Enhanced Mechanical and Electromagnetic Shielding Properties of Mg Matrix Layered Composites Reinforced with Hybrid Graphene Nanosheet (GNS)–Carbon Nanotube (CNT) Networks

Abstract

1. Introduction

2. Experimental Procedure

2.1. Raw Materials

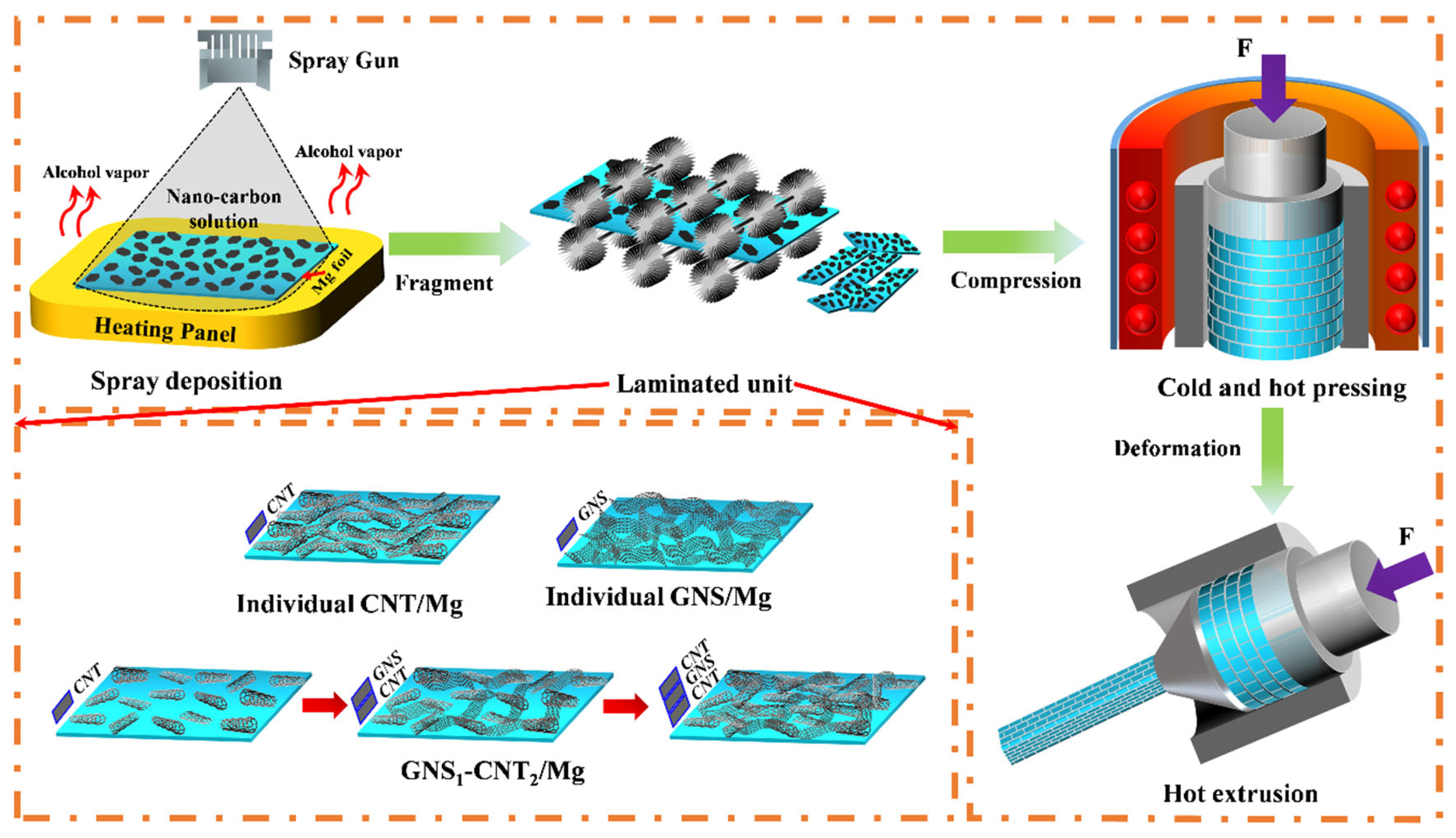

2.2. Fabrication Procedure of the GNS-CNT/Mg Layered Composites

2.3. Characterization

3. Results

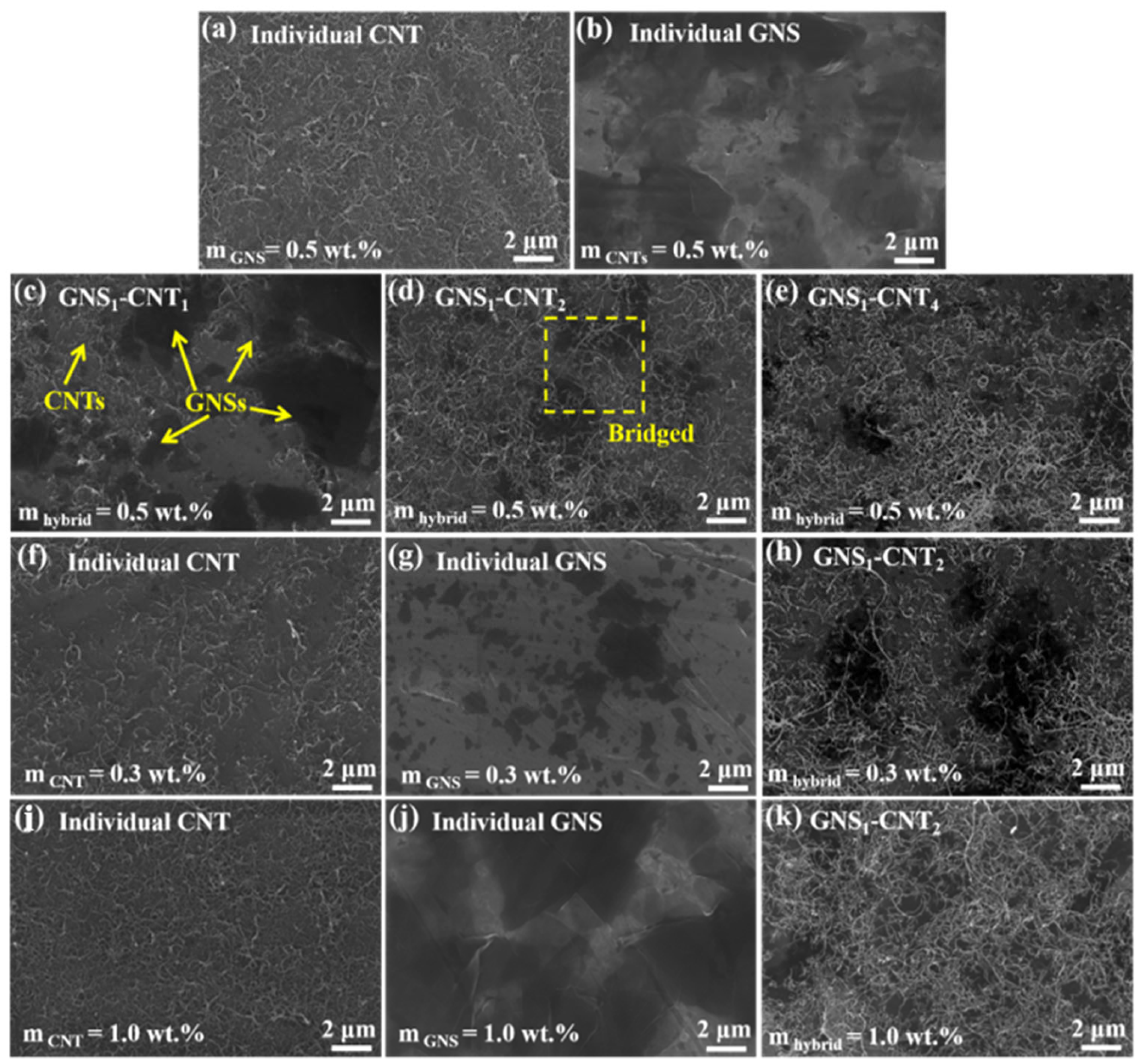

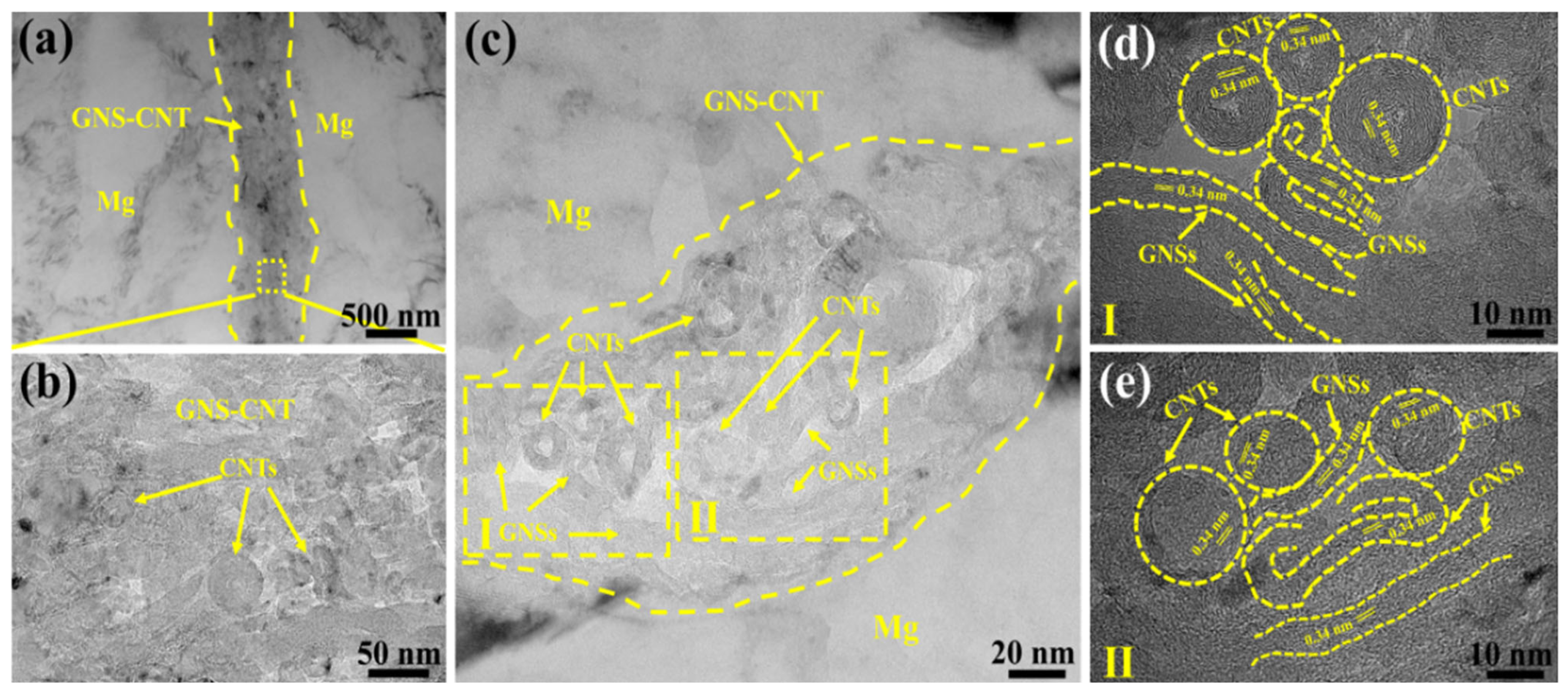

3.1. Alternating Spray Deposition of GNS-CNT Layer

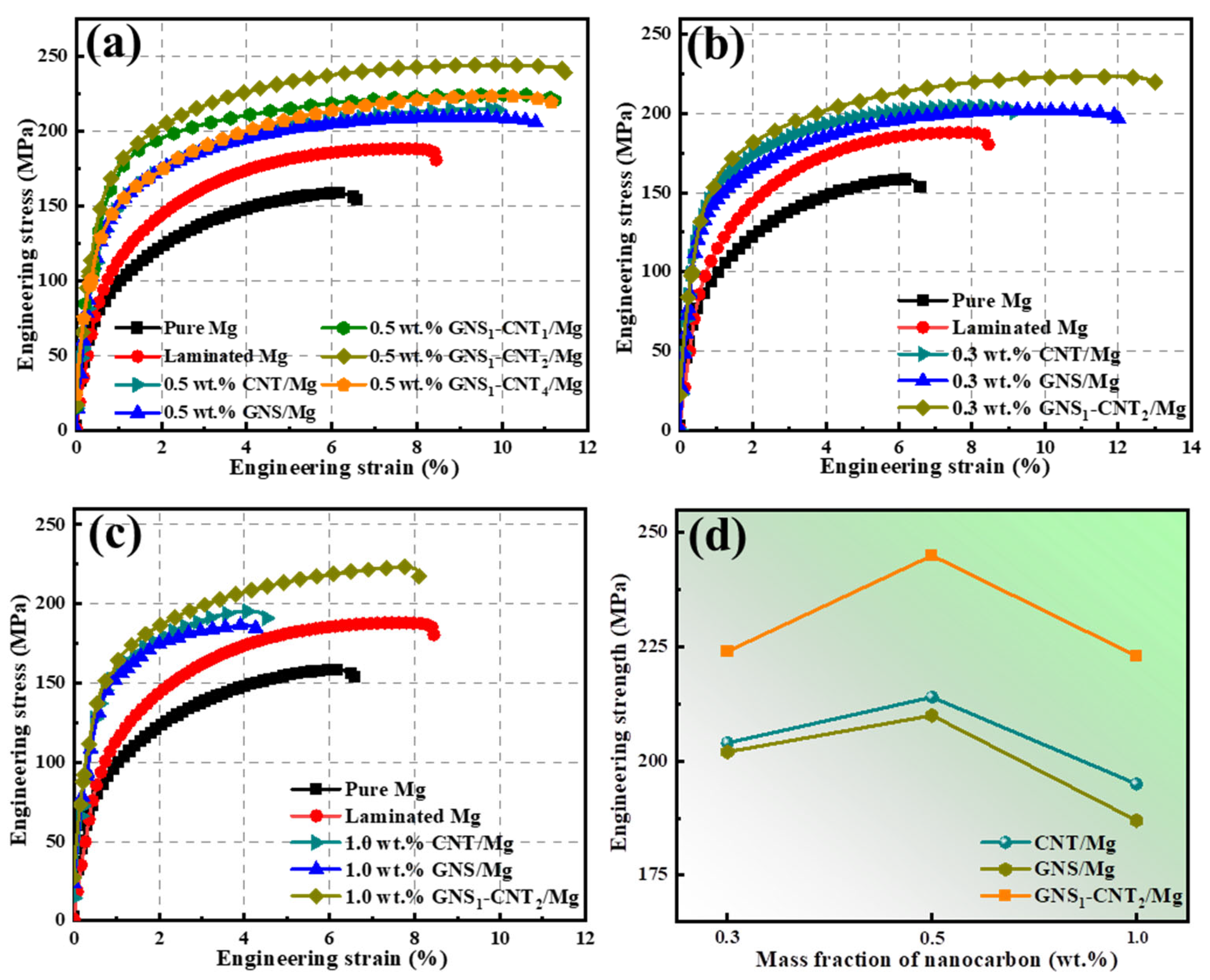

3.2. Mechanical Properties of Pure Mg and the CNT-GNS Composites

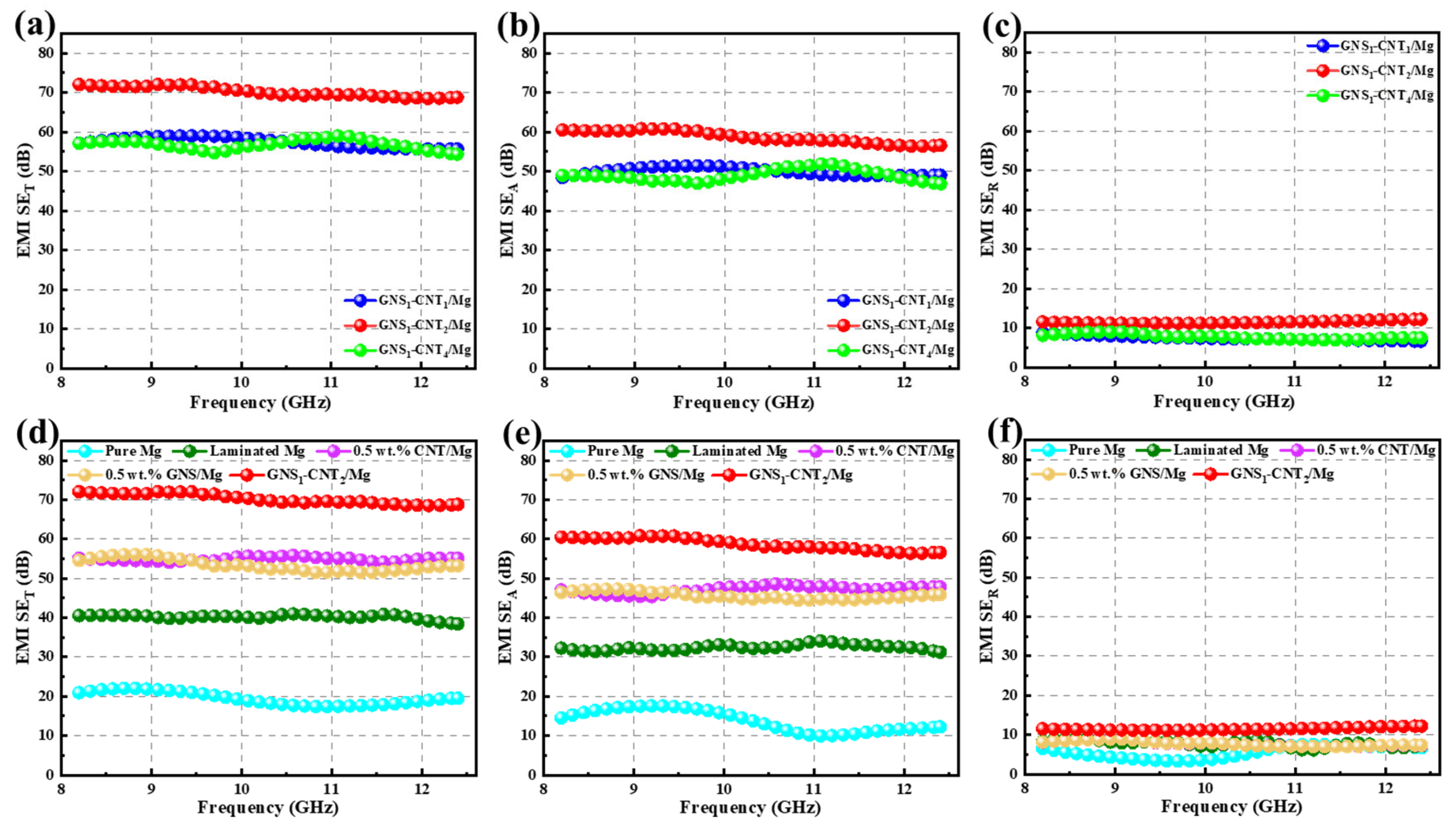

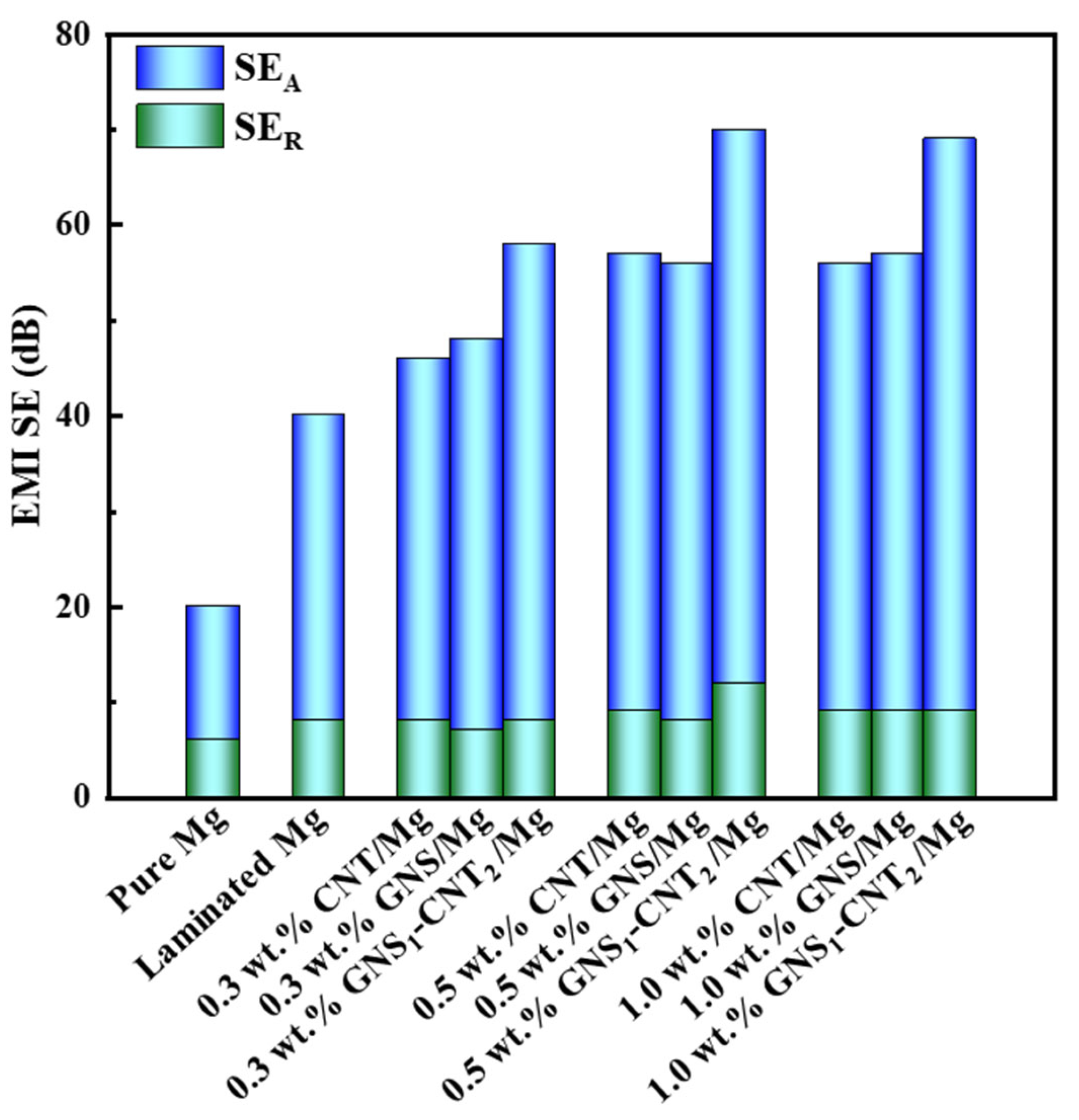

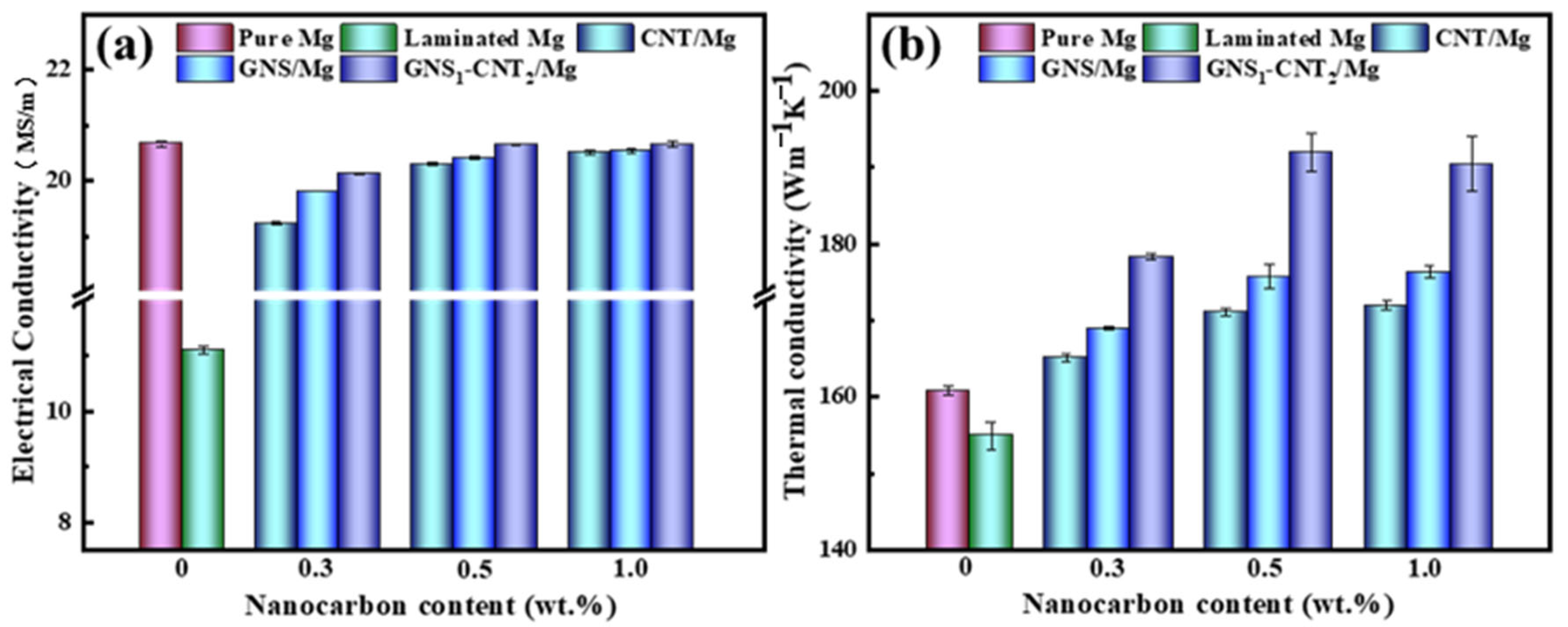

3.3. Electromagnetic Interference Shielding Performance of Pure Mg and GNS-CNT/Mg Composites

4. Discussion

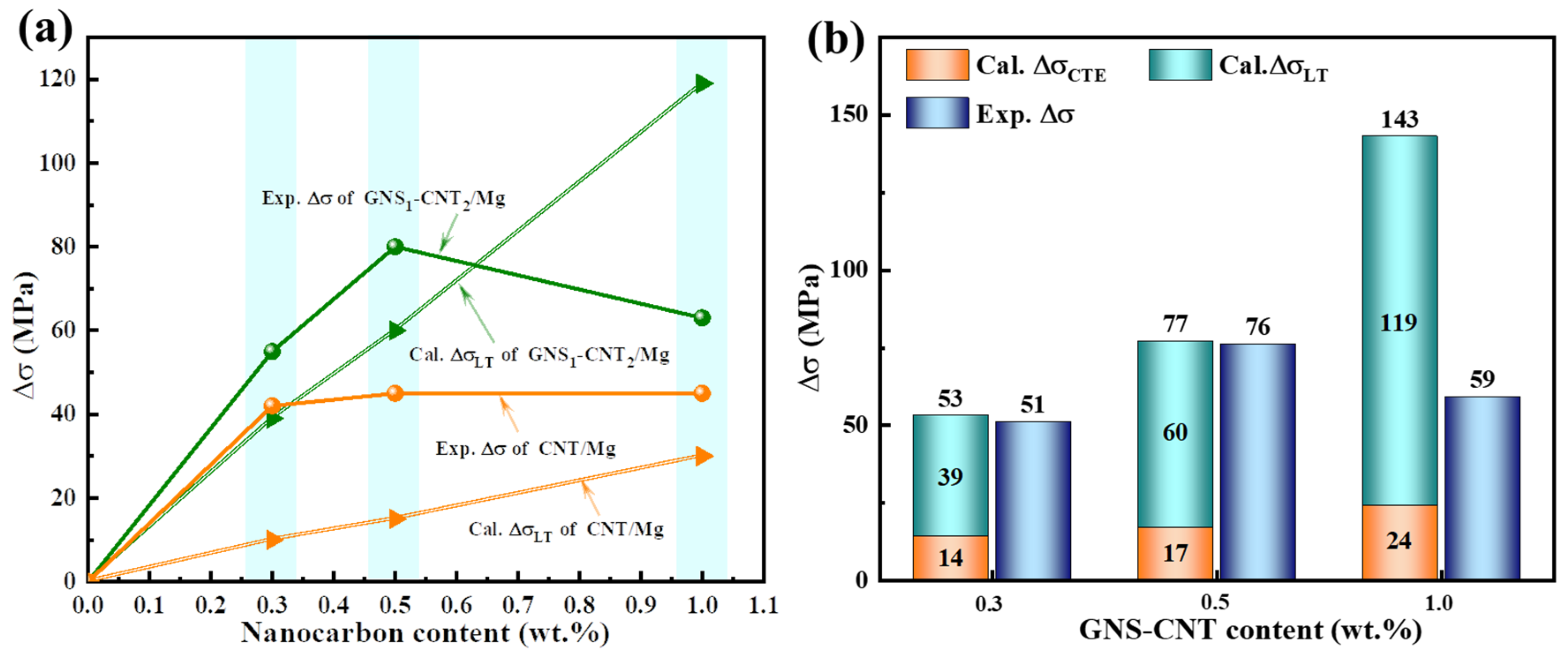

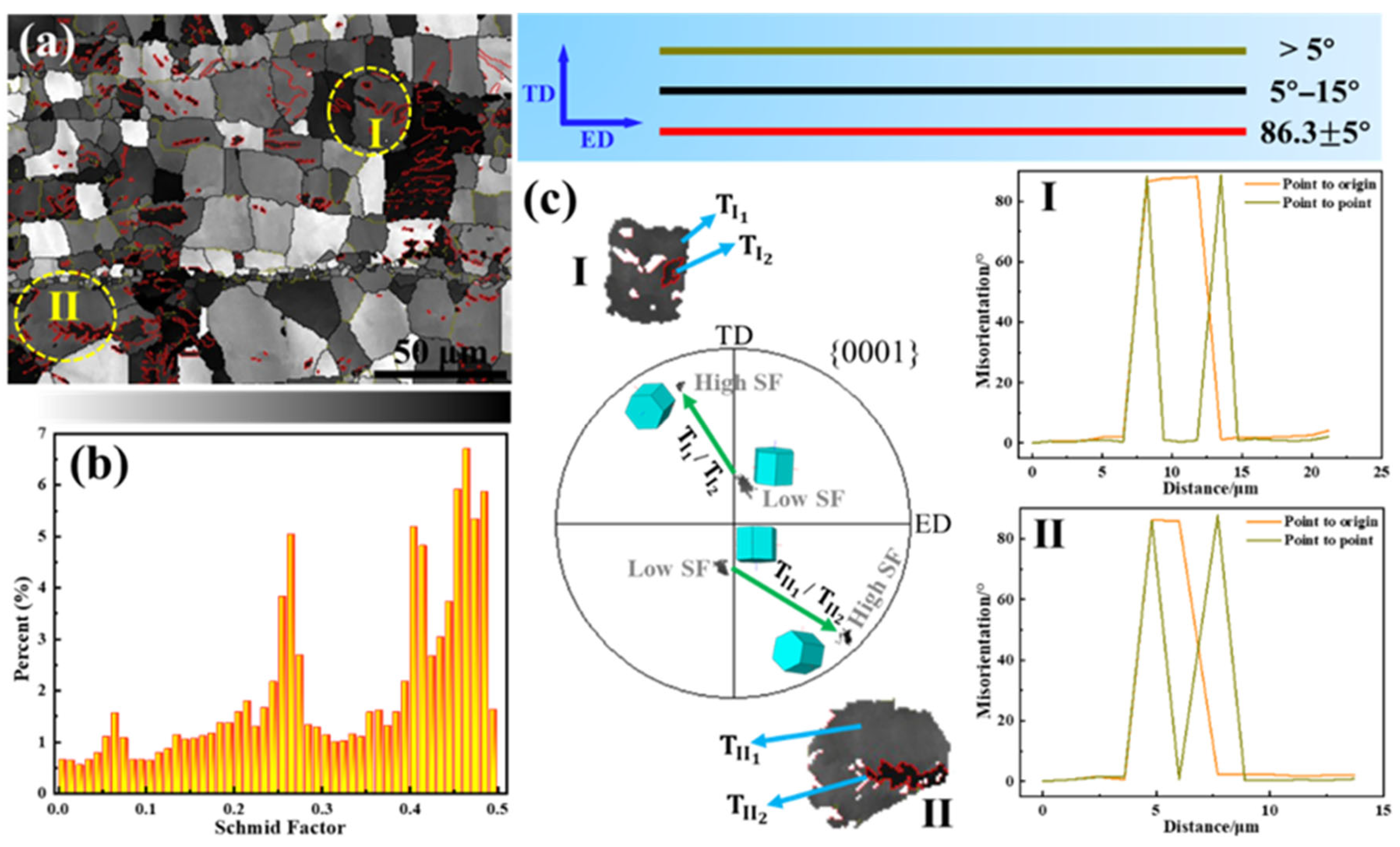

