Analysis of Strain Transfer Characteristics of Fiber Bragg Gratings for Asphalt Pavement Health Monitoring

Abstract

1. Introduction

2. Objective

3. Methodology

3.1. Strain Transfer Theory of Fiber Bragg Grating

3.2. Strain Transfer Behavior of Fiber Bragg Grating with Viscoelastic Response

3.3. Strain Transfer of Fiber Bragg Grating Under Plastic Deformation

4. Results and Discussion

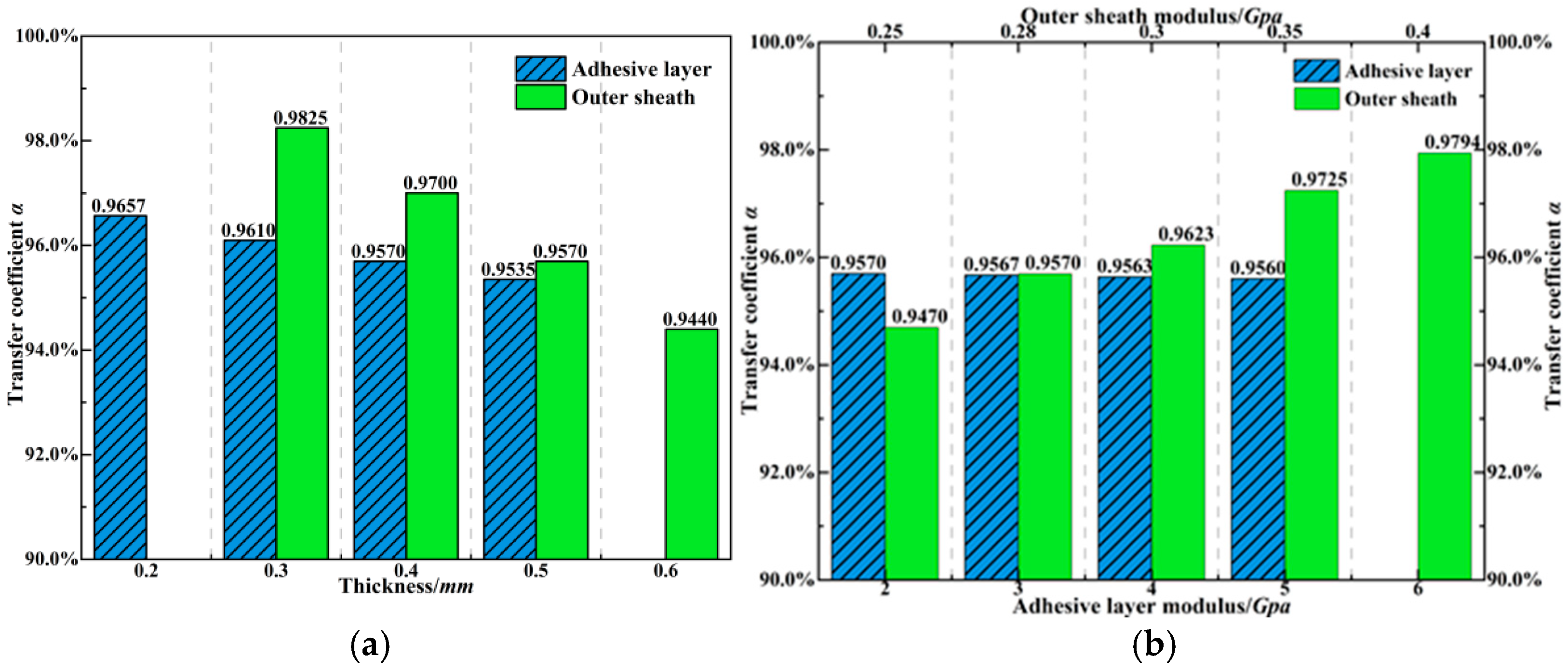

4.1. Sensitivity Analysis of Strain Transfer Parameters for Fiber Bragg Grating

4.2. Strain Transfer Analysis of Fiber Bragg Grating Embedded in Asphalt Mixture

4.3. Strain Transfer Analysis of Fiber Bragg Grating in Pavement Base Layer

5. Conclusions

- (1)

- The bond length is a key factor affecting the strain transfer efficiency of FBG. For embedded FBG, the actual bond length is the full length of the fiber; however, the contribution of strain from sections far from the grating region to the transfer coefficient significantly decreases. Therefore, a contribution rate threshold of 5% is used as the criterion to determine the effective bond length. For the braided metal armor FBG used in this study, the effective bonding length is 14 cm.

