Elastic–Plastic Analysis of Asperity Based on Wave Function

Abstract

1. Introduction

2. Methodology

2.1. Elastic–Plastic Contact Model of Wavy Asperity

2.1.1. Elastic Phase

2.1.2. Elastoplastic Phase

2.1.3. Fully Plastic Phase

2.2. Rough Surface Contact Model

2.3. Verification of Discretization of Wavy Asperity

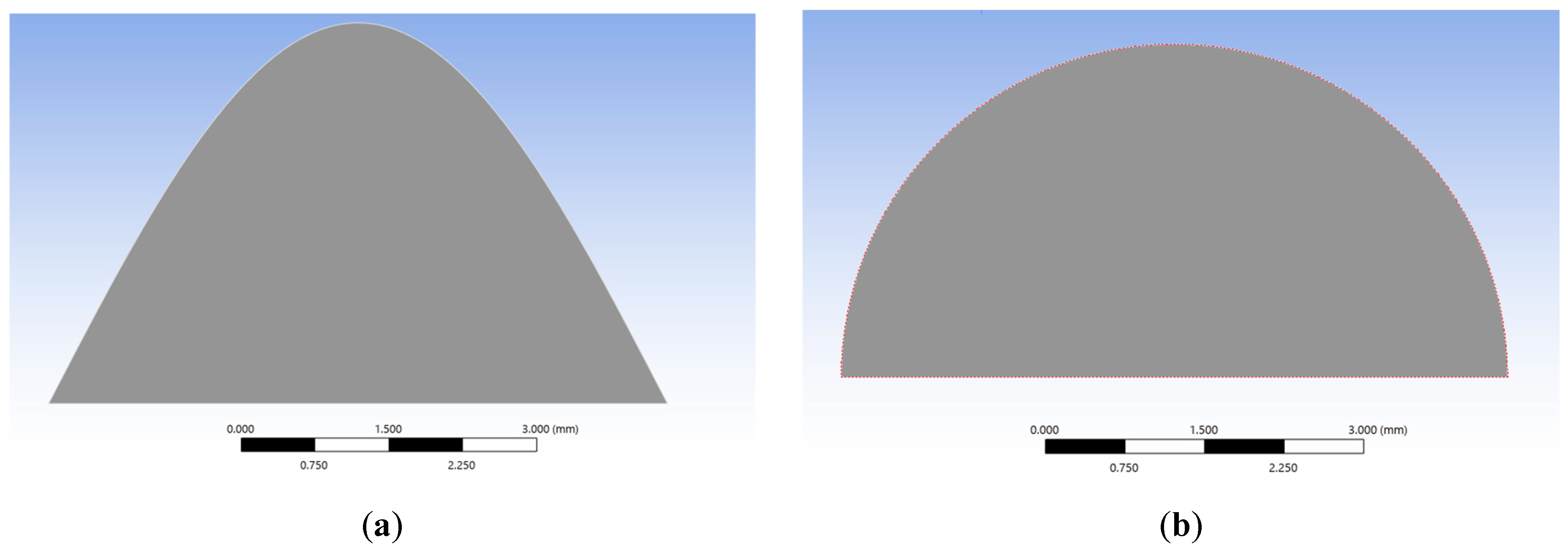

2.3.1. Asperity Model Construction

2.3.2. Discretization Error Analysis

2.4. Validation of Contact Model of Wavy Asperity

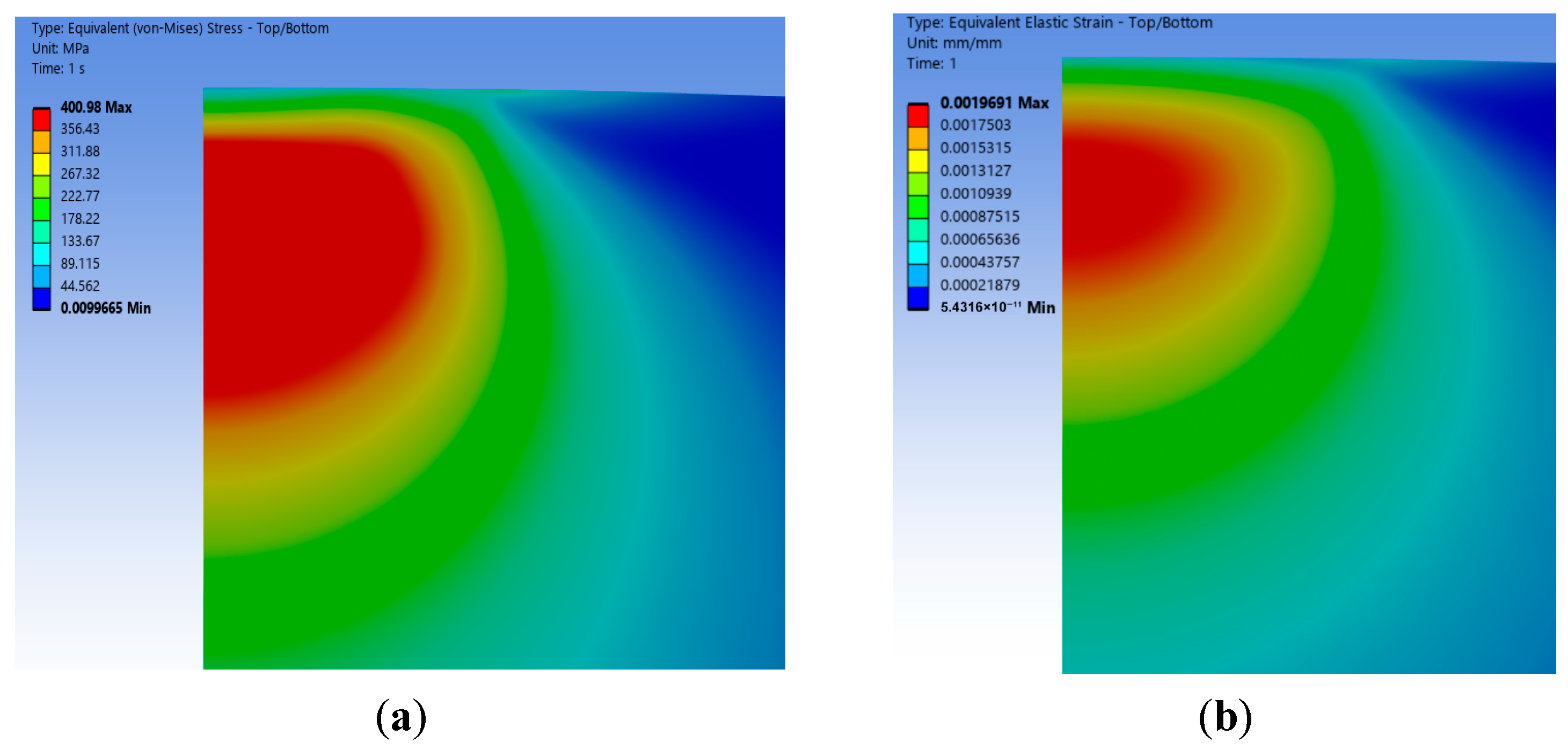

2.4.1. Stress–Strain Distribution

- (1)

- The equivalent stress value of the wavy asperity is 400.98 MPa, which is close to the yield strength limit of the asperity, and the stress size and distribution are in line with the real contact surface; observing the stress and strain distribution area, it is mainly concentrated in the downward position of the contact surface, presenting non-elliptic symmetry and showing nonlinear increasing and then decreasing changes along the axial y direction. Combined with the fact that the contact area is much smaller than the radius of the bottom surface R, which is still in the range of small deformation, it proves that the Hertz theory is also applicable to the wavy asperity.

- (2)

- According to the classic Hertz theory prediction, the maximum stress distribution of a spherical asperity is also concentrated at the lower position of the contact surface, and the stress concentration zone is closer to the bottom than that of the wavy asperity, with a stress value of 393.24 MPa, and it is axisymmetric and semi-ellipsoidal in distribution. In terms of numerical values, the difference between the spherical asperity and the specified material yield strength is greater than that of the wavy asperity, and the strain is also relatively small compared to the wavy asperity (0.00196691 mm). It is believed that based on Hertz’s elastic theory, the radius of curvature of the wavy asperity is 33% of that of the spherical one, which leads to a more centralized stress in the wavy asperity, and thus, the stress–strain distribution of the wavy asperity in the elastic phase is more accurate than that of the spherical one.

