Axial Compression Behavior of Bamboo Scrimber-Filled Steel Tubular (BSFST) Column Under Different Loading Modes

Highlights

- Novel bamboo scrimber filled-steel tubular columns were developed.

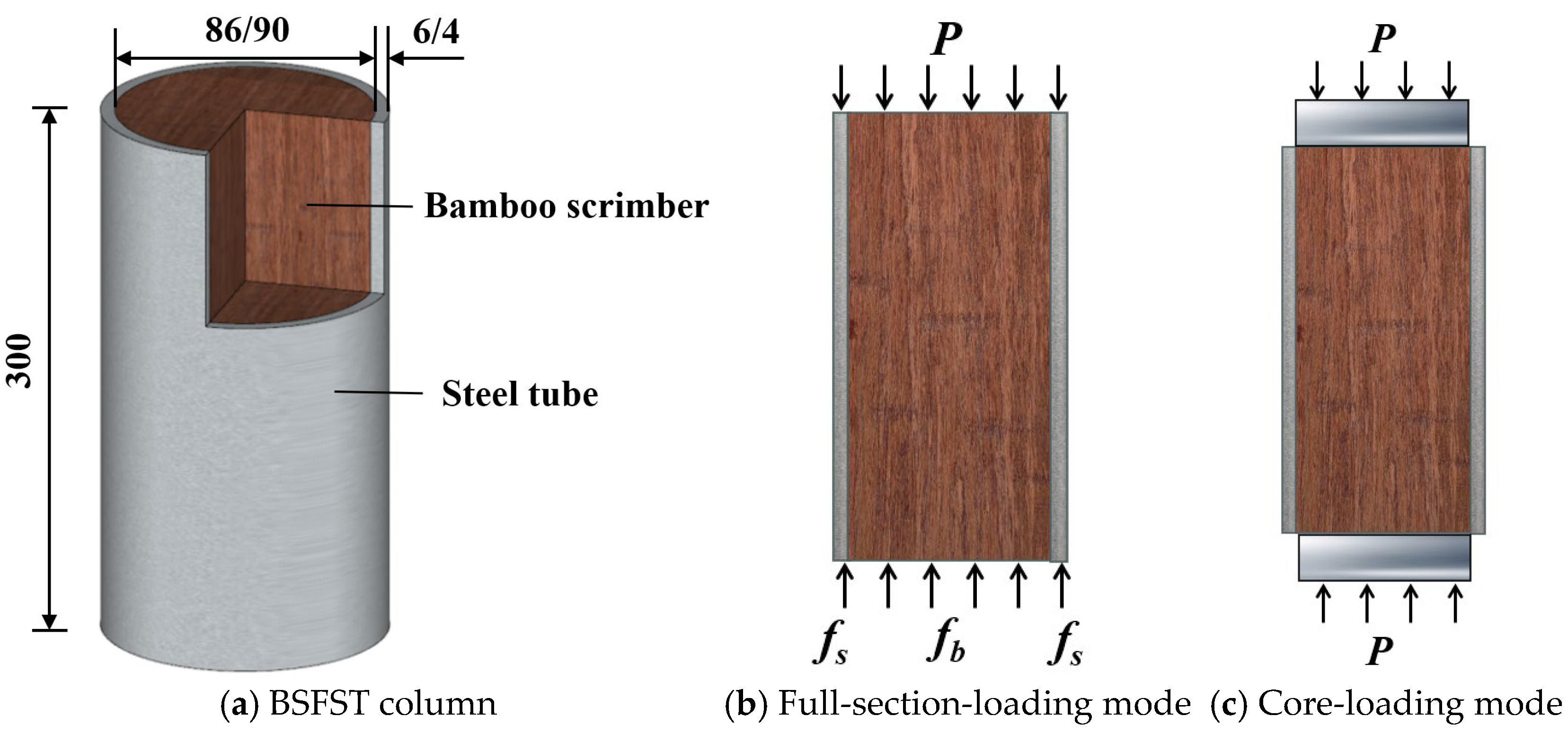

- Axial compression test of 18 columns under full section loading and core loading modes were carried out.

- Failure modes, stress–strain curves, and mechanical properties were investigated.

- Critical variables, including the steel ratio and the loading mode, were systematically analyzed.

- The ultimate stress and strain calculation models were proposed.

