Mechanical Properties and Fatigue Life Estimation of Selective-Laser-Manufactured Ti6Al4V Alloys in a Comparison Between Annealing Treatment and Hot Isostatic Pressing

Abstract

1. Introduction

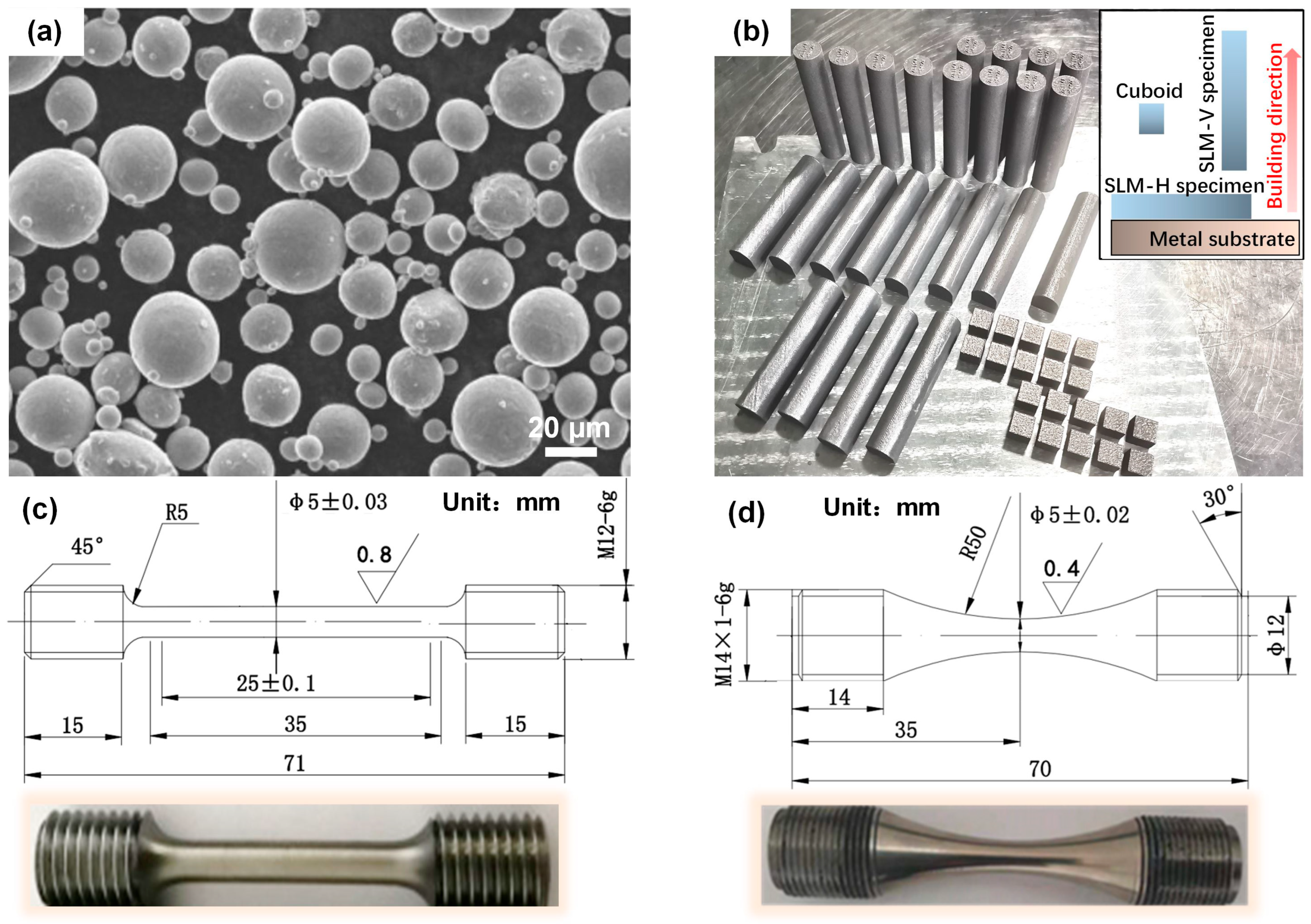

2. Experimental Details

2.1. Materials

2.2. Microscopic Analysis

2.3. Mechanical Testing

