Effect of Copper in Gas-Shielded Solid Wire on Microstructural Evolution and Cryogenic Toughness of X80 Pipeline Steel Welds

Highlights

- When Cu is added in excess, the AF content in the weld decreases by approximately 20%.

- The reduction in AF content led to a decrease in the critical crack size, high-angle grain boundary density, and crack propagation angle, and the low-temperature impact toughness dropped from 221.08 J to 151.59 J, a decrease of 31.4%.

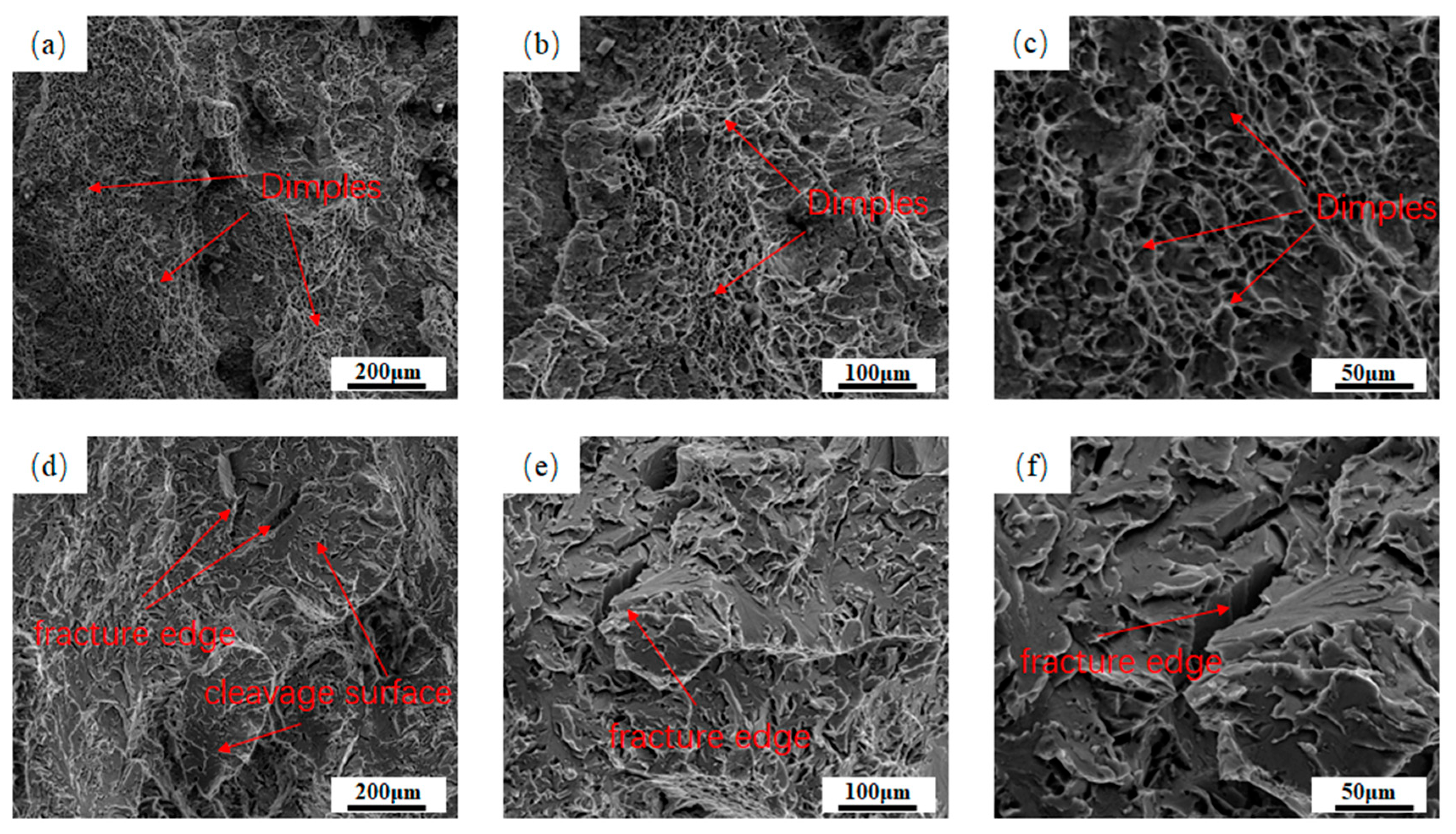

- The fracture surface of the high-Cu weld shows quasi-cleavage characteristics, the main crack propagation path is smooth, and there are micro-holes around the secondary crack, which stop at AF.

