Effect of Cr Content on the Microstructure and Toughness of the Supercritically Coarse-Grained Heat-Affected Zone in X80 Pipeline Steel

Abstract

1. Introduction

2. Experimental Procedures

2.1. Experimental Materials

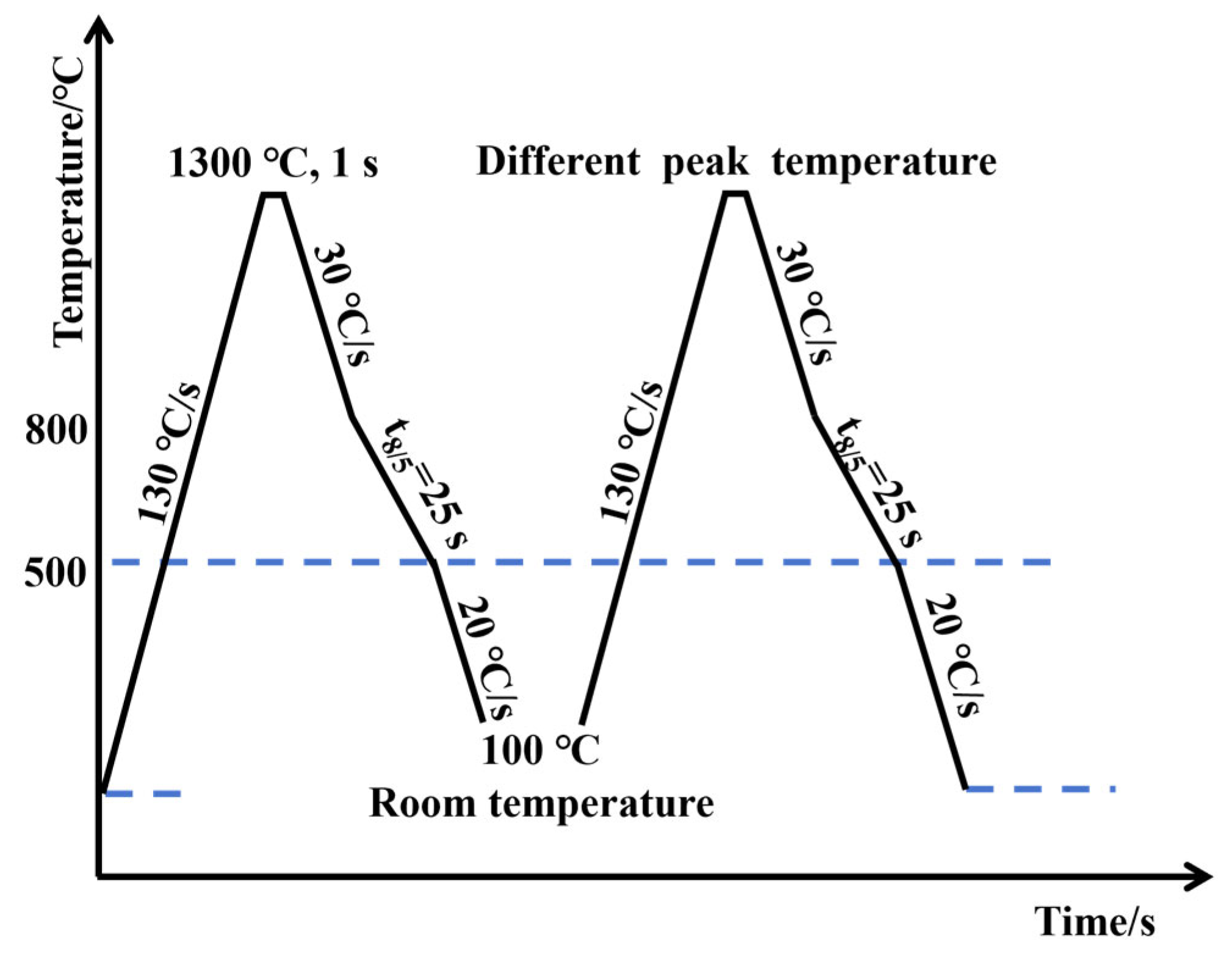

2.2. Welding Thermal Simulation Procedures

