef]

- Li, M.; Qiu, Y.; Shi, X.; Liu, Z.; Birbilis, N.; Zhu, Y.; Liu, J. Nano-dispersion strengthened and twinning-mediated CoCrNi medium-entropy alloy with excellent strength and ductility prepared by laser powder bed fusion. J. Alloys Compd. 2024, 1005, 176103. [Google Scholar] [CrossRef]

- Ma, J.; Niu, J.; Lin, Y.; Zhang, X.; Jin, F. Laser powder bed fusion of CoCrNi composite with high fraction of TiC: The microstructure and mechanical properties at different temperatures. Mater. Sci. Eng. A 2024, 911, 146929. [Google Scholar] [CrossRef]

- Hou, J.; Qiu, B.; Zhu, Z.; Zou, S.; Li, G.; Zhu, Q.; Lu, W. A mechanically strong yet ductile CoCrNi/Cr2B composite enabled by in-situ formed borides during laser powder bed fusion. Compos. Part B Eng. 2024, 278, 111428. [Google Scholar] [CrossRef]

- Ji, Z.; Qiu, C. Achieving superior high-temperature strength in an additively manufactured high-entropy alloy by controlled heat treatment. Appl. Mater. Today 2024, 40, 102412. [Google Scholar] [CrossRef]

- Li, L.; Song, K.; Gao, Q.; Zhou, C.; Liu, X.; Wang, Y.; Bai, X.; Cao, C. Enhancing strength-ductility synergy of CoCrNi-based medium-entropy alloy through coherent L12 nanoprecipitates and grain boundary precipitates. Acta Metall. Sin. (Engl. Lett.) 2024, 37, 78–88. [Google Scholar] [CrossRef]

- Ahn, J.-E.; Kim, Y.-K.; Yang, S.; Lee, K.-A. Interstitial carbon content effect on the microstructure and mechanical properties of additively manufactured NiCoCr medium-entropy alloy. J. Alloys Compd. 2022, 918, 165601. [Google Scholar] [CrossRef]

- Kim, S.; Park, S.-Y.; Lee, K.-A. High-temperature oxidation behavior of carbon-doped CoCrNi medium-entropy alloy fabricated by laser powder bed fusion. J. Mater. Res. Technol. 2025, 34, 2430–2442. [Google Scholar] [CrossRef]

- Park, S.-Y.; Ahn, J.-E.; Kim, Y.-K.; Ravi, K.; Lee, K.-A. Substructure boundary’s enhancing strain hardening ability in additively manufactured 0.75 at%C doping NiCoCr medium-entropy alloy. J. Mater. Res. Technol. 2024, 33, 1087–1096. [Google Scholar] [CrossRef]

- Park, S.-Y.; Kim, S.; Kim, Y.-K.; Lee, K.-A. Elevated-temperature mechanical properties of precipitates-hardened (NiCoCr)99.25C0.75 at% medium-entropy alloy fabricated by laser powder bed fusion. J. Alloys Compd. 2025, 1035, 181574. [Google Scholar] [CrossRef]

- Moravcik, I.; Hornik, V.; Minárik, P.; Li, L.; Dlouhy, I.; Janovska, M.; Raabe, D.; Li, Z. Interstitial doping enhances the strength-ductility synergy in a CoCrNi medium entropy alloy. Mater. Sci. Eng. A 2020, 781, 139242. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Lee, K.-A. Stabilized sub-grain and nano carbides-driven 1.2 GPa grade ultra-strong CrMnFeCoNi high-entropy alloy additively manufactured by laser powder bed fusion. J. Mater. Sci. Technol. 2022, 117, 8–22. [Google Scholar] [CrossRef]

- Pourbabak, S.; Montero-Sistiaga, M.L.; Schryvers, D.; Van Humbeeck, J.; Vanmeensel, K. Microscopic investigation of as-built and hot isostatic pressed Hastelloy X processed by selective laser melting. Mater. Charact. 2019, 153, 366–371. [Google Scholar] [CrossRef]

- Slone, C.E.; Miao, J.; George, E.P.; Mills, M.J. Achieving ultra-high strength and ductility in equiatomic CrCoNi with partially recrystallized microstructures. Acta Mater. 2019, 165, 496–507. [Google Scholar] [CrossRef]

- Liu, S.F.; Wu, Y.; Wang, H.T.; He, J.Y.; Liu, J.B.; Chen, C.X.; Liu, X.J.; Wang, H.; Lu, Z.P. Stacking fault energy of face-centered-cubic high-entropy alloys. Intermetallics 2018, 93, 269–273. [Google Scholar] [CrossRef]

- Kumar, P.; Michalek, M.; Cook, D.H.; Sheng, H.; Lau, K.B.; Wang, P.; Zhang, M.; Minor, A.M.; Ramamurty, U.; Ritchie, R.O. On the strength and fracture toughness of an additive manufactured CrCoNi medium-entropy alloy. Acta Mater. 2023, 258, 119249. [Google Scholar] [CrossRef]

- Tran, M.T.; Nguyen, T.H.; Kim, D.-K.; Woo, W.; Choi, S.-H.; Lee, H.W.; Wang, H.; Kim, J.G. Effect of hot isostatic pressing on the cryogenic mechanical properties of CrCoNi medium entropy alloy processed by direct energy deposition. Mater. Sci. Eng. A 2021, 828, 142110. [Google Scholar] [CrossRef]

- Peng, H.; Hu, L.; Huang, S.; Baker, I. Effects of heat treatment on the microstructure and mechanical properties of a nanoparticle-strengthened medium-entropy alloy produced by electron-beam powder bed fusion. J. Alloys Compd. 2025, 1021, 179598. [Google Scholar] [CrossRef]

