Manufacturing and Mechanical Behaviour of Scalmalloy® Lattice Structures: Experimental Validation and Model

Abstract

1. Introduction

2. Materials and Methods

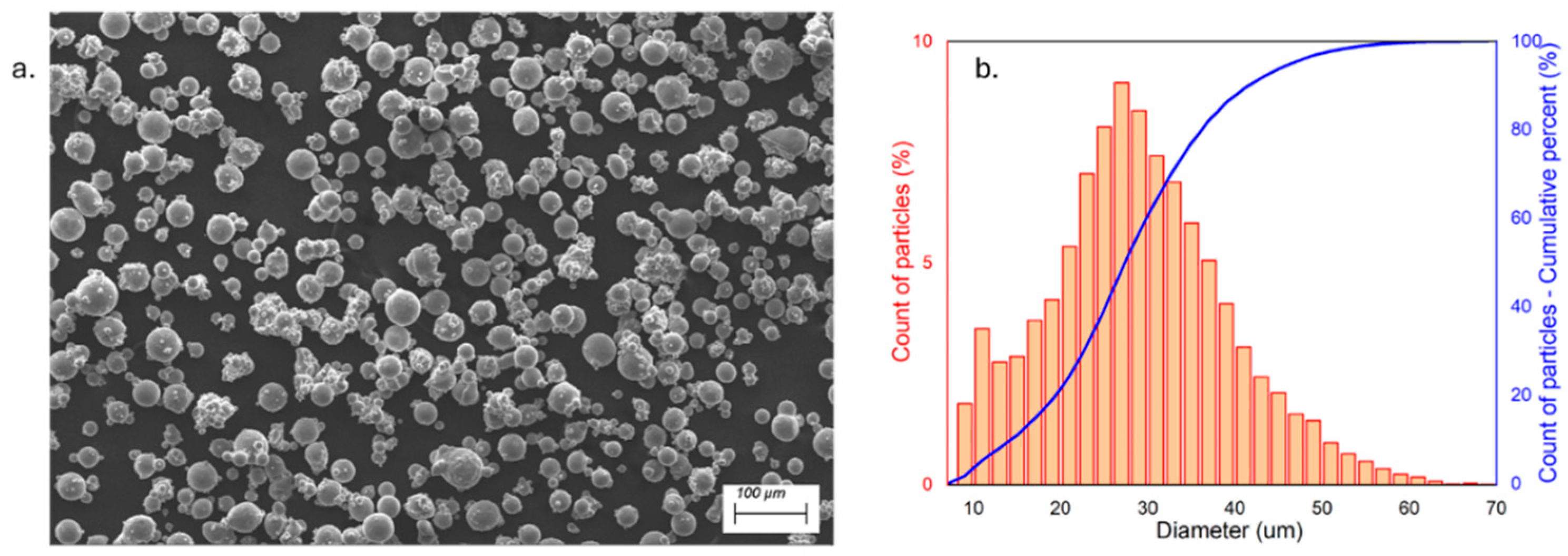

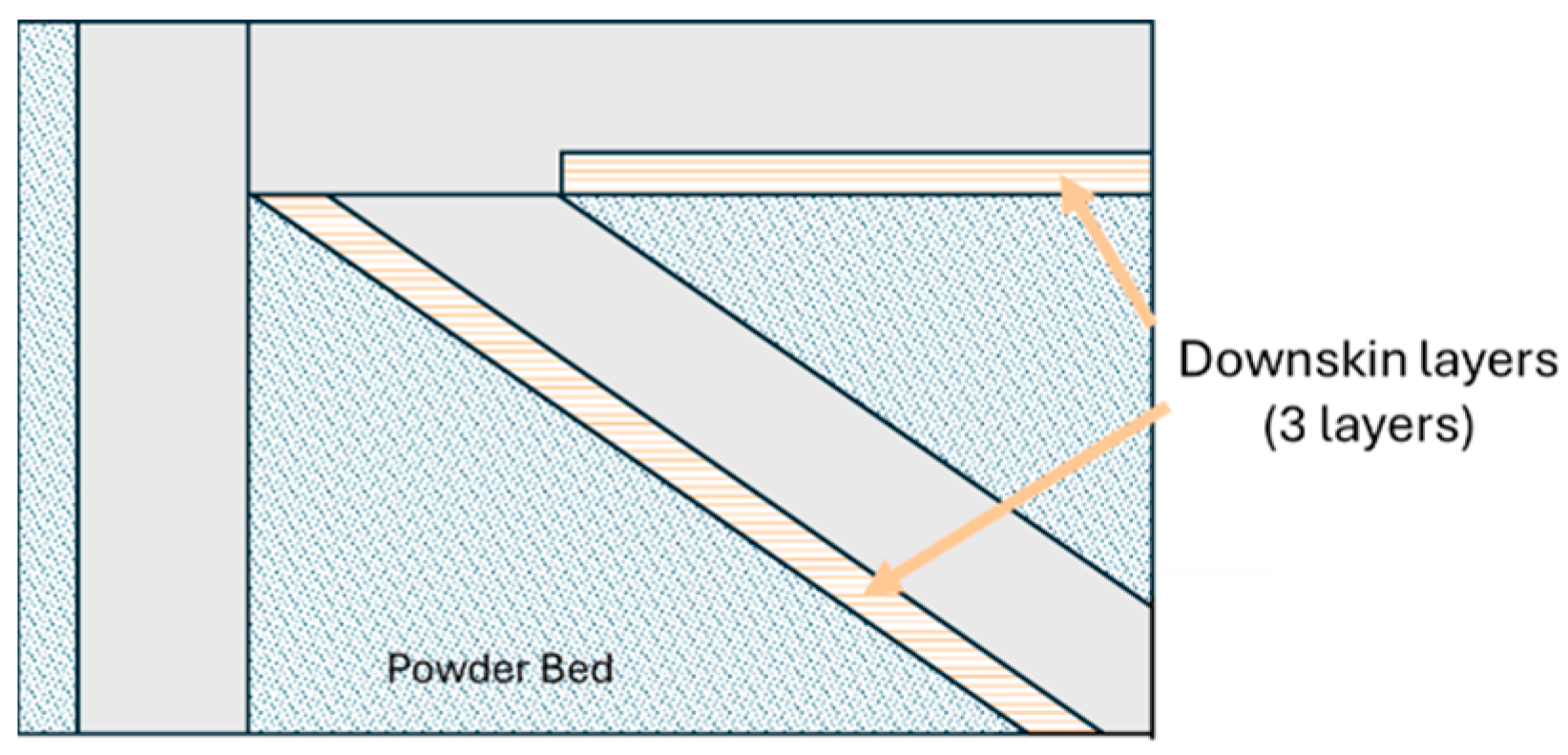

2.1. Samples Production