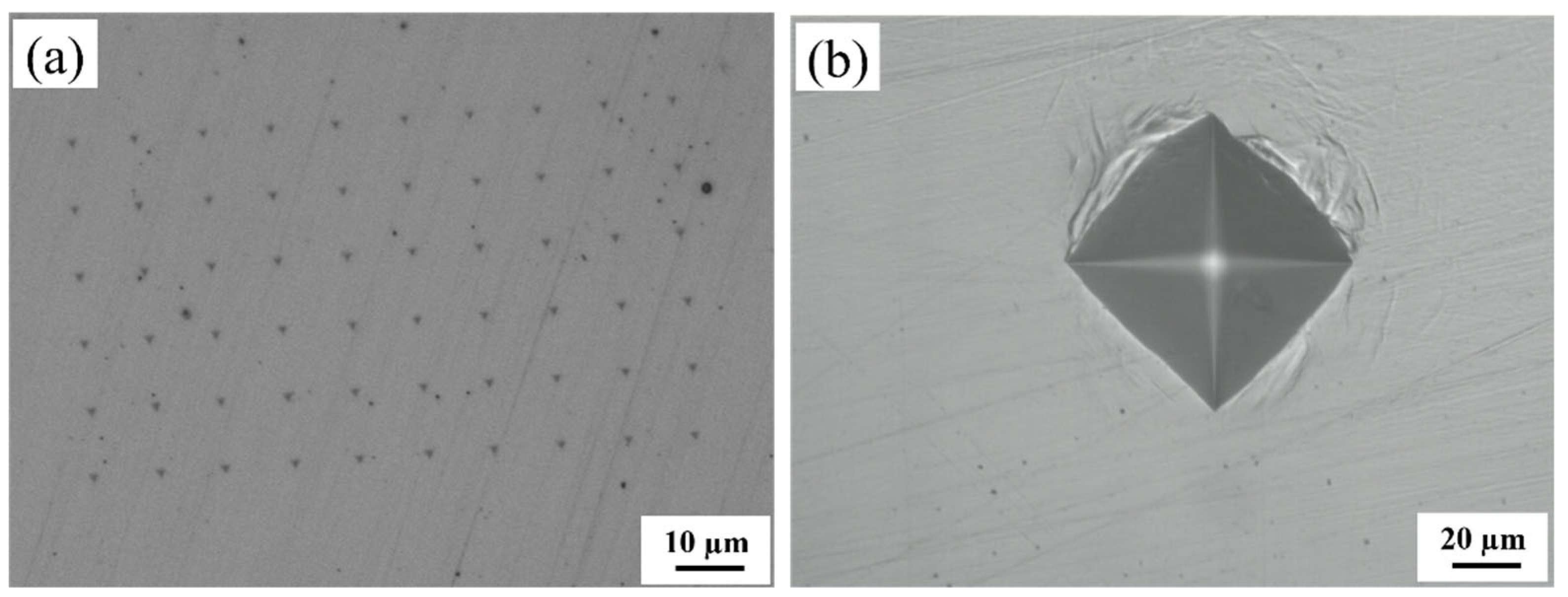

2.3. Microstructural Characterization and Mechanical Properties Test

3. Results

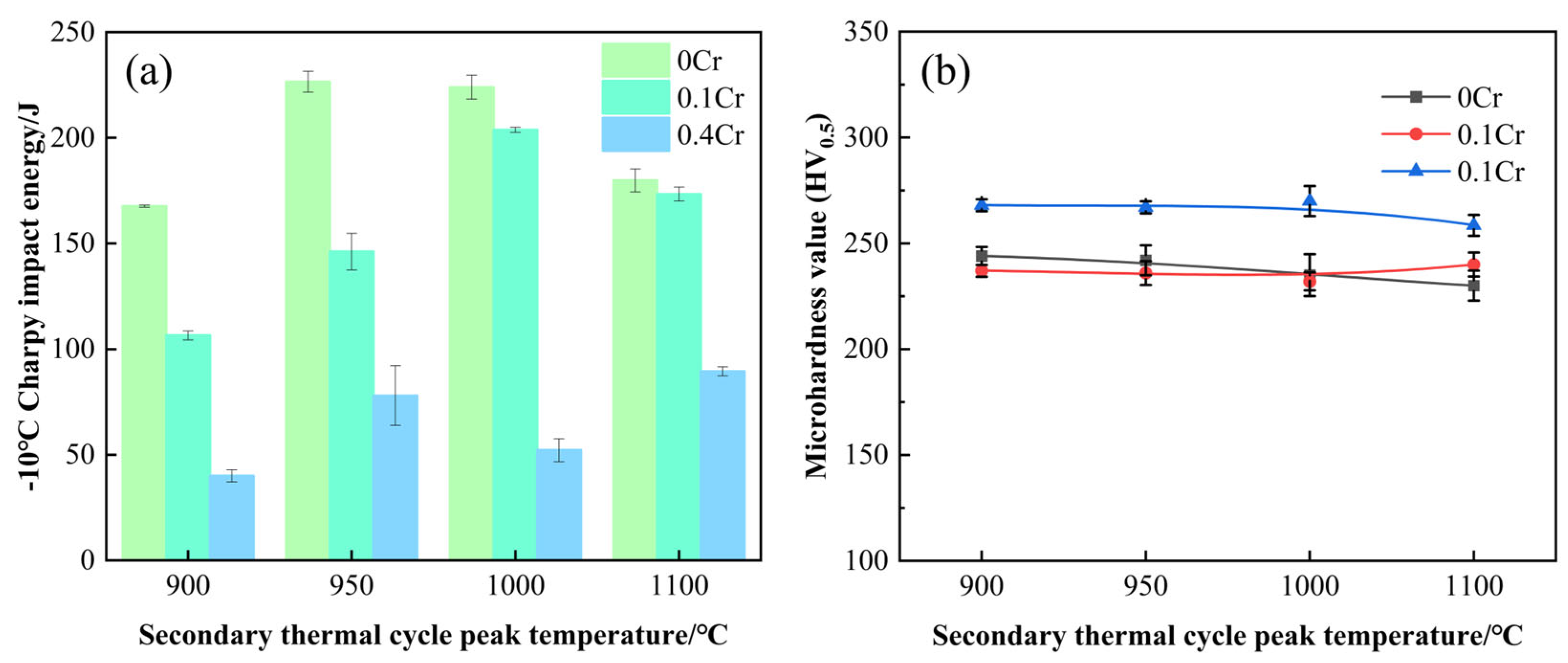

3.1. Mechanical Property

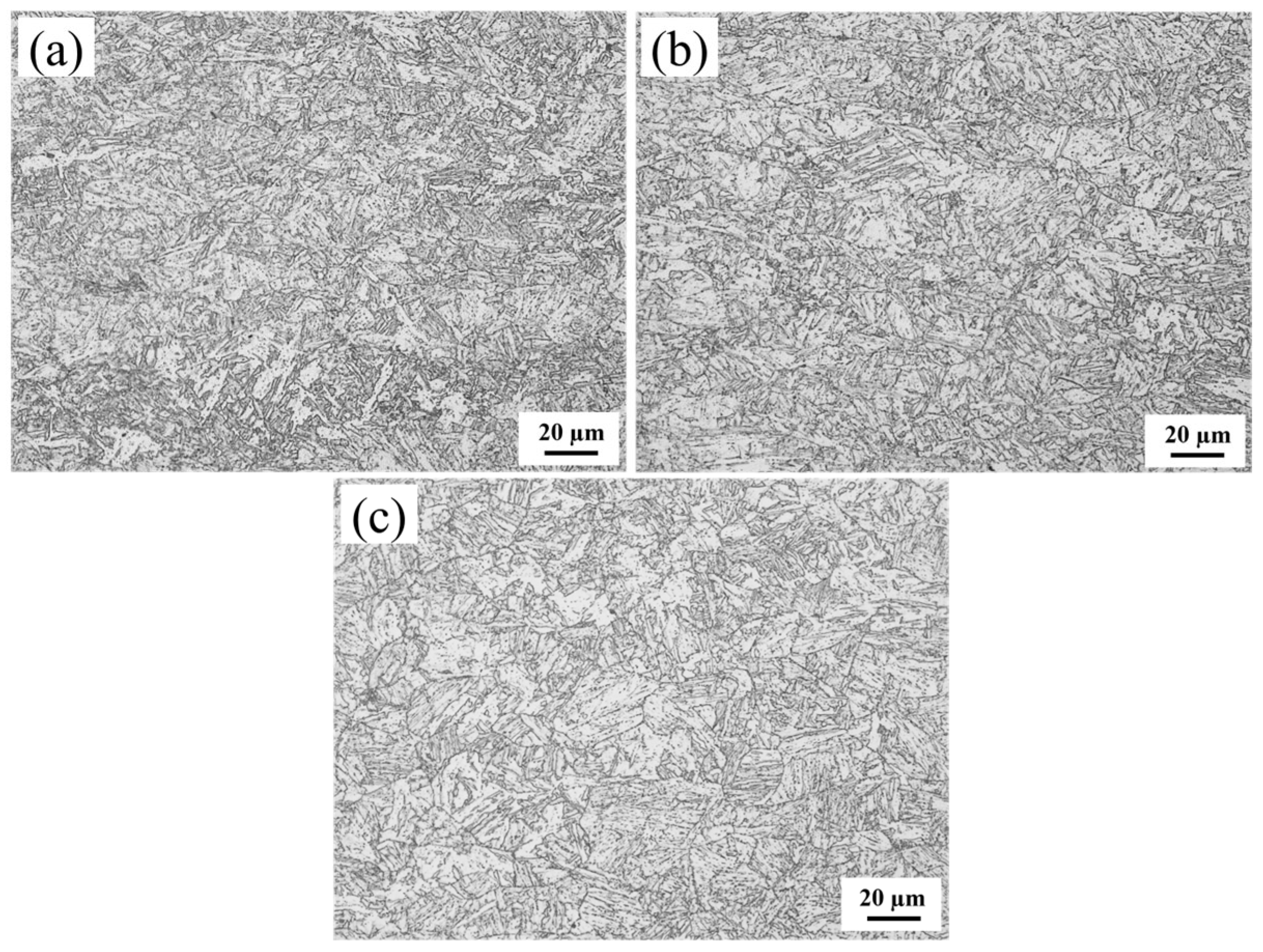

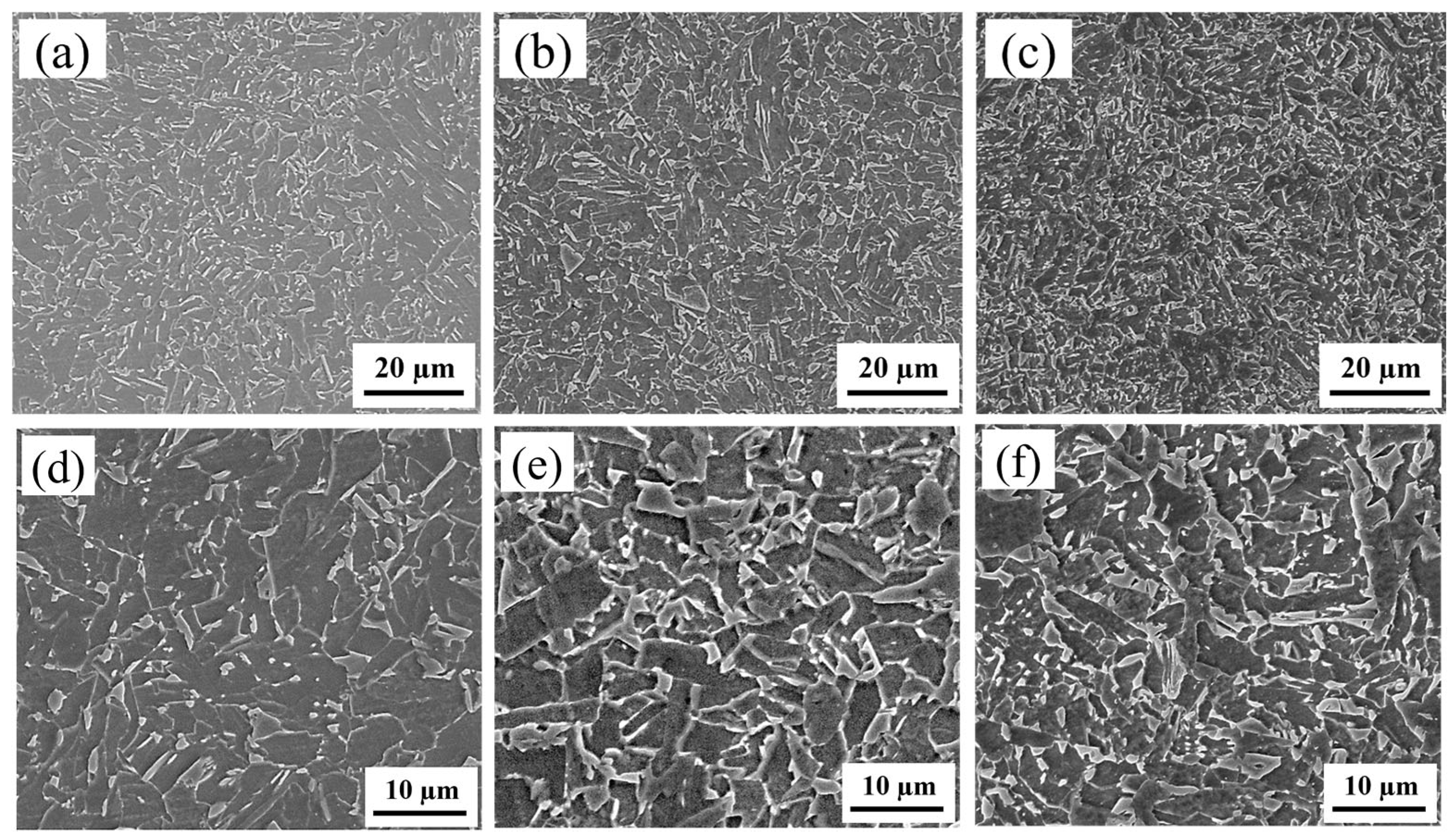