- (2)

- The outer sheath is the main internal factor affecting strain transfer efficiency. An increase in modulus or a decrease in thickness significantly enhances the strain transfer coefficient. Considering both the survival of embedded FBG and the sensitivity of monitoring, it is recommended to use high-modulus materials for the encapsulation layer while controlling the structural thickness to within 0.5 mm, thereby ensuring that the strain transfer coefficient does not below 95%.

- (3)

- FBG can capture the viscoelastic response behavior effectively within asphalt mixtures, and temperature is the major external factor affecting strain transfer efficiency. In particular, under high-temperature conditions in summer, the strain transfer coefficient of the FBG decreases by approximately 1.21% compared to a standard temperature of 20 °C. Under typical vehicle speeds, changes in load frequency have a negligible effect on the strain transfer coefficient.

- (4)

- When performing long-term strain monitoring on the pavement surface layer, the effect of plastic strain magnitude and distribution on the FBG strain transfer coefficient must be considered. The permanent deformation loading simulation results for cylindrical specimens show the increase in plastic strain enhances the FBG strain transfer coefficient, owing to the concave strain distribution. When the grating region is placed in the rut, the strain transfer coefficient can be improved by adjusting based on the monitored strain level.

- (5)

- The proposed polynomial fitting method eliminates the assumption boundary conditions during the differential equation solution, making it more consistent with the actual situation of embedded FBG. A fifth-order polynomial function is sufficient for fitting the strain distribution in cement-treated base, while a ninth-order polynomial function is required for asphalt-stabilized base due to the presence of viscoelastic effects. The results from the pavement numerical analysis model validate the accuracy of the strain transfer coefficient obtained through this polynomial fitting method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alhussein, A.N.D.; Qaid, M.; Agliullin, T.; Valeev, B.; Morozov, O.; Sakhabutdinov, A. Fiber Bragg Grating Sensors: Design, Applications, and Comparison with Other Sensing Technologies. Sensors 2025, 25, 2289. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.N.; Ma, T.J.; Zhang, F.J. Distributed optical fiber sensors for pavement Engineering: A-State-of-Art review. Measurement 2025, 246, 20. [Google Scholar] [CrossRef]

- Singh, M.J.; Choudhary, S.; Chen, W.B.; Wu, P.C.; Goyal, M.K.; Rajput, A.; Borana, L. Applications of fibre Bragg grating sensors for monitoring geotechnical structures: A comprehensive review. Measurement 2023, 218, 16. [Google Scholar] [CrossRef]

- Rebelo, F.J.P.; Oliveira, J.R.M.; Silva, H.; Sá, J.O.E. Material selection for efficient strain transfer in pavement monitoring using FBG sensors. Int. J. Pavement Eng. 2024, 25, 16. [Google Scholar] [CrossRef]

- Xu, P.Y.; Han, J.S.; Wang, C.S.; Wang, Y.; Yan, Y.F.; Wang, L.Y.; Wang, Z.H.; Yu, K.P.; Du, B.; Zhang, J.L.; et al. Data-Driven Deformation Reconstruction Method for Large Aperture Flexible Vehicle-Mounted Antenna. IEEE Sens. J. 2023, 23, 25323–25339. [Google Scholar] [CrossRef]

- Mrad, N.; Guo, H.L.; Xiao, G.Z.; Rocha, B.; Sun, Z.G. On the Use of a Compact Optical Fiber Sensor System in Aircraft Structural Health Monitoring. In Proceedings of the Conference on Photonic Applications for Aerospace, Transportation, and Harsh Environment III, Spie-Int Soc Optical Engineering, Baltimore, MD, USA, 23–27 April 2012. [Google Scholar]

- Mokhtar, M.R.; Owens, K.; Kwasny, J.; Taylor, S.E.; Basheer, P.A.M.; Cleland, D.; Bai, Y.; Sonebi, M.; Davis, G.; Gupta, A.; et al. Fiber-Optic Strain Sensor System with Temperature Compensation for Arch Bridge Condition Monitoring. IEEE Sens. J. 2012, 12, 1470–1476. [Google Scholar] [CrossRef]

