The Effect of Strain Aging on the Microstructure and Mechanical Properties of Steel for Reel-Lay Coiled Steel Pipelines

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Strain Aging Experiment

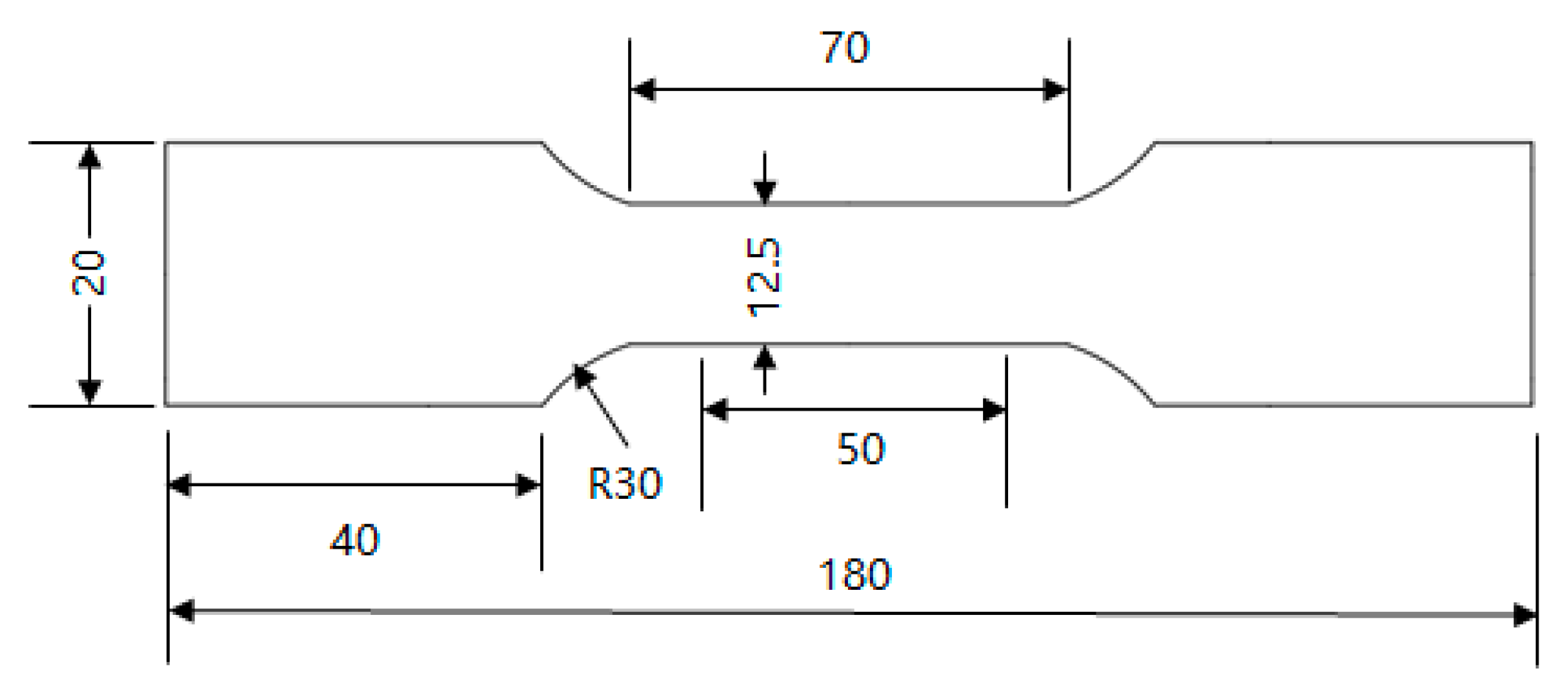

2.3. Mechanical Performance Experiment

2.4. Microstructure Characterization

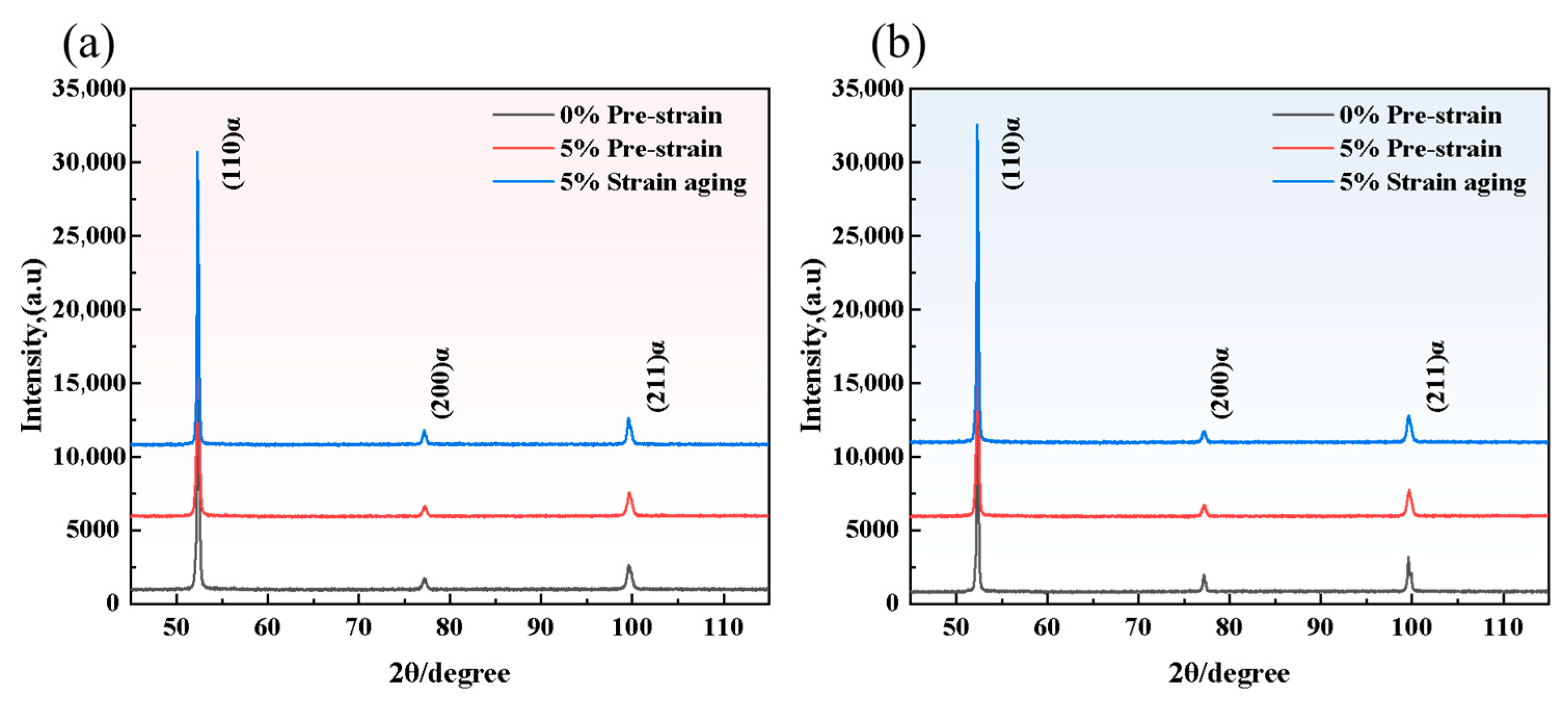

3. Experimental Results

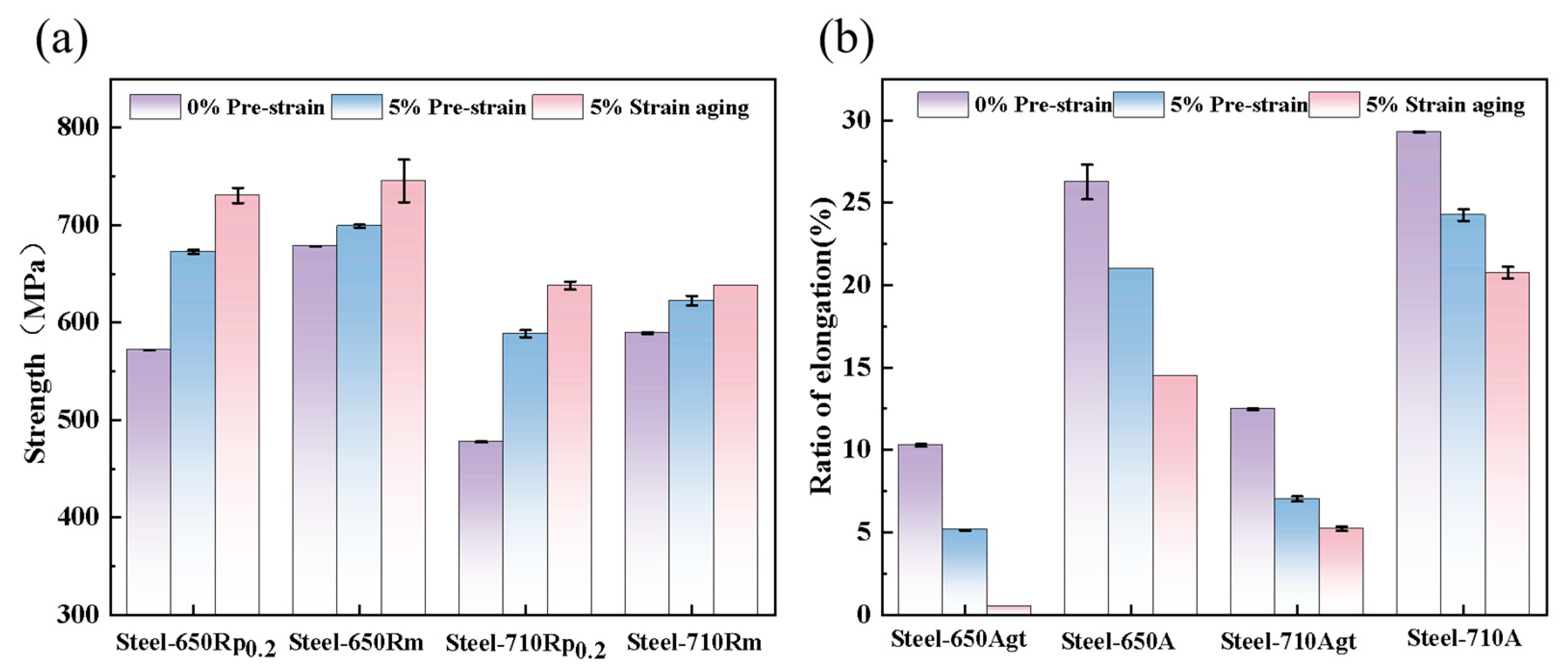

