Study on Stability and Fluidity of HPMC-Modified Gangue Slurry with Industrial Validation

Abstract

1. Introduction

2. Materials and Methods

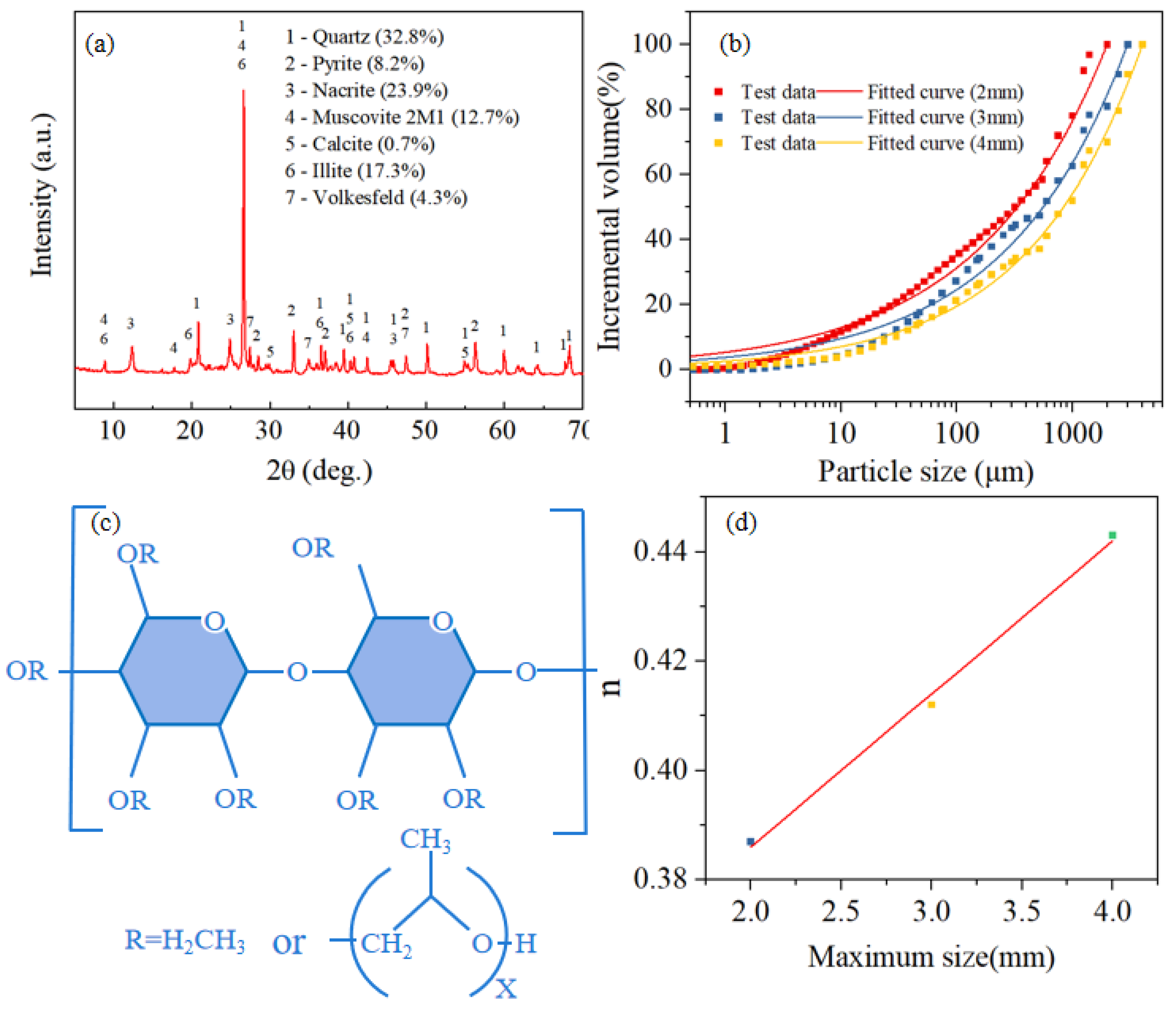

2.1. Materials

2.2. Experimental Design and Sample Preparation

2.3. Experimental Methods

2.3.1. Slurry Stability Test

2.3.2. Slurry Fluidity Test

2.3.3. Determining Water Distribution in Slurry

2.3.4. Microscopic Morphology Observation of Materials

3. Results and Discussion

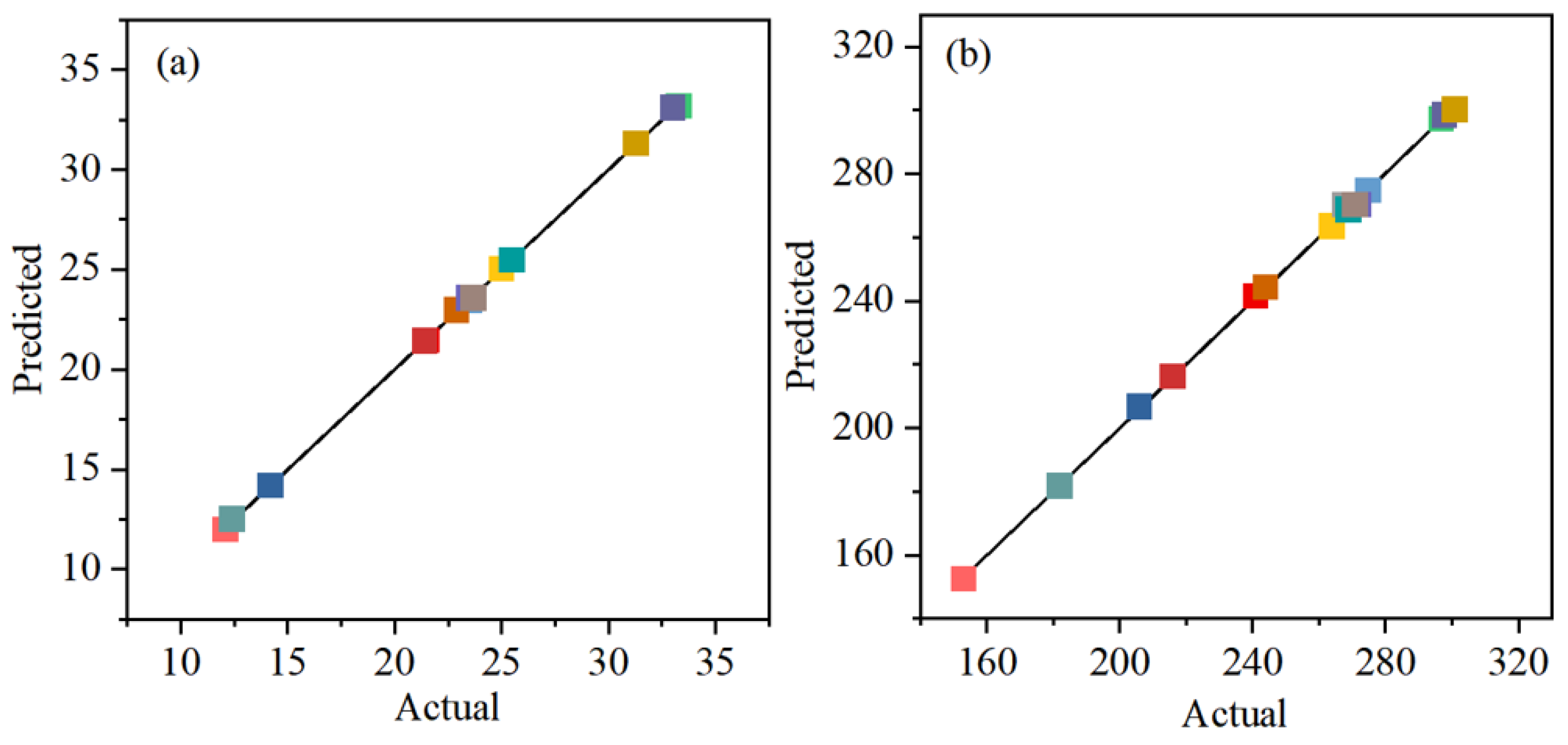

3.1. Experimental Results and Response Surface Regression Model

3.2. Variance Analysis of the Response Surface Regression Model

3.3. Influence of Single Factors on Slurry Performance