- Nazarian, E.; Ansari, F.; Zhang, X.T.; Taylor, T. Detection of Tension Loss in Cables of Cable-Stayed Bridges by Distributed Monitoring of Bridge Deck Strains. J. Struct. Eng. 2016, 142, 13. [Google Scholar] [CrossRef]

- Quan, Z.; Fang, X.; Xue, G.; Hu, X.; Gu, C. Strain Transfer Coupling Mechanism of Surface-Bonded Fiber Bragg Grating Sensor. Chin. J. Lasers 2020, 47, 0104004. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, Q.; Wang, Z.; Qiu, W.; He, Z. Research on permanent pavement structure response monitoring based on fiber Bragg grating sensor. Transducer Microsyst. Technol. 2021, 40, 76. [Google Scholar]

- Chen, S.; Zhang, X.; Xu, Q.; Meng, S. Experiment and Research of Grating Strain Sensor on Asphalt Pavement. Chin. J. Sens. Actuators 2006, 19, 396–398. [Google Scholar]

- Zhang, H.; Zang, G.; Sun, L. Measured Analysis of Dynamic Strain Response of Semi-Rigid Base Asphalt Pavement. Traffic Sci. Eng. 2017, 33, 12–17. [Google Scholar]

- Wang, S.; Chen, Z.; Wang, Y.; Yi, J. Data Processing Methods and Effectiveness Evaluation for Highway Subgrade and Pavement Health Monitoring. Munic. Technol. 2025, 43, 175–181. [Google Scholar]

- Ansari, F.; Libo, Y. Mechanics of bond and interface shear transfer in optical fiber sensors. J. Eng. Mech.-ASCE 1998, 124, 385–394. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, Z.; Liu, W.; Wang, J.; Cao, D. Analysis of strain transfer error in FBG sensors encapsulated with flexible matrix materials. J. Sens. Technol. 2015, 28, 492–497. [Google Scholar]

- Her, S.C.; Huang, C.Y. Effect of Coating on the Strain Transfer of Optical Fiber Sensors. Sensors 2011, 11, 6926–6941. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Shao, C.; Qu, W.; Zhou, W.; Cai, H. Basic Theoretical Model and Its Experimental Investigation for Standard Embedded Sensing Fiber Bragg Grating Packaging. Chin. J. Lasers 2010, 37, 1290–1293. [Google Scholar] [CrossRef]

- Yang, H.Y.; Huang, Y.; Zhou, Z.; Ou, J.P. Long-term performance of packaged fiber Bragg grating sensors for strain monitoring inside creep medium. Int. J. Smart Nano Mater. 2022, 13, 42–63. [Google Scholar] [CrossRef]

- Fu, J.C.; Shen, A.Q.; Zhang, H.Z.; Sun, T.W. Laboratory Investigation of Fiber Bragg Grating Strain Sensors for Semirigid Base Asphalt Pavements. Adv. Civ. Eng. 2021, 2021, 2235241. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Q.; Hao, X.; Yang, H.; Ou, J. Study on strain transfer of FBG sensors considering concrete matrix creep. Chin. J. Test. 2016, 42, 1–5+32. [Google Scholar]

- Wang, H. Strain Transfer of Optical Fibers Under Damage Conditions and Its Application in Multi-Layer Pavements. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2015. [Google Scholar]

- Zhu, L. Study on Sensing and Mechanical Performance of Embedded Optical Fiber Smart Composite Materials. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2018. [Google Scholar]

- Wu, R.; Zhang, X.; Zheng, B.; Chen, T. Bidirectional coupling analysis of strain transfer in fiber Bragg grating sensors. Acta Photonica Sin. 2020, 49, 64–73. [Google Scholar]

- Li, C. Experimental and Theoretical Study on Strain Transfer Mechanism of Fiber Bragg Gratings. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2016. [Google Scholar]

- Zhang, Y.; Gao, H.; Zhang, L.; Liu, Q.; Fu, X. Temperature and stress sensing of embedded gold-coated FBGs encapsulated in capillary copper tubes. Opto-Electron. Eng. 2021, 48, 59–69. [Google Scholar]

- Tan, Y.; Chen, F.; Dong, Z.; Liu, H. Calculation method for asphalt pavement permanent deformation based on FBG sensing technology. J. Dalian Marit. Univ. 2008, 34, 119–122. [Google Scholar]