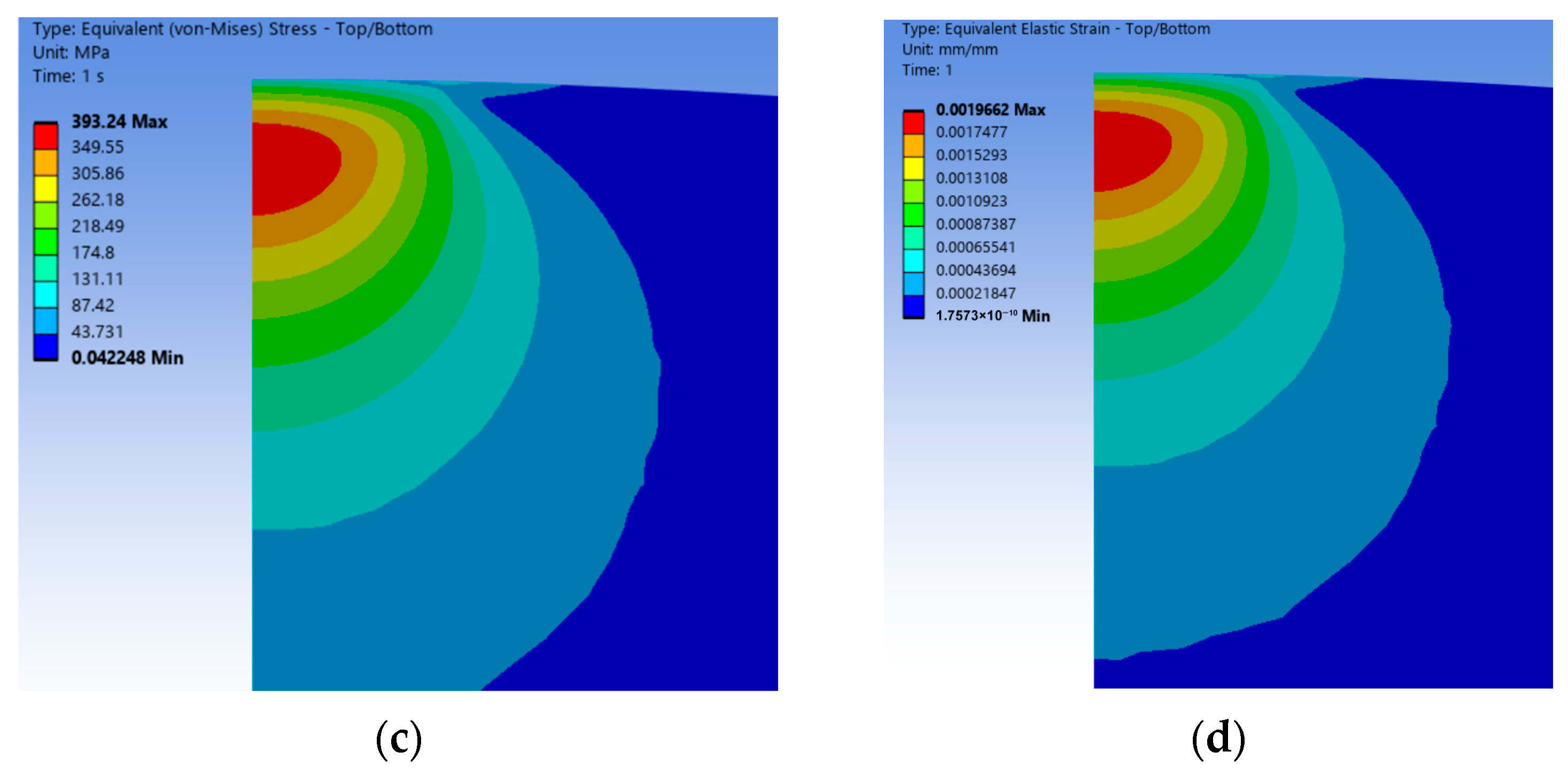

- (1)

- The equivalent stresses of the wavy asperity and the spherical asperity are closer to each other in the elastoplastic phase, and they jointly show that the stress in the elastic phase rises slightly with the increase in the contact depth, but the overall change is kept flat; in contrast, the upward trend of the plastic strain varies more, showing a rapid increase in the elastoplastic beginning, and then the upward trend tends to flatten out. The whole elastoplastic change behavior can conform to the predicted values of the elastoplastic model of ZMC [6] and Brake [9] et al.

- (2)

- The equivalent elastic strains of the wavy asperity and the spherical asperity at this phase are roughly similar in terms of the numerical values and the strain distribution cloud diagrams, with the elastic strains being around 0.002 mm, while the plastic strain of the wavy asperity is 0.0532 mm, which is about 52% of that of the spherical asperity, suggesting that the increase in plastic strain of the wavy asperity slows down with the increase in the depth of contact. Whereas the spherical asperity is a purely ideal case, the curvature does not change, which means that the plastic deformation of the spherical asperity is more rapid, and the trend of the stiffness is not as obvious as that of the wavy asperity. In the strain distribution region, the overall strain distribution of the wavy asperity shows asymmetric plastic flow (Figure 4c), with localized shear zones appearing at the contact edges. According to Chu et al.’s [13] indentation experiments, the real surface activates multiple localized contact points under load, which means that the real surface morphology generates a complex multiaxial stress state, and thus, the strain concentration phenomenon is more pronounced in the contacted individual asperity. While the single point of contact predicted by the spherical model (Hertz theory) is not consistent with the actual observation, the change in the wavy asperity in the elastoplastic phase is closer to the real physical mechanism.