3.4. Multi-Factor Interaction Effects

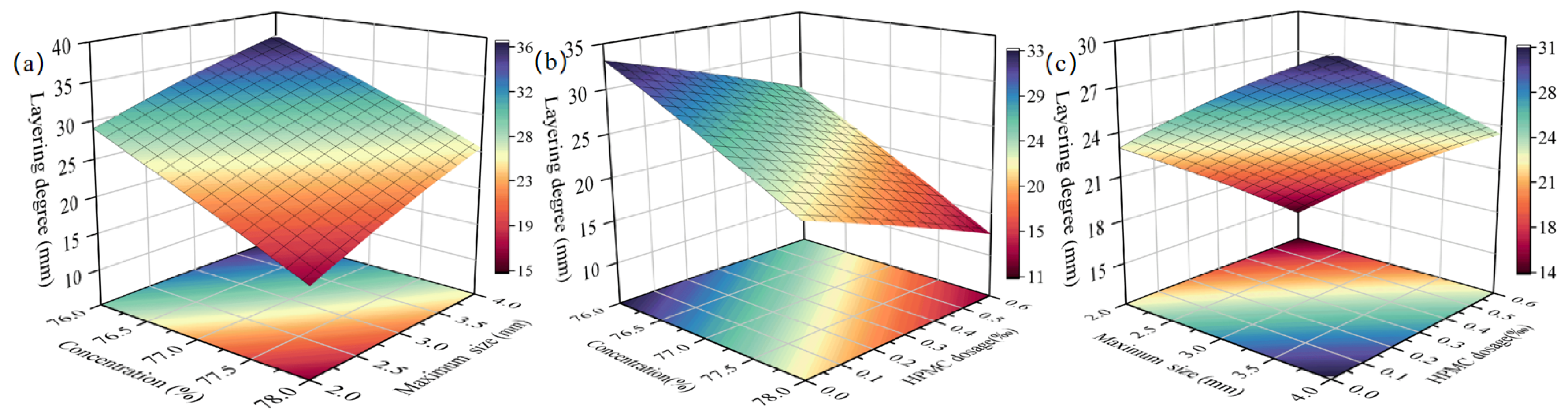

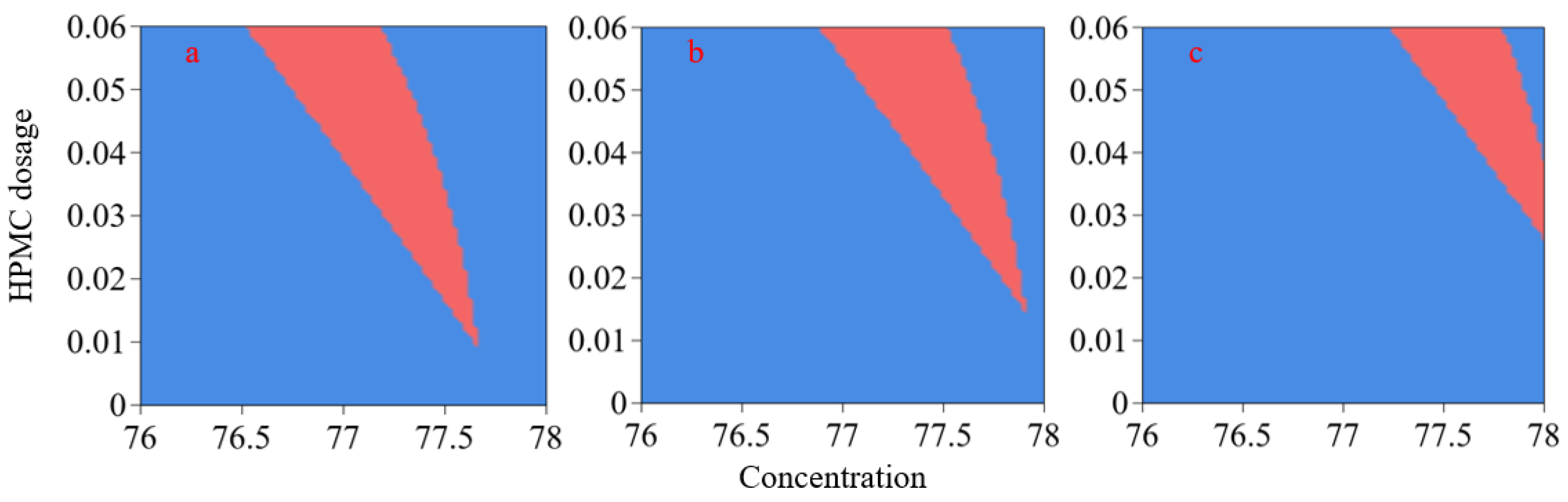

3.4.1. Slurry’s Layering Degree

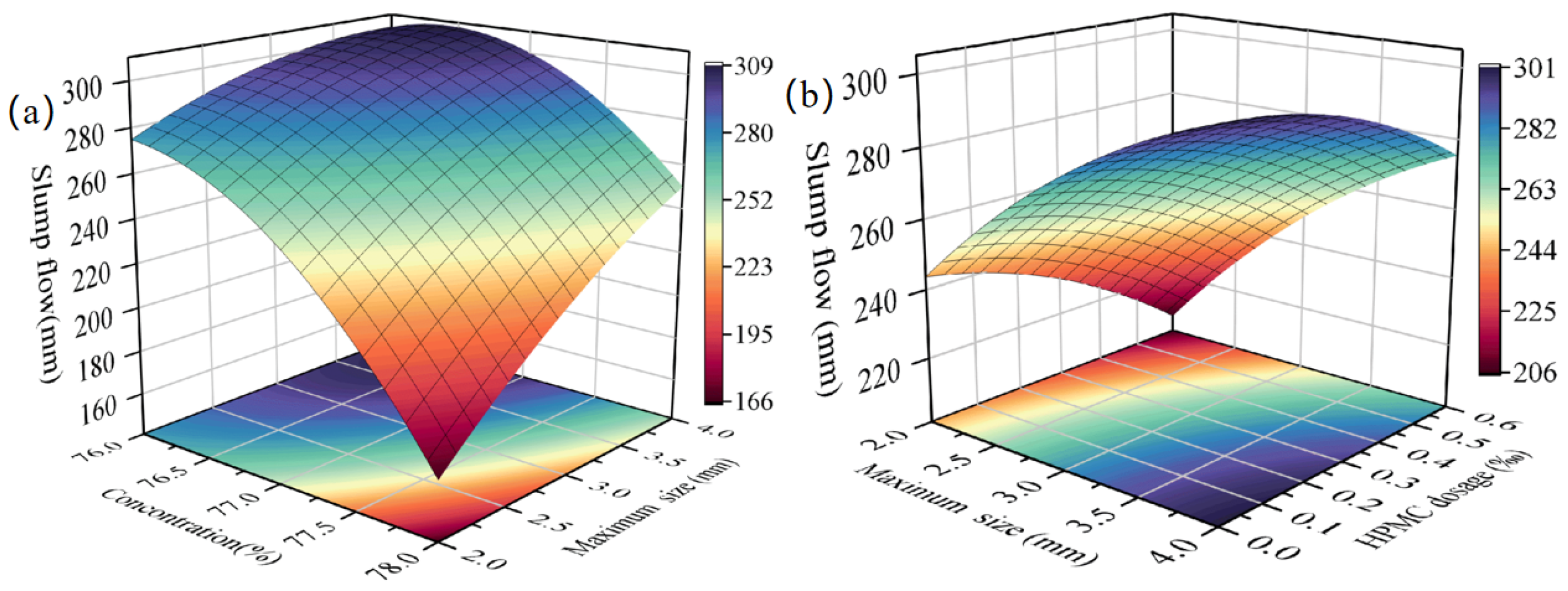

3.4.2. Slurry Fluidity

3.5. Mix Proportion Validation of Gangue Slurry

3.6. Microscopic Morphology Analysis of Slurry

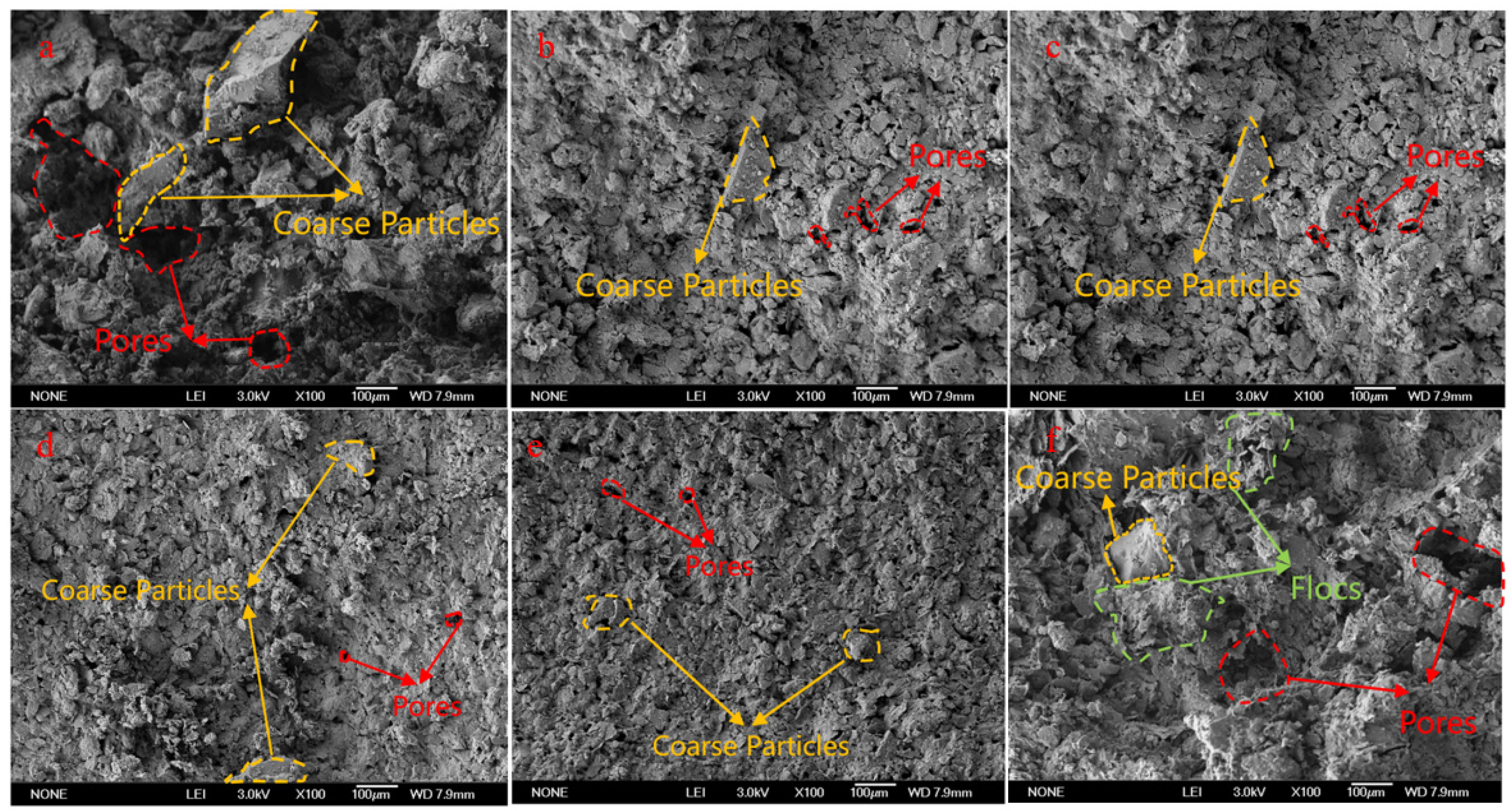

3.6.1. SEM Observation

3.6.2. PLM Observations

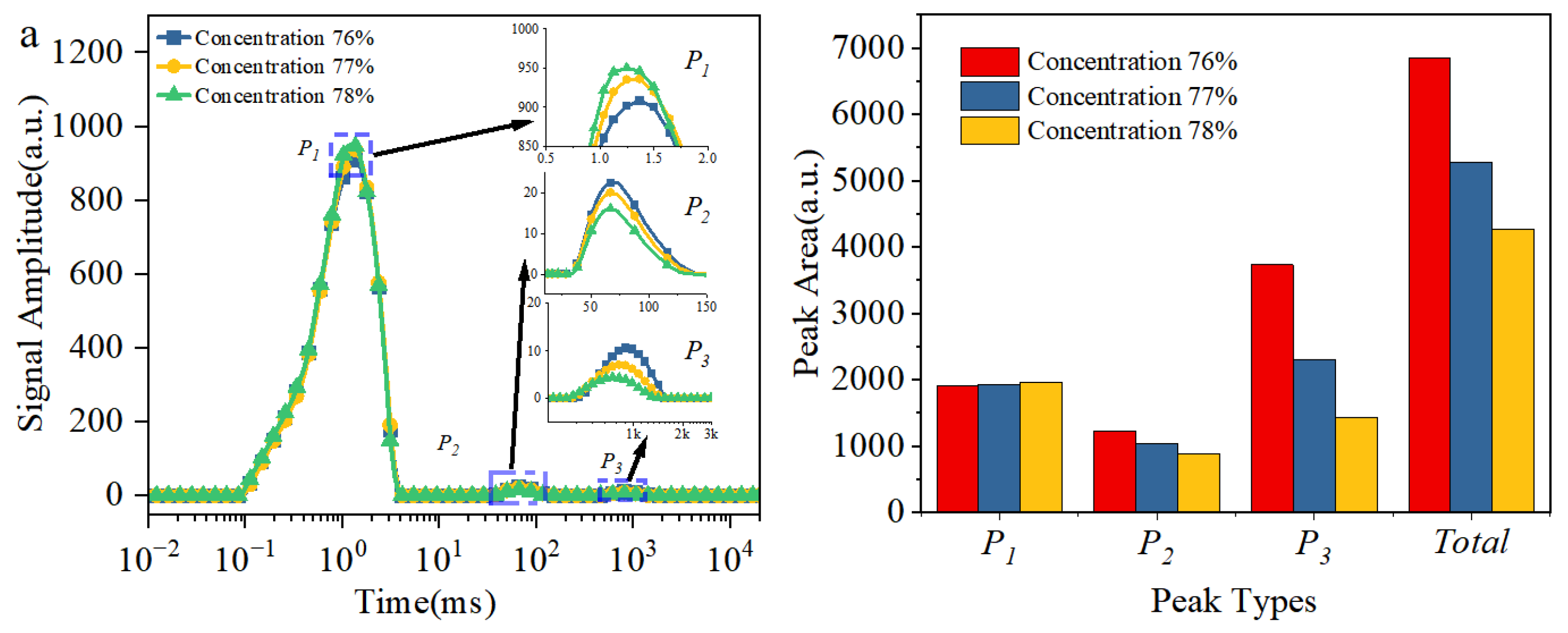

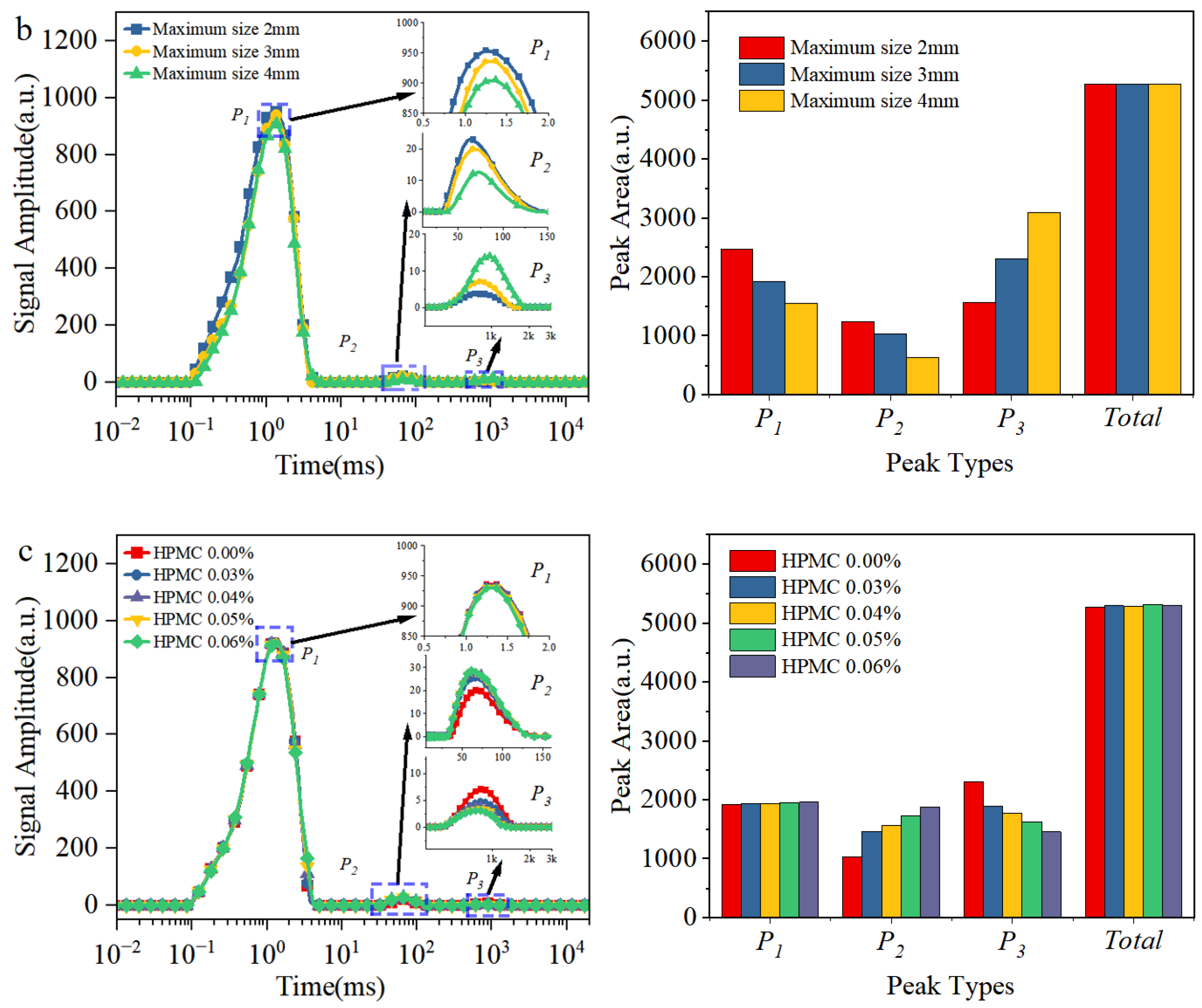

3.7. Water Distribution by LF-NMR

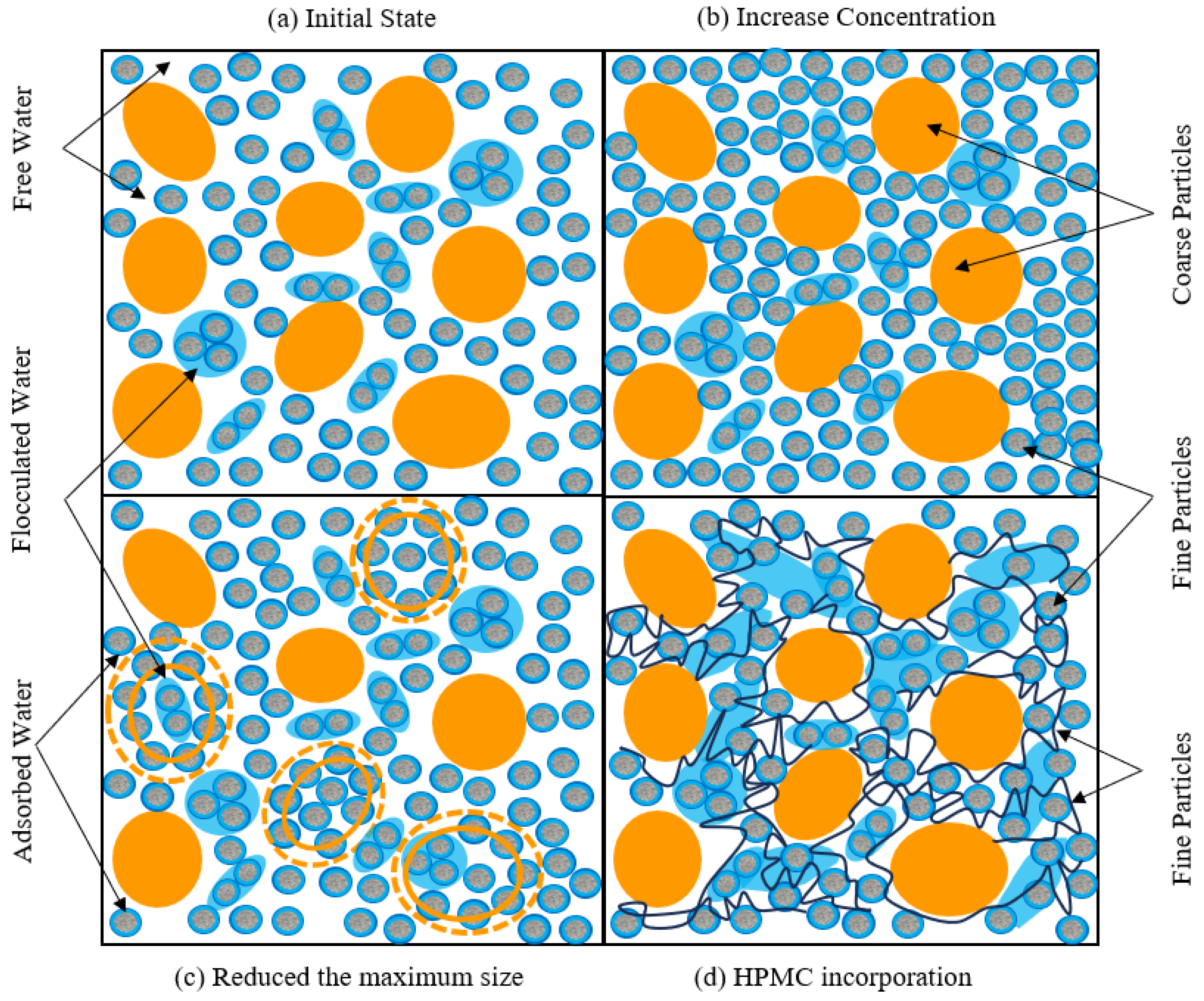

3.8. HPMC Action Mechanism

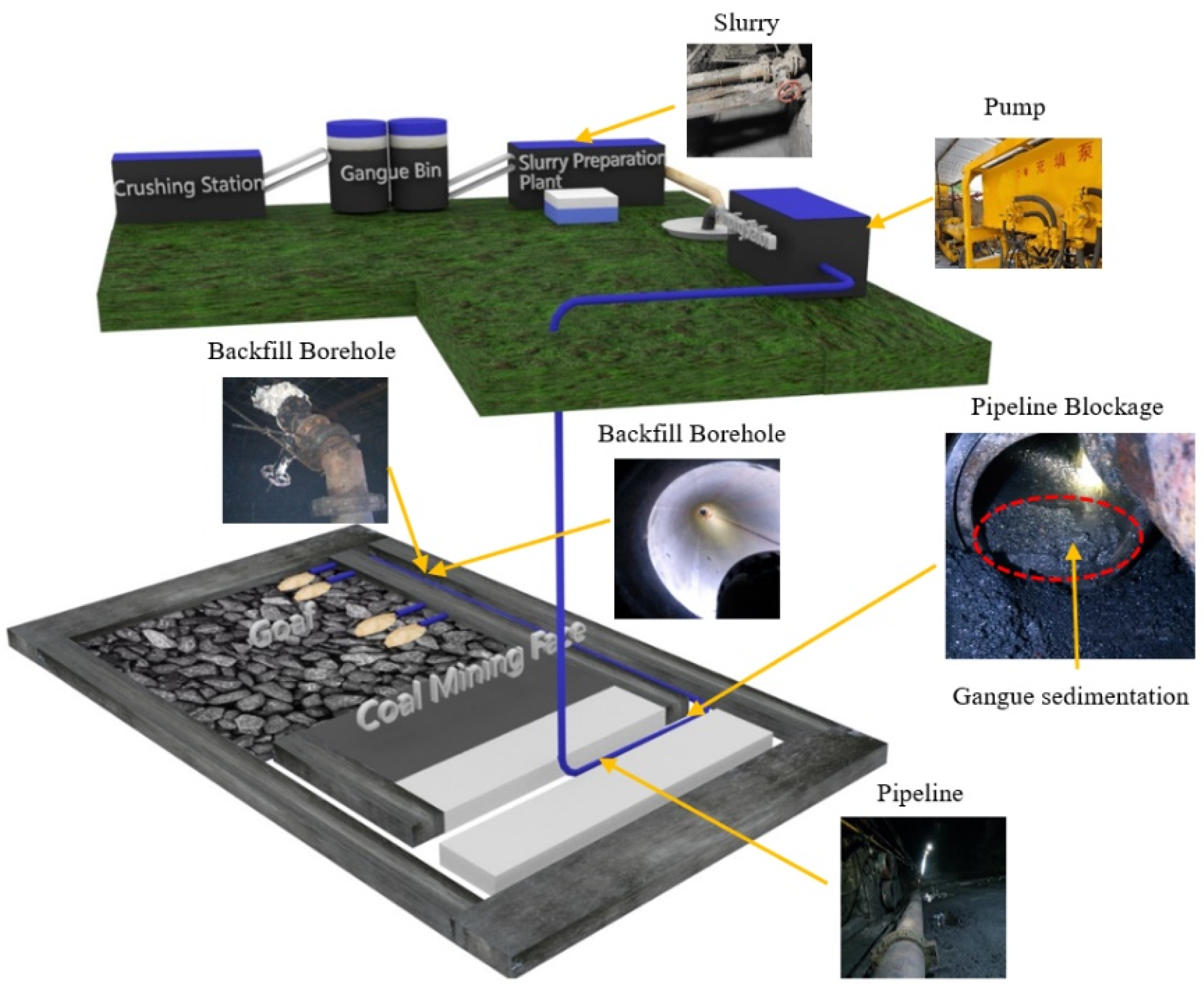

4. Engineering Application

4.1. Project Background