3. Experimental Results and Discussion

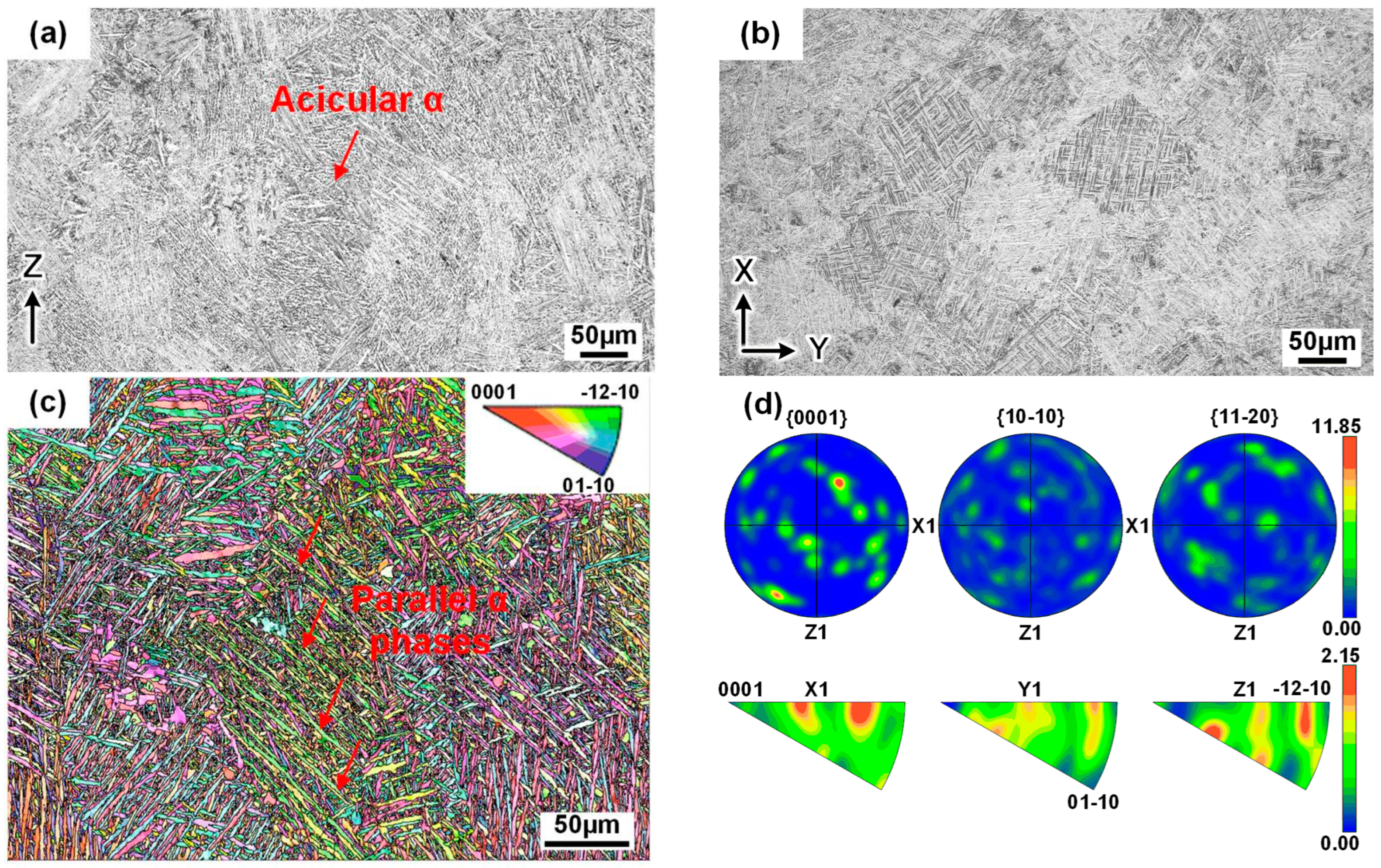

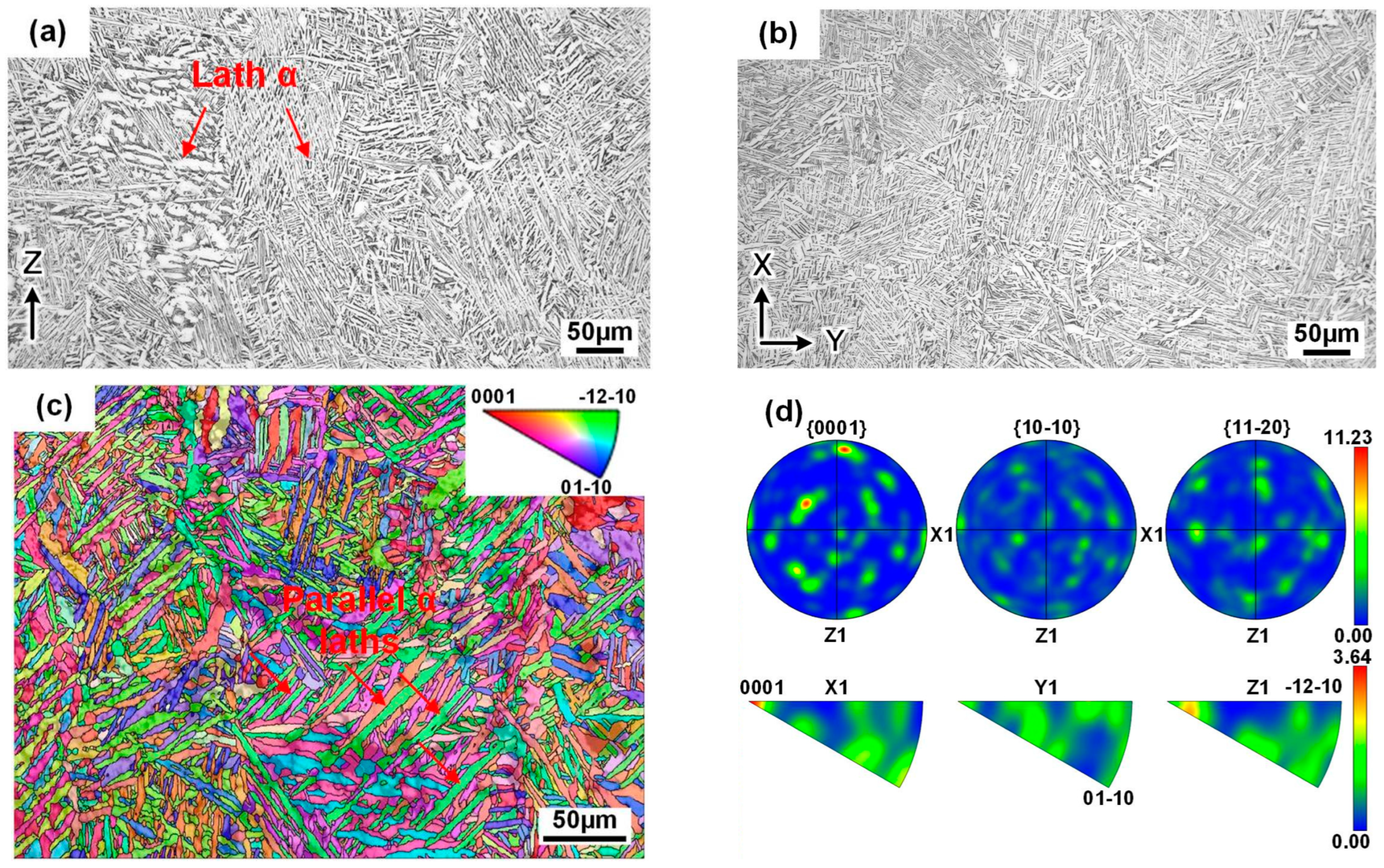

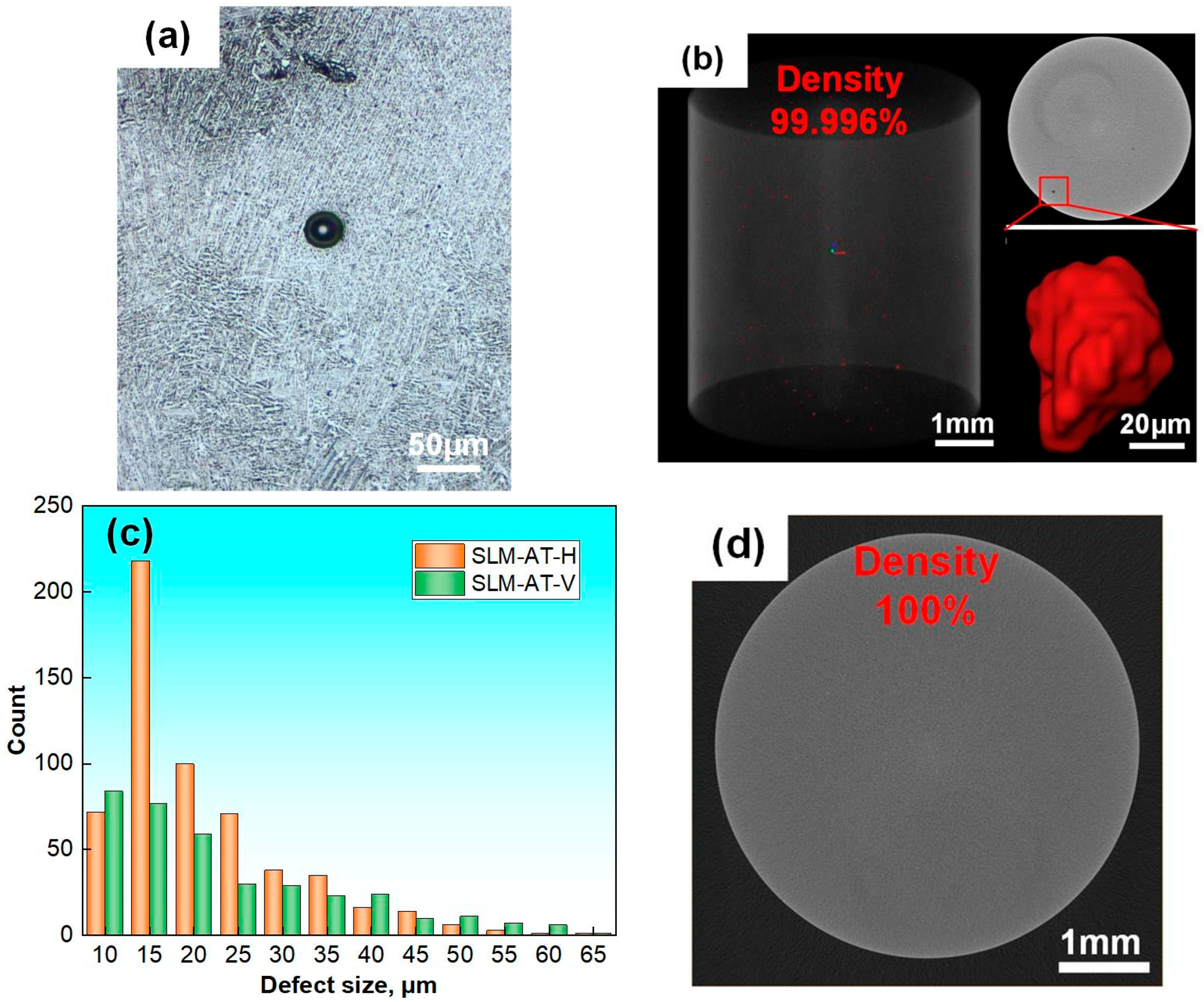

3.1. Microscopic Characteristics

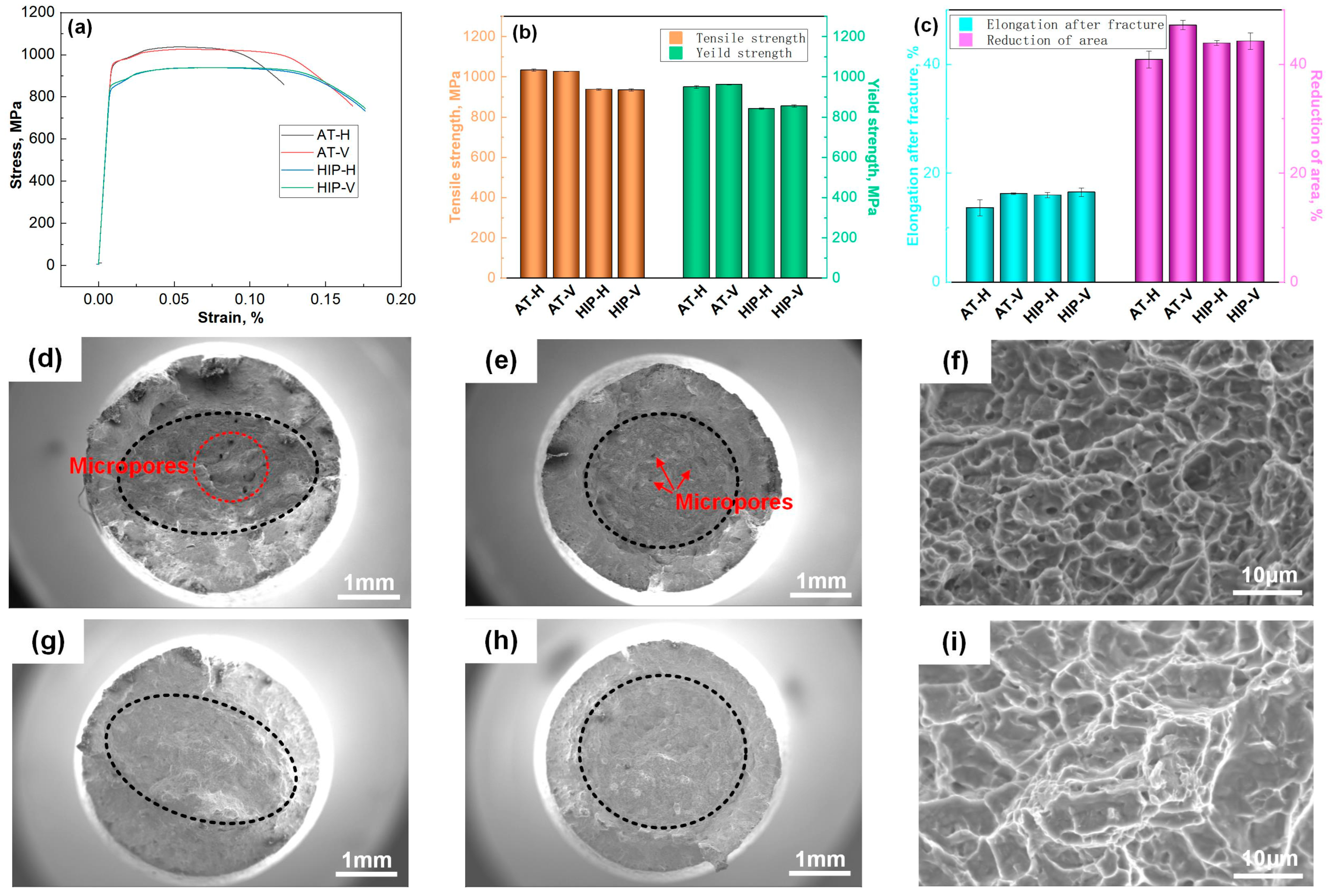

3.2. Tensile Properties

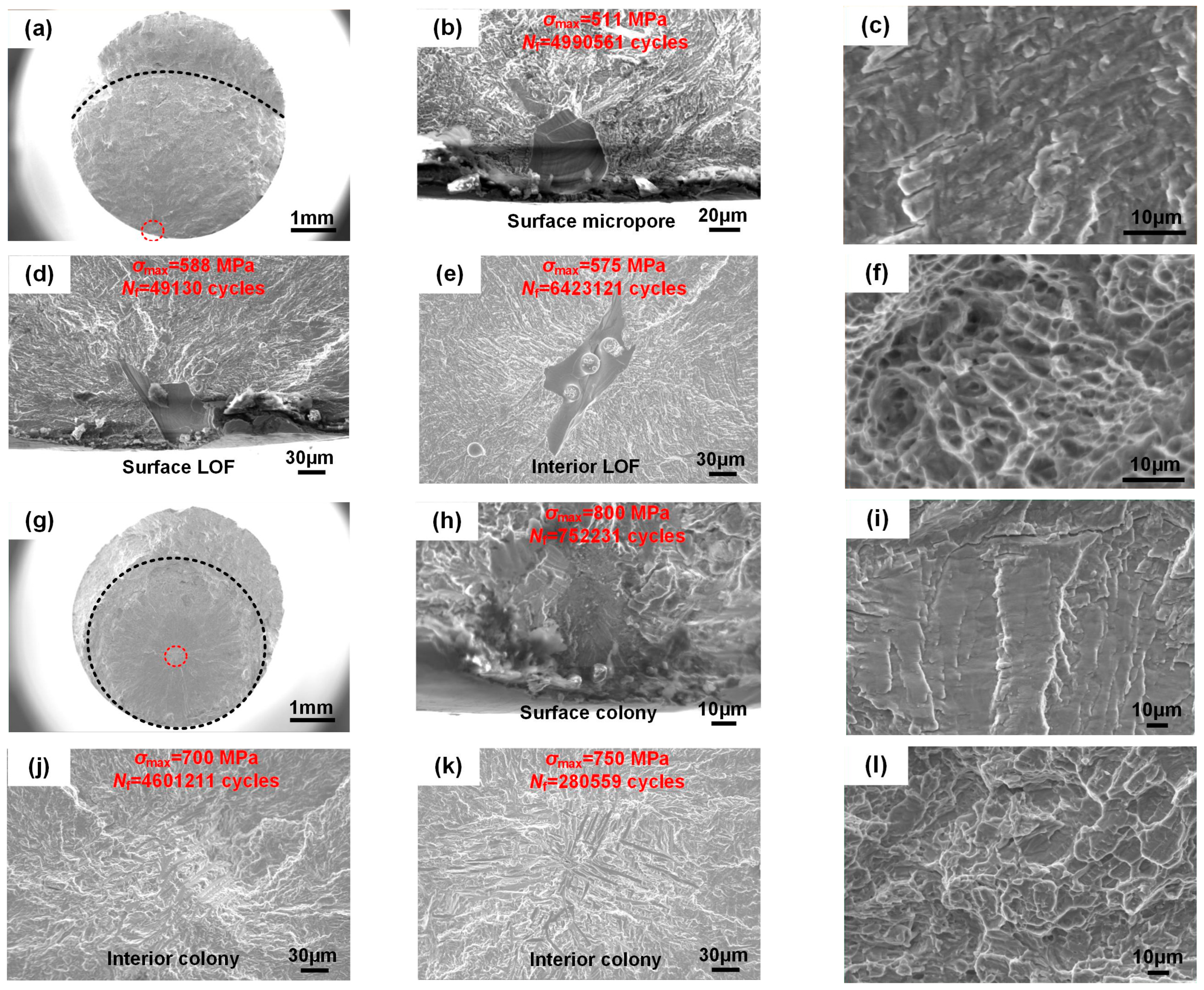

3.3. Fatigue Properties

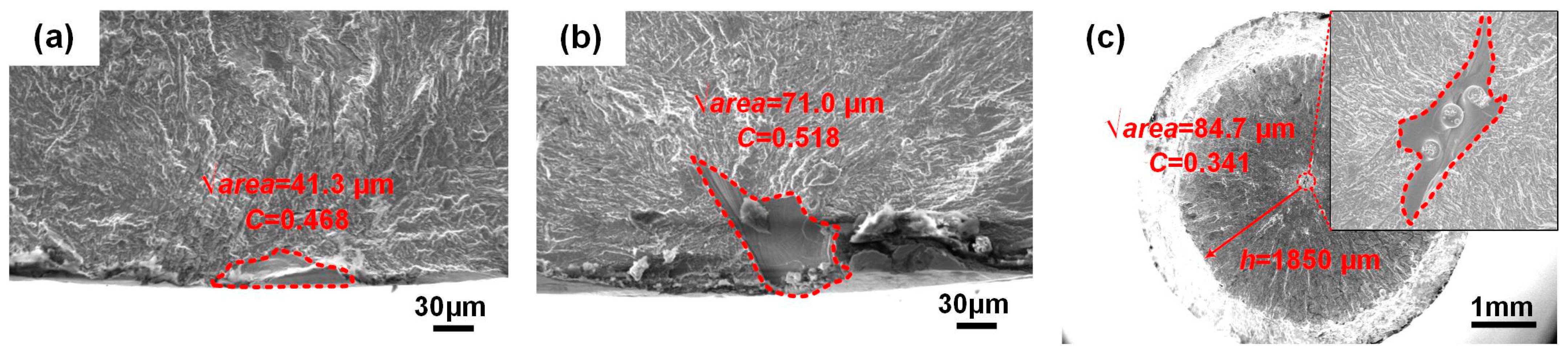