2.2. Design of Experiments and Characterisation Tests for Surface Texture and Dimensional Accuracy

2.3. Mechanical Tests

3. Results and Discussion

3.1. Process Parameters Analysis and Optimisation

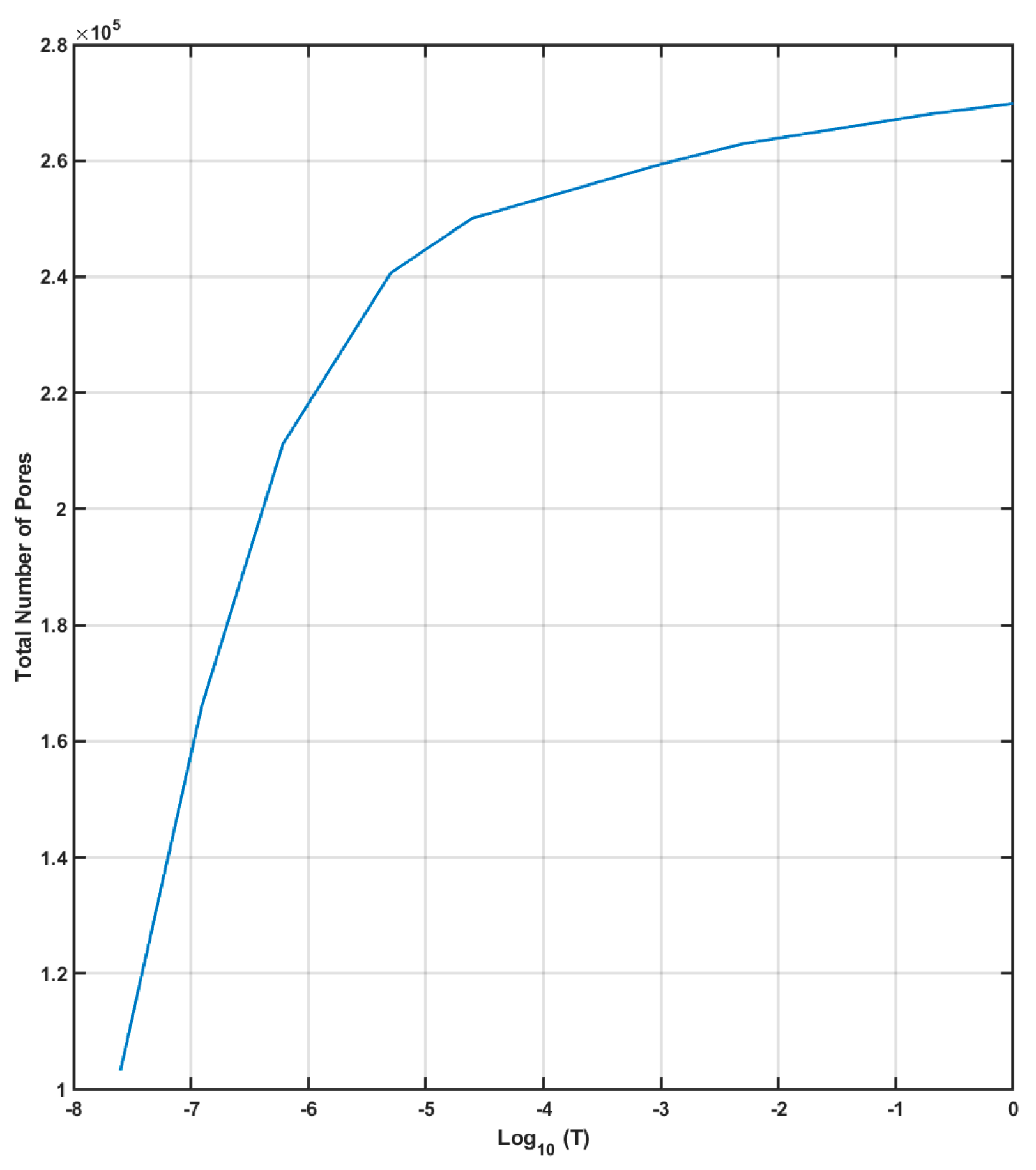

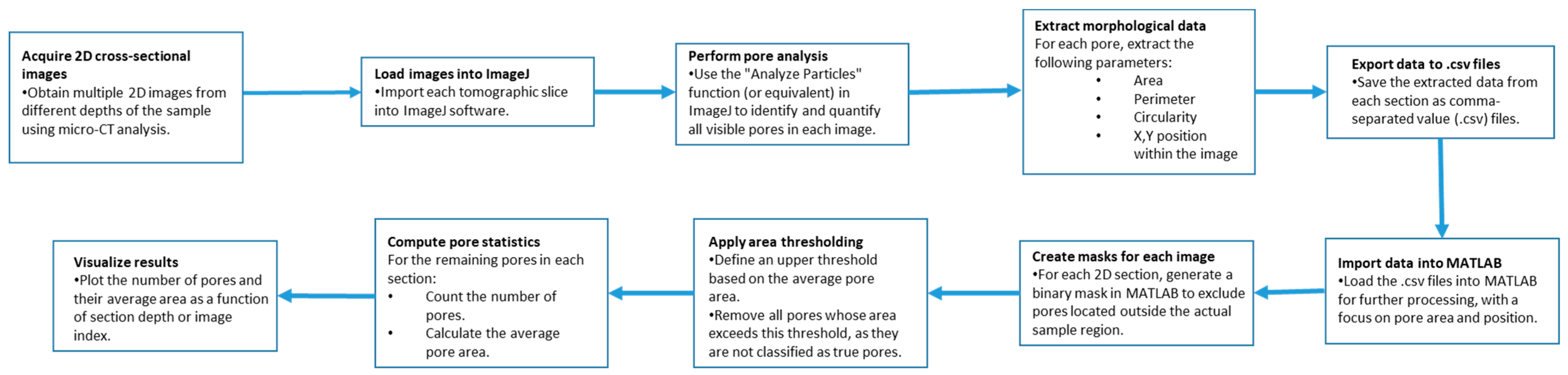

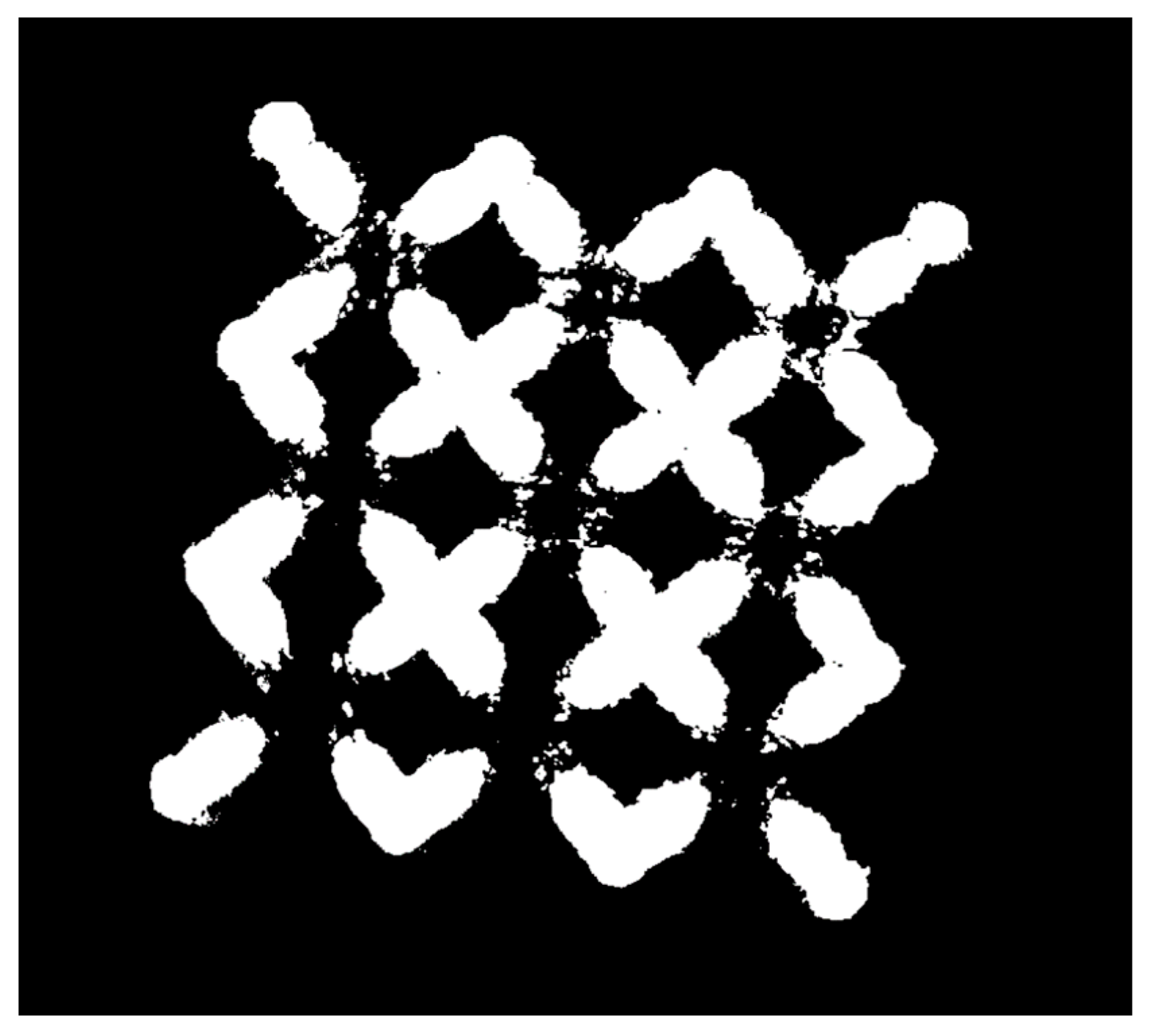