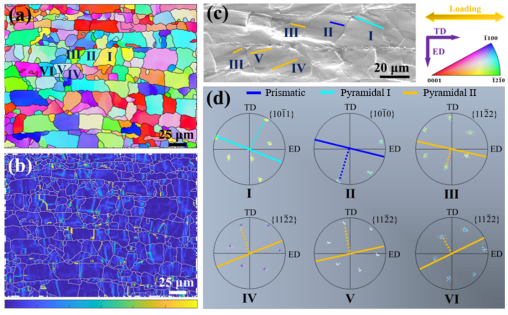

4.1. Strengthening Mechanism of Layered GNS-CNT/Mg Composites

4.1.1. Load Transfer Strengthening

4.1.2. Thermal Mismatch Strengthening

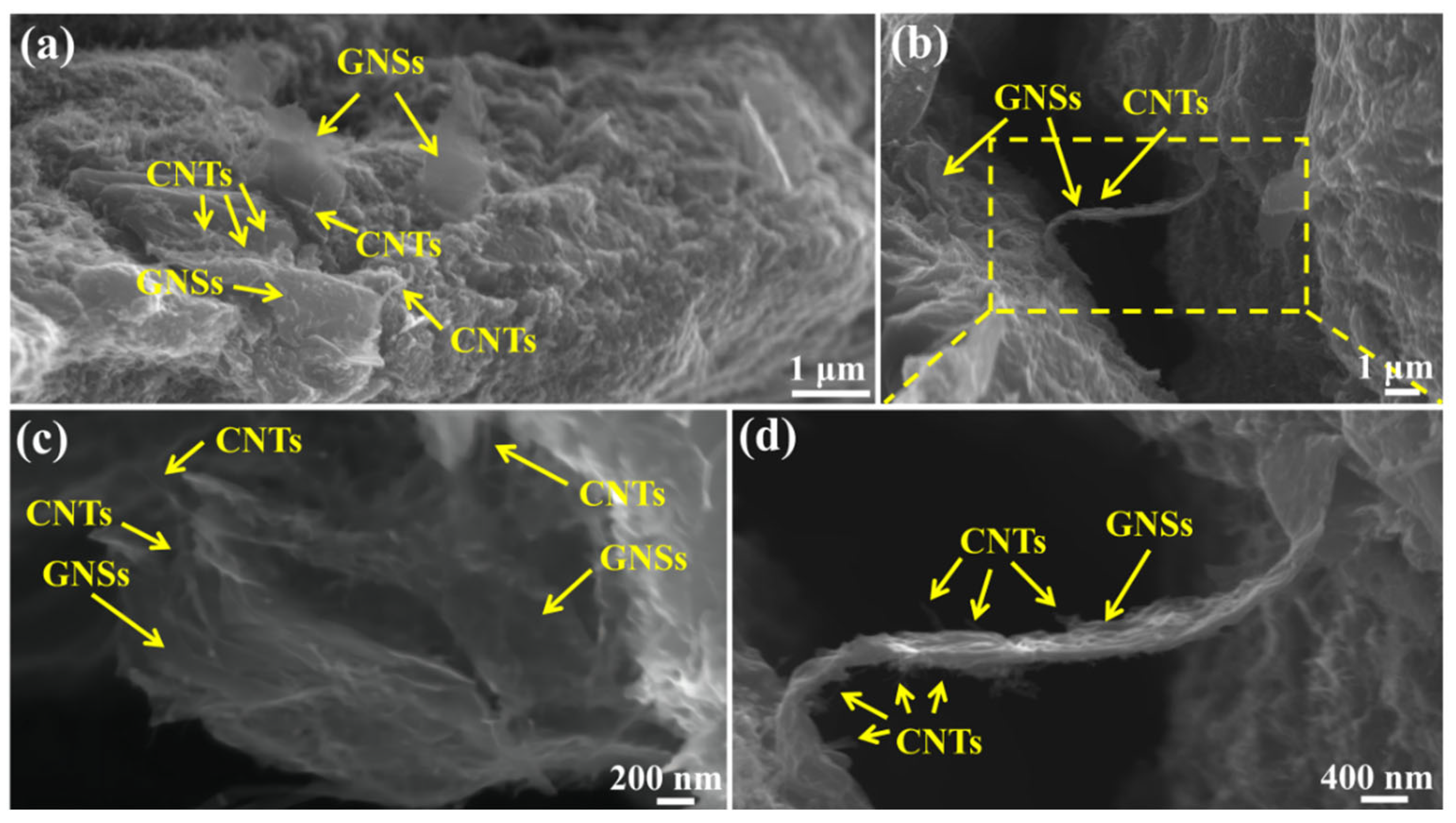

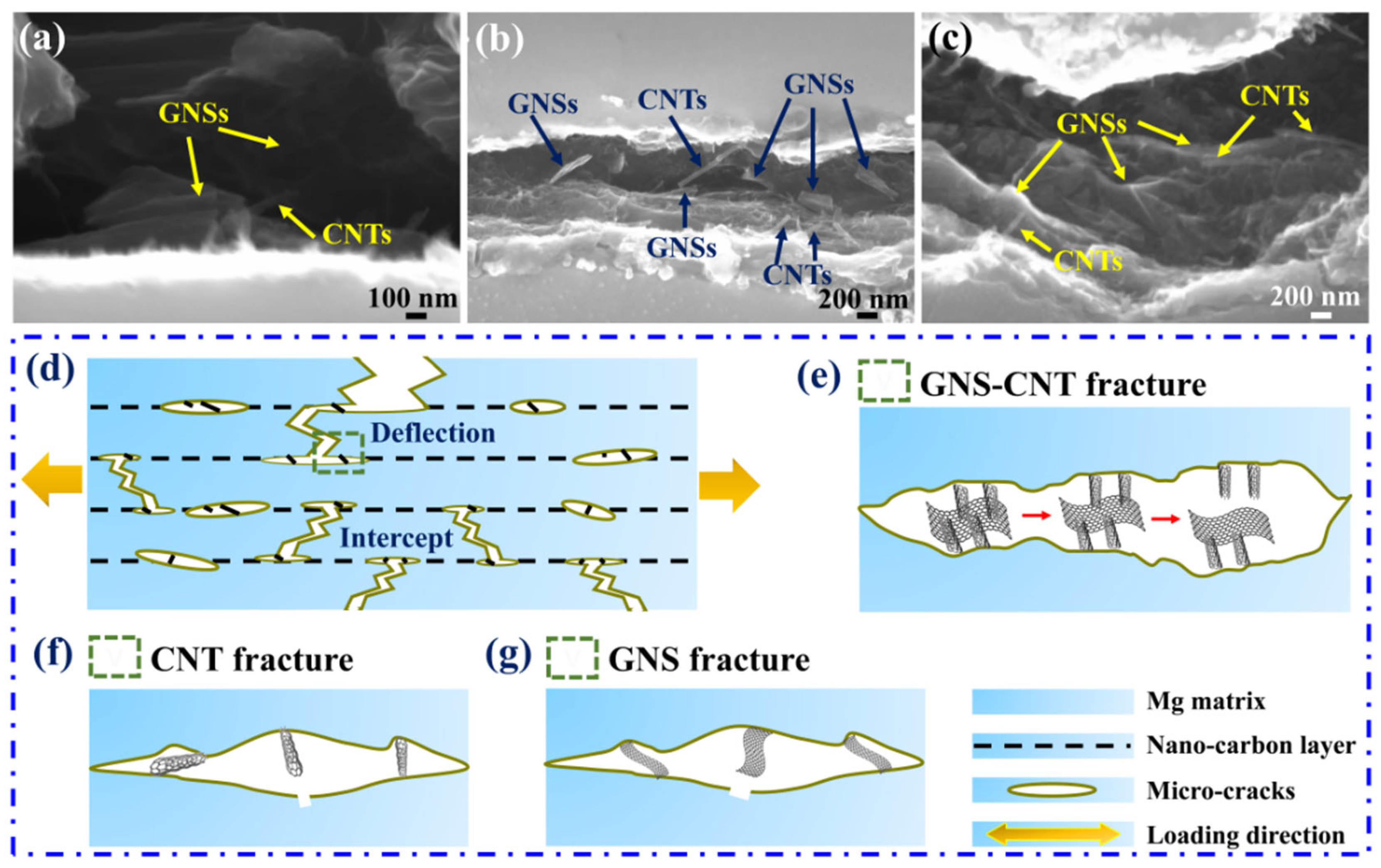

4.2. Toughening Mechanism of Layered GNS-CNT/Mg Composites

4.2.1. Effect of GNS-CNT on Dislocation Behavior

4.2.2. Direct Toughening Effect of GNS-CNT

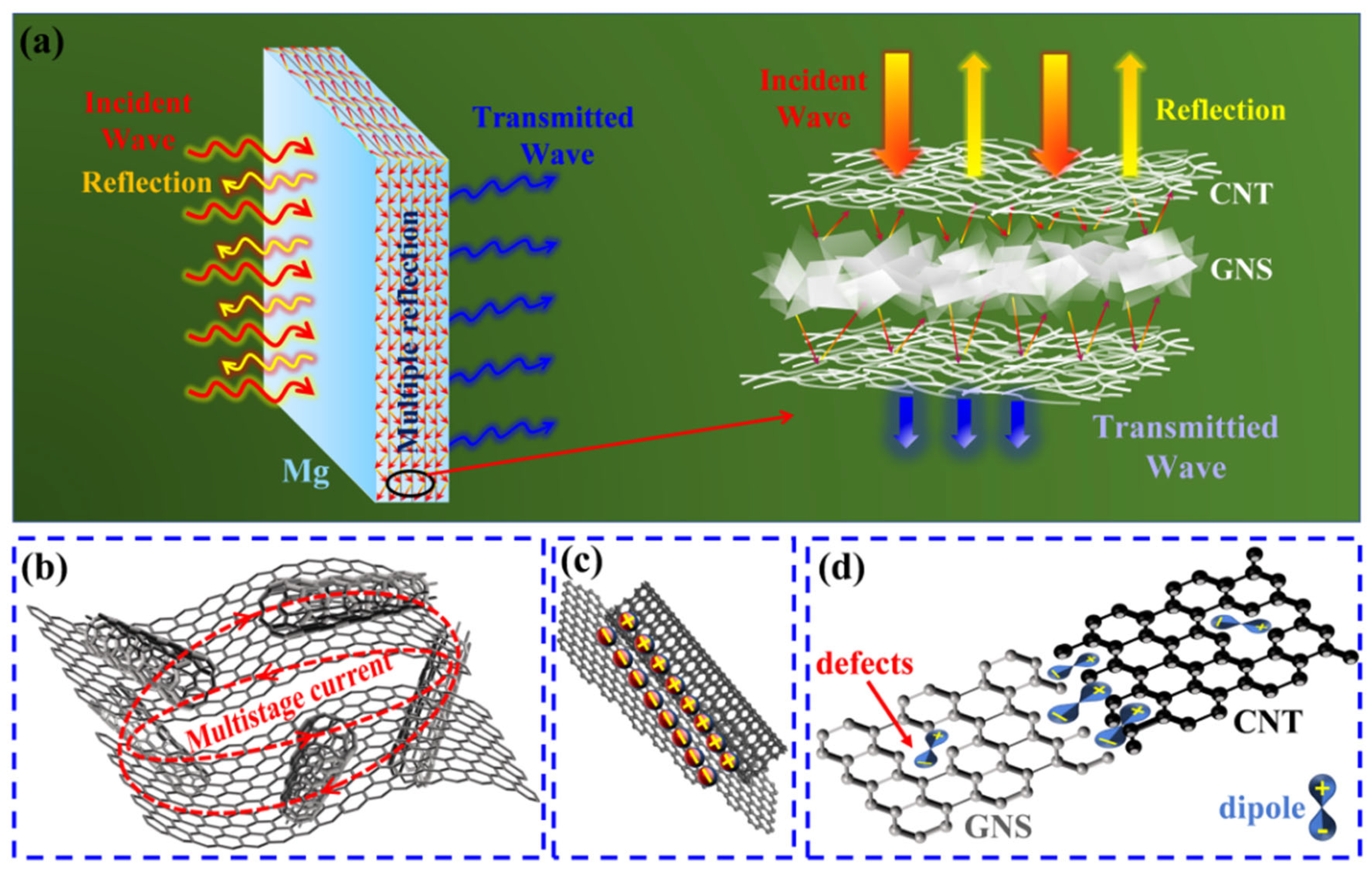

4.3. Electromagnetic Interference Shielding Mechanism of GNS-CNT/Mg Composites

5. Conclusions

- The GNS-CNT hybrid reinforcement significantly improved both the mechanical properties and electromagnetic shielding effectiveness of the Mg-based composite. At a nanocarbon content of 0.5 wt.% with a GNS-CNT ratio of 1:2, the composite achieved optimal performance, with tensile strength increased by up to 55% and total electromagnetic shielding effectiveness (SET) reaching 70 dB, outperforming composites reinforced with individual CNTs or GNSs.