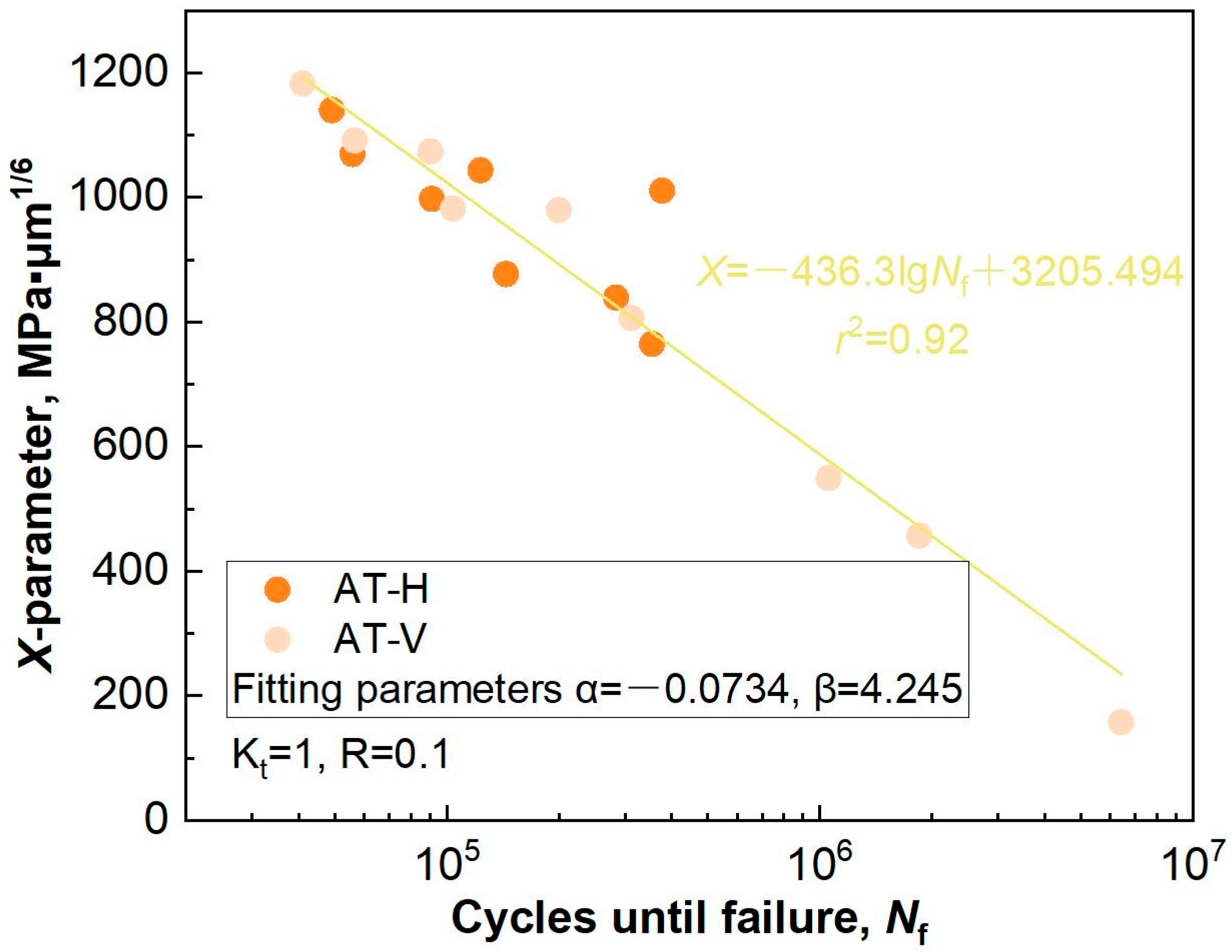

3.4. Defect-Based Fatigue Life Evaluation

4. Conclusions

- The SLM-manufactured specimens presented similarities in their microstructures, consisting of columnar grains, an α phase, and weak textures in the AT and HIP states. In contrast, α phase coarsening and defect closures occurred in cases of elevated temperature and high pressure. Predominantly, dispersed micropores and fewer large LOFs resided in specimens in the AT state, and a higher occurrence of defects in the H specimens compared with the V ones was found.

- The tensile properties and failure mechanism were intricately correlated with the α phase and defects. The formation of an acicular α phase resulted in superior strength/plasticity, as well as a ductile fracture characterized by microvoid coalescence. The coarsening of the lath α decreased the strength but preserves the plasticity. The plastic anisotropy was significantly alleviated through the reality of defect closure.

- The fatigue life of the SLM-manufactured specimens in the AT state featured notable anisotropy and scatter but was significantly improved with the HIP treatment. The predominant surface crack initiation and interior crack initiation were identified in the HCF regime. Furthermore, the failure origins were governed by process-induced micropores, LOF, and an α colony composed of parallel α phases.