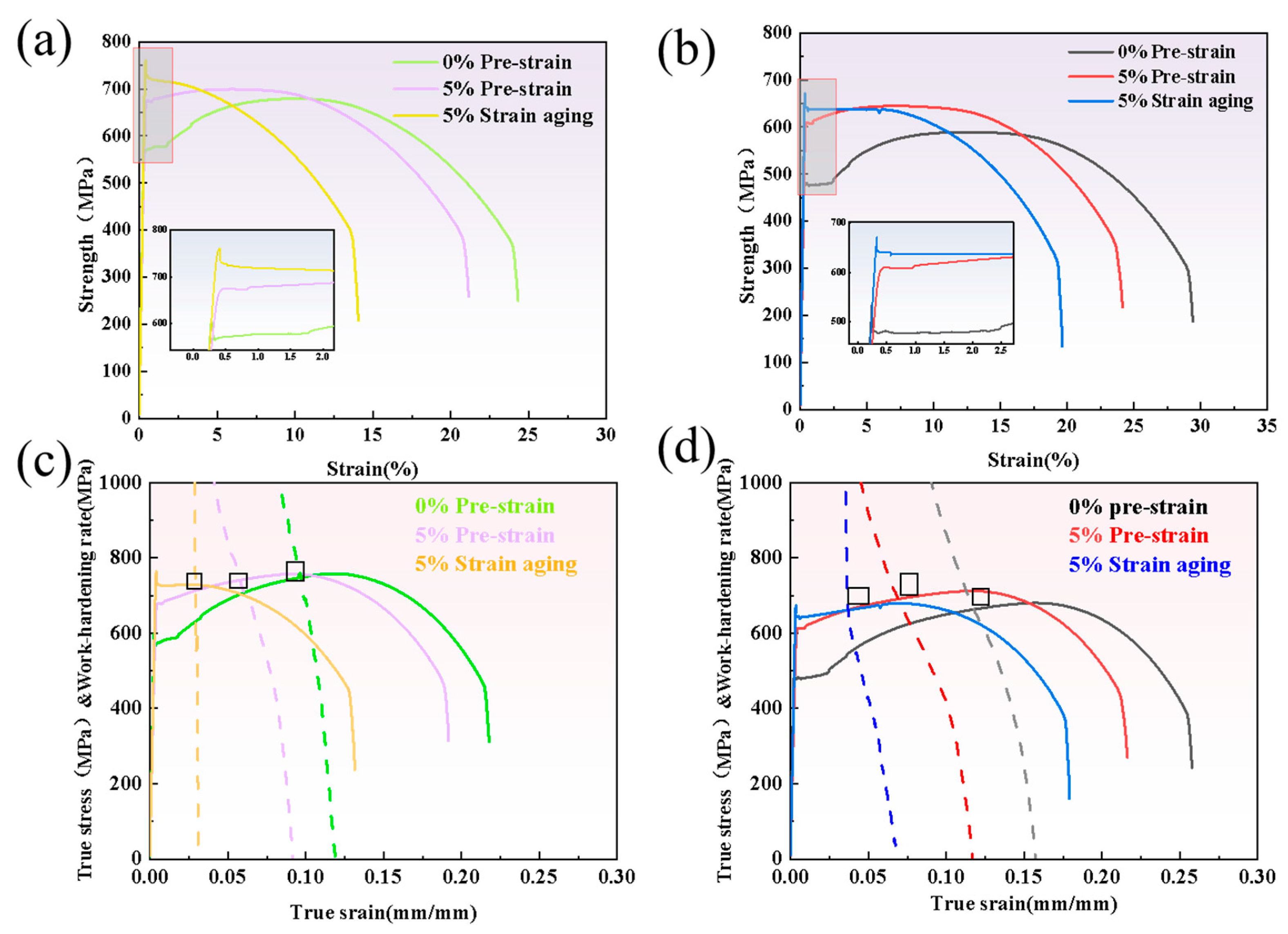

3.1. Mechanical Properties Before and After Strain Aging

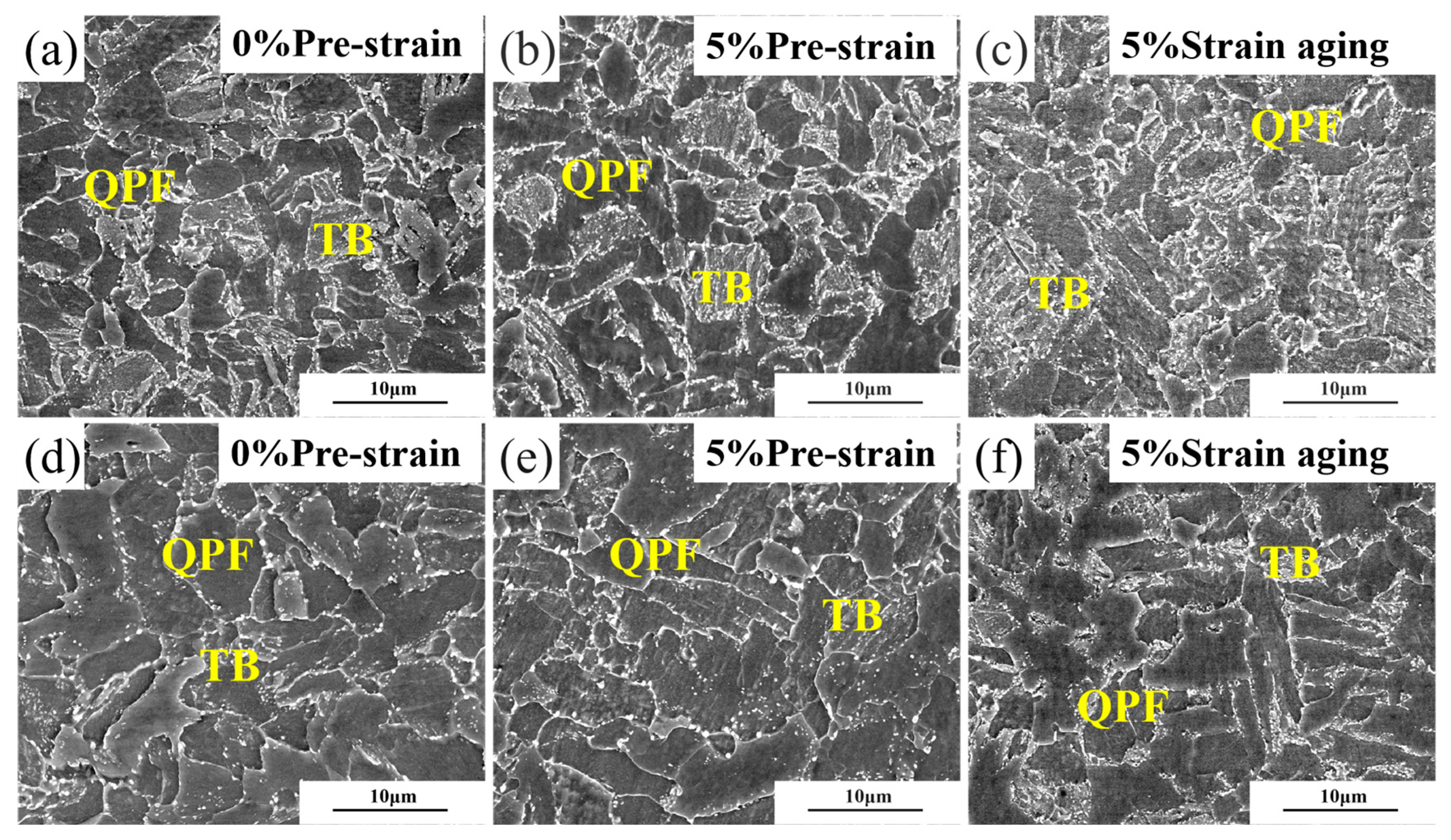

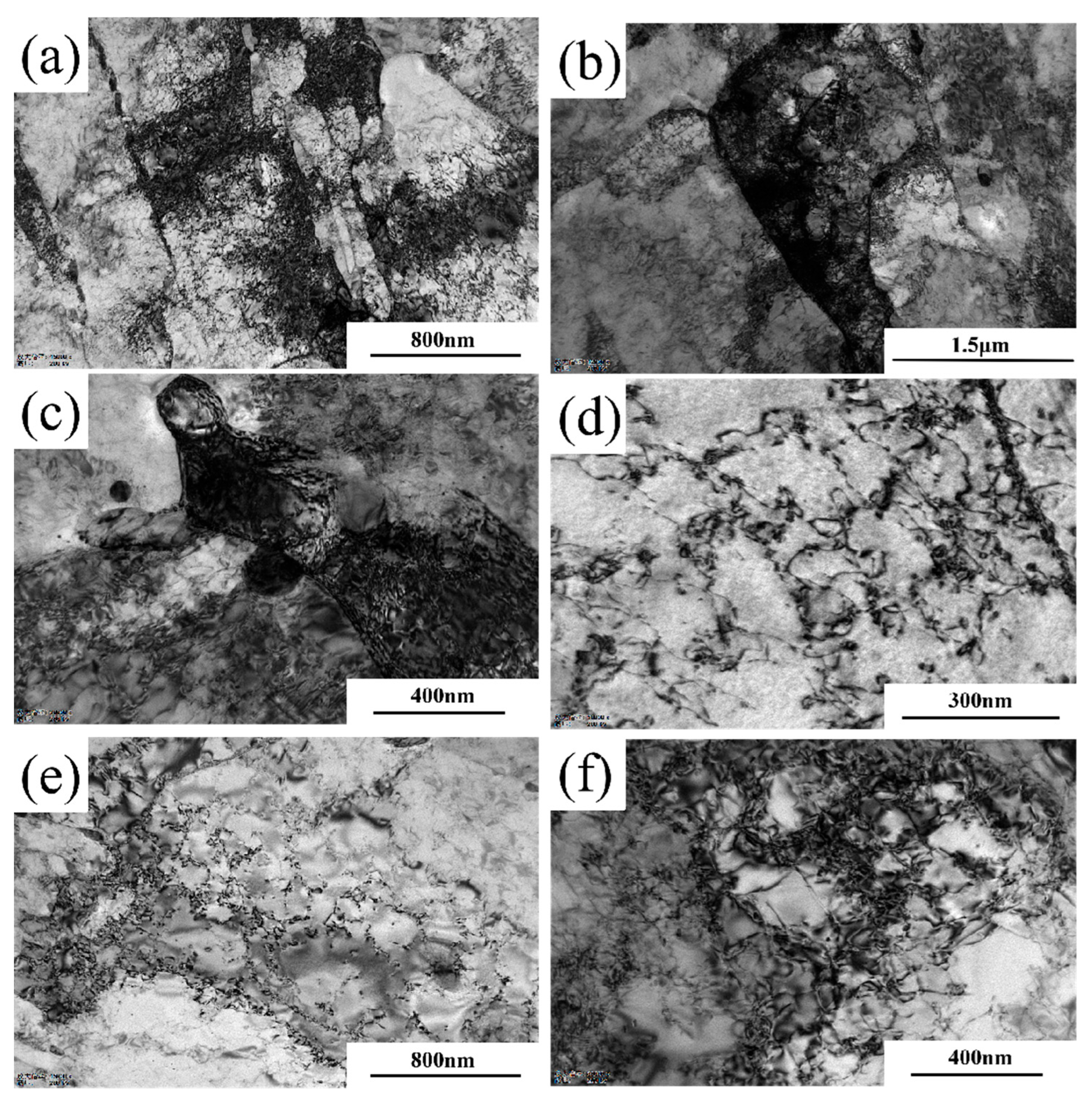

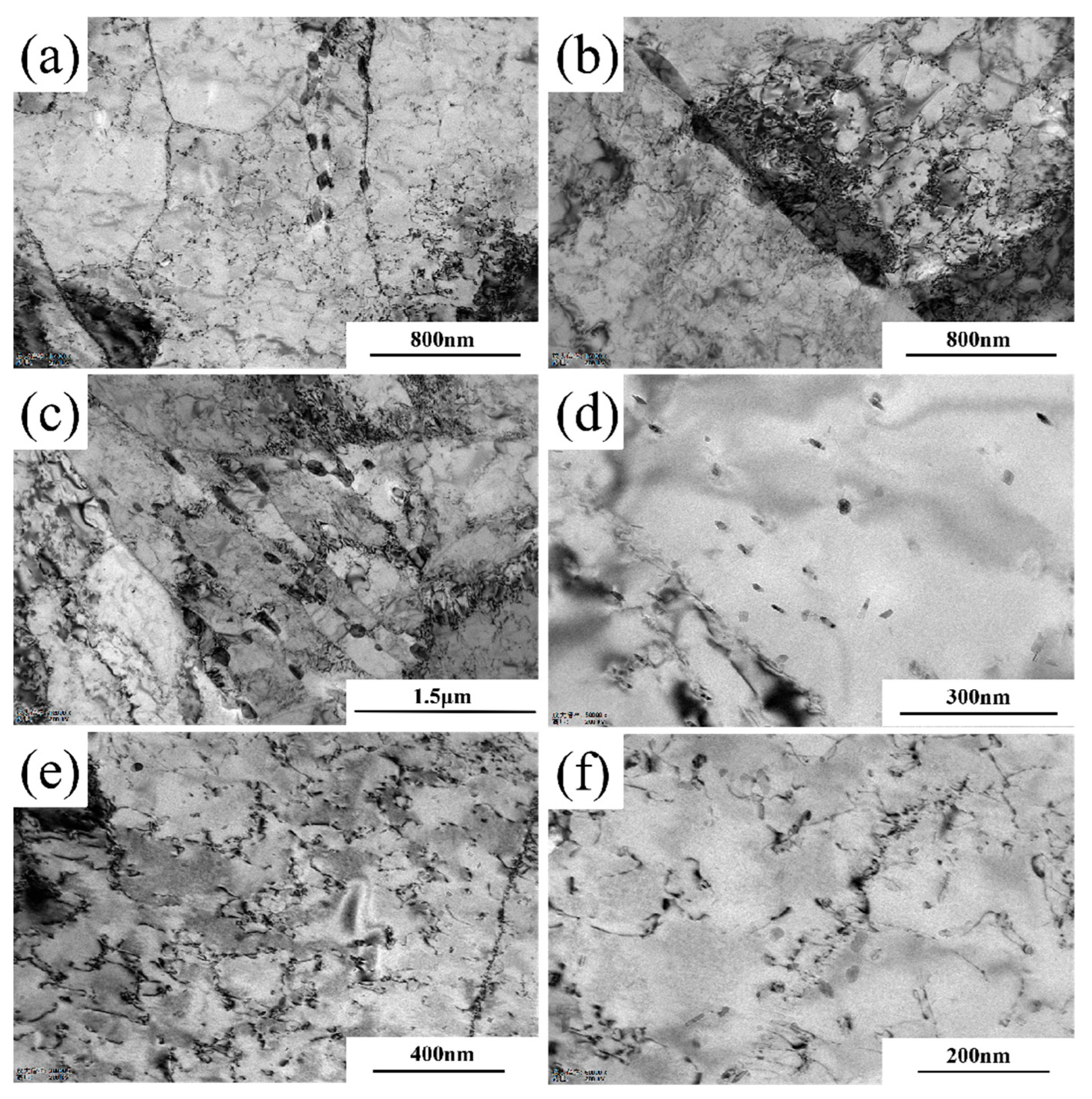

3.2. Microstructural Morphology Before and After Strain Aging

4. Discussion

4.1. Stress–Strain Response Before and After Strain Aging

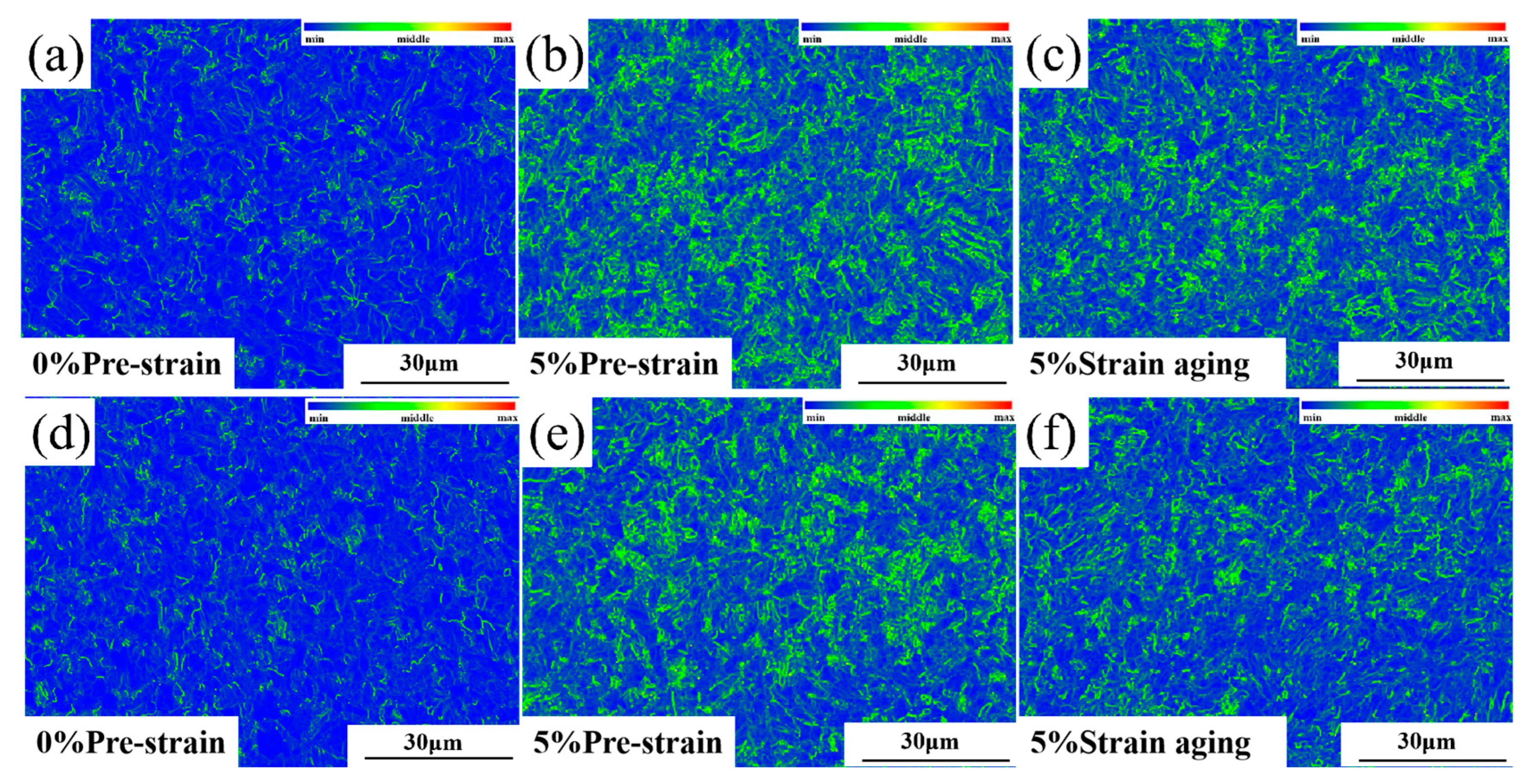

4.2. Evolution of Dislocation Morphology