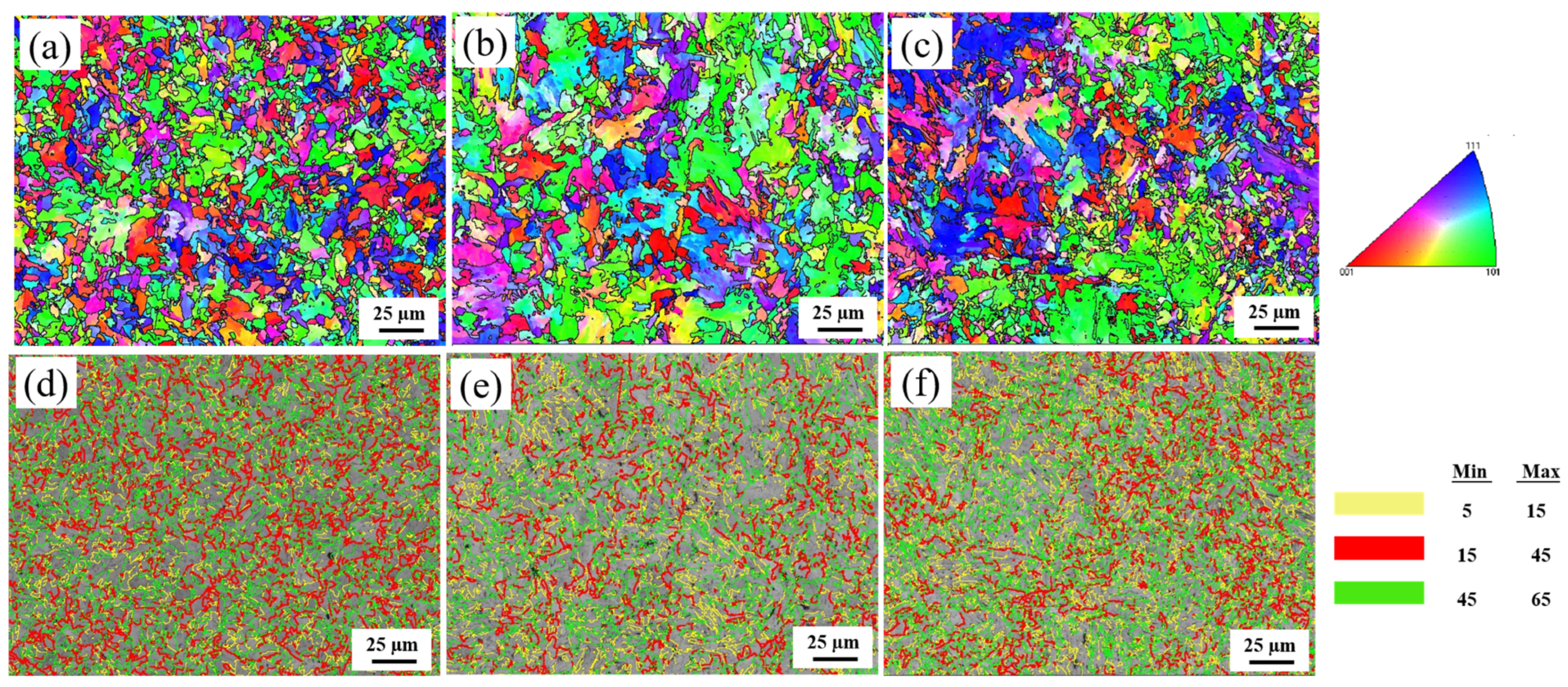

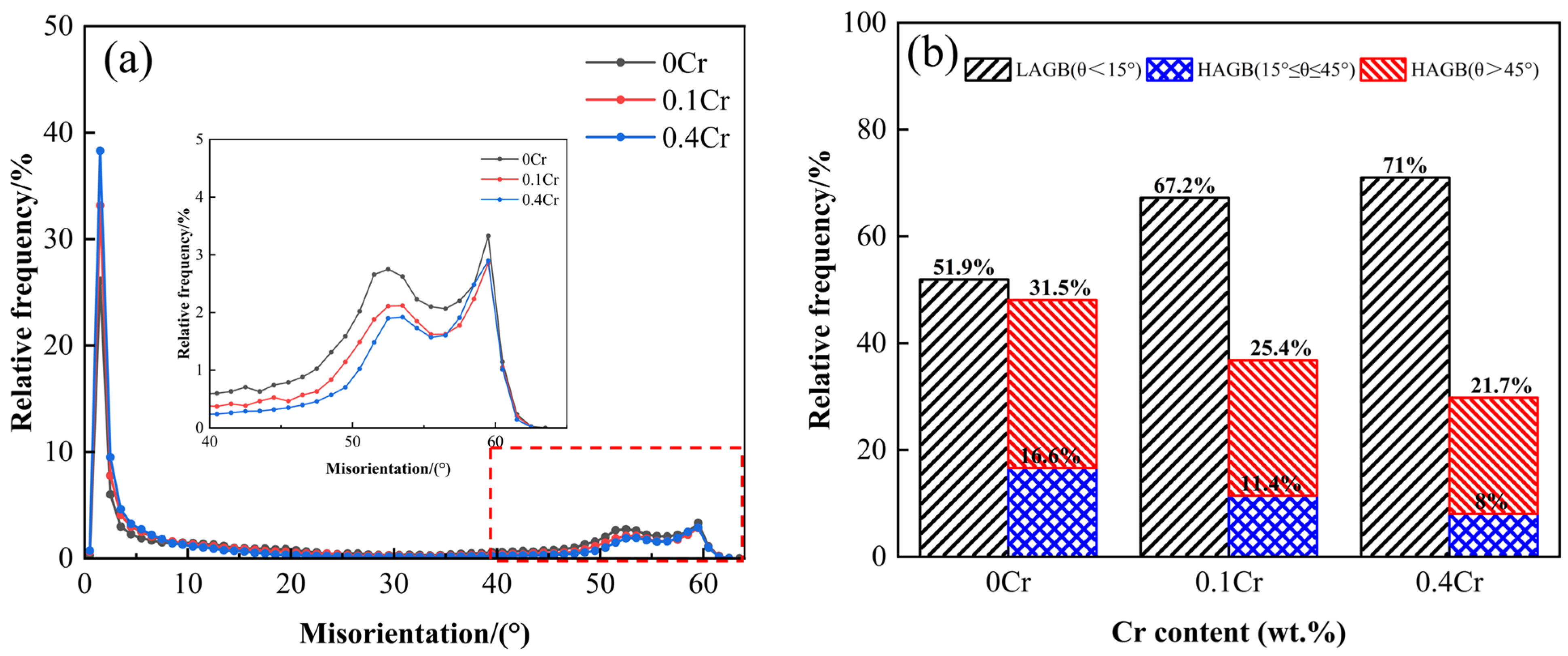

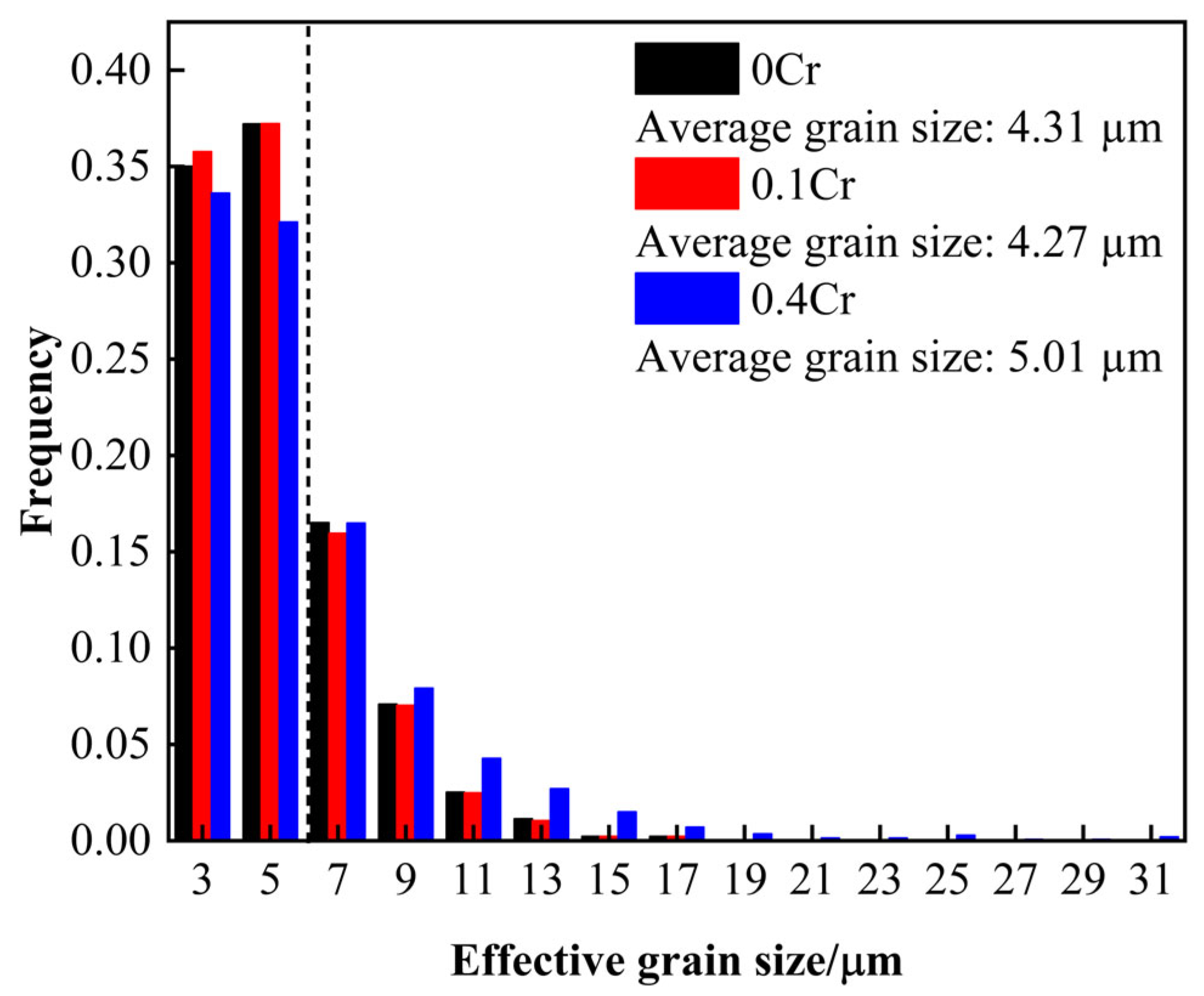

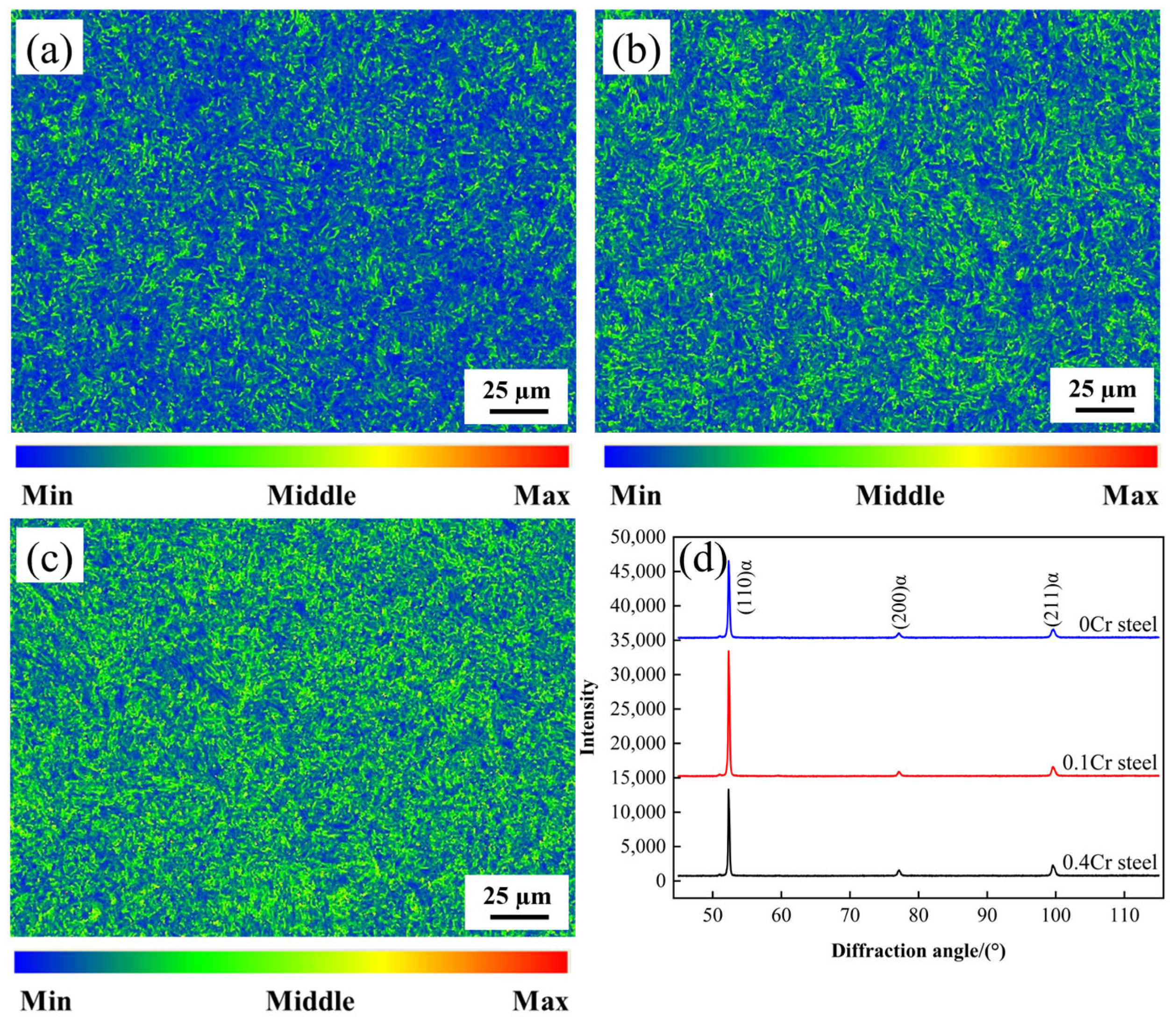

3.2. Microstructure Characterization

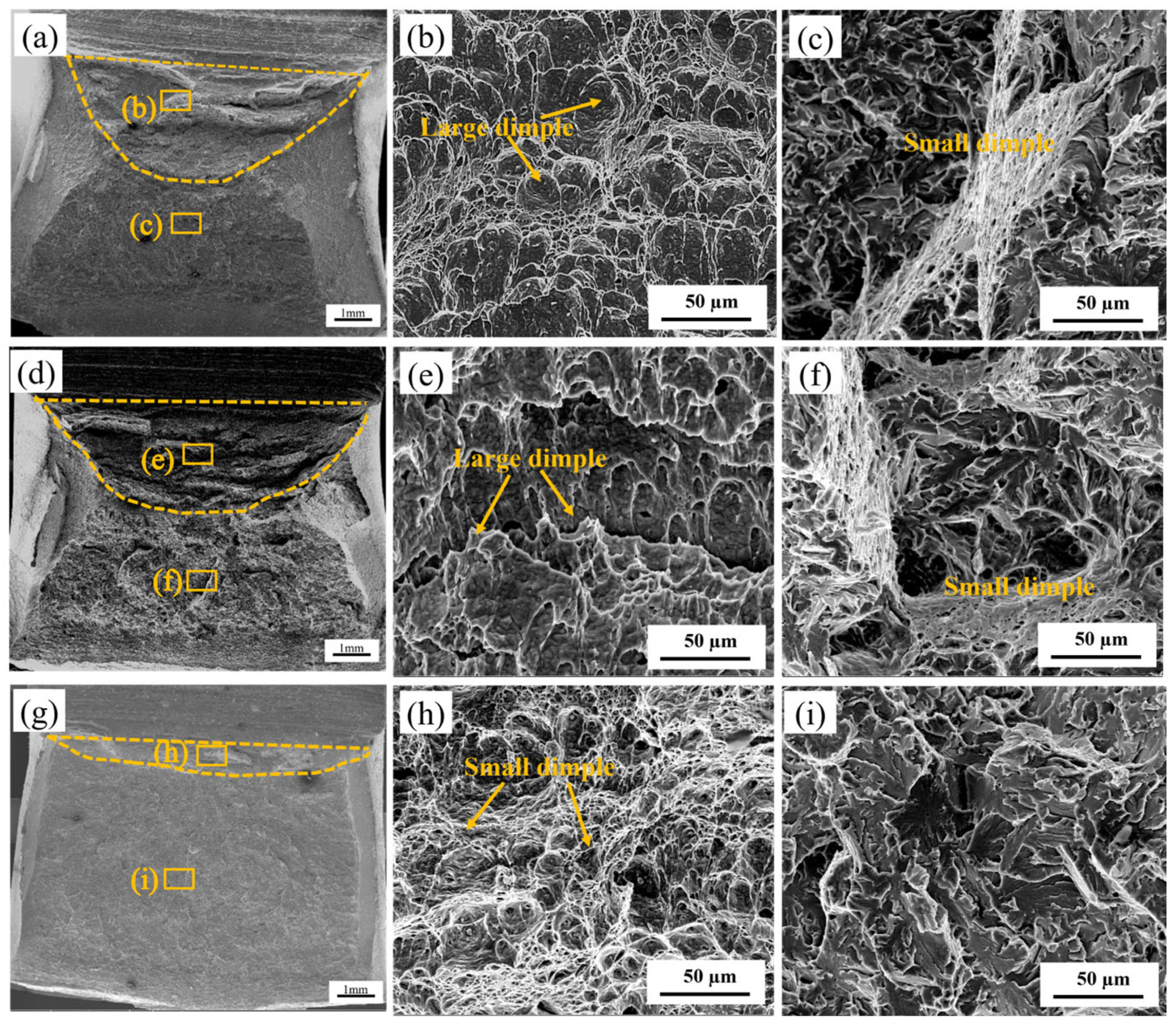

3.3. Fracture Analysis

4. Discussions