- The GNS1-CNT2 hybrid reinforcement provided a more effective load transfer mechanism compared to individual GNSs or CNTs. The three-dimensional network structure generated greater constraint and local internal stress at the interface, inducing more tensile twinning during deformation and effectively improving the plastic deformation capability and overall mechanical strength of the composite.

- The unique three-dimensional network of GNS1-CNT2 facilitated multiple internal reflections and better impedance matching, enhancing the absorption loss of incident electromagnetic waves. This, along with high electrical conductivity, resulted in a more efficient conversion of electromagnetic energy into heat, providing superior electromagnetic shielding compared to CNTs or GNSs alone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tzeng, S.-S.; Chang, F.-Y. EMI shielding effectiveness of metal-coated carbon fiber-reinforced ABS composites. Mater. Sci. Eng. A 2001, 302, 258–267. [Google Scholar] [CrossRef]

- Siddharth; Jana, P.; Dietrich, S.; Roy, S. Effect of SiC particle size on the strength and stiffness of porous Si3N4–SiC composites fabricated via a low-temperature sintering process. Mater. Sci. Eng. A 2023, 864, 144614. [Google Scholar] [CrossRef]

- Wang, D.; Cheng, E.; Qu, Z.; Wang, Y.; Wang, Q. The enhancement in microstructure, optical and electromagnetic shielding properties of Al-doped Ag thin films by annealing treatment. Surf. Interfaces 2024, 54, 105172. [Google Scholar] [CrossRef]

- Zhang, N.; Zhao, R.; He, D.; Ma, Y.; Qiu, J.; Jin, C.; Wang, C. Lightweight and flexible Ni-Co alloy nanoparticle-coated electrospun polymer nanofiber hybrid membranes for high-performance electromagnetic interference shielding. J. Alloys Compd. 2019, 784, 244–255. [Google Scholar] [CrossRef]