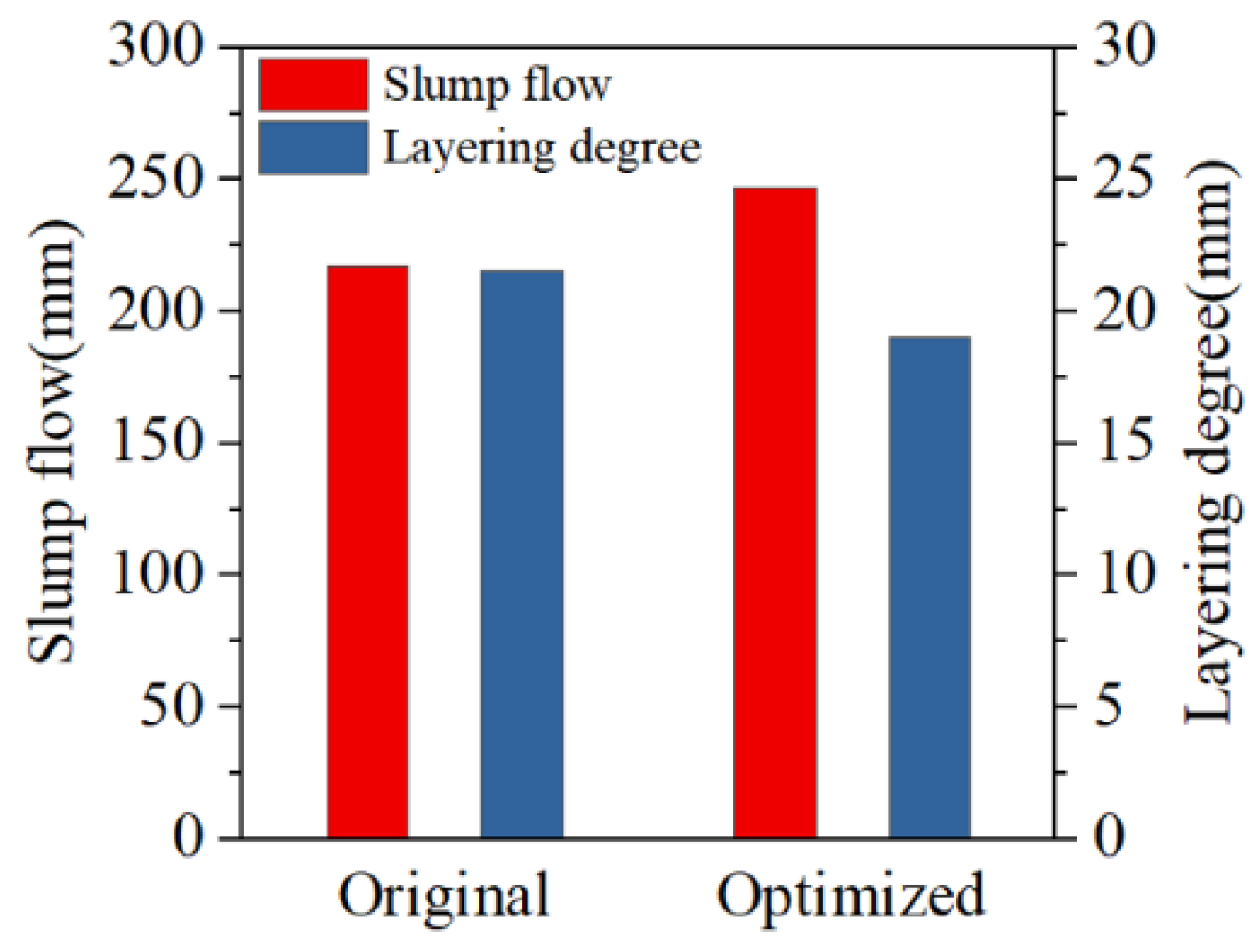

4.2. Slurry Ratio Optimization

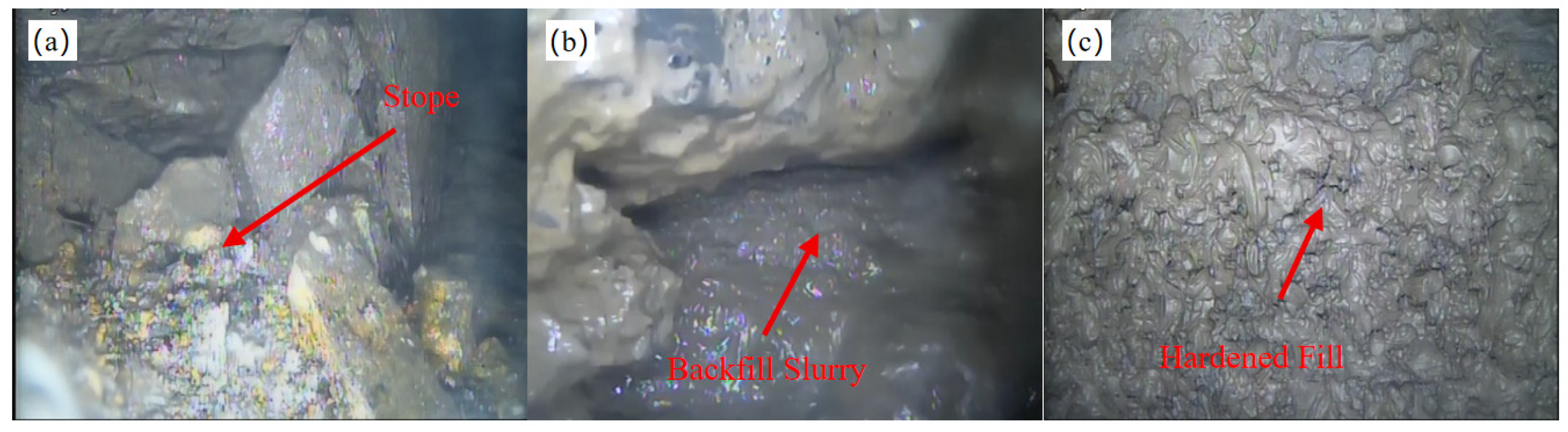

4.3. Backfilling Effectiveness Inspection

5. Conclusions

- (1)

- Slurry’s layering degree and slump flow decreased with increased X1 and X3; they decreased with reduced X2. Concentration exhibited the most significant influence, followed by maximum particle size and HPMC dosage. HPMC enhanced slurry stability while minimally compromising fluidity. X1X2 and X1X3 demonstrated significant effects on layering degree and slump flow. X2X3 significantly affected the layering degree but showed negligible influence on slump flow.

- (2)