Abstract

1. Introduction

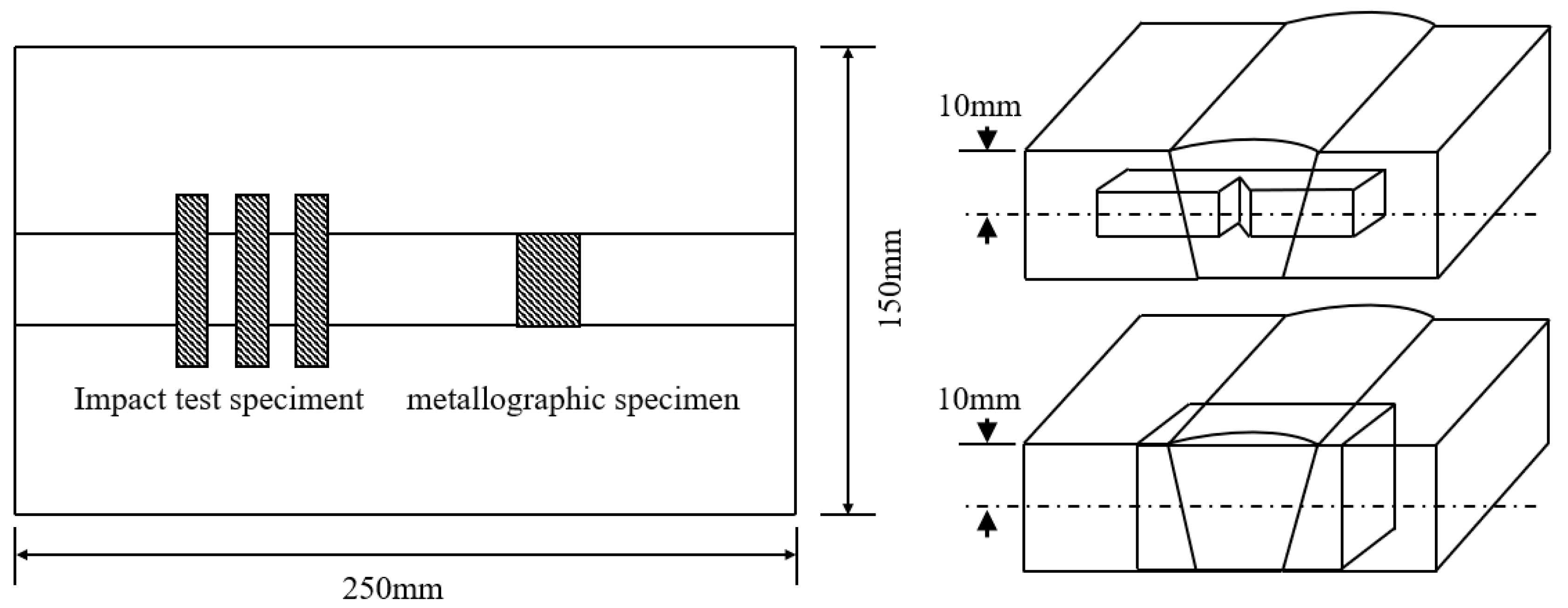

2. Experimental Materials and Methods

3. Experimental Results and Analysis

3.1. Mechanical Properties

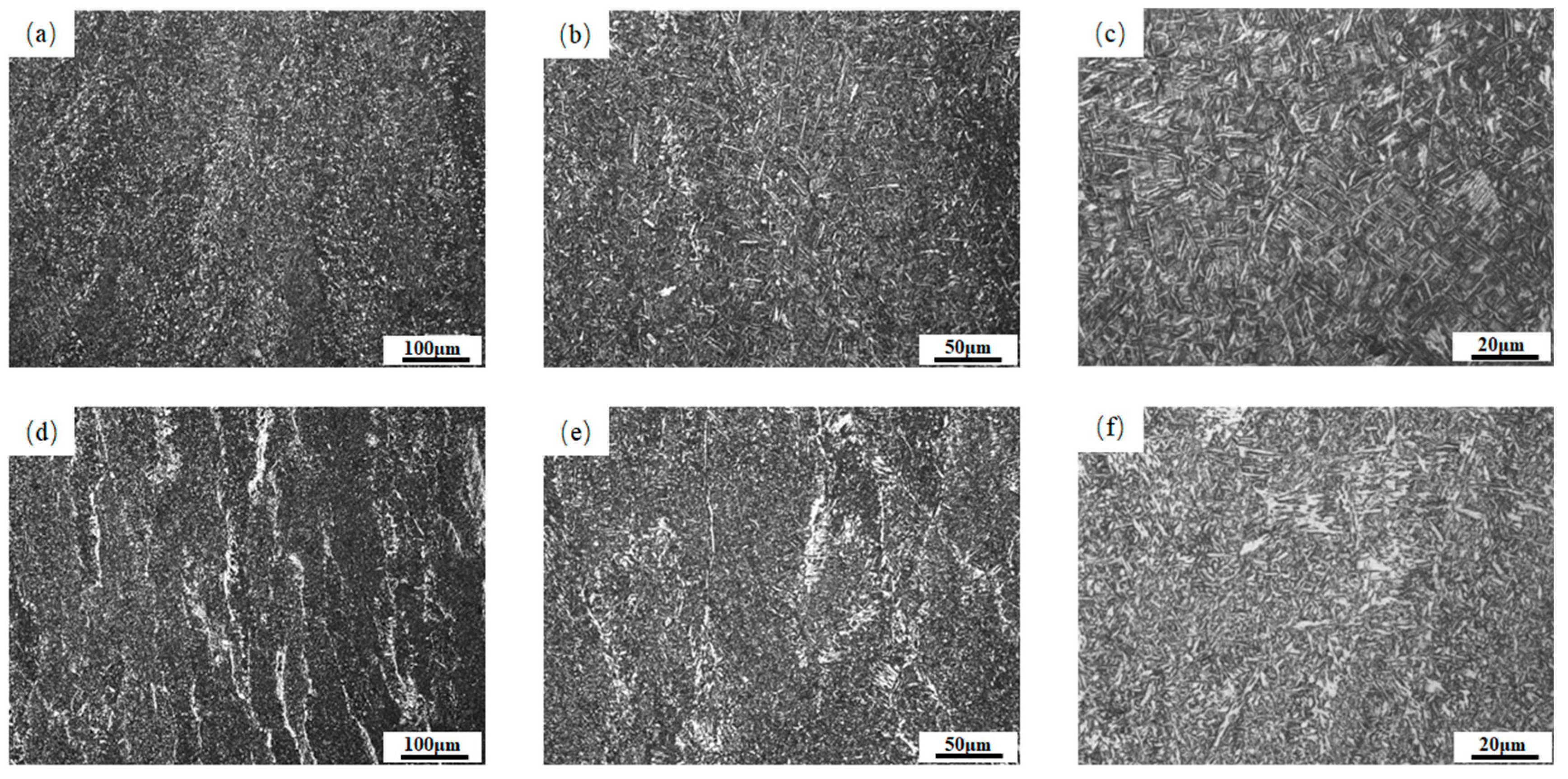

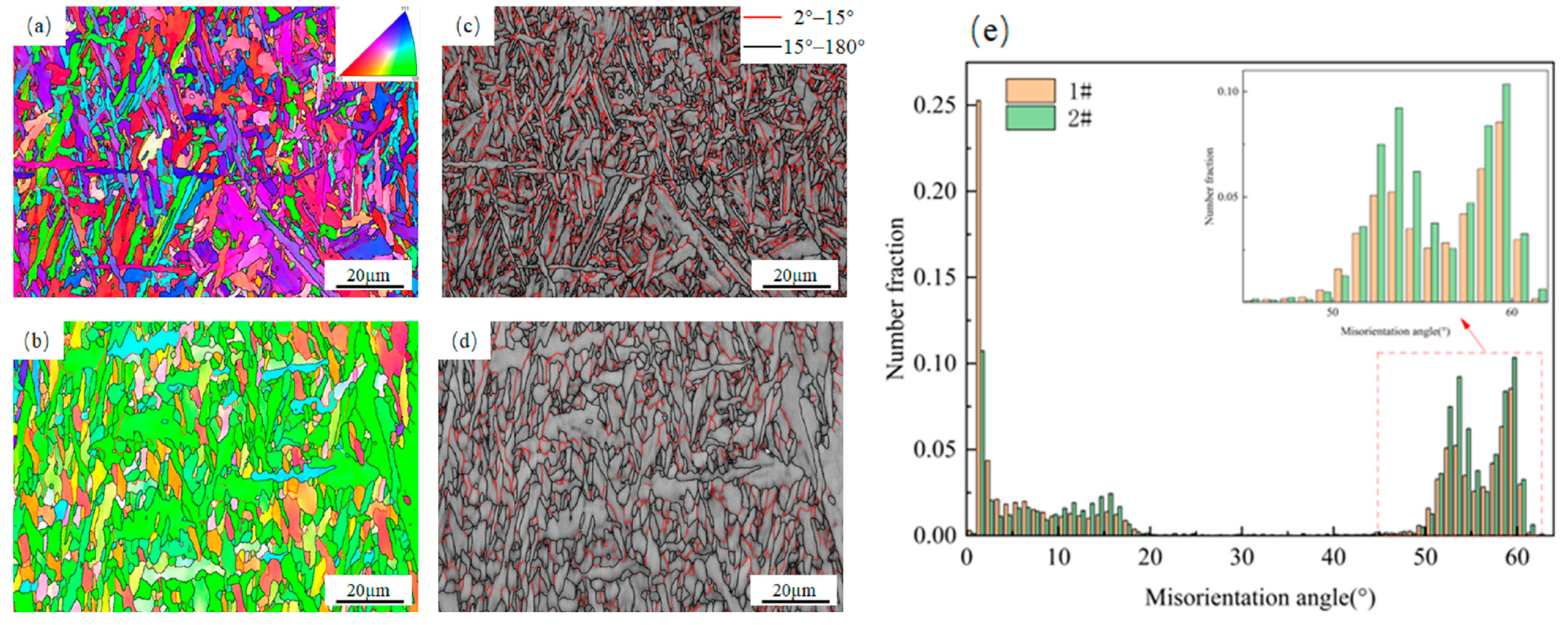

3.2. Weld Microstructure