- Ma, Y.; Yin, X.; Fan, X.; Ju, P.; Dang, X. Modification and toughening of 3D needled C/SiC composite by deformable MAX phase-based matrix. Mater. Sci. Eng. A 2018, 712, 397–405. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, H.; Hu, X.; Yan, M.; Wang, X. Synergistic Strengthening of Mechanical Properties and Electromagnetic Interference Shielding Performance of Carbon Nanotubes (CNTs) Reinforced Magnesium Matrix Composites by CNTs Induced Layered Structure. Materials 2021, 15, 300. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, H.; Hu, X.; Yan, M.; Wang, X. Simultaneously enhanced mechanical properties and electromagnetic interference shielding performance of a graphene nanosheets (GNSs) reinforced magnesium matrix composite by GNSs induced layered structure. J. Alloys Compd. 2022, 898, 162847. [Google Scholar] [CrossRef]

- Xie, L.; Min, P.; Ye, L.; He, P.; Yin, G.; Jin, M.; Zhang, H.-B.; Yu, Z.-Z. Interfacial enhancement enables highly conductive reduced graphene oxide-based yarns for efficient electromagnetic interference shielding and thermal regulation. Carbon 2024, 230, 119655. [Google Scholar] [CrossRef]

- Hasan, M.M.; Zhou, Y.; Mahfuz, H.; Jeelani, S. Effect of SiO2 nanoparticle on thermal and tensile behavior of nylon-6. Mater. Sci. Eng. A 2006, 429, 181–188. [Google Scholar] [CrossRef]

- Choi, H.K.; Lee, A.; Park, M.; Lee, D.S.; Bae, S.; Lee, S.-K.; Lee, S.H.; Lee, T.; Kim, T.-W. Hierarchical Porous Film with Layer-by-Layer Assembly of 2D Copper Nanosheets for Ultimate Electromagnetic Interference Shielding. ACS Nano 2021, 15, 829–839. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, J.; Tan, G.; Hu, R.; Wang, J.; Chang, C.; Wang, X. Thin and Flexible Fe–Si–B/Ni–Cu–P Metallic Glass Multilayer Composites for Efficient Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2017, 9, 42192–42199. [Google Scholar] [CrossRef] [PubMed]