4.1. Evolution of Microstructural Features During the Thermal Simulation Process

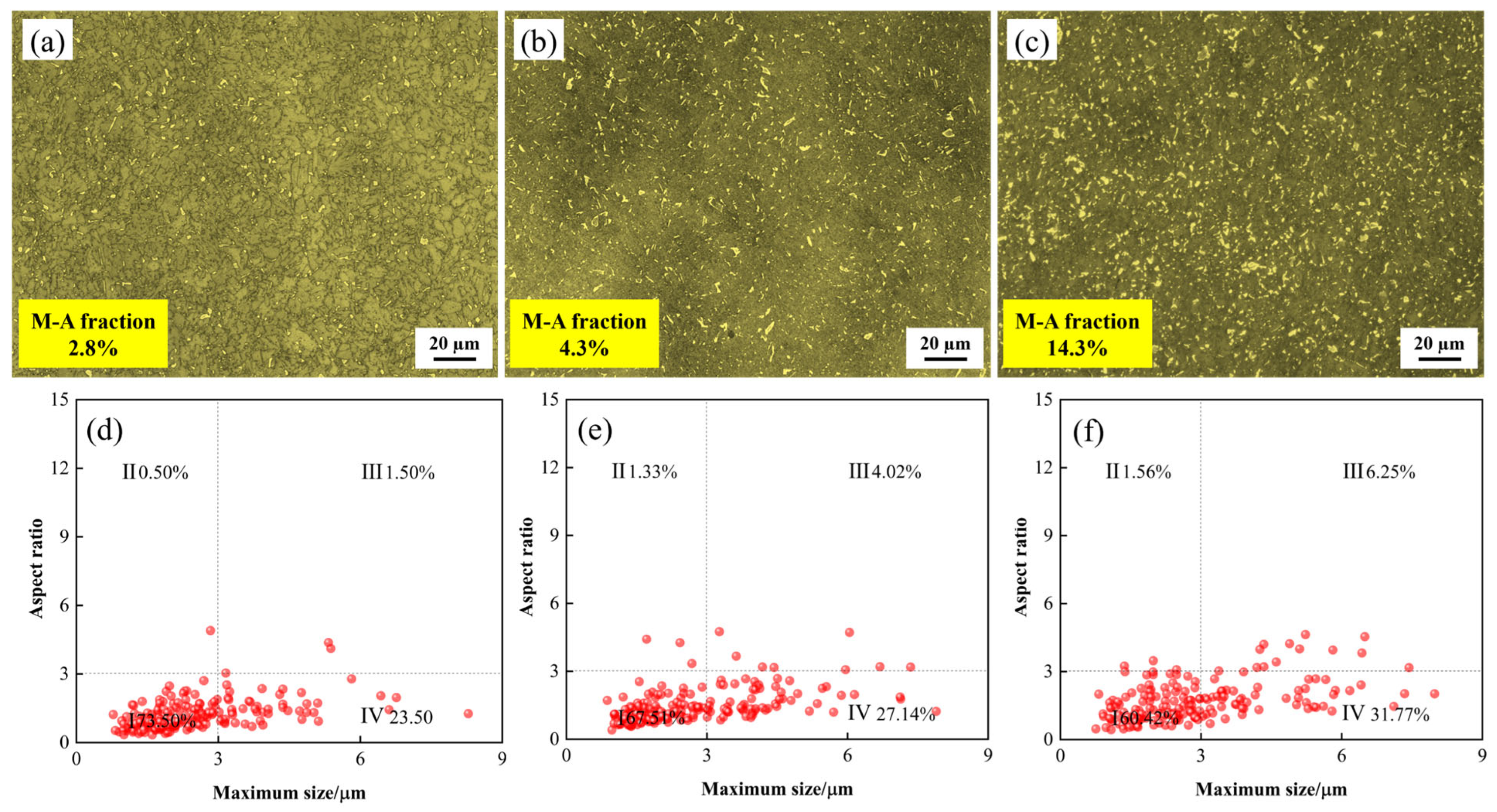

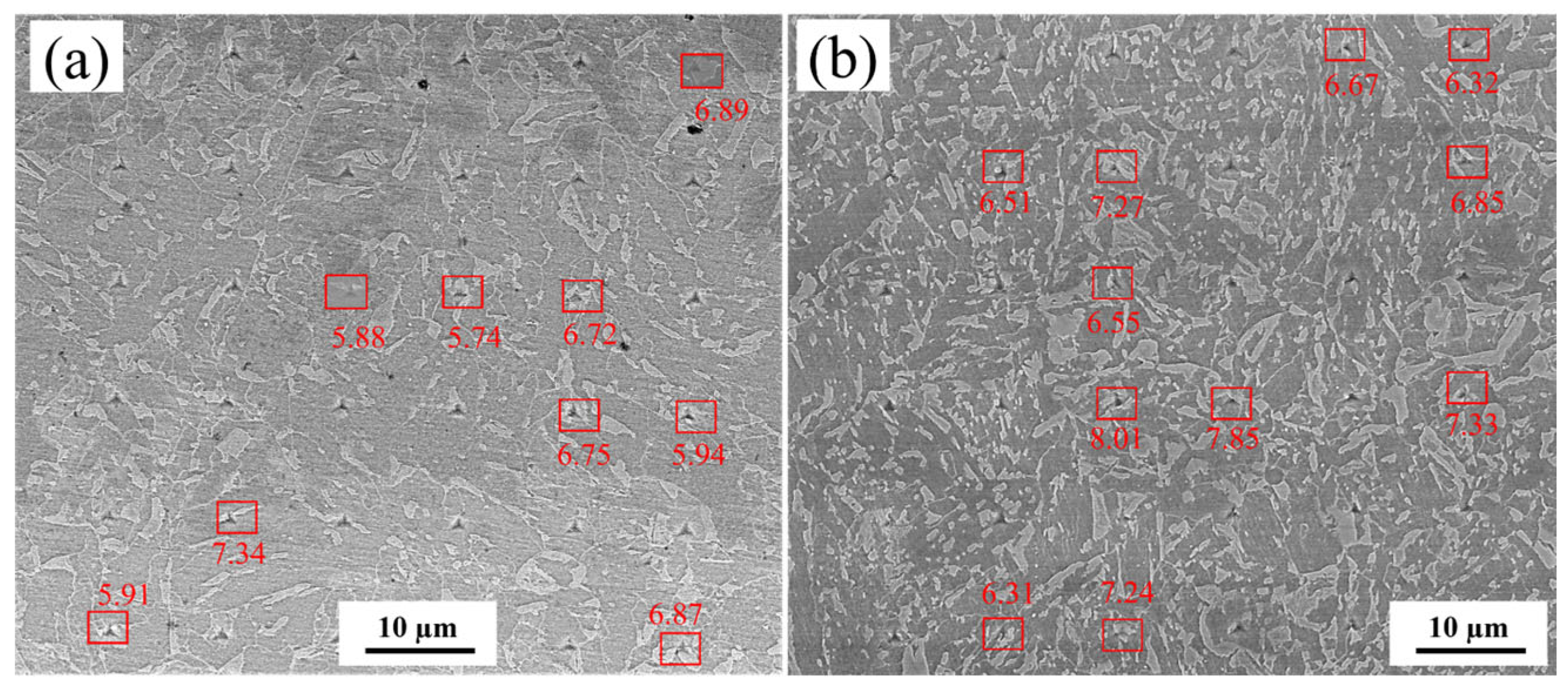

4.2. Effect of M-A Constituents on Impact Toughness

5. Conclusions

- (1)

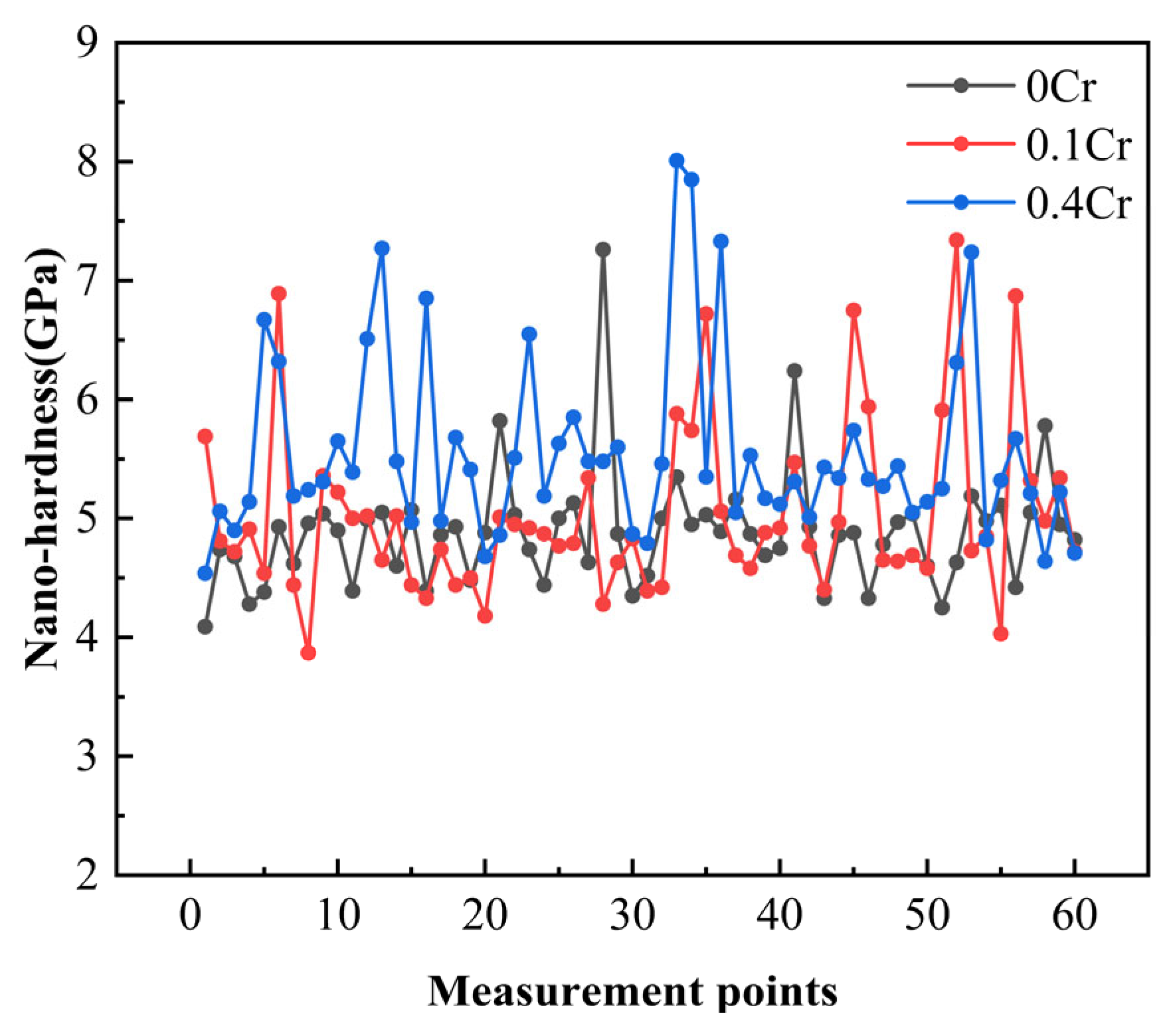

- In the SCCGHAZ, recrystallization and microstructure homogenization are promoted. Therefore, the peak temperature of the secondary thermal cycle has little effect on microhardness, and the hardness value remains at a relatively stable level. With the increase in Cr content, the dislocation density and volume fraction of M-A components increase, which makes the microhardness of experimental steel increase correspondingly. At the same time, the impact energy increases first and then decreases with the increase in the peak temperature of the secondary thermal cycle, and then it decreases gradually with the increase in the Cr content.