- The response surface regression models for slump flow and layering degree demonstrated excellent reliability (R2 > 0.99; p < 0.0001). The response surface regression model yielded an optimal gangue slurry ratio, with a gradation index of 0.40–0.428. Different gangue gradations corresponded to specific concentrations and HPMC dosages.

- (3)

- Increased slurry concentration or reduced maximum gangue particle size significantly decreased interparticle spacing. Slurry stability was enhanced by intensifying the interparticle friction force. However, this process reduced free water content, which substantially impaired slurry fluidity. Upon HPMC addition, its molecular chains facilitated the formation of a 3D flocculation network through adsorption-bridging effects with fine particles. This mechanism inhibited coarse particle sedimentation and improved slurry stability. Meanwhile, HPMC addition converted only a minimal amount of free water to floc water, which exerted a limited negative impact on fluidity.

- (4)

- Based on the response surface regression model, the gangue slurry ratio for mine A was optimized. The improved slurry demonstrated remarkable performance enhancement, with an increase of 30 mm in slump flow and a reduction of 2.5 mm in layering degree. The slurry filling process was free of pipe blockage, achieving a maximum spread radius of over 60 m and a maximum single-borehole filling volume of 2200 m3. This confirmed the effectiveness of HPMC in controlling gangue slurry performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Li, J.; Wang, J. Comprehensive utilization and environmental risks of coal gangue: A review. J. Clean. Prod. 2019, 239, 117946. [Google Scholar] [CrossRef]

- Li, L.; Shao, X.; Ling, T.-C. Life cycle assessment of coal gangue composite cements: From sole OPC towards low-carbon quaternary binder. J. Clean. Prod. 2023, 414, 137674. [Google Scholar] [CrossRef]

- Liu, X. Low-carbon utilization of coal gangue under the carbon neutralization strategy: A short review. J. Mater. Cycles Waste Manag. 2023, 25, 1978–1987. [Google Scholar] [CrossRef]