- Barani, Z.; Kargar, F.; Godziszewski, K.; Rehman, A.; Yashchyshyn, Y.; Rumyantsev, S.; Cywiński, G.; Knap, W.; Balandin, A.A. Graphene Epoxy-Based Composites as Efficient Electromagnetic Absorbers in the Extremely High-Frequency Band. ACS Appl. Mater. Interfaces 2020, 12, 28635–28644. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Tian, Q.; Zhao, B.; Hu, K. The microwave electromagnetic and absorption properties of some porous iron powders. Mater. Sci. Eng. A 2007, 445–446, 135–140. [Google Scholar] [CrossRef]

- Shen, Y.; Lin, Z.; Wei, J.; Xu, Y.; Wan, Y.; Zhao, T.; Zeng, X.; Hu, Y.; Sun, R. Facile synthesis of ultra-lightweight silver/reduced graphene oxide (rGO) coated carbonized-melamine foams with high electromagnetic interference shielding effectiveness and high absorption coefficient. Carbon 2022, 186, 9–18. [Google Scholar] [CrossRef]

- Zhu, S.; Hou, Y.; Song, Z.; Feng, X.; Shen, Y.; Zhang, Y.; Wang, L.; Zhang, Q. Ultra-broadband Cf/Fe microwave attenuation composite foam facilitated by 1D/2D coupling and metamaterial designing. Chem. Eng. J. 2025, 516, 164056. [Google Scholar] [CrossRef]

- Li, J.; Zhong, L.; Wang, J.; Feng, Z.; Qu, Y.; Xu, R. Synergistic improvement of mechanical and electromagnetic shielding properties of a Mg-Li-Y-Zn alloy following heat treatment. J. Magnes. Alloys 2024, 13, 1243–1257. [Google Scholar] [CrossRef]

- Xu, W.; Chen, X.; Deng, L.; Zhu, G.; Yuan, Y.; Pan, F. Effect of La content on mechanical properties and electromagnetic interference shielding effectiveness of Mg-Zn-Y-La-Zr alloy. J. Alloys Compd. 2024, 1008, 176611. [Google Scholar] [CrossRef]

- Wu, Q.; Zeng, Z.; Xiao, L. From 2D graphene and MXene nanolayers to 3D biomimetic porous composite aerogels for electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107939. [Google Scholar] [CrossRef]

- Zhao, B.; Zhao, C.; Li, R.; Hamidinejad, S.M.; Park, C.B. Flexible, Ultrathin, and High-Efficiency Electromagnetic Shielding Properties of Poly(Vinylidene Fluoride)/Carbon Composite Films. ACS Appl. Mater. Interfaces 2017, 9, 20873–20884. [Google Scholar] [CrossRef]

- Zheng, W.; Xie, H.; Li, J.; Yu, H.; Tang, Z.; Tian, G.; Wang, Q.; Wang, T. Design of polyimide/carbon nanotube@Ag@polyimide/graphene composite aerogel for infrared stealth and electromagnetic interference protection. Compos. Part A Appl. Sci. Manuf. 2024, 186, 108371. [Google Scholar] [CrossRef]

- Rasouli, A.; Kudyba, A.; Bruzda, G.; Safarian, J.; Tranell, G. High-Temperature Reactive Wetting of Natural Quartz by Liquid Magnesium. Materials 2024, 17, 1302. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Sahoo, S.; Joanni, E. Composites based on layered materials for absorption of microwaves and electromagnetic shielding. Carbon 2023, 211, 118072. [Google Scholar] [CrossRef]

- Li, C.; Qi, L.; Fei, J.; Yan, J.; Wu, Z.; Zhang, T.; Li, H. Construction of polydopamine functionalized porous carbon network structure in polymer composites for excellent mechanical and electromagnetic interference shielding properties. Carbon 2024, 217, 118620. [Google Scholar] [CrossRef]

- Gao, N.F.; Kume, S.; Watari, K. Zeolite–carbon composites prepared from industrial wastes: (II) evaluation of the adaptability as environmental materials. Mater. Sci. Eng. A 2005, 404, 274–280. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Wang, Z.; Du, P.; Xu, L.; Jia, L.; Yan, D. High-efficiency electromagnetic interference shielding and thermal management of high-graphene nanoplate-loaded composites enabled by polymer-infiltrated technique. Carbon 2023, 211, 118096. [Google Scholar] [CrossRef]

- ASTM E8/E8M-13a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- Xiao, Q.; Chen, Z.; Liao, J.; Li, Y.; Xue, L.; Guan, T. Electromagnetic interference shielding performance and mechanism of Fe/Al modified SiCf/SiC composites. J. Alloys Compd. 2021, 887, 161359. [Google Scholar] [CrossRef]

- Pandey, R.; Tekumalla, S.; Gupta, M. Magnesium-iron micro-composite for en hanced shielding of electromagnetic pollution. Compos. Part B Eng. 2019, 163, 150–157. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Wu, R.; Xu, L.; Zhang, Z.; Feng, J.; Zhang, J.; Hou, L.; Jiao, Y. X-band shielding properties of Mg-9Li matrix composite containing Ni0.4Zn0.4Co0.2Fe2O4 fabricated by multi-layer composite rolling. J. Alloys Compd. 2020, 843, 156053. [Google Scholar] [CrossRef]

- Liu, X.; Ye, Z.; Zhang, L.; Feng, P.; Shao, J.; Zhong, M.; Chen, Z.; Ci, L.; He, P.; Ji, H.; et al. Highly flexible electromagnetic interference shielding films based on ultrathin Ni/Ag composites on paper substrates. J. Mater. Sci. 2021, 56, 5570–5580. [Google Scholar] [CrossRef]

- Iqbal, S.; Shah, J.; Kotnala, R.K.; Ahmad, S. Highly efficient low cost EMI shielding by barium ferrite encapsulated polythiophene nanocomposite. J. Alloys Compd. 2019, 779, 487–496. [Google Scholar] [CrossRef]

- Liu, Z.; Bai, G.; Huang, Y.; Ma, Y.; Du, F.; Li, F.; Guo, T.; Chen, Y. Reflection and ab sorption contributions to the electromagnetic interference shielding of single- walled carbon nanotube/polyurethane composites. Carbon 2007, 45, 821–827. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, Y.; Bai, L.; Cao, C.; Chen, Q.; Huang, B.; Wu, C.; Qian, Q. Synergistically enhanced the EMI shielding performance and mechanical properties of UHMWPE-based composites through constructing a bio-inspired interface bridge between polydopamine and HGM. J. Mater. Res. Technol. 2024, 33, 8698–8709. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Fang, C.F.; Li, C.J.; Wang, R.; Zhang, X.P.; Tan, J.; Wang, Y.M. GO/MgO/Mg interface mediated strengthening and electromagnetic interference shielding in AZ31 composite. J. Magnes. Alloys 2023, 11, 3800–3814. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Fan, G.; Cao, L.; Zhang, D. The use of flake powder metallurgy to produce carbon nanotube (CNT)/aluminum composites with a homogenous CNT distribution. Carbon 2012, 50, 1993–1998. [Google Scholar] [CrossRef]

- Jin, Z.-Z.; Zha, M.; Yu, Z.-Y.; Ma, P.-K.; Li, Y.-K.; Liu, J.-M.; Jia, H.-L.; Wang, H.-Y. Exploring the Hall-Petch relation and strengthening mechanism of bimodal-grained Mg–Al–Zn alloys. J. Alloys Compd. 2020, 833, 155004. [Google Scholar] [CrossRef]

- Mu, X.N.; Zhang, H.M.; Chen, P.W.; Cheng, X.W.; Yang, L.; Chang, S.; Duan, H.; Liu, L. Achieving well-balanced strength and ductility in GNFs/Ti composite via layered architecture design. Carbon 2022, 189, 173–185. [Google Scholar] [CrossRef]

- Wang, P.; Shen, J.; Chen, T.; Li, Q.; Yue, X.A.; Wang, L. Fabrication of graphene nanoplatelets reinforced Mg matrix composites via powder thixoforging. J. Magnes. Alloys 2021, 10, 3113–3132. [Google Scholar] [CrossRef]