Abstract

1. Introduction

2. Material and Methods

2.1. Specimen Design

2.2. Material Properties

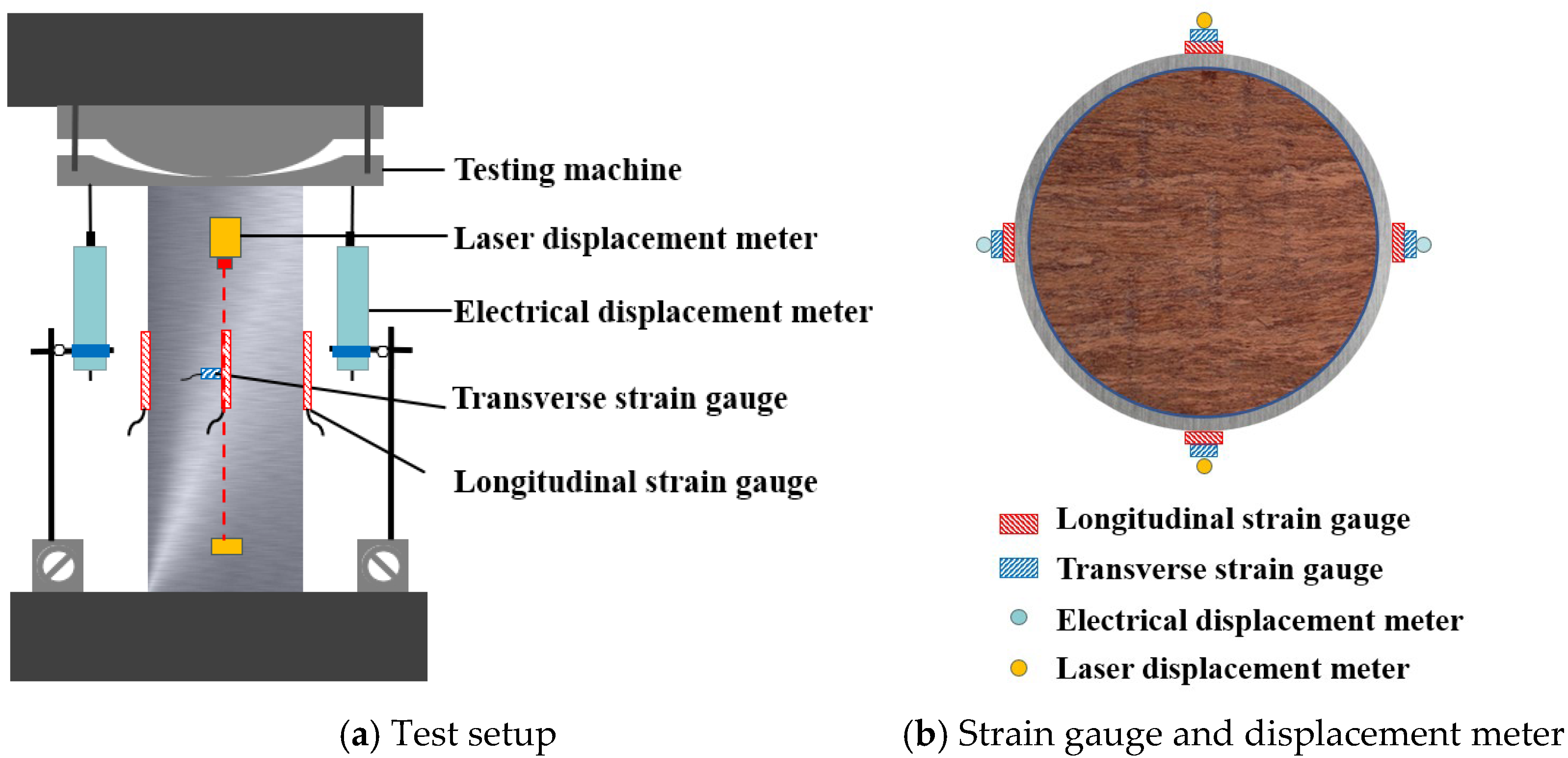

2.3. Test Program

3. Results

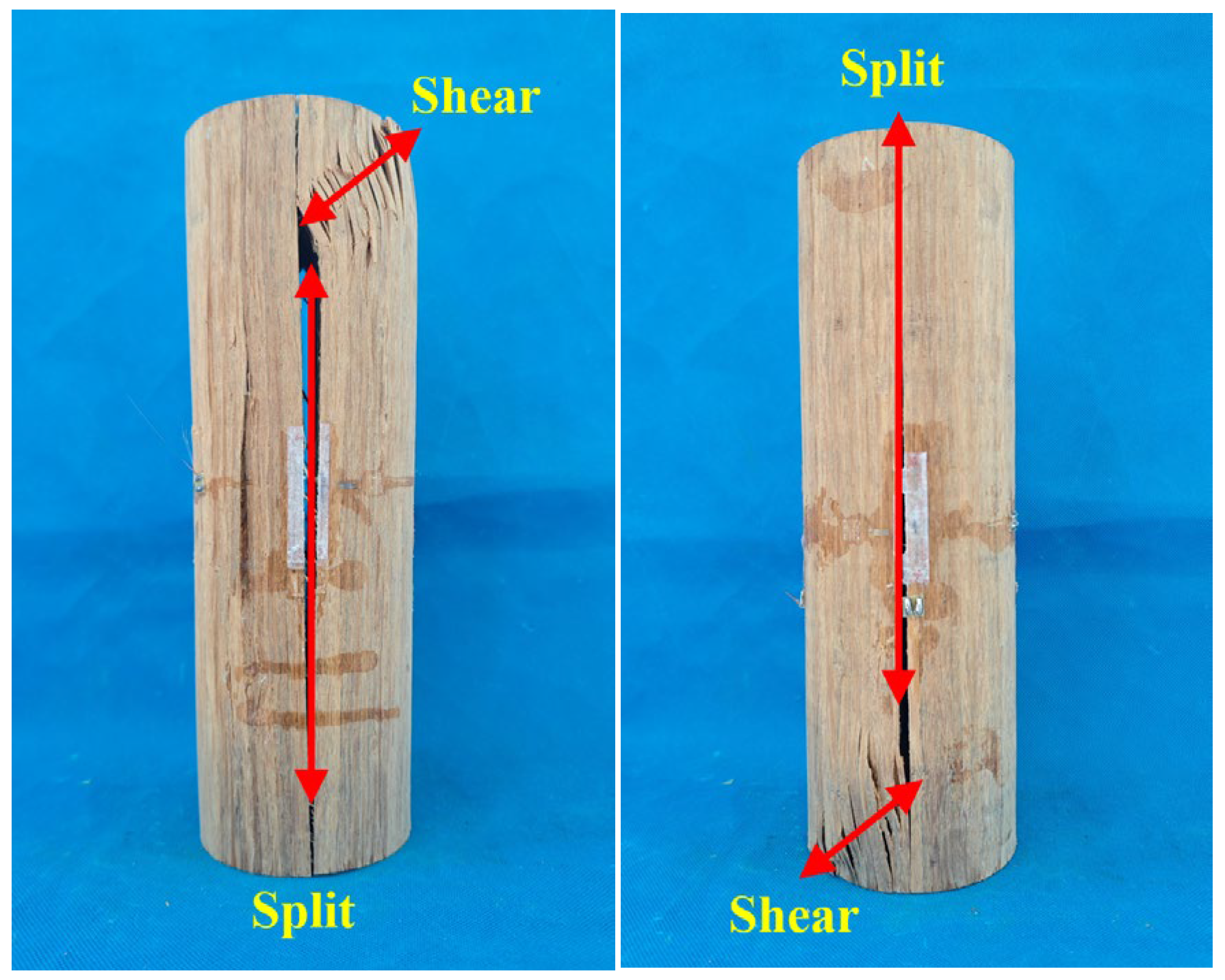

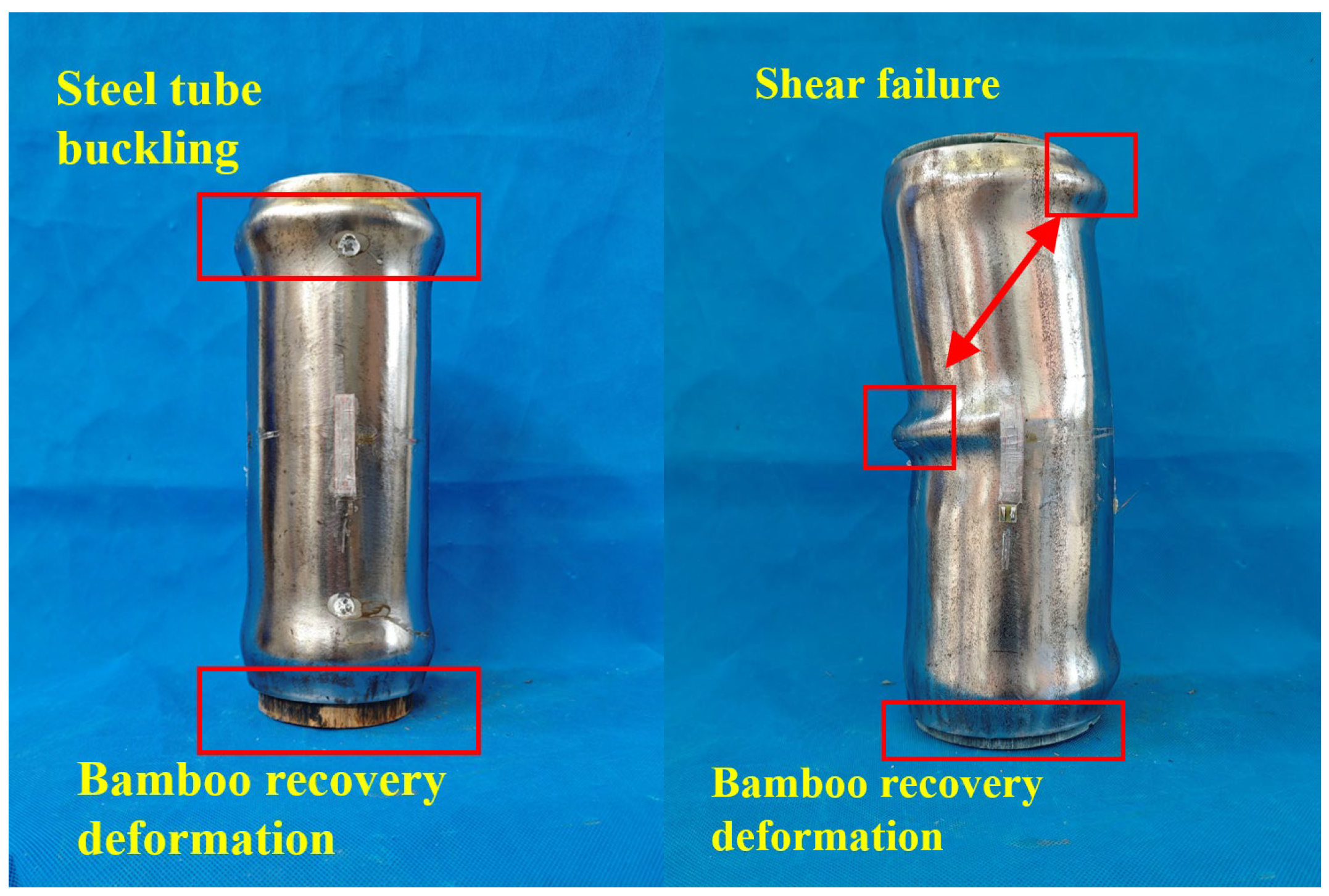

3.1. Experimental Phenomena and Failure Modes