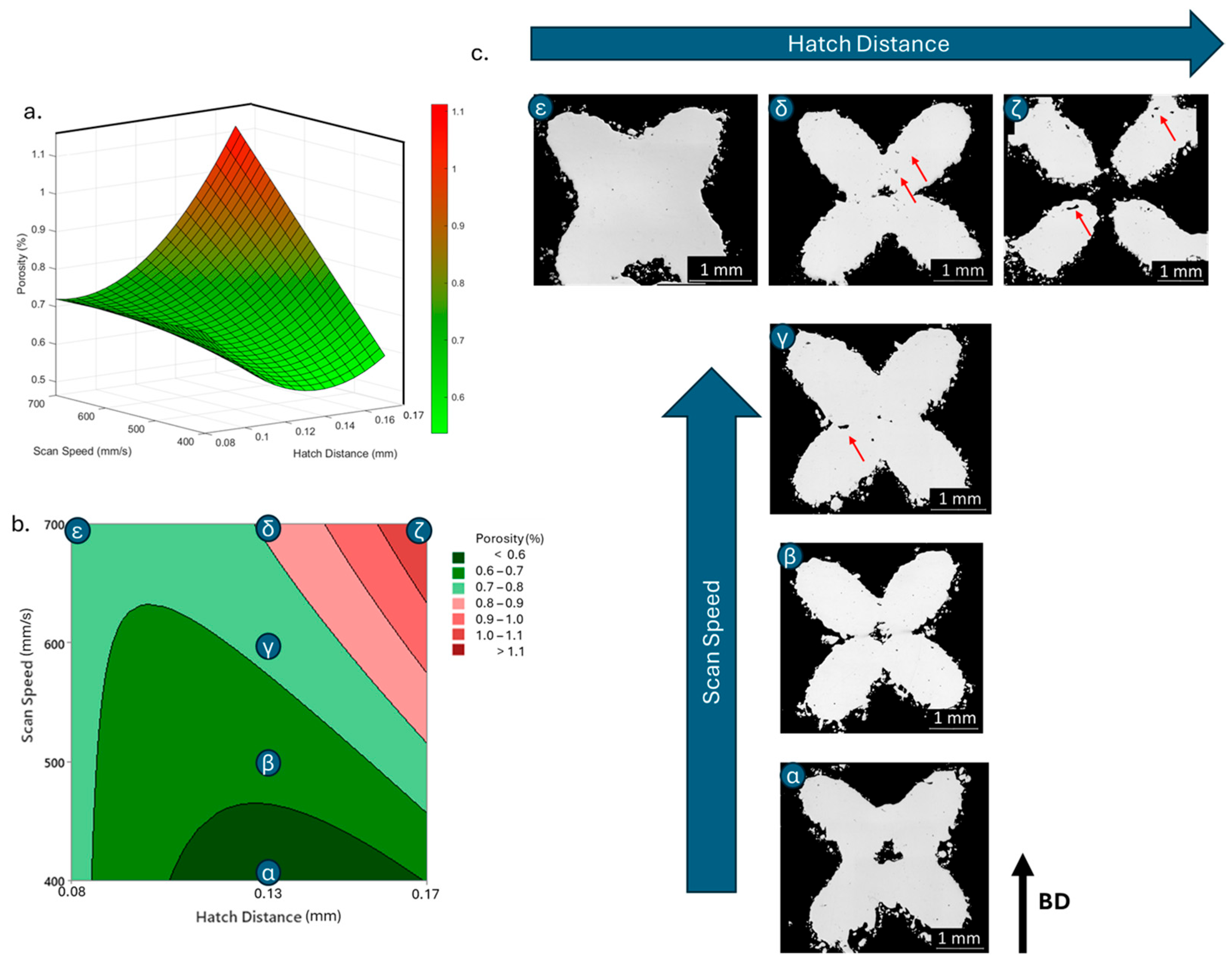

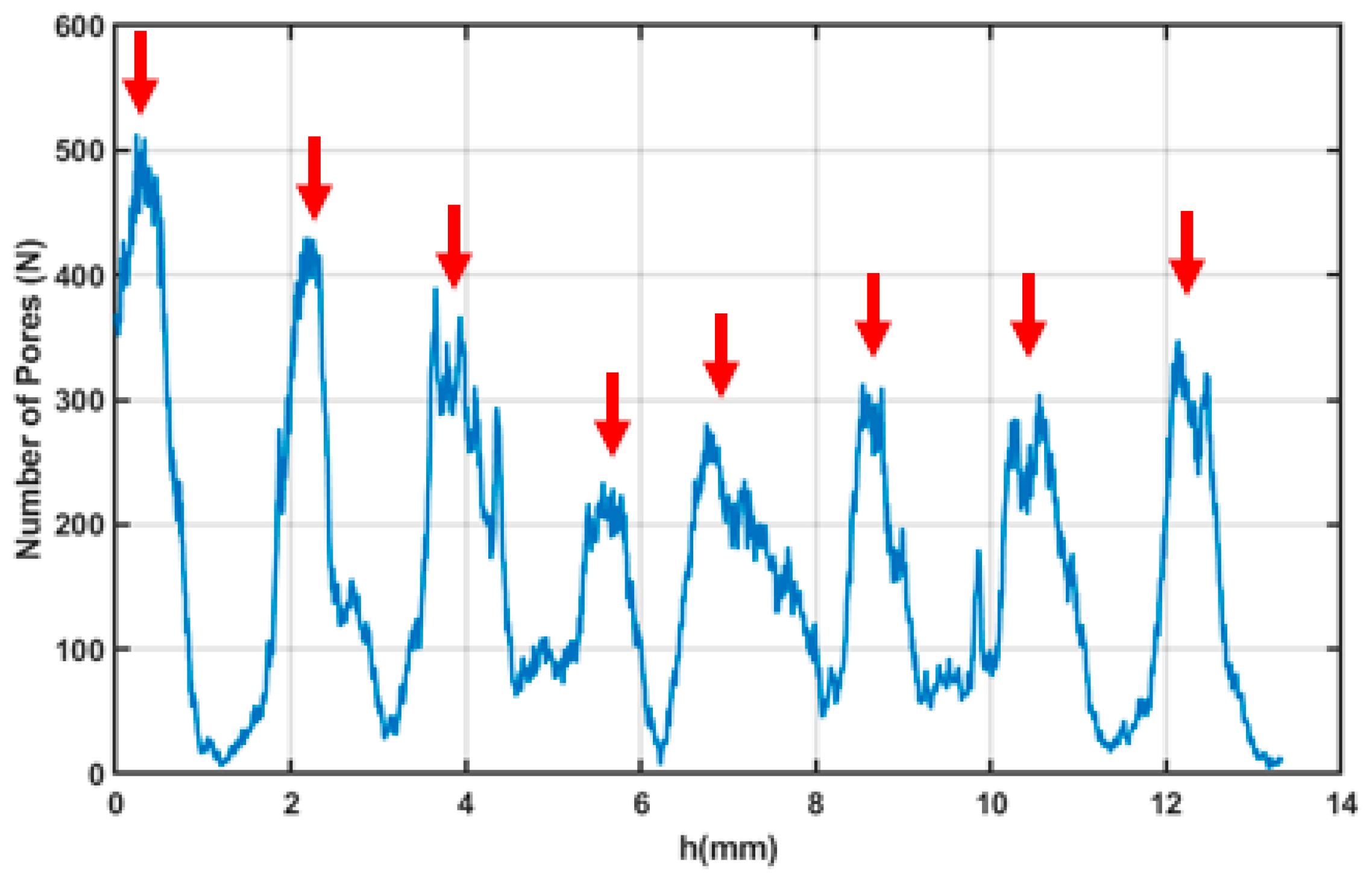

3.1.1. Influence of the Parameters on the Porosity

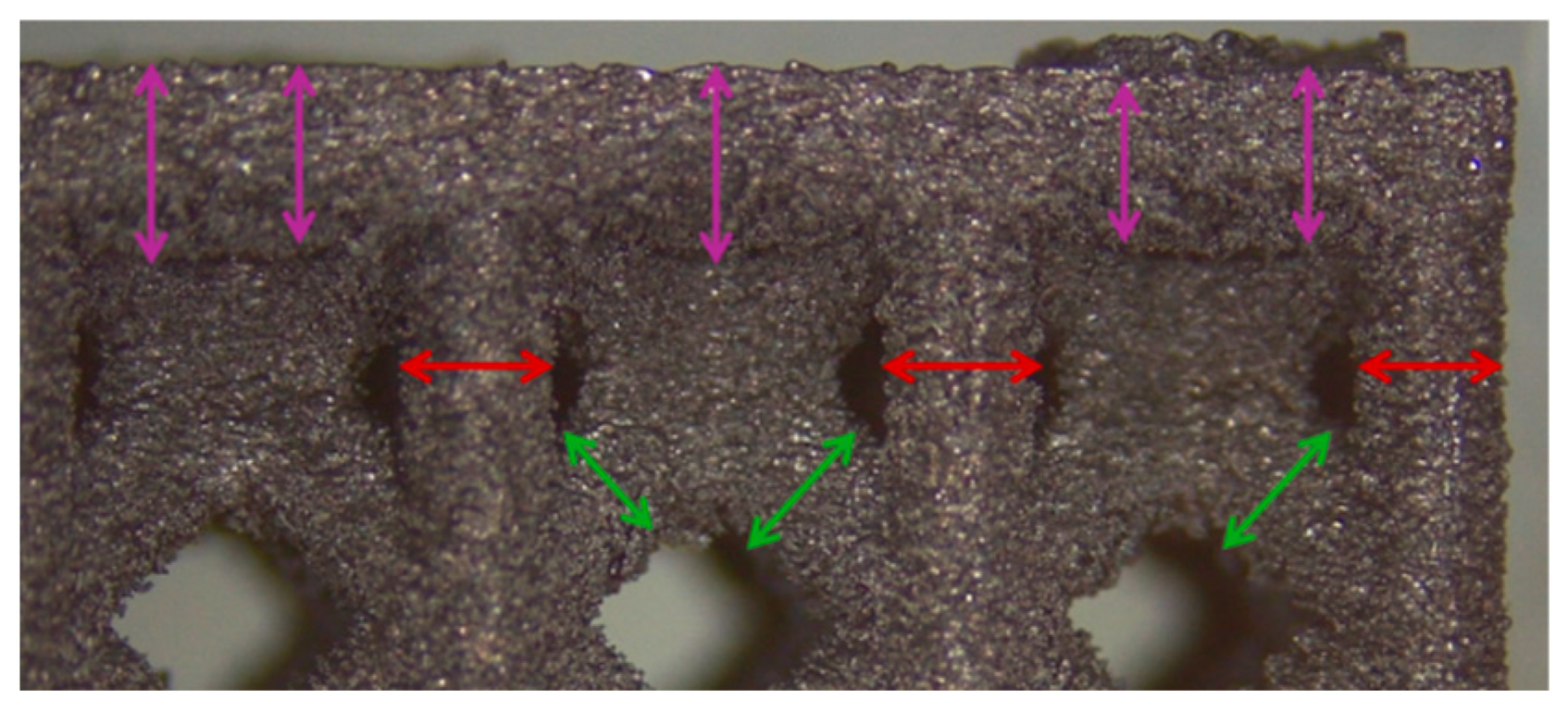

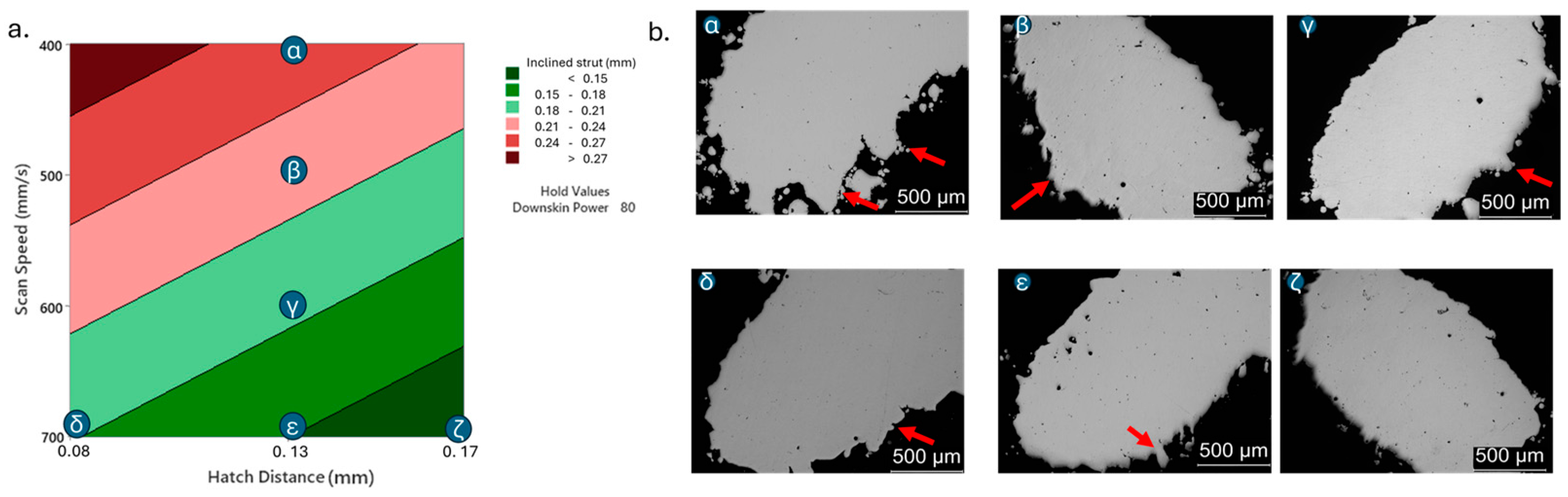

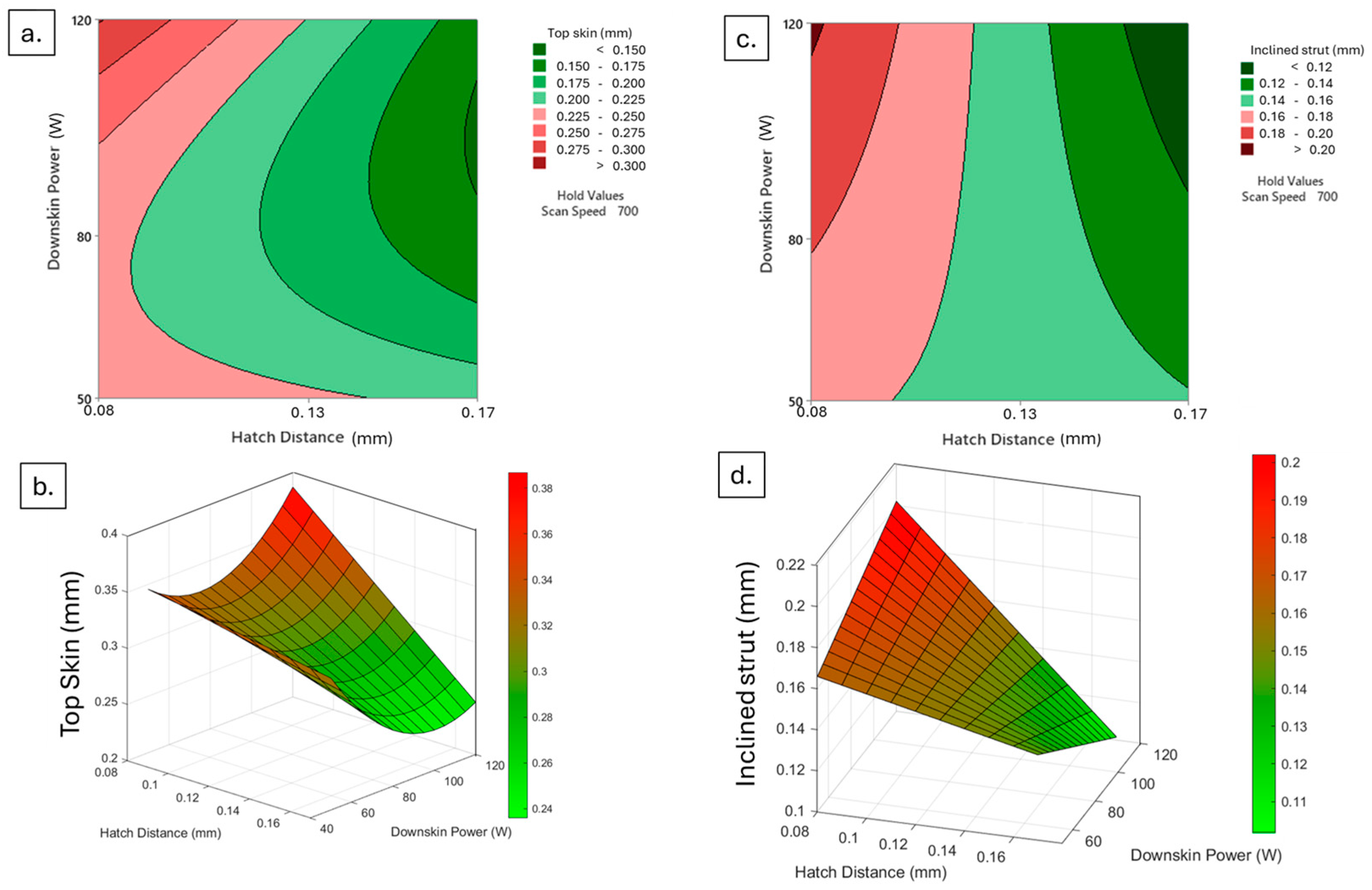

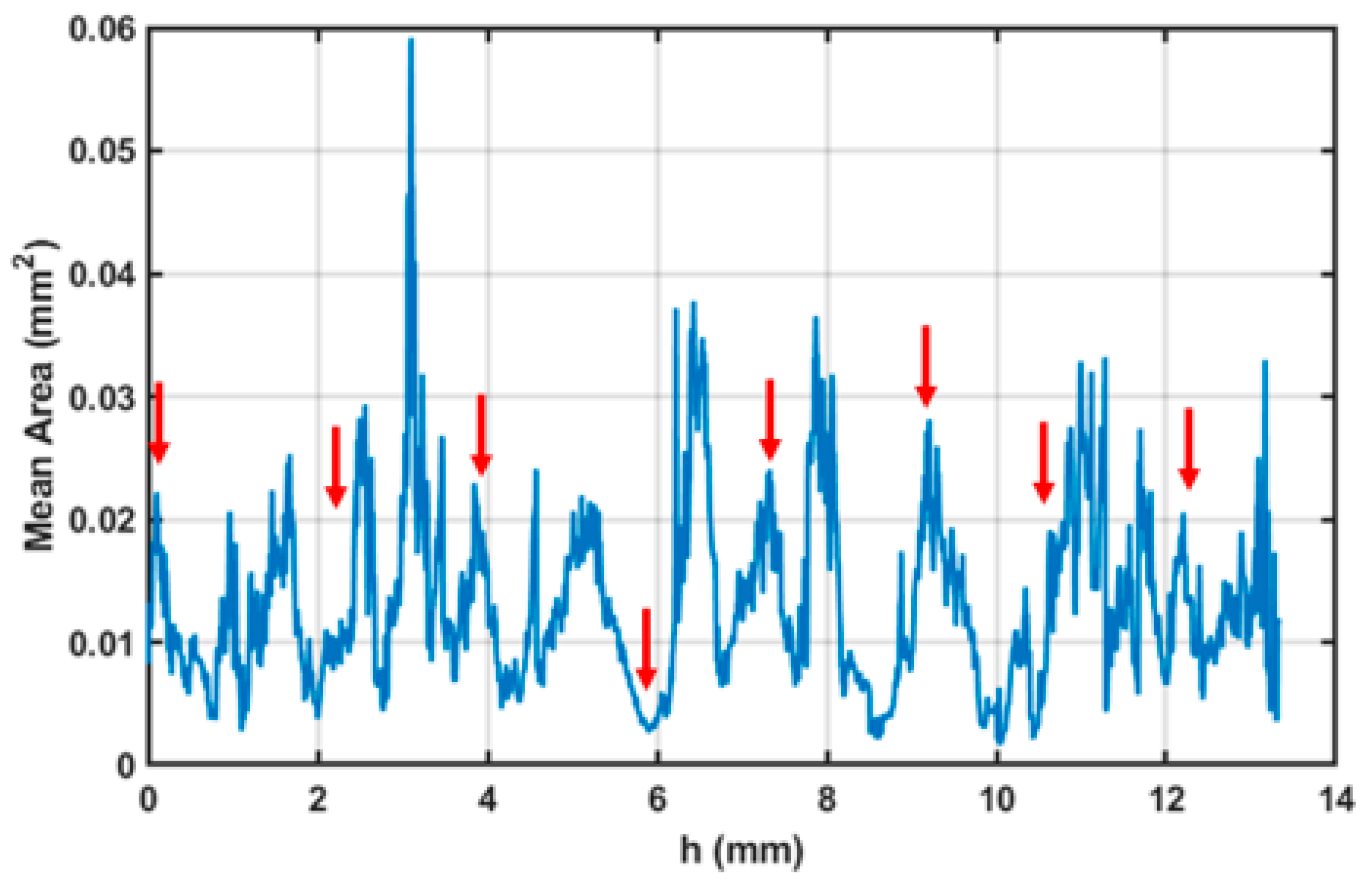