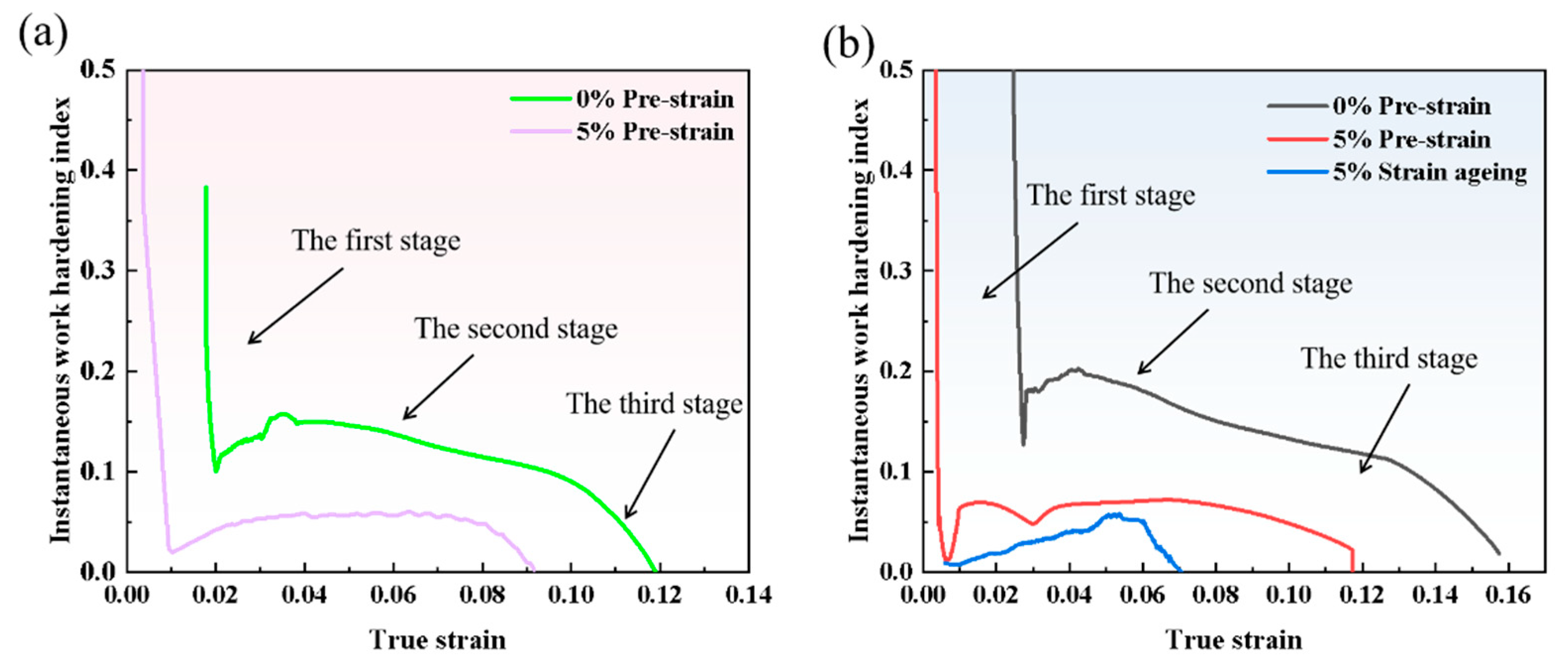

4.3. Effect of Strain Aging on Work Hardening Behavior

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Xie, X.; Song, C.; Yuan, X. Application and Performance Analysis of Carbon Fibber Composites in Deep Sea Oil and Gas Development. IOP Conf. Ser. Earth Environ. Sci. 2021, 632, 022081. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Q.; Cui, S.; Dai, L.; Liu, Q.; Jia, S.; Zhang, H.; Wu, H. Effect of