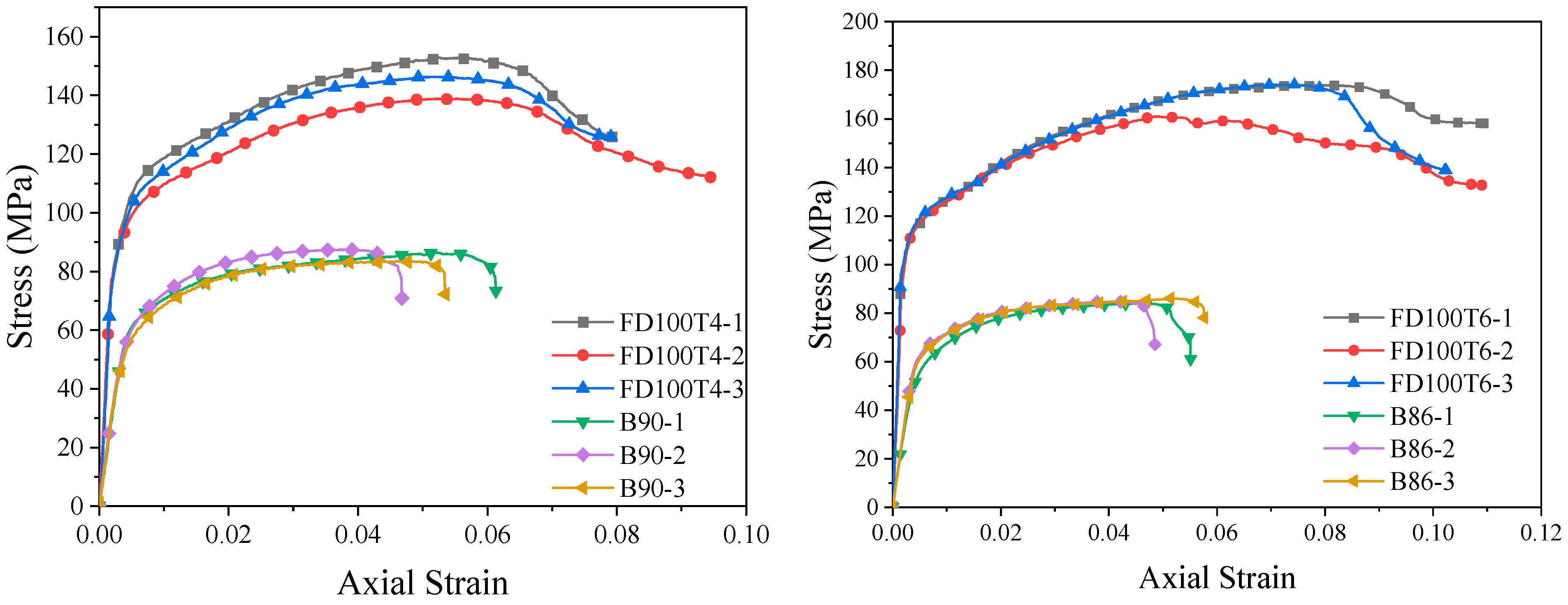

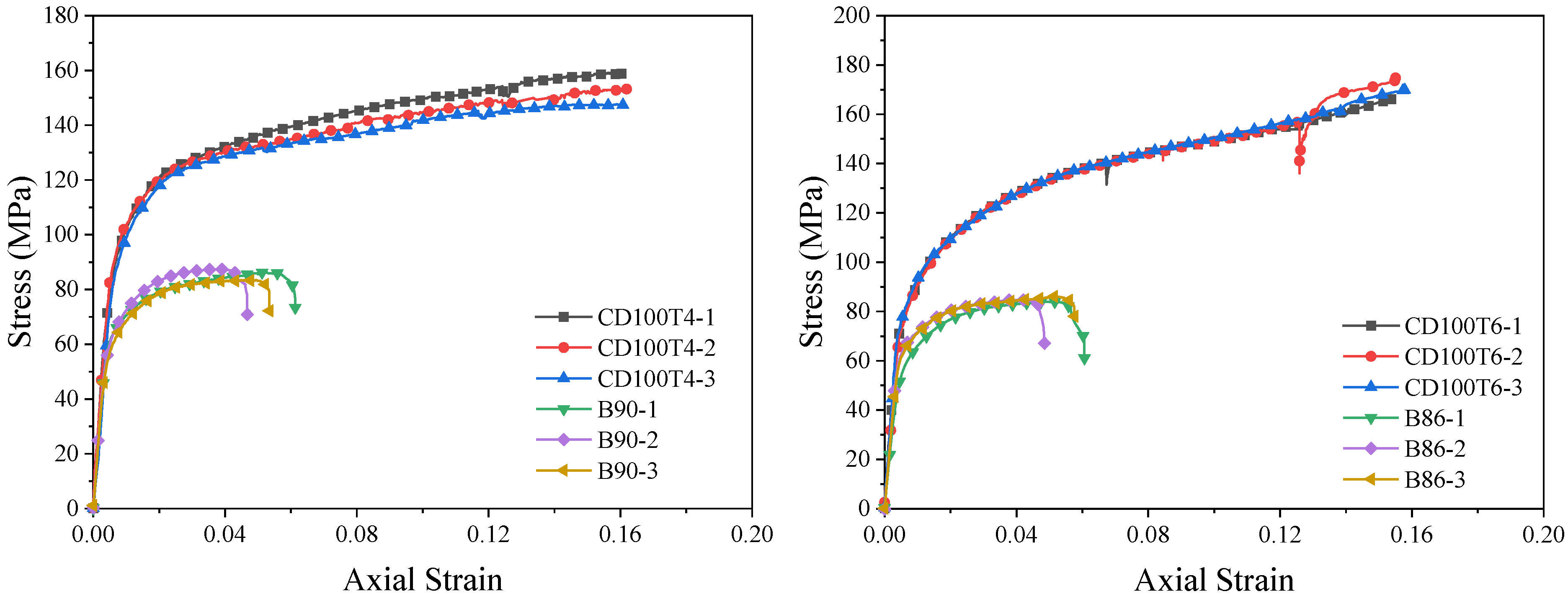

3.2. Stress–Strain Relationship Curves

3.3. Parameter Analysis

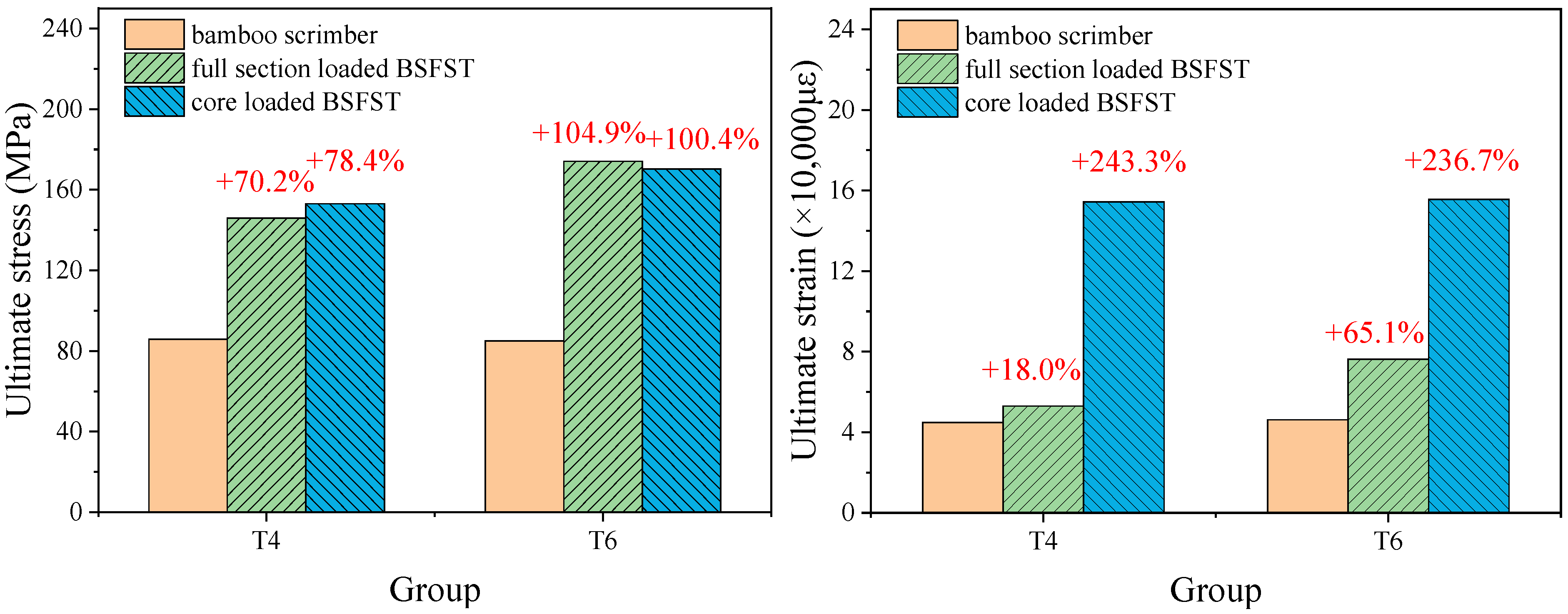

3.3.1. Comparative Analysis of the Bamboo Scrimber Columns and BSFST Columns