4. Discussion

4.1. The Influence of Cu on the Weld Microstructure

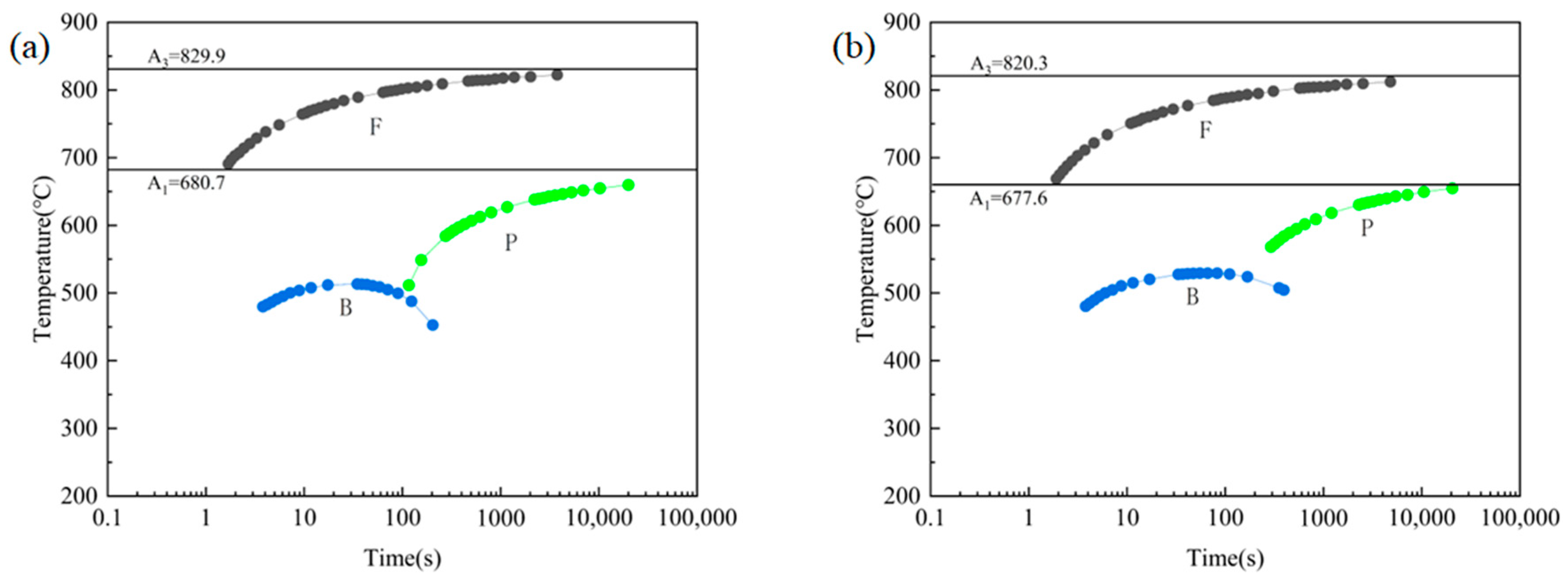

4.1.1. The Influence of Copper on the Phase Transformation Temperature

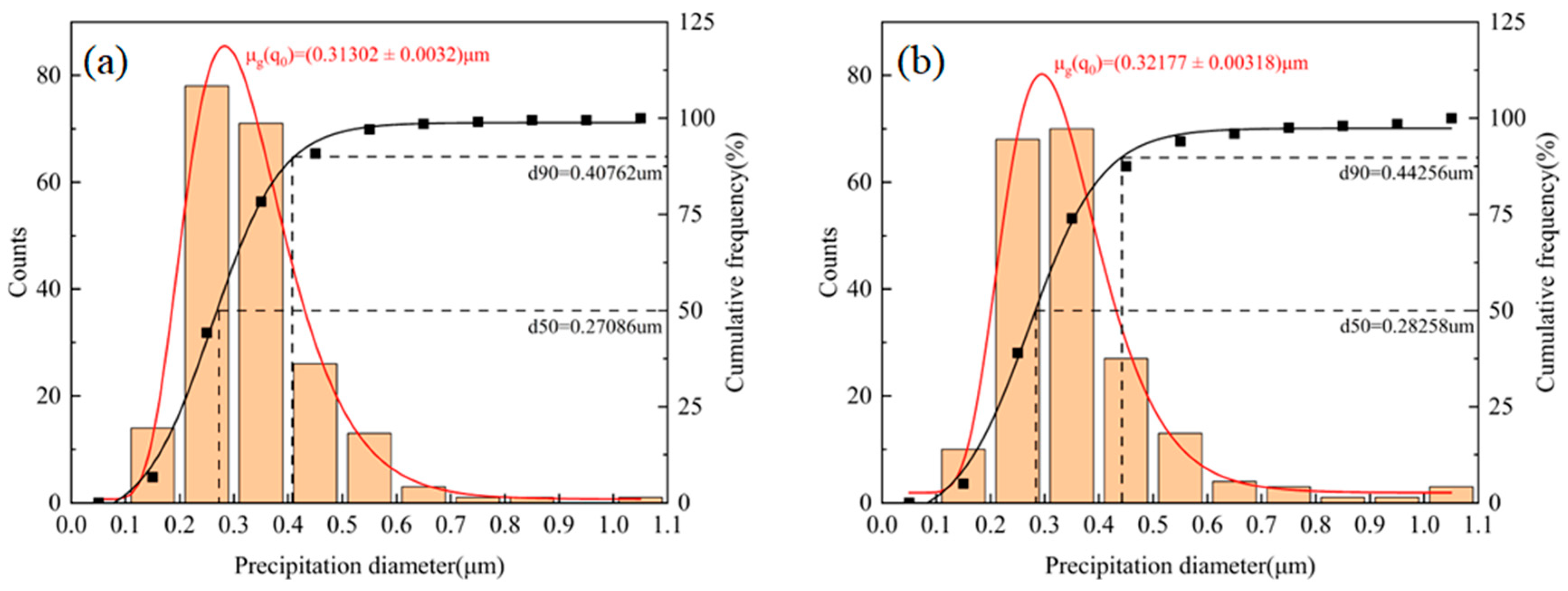

4.1.2. The Influence of Copper on the Characteristics of Inclusions