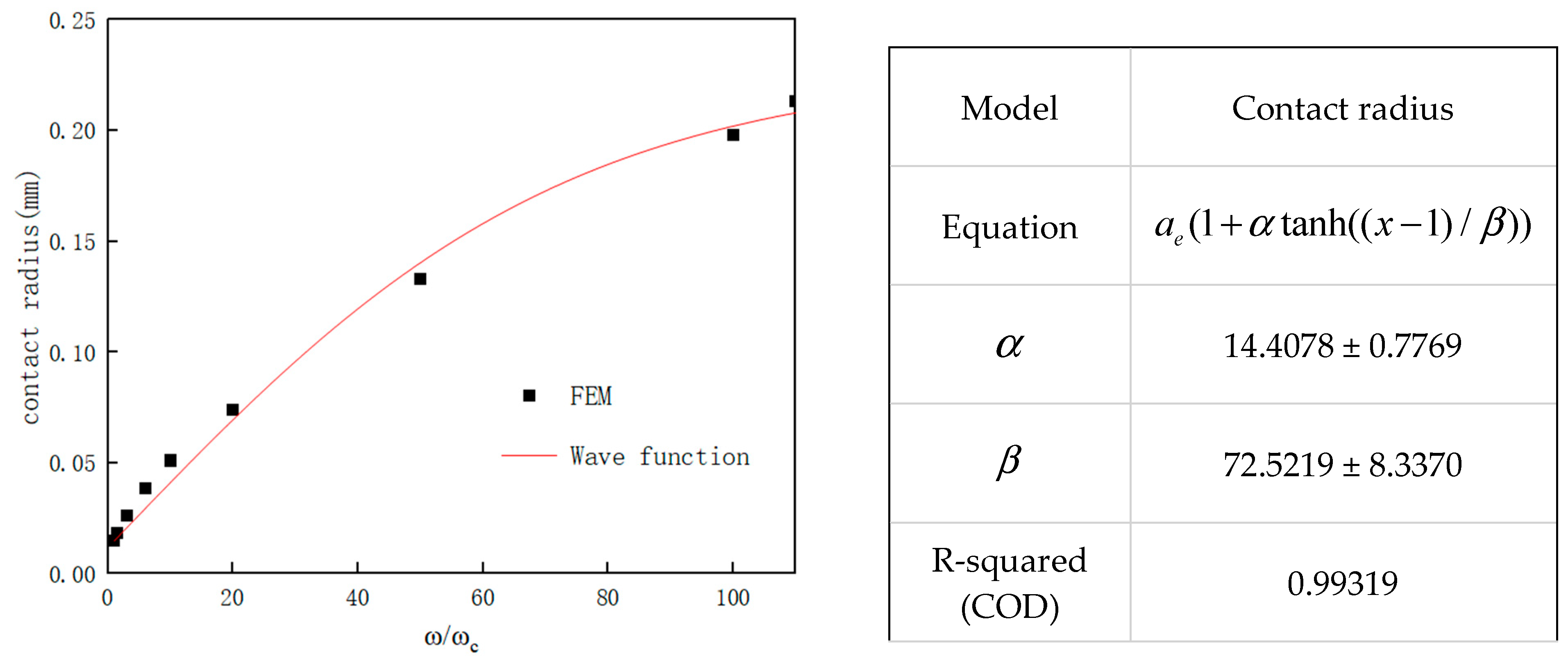

2.4.2. Elastoplastic Contact Model

- (1)

- Elastic phase : The contact area and load of the wavy asperity coincide with the results of the Hertz contact theory, while the initial contact area of the wavy asperity is smaller than that of the sphere due to the smaller radius of curvature of the contact vertices, which is 33% of that of the sphere, and the errors between the finite element values of both of them and the theoretical formulas are within 5%, which indicates that the use of the Hertz contact theory is correct in the elastic phase. The Hertz contact theory is correct and applicable to both types of asperities.

- (2)