- Bi, X.; Li, R.; Yuan, Z.; Cheng, J.; Guan, D.; Zhang, P. Laser-directed energy deposition of a high performance additively manufactured (CoCrNi)94(TiAl)6 medium-entropy alloy with a novel core-shell structured strengthening phase. Addit. Manuf. 2024, 80, 103971. [Google Scholar] [CrossRef]

- Wang, F.; Guo, Y.; Liu, Q.; Shang, X. Nanoparticle-strengthened Ni2CoCrNb0.2 medium-entropy alloy with an ultrastrong cryogenic yield strength fabricated by additive manufacturing. J. Mater. Sci. Technol. 2023, 163, 17–31. [Google Scholar] [CrossRef]

- Bi, X.; Li, R.; Li, T.; Wang, C.; Yuan, Z.; Cheng, J. Improvement of mechanical properties at cryogenic temperature of CoCrNi medium entropy alloy fabricated by hybrid additive manufacturing technology. Mater. Charact. 2023, 205, 113351. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Kim, M.-C.; Lee, K.-A. 1.45 GPa ultrastrong cryogenic strength with superior impact toughness in the in-situ nano oxide reinforced CrMnFeCoNi high-entropy alloy matrix nanocomposite manufactured by laser powder bed fusion. J. Mater. Sci. Technol. 2022, 97, 10–19. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Lee, K.-A. Influence of carbon contents on the cryogenic mechanical properties of precipitation-hardened CrMnFeCoNi high-entropy alloys manufactured by laser powder bed fusion. Mater. Sci. Eng. A 2023, 873, 145042. [Google Scholar] [CrossRef]

- Amar, A.; Li, J.; Xiang, S.; Liu, X.; Zhou, Y.; Le, G.; Wang, X.; Qu, F.; Ma, S.; Dong, W.; et al. Additive manufacturing of high-strength CrMnFeCoNi-based high-entropy alloys with TiC addition. Intermetallics 2019, 109, 162–166. [Google Scholar] [CrossRef]

- Xie, Z.; Fu, A.; Duan, H.; Wang, B.; Li, X.; Cao, Y.; Liu, B. Cryogenic mechanical behavior of a FeCrNi medium-entropy alloy fabricated by selected laser melting. Intermetallics 2023, 160, 107945. [Google Scholar] [CrossRef]

- Bidulský, R.; Bidulská, J.; Gobber, F.S.; Kvačkaj, T.; Petroušek, P.; Actis-Grande, M.; Wiss, K.-P.; Manfredi, D. Case study of the tensile fracture investigation of additive manufactured austenitic stainless steels treated at cryogenic conditions. Materials 2020, 13, 3328. [Google Scholar] [CrossRef] [PubMed]

- Gao, T.; Jin, X.; Qiao, J.; Yang, H.; Zhang, Y.; Wu, Y. Successive strain hardening mechanisms induced by transformation-induced plasticity in Fe60Mn20Co10Cr10 high-entropy alloys. J. Appl. Phys. 2021, 129, 081101. [Google Scholar] [CrossRef]

- Pei, B.; Fan, J.P.; Wang, Z.; Yang, H.J.; Qiao, J.W.; Bi, Z.N.; Gan, B. Excellent combination of strength and ductility in CoNiCr-based MP159 alloys at cryogenic temperature. J. Alloys Compd. 2022, 907, 164144. [Google Scholar] [CrossRef]

- Huang, S.; Li, W.; Lu, S.; Tian, F.; Shen, J.; Holmström, E.; Vitos, L. Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy. Scr. Mater. 2015, 108, 44–47. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, J.; Liu, C.; Yao, Z.; Fu, F.; Wei, F.; Hongxian, Y.; Cai, L.; Tan, N. Dislocation behavior in initial stage of plastic deformation for CoCrNi medium-entropy alloy. J. Alloys Compd. 2023, 943, 169057. [Google Scholar] [CrossRef]

- Li, W.; Sun, L.; Cheng, H.; Fan, M.; Zhang, Z. Improving the tensile ductility of the high-strength nanotwinned high manganese steel by a strategy combining cold rolling and warm rolling. Mater. Sci. Eng. A 2020, 902, 146626. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.-Y.; Kim, Y.-K.; Kim, H.S.; Lee, K.-A. Cryogenic Tensile Strength of 1.6 GPa in a Precipitation-Hardened (NiCoCr)99.25C0.75 Medium-Entropy Alloy Fabricated via Laser Powder Bed Fusion. Materials 2025, 18, 3656. https://doi.org/10.3390/ma18153656

Park S-Y, Kim Y-K, Kim HS, Lee K-A. Cryogenic Tensile Strength of 1.6 GPa in a Precipitation-Hardened (NiCoCr)99.25C0.75 Medium-Entropy Alloy Fabricated via Laser Powder Bed Fusion. Materials. 2025; 18(15):3656. https://doi.org/10.3390/ma18153656

Chicago/Turabian StylePark, So-Yeon, Young-Kyun Kim, Hyoung Seop Kim, and Kee-Ahn Lee. 2025. "Cryogenic Tensile Strength of 1.6 GPa in a Precipitation-Hardened (NiCoCr)99.25C0.75 Medium-Entropy Alloy Fabricated via Laser Powder Bed Fusion" Materials 18, no. 15: 3656. https://doi.org/10.3390/ma18153656

APA StylePark, S.-Y., Kim, Y.-K., Kim, H. S., & Lee, K.-A. (2025). Cryogenic Tensile Strength of 1.6 GPa in a Precipitation-Hardened (NiCoCr)99.25C0.75 Medium-Entropy Alloy Fabricated via Laser Powder Bed Fusion. Materials, 18(15), 3656. https://doi.org/10.3390/ma18153656