Mo microalloying on impact toughness of X80 pipeline steel in SCGHAZ. J. Mater. Res. Technol. 2024, 28, 2648–2659. [Google Scholar] [CrossRef]

- Wang, X.; Yuan, L.; Xu, P.; Ding, Z.; Wang, Y.; Gong, S. Evaluation of dynamic behaviour of pipe-in-pipe systems for deepwater J-lay method. Appl. Ocean. Res. 2024, 153, 104229. [Google Scholar] [CrossRef]

- Lu, Q.; Fan, Y.; Su, Q.; Zhang, T.; Lu, H.; Chen, J.; Yan, J.; Yin, Y. Study on contact force between umbilical and overboarding chute in deepwater S-lay process. Ocean. Eng. 2024, 302, 117693. [Google Scholar] [CrossRef]

- He, S.; Wu, Q.; Hu, P.; Liu, Y. Influence of reeling on mechanical properties of steel pipe. Baosteel Technol. 2022, 6, 1–7. [Google Scholar] [CrossRef]

- Yang, D.-y.; Zhang, S.-f.; Zhang, D.-m. Research Status of the Laying Technology of Offshore Pipeline. Contemp. Chem. Ind. 2017, 46, 2551–2555. [Google Scholar]

- Ju, M.; Jiang, Y.; Yun, F.; Chai, H.; Chen, X.; Zhang, M.; Wang, L. Research on Dynamic Response of Pipeline under the Reeling Process and Laying Process. J. Mar. Sci. Eng. 2023, 11, 1783. [Google Scholar] [CrossRef]

- Ruan, W.; Qi, K.; Han, X.; Sun, B.; Gao, X.; Li, J. Multi-scale coupling numerical modeling of metallic strip flexible pipe during reel-lay process. Ocean. Eng. 2023, 283, 115209. [Google Scholar] [CrossRef]