3.1.2. Influence of the Parameters on the Dimensional Accuracy

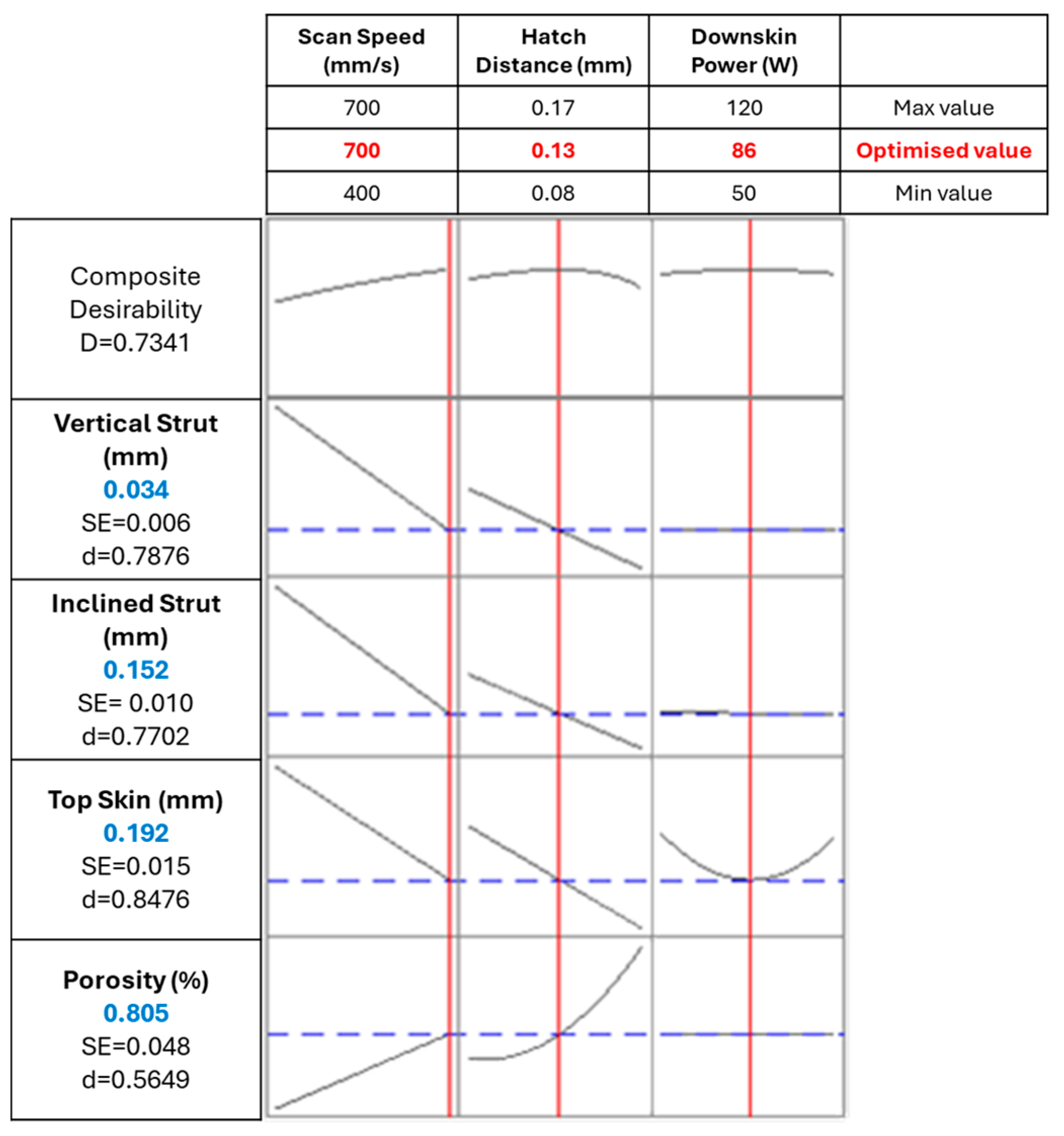

3.1.3. Process Parameters Optimisation

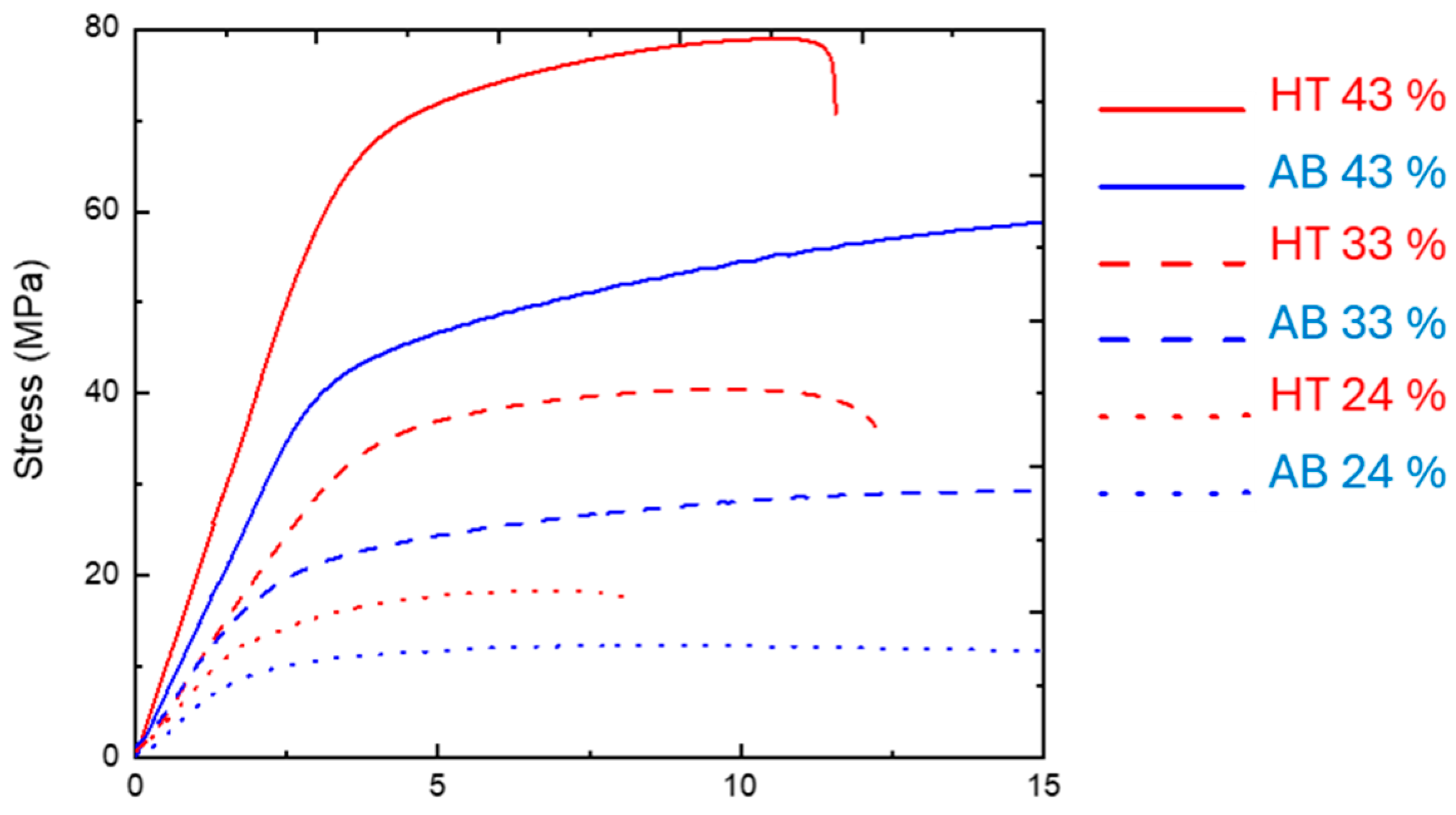

3.2. Mechanical Testing

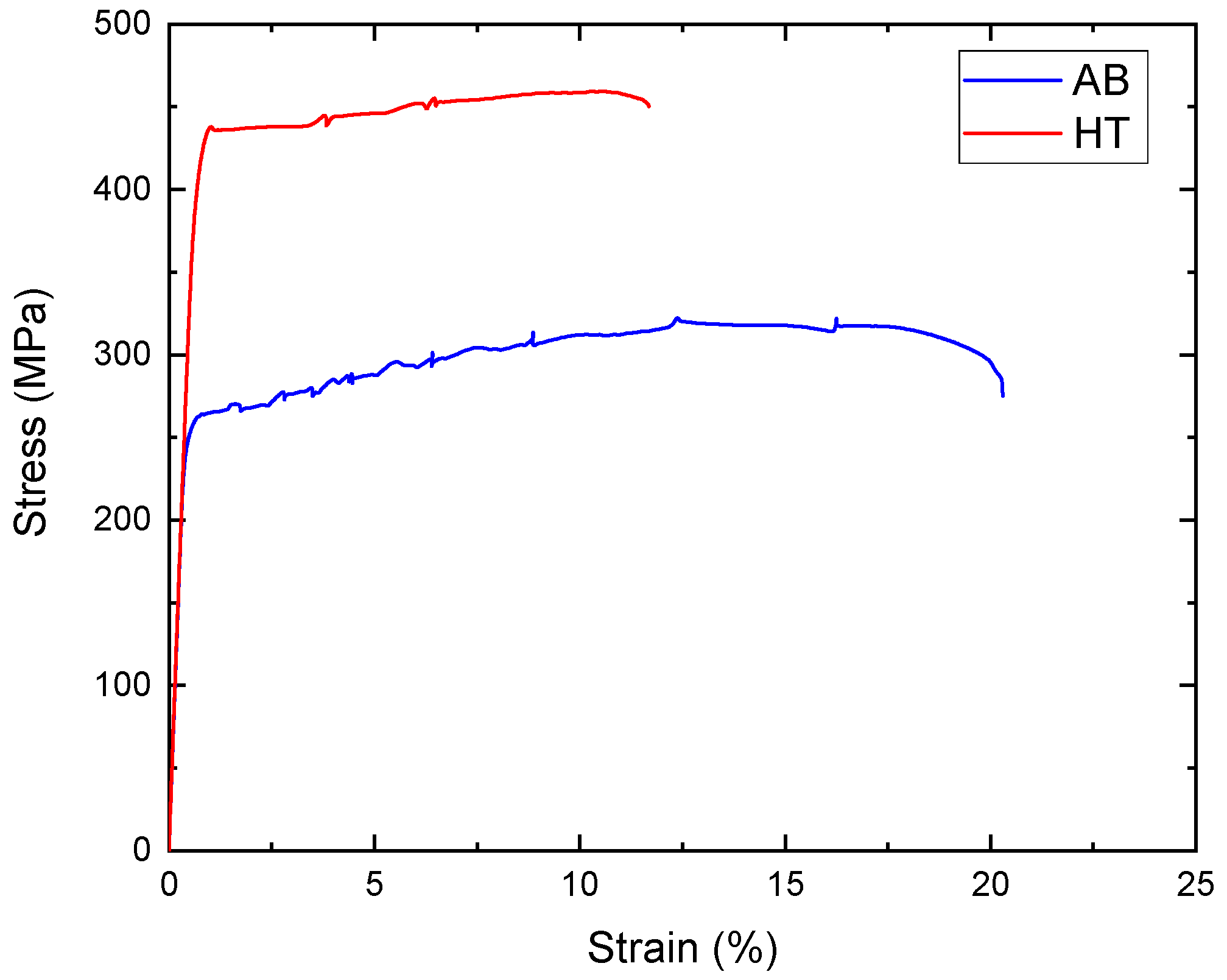

3.2.1. Tensile Tests

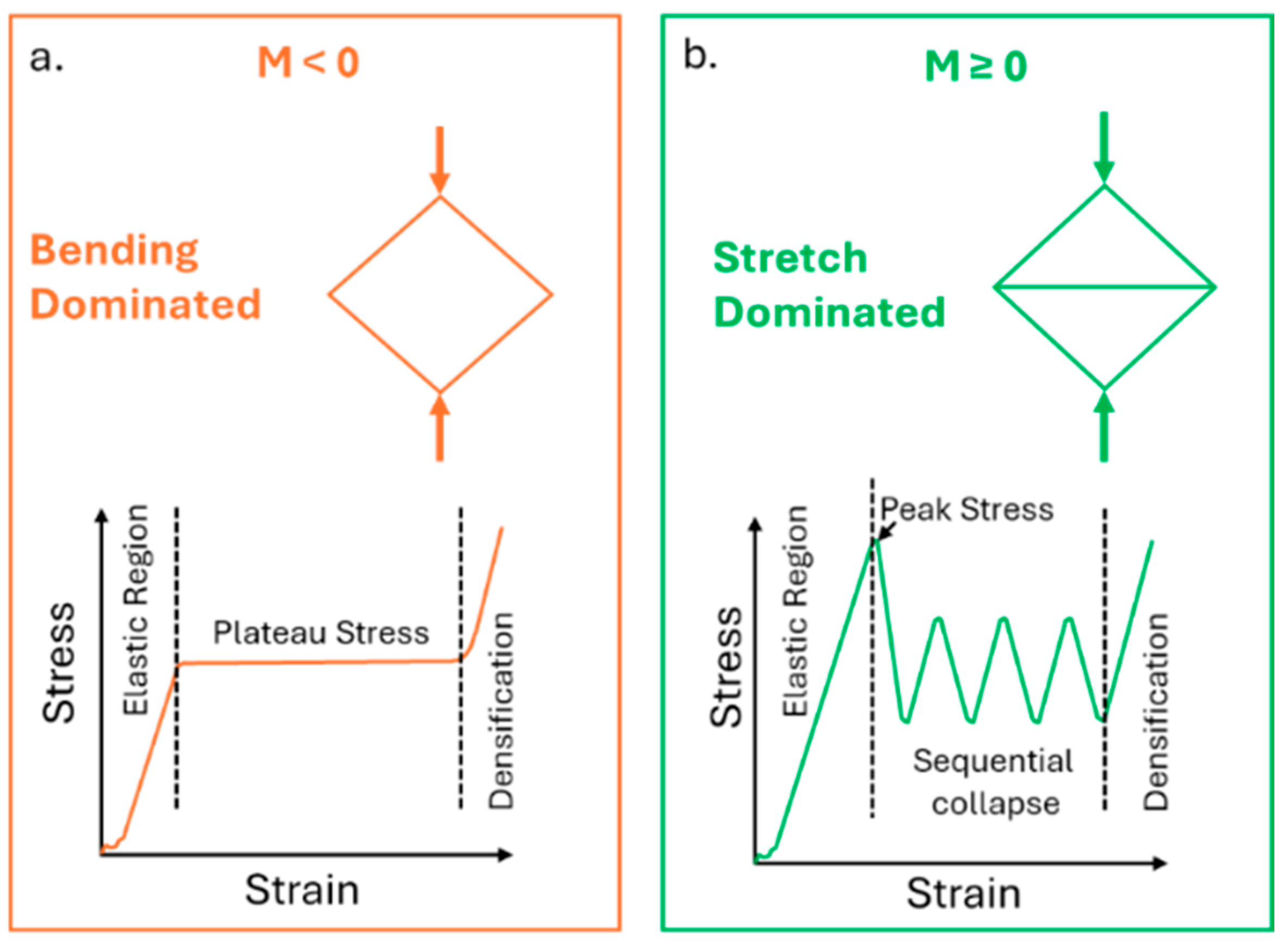

3.2.2. Compression Tests

3.2.3. Ashby–Gibson Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Factors | Responses | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| v (mm/s) | hd (mm) | Pd (W) | Porosity (%) | Deviation of Top Skin (mm) | Deviation of Inclined Strut (mm) | Deviation of Vertical Strut (mm) | |||||