- (2)

- After two recrystallizations, fine grains mainly composed of GB were formed in the SCCGHAZ. With the increase in Cr content, the proportion of the HAGB decreased, and the average EGS increased; specifically, when the Cr content was 0.4 wt.%, the HAGB content decreased to 29.7%, and the average EGS increased to 5.01 µm.

- (3)

- An increase in the volume fraction of M-A constituents, a higher proportion of blocky M-A constituents, and an elevation in their nanohardness led to a reduction in impact energy. When the Cr content reached 0.4 wt.%, the impact energy decreased to below 100 J.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Cheng, Q.; Zhao, W.; Liao, Q.; Zhang, H. Review on the transport capacity management of oil and gas pipeline network: Challenges and opportunities of future pipeline transport. Energy Strategy Rev. 2022, 43, 100933. [Google Scholar] [CrossRef]

- Soltani, M.; Hajipour, B.; Tayebinia, J. Identifying the factors affecting competitiveness: A case study of Iranian natural gas industry. Energy Strategy Rev. 2021, 36, 100674. [Google Scholar] [CrossRef]

- Afkhami, S.; Javaheri, V.; Amraei, M.; Skriko, T.; Piili, H.; Zhao, X.L.; Björk, T. Thermomechanical simulation of the heat-affected zones in welded ultra-high strength steels: Microstructure and mechanical properties. Mater. Des. 2022, 213, 110336. [Google Scholar] [CrossRef]

- Chang, Q.; Cao, Y.; Zhen, Y.; Wu, G.; Li, F. Study on the effect of loading conditions on the fracture behavior of pipeline with girth weld. Int. J. Press. Vessel. Pip. 2023, 203, 104940. [Google Scholar] [CrossRef]

- Wang, X.; Wang, D.; Dai, L.; Deng, C.; Li, C.; Wang, Y.; Shen, K. Effect of Post-Weld Heat Treatment on Microstructure and Fracture Toughness of X80 Pipeline Steel Welded Joint. Materials 2022, 15, 6646. [Google Scholar] [CrossRef]

- Jia, S.M.; Yang, D.; Jin, H.C.; Yang, L.Q.; Li, X.B. Effect of secondary thermal cycle on weld microstructure and toughness of X80 steel pipe. Weld. Technol. 2018, 47, 31–34+35. [Google Scholar] [CrossRef]

- Lan, L.; Qiu, C.; Zhao, D.; Gao, X.; Du, L. Microstructural characteristics and toughness of the simulated coarse grained heat affected zone of high strength low carbon bainitic steel. Mater. Sci. Eng. A 2011, 529, 192–200. [Google Scholar] [CrossRef]

- Nellikode, S.; Murugan, S.P.; Chung, J.-H.; Lee, C.-H.; Park, H.; Kim, S.-D.; Ku, N.; Park, Y.-D. Role of M-A constituents in bainitic microstructure on crack propagation behavior in the ICCGHAZ of HSLA steels for offshore applications. J. Mater. Res. Technol. 2024, 32, 250–260. [Google Scholar] [CrossRef]

- Li, Y.; Baker, T.N. Effect of morphology of martensite–austenite phase on fracture of weld heat affected zone in vanadium and niobium microalloyed steels. Mater. Sci. Technol. 2010, 26, 1029–1040. [Google Scholar] [CrossRef]

- Di, X.J.; Cheng, F.J.; Wang, D.P.; Guo, X.J.; Xue, Z.K. Effect of martensite–austenite constituent on toughness of simulated inter-critically reheated coarse-grained heat-affected zone in X70 pipeline steel. Sci. Technol. Weld. Join. 2016, 21, 366–373. [Google Scholar] [CrossRef]

- Luo, X.; Chen, X.; Wang, T.; Pan, S.; Wang, Z. Effect of morphologies of martensite–austenite constituents on impact toughness in intercritically reheated coarse-grained heat-affected zone of HSLA steel. Mater. Sci. Eng. A 2018, 710, 192–199. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Wang, X.L.; Nan, Y.R.; Shang, C.J.; Wang, X.M.; Liu, K.; Chen, B. Effect of Ni content on the microstructure and mechanical properties of weld metal with both-side submerged arc welding technique. Mater. Charact. 2018, 138, 67–77. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Q.; Jia, H.; Cui, S.; Dai, L.; Wu, H.; Liu, Q.; Zhang, H.; Jia, S. Multi-angle analysis of Mo on martensite–austenite component and toughness in SCGHAZ of X80 pipeline automatic ring welding. J. Mater. Res. Technol. 2024, 33, 115–129. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, Z.Q.; Dong, L.L.; Shang, C.J.; Ma, X.P.; Subramanian, S.V. New insights into the mechanism of cooling rate on the impact toughness of coarse grained heat affected zone from the aspect of variant selection. Mater. Sci. Eng. A 2017, 704, 448–458. [Google Scholar] [CrossRef]

- Jia, S.J.; Ma, Q.L.; Hou, Y.; Li, B.; Zhang, H.S.; Liu, Q.Y. Changes in microstructure and properties of weld heat-affected zone of high-strength low-alloy steel. J. Iron Steel Res. Int. 2024, 31, 2041–2052. [Google Scholar] [CrossRef]

- Qi, X.; Huan, P.; Wang, X.; Shen, X.; Liu, Z.; Di, H. Effect of microstructure homogeneity on the impact fracture mechanism of X100 pipeline steel laser–MAG hybrid welds with an alternating magnetic field. Mater. Sci. Eng. A 2022, 851, 143656. [Google Scholar] [CrossRef]

- Wang, L.; Wang, B.; Zhou, P. Misorientation, grain boundary, texture and recrystallization study in X90 hot bend related to mechanical properties. Mater. Sci. Eng. A 2018, 711, 588–599. [Google Scholar] [CrossRef]

- Jia, Z.; Misra, R.D.K.; O’malley, R.; Jansto, S.J. Fine-scale precipitation and mechanical properties of thin slab processed titanium–niobium bearing high strength steels. Mater. Sci. Eng. A 2011, 528, 7077–7083. [Google Scholar] [CrossRef]

- Xi, X.; Wang, J.; Chen, L.; Wang, Z. On the role of Cu addition in toughness improvement of coarse grained heat affected zone in a low carbon high strength steel. J. Mater. Sci. 2020, 55, 10863–10877. [Google Scholar] [CrossRef]

- Fu, W.; Li, C.; Di, X.; Fu, K.; Gao, H.; Fang, C.; Lou, S.; Wang, D. Refinement mechanism of nanoscale Cu-rich precipitates by Mo addition and its effect on strength-toughness of Cu-bearing low carbon high strength steel. Mater. Sci. Eng. A 2022, 849, 143469. [Google Scholar] [CrossRef]

- Xia, T.; Ma, Y.; Zhang, Y.; Li, J.; Xu, H. Effect of Mo and Cr on the Microstructure and Properties of Low-Alloy Wear-Resistant Steels. Materials 2024, 17, 2408. [Google Scholar] [CrossRef]

- Razzak, M.A. Heat treatment and effects of Cr and Ni in low alloy steel. Bull. Mater. Sci. 2011, 34, 1439–1445. [Google Scholar] [CrossRef]

- Rodriguez-Galeano, K.F.; Nutter, J.; Azakli, Y.; Slater, C.; Rainforth, W.M. Influence of Cr and Cr+Nb on the interphase precipitation and mechanical properties of V–Mo microalloyed steels. Mater. Sci. Eng. A 2024, 893, 146140. [Google Scholar] [CrossRef]

- Ledermueller, C.; Pratiwi, H.I.; Webster, R.F.; Eizadjou, M.; Ringer, S.P.; Primig, S. Microalloying effects of Mo versus Cr in HSLA steels with ultrafine-grained ferrite microstructures. Mater. Des. 2020, 185, 108278. [Google Scholar] [CrossRef]

- Tian, J.; Xu, G.; Zhou, M.; Hu, H.; Wan, X. The Effects of Cr and Al Addition on Transformation and Properties in Low—Carbon Bainitic Steels. Metals 2017, 7, 40. [Google Scholar] [CrossRef]

- Wu, G.X.; Liu, Y.C. Effect of Chromium on Microstructure and Properties of Thick Pipe Steel. Met. World 2018, 75–78. [Google Scholar]

- Yao, Z.; Xu, G.; Jiang, Z.; Tian, J.; Yuan, Q.; Ma, H. Effects of Ni and Cr on Cryogenic Impact Toughness of Bainite/Martensite Multiphase Steels. Met. Mater. Int. 2019, 25, 1151–1160. [Google Scholar] [CrossRef]

- GB/T 229-2020; Metallic Materials—Charpy Pendulum Impact Test Method. National Standards of the People’s Republic of China: Beijing, China, 2020.