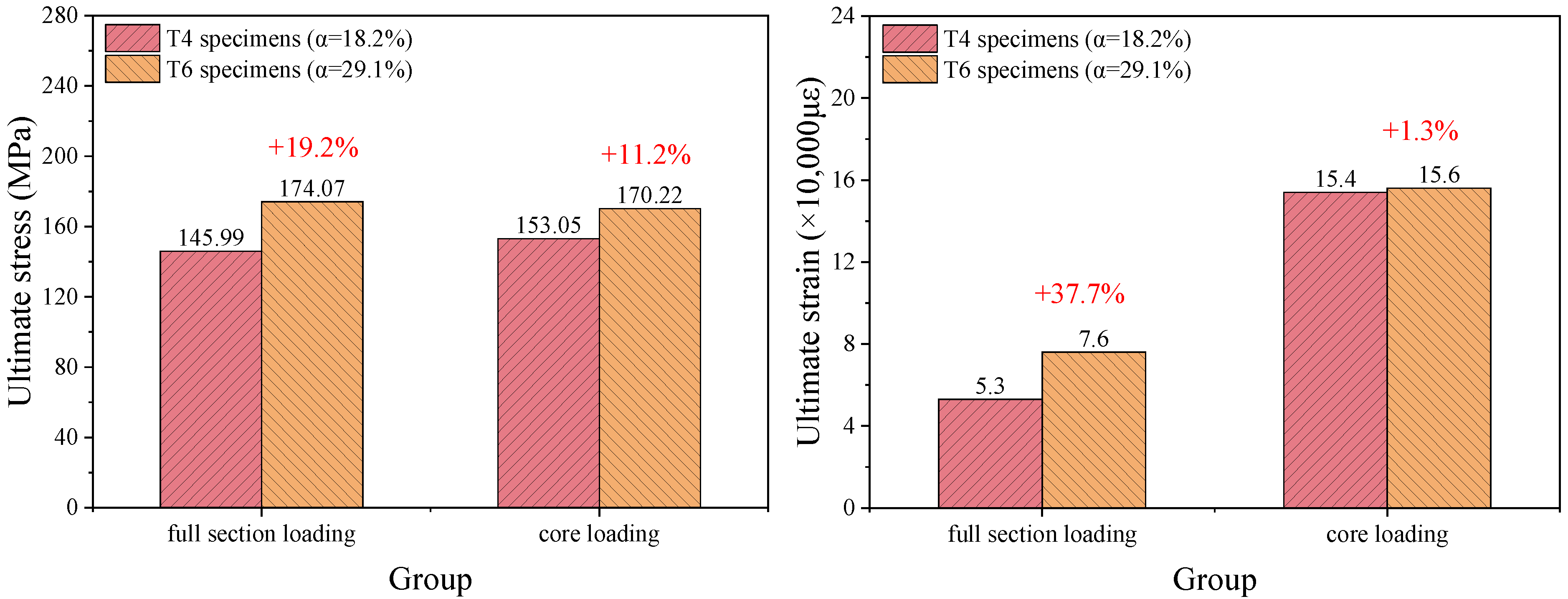

3.3.2. Influence of Steel Ratio

3.3.3. Influence of Loading Modes

4. Discussion

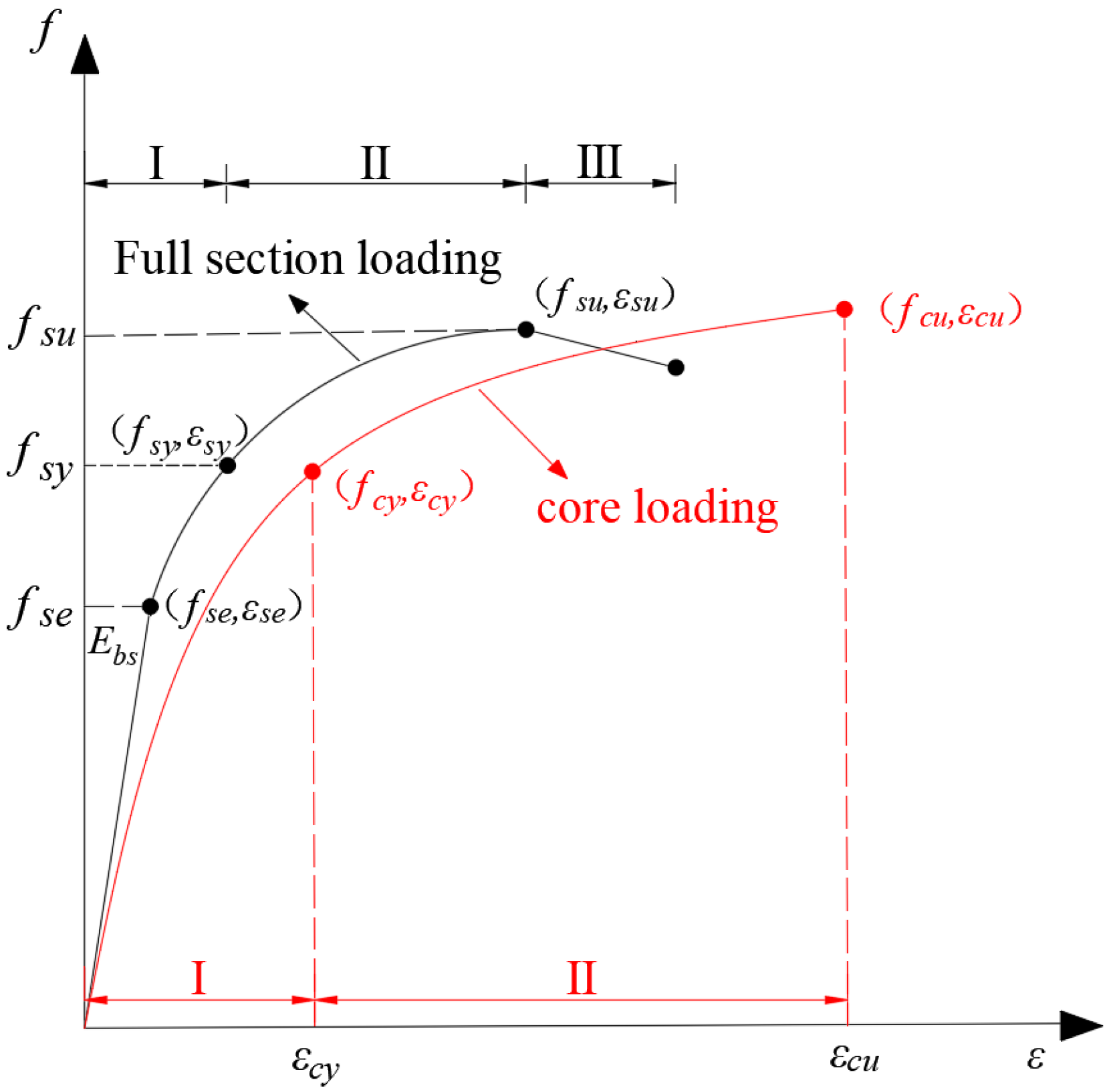

4.1. Typical Stress–Strain Curves of BSFST Columns

4.2. Calculation Models of the Full-Section-Loaded BSFST Columns