| Av. | Std Dev | Av. | Std Dev | Av. | Std Dev | Av. | Std Dev | ||||

| A1 | 400 | 0.08 | 50 | 0.588 | 0.032 | 0.303 | 0.227 | 0.298 | 0.259 | 0.111 | 0.098 |

| A2 | 400 | 0.08 | 80 | 1.012 | 0.046 | 0.367 | 0.187 | 0.246 | 0.089 | 0.124 | 0.089 |

| A3 | 400 | 0.08 | 120 | 0.579 | 0.017 | 0.362 | 0.152 | 0.230 | 0.129 | 0.073 | 0.079 |

| A4 | 400 | 0.13 | 50 | 0.480 | 0.013 | 0.234 | 0.188 | 0.205 | 0.109 | 0.074 | 0.070 |

| A5 | 400 | 0.13 | 80 | 0.458 | 0.098 | 0.248 | 0.158 | 0.264 | 0.079 | 0.091 | 0.062 |

| A6 | 400 | 0.13 | 120 | 0.440 | 0.042 | 0.308 | 0.127 | 0.246 | 0.077 | 0.076 | 0.070 |

| A7 | 400 | 0.17 | 50 | 0.520 | 0.088 | 0.354 | 0.216 | 0.215 | 0.105 | 0.054 | 0.083 |

| A8 | 400 | 0.17 | 80 | 0.612 | 0.030 | 0.231 | 0.183 | 0.246 | 0.104 | 0.093 | 0.066 |

| A9 | 400 | 0.17 | 120 | 0.616 | 0.011 | 0.256 | 0.191 | 0.237 | 0.104 | 0.076 | 0.059 |

| B1 | 500 | 0.08 | 50 | 0.701 | 0.038 | 0.366 | 0.209 | 0.253 | 0.070 | 0.092 | 0.062 |

| B2 | 500 | 0.08 | 80 | 0.532 | 0.038 | 0.330 | 0.150 | 0.291 | 0.092 | 0.110 | 0.052 |

| B3 | 500 | 0.08 | 120 | 0.953 | 0.018 | 0.469 | 0.140 | 0.382 | 0.072 | 0.158 | 0.062 |

| B4 | 500 | 0.13 | 50 | 0.854 | 0.018 | 0.318 | 0.191 | 0.277 | 0.091 | 0.098 | 0.062 |

| B5 | 500 | 0.13 | 80 | 0.873 | 0.074 | 0.285 | 0.119 | 0.263 | 0.088 | 0.097 | 0.043 |

| B6 | 500 | 0.13 | 120 | 0.679 | 0.089 | 0.281 | 0.093 | 0.214 | 0.073 | 0.048 | 0.054 |

| B7 | 500 | 0.17 | 50 | 0.779 | 0.087 | 0.342 | 0.130 | 0.251 | 0.090 | 0.072 | 0.051 |

| B8 | 500 | 0.17 | 80 | 0.787 | 0.026 | 0.218 | 0.090 | 0.216 | 0.076 | 0.053 | 0.052 |

| B9 | 500 | 0.17 | 120 | 0.702 | 0.039 | 0.207 | 0.076 | 0.171 | 0.057 | 0.041 | 0.045 |

| C1 | 600 | 0.08 | 50 | 0.901 | 0.096 | 0.280 | 0.205 | 0.187 | 0.088 | 0.050 | 0.060 |

| C2 | 600 | 0.08 | 80 | 0.620 | 0.014 | 0.232 | 0.122 | 0.236 | 0.079 | 0.061 | 0.065 |

| C3 | 600 | 0.08 | 120 | 0.651 | 0.089 | 0.306 | 0.178 | 0.217 | 0.066 | 0.062 | 0.073 |

| C4 | 600 | 0.13 | 50 | 0.639 | 0.052 | 0.247 | 0.128 | 0.179 | 0.064 | 0.064 | 0.064 |

| C5 | 600 | 0.13 | 80 | 0.686 | 0.100 | 0.198 | 0.151 | 0.180 | 0.055 | 0.048 | 0.059 |

| C6 | 600 | 0.13 | 120 | 0.696 | 0.064 | 0.205 | 0.098 | 0.150 | 0.061 | 0.033 | 0.043 |

| C7 | 600 | 0.17 | 50 | 1.117 | 0.050 | 0.236 | 0.102 | 0.127 | 0.054 | 0.034 | 0.055 |

| C8 | 600 | 0.17 | 80 | 1.008 | 0.053 | 0.197 | 0.106 | 0.180 | 0.073 | 0.046 | 0.027 |

| C9 | 600 | 0.17 | 120 | 0.924 | 0.079 | 0.205 | 0.106 | 0.120 | 0.076 | 0.049 | 0.040 |

| D1 | 700 | 0.08 | 50 | 0.709 | 0.055 | 0.257 | 0.180 | 0.145 | 0.064 | 0.031 | 0.041 |

| D2 | 700 | 0.08 | 80 | 0.638 | 0.024 | 0.226 | 0.163 | 0.139 | 0.098 | 0.055 | 0.049 |

| D3 | 700 | 0.08 | 120 | 0.834 | 0.072 | 0.236 | 0.097 | 0.214 | 0.079 | 0.061 | 0.051 |

| D4 | 700 | 0.13 | 50 | 0.840 | 0.013 | 0.270 | 0.106 | 0.175 | 0.078 | 0.055 | 0.051 |

| D5 | 700 | 0.13 | 80 | 0.770 | 0.058 | 0.213 | 0.097 | 0.165 | 0.062 | 0.048 | 0.049 |

| D6 | 700 | 0.13 | 120 | 0.735 | 0.019 | 0.227 | 0.100 | 0.164 | 0.078 | 0.028 | 0.038 |

| D7 | 700 | 0.17 | 50 | 0.982 | 0.011 | 0.205 | 0.094 | 0.149 | 0.055 | 0.022 | 0.039 |

| D8 | 700 | 0.17 | 80 | 0.979 | 0.016 | 0.142 | 0.110 | 0.116 | 0.061 | −0.006 | 0.043 |

| D9 | 700 | 0.17 | 120 | 1.279 | 0.039 | 0.175 | 0.086 | 0.083 | 0.060 | −0.003 | 0.037 |

| Top Skin | Diagonal Strut | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Scan Speed (mm/s) | Sq (µm) | Sz (µm) | Sa (µm) | Sv (µm) | Sp (µm) | Sq (µm) | Sz (µm) | Sa (µm) | Sv (µm) | Sp (µm) |

| 400 | 27.2 | 144.3 | 21.7 | 72.6 | 89.9 | 23.3 | 132.3 | 17.9 | 59.1 | 73.3 |

| 500 | 27.6 | 153.2 | 22.0 | 55.5 | 92.3 | 22.4 | 135.0 | 17.1 | 65.4 | 69.6 |

| 600 | 19.5 | 111.0 | 15.3 | 44.6 | 70.2 | 18.1 | 106.6 | 14.7 | 44.4 | 62.3 |

| 700 | 20.8 | 113.9 | 16.0 | 52.7 | 67.6 | 19.1 | 101.2 | 15.2 | 52.3 | 48.9 |

References

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning strategy in selective laser melting (SLM): A review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar] [CrossRef]

- Elambasseril, J.; Rogers, J.; Wallbrink, C.; Munk, D.; Leary, M.; Qian, M. Laser powder bed fusion additive manufacturing (LPBF-AM): The influence of design features and LPBF variables on surface topography and effect on fatigue properties. Crit. Rev. Solid State Mater. Sci. 2023, 48, 132–168. [Google Scholar] [CrossRef]

- Martucci, A.; Aversa, A.; Bondioli, F.; Fino, P.; Lombardi, M. Synergic strategies to improve the PBF-LB\M processability of a cracking-sensitive alloy. Mater. Des. 2022, 224, 111396. [Google Scholar] [CrossRef]

- Plessis, A.D.; Razavi, N.; Benedetti, M.; Murchio, S.; Leary, M.; Watson, M.; Bhate, D.; Berto, F. Properties and applications of additively manufactured metallic cellular materials: A review. Prog. Mater. Sci. 2022, 125, 100918. [Google Scholar] [CrossRef]

- Ashby, M.F. The properties of foams and lattices. Phil. Trans. R. Soc. A 2006, 364, 15–30. [Google Scholar] [CrossRef]

- Catchpole-Smith, S.; Sélo, R.R.J.; Davis, A.W.; Ashcroft, I.A.; Tuck, C.J.; Clare, A. Thermal conductivity of TPMS lattice structures manufactured via laser powder bed fusion. Addit. Manuf. 2019, 30, 100846. [Google Scholar] [CrossRef]

- Fernandes, M.C.; Aizenberg, J.; Weaver, J.C.; Bertoldi, K. Mechanically robust lattices inspired by deep-sea glass sponges. Nat. Mater. 2021, 20, 237–241. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Qin, R.; Chen, B. Laser-based additively manufactured bio-inspired crashworthy structure: Energy absorption and collapse behaviour under static and dynamic loadings. Mater. Des. 2021, 211, 110128. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, P.; Biyikli, E.; Bai, J.; Robbins, J.; To, A. Efficient design optimization of variable-density cellular structures for additive manufacturing: Theory and experimental validation. Rapid Prototyp. J. 2017, 23, 660–677. [Google Scholar] [CrossRef]