- Javanbakht, M.; Levitas, V.I. Phase field approach to dislocation evolution at large strains: Computational aspects. Int. J. Solids Struct. 2016, 82, 95–110. [Google Scholar] [CrossRef]

- Pham, M.; Solenthaler, C.; Janssens, K.; Holdsworth, S. Dislocation structure evolution and its effects on cyclic deformation response of AISI 316L stainless steel. Mater. Sci. Eng. A 2011, 528, 3261–3269. [Google Scholar] [CrossRef]

- Ji, L.K.; Xu, T.; Zhang, J.M.; Wang, H.T.; Tong, M.X.; Zhu, R.H.; Zhou, G.S. The Microstructure Evolution of Dual-Phase Pipeline Steel with Plastic Deformation at Different Strain Rates. J. Mater. Eng. Perform. 2017, 26, 3104–3111. [Google Scholar] [CrossRef]

- Chen, L.; Li, Z.; Chen, Y. Development of 26.4 mm X80HD SAW Pipe Basedon Strain Design. Met. Mater. Metall. Eng. 2022, 50, 17–20. [Google Scholar]

- Meissner, A.; Erdelen-Peppler, M.; Schmidt, T. Impact of Reel-Laying on Mechanical Pipeline Properties Investigated by Fulland Small-Scale Reeling Simulations. Int. J. Offshore Polar Eng. 2012, 22, 282–289. [Google Scholar] [CrossRef]

- Han, Y.; Song, S.; Jing, H.; Zhao, L.; Lv, X.; Xu, L. Effects of full-scale reel-lay simulation on mechanical properties of X65 grade pipeline girth welds. Mater. Test. 2018, 60, 1145–1154. [Google Scholar] [CrossRef]

- Yang, R.; He, Y.; Zhang, Y.; Duan, M.; Wang, S.; Wei, S. Strain capacity of metallurgically clad pipes with girth welds during deep-sea reel-lay installation. Ocean. Eng. 2025, 325, 120743. [Google Scholar] [CrossRef]

- Jack, T.A.; Pourazizi, R.; Ohaeri, E.; Szpunar, J.; Zhang, J.; Qu, J. Investigation of the hydrogen induced cracking behaviour of API 5L X65 pipeline steel. Int. J. Hydrogen Energy 2020, 45, 17671–17684. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, M.; Chen, S.; Qu, J. Static strain aging behavior of an X100 pipeline steel. Mater. Sci. Eng. A 2012, 550, 418–422. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, Z.; Liu, Y.; Chen, H. Strain aging behaviour of Cu-containing microalloyed low carbon seamless pipeline steel. Mater. Sci. Technol. 2016, 33, 72–76. [Google Scholar] [CrossRef]

- Peng, N.; Shi, S.; Luo, D.; Xiong, X.; Li, Z. Effect of Strain Aging on Tensile Properties of X80 Large-Diameter Pipeline Steel. Mater. Mech. Eng. 2018, 42, 5. [Google Scholar]

- Lee, S.-i.; Hwang, B. Correlation of microstructure with tensile behavior and properties of API X70 pipeline steels subjected to strain aging. J. Iron Steel Res. Int. 2020, 27, 6. [Google Scholar] [CrossRef]

- Li, L.; Yang, L.; Zhang, S. Effects of pre-strain and aging on low temperature impact properties ofX80HD2 steel thick wall high deformation longitudinal welded pipe. Heat Treat. Met. 2015, 3, 6. [Google Scholar] [CrossRef]

- Li, Y.-H.; Chi, Q.; Feng, H.; Chen, H.-Y.; Xu, X.-F. Effect of strain aging on properties of X90 line pipe. Eng. Fail. Anal. 2020, 118, 104844. [Google Scholar] [CrossRef]

- Sung, H.K.; Lee, D.H.; Lee, S.; Lee, B.-J.; Hong, S.-P.; Kim, Y.-W.; Yoo, J.Y.; Hwang, B.; Shin, S.Y. Effects of C and Si on strain aging of strain-based API X60 pipeline steels. Met. Mater. Int. 2017, 23, 1–9. [Google Scholar] [CrossRef]

- Shitamoto, H.; Hisamune, N. Effect of Full-and Small-Scale Reeling Simulation on Mechanical Properties of Weldable 13CR Seamless Line Pipe. In Proceedings of the ASME 32nd International Conference on Ocean, Offshore and Arctic Engineering 2013, OMAE2013, Nantes, France, 9–14 June 2013. [Google Scholar]

- Nagai, K.; Shinohara, Y.; Ozaki, M. Work-hardening Behavior of X65 ERW Line Pipe for Reel-lay Installation. In Proceedings of the Twenty-Sixth International Ocean and Polar Engineering Conference, Rhodes, Greece, 26 June–2 July 2016; International Society of Offshore and Polar Engineers: Rhodes, Greece, 2016; pp. 416–420. [Google Scholar]

- Jiang, Y.; Li, C.; Di, X.; Wang, D.; Lin, S.; Liu, J. Deformation Behavior and Microstructural Evolution of Reeled Pipeline Steels during Cyclic Plastic Deformation. J. Mater. Eng. Perform. 2019, 28, 6449–6457. [Google Scholar] [CrossRef]

- Lin, S.; Wang, D.; Li, C.; Liu, X.; Di, X.; Jiang, Y. Effect of cyclic plastic deformation on microstructure and mechanical properties of weld metals used for reel-lay pipeline steels. Mater. Sci. Eng. A 2018, 737, 77–84. [Google Scholar] [CrossRef]

- Ju, M.; Xing, X.; Wang, L.; Yun, F.; Wang, X.; Liao, H. Numerical Simulations and Experimental Study on the Reeling Process of Submarine Pipeline by R-Lay Method. J. Mar. Sci. Eng. 2021, 9, 579. [Google Scholar] [CrossRef]

- Chatzopoulou, G.; Karamanos, S.A.; Varelis, G.E. Finite Element Analysis of Cyclically-Loaded Steel Pipes During Deep Water Reeling Installation. Ocean. Eng. 2016, 124, 113–124. [Google Scholar] [CrossRef]

- GB/T 228.1-2021 SAC/TC 183; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2021.