4.1.3. The Influence of Copper on the Prior Austenite Grain Size

4.2. The Influence of Weld Microstructure on Critical Crack Size

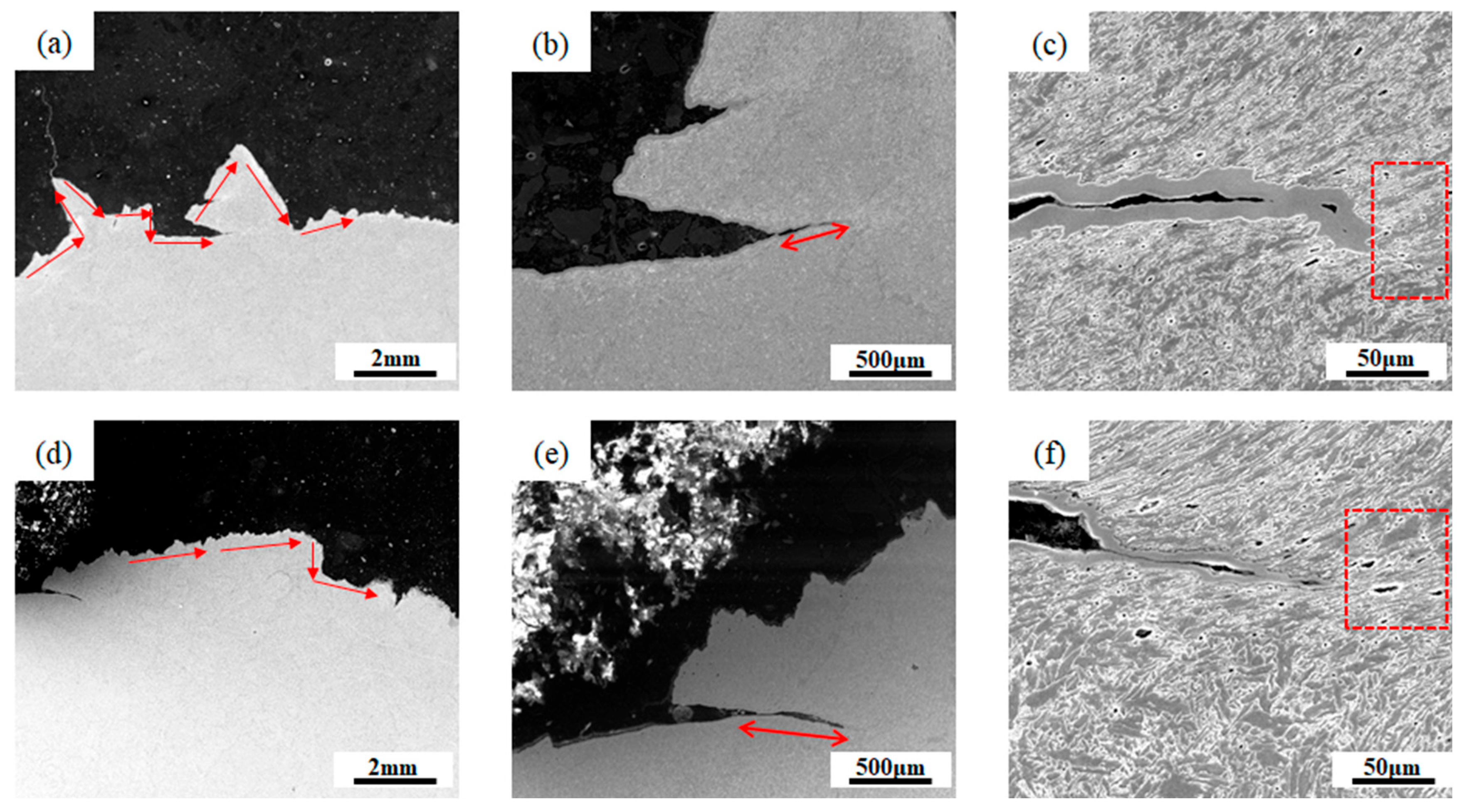

4.3. The Influence of Weld Microstructure on Crack Expansion Angle

4.4. Fracture Morphology Analysis

4.4.1. Fracture Morphology

4.4.2. Crack Propagation Path

5. Conclusions

- When the Cu content in the weld increases from 0.13% to 0.34%, the low-temperature impact toughness declines from 221.08 J down to 151.59 J, representing a 31.4% reduction in impact toughness.