- Guo, K.; Shi, Z.; Pan, T.; Luo, X.; Chai, F. Structure and morphology of M-A constituent in the CGHAZ of a quenched and tempered ultra-low-carbon steel. J. Mater. Sci. 2023, 58, 4587–4602. [Google Scholar] [CrossRef]

- Jiang, Q.M.; Deng, L.Y.; Wang, H.; Zhang, X.Q.; Zhen, Y.; Ren, D.D. Prediction formula and application of hardness in heat affected zone of X80 pipeline weld seam. Oil Gas Storage Transp. 2025, 44, 1–11. [Google Scholar]

- Kong, D.J.; Long, D.; Wu, Y.Z.; Ye, C.D. Analysis of Impact Toughnesss and Fracture Morphologies of X80 Pipeline Steel Welded Joints with Submerged-arc Welding. J. Mater. Eng. 2013, 41, 50–54. [Google Scholar]

- Wang, X.L.; Wang, Z.Q.; Ma, X.P.; Subramanian, S.V.; Xie, Z.J.; Shang, C.J.; Li, X.C. Analysis of impact toughness scatter in simulated coarse-grained HAZ of E550 grade offshore engineering steel from the aspect of crystallographic structure. Mater. Charact. 2018, 140, 312–319. [Google Scholar] [CrossRef]

- Wang, D.; Yang, S.; Jiang, H.; Cao, K.; Xiao, J.; Guo, H.; Liu, R.; Zhao, A. Study on the relationship between the refined hierarchical microstructure, yield strength and impact toughness of low-carbon martensitic steel at different quenching temperatures. Mater. Sci. Eng. A 2024, 896, 146271. [Google Scholar] [CrossRef]

- Niu, Y.; Jia, S.; Liu, Q.; Tong, S.; Li, B.; Ren, Y.; Wang, B. Influence of Effective Grain Size on Low Temperature Toughness of High-Strength Pipeline Steel. Materials 2019, 12, 3672. [Google Scholar] [CrossRef] [PubMed]

- Shin, S.; Hwang, B.; Lee, S.; Kim, N.J.; Ahn, S.S. Correlation of microstructure and charpy impact properties in API X70 and X80 line-pipe steels. Mater. Sci. Eng. A 2007, 458, 281–289. [Google Scholar] [CrossRef]

- Hajyakbary, F.; Sietsma, J.; Böttger, A.J.; Santofimia, M.J. An improved X-ray diffraction analysis method to characterize dislocation density in lath martensitic structures. Mater. Sci. Eng. A 2015, 639, 208–218. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Han, L.; Zhong, H.; Gu, J. Visualization of microstructural factors resisting the crack propagation in mesosegregated high-strength low-alloy steel. J. Mater. Sci. Technol. 2020, 42, 75–84. [Google Scholar] [CrossRef]

- Chen, X.W.; Qiao, G.Y.; Han, X.L.; Wang, X.; Xiao, F.R.; Liao, B. Effects of Mo, Cr and Nb on microstructure and mechanical properties of heat affected zone for Nb-bearing X80 pipeline steels. Mater. Des. 2014, 53, 888–901. [Google Scholar] [CrossRef]

- Bai, W.; Xu, X.; Liu, Y.; Liang, Y.; Shen, Y.; Han, Z.; Sheng, Z.; Chen, R.; Zhu, M. Microstructural evolutions and impact toughness in simulated welding heat affected zones for a high-strength carbide-free bainitic rail steel. Mater. Sci. Eng. A 2023, 880, 145325. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, H.-L.; Wang, B.-X.; Tian, Y. Impact of Mo/Ni alloying on microstructural modulation and low-temperature toughness of high-strength low-alloy steel. J. Iron Steel Res. Int. 2024, 31, 1746–1762. [Google Scholar] [CrossRef]

- Xie, G.; Duan, R.; Wang, Y.; Luo, Z.A.; Wang, G. Microstructure and toughness of thick-gauge pipeline steel joint via double-sided friction stir welding combined with preheating. Int. J. Miner. Metall. Mater. 2023, 30, 724–733. [Google Scholar] [CrossRef]

- Ramachandran, D.C.; Moon, J.; Lee, C.H.; Kim, S.D.; Chung, J.; Biro, E.; Park, Y.D. Role of bainitic microstructures with M-A constituent on the toughness of an HSLA steel for seismic resistant structural applications. Mater. Sci. Eng. A 2021, 801, 140390. [Google Scholar] [CrossRef]

- Takayama, N.; Miyamoto, G.; Furuhara, T. Chemistry and three-dimensional morphology of martensite-austenite constituent in the bainite structure of low-carbon low-alloy steels. Acta Mater. 2018, 145, 154–164. [Google Scholar] [CrossRef]

- Choi, B.; Seo, D.; Jang, J. A nanoindentation study on the micromechanical characteristics of API X100 pipeline steel. Met. Mater. Int. 2009, 15, 373–378. [Google Scholar] [CrossRef]

| Pipeline No. | C | Si | Mn | Cr | Ni | Mo | Nb | Ti | Ceq |

|---|---|---|---|---|---|---|---|---|---|

| 0Cr | 0.060 | 0.23 | 1.67 | 0.01 | 0.21 | 0.20 | 0.073 | 0.015 | 0.370 |

| 0.1C | 0.065 | 0.23 | 1.70 | 0.13 | 0.22 | 0.20 | 0.078 | 0.014 | 0.390 |

| 0.4Cr | 0.060 | 0.21 | 1.73 | 0.40 | 0.22 | 0.21 | 0.074 | 0.013 | 0.456 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Wang, F.; Li, Z.; Hu, Z.; Zhao, L.; Yin, S.; Jia, S. Effect of Cr Content on the Microstructure and Toughness of the Supercritically Coarse-Grained Heat-Affected Zone in X80 Pipeline Steel. Materials 2025, 18, 3466. https://doi.org/10.3390/ma18153466

Qin Y, Wang F, Li Z, Hu Z, Zhao L, Yin S, Jia S. Effect of Cr Content on the Microstructure and Toughness of the Supercritically Coarse-Grained Heat-Affected Zone in X80 Pipeline Steel. Materials. 2025; 18(15):3466. https://doi.org/10.3390/ma18153466

Chicago/Turabian StyleQin, Yuqin, Feng Wang, Zhikui Li, Zhiguo Hu, Longyi Zhao, Shubiao Yin, and Shujun Jia. 2025. "Effect of Cr Content on the Microstructure and Toughness of the Supercritically Coarse-Grained Heat-Affected Zone in X80 Pipeline Steel" Materials 18, no. 15: 3466. https://doi.org/10.3390/ma18153466

APA StyleQin, Y., Wang, F., Li, Z., Hu, Z., Zhao, L., Yin, S., & Jia, S. (2025). Effect of Cr Content on the Microstructure and Toughness of the Supercritically Coarse-Grained Heat-Affected Zone in X80 Pipeline Steel. Materials, 18(15), 3466. https://doi.org/10.3390/ma18153466