- DNV-OS-F101; Submarine Pipeline Systems. DNV: Høvik, Norway, 2013.

- GB/T 4340.1-2024; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. Standards Press of China: Beijing, China, 2024.

- Waseda, O.; Veiga, R.G.; Morthomas, J.; Chantrenne, P.; Becquart, C.S.; Ribeiro, F.; Jelea, A.; Goldenstein, H.; Perez, M. Formation of carbon Cottrell atmospheres and their effect on the stress field around an edge dislocation. Scr. Mater. 2017, 129, 16–19. [Google Scholar] [CrossRef]

- Katzarov, I.H.; Drenchev, L.B.; Pashov, D.L.; Zarrouk, T.N.A.T.; Al-Lahham, O.; Paxton, A.T. Dynamic strain aging and the role of the Cottrell atmosphere. Phys. Rev. Mater. 2022, 6, 063603. [Google Scholar] [CrossRef]

- Xu, L.-Z.; Qiao, G.-Y.; Gong, X.; Gu, Y.; Xu, K.; Xiao, F.-R. Effect of through-thickness microstructure inhomogeneity on mechanical properties and strain hardening behavior in heavy-wall X70 pipeline steels. J. Mater. Res. Technol. 2023, 25, 4216–4230. [Google Scholar] [CrossRef]

- Xu, L.-Z.; Qiao, G.-Y.; Lu, X.-X.; Gu, Y.; Xu, K.; Chen, X.-W.; Xiao, F.-R. Study on the relationship between microstructure and properties of heavy-wall X70 pipeline steel with different processing directions. Mater. Chem. Phys. 2024, 314, 128850. [Google Scholar] [CrossRef]

- De, A.; De Blauwe, K.; Vandeputte, S.; De Cooman, B. Effect of dislocation density on the low temperature aging behavior of an ultra low carbon bake hardening steel. J. Alloys Compd. 2000, 310, 405–410. [Google Scholar] [CrossRef]

- Ding, H. Material Forming Metallography; Metallurgical Industry Press: Beijing, China, 2016. [Google Scholar]

- Song, H.; Yoo, J.; Sohn, S.S.; Koo, M.; Lee, S. Achievement of high yield strength and strain hardening rate by forming fine ferrite and dislocation substructures in duplex lightweight steel. Mater. Sci. Eng. A 2017, 704, 287–291. [Google Scholar] [CrossRef]

- Okabayashi, T.Y. Tensile stress-strain analysis of cold worked metals and steels and dual-phase steels. Metall. Trans. A 1985, 16, 865–872. [Google Scholar]

| Fe | C | Si | Mn | Ni | Cr | Mo | V | Nb | Ti | Al | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| X65 | Bal. | 0.138 | 0.25 | 0.65 | 0.51 | 0.46 | 0.38 | 0.083 | 0.021 | 0.018 | 0.056 |

| Condition of the Test Steel | Rp0.2/Mpa | Rm/Mpa | Rp0.2/Rm | Agt/% | A% | HV (10 kg) | |

|---|---|---|---|---|---|---|---|

| Steel-650 | 0% Pre-strain | 571.5 | 678.5 | 0.84 | 10.235 | 25.5 | 221.23 |

| 572 | 678 | 0.84 | 10.34 | 27 | |||

| 5% Pre-strain | 671 | 700 | 0.97 | 5.12 | 21 | 254.3 | |

| 674 | 698 | 0.97 | 5.15 | 21 | |||

| 5% Strain aging | 730 | 730 | 1 | 0.5 | 14.5 | 231.2 | |

| 725 | 761 | 0.95 | 0.5 | 14.5 | |||

| Steel-710 | 0% Pre-strain | 477 | 588.5 | 0.81 | 12.505 | 29.25 | 193.1 |

| 478 | 590 | 0.81 | 12.43 | 29.3 | |||

| 5% Pre-strain | 591 | 626 | 0.94 | 7.13 | 24.5 | 224.3 | |

| 586 | 619 | 0.94 | 6.91 | 24 | |||

| 5% Strain aging | 635 | 638 | 0.99 | 5.12 | 21 | 210.6 | |

| 641 | 641 | 1.00 | 5.32 | 20.5 |

| Steel Grade | 0% Pre-Stretching | 5% Pre-Stretching | 5% Strain Aging |

|---|---|---|---|

| Steel-650 | 1.01108 × 1010 | 2.1824 × 1010 | 1.8174 × 1010 |

| Steel-710 | 8.5295 × 108 | 1.5864 × 1010 | 1.0854 × 1010 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Zuo, G.; Peng, Y.; Zhu, L.; Tong, S.; Yin, S.; Sun, X. The Effect of Strain Aging on the Microstructure and Mechanical Properties of Steel for Reel-Lay Coiled Steel Pipelines. Materials 2025, 18, 3462. https://doi.org/10.3390/ma18153462

Cao Y, Zuo G, Peng Y, Zhu L, Tong S, Yin S, Sun X. The Effect of Strain Aging on the Microstructure and Mechanical Properties of Steel for Reel-Lay Coiled Steel Pipelines. Materials. 2025; 18(15):3462. https://doi.org/10.3390/ma18153462

Chicago/Turabian StyleCao, Yuxi, Guofeng Zuo, Yang Peng, Lin Zhu, Shuai Tong, Shubiao Yin, and Xinjun Sun. 2025. "The Effect of Strain Aging on the Microstructure and Mechanical Properties of Steel for Reel-Lay Coiled Steel Pipelines" Materials 18, no. 15: 3462. https://doi.org/10.3390/ma18153462

APA StyleCao, Y., Zuo, G., Peng, Y., Zhu, L., Tong, S., Yin, S., & Sun, X. (2025). The Effect of Strain Aging on the Microstructure and Mechanical Properties of Steel for Reel-Lay Coiled Steel Pipelines. Materials, 18(15), 3462. https://doi.org/10.3390/ma18153462