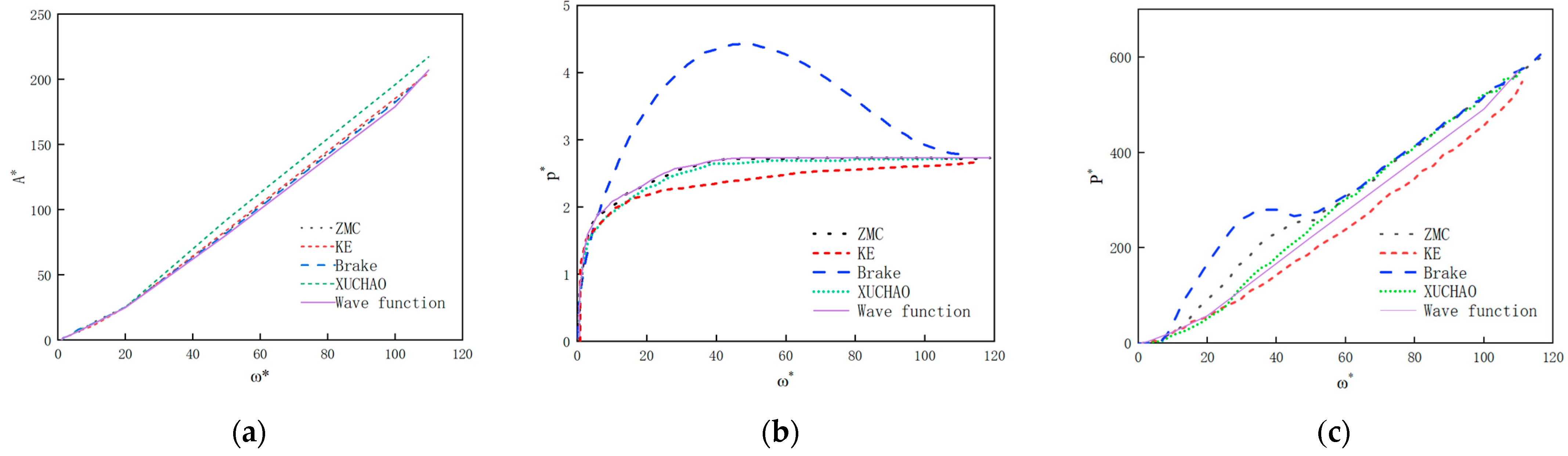

- Elastic–plastic phase : At the initial phase of , the contact area of the wavy asperity grows at a multiplier of about 1.83, and that of the spherical body is about 1.5, and the growth rate is about 22% faster than that of the spherical body. The growth rate of the contact load of the wavy body grows at a multiplier of about 1.89, and that of the spherical body is about 1.8, and the growth rate is similar. The contact pressure growth multiplier is about 1.2 for the wavy asperity and about 1.23 for the spherical body, and the growth rate is about 3% slower than that of spherical body because in this phase, the radius of curvature of the wavy asperity is small, which leads to the fast diffusion of the plastic region; while reaching the plastic phase at , the contact area, contact load, and average growth rate of the contact pressure of the wavy asperity and the spherical body converge to the same level, and the theoretical and numerical results converge to the same level. This indicates that the mechanical behaviors of the wavy and spherical asperities show monotonically increasing trends throughout the elastoplastic phase, but the increasing trend of the wavy asperity slows down, which is consistent with the conclusion that there is a critical point in the KE model in the elastoplastic phase.

- (3)

- Fully plastic phase : The contact area of the wavy asperity follows the projected area theory, and the flattening process of the numerically analyzed asperity is consistent, whereas the spherical model overestimates the contact area by nearly 20% due to the assumption of volume conservation (1.1014 mm2 versus 1.3028 mm2, calculated by ), which is consistent with the experimental situation in Ref. [13], and in terms of the contact radius, the contact radius is 18.8% of the radius of the asperity. It is debatable whether the small deformation assumption can be continued, so the wavy asperity is more consistent with the real contact situation than the spherical asperity.

2.4.3. Surface Contact Model

3. Results

- (1)

- This paper uses the finite element method to compare the stress–strain conditions of wavy and spherical asperities through numerical analysis. Under the assumption that discrete interference is excluded, we find that the wavy asperity exhibits asymmetric plastic flow and multiple stress concentration zones, with local shear force bands appearing at the contact edges. This is consistent with experimental observations of multi-axial stress states in real contact. Furthermore, under the same initial displacement load conditions, the behavior at and is more consistent with contact laws than that of a spherical body.

- (2)

- The theoretical models of the wavy asperity in the elastic, elastoplastic, and fully plastic phases are derived. The Hertz contact theory is adopted in the elastic phase, and the radius of curvature at the apex of the wavy asperity is , which is 33% of that of the spherical asperity of the equal bottom edge length, leading to a more centralized initial contact stress; in the elastoplastic phase, the hyperbolic tangent function () is introduced to describe the nonlinear transition, which ensures the continuity and monotonicity of the critical points ( and ). Combining finite element analysis and least squares fitting, the parameters , , , and are obtained, and the goodness-of-fit is more than 0.97. In the fully plastic phase, it follows the geometric projection theory (), which avoids the overestimation of the 20% area of the spherical asperity caused by the assumption of the conservation of volume.

- (3)