- Hauswirth, D.; Tsirantonaki, D.; Fischli, F.; Rabaiotti, C.; Puzrin, A.M. Measuring strain distributions in an asphalt pavement using fibre optic sensors under static loading by test vehicles. Road Mater. Pavement Des. 2025, 26, 1023–1040. [Google Scholar] [CrossRef]

- Cai, H. Application of fiber Bragg grating sensors in full-scale accelerated loading tests of asphalt pavements. North Transp. 2016, 12, 99–101. [Google Scholar]

- Park, S.W.; Schapery, R.A. Methods of interconversion between linear viscoelastic material functions. Part I—A numerical method based on Prony series. Int. J. Solids Struct. 1999, 36, 1653–1675. [Google Scholar] [CrossRef]

- Zhang, D. Study on Viscoelastic Continuous Damage and Fatigue Characteristics of Asphalt Mixtures. Master’s Thesis, Chang’an University, Xi’an, China, 2015. [Google Scholar]

- Sun, L.; Zhu, H.R.; Zhu, Y.T. Two-Stage Viscoelastic-Viscoplastic Damage Constitutive Model of Asphalt Mixtures. J. Mater. Civ. Eng. 2013, 25, 958–971. [Google Scholar] [CrossRef]

- Tong, J. Study on Rutting and Fatigue Prediction of Flexible Base Pavements. Master’s Thesis, Southeast University, Nanjing, China, 2019. [Google Scholar]

| Structural Layer | Outer Diameter/mm | Young’s Modulus/Gpa | Poisson’s Ratio |

|---|---|---|---|

| Optical fiber | 0.125 (2r0) | 72 | 0.2 |

| Coating layer | 0.4 (2r1) | 10 | 0.25 |

| Adhesive layer | 1.2 (2r2) | 2 | 0.3 |

| Braided steel mesh | 1.7 (2r3) | 195 | 0.3 |

| PVC outer sheath | 2.7 (2r4) | 0.28 | 0.4 |

| /Mpa | ||||||||

|---|---|---|---|---|---|---|---|---|

| 853.07 | 3214.52 | 5638.87 | 7184.66 | 8071.30 | 7549.23 | 3881.01 | 1906.39 | 2.82 |

| /S | ||||||||

| 10−5 | 10−4 | 10−3 | 10−2 | 10−1 | 100 | 101 | 102 | |

| 19,136.4 | /°C | 25 |

| Structural Layer | Thickness/cm | Modulus/Mpa | Poisson’s Ratio |

|---|---|---|---|

| AC13 | 4 | Prony1 | 0.25 |

| AC16 | 6 | Prony2 | 0.25 |

| AC20 | 8 | Prony3 | 0.25 |

| ATB25 | 12 | Prony4 | 0.25 |

| Cement-treated | 20 | 10,000 | 0.35 |

| Subgrade | 200 | 80 | 0.4 |

| Yield Parameters | Flow Parameters | Hardening Parameters | Temperature Parameters | |||||

|---|---|---|---|---|---|---|---|---|

| /rad | /10−16 | N | /kpa | /kap | /kpa | /°C | ||

| 0.2 | 3.18 | 2.4 | 82 | 354.7 | −250 | 50 | −13,790 | 4152 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Z.; Cao, D.; Peng, P.; Ding, X.; Ma, T.; Cheng, J. Analysis of Strain Transfer Characteristics of Fiber Bragg Gratings for Asphalt Pavement Health Monitoring. Materials 2025, 18, 3489. https://doi.org/10.3390/ma18153489

Hou Z, Cao D, Peng P, Ding X, Ma T, Cheng J. Analysis of Strain Transfer Characteristics of Fiber Bragg Gratings for Asphalt Pavement Health Monitoring. Materials. 2025; 18(15):3489. https://doi.org/10.3390/ma18153489

Chicago/Turabian StyleHou, Zhaojun, Dianguang Cao, Peng Peng, Xunhao Ding, Tao Ma, and Jianchuan Cheng. 2025. "Analysis of Strain Transfer Characteristics of Fiber Bragg Gratings for Asphalt Pavement Health Monitoring" Materials 18, no. 15: 3489. https://doi.org/10.3390/ma18153489

APA StyleHou, Z., Cao, D., Peng, P., Ding, X., Ma, T., & Cheng, J. (2025). Analysis of Strain Transfer Characteristics of Fiber Bragg Gratings for Asphalt Pavement Health Monitoring. Materials, 18(15), 3489. https://doi.org/10.3390/ma18153489