- Long, G.; Li, L.; Li, W.; Ma, K.; Dong, W.; Bai, C.; Zhou, J.L. Enhanced mechanical properties and durability of coal gangue reinforced cement-soil mixture for foundation treatments. J. Clean. Prod. 2019, 231, 468–482. [Google Scholar] [CrossRef]

- Guo, Y.; Yan, K.; Cui, L.; Cheng, F. Improved extraction of alumina from coal gangue by surface mechanically grinding modification. Powder Technol. 2016, 302, 33–41. [Google Scholar] [CrossRef]

- Wang, J.; Qin, Q.; Hu, S.; Wu, K. A concrete material with waste coal gangue and fly ash used for farmland drainage in high groundwater level areas. J. Clean. Prod. 2016, 112, 631–638. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Zhang, H.Y.; Guo, W.; Tian, Y.L. Sorption characteristics and mechanisms of ammonium by coal by-products: Slag, honeycomb-cinder and coal gangue. Int. J. Environ. Sci. Technol. 2013, 10, 1309–1318. [Google Scholar] [CrossRef]

- Zheng, Q.; Zhou, Y.; Liu, X.; Liu, M.; Liao, L.; Lv, G. Environmental hazards and comprehensive utilization of solid waste coal gangue. Prog. Nat. Sci. Mater. Int. 2024, 34, 223–239. [Google Scholar] [CrossRef]

- Zhang, Y.; Ling, T. Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials—A review. Constr. Build. Mater. 2020, 234, 117424. [Google Scholar] [CrossRef]

- Lin, Y.; Si, M.; Han, H.; Jin, H.; Long, Y.; Deng, L.; Gong, Z.; Feng, W.; Nie, T.; Xu, X.; et al. Advances in studies investigating the comprehensive utilization of coal gangue: A visualization analysis based on CiteSpace. Discov. Appl. Sci. 2024, 7, 38. [Google Scholar] [CrossRef]

- Jin, J.; Liu, T.; Li, M.; Lv, T.; Zhang, S.; Zuo, S. Mechanical properties and compression damage characteristics of coal gangue-filled backfill cemented by fly ash modified self-consolidating grouts. Case Stud. Constr. Mater. 2025, 22, e04687. [Google Scholar] [CrossRef]

- Liu, L.; Xia, L.; Fang, Z.; Jia, Q.; Gao, Y.; He, W.; Liu, Z. Performance study of modified magnesium-coal based solid waste negative carbon backfill material: Strength characteristics and carbon fixation efficiency. J. Environ. Chem. Eng. 2024, 12, 113281. [Google Scholar] [CrossRef]

- Feng, L.; Chen, L.; Li, Y.; Zhu, Y.; Bai, Y.; Sha, X. Status and progress of coal gangue resource utilization under dual carbon background in China. Multipurp. Util. Min. Resour. 2023, 1–14. Available online: https://link.cnki.net/urlid/51.1251.TD.20231120.1215.010 (accessed on 18 July 2025).

- Xu, Z.; Qian, Y.; Hong, X.; Luo, Z.; Gao, X.; Liang, H. Contamination characteristics of polycyclic aromatic compounds from coal sources in typical coal mining areas in Huaibei area, China. Sci. Total Environ. 2023, 873, 162311. [Google Scholar] [CrossRef]

- Nádudvari, Á.; Kozielska, B.; Abramowicz, A.; Fabiańska, M.; Ciesielczuk, J.; Cabała, J.; Krzykawski, T. Heavy metal- and organic-matter pollution due to self-heating coal-waste dumps in the Upper Silesian Coal Basin (Poland). J. Hazard. Mater. 2021, 412, 125244. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of coal gangue as coarse aggregates in structural concrete. Constr. Build. Mater. 2020, 268, 121212. [Google Scholar] [CrossRef]

- Zhou, N.; Yao, Y.; Song, W.; He, Z.; Meng, G.; Liu, Y. Present situation and prospect of coal gangue treatment technology. J. Min. Saf. Eng. 2020, 37, 136–146. [Google Scholar]

- Song, W.; Zhang, J.; Li, M.; Hao, Y.; Zhou, N.; Yao, Y.; Guo, Y. Underground disposal of coal gangue backfill in China. Appl. Sci. 2022, 12, 12060. [Google Scholar] [CrossRef]

- Hao, Y.; Guo, X.; Yao, X.; Han, R.; Li, L.; Zhang, M. Using Chinese coal gangue as an ecological aggregate and its modification: A review. Materials 2022, 15, 4495. [Google Scholar] [CrossRef]

- Lu, G.; Mamadou, F.; Cui, L. A multiphysics-viscoplastic cap model for simulating the blast response of cemented tailings backfill. J. Rock Mech. Geotech. Eng. 2017, 9, 551–564. [Google Scholar] [CrossRef]

- Yang, F.; Wu, F.; Yang, B.; Li, L.; Gao, Q. Preparation and performance of composite activated slag-based binder for cemented paste backfill. Chemosphere 2022, 309, 136649. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Ren, T.; Remennikov, A.; Yu, B. Mechanical behaviour of lump-grout backfill material for underground spaces. Geotech. Geol. Eng. 2023, 41, 4807–4819. [Google Scholar] [CrossRef]

- Roy, R.; Chakraborty, S.; Bisai, R.; Pal, S.K.; Mishra, S. Gravity blind backfilling of abandoned underground mine voids using suitablemix proportion of fill materials and method of filling. Geotech. Geol. Eng. 2023, 41, 1801–1819. [Google Scholar] [CrossRef]

- Lu, G.; Fall, M.; Yang, Z. An evolutive bounding surface plasticity model for early-age cemented tailings backfill under cyclic loading. Soil Dyn. Earthq. Eng. 2019, 117, 339–356. [Google Scholar] [CrossRef]

- Gu, W.; Yang, B.; Gu, C. Study on adjacent grouting filling technology of gangue slurry. Coal Technol. 2023, 42, 75–79. [Google Scholar]

- Zhu, L.; Gu, W.; Song, T.; Pan, H.; Liu, Z.; Zhang, P.; He, Z. Research progress and prospect of coal gangue slurry backfilling technology in goaf. Coal Sci. Technol. 2023, 51, 143–154. [Google Scholar]

- Zhu, L.; Li, Z.; Wu, Y.; Liu, C. CFD numerical simulation of slurry flow characteristics under the clogged form of coal gangue slurry transportation pipeline. Appl. Sci. 2025, 15, 1957. [Google Scholar] [CrossRef]

- Zhu, L.; Pan, H.; Gu, W.; Zhao, M.; Zhang, X.; Xu, K. Experimental study on flow and diffusion law of gangue filling slurry in caving zone. J. China Coal Soc. 2021, 46, 629–638. [Google Scholar]

- Yang, J.; Yang, B.; Li, T.; Yu, M. Fluidity study on chemical behavior of Bingham materials in pipe transportation. Chem. Eng. Trans. 2018, 71, 1051–1056. [Google Scholar]

- Jin, J.; Yang, F.; Gu, C.; Zhou, Y.; Wang, X. Study on rheological characteristics of uncemented coal gangue-fly ash backfill (UCGFB) slurry based on fractal theory. Adv. Mater. Sci. Eng. 2022, 2022, 7634951. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, J.; Wang, X.; Wu, R.; Wang, S. Effect of thickeners on the flow characteristics of paste filling slurry and its engineering application. Nonferrous Met. Sci. Eng. 2024, 15, 97–104. [Google Scholar]