- When the Cu content in the weld increases, the content of acicular ferrite in the weld tissue decreases by about 20%, and the effective grain size of the weld increases by about 25%.

- The reduction in acicular ferrite content in the weld leads to a decrease in the critical crack size and high-angle grain boundary density, which reduces the crack extension angle from 54.73° to 45°. The steady-state crack propagation energy is significantly reduced, leading to a smoother crack propagation path and ultimately diminishing the low-temperature toughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Zhang, L.Z.; Gao, W.X. Historical development and future prospects of pipeline steel. Oil Gas Storage Transp. 2022, 41, 1355–1362. [Google Scholar]

- Liu, Y.; Liu, J.; Zhang, B.; Wang, L.L.; Sun, S.Y.; Hou, J. Development status and trend of pipeline steel for long-distance natural gas transportation in China. Trans. Mater. Heat Treat. 2024, 45, 98–112. [Google Scholar]

- Feng, Y.R.; Huo, C.Y.; Ji, L.K.; Li, H.L. Progress and prospect of research and application of high grade pipeline steels & steel pipes in China. Pet. Sci. Bull. 2016, 1, 143–153. [Google Scholar]

- Kong, X.L.; Huang, G.J.; Huang, M.H.; Xu, F. Effect of Composition and Process on Microstructure and Property of X80 Pipeline Steel. Hot Work. Technol. 2011, 40, 20–23. [Google Scholar]

- Wang, X.X. New Challenges of Pipeline Safety to Welded Pipe Manufacturing Technology. Welded Pipe Tube 2020, 43, 1–5. [Google Scholar]

- Duan, H.; Shan, Y.-Y.; Yang, K. Experimental on process, microstructure and mechanical properties of X80 high strength pipeline steel for low temperature. Iron Steel 2020, 55, 103–111. [Google Scholar]

- Gao, H.L. The Challenges for Pipeline Projects & Development trends of Pipelin steel. Welded Pipe Tube 2010, 33, 5–18. [Google Scholar]

- Li, L.S.; Luan, J.Y.; Sun, X.H.; Fang, N.W. A Brief Analysis of the Development Status of Welding Materials in China. Electr. Appl. Ind. 2010, 1, 10–16. [Google Scholar]

- Xin, G.S. Application of mechanical descaling on production of gas shielded copper-plating welding wire. Met. Prod. 2017, 43, 32–35. [Google Scholar]

- Dong, L.M.; Yang, L.; Dai, J.; Zhang, Y.; Wang, X.; Shang, C.J. Effect of Mn, Ni, Mo Contentson Microstructure Transition and Low Temperature Toughness of Weld Metal for K65 Hot Bending Pipe. Acta Metall. Sin. 2017, 53, 657–668. [Google Scholar]

- Chu, Q.L.; Xu, S.; Tong, X.W.; Li, J.; Zhang, M.; Yan, F.; Zhang, W.P.; Bi, Z.Y.; Yan, C. Comparative Study of Microstructure and Mechanical Properties of X80 SAW Welds Prepared Using Different Wires and Heat Inputs. J. Mater. Eng. Perform. 2020, 29, 4322–4338. [Google Scholar] [CrossRef]

- Avazkonandeh-Gharavol, M.H.; Haddad-Sabzevar, M.; Haerian, A. Effect of copper content on the microstructure and mechanical properties of multipass MMA, low alloy steel weld metal deposits. Mater. Des. 2009, 30, 1902–1912. [Google Scholar] [CrossRef]

- Evans, G.M.; Es-Souni, M.; Beaven, E.A. Microstructure of Copper-bearing C-Mn Weld Metal: As-welded and Stress-relieved States. Mater. Sci. Eng. 1990, 130, 173–184. [Google Scholar]

- Li, K.; Shan, J.G.; Wang, C.X.; Tian, Z.L. The role of copper in microstructures and mechanical properties of laser-welded Fe-19Ni-3Mo-1.5Ti maraging steel joint. Mater. Sci. Eng. A 2017, A618, 41–49. [Google Scholar] [CrossRef]

- GB/T 19748-2019; Metallic Materials—Charpy V-Notch Pendulum Impact Test—Instrumented Test Method. Standardization Administration of the People’s Republic of China and Standardization Administration of China: Beijing, China, 2019.

- GB/T·228-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standardization Administration of the People’s Republic of China and Standardization Administration of China: Beijing, China, 2021.