- Approximately linear relationships, X-lgNf and σmax-lgNf, were, respectively, established in the AT and HIP states. An X-parameter fatigue life prediction model was proposed by considering the size, location, and shape of defects serving as failure origins. This approach effectively alleviates fatigue anisotropy and scatter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khorasani, A.; Gibson, I.; Goldberg, M.; Littlefair, G. Production of Ti-6Al-4V acetabular shell using selective laser melting: Possible limitations in fabrication. Rapid Prototyp. J. 2017, 23, 110–121. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Levy, G.; Klocke, F.; Childs, T. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann.-Manuf. Technol. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Shipley, H.; McDonnell, D.; Culleton, M.; Coull, R.; Lupoi, R.; O’DOnnell, G.; Trimble, D. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int. J. Mach. Tools Manuf. 2018, 128, 1–20. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Han, J.; Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Microstructure and mechanical property of selective laser melted Ti6Al4V dependence on laser energy density. Rapid Prototyp. J. 2017, 23, 217–226. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the texture formation of selective laser melted Ti-6Al-4V. Metall. Mater. Trans. A 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti-6Al-4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015; pp. 329–350. [Google Scholar]

- Teng, C.; Pal, D.; Gong, H.; Zeng, K.; Briggs, K.; Patil, N.; Stucker, B. A review of defect modeling in laser material processing. Addit. Manuf. 2017, 14, 137–147. [Google Scholar] [CrossRef]

- Gong, H.; Gu, H.; Zeng, K.; Dilip, J.J.S.; Pal, D.; Stucker, B. Melt pool characterization for selective laser melting of Ti-6Al-4V pre-alloyed powder. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014; pp. 256–267. [Google Scholar]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by selective laser melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Chen, B.; Wu, Z.; Yan, T.; He, Z.; Sun, B.; Guo, G.; Wu, S. Experimental study on mechanical properties of laser powder bed fused Ti-6Al-4V alloy under post-heat treatment. Eng. Fract. Mech. 2022, 261, 108264. [Google Scholar] [CrossRef]

- Tao, P.; Li, H.X.; Huang, B.Y.; Hu, Q.D.; Gong, S.L.; Xu, Q.Y. Tensile behavior of Ti-6Al-4V alloy fabricated by selective laser melting: Effects of microstructures and as-built surface quality. Res. Dev. 2018, 15, 243–252. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of L-PBF Ti-6Al-4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef]

- Cao, F.; Zhang, T.; Ryder, M.A.; Lados, D.A. A review of the fatigue properties of additively manufactured Ti-6Al-4V. J. Met. 2018, 70, 349–357. [Google Scholar] [CrossRef]

- Wycisk, E.; Siddique, S.; Herzog, D.; Walther, F.; Emmelmann, C. Fatigue performance of laser additive manufactured Ti-6Al-4V in very high cycle fatigue regime up to 109 cycles. Front. Mater. 2015, 2, 1–8. [Google Scholar] [CrossRef]

- Murr, L.; Quinones, S.; Gaytan, S.; Lopez, M.; Rodela, A.; Martinez, E.; Hernandez, D.; Medina, F.; Wicker, R. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.; Maier, H. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Gibson, I.; Ghaderi, A.; Mohammed, M.I. Investigation on the effect of heat treatment and process parameters on the tensile behaviour of SLM Ti-6Al-4V parts. Int. J. Adv. Manuf. Technol. 2019, 101, 3183–3197. [Google Scholar] [CrossRef]

- Wang, S.C.; Aindow, M.; Starink, M.J. Effect of self-accommodation on α/α boundary populations in pure titanium. Acta Mater. 2003, 51, 2485–2503. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Wang, Z.; Zeng, X. Effect of crystallographic orientation on mechanical anisotropy of selective laser melted Ti-6Al-4V alloy. Mater. Charact. 2017, 127, 137–145. [Google Scholar] [CrossRef]

- Günther, J.; Krewerth, D.; Lippmann, T.; Leuders, S.; Tröster, T.; Weidner, A.; Biermann, H.; Niendorf, T. Fatigue life of additively manufactured Ti-6Al-4V in the very high cycle fatigue regime. Int. J. Fatigue 2016, 94, 236–245. [Google Scholar] [CrossRef]

- Ziółkowski, G.; Chlebus, E.; Szymczyk, P.; Kurzac, J. Application of X-ray CT method for discontinuity and porosity detection in 316L stainless steel parts produced with SLM technology. Arch. Civ. Mech. Eng. 2014, 14, 608–614. [Google Scholar] [CrossRef]

- Mezzetta, J.; Choi, J.-P.; Milligan, J.; Danovitch, J.; Chekir, N.; Bois-Brochu, A.; Zhao, Y.F.; Brochu, M. Microstructure-properties relationships of Ti-6Al-4V parts fabricated by selective laser melting. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 5, 605–612. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance evaluation of selective laser melted Ti-6Al-4V. Mater. Sci. Eng. A 2014, 598, 327–337. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Withers, P.; Todd, I.; Prangnell, P. Porosity regrowth during heat treatment of hot isostatically pressed additively manufactured titanium components. Scr. Mater. 2016, 122, 72–76. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N. Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef]

- Gerov, M.V.; Vladislavskaya, E.Y.; Terent’ev, V.F.; Prosvirnin, D.V.; Kolmakov, A.G.; Antonova, O.S. Fatigue strength of a Ti-6Al-4V alloy produced by selective laser melting. Russ. Metall. (Met.) 2016, 10, 935–941. [Google Scholar] [CrossRef]