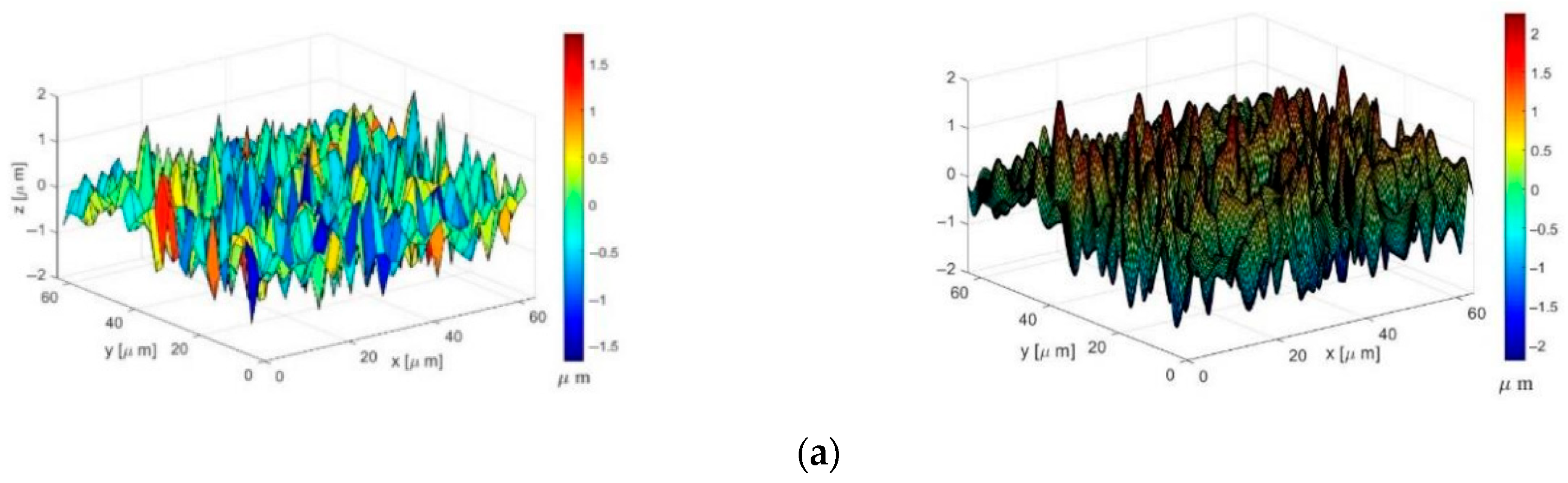

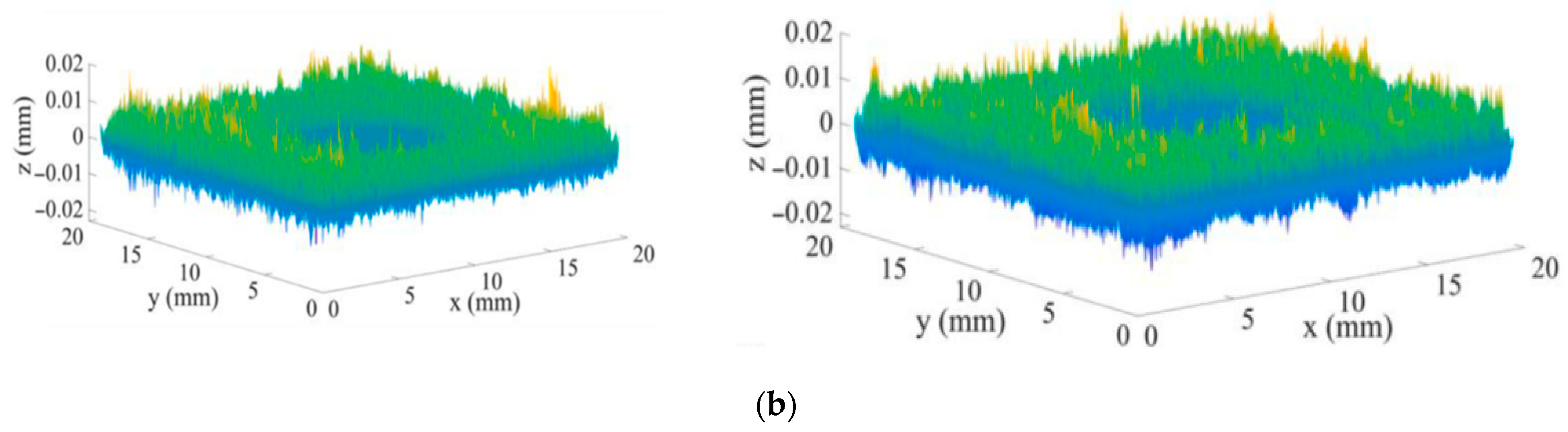

- Using the classical Gaussian distribution as the height distribution of the asperity, a rough surface contact model with a wave function is derived, whose contact stiffness changes are more obvious than those of the spherical shape in the initial elastic–plastic phase, and the overall contact behavior is more gentle. Combined with the rough surface topography mapping experiments, the wavy asperity can better describe the multi-peak topography and the feedback mechanism of alternating peaks and valleys by adjusting the parameters ( and ), which is superior to the spherical asperity in terms of power spectral density.

4. Discussion

- (1)

- Differences in mechanical response of asperity

- (2)

- Geometric characteristics of rough surfaces

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Segalman, D.J.; Gregory, D.L.; Starr, M.J.; Resor, B.R.; Jew, M.D.; Lauffer, J.P.; Ames, N.M. Handbook on Dynamics of Jointed Structures; SAND2009-4164; Sandia National Laboratories: Livermore, CA, USA, 2009. [Google Scholar]

- Greenwood, J.A.; Williamson, J.B.P. Contact of nominally flat surfaces. Proc. R Soc. London. Ser. A Math. Phys. Sci. 1966, 295, 300–319. [Google Scholar]

- Chang, W.R.; Etsion, I.; Bogy, D.B. An elastic-plastic model for the contact of rough surfaces. J. Tribol. 1987, 109, 257–263. [Google Scholar] [CrossRef]

- Chang, W.R.; Etsion, I.; Bogy, D.B. An elastic-plastic model for a rough surfaces with an ion-plated soft metallic coating. Wear 1997, 212, 229–237. [Google Scholar] [CrossRef]