- Dai, L.H.; Ling, Z.; Bai, Y.L. Size-dependent inelastic behavior of particle-reinforced metal-matrix composites. Compos. Sci. Technol. 2001, 61, 1057–1063. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Geng, L. Effect of heat treatment on interfacial bonding and strengthening efficiency of graphene in GNP/Al composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 487–498. [Google Scholar] [CrossRef]

- Du, X.; Du, W.; Wang, Z.; Liu, K.; Li, S. Ultra-high strengthening efficiency of graphene nanoplatelets reinforced magnesium matrix composites. Mater. Sci. Eng. A 2018, 711, 633–642. [Google Scholar] [CrossRef]

- Ai, D.; Ma, Y.; Yu, H.; Chang, Y.; Wu, C.; Han, Y.; Cheng, Y.; Dong, C. Lightweight graphene foam composites with enhanced electrical conductivity and microwave absorption for electromagnetic interference shielding. Mater. Res. Bull. 2024, 175, 112764. [Google Scholar] [CrossRef]

- Pang, Y.; Chao, G.; Luan, T.; Gong, S.; Wang, Y.; Jiang, Z.; Xiao, Z.; Jiang, Y.; Li, Z. Microstructure and properties of high strength, high conductivity and magnetic Cu–10Fe-0.4 Si alloy. Mater. Sci. Eng. A 2021, 826, 142012. [Google Scholar] [CrossRef]

- Li, C.; Kong, Y.; Dong, S.; Zhu, J.; Wang, J.; Lyu, Z.; Hu, D.; Sun, B. Flexible CNT/Cu/PDMS composite films with Joule heating properties for high-performance electromagnetic interference shielding. Colloids Surf. A Physicochem. Eng. Asp. 2025, 721, 137162. [Google Scholar] [CrossRef]

- Yang, Y.; Shao, L.; Wang, J.; Wang, W.; Su, C.; Li, C.; Di, H.; Ma, J.; Ji, Z. Flexible and multifunctional carboxylic styrene butadiene rubber/CNT@PDA/MXene composites film for effective electromagnetic interference shielding, thermal management, and energy harvesting. Compos. Commun. 2025, 54, 102267. [Google Scholar] [CrossRef]

- Tao, W.; Ma, M.; Liao, X.; Shao, W.; Chen, S.; Shi, Y.; He, H.; Wang, X. Cellulose nanofiber/MXene/mesoporous carbon hollow spheres composite films with porous structure for deceased reflected electromagnetic interference shielding. Compos. Commun. 2023, 41, 101647. [Google Scholar] [CrossRef]

- Lee, S.; Nguyen, N.K.; Kim, M.; Kim, M.; Park, P.; Nah, J. Enhanced electromagnetic interference shielding via surface-bound molecules and synergistically amplified polarization and triboelectrification. Nano Energy 2024, 130, 110103. [Google Scholar] [CrossRef]

- Stupar, S.; Wang, Y.; Wang, J.; Timotijević, M.; Mijin, D.; Rakočević, L.; Milović, M.; Vučković, N. Effects of silver coated graphite particles on mechanical and electromagnetic shielding properties of an epoxy resin. Surf. Interfaces 2025, 68, 106663. [Google Scholar] [CrossRef]

| Element | Fe | Si | Ni | Cu | Al | Cl | Mn | Ti | Mg |

|---|---|---|---|---|---|---|---|---|---|

| Content (wt.%) | 0.004 | 0.005 | 0.0007 | 0.003 | 0.006 | 0.003 | 0.010 | 0.014 | 0.9543 |

| Samples | YS (MPa) | UTS (MPa) | Elongation (%) |

|---|---|---|---|

| Pure Mg | 89 ± 3 | 158 ± 6 | 6.4 ± 0.2 |

| Layered Mg | 93 ± 2 | 187 ± 4 | 8.3 ± 0.3 |

| 0.3 wt.% CNT/Mg | 123 ± 4 | 204 ± 3 | 9.2 ± 0.6 |

| 0.3 wt.% GNS/Mg | 122 ± 6 | 202 ± 4 | 12.0 ± 0.4 |

| 0.3 wt.% GNS1-CNT2/Mg | 140 ± 5 | 224 ± 8 | 13.1 ± 0.7 |

| 0.5 wt.% CNT/Mg | 128 ± 2 | 214 ± 3 | 10.1 ± 0.9 |

| 0.5 wt.% GNS/Mg | 125 ± 3 | 210 ± 5 | 10.8 ± 0.5 |

| 0.5 wt.% GNS1-CNT2/Mg | 142 ± 4 | 224 ± 7 | 11.0 ± 0.4 |

| 0.5 wt.% GNS1-CNT2/Mg | 165 ± 3 | 245 ± 4 | 11.5 ± 0.8 |

| 0.5 wt.% GNS1-CNT4/Mg | 133 ± 5 | 222 ± 3 | 10.9 ± 0.5 |

| 1.0 wt.% CNT/Mg | 130 ± 4 | 195 ± 5 | 4.5 ± 1.1 |

| 1.0 wt.% GNS/Mg | 123 ± 7 | 187 ± 4 | 4.2 ± 0.6 |

| 1.0 wt.% GNS1-CNT2/Mg | 148 ± 6 | 223 ± 5 | 8.1 ± 0.7 |

| 0.3 wt.% GNS1-CNT2/Mg | 140 ± 5 | 224 ± 8 | 13.1 ± 0.7 |

| Materials | Mass Fraction (wt. %) | SE(dB) | Reference |

|---|---|---|---|

| GNS1-CNT2/Mg composite | 0.5 | 70 | this work |

| CNTs/Mg | 0.5 | 58 | [6] |

| GNSs/Mg | 0.5 | 55 | [7] |

| Mg/15Fe | 15 | 55 | [28] |

| 6NZCF/Mg-9Li | 6 | 58 | [29] |

| Ni/Ag | 14 | 47 | [30] |

| MWCNT/PANI | 25 | 39 | [31] |

| SWCNT/PU | 20 | 17 | [32] |

| (SLG-FLG)/EP | 4 | 30 | [12] |

| Materials | SE(dB) | YS (MPa) | UTS (MPa) | Elongation (%) | Reference |

|---|---|---|---|---|---|

| 0.50 wt% GNS1-CNT2/Mg composite | 70 | 168 | 249 | 12.3 | this work |

| 0.50 wt% CNTs/Mg | 58 | 130 | 213 | 12.1 | [6] |

| 0.50 wt% GNSs/Mg | 55 | 125 | 216 | 12.3 | [7] |

| PDA@HGM5 | 49.8 | - | 32.31 | - | [33] |

| GO/AZ31 | 23.8 | 230 | 290 | 13.6 | [34] |

| GO-SnO2/AZ31 | 30 | 266 | 310 | 13.2 | [34] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, H.; Zhao, J.; Sun, Z.; Wang, X.; Hu, X.; Li, X.; Xu, C.; Gan, W.; Ding, C. Enhanced Mechanical and Electromagnetic Shielding Properties of Mg Matrix Layered Composites Reinforced with Hybrid Graphene Nanosheet (GNS)–Carbon Nanotube (CNT) Networks. Materials 2025, 18, 3455. https://doi.org/10.3390/ma18153455

Shi H, Zhao J, Sun Z, Wang X, Hu X, Li X, Xu C, Gan W, Ding C. Enhanced Mechanical and Electromagnetic Shielding Properties of Mg Matrix Layered Composites Reinforced with Hybrid Graphene Nanosheet (GNS)–Carbon Nanotube (CNT) Networks. Materials. 2025; 18(15):3455. https://doi.org/10.3390/ma18153455

Chicago/Turabian StyleShi, Hailong, Jiancheng Zhao, Zhenming Sun, Xiaojun Wang, Xiaoshi Hu, Xuejian Li, Chao Xu, Weimin Gan, and Chao Ding. 2025. "Enhanced Mechanical and Electromagnetic Shielding Properties of Mg Matrix Layered Composites Reinforced with Hybrid Graphene Nanosheet (GNS)–Carbon Nanotube (CNT) Networks" Materials 18, no. 15: 3455. https://doi.org/10.3390/ma18153455

APA StyleShi, H., Zhao, J., Sun, Z., Wang, X., Hu, X., Li, X., Xu, C., Gan, W., & Ding, C. (2025). Enhanced Mechanical and Electromagnetic Shielding Properties of Mg Matrix Layered Composites Reinforced with Hybrid Graphene Nanosheet (GNS)–Carbon Nanotube (CNT) Networks. Materials, 18(15), 3455. https://doi.org/10.3390/ma18153455