- Lai, X.; Wang, C.; Peng, D.; Yang, H.; Wei, Z. Analysis of Heat Transfer Characteristics of a Heat Exchanger Based on a Lattice Filling. Coatings 2021, 11, 1089. [Google Scholar] [CrossRef]

- Deng, H.; Zhao, J. Wang. Leaf Vein-Inspired Bionic Design Method for Heat Exchanger Infilled with Graded Lattice Structure. Aerospace 2021, 8, 237. [Google Scholar] [CrossRef]

- Lietaert, K.; Zadpoor, A.A.; Sonnaert, M.; Schrooten, J.; Weber, L.; Mortensen, A.; Vleugels, J. Mechanical properties and cytocompatibility of dense and porous Zn produced by laser powder bed fusion for biodegradable implant applications. Acta Biomater. 2020, 110, 289–302. [Google Scholar] [CrossRef]

- McGregor, M.; Patel, S.; McLachlin, S.; Vlasea, M. Architectural bone parameters and the relationship to titanium lattice design for powder bed fusion additive manufacturing. Addit. Manuf. 2021, 47, 102273. [Google Scholar] [CrossRef]

- Ashby, M.F. Metal Foams: A Design Guide; Butterworth-Heinemann: Boston, MA, USA, 2000. [Google Scholar]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Ahmadi, S.M.; Yavari, S.A.; Wauthle, R.; Pouran, B.; Schrooten, J.; Weinans, H.; Zadpoor, A.A. Additively Manufactured Open-Cell Porous Biomaterials Made from Six Different Space-Filling Unit Cells: The Mechanical and Morphological Properties. Mater. 2015, 8, 1871–1896. [Google Scholar] [CrossRef] [PubMed]

- Mazur, M.; Leary, M.; Sun, S.; Vcelka, M.; Shidid, D.; Brandt, M. Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2015, 84, 1391–1411. [Google Scholar] [CrossRef]

- Benedetti, M.; Plessis, A.D.; Ritchie, R.O.; Dallago, M.; Razavi, N.; Berto, F. Architected cellular materials: A review on their mechanical properties towards fatigue-tolerant design and fabrication. Mater. Sci. Eng. R Rep. 2021, 144, 100606. [Google Scholar] [CrossRef]

- Ho, J.Y.; Leong, K.C.; Wong, T.N. Additively-manufactured metallic porous lattice heat exchangers for air-side heat transfer enhancement. Int. J. Heat Mass Transf. 2020, 150, 119262. [Google Scholar] [CrossRef]

- Li, Z.; Nie, Y.; Liu, B.; Kuai, Z.; Zhao, M.; Liu, F. Mechanical properties of AlSi10Mg lattice structures fabricated by selective laser melting. Mater. Des. 2020, 192, 108709. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Tran, P.; Harris, J.; Liu, Q.; Lu, G.; Ruan, D.; Faruque, O.; Brandt, M. The effect of topology on the quasi-static and dynamic behaviour of SLM AlSi10Mg lattice structures. Int. J. Adv. Manuf. Technol. 2022, 118, 4085–4104. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- Di Egidio, G.; Ceschini, L.; Morri, A.; Martini, C.; Merlin, M. A Novel T6 Rapid Heat Treatment for AlSi10Mg Alloy Produced by Laser-Based Powder Bed Fusion: Comparison with T5 and Conventional T6 Heat Treatments. Metall. Mater. Trans. B 2022, 53, 284–303. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the Selective Laser Melting (SLM) of the AlSi10Mg Alloy: Process, Microstructure, and Mechanical Properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [PubMed]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.D.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Ferro, C.G.; Varetti, S.; Maggiore, P.; Lombardi, M.; Biamino, S.; Manfredi, D.; Calignano, F. Design and characterization of trabecular structures for an anti-icing sandwich panel produced by additive manufacturing. J. Sandw. Struct. Mater. 2020, 22, 1111–1131. [Google Scholar] [CrossRef]

- Kety, S. Additive Manufacturing Material Scalmalloy® is Approved for Formula 1. Available online: www.3dadept.com (accessed on 12 February 2025).

- Spierings, A.B.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc- and Zr- modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Martucci, A.; Aversa, A.; Manfredi, D.; Bondioli, F.; Biamino, S.; Ugues, D.; Lombardi, M.; Fino, P. Low-Power Laser Powder Bed Fusion Processing of Scalmalloy®. Materials 2022, 15, 3123. [Google Scholar] [CrossRef]

- Cabrera-Correa, L.; González-Rovira, L.; De Dios López-Castro, J.; Castillo-Rodríguez, M.; Botana, F.J. Effect of the heat treatment on the mechanical properties and microstructure of Scalmalloy® manufactured by Selective Laser Melting (SLM) under certified conditions. Mater. Charact. 2023, 196, 112549. [Google Scholar] [CrossRef]

- Cerri, E.; Curti, L.; Ghio, E. Main Heat Treatments Currently Applied on Laser Powder Bed-Fused Scalmalloy®: A Review. Crystals 2024, 15, 25. [Google Scholar] [CrossRef]

- Shakil, S.I.; González-Rovira, L.; Cabrera-Correa, L.; de Dios López-Castro, J.; Castillo-Rodríguez, M.; Botana, F.J.; Haghshenas, M. Insights into laser powder bed fused Scalmalloy®: Investigating the correlation between micromechanical and macroscale properties. J. Mater. Res. Technol. 2023, 25, 4409–4424. [Google Scholar] [CrossRef]

- Schmidtke, K.; Palm, F.; Hawkins, A.; Emmelmann, C. Process and Mechanical Properties: Applicability of a Scandium modified Al-alloy for Laser Additive Manufacturing. Phys. Procedia 2011, 12, 369–374. [Google Scholar] [CrossRef]

- Bi, J.; Wu, L.; Liu, Z.; Wang, H.; Jia, X.; Chen, X.; Starostenkov, M.D.; Dong, G. Formability, surface quality and compressive fracture behavior of AlMgScZr alloy lattice structure fabricated by selective laser melting. J. Mater. Res. Technol. 2022, 19, 391–403. [Google Scholar] [CrossRef]

- Liu, H.; Gu, D.; Qi, J.; Zhang, H.; Yuan, L.; Shi, K.; Li, L.; Zhang, Y. Dimensional effect and mechanical performance of node-strengthened hybrid lattice structure fabricated by laser powder bed fusion. Virtual Phys. Prototyp. 2023, 18, e2240306. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, H.; Sun, H.; Sun, T.; Wu, Y.; Leung, C.L.A.; Wang, H. Additively manufactured high-energy-absorption metamaterials with artificially engineered distribution of bio-inspired hierarchical microstructures. Compos. B Eng. 2022, 247, 110345. [Google Scholar] [CrossRef]

- Tian, Y.; Tomus, D.; Rometsch, P.; Wu, X. Influences of processing parameters on surface roughness of Hastelloy X produced by selective laser melting. Addit. Manuf. 2017, 13, 103–112. [Google Scholar] [CrossRef]

- Charles, A.; Elkaseer, A.; Paggi, U.; Thijs, L.; Hagenmeyer, V.; Scholz, S. Down-facing surfaces in laser powder bed fusion of Ti6Al4V: Effect of dross formation on dimensional accuracy and surface texture. Addit. Manuf. 2021, 46, 102148. [Google Scholar] [CrossRef]

- Lin, P.; Wang, M.; Trofimov, V.A.; Yang, Y.; Song, C. Research on the Warping and Dross Formation of an Overhang Structure Manufactured by Laser Powder Bed Fusion. Appl. Sci. 2023, 13, 3460. [Google Scholar] [CrossRef]

- De Pasquale, G.; Luceri, F.; Riccio, M. Experimental evaluation of selective laser melting process for optimized lattice structures. Proc. Inst. Mech. Eng. E J. Process Mech. Eng. 2019, 233, 763–775. [Google Scholar] [CrossRef]

- Qiu, C.; Yue, S.; Adkins, N.J.; Ward, M.; Hassanin, H.; Lee, P.D.; Withers, P.J.; Attallah, M.M. Attallah. Influence of processing conditions on strut structure and compressive properties of cellular lattice structures fabricated by selective laser melting. Mater. Sci. Eng. A 2015, 628, 188–197. [Google Scholar] [CrossRef]

- Han, X.; Zhu, H.; Nie, X.; Wang, G.; Zeng, X. Investigation on Selective Laser Melting AlSi10Mg Cellular Lattice Strut: Molten Pool Morphology, Surface Roughness and Dimensional Accuracy. Materials 2018, 11, 392. [Google Scholar] [CrossRef]

- Virgillito, E.; Aversa, A.; Calignano, F.; Lombardi, M.; Manfredi, D.; Ugues, D.; Fino, P. Failure mode analysis on compression of lattice structures with internal cooling channels produced by laser powder bed fusion. Adv. Manuf. 2021, 9, 403–413. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- ISO 25178; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. BSI: London, UK, 2022.

- Burton, H.E.; Eisenstein, N.M.; Lawless, B.M.; Jamshidi, P.; Segarra, M.A.; Addison, O.; Shepherd, D.E.; Attallah, M.M.; Grover, L.M.; Cox, S.C. The design of additively manufactured lattices to increase the functionality of medical implants. Mater. Sci. Eng. C 2019, 94, 901–908. [Google Scholar] [CrossRef]

- Minitab. Minitab, LLC. 2021. Available online: https://www.minitab.com (accessed on 1 June 2024).

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Riener, K.; Pfalz, T.; Funcke, F.; Leichtfried, G. Processability of high-strength aluminum 6182 series alloy via laser powder bed fusion (LPBF). Int. J. Adv. Manuf. Technol. 2022, 119, 4963–4977. [Google Scholar] [CrossRef]

- Charles, A.; Elkaseer, A.; Thijs, L.; Hagenmeyer, V.; Scholz, S. Effect of Process Parameters on the Generated Surface Roughness of Down-Facing Surfaces in Selective Laser Melting. Appl. Sci. 2019, 9, 1256. [Google Scholar] [CrossRef]

- ISO 13314-2011; Mechanical testing of metals—Ductility testing—Compression test for porous and cellular metals. ISO: Geneva, Switzerland, 2011.