- Li, Y.L.; Li, Z.H. Research on Material Selection Method and Brittle Fracture Mechanism of High-Pressure Pipeline. Shock. Vib. 2023, 15, 9541736.3148–3163. [Google Scholar] [CrossRef]

- Yang, Y.L.; Jia, X.; Ma, Y.X.; Wang, P.; Zhu, F.X.; Yang, H.F.; Wang, C.; Wang, S.G. Effect of Nb on microstructure and mechanical properties between base metal and high heat input coarse-grain HAZ in a Ti-deoxidized low carbon high strength steel. J. Mater. Res. Technol. 2022, 18, 2399–2412. [Google Scholar] [CrossRef]

- Xi, X.H.; Wang, J.L.; Chen, L.Q.; Wang, Z. On the role of Cu addition in toughness improvement of coarse grained heat affected zone in a low carbon high strength steel. J. Mater. Sci. 2020, 55, 10863–10877. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Jia, T.; Zhang, X.J.; Liu, Z.; Misra, R.D.K. Microstructure and toughness of the CGHAZ of an offshore platform steel. J. Mater. Process. Technol. 2015, 219, 314–320. [Google Scholar] [CrossRef]

- Jorge, J.C.F.; De Souza, L.F.G.; Mendes, M.C.; Bott, I.S.; Araújo, L.S.; dos Santos, V.R.; Rebello, J.M.A.; Evans, G.M. Microstructure characterization and its relationship with impact toughness of C–Mn and high strength low alloy steel weld metals—A review. J. Mater. Res. Technol. 2021, 10, 471–501. [Google Scholar] [CrossRef]

- Zhong, Y.; Xiao, F.; Zhang, J.W.; Shan, Y.; Wang, W.; Yang, K. In situ TEM study of the effect of M/A films at grain boundaries on crack propagation in an ultra-fine acicular ferrite pipeline steel. Acta Mater. 2006, 54, 435–443. [Google Scholar] [CrossRef]

- Rodriguez-Ibabe, J.M. The role of microstructure in toughness behaviour of microalloyed steels. Mater. Sci. Forum 1998, 284–286, 51–62. [Google Scholar] [CrossRef]

- Perlovich, Y.A.; Isaenkova, M.G.; Krymskaya, O.A.; Morozov, N.S. Layer texture of hot-rolled BCC metals and its significance for stress-corrosion cracking of main gas pipelines. AIP Conf. Proc. 2016, 1769, 130011. [Google Scholar]

- Nedjad, S.H.; Moghaddam, Y.Z.; Vazirabadi, A.M.; Shirazi, H.; Ahmadabadi, M.N. Grain refinement by cold deformation and recrystallization of bainite and acicular ferrite structures of C–Mn steels. Mater. Sci. Eng. A 2011, 528, 1521–1526. [Google Scholar] [CrossRef]

- Yang, Y.L.; Jia, X.; Wang, P.; Zhu, F. Research Progeress on Control Technology of Acicular Ferrite in CGHAZ for Large Heat input Welding Steels. Mater. Rep. 2022, 36, 149–159. [Google Scholar]

- Wan, X.L.; Wu, K.M.; Nune, K.C.; Li, Y.; Cheng, L. In situ observation of acicular ferrite formation and grain refinement in simulated heat affected zone of high strength low alloy steel. Sci. Technol. Weld. Join. 2015, 20, 254–263. [Google Scholar] [CrossRef]

- Barbaro, F.J.; Krauklis, P.; Easterling, K.E. Formation of acicular ferrite at oxide particles in steels. Mater. Sci. Technol. 1989, 5, 1057–1068. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, A.H.; Xiao, H.J.; Tian, Z.L. Effect of Cu on microstructure forming and refining of weld metal in 690 MPa grade HSLA steel. Acta Metall. Sin. 2012, 48, 1281–1289. [Google Scholar] [CrossRef]

- Huang, G.; Wan, X.; Wu, K.; Isayev, O.; Hress, O.; Rodionova, I.; Shirzadi, A.A. Effect of Cu addition on microstructure and impact toughness in the simulated coarse-grained heat-affected zone of high-strength low-alloy steels. Mater. Sci. Technol. 2017, 33, 602–614. [Google Scholar] [CrossRef]

- Yao, H.; Liu, C.J.; Zhang, L.F. Effect of austenite grain size on the acicular ferrite transformation in Ti-Zr treated steel. Chin. J. Eng. 2023, 45, 907–914. [Google Scholar]

- Li, H.; Hui, W.J.; Wang, J. Effect of Cu Element on the Corrosion Behavior of 42CrMoV High Strength Bolt Steel in Simulated Weathering Environment. Mater. Prot. 2020, 53, 13–20. [Google Scholar]

- Wang, J.; Wang, Z.; Chen, T. Numerical Study of Effect of Fatigue Cracking on Life of Submarine Pipeline Elbows. Process Autom. Instrum. 2025, 46, 117–126. [Google Scholar]

- Xu, D.M.; Qin, G.W.; Li, F.; Wang, Z.; Zhong, J.; Li, Z.; He, L. Tensile deformation and fracture behavior of polycrystalline Be at room temperature. Acta Metall. Sin. 2014, 50, 1078–1086. [Google Scholar]