- Zhao, H.; Zhao, X.; Guo, M.; Cao, F.; Wu, J. Rheological properties of mortar and concrete with low binder content. Concrete 2012, 2012, 30–33. [Google Scholar]

- Yang, J. Coal Gangue Particle Suspension Study with High-Concentration Cemented Backfilling on Coal Mine. Ph.D. Thesis, China University of Mining and Technology-Beijing, Beijing, China, 2019. [Google Scholar]

- Yin, Y.; Huang, J.; Wang, T.; Yang, R.; Hu, H.; Manuka, M.; Zhou, F.; Min, J.; Wan, H.; Yuan, D.; et al. Effect of Hydroxypropyl methyl cellulose (HPMC) on rheology and printability of the first printed layer of cement activated slag-based 3D printing concrete. Constr. Build. Mater. 2023, 405, 133347. [Google Scholar] [CrossRef]

- Ebru, K.; Baraka, C.; Çağlar, Y.; Burak, F.; Halit, Y.; Oğuzhan, Ç. Effect of hydroxypropyl methylcellulose and aggregate volume on fresh and hardened properties of 3D printable concrete. Constr. Build. Mater. 2024, 456, 139253. [Google Scholar] [CrossRef]

- Parham, S.; Harrison, G.; Victormartínez, P.; Ramón, P.; Annalena, K.; Shima, P. Comparative analysis of 3D printing of Portland cement mortars with hydroxypropyl methylcellulose and microfibrillated cellulose as viscosity modifying agents. Mater. Des. 2024, 244, 113124. [Google Scholar] [CrossRef]

- Wang, B.; Shi, K.; Ma, X. Influence of different raw material ratios on the workability of gangue slurry. Shaanxi Coal 2025, 44, 47–51+103. [Google Scholar]

- Ma, X.; Wang, Y.; Wei, Y. Research on influence of additives on stability and flowability of coal gangue slurry materials. Coal Technol. 2025, 44, 72–76. [Google Scholar]

- Gao, Q.; Yang, X.; Wen, Z.; Chen, D.; He, J. Optimization of Proportioning of Mixed Aggregate Filling Slurry Based on BBD Response Surface Method. J. Hunan Univ. Nat. Sci. 2019, 46, 47–55. [Google Scholar]

- GB 5749-2022; Standards for Drinking Water Quality. China Quality and Standards Publishing House: Beijing, China, 2022.

- JGJ/T 70-2009; Standard for Test Methods of Basic Performance of Building Mortar. China Architecture & Building Press: Beijing, China, 2009.

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. China Standards Press: Beijing, China, 2005.

- Liu, C.; Cheng, Y.; Xiong, Y.; Jia, L.; Ma, L.; Wang, X.; Cheng, C.; Banthia, N.; Zhang, Y. Influence of HPMC and SF on buildability of 3D printing foam concrete: From water state and flocculation point of view. Compos. Part B 2022, 242, 110075. [Google Scholar] [CrossRef]

| Independent Variable | Horizontal Encoding | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| X1 | 76 | 77 | 78 |

| X2 | 2 | 3 | 4 |

| X3 | 0.0 | 0.03 | 0.06 |

| Serial No. | Concentration/% | Maximum Gangue Particle Size/mm | HPMC Dosage/% | Layering Degree/mm | Slump Flow/mm |

|---|---|---|---|---|---|

| 1 | 78 | 4 | 0.03 | 241 | 21.5 |

| 2 | 77 | 2 | 0.06 | 206 | 14.2 |

| 3 | 76 | 2 | 0.03 | 264 | 25 |

| 4 | 76 | 3 | 0 | 297 | 33.3 |

| 5 | 76 | 4 | 0.03 | 298 | 33 |

| 6 | 77 | 3 | 0.03 | 268 | 23.5 |

| 7 | 78 | 2 | 0.03 | 153 | 12.1 |

| 8 | 77 | 4 | 0.06 | 275 | 23.5 |

| 9 | 77 | 2 | 0 | 244 | 22.9 |

| 10 | 76 | 3 | 0.06 | 269 | 25.5 |

| 11 | 77 | 3 | 0.03 | 272 | 23.5 |

| 12 | 77 | 3 | 0.03 | 271 | 23.7 |

| 13 | 78 | 3 | 0 | 216 | 21.4 |

| 14 | 78 | 3 | 0.06 | 182 | 12.4 |

| 15 | 77 | 4 | 0 | 301 | 31.3 |

| Source | Layering Degree | Slump Flow | ||

|---|---|---|---|---|

| F | p | F | p | |

| Model | 3537.4 | <0.0001 | 1331.97 | <0.0001 |

| X1-X1 | 16,197.08 | <0.0001 | 6318.81 | <0.0001 |

| X2-X2 | 8177.06 | <0.0001 | 3442.39 | <0.0001 |

| X3-X3 | 7359.89 | <0.0001 | 888.58 | <0.0001 |

| X1X2 | 26.02 | 0.0038 | 326.42 | <0.0001 |

| X1X3 | 19.12 | 0.0072 | 4.03 | 0.101 |

| X2X3 | 10.75 | 0.022 | 16.12 | 0.0102 |

| X12 | 11.85 | 0.0184 | 906.56 | <0.0001 |

| X22 | 34.72 | 0.002 | 103.62 | 0.0002 |

| X32 | 5.72 | 0.0622 | 57.88 | 0.0006 |

| Group No. | Slurry Concentration/% | Maximum Size/mm | HPMC Dosage/% | Measured Slump Flow/mm | Predicted Slump Flow/mm | Measured Layering Degree/mm | Predicted Layering Degree/mm |

|---|---|---|---|---|---|---|---|

| S1 | 77.25 | 2.5 | 0.045 | 217.7 | 228.9 | 16.8 | 17.4 |

| S2 | 77.50 | 3.0 | 0.045 | 238.3 | 233.8 | 19.1 | 18.2 |

| S3 | 77.25 | 3.0 | 0.050 | 237.8 | 245.0 | 18.3 | 19.1 |

| S4 | 77.80 | 3.5 | 0.045 | 241.4 | 231.5 | 18.9 | 18.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J.; Jin, X.; Wang, Y.; Qiao, F. Study on Stability and Fluidity of HPMC-Modified Gangue Slurry with Industrial Validation. Materials 2025, 18, 3461. https://doi.org/10.3390/ma18153461

Jin J, Jin X, Wang Y, Qiao F. Study on Stability and Fluidity of HPMC-Modified Gangue Slurry with Industrial Validation. Materials. 2025; 18(15):3461. https://doi.org/10.3390/ma18153461

Chicago/Turabian StyleJin, Junyu, Xufeng Jin, Yu Wang, and Fang Qiao. 2025. "Study on Stability and Fluidity of HPMC-Modified Gangue Slurry with Industrial Validation" Materials 18, no. 15: 3461. https://doi.org/10.3390/ma18153461

APA StyleJin, J., Jin, X., Wang, Y., & Qiao, F. (2025). Study on Stability and Fluidity of HPMC-Modified Gangue Slurry with Industrial Validation. Materials, 18(15), 3461. https://doi.org/10.3390/ma18153461