4.3. Discussion

5. Conclusions

- (1)

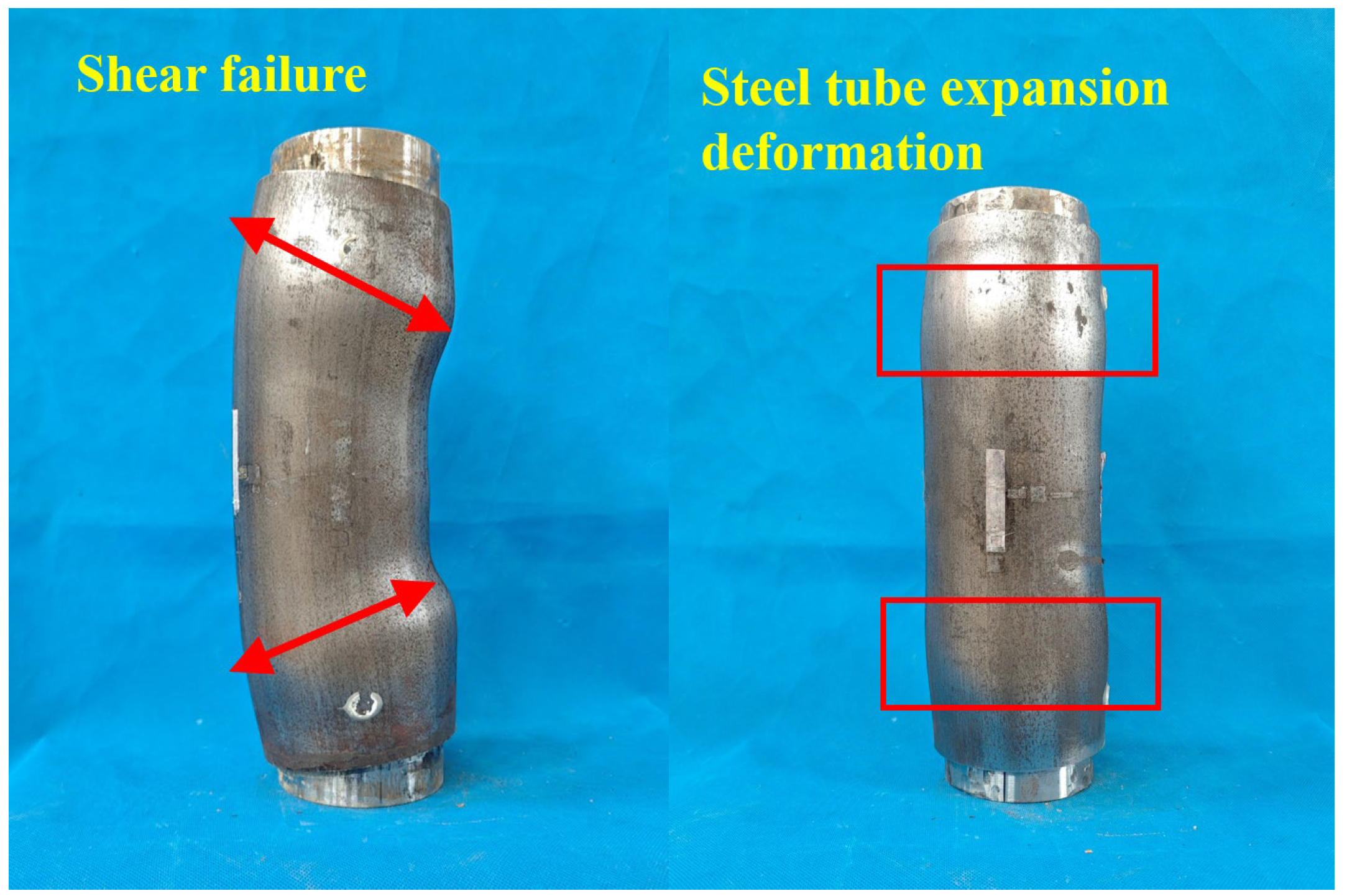

- The primary failure modes of bamboo-scrimber-filled steel tubular columns under axial compression are shear failure and buckling. For the full-section-loaded specimens, evident local buckling, ring-like bulging, and inclined shear cracks were observed on the steel tube surface. For the core-loaded specimens, the steel tube showed outward bulging with little buckling. Specimens with a tube thickness of 4 mm exhibited pronounced shear failure on the surface.