- Abbott, E.; Firestone, F. Specifying surface quality: A meth of based on accurate measurement and comparison. Mech. Eng. 1993, 55, 569–572. [Google Scholar]

- Zhao, Y.; Maietta, D.M.; Chang, L. An asperity microcontact model incorporating the transition from elastic deformation to fully plastic flow. J. Tribol. 2000, 122, 86–93. [Google Scholar] [CrossRef]

- Zhao, Y.W.; Chang, L. A model of asperity interactions in elastic-plastic contact of rough surfaces. J. Tribol. 2001, 123, 857–864. [Google Scholar] [CrossRef]

- Kougut, L.; Etsion, I. A finite Element Based Elastic-plastic Model for the contact of rough surfaces. Tribol. Trans. 2003, 46, 383–390. [Google Scholar] [CrossRef]

- Brake, M.R. An analytical elastic-perfectly plastic contact model. Int. J. Solids Struct. 2012, 49, 3129–3144. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, J.; Zhu, L.; Hong, J. Analysis and improvement of rough surface elastic-plastic microcontact model. J. Zhejiang Univ. 2019, 53, 1674–1680. [Google Scholar]

- Xu, C.; Wang, D. An improved elastic-plastic model for rough surface normal direction. J. Xi’an Jiaotong Univ. 2014, 48, 115–121. [Google Scholar]

- Wang, D.; Xu, C.; Wan, Q. A rough surface mechanics model considering normal elastic-plastic contact of micro convex bodies. J. Shanghai Jiaotong Univ. 2016, 50, 1264–1269. [Google Scholar]

- Chu, R.Y.; Jackson, R.L.; Wang, X. Evaluating elastic-plastic wavy and spherical asperity-based statistical and multi-scale rough surface contact models with deterministic results. Materials 2021, 14, 3864. [Google Scholar] [CrossRef]

- Jackson, R.L.; Green, I. A statistical model of elastic-plastic asperity contact between rough surfaces. Tribol. Int. 2006, 39, 906–914. [Google Scholar] [CrossRef]

- Tabor, D. The Hardness of Metals; Clarendon Press: Oxford, UK, 1951. [Google Scholar]

- Chang, W.R.; Etsion, I.; Bogy, D.B. Static Friction Coefficient Model for Metallic Rough Surfaces. ASME J. Tribol. Int. 1988, 110, 57–63. [Google Scholar] [CrossRef]

- Johson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and the contact of elastic solids. Math. Phys. Sci. 1971, 324, 301–313. [Google Scholar]

- Wang, Z.; Yu, H.; Wang, Q. Analytical solutions for elastic fields caused by eigenstrains in two joined and perfectly bonded half-spaces and related problems. Int. J. Plast. 2016, 76, 1–28. [Google Scholar] [CrossRef]

- Wagner, P.; Wriggers, P.; Klapproth, C.; Prange, C.; Wies, B. Multiscale FEM approach for hysteresis friction of rubber on rough surfaces. Comput. Methods Appl. Mech. Eng. 2015, 296, 150–168. [Google Scholar] [CrossRef]

- Majumdar, A.; Bhushan, B. Fractal model of elastic-plastic contact between rough surfaces. J. Tribol. 1991, 113, 1–11. [Google Scholar] [CrossRef]

- Waddad, Y.; Magnier, V.; Dufrenoy, P.; De Saxcé, G. A multiscale method for frictionless contact mechanics of rough surfaces. Tribol. Int. 2016, 96, 109–121. [Google Scholar] [CrossRef]

- Pei, L.; Hyun, S.; Molinari, J.F.; Robbins, M.O. Finite element modeling of elastoplastic contact between rough surfaces. J. Mech. Phys. Solids 2005, 53, 2385–2409. [Google Scholar] [CrossRef]

- Jamil, A.; Kambiz, F. Elastic-plastic contact model for rough surfaces based on plastic asperity concept. Int. J. Non-Linear Mech. 2005, 40, 495–506. [Google Scholar]

- Johnson, K.L.; Greenwood, J.A.; Higginson, J.G. The contact of elastic regular wavy surfaces. Int. J. Mech. Sci. 1985, 27, 383–396. [Google Scholar] [CrossRef]