- Heinz, S.; Balle, F.; Wagner, G.; Eifler, D. Analysis of fatigue properties and failure mechanisms of Ti6Al4V in the very high cycle fatigue regime using ultrasonic technology and 3D laser scanning vibrometry. Ultrasonics 2013, 53, 1433–1440. [Google Scholar] [CrossRef] [PubMed]

- Walker, K.F.; Liu, Q.; Brandt, M. Evaluation of fatigue crack propagation behavior in Ti-6Al-4V manufactured by selective laser melting. Int. J. Fatigue 2017, 104, 302–308. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and forming mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Gilbert, J.L.; Piehler, H.R. On the nature and crystallographic orientation of subsurface cracks in high cycle fatigue of Ti-6Al-4V. Metall. Mater. Trans. A 1993, 24, 669–680. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, S.; Xie, C.; Wu, W.; Zhang, J. Fatigue life evaluation of Ti-6Al-4V welded joints manufactured by electron beam melting. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2210–2221. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Academic Press: New York, NY, USA, 2002. [Google Scholar]

- Pagliari, L.; Gerosa, R. High- and low-cycle fatigue behavior of additively manufactured Ti6Al4V and influence of surface finish. Eng. Fail. Anal. 2025, 180, 109825. [Google Scholar] [CrossRef]

- Pertuz-Comas, A.D.; González-Estrada, O.A.; Martínez-Díaz, E.; Villegas-Bermúdez, D.F.; Díaz-Rodríguez, J.G. Strain-based fatigue experimental study on Ti-6Al-4V alloy manufactured by electron beam melting. J. Manuf. Mater. Process. 2023, 7, 25. [Google Scholar] [CrossRef]

| Specimens | Maximum Stress Amplitude, σmax/MPa | Fatigue Life, Nf/Cycles | Size, √area/µm | Location, D/µm | Shape, C |

|---|---|---|---|---|---|

| AT-H1 | 575.0 | 377,572 | 41.3 | 1 | 0.468 |

| AT-H2 | 450.0 | 354,754 | 31.2 | 1 | 0.558 |

| AT-H3 | 514.7 | 91,159 | 65.3 | 1 | 0.626 |

| AT-H4 | 440.3 | 284,041 | 54.8 | 1 | 0.738 |

| AT-H5 | 588.2 | 49,130 | 71.0 | 1 | 0.518 |

| AT-H6 | 595.2 | 55,858 | 38.6 | 1 | 0.739 |

| AT-H7 | 572.7 | 123,060 | 50.2 | 1 | 0.490 |

| AT-H8 | 478.7 | 143,928 | 44.2 | 1 | 0.703 |

| AT-V1 | 498.4 | 103,769 | 60.4 | 1 | 0.938 |

| AT-V2 | 617.6 | 41,072 | 69.8 | 1 | 0.456 |

| AT-V3 | 588.2 | 90,355 | 42.7 | 1 | 0.726 |

| AT-V4 | 413.0 | 312,444 | 72.8 | 1 | 0.540 |

| AT-V5 | 542.1 | 199,436 | 40.4 | 1 | 0.715 |

| AT-V6 | 575.0 | 6,423,121 | 84.7 | 0.631 | 0.341 |

| AT-V7 | 550.0 | 56,607 | 134.5 | 1 | 0.167 |

| AT-V8 | 625.0 | 1,846,441 | 38.4 | 0.816 | 0.459 |

| AT-V9 | 576.7 | 1,054,956 | 142.4 | 0.836 | 0.211 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Ye, X.; He, Y.; Ma, S.; Liu, P. Mechanical Properties and Fatigue Life Estimation of Selective-Laser-Manufactured Ti6Al4V Alloys in a Comparison Between Annealing Treatment and Hot Isostatic Pressing. Materials 2025, 18, 3475. https://doi.org/10.3390/ma18153475

Gao X, Ye X, He Y, Ma S, Liu P. Mechanical Properties and Fatigue Life Estimation of Selective-Laser-Manufactured Ti6Al4V Alloys in a Comparison Between Annealing Treatment and Hot Isostatic Pressing. Materials. 2025; 18(15):3475. https://doi.org/10.3390/ma18153475

Chicago/Turabian StyleGao, Xiangxi, Xubin Ye, Yuhuai He, Siqi Ma, and Pengpeng Liu. 2025. "Mechanical Properties and Fatigue Life Estimation of Selective-Laser-Manufactured Ti6Al4V Alloys in a Comparison Between Annealing Treatment and Hot Isostatic Pressing" Materials 18, no. 15: 3475. https://doi.org/10.3390/ma18153475

APA StyleGao, X., Ye, X., He, Y., Ma, S., & Liu, P. (2025). Mechanical Properties and Fatigue Life Estimation of Selective-Laser-Manufactured Ti6Al4V Alloys in a Comparison Between Annealing Treatment and Hot Isostatic Pressing. Materials, 18(15), 3475. https://doi.org/10.3390/ma18153475