- (2)

- The stress–strain curve of a full-section-loaded BSFST column can be divided into three stages, namely elastic, elastic–plastic, and descending stage. For the core-loaded specimens, the stress–strain curve includes two stages, namely elastic and elastic–plastic. With an increasing steel ratio, the elastic stage becomes longer and the slope of the elastic–plastic stage increases, indicating a significant enhancement in both load-bearing and deformation capacity. With the steel ratio increasing, the ultimate stress of the specimen rises up to 19.2%, while the ultimate strain increases by as much as 37.7%.

- (3)

- The ultimate stresses of the core-loaded and full-section-loaded BSFST specimens are comparable, while the core-loaded specimens exhibit higher ultimate strains. Under core loading, only the bamboo bears the axial load exclusively, while the steel tube functions solely as lateral confinement. In contrast, in full-section-loaded specimens, the steel tube is subjected to direct axial compression and tends to yield prematurely, leading to reduced confinement effectiveness and limited overall deformability.

- (4)

- The existing prediction model for the ultimate stress and strain of BSFST columns was modified by incorporating the hoop confinement coefficient of the steel tube. By validating with both current and previously published experimental data, the proposed modified model characterizes a good agreement between the predicted and experimental results, indicating an excellent prediction for future engineering applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Harelimana, V.; Zhu, J.; Yuan, J.; Uwitonze, C. Investigating the bamboo as alternative partial replacement of steel bars inconcrete reinforcement members. Struct. Des. Tall Spec. Build. 2022, 31, e1921. [Google Scholar] [CrossRef]

- Sharma, B.; Gat’oo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Construct. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Zhong, Z.; Zhou, X.; He, Z.; Wang, J. Creep behavior of full-culm Moso bamboo under long-term bending. J. Build. Eng. 2022, 46, 103710. [Google Scholar] [CrossRef]

- He, Z.; Zhou, H.; Zhou, X.; Du, Y.; Shi, L. Shear failure characteristics and stress-strain relationship of Moso bamboo parallel to the fibers. Ind. Crops Prod. 2024, 222, 119694. [Google Scholar] [CrossRef]

- Wang, R.; Pan, H.; Li, Z.; Xiao, Y. Mechanical behavior of glued laminated bamboo moment-resisting connections. J. Struct. Eng. 2023, 149, 04022220. [Google Scholar] [CrossRef]

- Yu, L.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Zhen, X.; Li, X.; Li, P.; Mou, Q.; Wu, Y.; Yu, Z.; Li, T.; Li, X. High-strength and sustainable bamboo scrimber manufactured with lignin-based biomass adhesive for indoor application. Ind. Crop. Prod. 2025, 233, 121450. [Google Scholar] [CrossRef]

- Sheng, Y.; Tu, D.; Liao, F.; He, C.; Zhang, W.; Meng, C. Flexural behavior and design methodology for bamboo scrimber-aluminum plate composite beams. Eng. Struct. 2023, 292, 116570. [Google Scholar] [CrossRef]

- Wang, M.; Cai, X.; Lu, Y.; He, C.; Noori, A.; Chen, F.; Chen, L.; Jiang, X.; Liu, J. Tensile mechanical properties and failure mechanism of bamboo scrimber under different strain rates. Constr. Build. Mater. 2021, 299, 124258. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, H.; Qi, Y.; Zhu, R.; Li, X.; Yu, W.; Rao, F. Study of the long-term degradation behavior of bamboo scrimber under natural weathering. NPJ Mater. Degrad. 2022, 6, 63. [Google Scholar] [CrossRef]

- Wei, Y.; Zhou, M.; Zhao, K.; Zhao, K.; Li, G. Stress–strain relationship model of glulam bamboo under axial loading. Adv. Compos. Lett. 2020, 29, 2633366x2095872. [Google Scholar] [CrossRef]

- Wei, Y.; Tang, S.; Ji, X.; Zhao, K.; Li, G. Stress-strain behavior and model of bamboo scrimber under cyclic axial compression. Eng. Struct. 2020, 209, 110279. [Google Scholar] [CrossRef]

- Hong, C.; Li, H.; Xiong, Z.; Lorenzo, R.; Corbi, I.; Corbi, O. Experimental and numerical study on eccentric compression properties of laminated bamboo columns with a chamfered section. J. Build. Eng. 2021, 43, 102901. [Google Scholar] [CrossRef]

- Mashrah, W.; Boufendassa, R.; Fu, X.; Mansour, A.; Yu, Y.; Mohammed, A.; Mo, S. Comprehensive review of engineered bamboo in structural engineering: Comparative insights into laminated bamboo and bamboo scrimber. Structures 2025, 76, 108896. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Z.; Tong, K.; Wang, J.; Li, Y. Bond performance of adhesively bonding interface of steel-bamboo composite structure. J. Renew. Mater. 2020, 8, 687–702. [Google Scholar] [CrossRef]

- Zhang, J.; Tong, K.; Shan, Q.; Li, Y. Examining mechanical behavior of steel-bamboo composite I-section column under long-term loading. J. Build. Eng. 2022, 45, 103583. [Google Scholar] [CrossRef]

- Zhao, W.; Zhou, J.; Long, Z.; Peng, W. Compression performance of thin-walled square steel tube/bamboo-plywood composite hollow columns with binding bars. Adv. Struct. Eng. 2018, 21, 347–364. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Y.; Zhao, W.; Yi, D. Compression behaviour of stone dust concrete composite columns comfined with bamboo-plywood and thin-walled steel-tube systems. J. Build. Eng. 2021, 38, 102164. [Google Scholar] [CrossRef]

- Jin, B.; Tian, L.; Hao, J.; Wang, H.; Wang, Y. Axial compressive behavior of twining-bamboo-confined thin-walled steel tubular columns. J. Constr. Steel. Res. 2022, 192, 107246. [Google Scholar] [CrossRef]

- Gan, D.; Li, Z.; Zhang, T.; Zhou, X.; Chung, K. Axial compressive behaviour of circular concrete-filled steel tubular stub columns with an inner bamboo culm. Structures 2020, 26, 156–168. [Google Scholar] [CrossRef]

- Zhang, Z.; Wei, Y.; Yi, J.; Wei, B.; Lin, Y.; Huang, S. Experiments and design of laminated bamboo and concrete-filled steel tube columns under axial compression. Eng. Struct. 2024, 318, 118692. [Google Scholar] [CrossRef]

- Dong, X.; Wei, Y.; Lin, Y.; Xing, Z.; Chen, S. Experimental study of partially encased bamboo scrimber columns under axial compression. Wood Mater. Sci. Eng. 2024, 19, 644–659. [Google Scholar] [CrossRef]

- Feng, P.; Qiang, H.; Ye, L. Discussion and definition on yield points of materials, members and structures. Eng. Mech. 2017, 34, 36–46. (In Chinese) [Google Scholar] [CrossRef]

- GB/T 228.1–2010; Tensile Test of Metallic Materials: Part 1: Test Method at Room Temperature. Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- ASTM D143-23; Standard Test Method for Small Clear Specimens of Timber. American Society for Testing Materials: West Conshohocken, PA, USA, 2023.