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. Effect of Selective Laser Melting Process Parameters on the Quality of Al Alloy Parts: Powder Characterization, Density, Surface Roughness, and Dimensional Accuracy. Materials 2018, 11, 2343. [Google Scholar] [CrossRef] [PubMed]

- Li, E.; Zhou, Z.; Wang, L.; Zou, R.; Yu, A. Modelling of keyhole dynamics and melt pool flow in laser powder bed fusion process. Powder Technol. 2022, 400, 117262. [Google Scholar] [CrossRef]

- Pyka, G.; Kerckhofs, G.; Papantoniou, I.; Speirs, M.; Schrooten, J.; Wevers, M. Surface Roughness and Morphology Customization of Additive Manufactured Open Porous Ti6Al4V Structures. Materials 2013, 6, 4737–4757. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Zou, J.; Zhou, H.; Zheng, Q.; Bi, J.; Starostenkov, M.D.; Dong, G.; Tan, C. Recent progress on the control strategies of microstructure and mechanical properties of LPBF-printed aluminum alloys. Int. J. Adv. Manuf. Technol. 2024, 134, 4015–4039. [Google Scholar] [CrossRef]

- Dhillon, J.S.; Su, S.; Sanchez Mata, O.; Ramakrishnan, T.; Brochu, M. Surface Roughness Studies on F357 Aluminum Alloy Fabricated Using Laser Powder Bed Fusion Process. Eng. Proc. 2023, 43, 8. [Google Scholar] [CrossRef]

- Boniotti, L.; Beretta, S.; Patriarca, L.; Rigoni, L.; Foletti, S. Experimental and numerical investigation on compressive fatigue strength of lattice structures of AlSi7Mg manufactured by SLM. Int. J. Fatigue 2019, 128, 105181. [Google Scholar] [CrossRef]

- Emmelmann, C.; Scheinemann, P.; Munsch, M.; Seyda, V. Laser Additive Manufacturing of Modified Implant Surfaces with Osseointegrative Characteristics. Phys. Procedia 2011, 12, 375–384. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Salem, H.; Carter, L.N.; Attallah, M.M.; Salem, H.G. Influence of processing parameters on internal porosity and types of defects formed in Ti6Al4V lattice structure fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 767, 138387. [Google Scholar] [CrossRef]

- Reiber, T.; Rüdesheim, J.; Weigold, M.; Abele, E.; Musekamp, J. Oechsner. Influence of contour scans on surface roughness and pore formation using Scalmalloy® manufactured by laser powder bed fusion (PBF-LB). Mater. Werkst. 2021, 52, 468–481. [Google Scholar] [CrossRef]

- Majeed, A.; Ahmed, A.; Salam, A.; Sheikh, M.Z. Surface quality improvement by parameters analysis, optimization and heat treatment of AlSi10Mg parts manufactured by SLM additive manufacturing. Int. J. Lightweight Mater. Manuf. 2019, 2, 288–295. [Google Scholar] [CrossRef]

- Zhao, M.; Liu, F.; Fu, G.; Zhang, D.Z.; Zhang, T.; Zhou, H. Improved Mechanical Properties and Energy Absorption of BCC Lattice Structures with Triply Periodic Minimal Surfaces Fabricated by SLM. Materials 2018, 11, 2411. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.O.; Tuck, C.J.; Ashcroft, I.A.; Wildman, R.D.; Hague, R.J.M. A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting. Mater. Sci. Eng. A 2016, 670, 264–274. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Li, S.J.; Murr, L.E.; Zhang, Z.B.; Hao, Y.L.; Yang, R.; Medina, F.; Wicker, R.B. Compression deformation behavior of Ti–6Al–4V alloy with cellular structures fabricated by electron beam melting. J. Mech. Behav. Biomed. Mater. 2012, 16, 153–162. [Google Scholar] [CrossRef]

- Banait, S.; Jin, X.; Campos, M.; Pérez-Prado, M.T. Precipitation-induced transition in the mechanical behavior of 3D printed Inconel 718 bcc lattices. Scr. Mater. 2021, 203, 114075. [Google Scholar] [CrossRef]

- Leary, M. Design of titanium implants for additive manufacturing. In Titanium in Medical and Dental Applications; Elsevier: Amsterdam, The Netherlands; pp. 203–224. [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Kadkhodapour, J.; Montazerian, H.; Darabi, A.C.; Anaraki, A.P.; Ahmadi, S.M.; Zadpoor, A.A.; Schmauder, S. Failure mechanisms of additively manufactured porous biomaterials: Effects of porosity and type of unit cell. J. Mech. Behav. Biomed. Mater. 2015, 50, 180–191. [Google Scholar] [CrossRef] [PubMed]

- Bobbert, F.S.L.; Lietaert, K.; Eftekhari, A.A.; Pouran, B.; Ahmadi, S.M.; Weinans, H.; Zadpoor, A.A. Additively manufactured metallic porous biomaterials based on minimal surfaces: A unique combination of topological, mechanical, and mass transport properties. Acta Biomater. 2017, 53, 572–584. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Hao, L.; Hussein, A.; Young, P.; Raymont, D. Advanced lightweight 316L stainless steel cellular lattice structures fabricated via selective laser melting. Mater. Des. 2014, 55, 533–541. [Google Scholar] [CrossRef]

- Li, S.J.; Murr, L.E.; Cheng, X.Y.; Zhang, Z.B.; Hao, Y.L.; Yang, R.; Medina, F.; Wicker, R.B. Compression fatigue behavior of Ti–6Al–4V mesh arrays fabricated by electron beam melting. Acta Mater. 2012, 60, 793–802. [Google Scholar] [CrossRef]

- Echeta, I.; Dutton, B.; Leach, R.K.; Piano, S. Finite Element Modelling of Defects in Additively Manufactured Strut-Based Lattice Structures. Addit. Manuf. 2021, 47, 102301. [Google Scholar] [CrossRef]

| Mg | Sc | Mn | Zr | Si | Fe | Other Elements | Al | |

|---|---|---|---|---|---|---|---|---|

| %wt | 4.77 | 0.78 | 0.51 | 0.27 | 0.06 | 0.12 | <0.8 | Bal. |

| Factors | ||||

|---|---|---|---|---|

| Name | Level 1 | Level 2 | Level 3 | Level 4 |

| Scan Speed, y (mm/s) | 400 | 500 | 600 | 700 |

| Hatch Distance, hd (mm) | 0.08 | 0.13 | 0.17 | / |

| Downskin Power, Pd, (W) | 50 | 80 | 120 | / |

| Responses | ||||

| Porosity | (%) | |||

| (deviation from CAD of) Top skin | (mm) | |||

| (deviation from CAD of) Inclined Strut | (mm) | |||

| deviation from CAD of) Vertical Strut | (mm) | |||

| Model Optimisation | Experimental Value | |

|---|---|---|

| Scan speed (mm/s) | 700 | 700 |

| Hatch Distance (mm) | 0.13 | 0.13 |

| Downskin Power (W) | 86 | 80 |

| Porosity (%) | 0.805 ± 0.048 | 0.770 ± 0.058 |

| Top skin (mm) | 0.192 ± 0.015 | 0.213 ± 0.097 |

| Inclined strut (mm) | 0.152 ± 0.010 | 0.165 ± 0.062 |

| Vertical strut (mm) | 0.034 ± 0.006 | 0.048 ± 0.049 |

| Optimised Porosity | Overall Optimisation | Optimised Dimensional Accuracy | |||||

|---|---|---|---|---|---|---|---|

| v | 400 mm/s | 700 mm/s | 700 mm/s | ||||

| hd | 0.13 mm | 0.13 mm | 0.17 mm | ||||

| Pd | 80 W | 80 W | 80 W | ||||

| Top skin (µm) | Sq | 25.6 |  | 14.8 |  | 9.5 |  |

| Sz | 152.0 | 99.1 | 69.6 | ||||

| Sa | 19.8 | 11.5 | 7.1 | ||||

| Sv | 66.5 | 53.3 | 28.7 | ||||

| Sp | 85.4 | 45.8 | 41.2 | ||||

| Diagonal Strut (µm) | Sq | 14.6 |  | 10.9 |  | 10.7 |  |

| Sz | 121.0 | 88.7 | 75.0 | ||||

| Sa | 11.0 | 7.5 | 8.1 | ||||

| Sv | 48.4 | 41.3 | 36.8 | ||||

| Sp | 72.6 | 47.4 | 38.4 | ||||

| [GPa] | |||||

|---|---|---|---|---|---|

| AB | HT | AB | HT | ||

| Relative density | 24% | 0.40–15.83 | 0.40–16.04 | 3.04–30.38 | 5.02–50.25 |

| 33% | 0.74–29.65 | 0.75–30.03 | 4.86–48.63 | 8.04–80.43 | |

| 43% | 1.26–50.40 | 1.28–51.04 | 7.24–72.41 | 11.97–119.74 | |

| Quasi-Elastic Gradient [GPa] | Yield Stress [MPa] | ||||

|---|---|---|---|---|---|

| AB | HT | AB | HT | ||

| Relative density | 24% | 0.60 ± 0.01 | 0.78 ± 0.01 | 8.32 ± 0.11 | 12.54 ± 0.03 |

| 33% | 1.01 ± 0.01 | 1.08 ± 0.02 | 16.54 ± 0.09 | 26.08 ± 1.51 | |

| 43% | 1.42 ± 0.02 | 2.00 ± 0.02 | 39.87 ± 0.04 | 62.19 ± 0.60 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lagalante, I.; Manfredi, D.; Balestrieri, S.; Mocella, V.; El Hassanin, A.; Coppola, G.; Lombardi, M.; Fino, P. Manufacturing and Mechanical Behaviour of Scalmalloy® Lattice Structures: Experimental Validation and Model. Materials 2025, 18, 3479. https://doi.org/10.3390/ma18153479

Lagalante I, Manfredi D, Balestrieri S, Mocella V, El Hassanin A, Coppola G, Lombardi M, Fino P. Manufacturing and Mechanical Behaviour of Scalmalloy® Lattice Structures: Experimental Validation and Model. Materials. 2025; 18(15):3479. https://doi.org/10.3390/ma18153479

Chicago/Turabian StyleLagalante, Ilaria, Diego Manfredi, Sergio Balestrieri, Vito Mocella, Andrea El Hassanin, Giuseppe Coppola, Mariangela Lombardi, and Paolo Fino. 2025. "Manufacturing and Mechanical Behaviour of Scalmalloy® Lattice Structures: Experimental Validation and Model" Materials 18, no. 15: 3479. https://doi.org/10.3390/ma18153479

APA StyleLagalante, I., Manfredi, D., Balestrieri, S., Mocella, V., El Hassanin, A., Coppola, G., Lombardi, M., & Fino, P. (2025). Manufacturing and Mechanical Behaviour of Scalmalloy® Lattice Structures: Experimental Validation and Model. Materials, 18(15), 3479. https://doi.org/10.3390/ma18153479