- Yang, H.; Li, D.; Sun, J.; Xu, C. Multiscale modeling of friction hysteresis at bolted joint interfaces. Int. J. Mech. Sci. 2024, 282, 109586. [Google Scholar] [CrossRef]

| Phase | Contact Radius | Contact Area | Contact Load | Average Contact Pressure |

|---|---|---|---|---|

| Elastic | ||||

| Elastoplastic | ||||

| Fully plastic |

| Parameter Type | Modulus of Elasticity (GPa) | Poisson’s Ratio | Yield Strength (MPa) | Hardness |

|---|---|---|---|---|

| Asperity | 200 | 0.3 | 400 | 2.8Y |

| Flat plate | 200 | 0.3 | 460 | 2.8Y |

| Shape | Bottom Edge Length(mm) | Area (mm2) | Functional Expression |

|---|---|---|---|

| Wave function | |||

| Semicircular |

| Mesh Size (mm) | Number of Grid Cells | Cell Mass | Jacobi Coefficient | Equivalent Strain (mm) | Equivalent Stress (MPa) |

|---|---|---|---|---|---|

| 0.03 | 20,400 | 0.98557 | 0.96918 | 0.0023024 | 452.91 |

| 0.01 | 190,334 | 0.98872 | 0.99073 | 0.0023954 | 461.97 |

| Wavy Asperity | ||||

|---|---|---|---|---|

| Contact Radius (mm) | Contact area (mm2) | Contact Load (N) | Average Contact Pressure (MPa) | |

| 1 | 0.0148 | 0.0006 | 0.42 | 648.86 |

| 1.5 | 0.0183 | 0.0011 | 0.87 | 781.83 |

| 3 | 0.0260 | 0.0021 | 2.05 | 965.02 |

| 6 | 0.0384 | 0.0046 | 4.79 | 1034.25 |

| 10 | 0.0510 | 0.0082 | 8.81 | 1077.87 |

| 20 | 0.0740 | 0.0172 | 20.47 | 1099.12 |

| 50 | 01551 | 0.0756 | 83.94 | 1110.35 |

| 100 | 0.1980 | 0.1236 | 124.25 | 1119.22 |

| 110 | 0.2130 | 0.1425 | 160.06 | 1123.17 |

| Spherical Asperity | ||||

|---|---|---|---|---|

| Contact Radius (mm) | Contact Area (mm2) | Contact Load (N) | Average Contact Pressure (MPa) | |

| 1 | 0.0371 | 0.0043 | 3.1276 | 723.3 |

| 1.5 | 0.0450 | 0.0064 | 5.6823 | 893.2 |

| 3 | 0.0635 | 0.0127 | 13.4277 | 1060.0 |

| 6 | 0.0924 | 0.0268 | 29.9309 | 1115.9 |

| 10 | 0.1430 | 0.0642 | 72.1699 | 1123.4 |

| 20 | 0.2011 | 0.1270 | 143.5409 | 1129.8 |

| 50 | 0.3731 | 0.4373 | 495.7909 | 1133.7 |

| 100 | 0.5450 | 0.9331 | 1060.2241 | 1136.2 |

| 110 | 0.5921 | 1.1014 | 1253.9292 | 1138.5 |

| Model | Contact Properties of Asperity | Critical Point | ||||

|---|---|---|---|---|---|---|

| Contact Area | Average Contact Pressure | Contact Load | Yield | Elasticity | Full Plasticity | |

| ZMC | 4th-degree polynomial | Logarithmic polynomial | Product of contact area and average contact pressure | |||

| KE | Segmental function | Exponential function | ||||

| Brake | 3rd-degree polynomial | 3rd-degree polynomial | ||||

| XU CHAO | Brake model | Elliptic curve | ||||

| Wave function | Hyperbolic tangent | Hyperbolic tangent | ||||

| Model | Geometric Assumptions | Elastic-Plastic Transfer Function | Continuity | Oscillation Issues | Applicable Scenarios |

|---|---|---|---|---|---|

| ZMC | spherical | Higher-order polynomial | Partially satisfied | Serious (Runge) | Small deformation |

| KE | spherical | Piecewise function | Satisfied | Minor | Moderate plasticity |

| Brake | spherical | Hermite interpolation | Satisfied | Serious | Theoretical analysis |

| Xu Chao | spherical | Elliptic curve | Satisfied | None | Moderate deformation |

| Wave function | wavy | Hyperbolic tangent function | Strictly complies with | None | Large deformation/ multiscale |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Zhu, M.; Wang, W.; Guo, M.; Wang, S.; Lu, X.; Li, Z. Elastic–Plastic Analysis of Asperity Based on Wave Function. Materials 2025, 18, 3507. https://doi.org/10.3390/ma18153507

Xu Z, Zhu M, Wang W, Guo M, Wang S, Lu X, Li Z. Elastic–Plastic Analysis of Asperity Based on Wave Function. Materials. 2025; 18(15):3507. https://doi.org/10.3390/ma18153507

Chicago/Turabian StyleXu, Zijian, Min Zhu, Wenjuan Wang, Ming Guo, Shengao Wang, Xiaohan Lu, and Ziwei Li. 2025. "Elastic–Plastic Analysis of Asperity Based on Wave Function" Materials 18, no. 15: 3507. https://doi.org/10.3390/ma18153507

APA StyleXu, Z., Zhu, M., Wang, W., Guo, M., Wang, S., Lu, X., & Li, Z. (2025). Elastic–Plastic Analysis of Asperity Based on Wave Function. Materials, 18(15), 3507. https://doi.org/10.3390/ma18153507