- Montuori, R.; Piluso, V.; Tisi, A. Ultimate behaviour of FRP wrapped sections under axial force and bending: Influence of stress–strain confinement model. Compos. Part B-Eng. 2013, 54, 85–96. [Google Scholar] [CrossRef]

- Montuori, R.; Piluso, V.; Tisi, A. Comparative analysis and critical issues of the main constitutive laws for concrete elements confined with FRP. Compos. Part B-Eng. 2012, 43, 3219–3230. [Google Scholar] [CrossRef]

- Wu, F.; Wei, Y.; Lin, Y.; Zhao, K.; Huang, L. Experimental study of bamboo scrimber-filled steel tube columns under axial compression. Eng. Struct. 2023, 280, 115669. [Google Scholar] [CrossRef]

- Wu, F.; Wei, Y.; Lin, Y.; Wang, G.; Ding, M. Confinement effectiveness of bamboo scrimber-filled steel tube columns under axial compression. J. Build. Eng. 2023, 68, 106157. [Google Scholar] [CrossRef]

| Specimens | D (mm) | T (mm) | α | Pu (kN) | fy (MPa) | εy | fu (MPa) | εu |

|---|---|---|---|---|---|---|---|---|

| B86-1 | 86 | / | / | 530.49 | 81.02 | 0.0269 | 83.99 | 0.0468 |

| B86-2 | 86 | / | / | 536.40 | 81.71 | 0.0238 | 84.74 | 0.0405 |

| B86-3 | 86 | / | / | 543.87 | 83.07 | 0.0291 | 86.11 | 0.0514 |

| B90-1 | 90 | / | / | 547.07 | 83.33 | 0.0352 | 86.42 | 0.0518 |

| B90-2 | 90 | / | / | 553.52 | 84.41 | 0.0224 | 87.44 | 0.0369 |

| B90-3 | 90 | / | / | 528.77 | 80.61 | 0.0243 | 83.53 | 0.0461 |

| FD100T4-1 | 100 | 4 | 18.2% | 1199.85 | 110.90 | 0.0061 | 152.85 | 0.0525 |

| FD100T4-2 | 100 | 4 | 18.2% | 1089.66 | 102.29 | 0.0060 | 138.81 | 0.0530 |

| FD100T4-3 | 100 | 4 | 18.2% | 1148.57 | 107.29 | 0.0063 | 146.31 | 0.0536 |

| FD100T6-1 | 100 | 6 | 29.1% | 1365.47 | 116.04 | 0.0046 | 173.95 | 0.0810 |

| FD100T6-2 | 100 | 6 | 29.1% | 1263.40 | 116.92 | 0.0046 | 160.94 | 0.0487 |

| FD100T6-3 | 100 | 6 | 29.1% | 1367.49 | 118.46 | 0.0047 | 174.20 | 0.0716 |

| CD100T4-1 | 100 | 4 | 18.2% | 1055.57 | 122.08 | 0.0209 | 158.87 | 0.1557 |

| CD100T4-2 | 100 | 4 | 18.2% | 1014.64 | 118.07 | 0.0179 | 152.71 | 0.1559 |

| CD100T4-3 | 100 | 4 | 18.2% | 980.56 | 119.76 | 0.0214 | 147.58 | 0.1512 |

| CD100T6-1 | 100 | 6 | 29.1% | 1009.85 | 116.01 | 0.0249 | 166.12 | 0.1537 |

| CD100T6-2 | 100 | 6 | 29.1% | 1062.13 | 118.03 | 0.0273 | 174.72 | 0.1551 |

| CD100T6-3 | 100 | 6 | 29.1% | 1032.40 | 119.05 | 0.0289 | 169.83 | 0.1579 |

| Steel Tube | Yield Stress (MPa) | Ultimate Stress (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|

| T4 | 356.15 | 489.52 | 205.96 |

| T6 | 316.35 | 469.76 | 205.47 |

| Tension | Compression | ||||

|---|---|---|---|---|---|

| Ultimate Stress (MPa) | Ultimate Strain | Elastic Modulus (GPa) | Ultimate Stress (MPa) | Ultimate Strain | Elastic Modulus (GPa) |

| 154.32 | 0.0084 | 18.50 | 88.88 | 0.0352 | 16.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Z.; Wei, Y.; Zhao, K.; Lu, J.; Wei, B.; Lin, Y. Axial Compression Behavior of Bamboo Scrimber-Filled Steel Tubular (BSFST) Column Under Different Loading Modes. Materials 2025, 18, 3607. https://doi.org/10.3390/ma18153607

Xing Z, Wei Y, Zhao K, Lu J, Wei B, Lin Y. Axial Compression Behavior of Bamboo Scrimber-Filled Steel Tubular (BSFST) Column Under Different Loading Modes. Materials. 2025; 18(15):3607. https://doi.org/10.3390/ma18153607

Chicago/Turabian StyleXing, Ze, Yang Wei, Kang Zhao, Jinwei Lu, Baoxing Wei, and Yu Lin. 2025. "Axial Compression Behavior of Bamboo Scrimber-Filled Steel Tubular (BSFST) Column Under Different Loading Modes" Materials 18, no. 15: 3607. https://doi.org/10.3390/ma18153607

APA StyleXing, Z., Wei, Y., Zhao, K., Lu, J., Wei, B., & Lin, Y. (2025). Axial Compression Behavior of Bamboo Scrimber-Filled Steel Tubular (BSFST) Column Under Different Loading Modes. Materials, 18(15), 3607. https://doi.org/10.3390/ma18153607