- Sreenivasan, P.R.; Ray, S.K.; Mannan, S.L.; Rodriguez, P. Dynamic fracture toughness and Charpy impact properties of an AISI403 martensitic stainless steel. J. Nucl. Mater. 1996, 228, 338–345. [Google Scholar] [CrossRef]

- Di Schino, A.; Guarnaschelli, C. Effect of microstructure on cleavage resistance of high-strength quenched and tempered steels. Mater. Lett. 2009, 63, 1968–1972. [Google Scholar] [CrossRef]

- Li, X.D.; Ma, X.P.; Subramanian, S.V.; Shang, C.; Misra, R.D.K. Influence of prior austenite grain size on martensite–austenite constituent and toughness in the heat affected zone of 700 MPa high strength linepipe steel. Mater. Sci. Eng. A 2014, 616, 141–147. [Google Scholar] [CrossRef]

- Lan, L.Y.; Qiu, C.L.; Zhao, D.W.; Gao, X.; Du, L. Microstructural characteristics and toughness of the simulated coarse grained heat affected zone of high strength low carbon bainitic steel. Mater. Sci. Eng. A 2011, 529, 192–200. [Google Scholar] [CrossRef]

- Gai, D.Y.; Liu, J.; Li, Q.X.; Chen, Z.; Zhang, M. Influence of the Hot Deformation Conditions on the Texture Evolution in Mg-8Li-5Zn-2Re Alloy. Rare Met. Mater. Eng. 2013, 42, 673–678. [Google Scholar] [CrossRef]

- Huang, Y.; Guo, W.; Wang, Y.L. Effects of introductions of oxygen and nitrogen elements on impact toughness of gas pool coupled activating TIG weld metal. Trans. China Weld. Inst. 2022, 43, 83–89. [Google Scholar]

- Lan, L.Y.; Qiu, C.L.; Zhao, D.W.; Gao, X.; Du, L. Analysis of microstructural variation and mechanical behaviors in sub-merged arc welded joint of high strength low carbon bainitic steel. Mater. Sci. Eng. A 2012, 558, 592–601. [Google Scholar] [CrossRef]

- Caty, O.; Buffiere, J.-Y.; Maire, E.; Adrien, J. 3D Characterization of the Influence of Porosity on Fatigue Properties of a Cast Al Alloy. Adv. Eng. Mater. 2011, 13, 194–198. [Google Scholar] [CrossRef]

| No. | C | Si | P | S | Ti | Cr | Mn | Ni | Cu | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| 1# | 0.091 | 0.72 | 0.007 | 0.005 | 0.045 | 0.053 | 1.38 | 0.81 | 0.13 | 0.034 |

| 2# | 0.095 | 0.65 | 0.005 | 0.008 | 0.042 | 0.057 | 1.41 | 0.80 | 0.34 | 0.052 |

| No. | Fy (kN) | Fm (kN) | Fa (kN) | Wi (J) | Wp (J) | Cryogenic Impact Toughness (J) |

|---|---|---|---|---|---|---|

| 1# | 15.37 | 22.46 | 6.88 | 72.64 | 140.96 | 221.08 ± 10.12 |

| 2# | 16.02 | 21.54 | 4.05 | 58.93 | 81.29 | 151.59 ± 12.38 |

| NO. | Ti | Mn | S | O | Si | Fe |

|---|---|---|---|---|---|---|

| 1# | 16.6 | 6.6 | 0.4 | 22.1 | 0.8 | 53.5 |

| 2# | 18 | 9 | 0.8 | 20 | 0.4 | 51.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, L.; Hong, R.; Ma, Q.-L.; Liu, N.-S.; Yin, S.-B.; Jia, S.-J. Effect of Copper in Gas-Shielded Solid Wire on Microstructural Evolution and Cryogenic Toughness of X80 Pipeline Steel Welds. Materials 2025, 18, 3519. https://doi.org/10.3390/ma18153519

Peng L, Hong R, Ma Q-L, Liu N-S, Yin S-B, Jia S-J. Effect of Copper in Gas-Shielded Solid Wire on Microstructural Evolution and Cryogenic Toughness of X80 Pipeline Steel Welds. Materials. 2025; 18(15):3519. https://doi.org/10.3390/ma18153519

Chicago/Turabian StylePeng, Leng, Rui Hong, Qi-Lin Ma, Neng-Sheng Liu, Shu-Biao Yin, and Shu-Jun Jia. 2025. "Effect of Copper in Gas-Shielded Solid Wire on Microstructural Evolution and Cryogenic Toughness of X80 Pipeline Steel Welds" Materials 18, no. 15: 3519. https://doi.org/10.3390/ma18153519

APA StylePeng, L., Hong, R., Ma, Q.-L., Liu, N.-S., Yin, S.-B., & Jia, S.-J. (2025). Effect of Copper in Gas-Shielded Solid Wire on Microstructural Evolution and Cryogenic Toughness of X80 Pipeline Steel Welds. Materials, 18(15), 3519. https://doi.org/10.3390/ma18153519